1. Introduction

The number of cars in the world is constantly growing [

1]. The main power plant of cars is internal combustion engines, which use fuels of petroleum origin—gasoline and diesel fuel, stocks of which are limited [

2]. Therefore, the search for ways to reduce fossil fuel consumption by internal combustion engines is urgent. However, the implementation of such measures is often associated with the introduction of structural changes or is only suitable for a certain category of engines. For example, the use of combined power regulation by turning off a group of cylinders in light load modes is more relevant for engines with the number of 6 or more cylinders [

3]. There is a search for new fuels and the expansion of the use of known fuels, which are similar in their properties to fuels of petroleum origin [

4]. The latter includes liquefied petroleum gas (LPG) as it is able to meet the needs of consumers in terms of its positive performance as a motor fuel, relative environmental safety, and low operating cost [

5]. In order to use LPG fuel, double supply systems are being developed [

6,

7], in which petrol and gas are provided separately. To match the most suitable gas supply, it is necessary to experimentally select the supply parameters as fully open throttle conditions and the configuration of the gas supply system with an injection pressure of 120 kPa and a nozzle diameter of 1 mm [

8]. It is also important to determine the most suitable fuel injection process for gasoline and LPG fuel systems [

9]. Research has shown that the optimal injection of LPG is achieved at 25° before top dead center, while the maximum peak pressure of gasoline and LPG fuel is achieved at 10° after top dead center [

10].

Compared to gasoline, LPG results in better BSFC, CO, CO

2 and HC values, but correspondingly lower BTE [

10]. It was also observed that an approximately linear variation with the engine power is observed using the assessment of environmental parameters (CO and HC) [

11]. An ANOVA optimization model was used in order to find out the appropriate limit of the LPG optimal proportion at which the above-mentioned indicators reach their optimal value (in the case of BTE—max, and in the case of BSFC, CO, CO

2 and HC—min.). After carrying out the optimization assessment, it was determined that the optimal proportion of LPG gas was 35% [

12]. However, with partial LPG substitutability, the maximum values of both fuel consumption and ecological indicator values are not reached compared to full LPG substitutability [

13], whereas, e.g., fuel consumption using only LPG can be reduced by up to 28.38% compared to using only gasoline [

14]. It is noted that when using a separate LPG injection system, the engine brake power loss increased by 1.85% [

15]. These values are also highly dependent on LPG gas blowdown, which is influenced by the settings of the LPG vaporizer and mechanical systems [

9]. The determination of these processes is complex and requires further research, and various mathematical models, such as artificial neural network (ANN) model, capable of estimating exhaust gas emissions are proposed for the optimization of processes using LPG. However, this requires constant validation using experimental data [

6]. Another option that allows one to more accurately assess the benefits of using LPG is real-time driving cycle measurements, which assess both fuel consumption and exhaust gas emissions [

8].

One of the most common ways to use LPG as a motor fuel in the rolling stock of motor transport is to equip a serial gasoline engine with a gas supply system, which preserves the standard fuel system and the ability to work properly on gasoline and LPG.

The literature sources did not reveal the results of studies that would assess the impact of retrofitting a modern gasoline engine with an LPG injection system under operating conditions on the operational properties of a car and the economic feasibility of such a conversion.

The conducted research is devoted to the solution of this problem. To reduce the complexity of research, mathematical modeling was used with verification of the reliability of the results obtained by experimental tests. The refined mathematical model and the results of comparative studies of a car running on different types of fuel, taking into account the operating conditions, constitute the scientific novelty of this article.

2. Materials and Methods

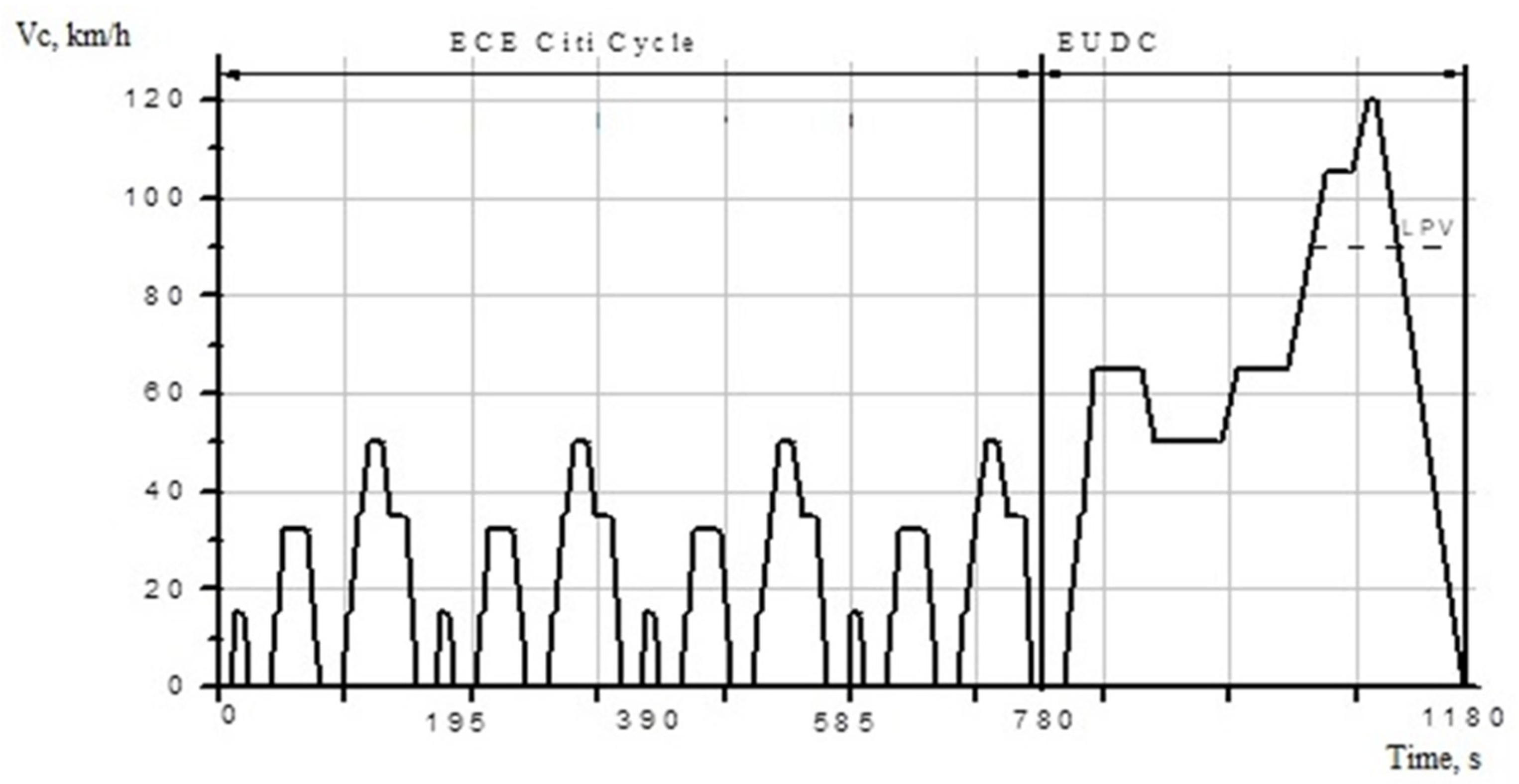

To study the influence of the type of fuel on the performance of a passenger car, the NEDC (New European Driving Cycle) driving cycle was chosen, which is used in European countries to assess the toxicity of exhaust gas and determine the fuel consumption of cars and trucks with a gross weight of up to 3.5 tons (

Figure 1).

This cycle lasts 1180 s and consists of two parts (

Figure 1). The first part is a UDC (Urban Driving Cycle) with a maximum speed of 50 km/h, which includes four consecutive driving cycles and simulates the driving conditions of a car in a city. The second part of the cycle is the EUDC (ExtraUrban Driving Cycle) high-speed extra-urban driving cycle with a maximum speed of 120 km/h (for a car with a low power engine—90 km/h), simulating the conditions of a car driving on a highway. In the NEDC driving cycle, the vehicle is tested on treadmills after starting a cold engine and warming it up at idle for 40 s.

The European driving cycle, the modes of which include the dependence of the conditional speed of the car on time, shown in

Figure 1, has some features.

Firstly, it includes unsteady modes of movement of the car and engine operation. Secondly, it does not set certain parameters of the car, including the angle of the throttle, and the operator during the driving cycle selects them to ensure the movement of the car from a given acceleration or deceleration.

If the value of acceleration or deceleration does not correspond to those specified in the table, adjustments are made to the parameters of driving. At the same time, during performance of a driving cycle on the brake stand, adjustment of the stand is selected such that corresponds to resistance of movement of the car on the road with a hard covering. In contrast to this pattern of changes in the resistance of the car in the mathematical model, the resistance of the car was calculated as calculated in motion in road conditions.

The method for calculating harmful emissions and fuel consumption by a car is based on determining the speed and loading modes of operation of an automobile engine in the movement of a car according to a driving cycle, and by using parameters characterizing the engine’s operating mode to determine mass emissions of harmful substances and fuel consumption, taking into account the peculiarities of engine operation in these modes.

When the refined mathematical model was created, it was taken as the basis and developed at the Department of Engines and Heat Engineering of the National Transport University [

16]. The original mathematical model was implemented in the Fortran environment and described the movement of the car in the “Car-Driver-Road” system without being tied to any specific driving cycle. To describe the movement of a car in the European driving cycle, this model was improved in work [

17].

The mathematical model presented in this work is implemented in the Mathcad program. A feature of this model is that, having mathematical models of a car engine when operating on various fuels, it is possible to calculate fuel consumption in motion according to the driving cycle or in operating conditions, taking into account not only the parameters of the car, type of fuel and type of road surface, but also the features of driving from the side driver (throttle opening time and amount and clutch pedal release time). This allows one to simulate identical tests of the car when powered by different types of fuels and perform more accurate modeling of transients in the movement of the car through the driving cycle in order to obtain car performance indicators close to real ones.

The mathematical model consists of differential and algebraic equations that describe the motion of the car in individual modes. These classical equations are well-known from the theory of automobiles [

18,

19,

20]. The input data for the calculation on the mathematical model are polynomial dependences of the car engine on different fuels, obtained by determining the experimental load characteristics, the parameters of the road surface, the fuel used, the engine, and the car as a whole. In addition, the input variables are the magnitude and speed of the throttle, the speed of the clutch, the selected gear, the moments of change of transmission, and the time of switching gears, which correspond to the laws of change in vehicle speed in the driving cycle.

Typical modes of the selected driving cycle will be considered in its fragment, which determines all possible modes of movement of the car and its engine:

Operation of the engine in the mode of the minimum frequency of rotation of idling on the motionless car before the beginning of movement;

Acceleration of the car engine without external load;

Acceleration of the car with a slip clutch;

Acceleration of the car when the clutch is engaged;

The movement of the car when changing gears;

Steady movement of the car;

Braking the vehicle with the clutch engaged;

Braking the car with the clutch off.

On the basis of the laws known from the theory of the car, the motion of the car in each mode was described by a system of differential and algebraic equations, which determined the parameters of the engine.

The engine as a consumer of fuel and air and as a source of harmful emissions is described by mathematical models depending on the opening of the throttle valves (vacuum behind them or torque) and the speed of the crankshaft. The output parameters of the engine in each mode are φth and ne.

Shown in

Figure 2, modes of motion of the car equations of mathematical model have the form:

Mode 1 (operation of the engine in the mode of the minimum frequency of rotation of idling on the motionless car before the beginning of movement):

where:

Me—engine torque;

ne—engine speed, rpm;

nidle—minimum engine speed at idle, rpm.

Mode 2 (acceleration of the car engine without external load):

where

φth—throttle opening angle.

Mode 3 (acceleration of the car with a slip clutch):

—deceleration or acceleration of the engine crankshaft, rpm−1·s−1;

—engine torque in unsteady mode, N·m;

Mcl—clutch friction torque, N·m;

Ie—moment of inertia of the engine (determined from the manual), kg·m2.

Driven part of the clutch of the car transmission:

where:

—acceleration of the driven part of the clutch, min−1·s−1;

Icl—the moment of inertia of the rotating masses of the vehicle is reduced to the clutch, kg·m2;

Mres—moment of resistance of the car, N·m.

Mode 4 (Acceleration of the car when the clutch is engaged):

where:

ηT—Transmission efficiency;

δ—coefficient of taking into account the rotating masses;

Ui—gear ratio;

Up—gear ratio of the main transmission;

Pf—rolling resistance of the car, N;

Pi—lifting resistance force, N;

PW—air resistance force, N;

m0, mδ—weight of the car and cargo.

Mode 5 (the movement of the car when changing gears):

MB—the moment of mechanical losses of the engine at the closed throttle valves, N·m;

rd—dynamic wheel radius, m.

Mode 6 (steady movement of the car):

Vehicle:

Vc = const,

ne = const

where:

A—the coefficient of unsteady movement of the car (A = 4…5 × 10−5);

f0—coefficient of rolling resistance of car wheels;

kF—fluidity factor, (N·s2)/m2;

Vc—car speed, m/s.

Mode 7 (braking the vehicle with the clutch engaged):

where:

rr—wheel rolling radius, m.

Mode 8 (braking the car with the clutch off):

δ—coefficient of taking into account the rotating masses.

As a result of the calculations for the car, which were the subject of research, the parameters of the engine in motion of the car were determined according to the modes of the European driving cycle. Such parameters take the vacuum in the intake manifold Δ

pk (loading mode) and the engine shaft speed

n (speed mode). Using experimental dependences of fuel consumption and concentrations of harmful substances in the exhaust gases (EG) on these parameters for gasoline and LPG, fuel consumption and harmful emissions of the car for work on these fuels were calculated. For example, the experimental dependence of the hourly fuel consumption was described by a polynomial of the second degree:

Using polynomial dependences of hourly fuel and air consumption and concentrations of harmful substances in the VG, mass emissions of harmful substances were calculated.

For example, the dependence for the calculation of carbon monoxide emissions has the form:

where:

a i b—calculated coefficients depending on the composition of the fuel–air mixture and the type of fuel;

µCO and KCO—molecular weight and concentration of carbon monoxide in EG.

Mass total emissions of harmful substances, reduced to CO, were calculated taking into account the coefficients of relative aggressiveness of individual components, conditional

t:

The 2007 Daewoo Lanos production car (

Figure 3) equipped with a four-cylinder, four-stroke A15SMS petrol engine with liquid cooling and spark ignition was chosen as the object of research, as cars of this brand are the most common representatives of imported cars in Ukraine [

21].

The engine of the production car with a petrol engine with an injection system, feedback, and catalytic converter were upgraded with a fourth-generation gas injection system STAG-4 (AC S.A. Bialystok, Poland), which includes: Tomasetto Alaska gearbox, Valtek Type 30 injectors, Toma-00 class A, and Novogas cylinder (42 L).

3. Results and Analysis

The coefficients of polynomial dependences of hourly fuel and air consumption, concentrations of harmful substances in VG from Δ

pk, and n were determined by a series of load characteristics and engine idling characteristics for gasoline and LPG [

21].

Table 1 presents the polynomial dependence of coefficients of various parameters.

The obtained mathematical dependences make it possible to calculate fuel consumption and harmful emissions of the Daewoo Lanos engine when powered by gasoline and LPG in a wide range of speed and load modes typical of real operating conditions. These mathematical dependencies describe the operation of the Daewoo Lanos engine as a source of harmful emissions and fuel consumption. Subsequently, these dependencies, taking into account the type of fuel used, are included in the mathematical models of Daewoo Lanos, which allow us to determine the energy, fuel, economic, and environmental performance of this car when powered by gasoline and LPG.

Verification of the adequacy of the obtained mathematical dependences, which describe the fuel, economic and environmental performance of the engine for work on both types of fuel was performed using Fisher’s test (F) and standard deviation (σ).

To determine the possibility of using a refined mathematical model to calculate fuel economy and harmful emissions of the car and the reliability of the results for the case of car traffic on the program of urban driving cycle, calculations of fuel consumption and environmental performance on the mathematical model were conducted. These indicators were compared with experimental data [

16].

As the movement of the car in the city is quite complex and consists of unstable modes, in order to reproduce the conditions as close as possible to the experimental one, the car was tested according to the European Urban Cycle Program, which objectively reflects the typical conditions of the car engine. The cycle was performed on a modeling AVL roller stand in accordance with UNECE Regulation Nº83, which was adjusted according to the vehicle parameters.

Research on a mathematical model allowed us to calculate the value of hourly fuel consumption in each mode of the driving cycle, both when running on gasoline and LPG (

Figure 4).

Analyzing the obtained data, we can conclude that under the same conditions of the driving cycle, gas consumption, determined in mass units, is lower than gasoline consumption. In load modes, this difference is ≈8%; in idle mode, it reaches 16–18%.

As a result of the research on the mathematical model, the calculated values of fuel consumption (

Table 2) and environmental indicators (

Table 3) when driving a car on gasoline and LPG according to the European urban driving cycle were obtained. There are also results of experimental studies.

As can be seen from

Table 2, fuel consumption in mass units for work on LPG is 14.18% lower than for work on gasoline. At the same time, the fuel consumption in liters per 100 km of mileage for work on LPG is 16.6% higher than for work on gasoline. This can be explained by the lower density of LPG compared to gasoline. Fuel consumption, expressed in thermal equivalent, when the car engine is running on LPG is 10.38% lower.

Comparing the above data (

Table 2), it is seen that the distance traveled by the car during the driving cycle and the time of its execution is almost no different from the values provided by the test program. The deviation of the calculated fuel consumption data from the experimental data in the case of the driving cycle on gasoline is 0.44% and on LPG is 0.86%.

The values of environmental indicators (

Table 3) obtained by calculations on the mathematical model differ from the experimental ones by an average of 15%.

The values of mass emissions of carbon monoxide per cycle are almost the same for both types of fuel and are equal to 0.019–0.022 g/km. Emissions of hydrocarbons when working on LPG increased from 0.047 to 0.153 g/km, and nitrogen oxides increased from 0.124 to 0.242 g/km. Mass emissions of carbon dioxide when fueling a car with LPG decreased from 210.53 to 165.08 g/km.

Some deviation of the data is explained by the difficulty of reproducing the driving cycle on the stand, which is the inability to perform the driving cycle at a constant average planned speed and strict compliance with the requirements of transient modes by the driver, and the mathematical model excludes this.