Diverse and Flexible Coping Strategy for Nuclear Safety: Opportunities and Challenges

Abstract

:1. Introduction

2. Brief Introduction of the FLEX Strategy

2.1. Resources

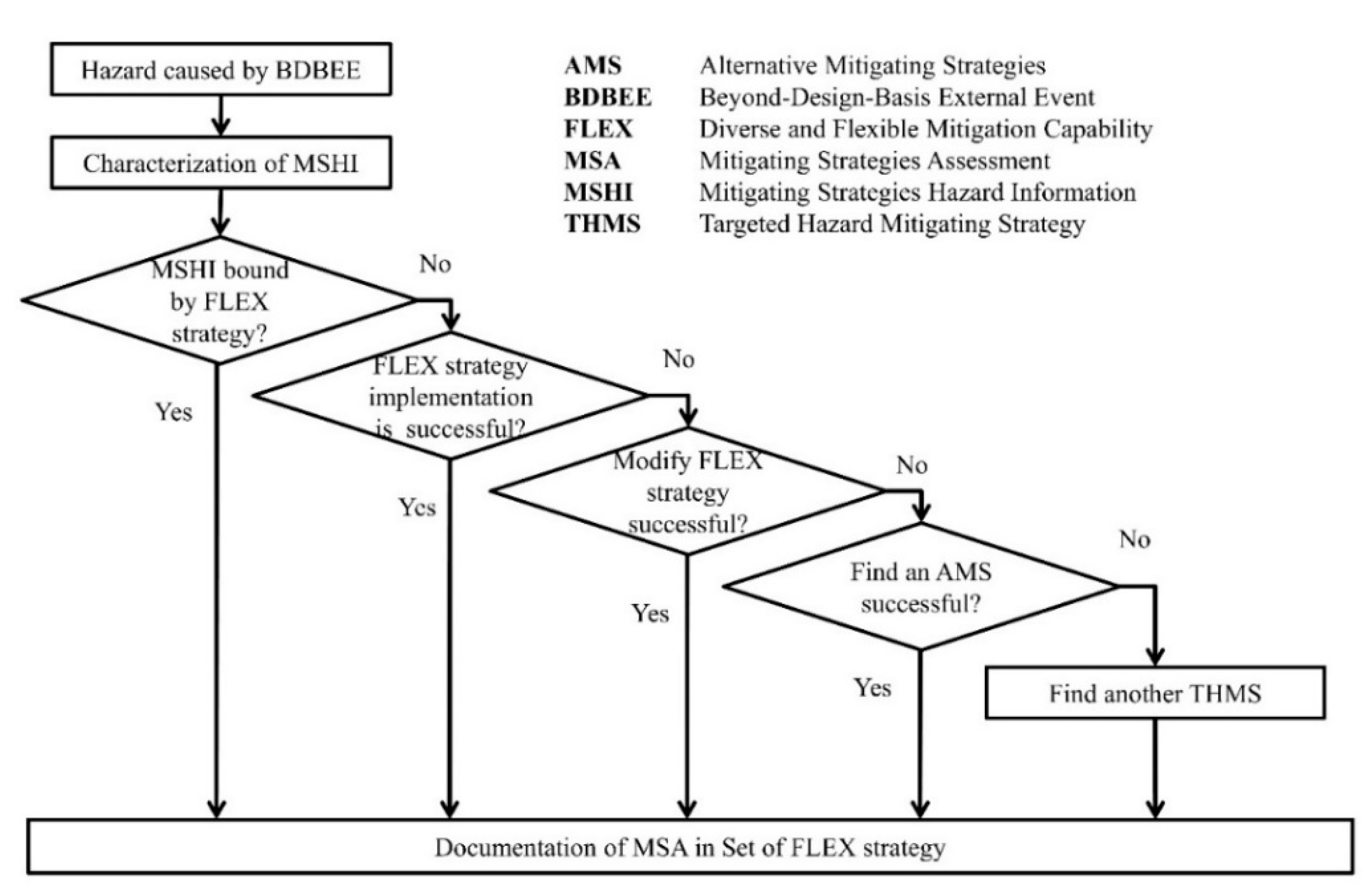

2.2. Development of the FLEX Strategy

- (1).

- establish a plant-specific baseline coping capability.

- (2).

- determine applicable site-specific BDBEEs.

- (3).

- identify enhancements to the baseline capability to address applicable site-specific scenarios.

2.3. Staffing and Training

3. Opportunities

3.1. Concept Enhancement of DID and Theory Improvement for Nuclear Safety

3.2. Promotion of Discipline Development

3.3. Promotion of On-Site and Off-Site Joint Response Mechanism

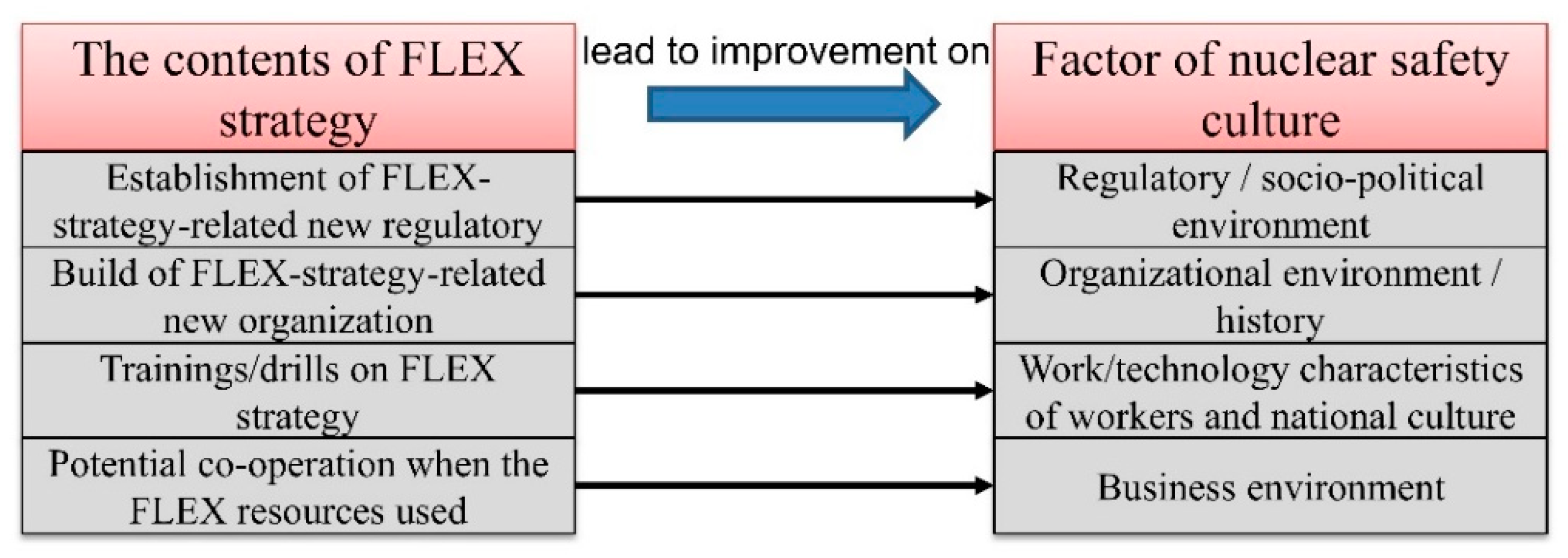

3.4. Improvement of the Nuclear Safety Culture

4. Challenges

- (1)

- knowledge of CEEs: BDBEEs may challenge the safety functions of NPPs and lead to severe accidents. Enhancing the understanding of the challenges that NPPs face under BDBEEs and possible new phenomena based on CEEs that may be introduced is crucial for the development of the FLEX strategy [47,48]. Especially, the common causes of failure, which are the kind of CEEs and the challenge of understanding the nature, need to be paid attention to in the BDBEEs analysis [49,50].

- (2)

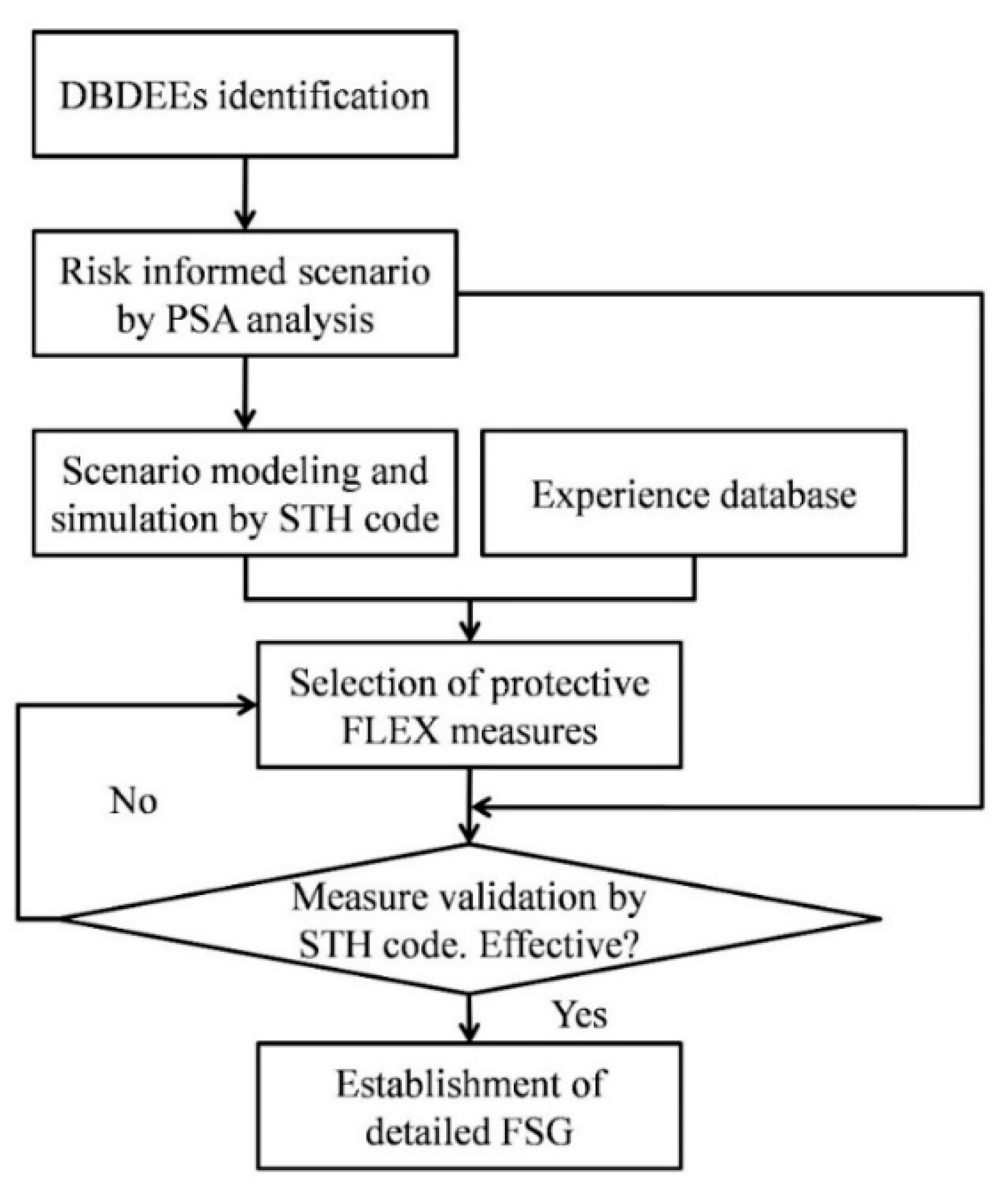

- credit FLEX strategy in the PSA/determination method: both the PSA and determination method are used for technical evaluations and formal calculations to validate the capabilities and effectiveness of the FLEX strategy [51]. The verification and validation (V & V) of the strategy should be highlighted in the future. Furthermore, the trend is to combine the PSA and determination methods together to build a comprehensive methodology [52], which rarely appears in the literature.

- (3)

- FLEX strategy time constraint: the characteristics and phenomena change quickly during the accident transient. In the case that the time limit/window of the FLEX equipment deployment is not satisfied, the strategy cannot be effective. Specific methodologies (for example, the sensitivity study [53]) need to be introduced to ensure the time constraint can be met. It is suggested that the time window for the installation and deployment of the FLEX equipment should be considered quantitatively by the method of spatiotemporal analysis [54].

- (4)

- emergency management: at present, there is a large scatter in EOPs, SAMGs, EDMG, and FLEX, etc. As the goals of plants’ accident management tools are almost identical, it is amazing that so many different approaches exist. In order to strengthen the emergency management level for nuclear safety under BDBEEs, the integration of the EOPs/SAMGs with FSGs/EDMGs is essential work for the future [55,56]. Furthermore, most of the literature about the FLEX strategy focused on Light Water Reactors. It is strongly suggested for other kinds of NPPs (including the new types of NPPs under development) since their emergency management is much different.

- (5)

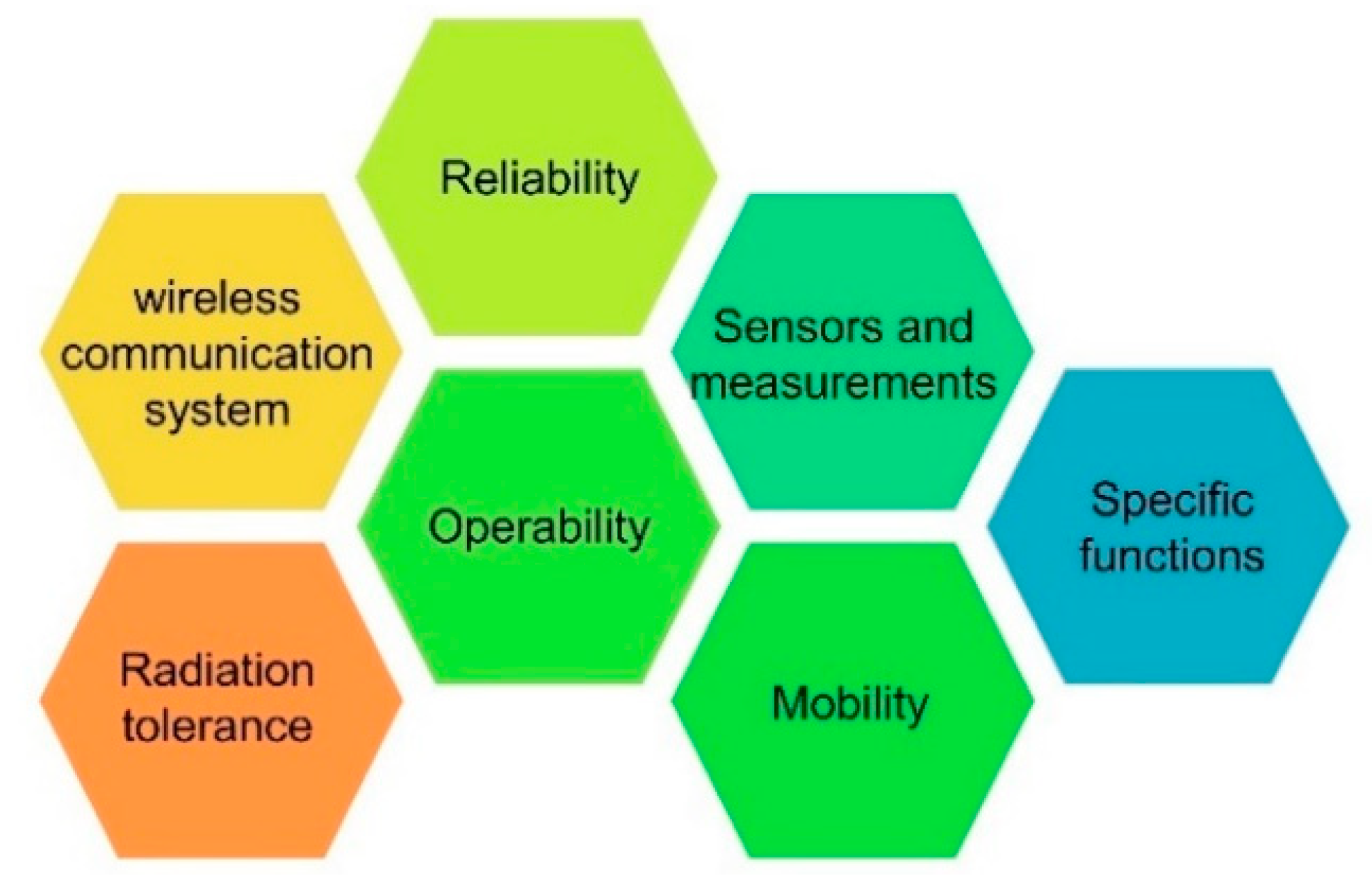

- measurement and data analysis: the measurement in the accident is very important for the analysis of the scenario and the implementation of the strategy [57]. However, the lack of measurement data or the failure of the measurement may lead to a handicap for data analysis. The Internet of Things used in the NPPs, which is the basic technology for the corresponding digital twin of the NPP and the remote response (e.g., the remote emergency response robot), may be challenged by the extreme scenario. Specific methods, such as the artificial neural network [58], should be introduced or developed for this issue to support the analysis of the FLEX strategy.

- (6)

- (7)

- uncertainty and sensitivity analysis: the portable equipment in the FLEX strategy is more “flexible” than the traditional installed equipment, but more “flexible” also means more “uncertainty” during its usage. Uncertainty and sensitivity analyses are suggested for the FLEX strategy implementation [61]. A new uncertainty methodology may be introduced or developed for the deployment of FLEX equipment/devices. The uncertainty related to the FLEX strategy is from several kinds of sources, for example, the scale of the BDBEE and its affected area [62], the unknown or ambiguous phenomena that may occur, the models in the STH codes (which are used for accident analysis), etc.

- (8)

- human/equipment reliability: compared to the traditional installed equipment (they are normally automatically controlled by the operators in the control room), the usage of “flexible” equipment may introduce the local manual operation which will lead to a higher risk of human errors. In order to achieve the objectives of the FLEX strategy, the reliability of both operators of the equipment should be considered in detail, using specific methodologies such as the human reliability analysis (HRA) method [63] and Bayesian theory [64].

- (9)

- equipment management and staging routing: in principle, FLEX equipment is available in redundancy and is stored separately. Some countries (such as the USA and Canada [65]) have built specific Emergency Mitigating Equipment Guidelines that can be used for the management of the FLEX equipment. However, BDBEEs may induce challenges to the protection of FLEX equipment, the deployment of FLEX equipment, and considerations in utilizing off-site resources [66]. Additionally, the on-site staging routing is strongly based on the situation of the affected site, especially the accessibility and radiation level of the target area for equipment deployment.

- (10)

- strategy for the multi-unit site: more attention should be paid to the FLEX strategies for multi-unit sites since the BDBEE may lead to more severe hazard to them and the FLEX strategies will be more complicated [67], especially in countries with a high density of units on one site (for example, South Korea) [68].

5. Future Work Recommendation

5.1. More Detailed PSA Analysis of the FLEX Strategy

- (1)

- Multi-unit and multi-site PSAs

- (2)

- Human reliability analysis (HRA)

- (1)

- decisions to enter a procedure and the time window evaluation (i.e., the third item of the identified challenges);

- (2)

- command and control evaluation for the FLEX strategy;

- (3)

- actions to transport and install portable equipment;

- (4)

- complex actions needed to achieve strategies, for example, actions that require many people working in coordination to complete a single task.

- (3)

- Cost–benefit analysis of the FLEX equipment

5.2. BDBEE Analysis and Supporting System

- (1)

- BDBEE characterization analysis

- (2)

- Fragility assessment of NPP critical SSCs

- (3)

- Strategies development and V & V

- (1)

- uncertainty analysis (i.e., the seventh item of challenges) is suggested for the evaluation of the stability and convergence of the BDBEE analysis and supporting system;

- (2)

- the stability and the reliability of the FLEX devices/equipment is an inevitable issue for their implementation;

- (3)

- special attention should be paid to common causes of failure, especially specific failure-to-start, failure-to-run modes [102];

- (4)

- it is necessary to validate the FLEX strategies and the related equipment for BDBEEs in the experiment of thermal-hydraulic test facilities if feasible [103].

- (4)

- Build integrated accident management guideline

5.3. Remote Response Technology Enhancement during NPP BDBEEs

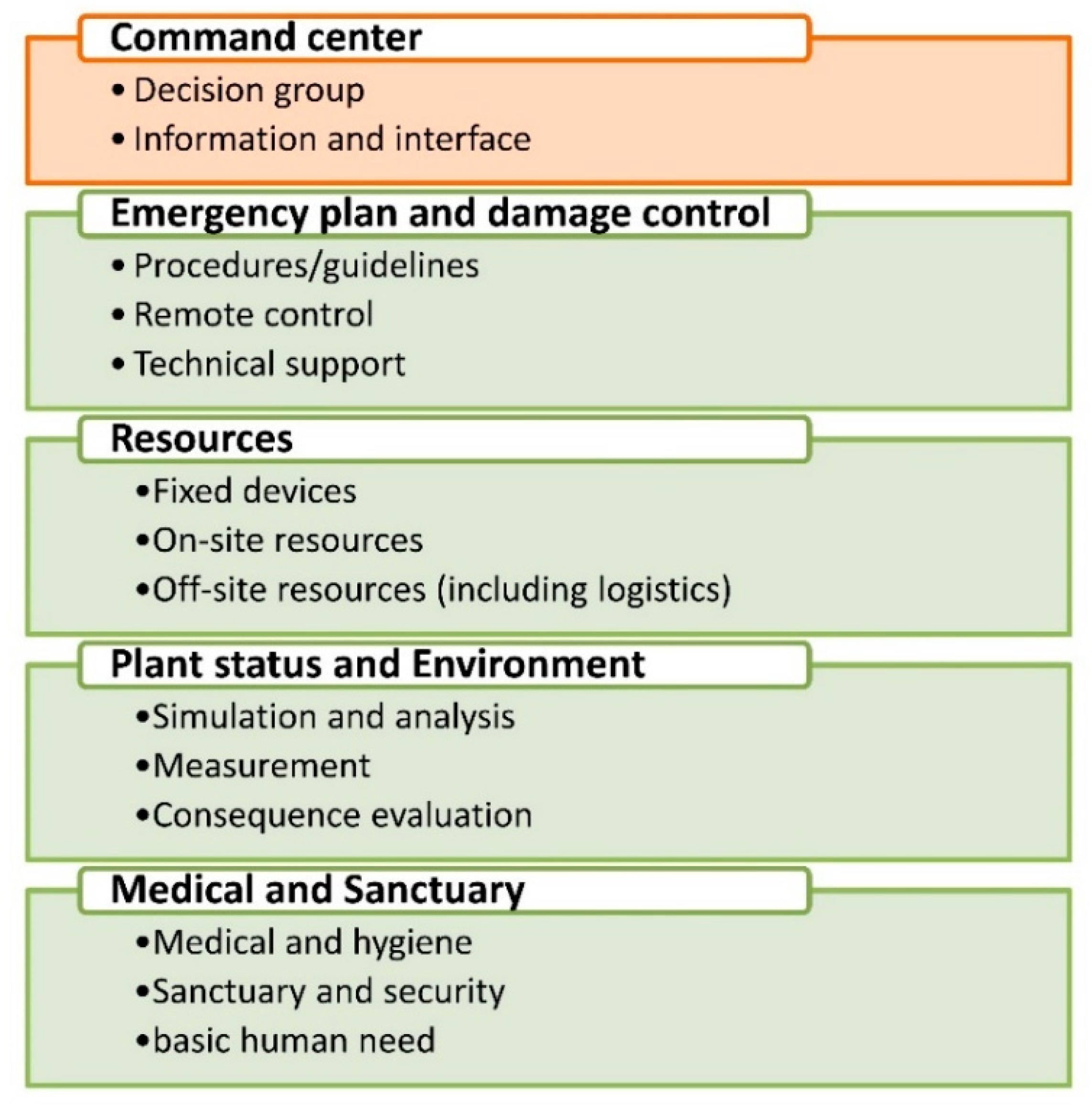

5.4. Emergency Management Support System

- (1).

- confirm that the distribution of abilities, skills, and on- and off-site communication are intact;

- (2).

- possess adaptability as the group develops and changes, either adding or canceling skills as needed [109];

- (3).

- consider the method of remote control and the strategies to regain control over the site and limit site damage (e.g., firefighting) during BDBEEs;

- (4).

- confirm the sufficiency of the necessary portable/mobile resources (e.g., AC power, direct current power, water, pneumatic air, diesel fuel) for the FLEX strategy and necessary staff;

- (5).

- confirm the capability of logistics, especially under the following two conditions: (a) the ultimate “common cause event”—Black Sky Events—with the potential to prevent the off-site world from rendering meaningful assistance to the damaged NPP in a timely manner, and (b) when several NPPs are simultaneously in need of FLEX equipment and resources from the FLEX regional response centers [110];

- (6).

- confirm the capabilities of simulation, analysis, and consequence evaluation;

- (7).

- confirm enough measurement to check the condition of the key SSCs;

- (8).

- evacuate the personnel on- and off-site and take care of wounded people, providing basic medical and sanitation, sanctuary, and daily necessities;

- (9).

- confirm the capability of improvisation, especially using the on- and off-site FLEX resources, in case of a situation without corresponding procedures/guidelines [111].

5.5. Full-Range Simulator for the Multi-Unit Site

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| CEE | Cliff-Edge Effect |

| EDMG | Extensive Damage Mitigation Guideline |

| EOP | Emergency Operating Procedure |

| FSG | FLEX Support Guideline |

| HRA | Human Reliability Analysis |

| LUHS | Loss of Ultimate Heat Sink |

| NPP | Nuclear Power Plant |

| PSA | Probabilistic Safety Assessment |

| SAMG | Severe Accident Management Guideline |

| SPAR-H | Standardized Plant Analysis Risk-Human |

| STH | System Thermal-Hydraulic (code) |

| BDBEE | Beyond-Design-Basis External Event |

| DID | Defense in Depth |

| ELAP | Extended Loss of Alternating current (AC) Power |

| FLEX | Diverse and Flexible Coping Strategy |

| HEP | Human Error Probability |

| KAERI | Korea Atomic Energy Research Institute |

| NEI | Nuclear Energy Institute |

| NRC | Nuclear Regulatory Commission |

| RCS | Reactor Cooling System |

| SFP | Spent Fuel Pool |

| SSC | Structure, Systems, and Components |

| V & V | Verification and Validation |

References

- International Atomic Energy Agency. World Nuclear Performance Report 2019; Report No. 2019/007; International Atomic Energy Agency: Vienna, Austria, 2019. [Google Scholar]

- Rachamin, R.; Fridman, E.; Galperin, A. Feasibility assessment of the once-through thorium fuel cycle for the PTVM LWR concept. Ann. Nucl. Energy 2015, 85, 1119–1130. [Google Scholar] [CrossRef]

- Xu, H. Improvement of PWR (LOCA) Safety Analysis Based on PKL Experimental Data. Ph.D. Thesis, Karlsruhe Technology of Institute, Karlsruhe, Germany, 2020. [Google Scholar]

- International Atomic Energy Agency. Defence in Depth in Nuclear Safety; Report No. INSAG-10; International Atomic Energy Agency: Vienna, Austria, 1996. [Google Scholar]

- International Nuclear Safety Advisory Group. Basic Safety Principles for Nuclear Power Plants: 75-INSAG-3 Rev. 1; Report No. INSAG-12; International Atomic Energy Agency: Vienna, Austria, 1999. [Google Scholar]

- Lim, J.; Kim, H.; Park, Y. Review of the regulatory periodic inspection system from the viewpoint of defense-in-depth in nuclear safety. Nucl. Eng. Technol. 2018, 50, 997–1005. [Google Scholar] [CrossRef]

- Nuclear Energy Institute. B.5.b Phase 2&3 Submittal Guideline; NEI 06-12 (Revision 3); Nuclear Energy Institute: Washington, DC, USA, 2009. [Google Scholar]

- Xu, H.; Zhang, B.; Liu, Y. New safety strategies for nuclear power plants: A review. Int. J. Energy Res. 2021, 45, 11564–11588. [Google Scholar] [CrossRef]

- Nuclear Energy Institute. Diverse and Flexible Coping Strategies (FLEX) Implementation Guide; NEI 12-06 (Draft Revision 0); Nuclear Energy Institute: Washington, DC, USA, 2012. [Google Scholar]

- Nuclear Energy Institute. Diverse and Flexible Coping Strategies (FLEX) Implementation Guide; NEI 12-06 (Revision 5), ML18120A300; Nuclear Energy Institute: Washington, DC, USA, 2018. [Google Scholar]

- Xu, H.; Zhang, B. A review on the Defense-in-Depth concept and the FLEX strategies in different countries after Fukushima accident. Nucl. Technol. Radiat. Prot. 2021, 36, 116–127. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Safety of Nuclear Power Plants: Design; IAEA Safety Standards Series No. SSR-2/1 (Rev. 1); IAEA: Vienna, Austria, 2016. [Google Scholar]

- International Atomic Energy Agency. Deterministic Safety Analysis for Nuclear Power Plants; IAEA Safety Standards Series No. SSG-2 (Rev. 1); IAEA: Vienna, Austria, 2019. [Google Scholar]

- International Atomic Energy Agency. Accident Management Programmes for Nuclear Power Plants; IAEA Safety Standards Series No. SSG-54; IAEA: Vienna, Austria, 2019. [Google Scholar]

- Xu, H.; Zhang, B. A review of the FLEX strategy for nuclear safety. Nucl. Eng. Des. 2021, 382, 111396. [Google Scholar] [CrossRef]

- Webster, W.E., Jr. U.S. Industry Response to the Fukushima Daiichi Nuclear Accident; Institute of Nuclear Power Operations: Atlanta, GA, USA, 2012.

- International Atomic Energy Agency. Safety of Nuclear Power Plants: Design; Specific Safety Requirements, No. SSR-2/1; International Atomic Energy Agency: Vienna, Austria, 2012. [Google Scholar]

- U.S. Nuclear Regulatory Commission. Standard Review Plan; NUREG-0800, ML092330826; U.S. Nuclear Regulatory Commission: Rockville, MD, USA, 2007. [Google Scholar]

- Fujioka, B.; Hirokawa, N.; Taniguchi, D. Probabilistic Assessment of Countermeasures for Loss of Ultimate Heat Sink to Spent Fuel Pool. In Proceedings of the 25th International Conference on Nuclear Engineering (ICONE25), Shanghai, China, 2–6 July 2017. [Google Scholar]

- Hwang, S.H.; Seo, D.U.; Jung, S.I.; Kim, N.S.; Kim, Y.I. Long Term Core Cooling Analysis on Loss of Ultimate Heat Sink for APR1400. In Proceedings of the Transactions of the Korean Nuclear Society Spring Meeting, Jeju, Korea, 17–19 May 2017. [Google Scholar]

- Gjorgiev, B.; Volkanovski, A.; Sansavini, G. Improving nuclear power plant safety through independent water storage systems. Nucl. Eng. Des. 2017, 323, 8–15. [Google Scholar] [CrossRef]

- Nuclear Energy Institute. Enhancements to Emergency Response Capabilities for Beyond Design Basis Events and Severe Accidents; NEI 13-06, Revision 1; Nuclear Energy Institute: Washington, DC, USA, 2016. [Google Scholar]

- Xu, H.; Badea, A.F.; Cheng, X. Sensitivity analysis of thermal-hydraulic models based on FFTBM-MSM two-layer method for PKL IBLOCA experiment. Ann. Nucl. Energy 2020, 147, 107732. [Google Scholar] [CrossRef]

- Xu, H.; Badea, A.F.; Cheng, X. Analysis of two phase critical flow with a non-equilibrium model. Nucl. Eng. Des. 2021, 372, 110998. [Google Scholar] [CrossRef]

- Xu, H.; Badea, A.F.; Cheng, X. Development of a new full-range critical flow model based on non-homogeneous non-equilibrium model. Ann. Nucl. Energy 2021, 158, 108286. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, P.; Zhou, Z. IVR model study for passive PWR. In Proceedings of the 20th International Conference on Nuclear Engineering and the ASME 2012 Power Conference (ICONE20-POWER2012), Anaheim, CA, USA, 30 July–3 August 2012. [Google Scholar]

- Xu, H. Study on Mitigation Strategy of AP1000 Spent Fuel Pool Exterior Disaster. At. Energy Sci. Technol. 2012, 46, 473–478. [Google Scholar]

- Xu, H.; Li, G. Research on key technical requirements for the FLEX strategy development. In Proceedings of the Conference of NPIC FLEX Project, Chengdu, China, 25 November 2020. [Google Scholar]

- Xu, H.; Tang, T.; Zhang, B.; Liu, Y. Application of Artificial Neural Network for the Critical Flow Prediction of Discharge Nozzle. Nucl. Eng. Technol. 2021, 54, 834–841. [Google Scholar] [CrossRef]

- Takada, T.; Itoi, T.; Hida, T.; Muramatsu, K.; Muta, H.; Furuya, O.; Minagawa, K.; Yamano, H.; Nishida, A. Development of Seismic Countermeasures Against Cliff Edges for Enhancement of Comprehensive Safety of NPPs—Part 1: Conceptual Study on Identification and Avoidance of Cliff Edges of NPPs Against Earthquakes. In Proceedings of the SMiRT-24, Busan, Korea, 20–25 August 2017. [Google Scholar]

- Omoto, A. Where Was the Weakness in Application of Defense-in-Depth Concept and Why? Reflections on the Fukushima Daiichi Nuclear Accident; Springer: Berlin/Heidelberg, Germany, 2015; pp. 131–164. [Google Scholar]

- Schmitt, K.A. Function Allocation in Complex Socio-Technical Systems: Procedure Usage in Nuclear Power and the Context Analysis Method for Identifying Design Solutions (CAMIDS) Model. Ph.D. Thesis, Florida Institute of Technology, Melbourne, FL, USA, 2013. [Google Scholar]

- U.S. Nuclear Regulatory Commission. 10 CFR Parts 50 and 52. Fed. Regist. 2015, 80, 70610–70647. [Google Scholar]

- Canadian Nuclear Safety Commission. Nuclear Research Trends Post-Fukushima; Final Report, RSP-0292; Canadian Nuclear Safety Commission: Ottawa, ON, Canada, 2013. [Google Scholar]

- Rumelt, R.P.; Schendel, D.; Teece, D.J. Strategic management and economics. Strateg. Manag. J. 1991, 12, 5–29. [Google Scholar] [CrossRef]

- Patterson, E.A.; Taylor, R.J.; Bankhead, M. A framework for an integrated nuclear digital environment. Prog. Nucl. Energy 2016, 87, 97–103. [Google Scholar] [CrossRef]

- Ashley, S.F.; Vaughan, G.J.; Nuttall, W.J.; Thomas, P.J. Considerations in relation to off-site emer-gency procedures and response for nuclear accidents. Process Saf. Environ. Prot. 2017, 112, 77–95. [Google Scholar] [CrossRef]

- Vayssier, G.; Lutz, B. Lessons From SAMG Exercises for Existing and New Reactors. Topical Issues in Nuclear Installation Safety, Safety Demonstration of Advanced Water Cooled Nuclear Power Plants. In Proceedings of the International Conference, Vienna, Austria, 6–9 June 2017. [Google Scholar]

- O’Brien, J. Beyond Design Basis Event Pilot Evaluations at US Department of Energy Nuclear Facilities. Trans. Am. Nucl. Soc. 2013, 108, 562–564. [Google Scholar]

- Caro, R.J. CAE—The Spanish Emergency Support Center: A Centralized and Shared Emergency Support Service for Beyond Design Basis Events. J. Nucl. Eng. Radiat. Sci. 2016, 2016, 044504. [Google Scholar] [CrossRef]

- Caro, R.J. Enhancements to Emergency Preparedness and Response in Spain. Int. Nucl. Saf. J. 2016, 5, 88–99. [Google Scholar]

- Lee, Y.H. Current Status and Issues of Nuclear Safety Culture. J. Ergon. Soc. Korea 2016, 35, 247–261. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. IAEA Safety Series 75-INSAG-3: Basic Safety Principles for Nu-clear Power Plants; International Atomic Energy Agency: Vienna, Austria, 1988. [Google Scholar]

- International Atomic Energy Agency. IAEA Safety Series 75-INSAG-4: Safety Culture; International Atomic Energy Agency: Vienna, Austria, 1991. [Google Scholar]

- Tronea, M.; Ciurea, C. Nuclear safety culture attributes and lessons to be learned from past accidents. Int. Nucl. Saf. J. 2014, 3, 1–7. [Google Scholar]

- Farcasiu, M.; Nitoi, M. Requirements to amend the main influence factors on the safety culture after Fukushima accident. In Proceedings of the Annual International Conference on Sustainable Development through Nuclear Research and Education, Pitesti, Romania, 27–29 May 2015. [Google Scholar]

- Westinghouse Electric Company. Implementation of FLEX Equipment in Plant-Specific PRA Models; PWROG-14003-NP; Westinghouse Electric Company: Pittsburgh, PA, USA, 2016. [Google Scholar]

- Kim, I.S.; Kim, B.G.; Choi, D.I.; Lee, E.C. Incorporating MACST Mitigation Strategies into PSA Models: HRA and Data Issues. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Gyeongju, Korea, 25–27 October 2017. [Google Scholar]

- Eide, S.A. Historical perspective on failure rates for US commercial reactor components. Reliab. Eng. Syst. Saf. 2003, 80, 123–132. [Google Scholar] [CrossRef]

- O’Connor, A.; Mosleh, A. A general cause based methodology for analysis of common cause and dependent failures in system risk and reliability assessments. Reliab. Eng. Syst. Saf. 2016, 145, 341–350. [Google Scholar] [CrossRef]

- Harter, R. Beyond Design Bases Event Response: FLEX. In Proceedings of the IAEA Workshop on the Development of SAMGs Using the IAEA’s SAMG Development Toolkit, Vienna, Austria, 11–15 December 2017. [Google Scholar]

- Schumock, G.; Zhang, S.; Farshadmanesh, P.; Owens, J.G.; Kasza, N.; Stearns, J.; Sakurahara, T.; Mohaghegh, Z. Integrated Risk-Informed Design (I-RID) methodological framework and computational application for FLEX equipment storage buildings of Nuclear Power Plants. Prog. Nucl. Energy 2020, 120, 103186. [Google Scholar] [CrossRef]

- Cordelle, F.; Champ, M.; Pochard, R. Primary break with total loss of high pressure safety injection. In Proceedings of the ENS/ANS International Conference on Thermal Reactor Safety, Avignon, France, 2–7 October 1988. [Google Scholar]

- Bui, H.; Sakurahara, T.; Pence, J.; Reihani, S.; Kee, E.; Mohaghegh, Z. An Algorithm for Enhancing Spatiotemporal Resolution of Probabilistic Risk Assessment to Address Emergent Safety Concerns in Nuclear Power Plants. Reliab. Eng. Syst. Saf. 2019, 185, 405–428. [Google Scholar] [CrossRef]

- U.S. Nuclear Regulatory Commission. 10 CFR Parts 50 and 52 Mitigation of Beyond-Design-Basis Events. Fed. Regist. 2019, 84, 154. [Google Scholar]

- Nuclear Energy Agency. Accident Management Insights after the Fukushima Daiichi NPP Accident; NEA/CNRA/R(2014)2; Organization for Economic Co-Operation and Development: Paris, France, 2014. [Google Scholar]

- Oh, D.Y.; No, H.C. Instrument failure detection and estimation methodology for the nuclear power plant. IEEE Trans. Nucl. Sci. 1990, 37, 21–30. [Google Scholar] [CrossRef]

- Xu, H.; Tang, T.; Zhang, B.; Liu, Y. Identification of two-phase flow regime in the energy industry based on modified convolutional neural network. Prog. Nucl. Energy. 2022, 147, 104191. [Google Scholar] [CrossRef]

- Yadav, V.; Hansen, J.K.; Germain, S.S.; Christina, R. Risk and Cost Analysis of Utilizing FLEX Equipment for O&M Cost Reduction in Nuclear Power Plants; INL/EXT-18-51531; Idaho National Laboratory: Idaho Falls, ID, USA, 2018. [Google Scholar]

- Yadav, V.; Biersdorf, J. Utilizing FLEX Equipment for O&M Cost Reduction in Nuclear Power Plants; INL/EXT-19-55445; Idaho National Laboratory: Idaho Falls, ID, USA, 2019. [Google Scholar]

- Tavares de Sousa, J.R.; Diab, A. A Systems Engineering Approach for Uncertainty Analysis of a Station Blackout Scenario. J. Korea Soc. Syst. Eng. 2019, 15, 51–59. [Google Scholar]

- Wang, Q.; Chen, X.; Xu, Y. Accident like the Fukushima unlikely in a country with effective nuclear regulation: Literature review and proposed guidelines. Renew. Sustain. Energy Rev. 2013, 17, 126–146. [Google Scholar] [CrossRef]

- Kichline, M. Human reliability analysis for using portable equipment [presentation]. In Proceedings of the United States Nuclear Regulatory Commission, EPRI HRA for FLEX Workshop, Washington, DC, 28 February–1 March 2018. [Google Scholar]

- Compare, M.; Baraldi, P.; Bani, I.; Zio, E.; McDonnell, D. Industrial Equipment Reliability Estimation: A Bayesian Weibull Regression Model with Covariate Selection. Reliab. Eng. Syst. Saf. 2020, 200, 106891. [Google Scholar] [CrossRef]

- Dermarkar, F. Human and organizational considerations in severe accidentmanagement. In IAEA International Experts’ Meeting on Severe Accident Man-Agement in the Light of the Accident at the Fukushima Daiichi Nuclear PowerPlant; International Atomic Energy Agency: Vienna, Austria, 2014. [Google Scholar]

- Zhou, D. Introduction to Seismic Mitigating Strategies Assessment (MSA) for BDBEE. 2016. Available online: http://www.chns.org/index.php/2017-04-04-09-16-38/194-flex2016-materials (accessed on 6 September 2016).

- Yu, Y.; Zhao, B.; Yu, X.L. An Integrated EDMG to Deal With Extensive Damage for NPPs in China. In Proceedings of the 2017 25th International Conference on Nuclear Engineering (ICONE25), Shanghai, China, 2–6 July 2017. [Google Scholar]

- Miller, C.; Cubbage, A.; Dorman, D.; Grobe, J.; Holahan, G.; Sanflippo, N. Recommendations for Enhancing Reactor Safety in the 21st Century: The Near-Term Task Force Review of Insights from the Fukushima Dai-Ichi Accident; SECY-11-0093, ML111861807; United States Nuclear Regulatory Commission: Washington, DC, USA, 2011.

- Vayssier, G. Present Day EOPS and SAMG—Where Do We Go from Here? Nucl. Eng. Technol. 2012, 44, 225–236. [Google Scholar] [CrossRef]

- Chang, J.; Xing, J. The General Methodology of an Integrated Human Event Analysis System (IDHEAS) for Human Reliability Analysis Method Development. In Proceedings of the 13th International Conference on Probabilistic Safety Assessment, and Management (PSAM 13), Seoul, Korea, 2–7 October 2016. [Google Scholar]

- Nuclear Energy Institute. Crediting Mitigating Strategies in Risk-Informed Decision Making; NEI 16-06, (Revision 0), ML16286A297; Nuclear Energy Institute: Washington, DC, USA, 2016. [Google Scholar]

- Queral, C.; Gómez-Magán, J.; París, C.; Rivas-Lewicky, J.; Sánchez-Perea, M.; Gil, J.; Mula, J.; Meléndez, E.; Hortal, J.; Izquierdo, J.M.; et al. Dynamic event trees without success criteria for full spectrum LOCA sequences applying the integrated safety as-sessment (ISA) methodology. Reliab. Eng. Syst. Saf. 2018, 171, 152–168. [Google Scholar] [CrossRef]

- París, C.; Queral, C.; Mula, J.; Gómez-Magán, J.; Sánchez-Perea, M.; Meléndez, E.; Gil, J. Quantitative Risk Reduction by Means of Recovery Strategies. Reliab. Eng. Syst. Saf. 2019, 182, 13–32. [Google Scholar] [CrossRef]

- Na, J.H. KHNP’s Strategies for Multi-Unit Extreme Hazards Response; Safety Technology Center Central Research Institute, KHNP: Seoul, Korea, 2018. [Google Scholar]

- Kim, S.C.; Park, J.S.; Chang, D.J.; Kim, D.H.; Lee, S.W.; Lee, Y.J. Development of an Evaluation Methodology for Loss of Large Area induced from Extreme Events with malicious origin. J. Energy 2016, 65, 12–20. [Google Scholar] [CrossRef]

- Smith, C.L.; Vedros, K.; Kvarfordt, K.J. Systems Analysis Programs for Hands-on Integrated Reliability Evaluations (SAPHIRE) Version 8 Volume 3 Users’ Guide; INL/EXT-09-17011; Idaho National Laboratory: Idaho Falls, ID, USA, 2011. [Google Scholar]

- Zhang, S.; Ma, Z.G. Incorporating FLEX Strategies in Multi-Unit Probabilistic Risk Assessment. In Proceedings of the 2020 28th International Conference on Nuclear Engineering (ICONE28), Virtual, Online, 4–5 August 2020. [Google Scholar]

- Guarnieri, F.; Travadel, S. Engineering thinking in emergency situations: A new nuclear safety concept. Bull. At. Sci. 2014, 70, 79–86. [Google Scholar] [CrossRef]

- Kim, Y.; Park, J.; Jung, W. A classification scheme of erroneous behaviors for human error probability estimations based on simulator data. Reliab. Eng. Syst. Saf. 2017, 163, 1–13. [Google Scholar] [CrossRef]

- Lim, H.K. A Conceptual comparative study of FLEX strategies to cope with Extended Station Blackout (SBO). In Proceedings of the 14th International Topical Meeting on Probabilistic Safety Assessment and Management (PSAM14), Los Angeles, CA, USA, 16–21 September 2018. [Google Scholar]

- Electric Power Research Institute. Incorporating Flexible Mitigation Strategies into PRA Models, Phase 1: Gap Analysis and Early Lessons Learned; 3002003151; Electric Power Research Institute: Washington, DC, USA, 2014. [Google Scholar]

- Kim, J.; Jung, W.; Park, J. Human Reliability Analysis of the FLEX/MACST Actions deploying Portable Equipment. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Yeosu, Korea, 25–26 October 2018. [Google Scholar]

- Kim, J.; Cho, J. Technical Challenges in Modeling Human and Organizational Actions under Severe Accident Conditions for Level 2 PSA. Reliab. Eng. Syst. Saf. 2020, 194, 106239. [Google Scholar] [CrossRef]

- Xing, J.; Kichline, M.; Hughey, J.; Humberstone, M. Applying HRA to FLEX—Expert Elicitation Volume 1. U.S.; RIL 2020-13, ML20345A318; Nuclear Regulatory Commission: Washington, DC, USA, 2020. [Google Scholar]

- Cooper, S.; Franklin, C. Applying HRA to FLEX—Using IDHEAS-ECA Volume 2. U.S.; RIL 2020-13, ML21032A119; Nuclear Regulatory Commission: Washington, DC, USA, 2020. [Google Scholar]

- Suh, Y.A.; Kim, J.; Park, S.Y. Time uncertainty analysis method for level 2 human reliability analysis of severe accident management strategies. Nucl. Eng. Technol. 2021, 53, 484e497. [Google Scholar] [CrossRef]

- Lee, H.; Choi, W.; Kim, S.J. Sensitivity Analysis at the Time of MACST Action in Severe Accidents caused by Station Black Out (SBO). In Proceedings of the Transactions of the Korean Nuclear Society Virtual Spring Meeting, Virtual, 9–10 July 2020. [Google Scholar]

- Shah, A.U.A.; Christian, R.; Kim, J.; Kang, H.G. Coping Time Analysis for Chromium Coated Zircaloy for Station Blackout Scenario based on Dynamic Risk Assessment. In Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venice, Italy, 1–6 November 2020. [Google Scholar]

- Park, J.; Arigi, A.M.; Kim, J. Treatment of human and organizational factors for multi-unit HRA: Ap-plication of SPAR-H method. Ann. Nucl. Energy 2019, 132, 656–678. [Google Scholar] [CrossRef]

- Mancuso, A.; Compare, M.; Salo, A.; Zio, E. Portfolio optimization of safety measures for reducing risks in nuclear systems. Reliab. Eng. Syst. Saf. 2017, 167, 20–29. [Google Scholar] [CrossRef]

- Smith, C.L. Risk-Informed Incident Management for Nuclear Power Plants. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2002. [Google Scholar]

- Rahni, N.; Raimond, E.; Jan, P.; Lopez, J.; Löffler, H.; Mildenberger, O.; Kubicek, J.; Vitazkova, J.; Ivanov, I.; Groudev, P.; et al. Guidance on the Verification and Improvement of SAM Strategies with L2 PSA; Technical Report ASAMPSA_E/WP40/D40.5/2016-05; IRSN: Fontenay-aux-Roses, France, 2016. [Google Scholar]

- Karamizadeh, S.; Abdullah, S.M.; Manaf, A.A.; Zamani, M.; Hooman, A. An overview of principal component analysis. J. Signal Inf. Process. 2013, 4, 173. [Google Scholar] [CrossRef]

- Wang, Z.; Pedroni, N.; Zentner, I.; Zio, E. Seismic fragility analysis with artificial neural networks: Application the niclear power plant equipment. Eng. Struct. 2018, 162, 213–225. [Google Scholar] [CrossRef]

- Nielsen, T.D.; Jensen, F.V. Bayesian Networks and Decision Graphs; Springer: New York, NY, USA, 2009. [Google Scholar]

- Ma, Z.; Smith, C.; Prescott, S. A simulation-based dynamic approach for external flooding analysis in nuclear power plants. In Proceedings of the 20th Pacific Basin Nuclear Conference; Springer: Singapore, 2017. [Google Scholar]

- Tabadar, Z.; Ansarifara, G.R.; Pirouzmand, A. Probabilistic safety assessment of portable equipment applied in VVER1000/V446 nuclear reactor during loss of ultimate heat sink accident for stress test program development. Prog. Nucl. Energy 2019, 117, 103101. [Google Scholar] [CrossRef]

- Tabadar, Z.; Ansarifar, G.R.; Pirouzmand, A. Thermal-hydraulic modeling for deterministic safety analysis of portable equipment application in the VVER-1000 nuclear reactor during loss of ultimate heat sink accident using RELAP5/MOD3.2 code. Ann. Nucl. Energy 2019, 127, 53–67. [Google Scholar] [CrossRef]

- Coleman, J.; Sabharwall, P. Seismic Risk Management Solution for Nuclear Power Plants. Public Interest Rep. 2014, 67. [Google Scholar]

- Campbell, R.D.; Hardy, G.S.; Ravindra, M.K.; Johnson, J.J.; Hoy, A.J. Seismic re-evaluation of nuclear facilities worldwide: Overview and status. Nucl. Eng. Des. 1998, 182, 17–34. [Google Scholar] [CrossRef]

- Kobare, S.K.; Kafka, P. Expert systems for emergency alarms analysis during accident situations in nuclear reactors. Reliab. Eng. Syst. Saf. 1992, 37, 139–149. [Google Scholar] [CrossRef]

- Zubair, M.; Amjad, Q.M.N. Calculation and updating of Common Cause Failure unavailability by using alpha factor model. Ann. Nucl. Energy 2016, 90, 106–114. [Google Scholar] [CrossRef]

- Farmer, M.T. Reactor Safety Technologies Pathway Technical Program Plan; INL/EXT-11-23452; U.S. Department of Energy: Washington, DC, USA, 2017.

- Kim, J.; Park, S.Y.; Ahn, K.I.; Yang, J.E. iROCS: Integrated accident management framework for coping with beyond-design-basis external events. Nucl. Eng. Des. 2016, 298, 1–13. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, Y.; Jeong, K.M. A new approach to quantify safety benefits of disaster robots. Nucl. Eng. Technol. 2017, 49, 1414–1422. [Google Scholar] [CrossRef]

- Yoshida, T.; Nagatani, K.; Tadokoro, S.; Nishimura, T.; Koyanagi, E. Improvements to the Rescue Robot Quince Toward Future Indoor Surveillance Missions in the Fukushima Daiichi Nuclear Power Plant. In Field and Service Robotics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 19–32. [Google Scholar]

- Asama, H. Utilization of Robot Technology for Accident Response and Decommissioning of Fukushima Daiichi Nuclear Power Station. J. Jpn. Soc. Mech. Eng. 2014, 117, 648–651. [Google Scholar]

- Vayssier, G. Accident management under extreme events. Int. J. Perform. Eng. 2014, 10, 669–680. [Google Scholar] [CrossRef]

- Wybo, J.L.; Kowalski, K.M. Command centers and emergency management support. Saf. Sci. 1998, 30, 131–138. [Google Scholar] [CrossRef]

- Greene, S.R. Nuclear Power and Electric Grid Resilience: Current Realities and Future Prospects. Ph.D. Thesis, University of Tennessee, Knoxville, TN, USA, 2018. [Google Scholar]

- Vayssier, G. Accident management under extreme events. J. Energy 2016, 65, 21–31. [Google Scholar] [CrossRef]

- Duffey, R.B. Dynamic Theory of Losses in Warfare. Eur. J. Oper. Res. 2017, 261, 1013–1027. [Google Scholar] [CrossRef]

- Po, L.C.C. Conceptual Design of an Accident Prevention System for Light Water Reactors Using Artificial Neural Network and High-Speed Simulator. Nucl. Technol. 2020, 206, 505–513. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Y.; Luo, H. Research and Development of Validation and Drill System for Full Scope of Severe Accident Management Guideline. J. Nucl. Eng. Radiat. Sci. 2017, 2017, 041011. [Google Scholar] [CrossRef]

- Luo, H. PSA-HD User Guide. UG PSA-HD; GSE Power Systems, Inc.: Sykesville, MD, USA, 2013; p. 6. [Google Scholar]

| Phase | Staging Time | Types of Resources | Resources (Examples) |

|---|---|---|---|

| 1 | 0–8 h | Installed equipment and devices |

|

| 2 | 8–72 h | On-site portable equipment/consumables |

|

| 3 | 72 h | Off-site resources |

|

| Discipline | Examples of Applications in FLEX Strategies |

|---|---|

| Nuclear safety |

|

| Equipment reliability and management |

|

| Probabilistic safety assessment (PSA) |

|

| Human factors engineering (HFE) |

|

| Radiation protection |

|

| Strategy optimization and economics |

|

| Logistics and transportation |

|

| Software engineering |

|

| Internet of Things, big data, and machine learning |

|

| Artificial intelligence and robotics |

|

| Emergency management |

|

| Social studies |

|

| Opportunity | Challenge |

|---|---|

| concept enhancement of DID and theory improvement for nuclear safety | knowledge of CEEs |

| credit FLEX strategy in the PSA/determination method | |

| FLEX strategy time constraint | |

| emergency management | |

| promotion of discipline development | measurement and data analysis |

| strategic economic considerations | |

| uncertainty and sensitivity analysis | |

| human/equipment reliability | |

| promotion of on-site and off-site joint response mechanism | equipment management and staging routing |

| strategy for the multi-unit site | |

| improvement of the nuclear safety culture | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Zhang, B. Diverse and Flexible Coping Strategy for Nuclear Safety: Opportunities and Challenges. Energies 2022, 15, 6275. https://doi.org/10.3390/en15176275

Xu H, Zhang B. Diverse and Flexible Coping Strategy for Nuclear Safety: Opportunities and Challenges. Energies. 2022; 15(17):6275. https://doi.org/10.3390/en15176275

Chicago/Turabian StyleXu, Hong, and Baorui Zhang. 2022. "Diverse and Flexible Coping Strategy for Nuclear Safety: Opportunities and Challenges" Energies 15, no. 17: 6275. https://doi.org/10.3390/en15176275