Abstract

Mechanical pigging is a major wax removal technique in crude oil pipeline transportation. To lower the risk of pig stalling accidents in pigging, a superparamagnetic nanoparticle (SPM-NP) pigging system that consists of an electromagnetic pig and nanopaint is designed to soften the wax deposit and reduce the wax resistive force. During pigging, the induction coil on the pig generates an alternating magnetic field, which induces heat production of the nanopaint on the pipe wall. The COMSOL software is used to simulate the temperature distribution of the wax layer. Yield stress measurements reveal that the wax layer yield stress is nearly linearly correlated to temperature. Compared with a regular pig, the SPM-NP pigging system reduces the wax resistive force by up to 20~40%, with an acceptable electrical current intensity of about 20 A in the given cases. Multiple factors affecting the wax layer temperature were analyzed. SPM-NP heating could be a promising technique for wax remediation and hydrate prevention.

1. Introduction

Wax depositions have long been an intractable flow assurance challenge in oil and gas production and transportation [1,2]. When the oil temperature drops below its wax precipitation temperature (WAT), the wax components will precipitate and deposit onto the pipe wall. The deposited wax occupies the flow channel of crude oil and harms the transportation capacity of the pipe; a higher pumping cost is accordingly required. In worst cases, the wax deposition could even cause complete blockage of the pipe. Economic loss caused by wax deposition is prohibitively expensive. For example, in dealing with the wax plugging accident in the Azeri-Chirag-Gunashli (ACG) oil field, the operators had to shut down the well and remove the blocked pipe section for manual cleaning [3]. Production problems caused by wax deposition in offshore pipelines are even worse due to the low seawater temperature [4]. Efficient and economic wax removal technology is urgently required by the petroleum industry.

For wax prevention and remediation, varieties of methods have been proposed, including chemical injection, inductive heating (namely heating the pipe wall by eddy currents under a coil-induced magnetic field), mechanical pigging [5,6], etc., among which pipeline pigging is most widely used [7,8]. During pigging, the pig is pushed by the bulk flow, and the wax layer on the pipe is cleaned by the scrapers. This process is quite risky because the wax deposit could exert a huge resistive force on the pig. Once the wax resistive force exceeds the oil driving force, the pig would get clogged in the pipe, and a pig stalling accident occurs [9]. Moreover, the bypass holes on the pig impairs the oil driving force; thus, the pig could more easily get blocked by wax deposit.

To lower the risk of pig stalling, raising the temperature to weaken the wax layer is a good option. To this end, electric heating is traditionally used in oil and gas gathering systems. It introduces Joule heat (i.e., the heat produced by electric current when it passes through a conductor) to soften the wax deposit without disturbing oil flow [10]. The temperature can be controlled by adjusting the power input. However, the high cost and difficulty in the maintenance of the system confine its application to offshore pipelines. Recently, the employment of superparamagnetic nanoparticles (SPM-NPs) in alternating magnetic fields to heat the wax layer has drawn special attention from the petroleum industry [11,12]. It might be a promising technique for wax remediation.

SPM-NPs have long been used in magnetic hyperthermia [13,14]. Magnetic hyperthermia is an important tumor treatment modality ranked after radiotherapy and chemotherapy [15]. It is based on the selective SPM-NP absorbency of tumor cells and the heat-producing capability of SPM-NPs in alternating magnetic fields. In magnetic hyperthermia treatments, SPM-NPs are stably dispersed in a liquid carrier and injected into the tumor tissue. High microvascular permeability and interstitial diffusion allow the SPM-NPs to extravasate into the neoplastic tissue [16]. Tumor cells are rather heat-sensitive and can be killed at 42~46 °C, whereas normal cells can survive at this temperature [17,18]. In the presence of alternating magnetic fields, the SPM-NPs generate highly localized and focused heat to destroy the tumor cells. Parameters, such as the SPM-NP size and concentration, magnetic field amplitude, and frequency, are carefully controlled to maintain an appropriate heating temperature. Iron oxide nanoparticles, including Fe3O4 and γ-Fe2O3, are commercially available and commonly used in magnetic hyperthermia [19].

The high heat release efficiency and stability of SPM-NPs also attract the petrochemical industry. Davidson et al. [20] costed a tube with SPM-NPs on the inner wall of a PVC pipe and used an induction coil outside the pipe for heat production to prevent hydrate and wax deposition. Due to the magnetic shielding effect of carbon steel, this design may not be feasible for field pipes because the outside-generated alternating magnetic field is not capable of penetrating the carbon steel pipe. Mehta et al. [12] compared the heating performance of solid nanopaint and SPM-NP dispersion in alternating the magnetic field and proved the feasibility of SPM-NPs in wax remediation. Wang et al. [11] employed nanopaint to melt the wax layer in pigging. An induction coil was installed on the pig to directly exert an alternating magnetic field on the nanopaint from the inside of the pipe. However, the electrical current intensity required for melting the wax deposit was up to 300 A in the simulation, which is almost unavailable in field practice.

To lower the required current intensity to an acceptable level, we tried to soften the wax layer instead of melting it. To this end, an SPM-NP pigging system that consists of an electromagnetic pig and a nanopaint was designed. During pigging, the electromagnetic pig generates an alternating magnetic field to produce heat within the nanopaint; thus, the wax layer is heated and softened, and it could be easily removed from the pipe wall by the pig. Experiments were conducted to obtain the relationship between the mechanical strength of the wax layer to the temperature. A methodology to estimate the wax resistive force of a regular pig and the SPM-NP pigging system has been proposed. The effectiveness of the system in lowering the risk of pig stalling is proved by comparing the wax resistive forces of the electromagnetic and regular pigs. Multiple factors affecting the heating performance of the system were investigated. The SPM-NP pigging system could be a promising supplement for traditional pigging.

2. SPM-NP Pigging System

2.1. Heating Mechanism of Superparamagnetic Nanopaint

In our everyday life, ferromagnetism is responsible for many common magnetic phenomena. A daily example is the refrigerator door attracted by ferromagnetic materials to seal the freezing chamber. From the point of view of magnetic theory, macroscopical ferromagnetic material is an ensemble of particles that have enormous magnetic domains inside them. The magnetic domain is a cluster of massive atoms whose intrinsic magnetic dipole moments almost align in the same direction; thus, within each magnetic domain, the magnetism is very strong. Since the magnetic moment orientations of different domains distribute randomly and cancels each other out, multi-domain materials present no overall magnetism. Generally, the diameter of a single magnetic domain is dozens of nanometers. When a ferromagnetic particle shrinks to a certain size where it contains only one magnetic domain, it becomes a single-domain particle. As it continues to shrink to a critical point where thermal disturbance is strong enough to reverse the domain magnetization, a superparamagnetic nanoparticle (SPM-NP) is obtained. The critical transformation size of an SPM-NP is highly correlated to its structure and anisotropy. Different from ferromagnets, SPM-NPs present no magnetic hysteresis. That is to say, SPM-NPs have zero coercivity and zero remanences [12].

When put into an alternating magnetic field, magnetic moments of the SPM-NPs would oscillate with the field to overcome the potential barrier of magnetic anisotropy, which converts electromagnetic radiation to thermal energy. This process is called Néel relaxation. If the SPM-NPs are immersed in a fluid, an alternating magnetic field will induce the reorientation of the particles themselves, and frictional heating is triggered by the interaction between the particles and the fluid. This process is called Brownian relaxation. Obviously, Néel relaxation is decisive for nanopaint heating in this work be the nanopaint has already solidified. The thermal effect of SPM-NPs in alternating magnetic fields is characterized by a specific absorption rate (SAR), i.e., the produced heat in the unit time by the unit weight of the nanoparticles [21,22]:

where is the initial dc susceptibility of the material; is the magnetic field intensity, A/m; is the magnetic field frequency, Hz; is the permeability of the free space, equal to H/m; is the Néel relaxation time, which is given by [23]

where is the attempt time, which is assumed to be 10−9 s hereby; is the magnetic anisotropy constant of the nanoparticles, J/m3; is the Boltzmann constant, equal to 1.38 × 10−23 J/K; is the volume of the particle core, m3.

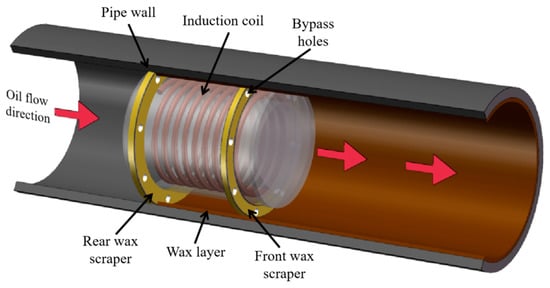

2.2. Configuration of the SPM-NP Pigging System

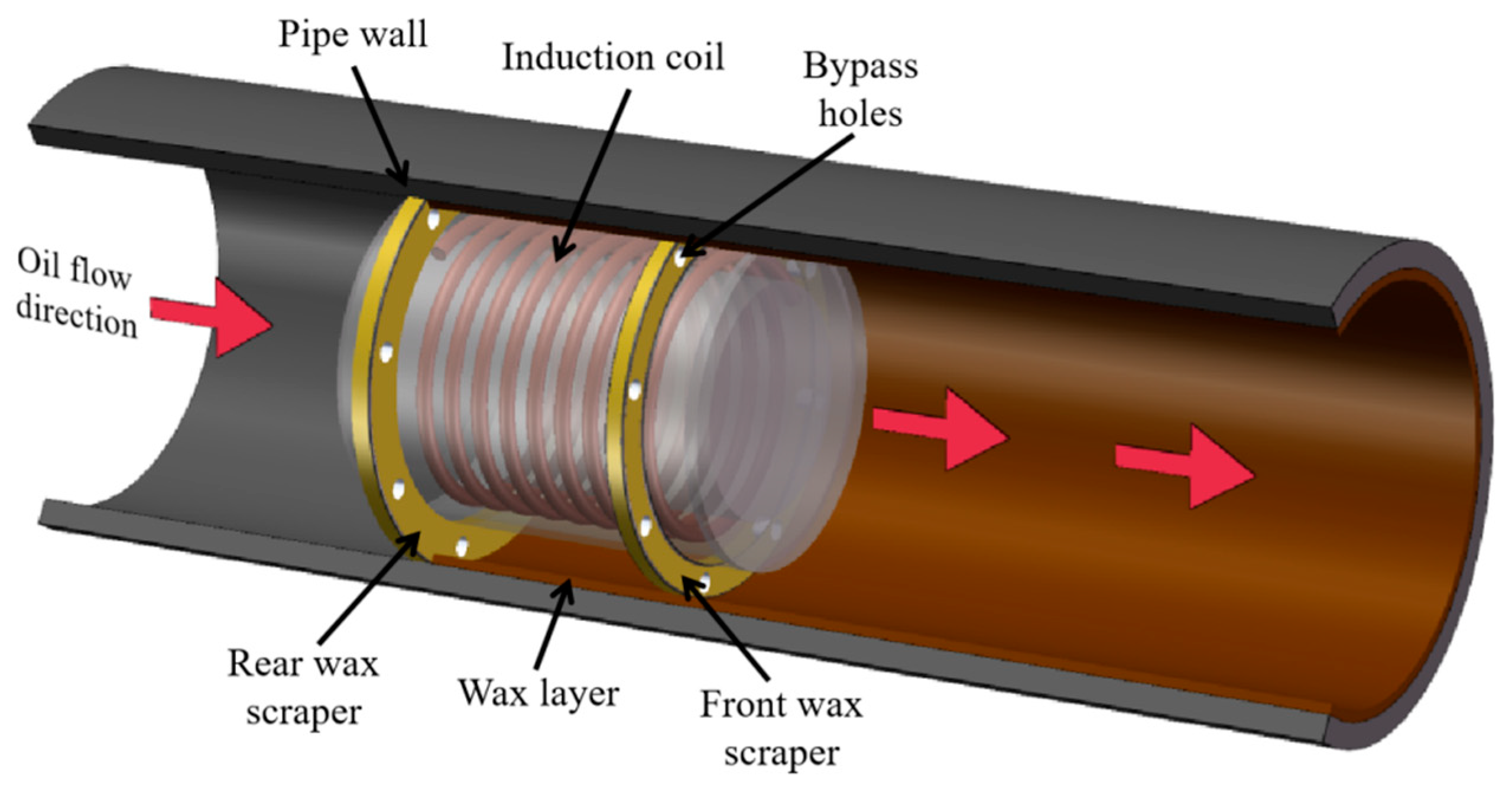

During pigging, if the wax layer is too thick and hard, the wax resistive force may exceed the oil driving force, then the pig would be stuck in the pipe, causing a pig stalling accident. Obviously, if the wax layer is heated and softened, it can be more easily removed by the pig, and better cleaning efficacy can also be expected. For this purpose, an electromagnetic pig is designed. It is realized by installing an induction coil on a regular pig. The induction coil is powered by batteries to generate a high-frequency alternating magnetic field. The pipe wall is coated with a nanopaint that contains nanoparticles for heat production. During pigging, the alternating magnetic field induces heat in the nanopaint to soften the wax layer. Figure 1 gives the schematic of the SPM-NP pigging system. In order to flush the removed wax particles downstream to avoid wax accumulation, bypass holes were drilled on the scrapers.

Figure 1.

Schematic diagram of the SPM-NP pigging system.

Due to the shielding effect of the steel pipe wall on the magnetic field, the magnetic flux generated by the induction coil is well confined within the pipe, which benefits a lot by enhancing the magnetic field strength near the pipe wall and thus helps to improve the heating efficacy. Moreover, it is worth noting that the front wax scraper is smaller than the rear one, which allows it to ride on the wax layer for guidance instead of scraping during pigging. The wax layer is actually removed by the rear scraper.

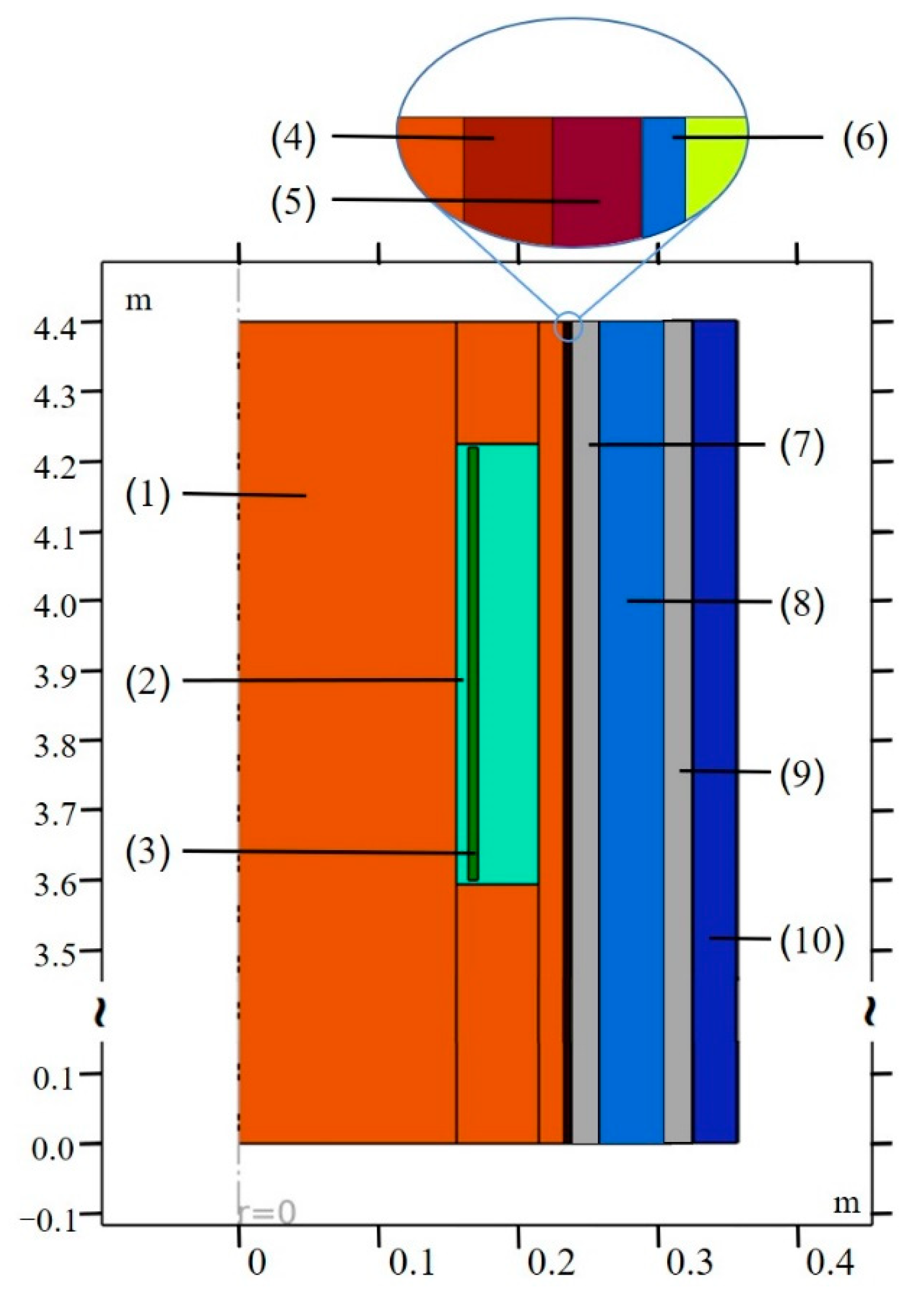

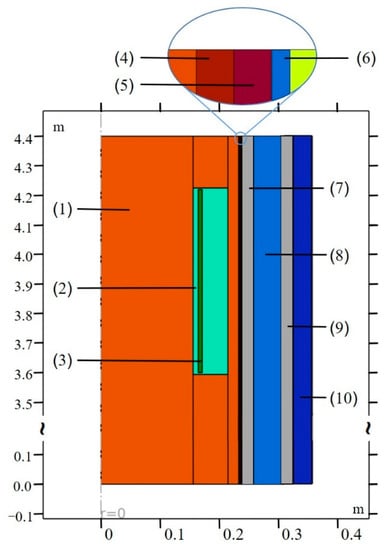

2.3. Parameters

During pigging, heat production occurs in the nanopaint by the alternating magnetic field. As shown in Figure 2, to minimize heat dissipation to the steel pipe, an insulation layer is set between the inner steel and the nanopaint. Another thermal insulation layer is sandwiched by two steel pipes for heat preservation. Wax deposition actually occurs on the nanopaint instead of the pipe wall. Relevant geometric and physical parameters are listed in Table 1 and Table 2. The wax layer was set to be 2 mm.

Figure 2.

Configuration of the pipe: (1) oil; (2) pig; (3) induction coil; (4) wax layer; (5) nanopaint; (6) inner thermal insulation layer; (7) inner steel pipe; (8) outer thermal insulation layer; (9) outer steel pipe; (10) seawater.

Table 1.

Geometric parameters of the pipe wall and electromagnetic pig.

Table 2.

Physical properties of relevant materials in the numerical simulation.

2.4. Heating Efficacy of the SPM-NP Pigging System

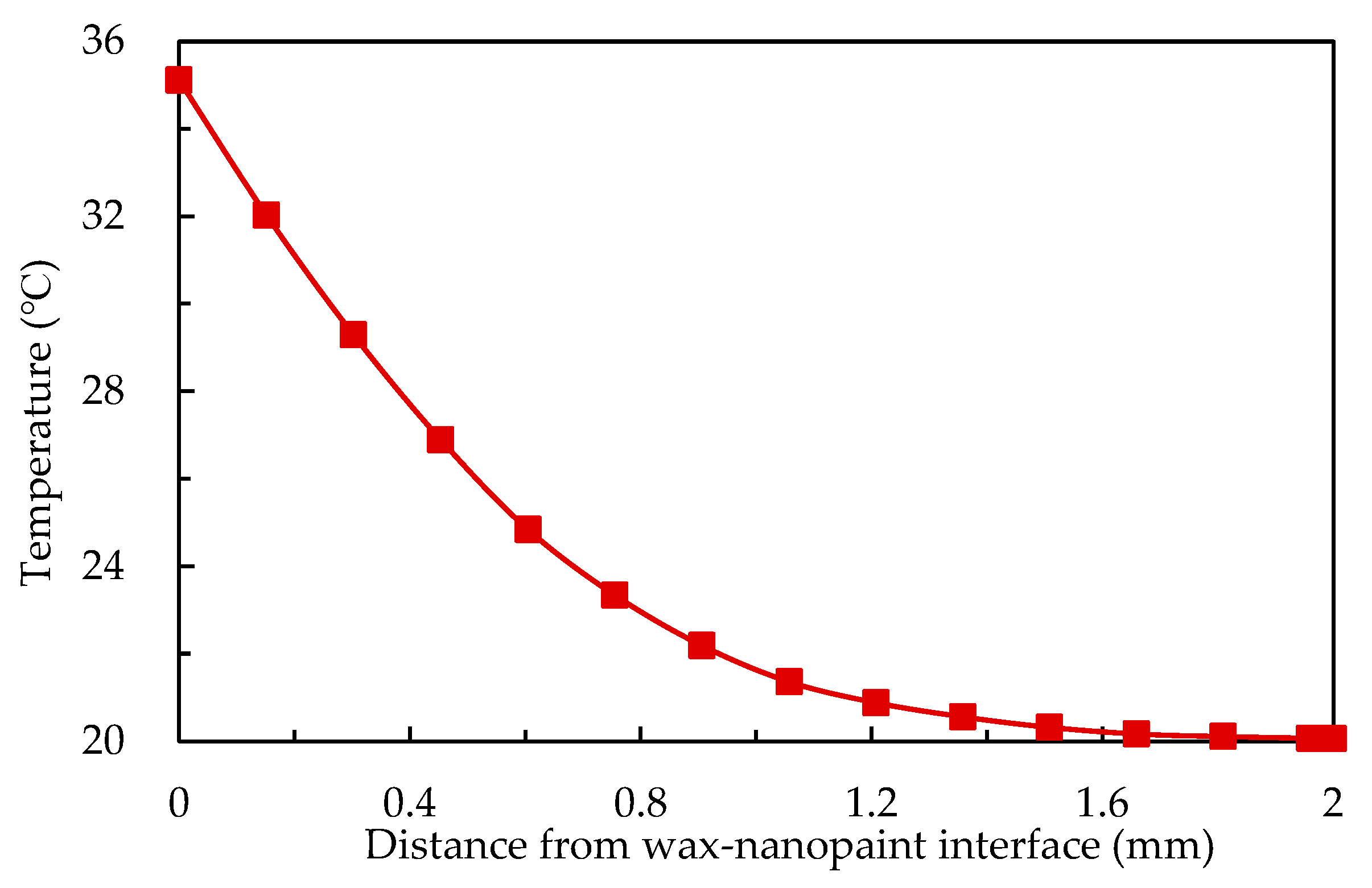

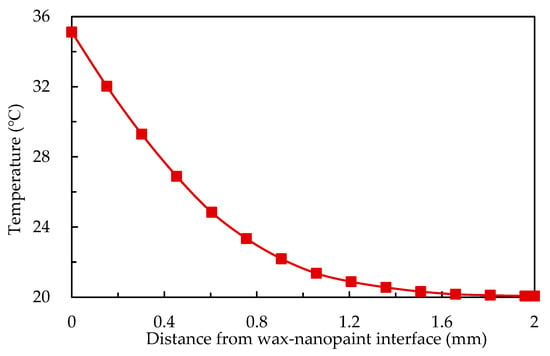

The commercial multiphysics simulation software COMSOL was used to simulate the temperature field of the wax layer. Figure 3 shows the radial temperature distribution of the wax layer after heating. Due to the low heat conductivity of the wax deposit, the temperature near the wax–oil interface almost remains unheated for such a short time that the pig passes through it. However, the temperature increment at the wax-nanopaint interface is up to 15 °C, which greatly softens the wax deposit near the pipe wall and reduces the adhesion of the wax deposit to the nanopaint. The wax resistive force accordingly gets lowered.

Figure 3.

Radial temperature distribution of the wax layer after heating (original wax layer temperature is 20 °C; magnetic field frequency is 500 kHz; electrical current intensity is 20 A; SPM-NP diameter is 18 nm; pig velocity is 0.4 m/s; flow rate is 0.4 m/s; induction coil turn number is 310 turns; nanoparticle content is 10%).

3. Comparison of Wax Resistive Forces of Electromagnetic and Regular Pigs

3.1. The Relationship between Wax Layer Yield Stress and Temperature

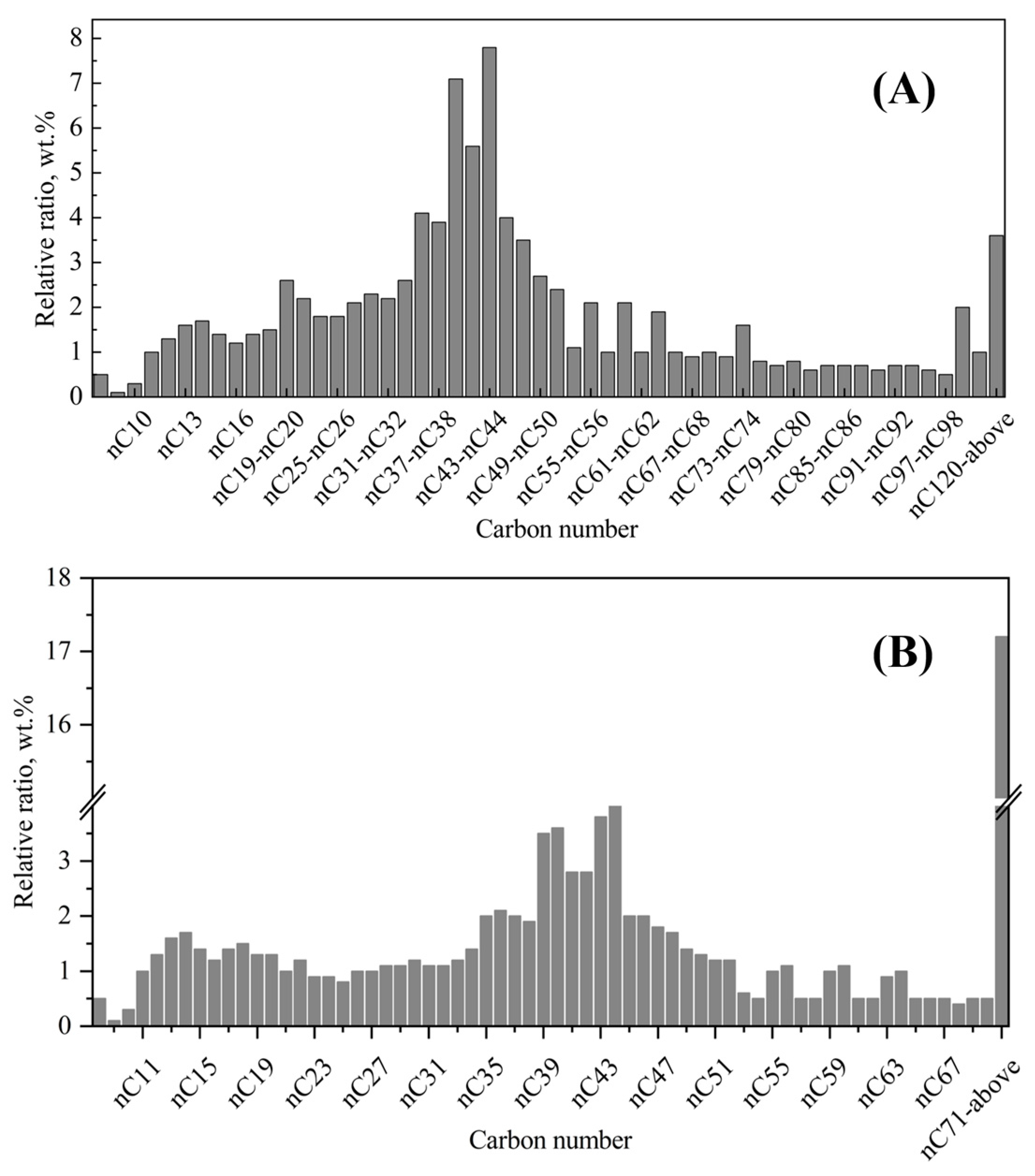

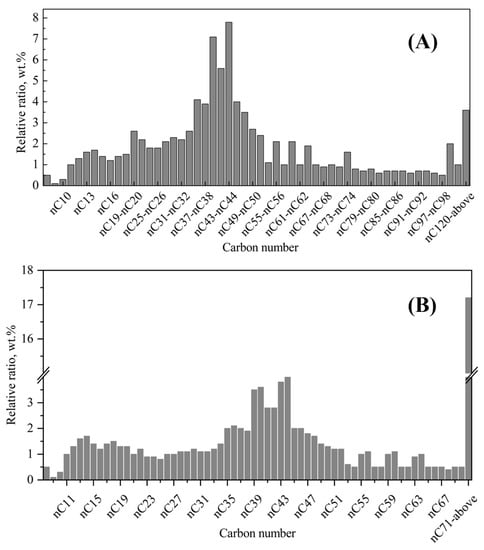

To investigate the relationship of the wax layer yield stress to the temperature, we prepared wax samples by dissolving a field-collected wax deposit into crude oil. High-temperature gas chromatography (HTGC) was used to determine the carbon number distributions of the crude oil and the wax deposit. The results are given in Figure 4. The wax–oil mixture was prepared as follows: Firstly, we heated the crude oil to 80 °C in a beaker. Then, we sliced the wax deposit into thin pieces and gradually added them to the beaker to obtain an oil–wax deposit mixture. The solution was stirred by an electric agitator at 800 r/min. After adding it, we kept stirring for another 15 min to ensure the complete dissolution of the wax deposit. Both the wax deposit and crude oil were carefully weighed to get the wax mixing ratio, i.e., the weight ratio of the wax deposit to the whole solution.

Figure 4.

Carbon number distributions of the (A) crude oil and (B) wax deposit.

A controlled-stress rheometer (RheolabQC, Anton Paar GmbH., Graz, Austria) was used to determine the yield stress of the wax layer. In rheological measurements, the measuring geometry affects the spatially inhomogeneous deformation of the tested material, thus significantly impacting the yield stress determination of the wax–oil gel. In this work, we adopted a four-bladed vane system as it effectively avoids wall slippage and improves measurement reproducibility while ensuring a cohesive breakage of high solid-fraction wax gels [24]. The yield stress measurement proceeds as follows: Firstly, we loaded the prepared oil–wax deposit solution into the test system that had been preheated to 80 °C and held it there for 10 min. Then, we cooled the sample to the test temperature at 1 °C/min. One hour after the test temperature was reached, we logarithmically applied stress on the sample with an initial value of 0.1 Pa. The data logging frequency was 5 Hz.

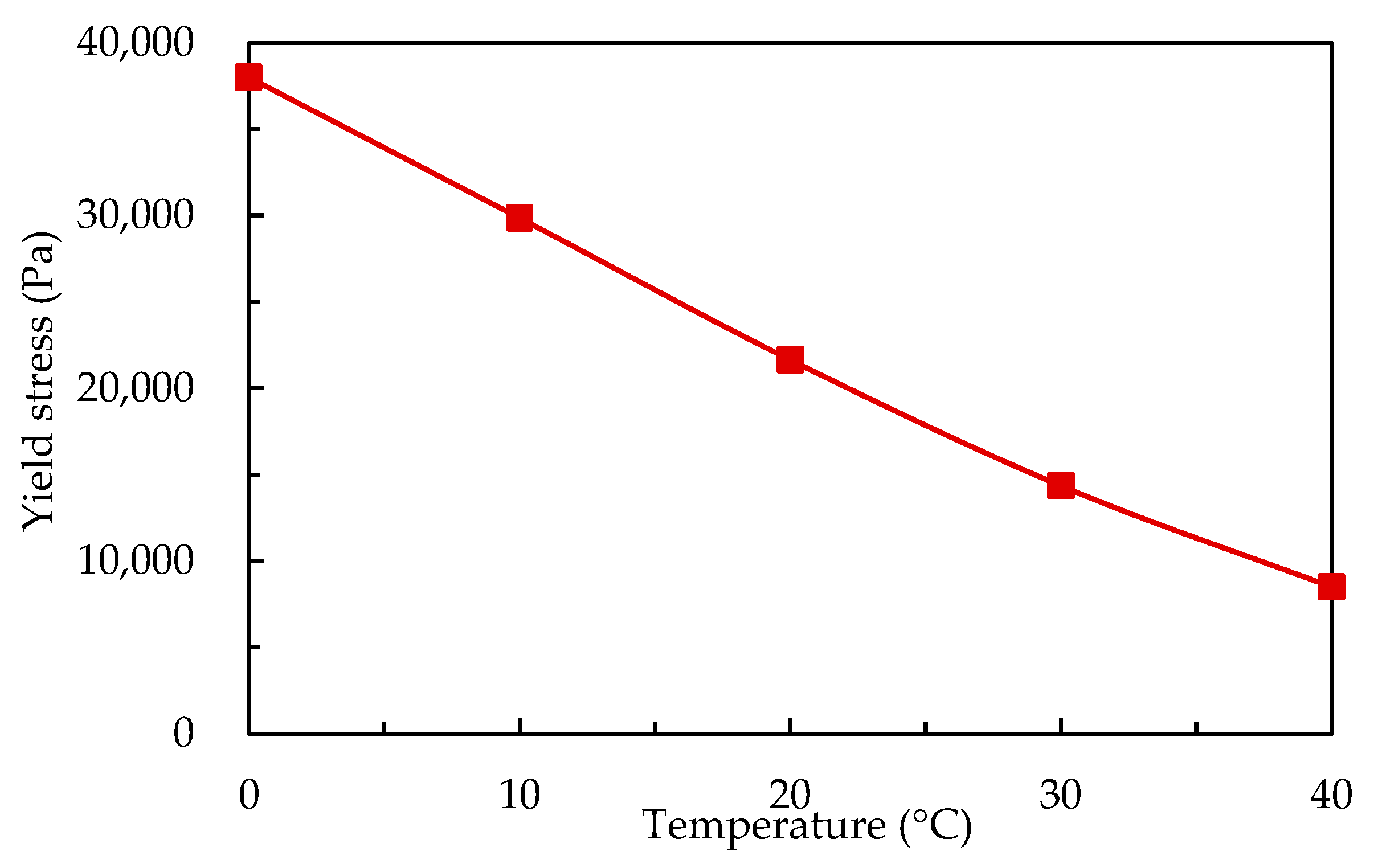

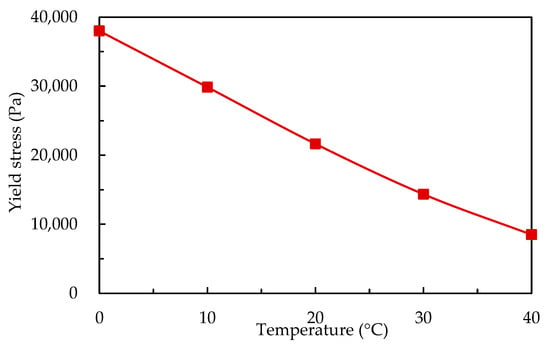

The wax samples with a 30% wax mixing ratio were prepared. Following the above procedures, we tested the yield stresses of the prepared wax samples at test temperatures of 0 °C, 10 °C, 20 °C, 30 °C, and 40 °C. The result is given in Figure 5.

Figure 5.

Relationship between the wax sample yield stress and temperature.

It can be seen that the yield stress of the wax sample is approximately linearly correlated to the temperature. The data regression of Figure 4 gives the yield stress–temperature correlation of the wax sample with a 30% wax mixing ratio:

where is the wax layer yield stress, Pa; t is the temperature, °C.

3.2. Wax Resistive Forces of Electromagnetic and Regular Pigs

Wax resistive force in pigging is the resistance experienced by the pig when removing the wax layer. Obviously, the yield stress of the wax layer is a decisive factor affecting the wax resistive force. Assuming that wax breakage would occur when the exerted stress by the pig reaches the yield stress, the relationship between the wax resistive force and wax layer yield stress can be given by

where is the wax resistive force, N; is the yield stress of the wax layer, Pa; is the inside diameter of the pipe, m; is the wax layer thickness, m.

When the wax deposit is heated by the SPM-NP heating system, a radial temperature gradient is estimated from the oil to the pipe wall within the wax layer. On this occasion, the integral of Equation (4) from the oil–wax interface to the wax–nanopaint interface is conducted to calculate the overall wax resistive force of the wax layer:

where R is the radius of the oil flow passage, m.

As shown in Table 3, the superiority of the SPM-NP heating system is verified by comparing the wax resistive forces of electromagnetic and regular pigs using Equations (4) and (5) on different wax layer thicknesses. The SPM-NP heating system dramatically reduces the wax resistive force by up to 20~40%, with an electrical current of about 20 A. It is acceptable in field practice compared with the wax melting formula that requires an electrical current of 300 A [25]. The SPM-NP heating system helps a lot to lower the risk of a pig stalling accident in pigging.

Table 3.

Comparison of wax resistive forces of electromagnetic and regular pigs *.

From Table 3, we see that the SPM-NP pigging system has a better heating efficacy on thinner wax layers. This is ascribed to the poor thermal conductivity of the nanopaint, which confines the heated area of the wax layer to the wax–nanopaint interface. Therefore, the overall temperature increment of the thin wax layer is larger than that of the thick wax layer. As aforementioned, 2 mm of the wax deposit is taken as a pigging criterion in field practice. The actual wax layer thickness during pigging is often thinner than 2 mm. Thus, we can expect a better heating efficacy of the SPM-NP pigging system in actual pigging operations than in the simulated cases, which adopt a wax layer thickness of 2 mm.

4. Factors Affecting Wax Layer Temperature

Wax layer temperature is decisive in determining the wax resistive force and pig stalling risk. In this part, we focus on the wax layer temperature and investigate the impacts of multiple factors involved, which helps to optimize the SPM-NP pigging system. Note that the temperature in the following sections is the temperature of the wax layer at a depth of 1.9 mm from the wax–oil interface when the pig just passes through.

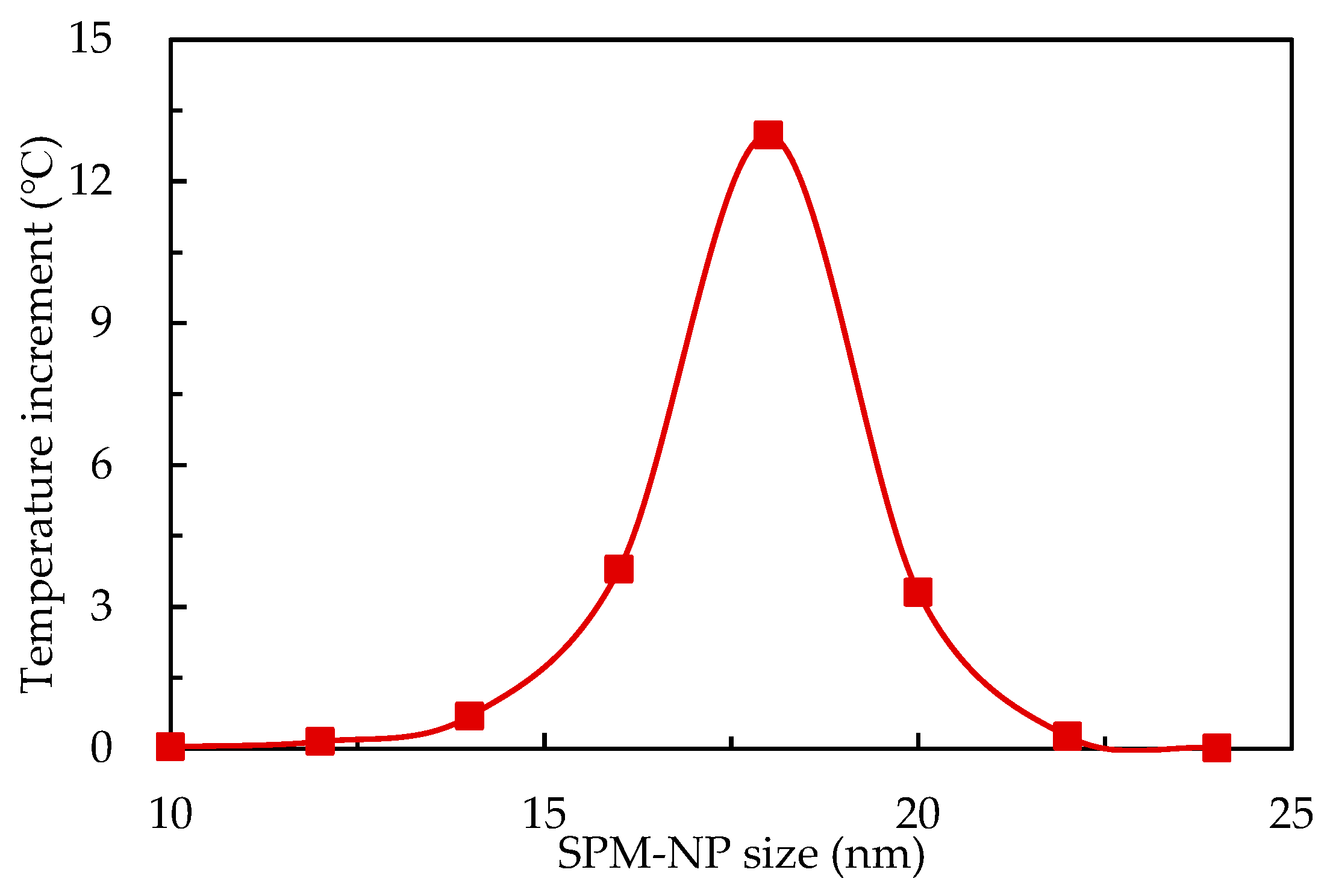

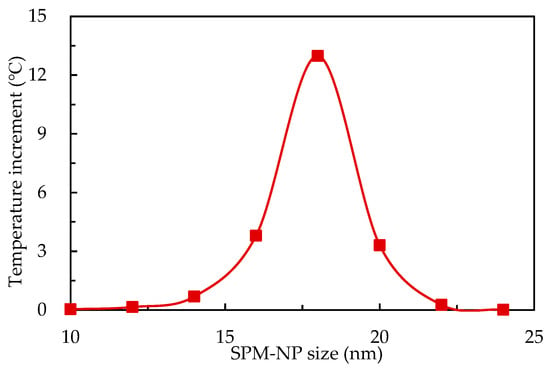

4.1. SPM-NP Size and Concentration

From Equations (1) and (2), we see that nanoparticle size is an important parameter for Néel relaxation time and SAR; thus, it further impacts the heating efficacy. Figure 6 shows the variation of the wax layer temperature against the SPM-NP size. It can be seen that the wax layer temperature is non-monotonically correlated to the nanoparticle size. The optimal particle size is 18 nm. If the nanoparticle is too large, the material is no longer superparamagnetic. Too small a nanoparticle also deteriorates the increment of the wax layer temperature.

Figure 6.

Effect of nanoparticle diameter on wax layer temperature increment (original wax layer temperature is 20 °C, magnetic field frequency is 500 kHz, the electrical current intensity is 20 A, pig velocity is 0.4 m/s, the flow rate is 0.4 m/s, induction coil turn number is 310 turns, and nanoparticle content is 10%).

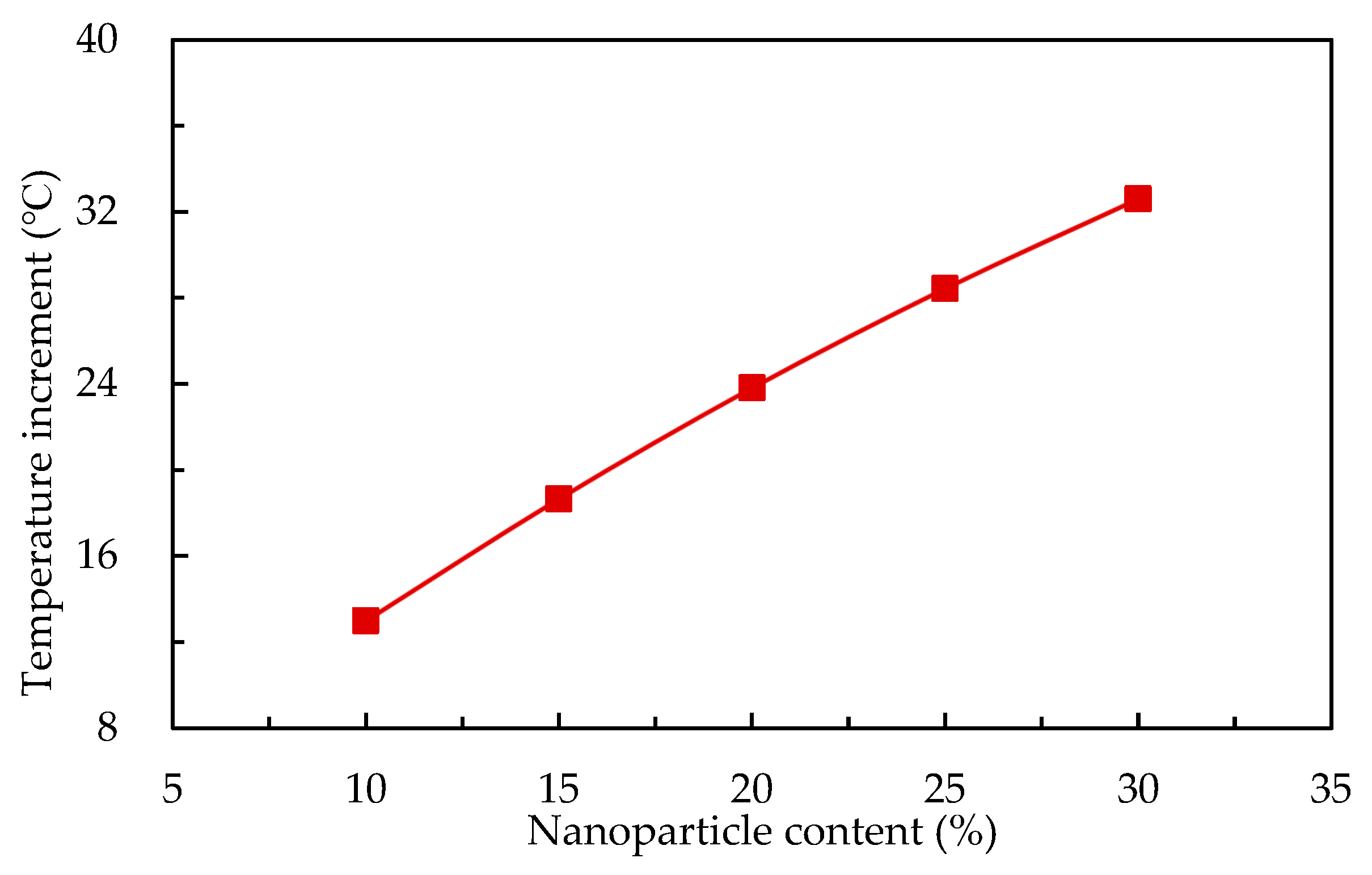

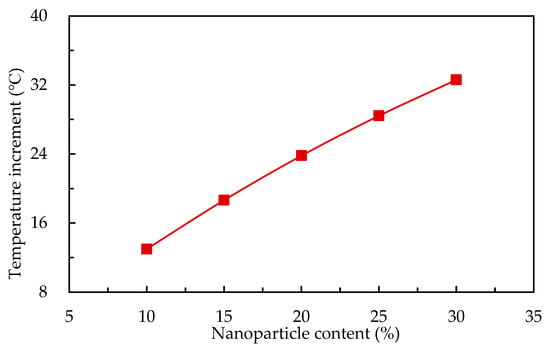

The effect of nanoparticle concentration on the heating effect of nanopaint is shown in Figure 7. The increment of the wax layer temperature and SPM-NP concentration is positively correlated. For the SPM-NP pigging system, the nanoparticles in the nanopaint are actually the heat source to soften the wax layer. Thus, a larger SPM-NP concentration implies a stronger heat source, and a better heating efficacy on the wax layer is expected.

Figure 7.

Effect of nanoparticle concentration on wax layer temperature increment (original wax layer temperature is 20 °C, magnetic field frequency is 500 kHz, the electrical current intensity is 20 A, SPM-NP diameter is 18 nm, pig velocity is 0.4 m/s, the flow rate is 0.4 m/s, and induction coil turn number is 310 turns).

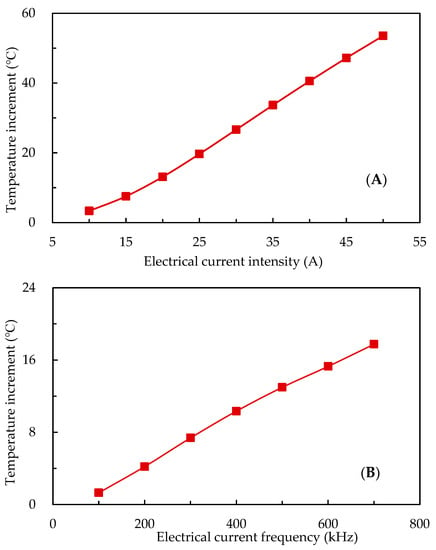

4.2. Electrical Current Intensity and Frequency

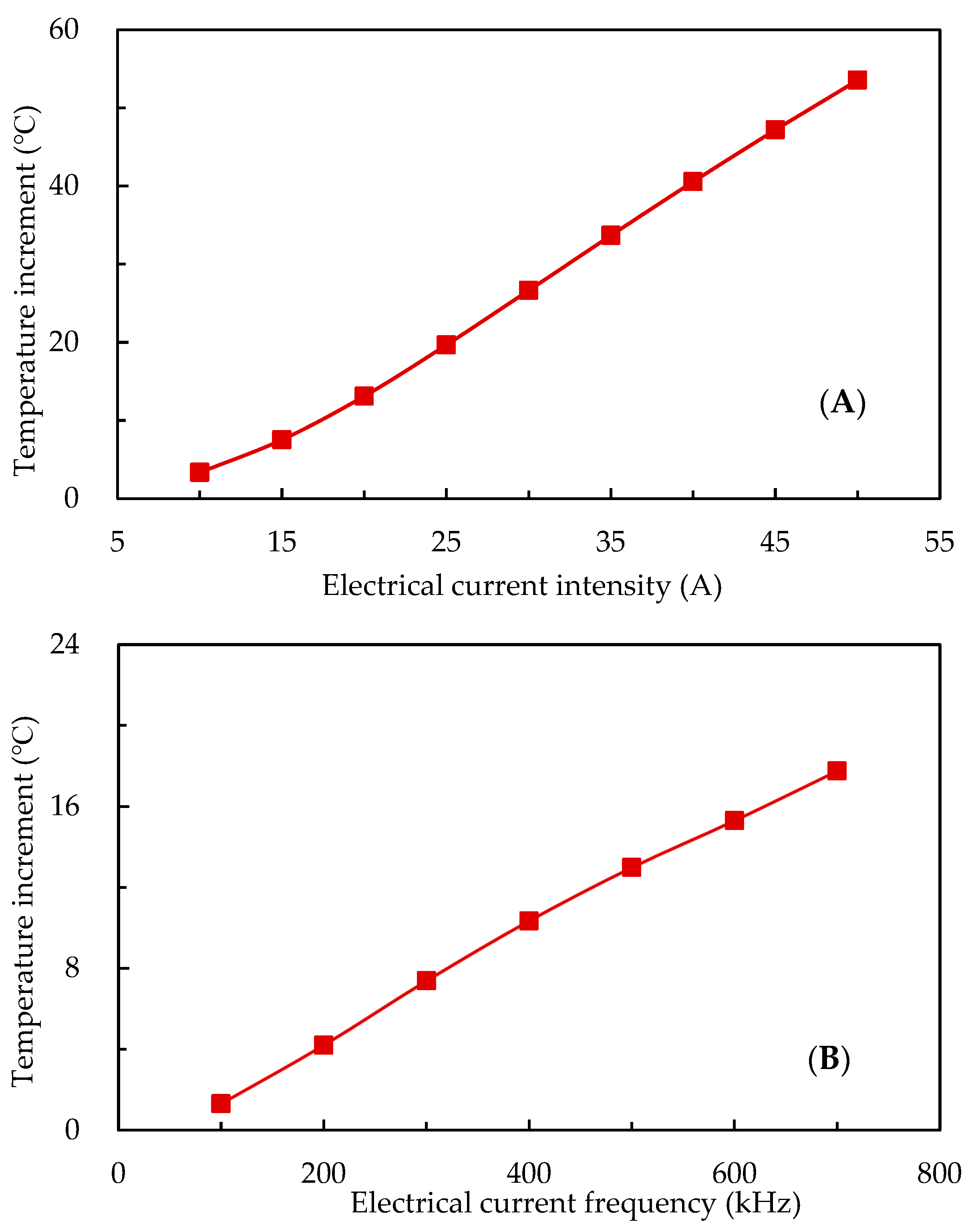

During pigging, the alternating magnetic field for heat production is actually induced by the electric current in the induction coil. Manipulation of the magnetic field is realized by adjusting the electric current. Thus, we investigated the impacts of electrical current intensity and frequency instead of magnetic field strength and frequency. Figure 8 shows that wax layer temperature increases with both electrical current intensity and frequency. This can be explained by Equation (1), which indicates that SAR is positively correlated to magnetic strength and frequency. Therefore, in field practice, a larger electrical current intensity and higher frequency are preferred. However, a larger magnetic field frequency also enhances the impedance of the induction coil, which requires a stronger power supply capability of the battery. A compromise between magnetic field frequency and the cost of the equipment is required to obtain a better economic benefit.

Figure 8.

Effects of electrical current intensity and frequency on wax layer temperature increment (A) electrical current intensity (original wax layer temperature is 20 °C, magnetic field frequency is 500 kHz, SPM-NP diameter is 18 nm, pig velocity is 0.4 m/s, the flow rate is 0.4 m/s, induction coil turn number is 310 turns, and nanoparticle content is 10%) and (B) electrical current frequency (original wax layer temperature is 20 °C, electrical current intensity is 20 A, SPM-NP diameter is 18 nm, pig velocity is 0.4 m/s, the flow rate is 0.4 m/s, induction coil turn number is 310 turns, and nanoparticle content is 10%).

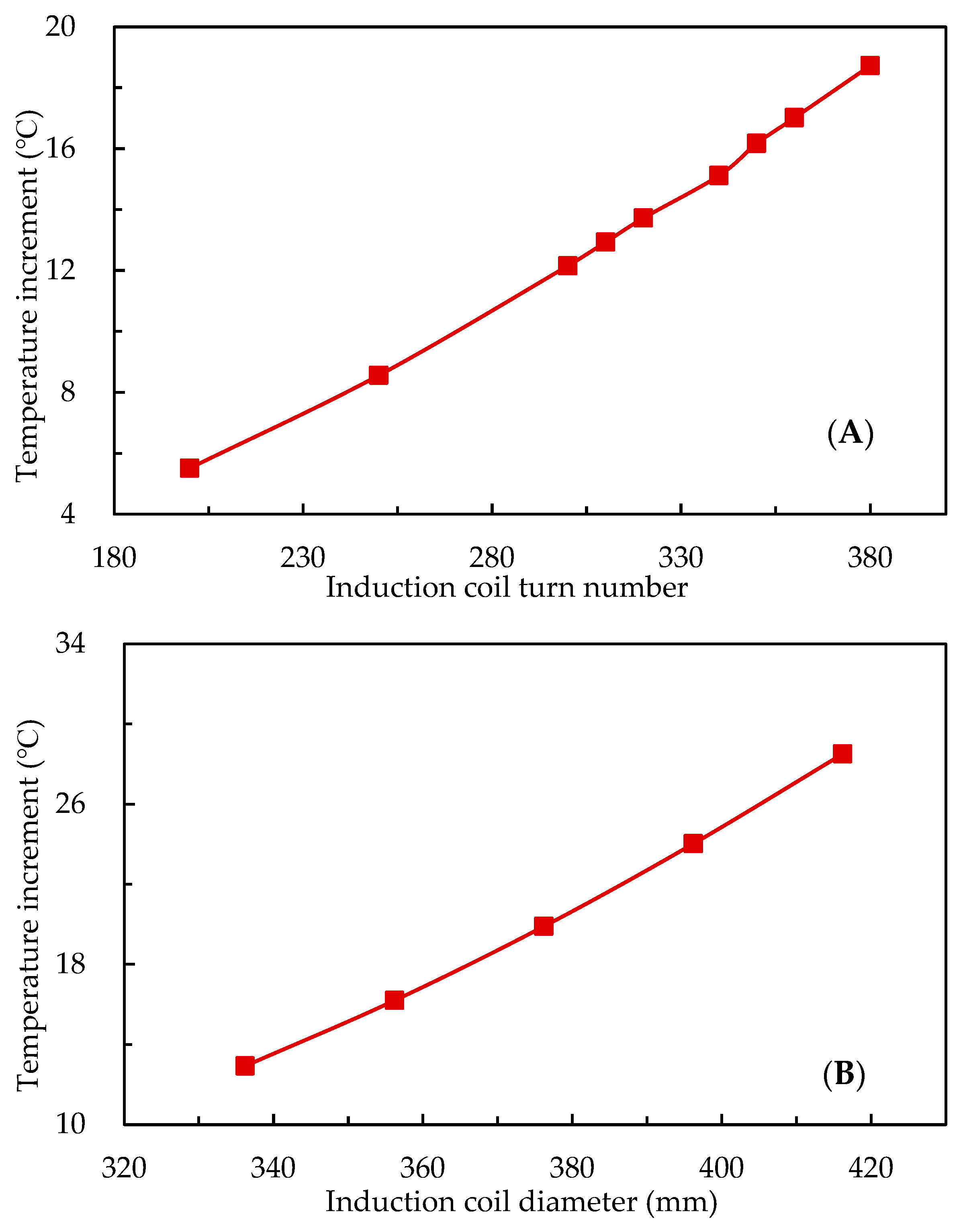

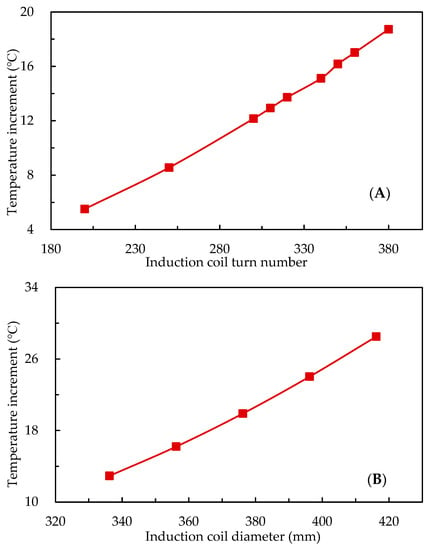

4.3. Induction Coil Turn Number and Diameter

The turn number and diameter of the induction coil are key parameters in determining the magnetic field; thus, they further impact the heating efficacy of the SPM-NP pigging system. Figure 9 shows that the increased turn number and diameter of the induction coil bring about a higher wax layer temperature. From Faraday’s law of electromagnetic induction, we know that more coil turns result in stronger electrodynamic potential, which helps to increase the magnetic field strength and improve the heating efficacy. Moreover, a larger induction coil narrows the annular space between the coil and the pipe wall. Due to the shielding effect of the steel pipe on the magnetic field, the magnetic flux is confined within the annular space between the induction coil and the pipe wall. Thus, the magnetic flux density is enhanced with a larger induction coil diameter, which benefits the raising of the wax layer temperature.

Figure 9.

Effects of induction coil turn number and diameter on wax layer temperature increment. (A) Induction coil turn number (original wax layer temperature is 20 °C, electrical current intensity is 20 A, magnetic field frequency is 500 kHz, SPM-NP diameter is 18 nm, pig velocity is 0.4 m/s, the flow rate is 0.4 m/s, and nanoparticle content is 10%) and (B) induction coil diameter (original wax layer temperature is 20 °C, electrical current intensity is 20 A, magnetic field frequency is 500 kHz, SPM-NP diameter is 18 nm, pig velocity is 0.4 m/s, the flow rate is 0.4 m/s, induction coil turn number is 310 turns, and nanoparticle content is 10%).

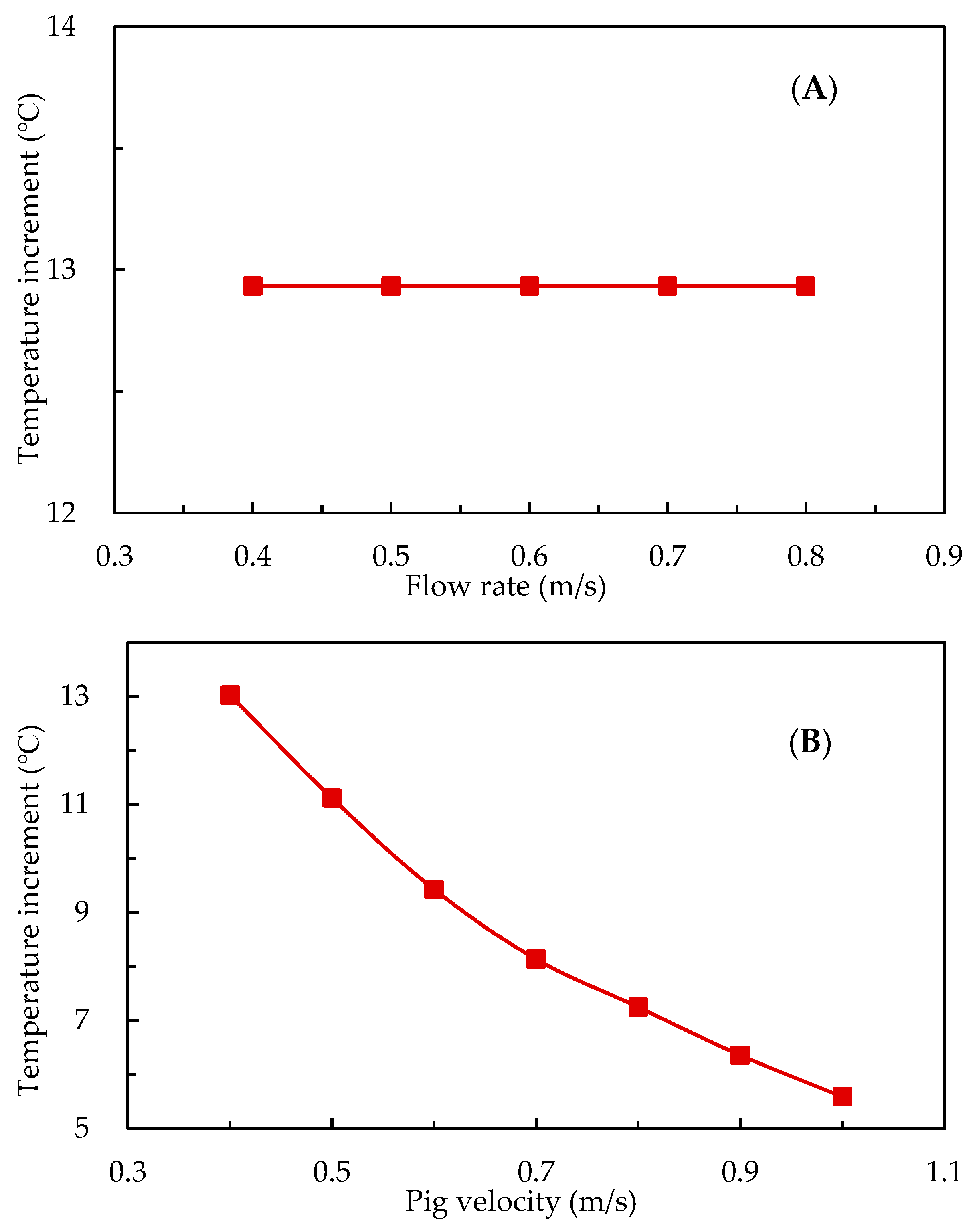

4.4. Flow Rate and Pig Velocity

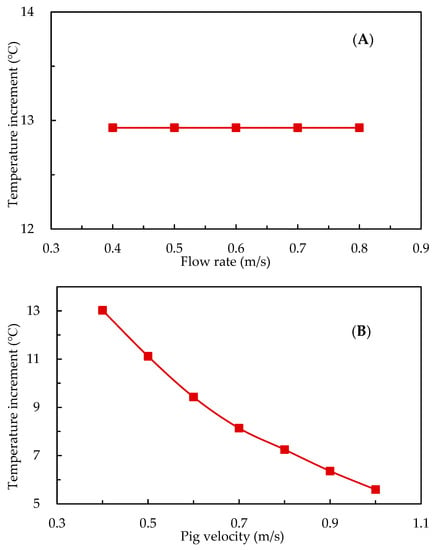

The impacts of the flow rate on the wax layer temperature are given in Figure 10. Due to the poor thermal conductivity of the wax deposit, the generated heat by the nanopaint is not strong enough to penetrate the whole wax layer in such a short time that the pig passes through; thus, the oil flow rate has little effect on the heating effect. Figure 10 indicates that increasing the pig velocity weakens the increment of the wax layer temperature. When the pig velocity increases, the duration of the nanopaint in the alternating magnetic field is reduced, hence the produced heat is decreased, and the increment of the wax layer temperature is weakened. To achieve a good heating performance, the pig velocity must slow down. Therefore, the SPM-NP pigging system is particularly feasible for low flow rate pipelines.

Figure 10.

Effect of flow velocity and pig velocity on wax layer temperature increment. (A) flow velocity (original wax layer temperature is 20 °C, magnetic field frequency is 500 kHz, the electrical current intensity is 20 A, SPM-NP diameter is 18 nm, pig velocity is 0.4 m/s, induction coil turn number is 310 turns, and nanoparticle content is 10%) and (B) pig velocity (original wax layer temperature is 20 °C, magnetic field frequency is 500 kHz, electrical current intensity is 20 A, SPM-NP diameter is 18 nm, the flow rate is 0.4 m/s, induction coil turn number is 310 turns, and nanoparticle content is 10%).

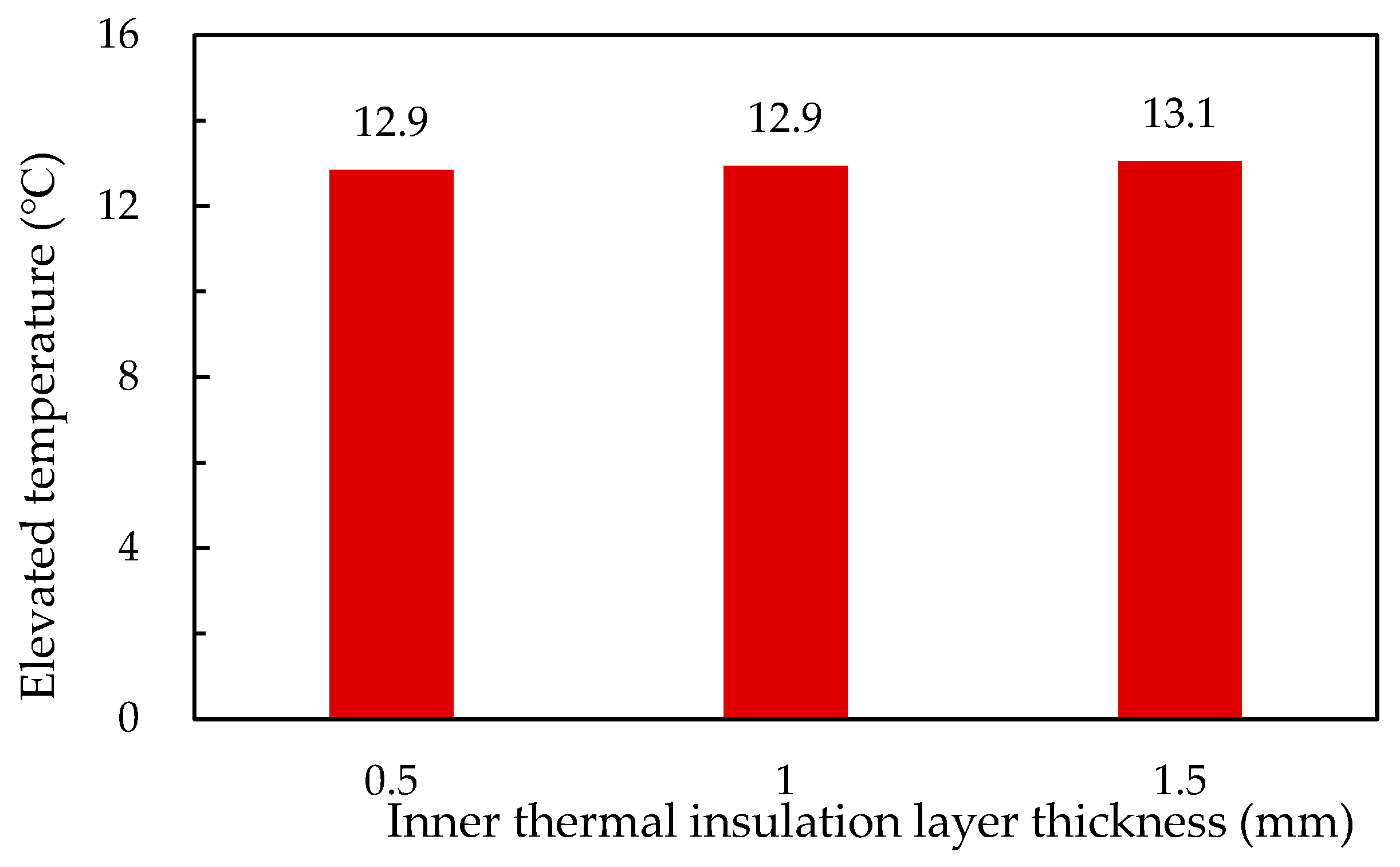

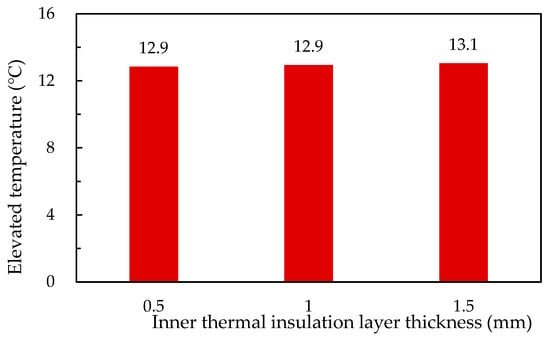

4.5. Inner Thermal Insulation Layer Thickness

As showcased in Figure 2, an inner thermal insulation layer is set between the nanopaint and the inner steel pipe to minimize heat dissipation. The impacts of the inner thermal insulation layer thickness on the wax layer temperature are given in Figure 11. The inner thermal insulation layer thickness was set to 0.5 mm, 1 mm, and 1.5 mm in the simulation. It can be seen that the wax layer temperature increments of the three inner thermal insulation layer thicknesses are very close to each other. Thus, 0.5 mm is thick enough for heat preservation. Further increasing the inner thermal insulation layer thickness is unnecessary.

Figure 11.

Effects of inner thermal insulation layer thickness on wax layer temperature increment (original wax layer temperature is 20 °C; magnetic field frequency is 500 kHz; the electrical current intensity is 20 A; SPM-NP diameter is 18 nm; pig velocity is 0.4 m/s; the flow rate is 0.4 m/s; induction coil turn number is 310 turns; nanoparticle content is 10%).

5. Conclusions

To lower the risk of pig stalling accidents, superparamagnetic nanoparticle (SPM-NP) heating is employed to soften the wax layer during pigging. An SPM-NP pigging system that consists of an electromagnetic pig and nanopaint has been designed. The electromagnetic pig is equipped with an induction coil to generate an alternating magnetic field to induce heat in the nanopaint; thus, the wax layer is heated and softened. The COMSOL software was used to simulate the temperature distribution of the wax layer. Yield stress measurements reveal that the mechanical strength of the wax deposit is almost linearly correlated to the temperature. A methodology for calculating the wax resistive force has been proposed. Compared with a regular pig, the electromagnetic pig reduces the wax resistive force by up to 20~40%, with an acceptable electrical current intensity of about 20 A in the given cases, which proves the effectiveness of the SPM-NP pigging system in lowering the risk of a pig stalling accident. Moreover, varieties of factors affecting the wax layer temperature, including the SPM-NP size and concentration, electrical current intensity and frequency, induction coil turn number and diameter, flow rate, pig velocity, as well as the inner thermal insulation thickness, were analyzed, which helps to optimize the design of the SPM-NP pigging system. This work provides a new idea for risk control of pig stalling accidents in pigging. It may also benefit hydrate prevention in pipelines.

Author Contributions

Conceptualization, W.L. and W.W.; methodology, H.Z.; software, H.Z. and Y.Z.; validation, P.Y. and X.H.; formal analysis, H.L. and X.H.; data curation, J.W.; writing—original draft preparation, H.Z. and L.T.; supervision, W.L.; funding acquisition, W.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the National Natural Science Foundation of China (NNSF, Grant No. 52104066) and the Natural Science Foundation of Fujian Province, China (Grant No. 2020J05097).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hammami, A.; Raines, M.A. Paraffin deposition from crude oils: Comparison of laboratory results with field data. SPE J. 1999, 4, 9–18. [Google Scholar] [CrossRef]

- Japper-Jaafar, A.; Bhaskoro, P.T.; Sean, L.L.; Sariman, M.Z.; Nugroho, H. Yield stress measurement of gelled waxy crude oil: Gap size requirement. J. Non Newton. Fluid Mech. 2015, 218, 71–82. [Google Scholar] [CrossRef]

- Stevenson, C.J.; Davies, S.R.; Gasanov, I.; Hawkins, P.; Demiroglu, M.; Marwood, A.P. Development and execution of a wax remediation pigging program for a subsea oil export pipeline. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2015. [Google Scholar]

- Rønningsen, H.P. Production of Waxy Oils on the Norwegian Continental Shelf: Experiences, Challenges, and Practices. Eng. Fuel 2012, 26, 4124–4136. [Google Scholar] [CrossRef]

- Aiyejina, A.; Chakrabarti, D.P.; Pilgrim, A.; Sastry, M. Wax formation in oil pipelines: A critical review. Int. J. Multiph. Flow 2011, 37, 671–694. [Google Scholar] [CrossRef]

- White, M.; Pierce, K.; Acharya, T. A review of wax-formation/mitigation technologies in the petroleum industry. SPE Prod. Oper. 2017, 33, 476–485. [Google Scholar] [CrossRef]

- Halstensen, M.; Arvoh, B.K.; Amundsen, L.; Hoffmann, R. Online estimation of wax deposition thickness in single-phase sub-sea pipelines based on acoustic chemometrics: A feasibility study. Fuel 2013, 105, 718–727. [Google Scholar] [CrossRef]

- Zheng, S.; Zhang, F.; Huang, Z.; Fogler, H.S. Effects of operating conditions on wax deposit carbon number distribution: Theory and experiment. Eng. Fuel 2013, 27, 7379–7388. [Google Scholar] [CrossRef]

- Li, W.; Huang, Q.; Wang, W.; Gao, X. Advances and future challenges of wax removal in pipeline pigging operations on crude oil transportation systems. Energy Technol. 2020, 8, 1901412. [Google Scholar] [CrossRef]

- Sarmento, R.C.; Ribbe, G.A.S.; Azevedo, L.F.A. Wax blockage removal by inductive heating of subsea pipelines. Heat Transf. Eng. 2004, 25, 2–12. [Google Scholar] [CrossRef]

- Wang, N.; Prodanovic, M.; Daigle, H. Nanopaint-aided electromagnetic pigging in pipelines and production tubing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar]

- Mehta, P.; Huh, C.; Bryant, S.L. Evaluation of superparamagnetic nanoparticle-based heating for flow assurance in subsea flowlines. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 10–12 December 2014. [Google Scholar]

- Périgo, E.A.; Hemery, G.; Sandre, O.; Ortega, D.; Garaio, E.; Plazaola, F.; Teran, F.J. Fundamentals and advances in magnetic hyperthermia. Appl. Phys. Rev. 2015, 2, 041302. [Google Scholar] [CrossRef] [Green Version]

- Yao, X.; Niu, X.; Ma, K.; Huang, P.; Grothe, J.; Kaskel, S.; Zhu, Y. Graphene quantum dots-capped magnetic mesoporous silica nanoparticles as a multifunctional platform for controlled drug delivery, magnetic hyperthermia, and photothermal therapy. Small 2017, 13, 1602225. [Google Scholar] [CrossRef] [PubMed]

- Manohar, A.; Vijayakanth, V.; Pallavolu, M.R.; Kim, K.H. Effects of Ni-substitution on structural, magnetic hyperthermia and photocatalytic properties of MgFe2O4 nanoparticles. J. Alloys Compd. 2021, 879, 160515. [Google Scholar] [CrossRef]

- Kappiyoor, R.; Liangruksa, M.; Ganguly, R.; Puri, I.K. The effects of magnetic nanoparticle properties on magnetic fluid hyper-thermia. J. Appl. Phys. 2010, 108, 094702. [Google Scholar] [CrossRef]

- Gupta, A.K.; Gupta, M. Synthesis and surface engineering of iron oxide nanoparticles for biomedical applications. Biomaterials 2005, 26, 3995–4021. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Gu, H.; Yang, Z. The heating effect of magnetic fluids in an alternating magnetic field. J. Magn. Magn. Mater. 2005, 293, 334–340. [Google Scholar] [CrossRef]

- Lahiri, B.; Muthukumaran, T.; Philip, J. Magnetic hyperthermia in phosphate coated iron oxide nanofluids. J. Magn. Magn. Mater. 2016, 407, 101–113. [Google Scholar] [CrossRef]

- Davidson, A.; Huh, C.; Bryant, S.L. Focused magnetic heating utilizing superparamagnetic nanoparticles for improved oil production applications. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, Noordwijk, The Netherlands, 12–14 June 2012. [Google Scholar]

- Hedayatnasab, Z.; Abnisa, F.; Daud, W.M.A.W. Review on magnetic nanoparticles for magnetic nanofluid hyperthermia application. Mater. Design 2017, 123, 174–196. [Google Scholar] [CrossRef]

- Gonzales-Weimuller, M.; Zeisberger, M.; Krishnan, K.M. Size-dependant heating rates of iron oxide nanoparticles for magnetic fluid hyperthermia. J. Magn. Magn. Mater. 2009, 321, 1947–1950. [Google Scholar] [CrossRef]

- Brown, W.F., Jr. Thermal fluctuations of a single-domain particle. Phys. Rev. 1963, 130, 1677. [Google Scholar] [CrossRef]

- Rodriguez-Fabia, S.; Fyllingsnes, R.L.; Winter-Hjelm, N.; Norrman, J.; Paso, K.G. Influence of measuring geometry on rheomalaxis of macrocrystalline wax–oil gels: Alteration of breakage mechanism from adhesive to cohesive. Eng. Fuel. 2019, 33, 654–664. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Prodanović, M.; Daigle, H. Nanopaint application for flow assurance with electromagnetic pig. J. Petrol. Sci. Eng. 2019, 180, 320–329. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).