Application of Pre-Splitting and Roof-Cutting Control Technology in Coal Mining: A Review of Technology

Abstract

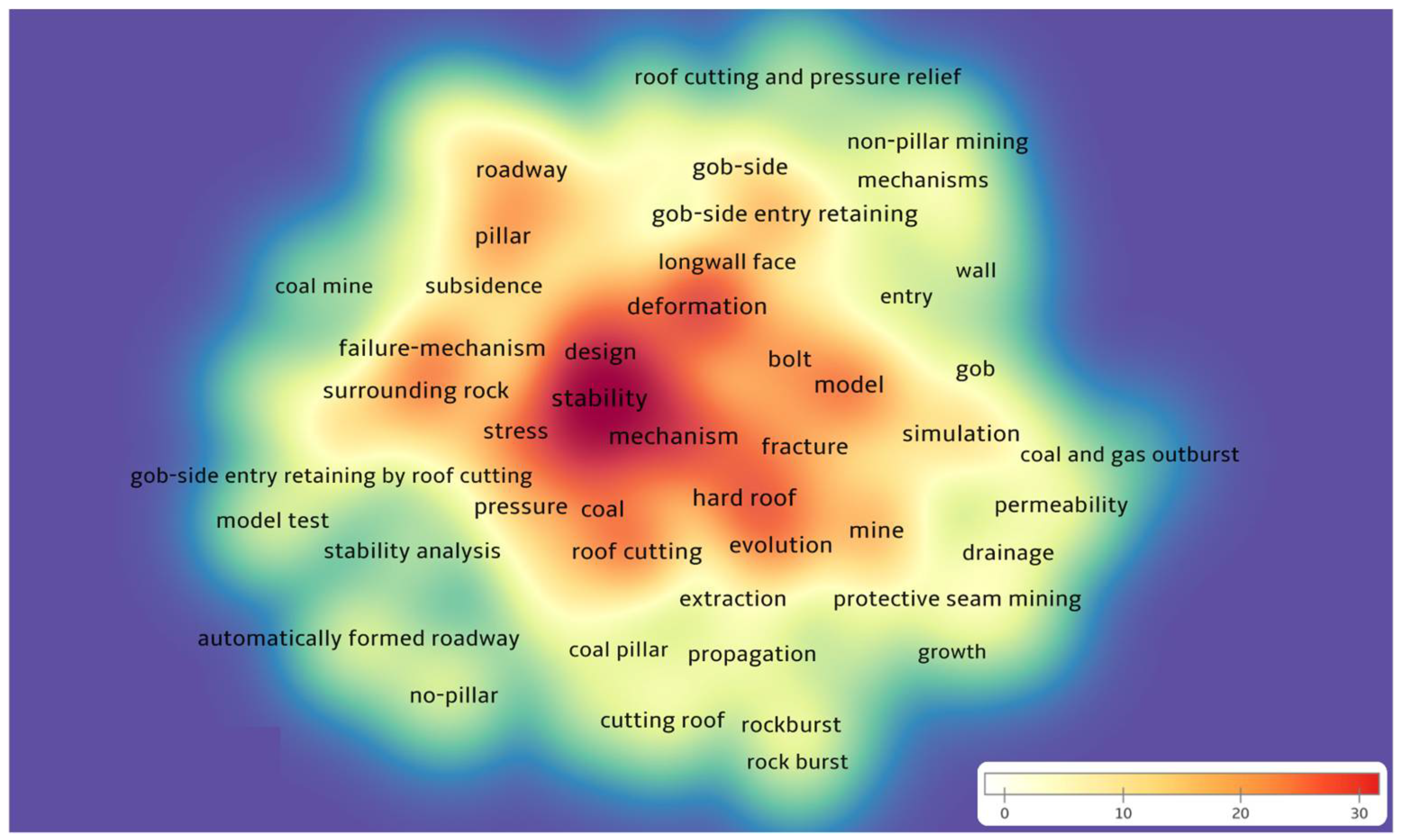

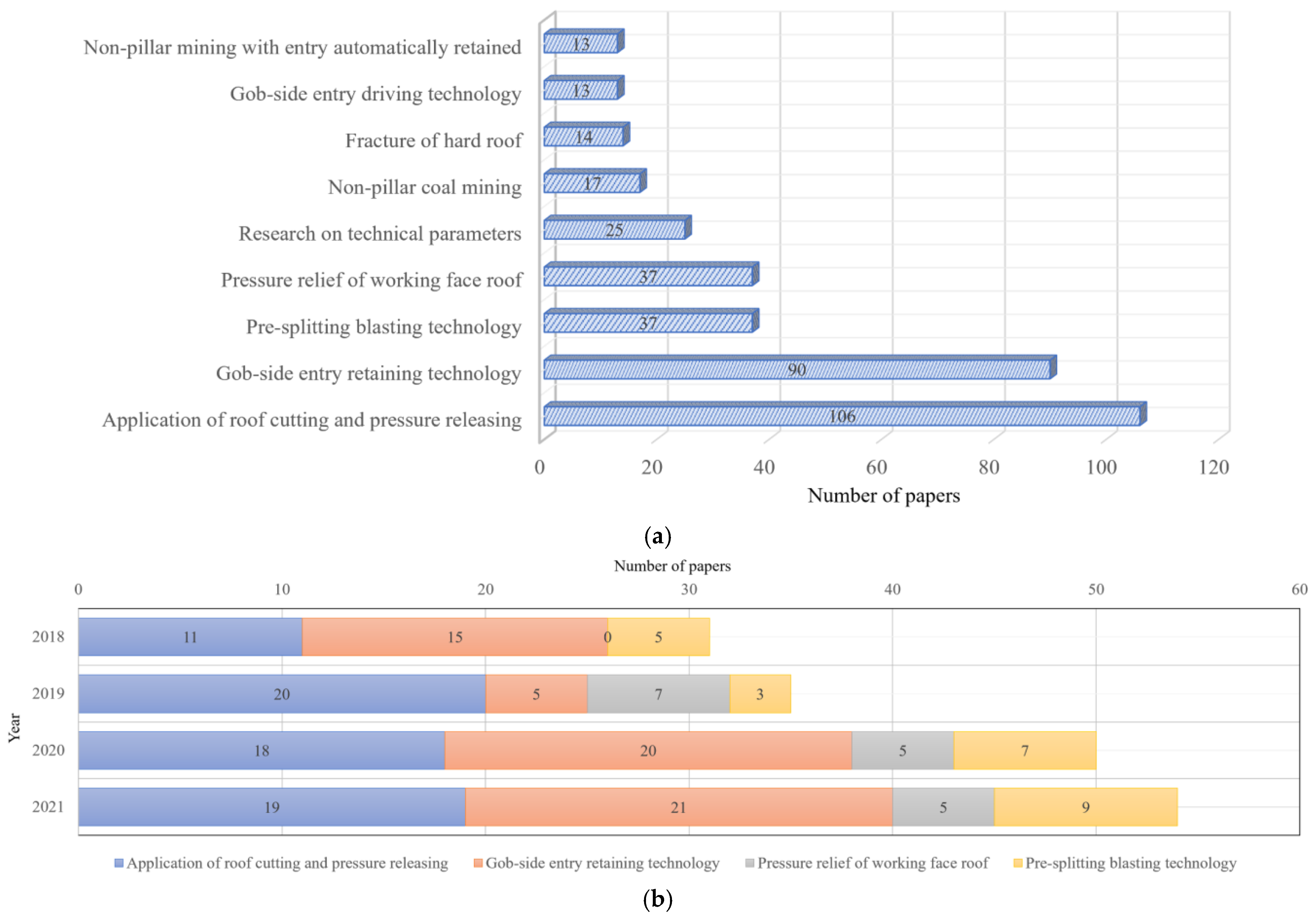

:1. Introduction

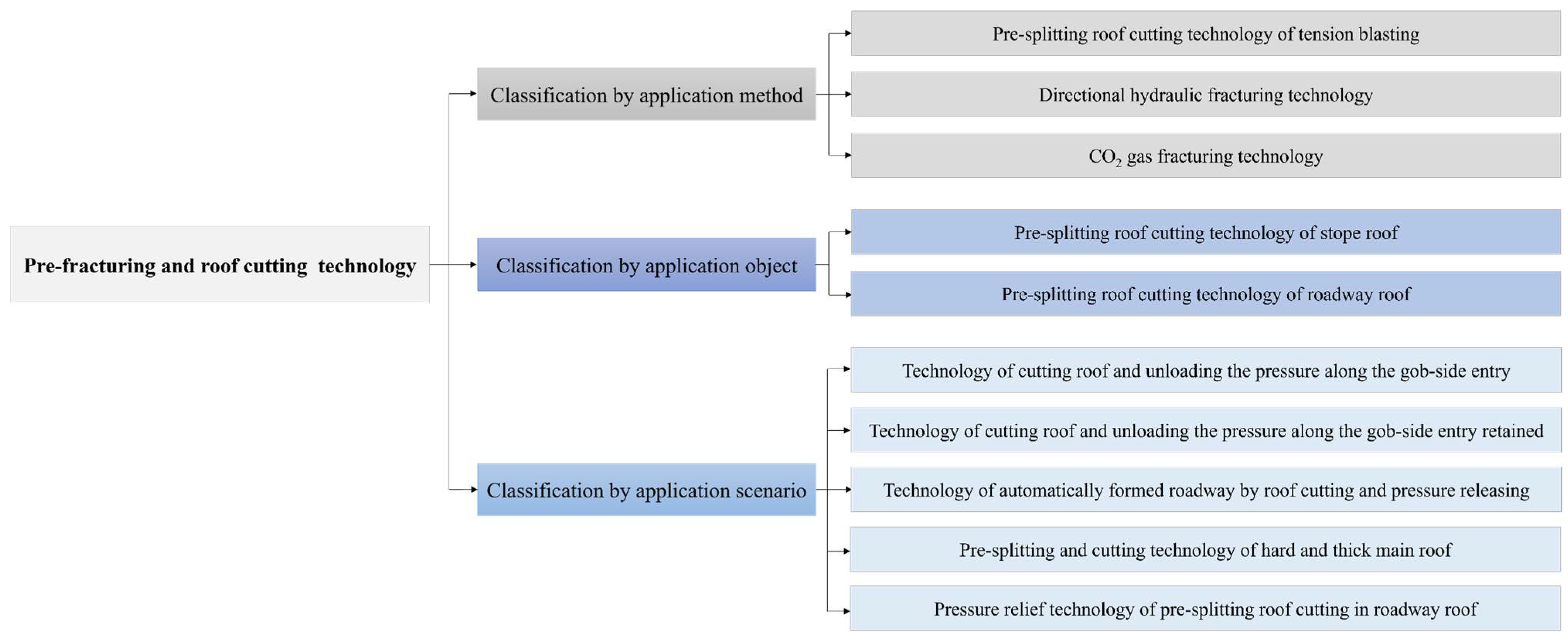

2. Forms of Pre-Splitting Technology for the Roof

2.1. Pre-Splitting Roof Technology of Explosive Blasting

2.1.1. Directional Concentrated Blasting Technology

2.1.2. Directional Pre-Splitting Technology of Liquid Explosive

2.1.3. Directional Seam-Making Technology of Composite Blasting

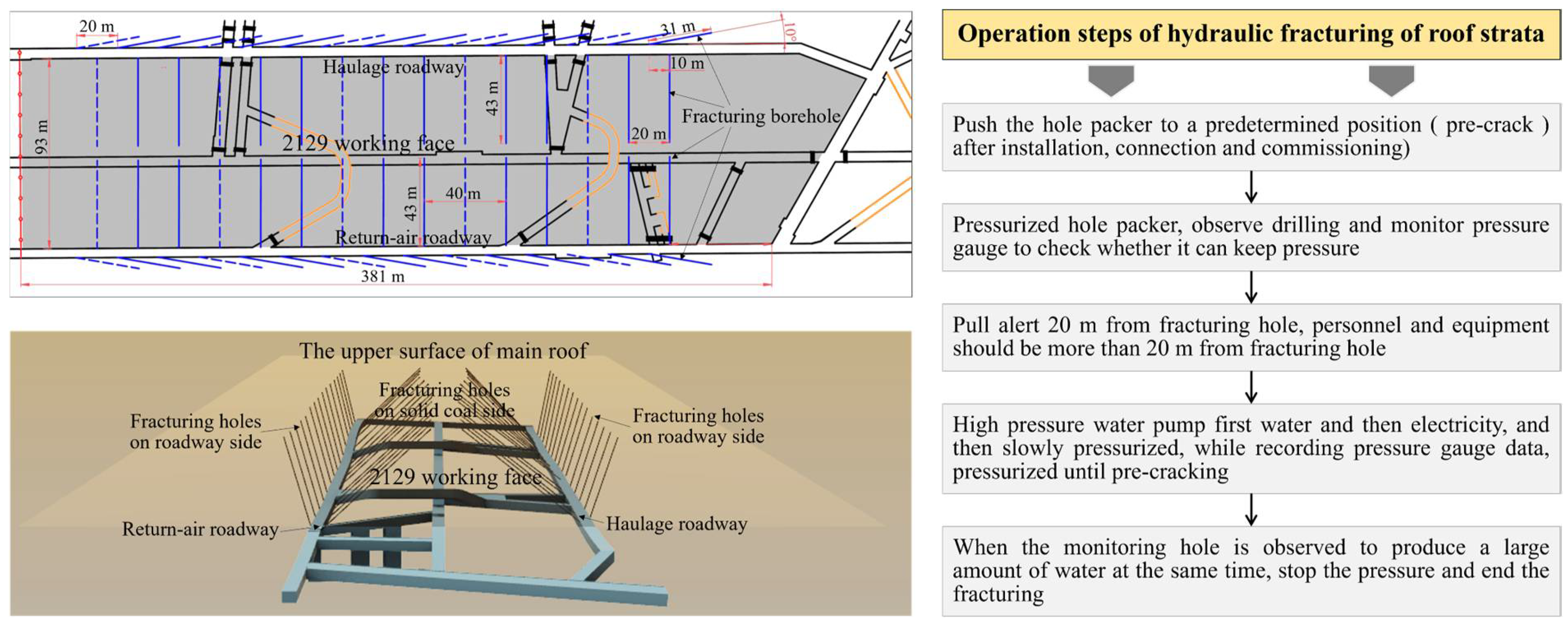

2.2. Hydraulic Fracturing Pre-Splitting Roof Technology

2.2.1. Hydraulic Fracturing Principle

2.2.2. Application of Hydraulic Fracturing Technology

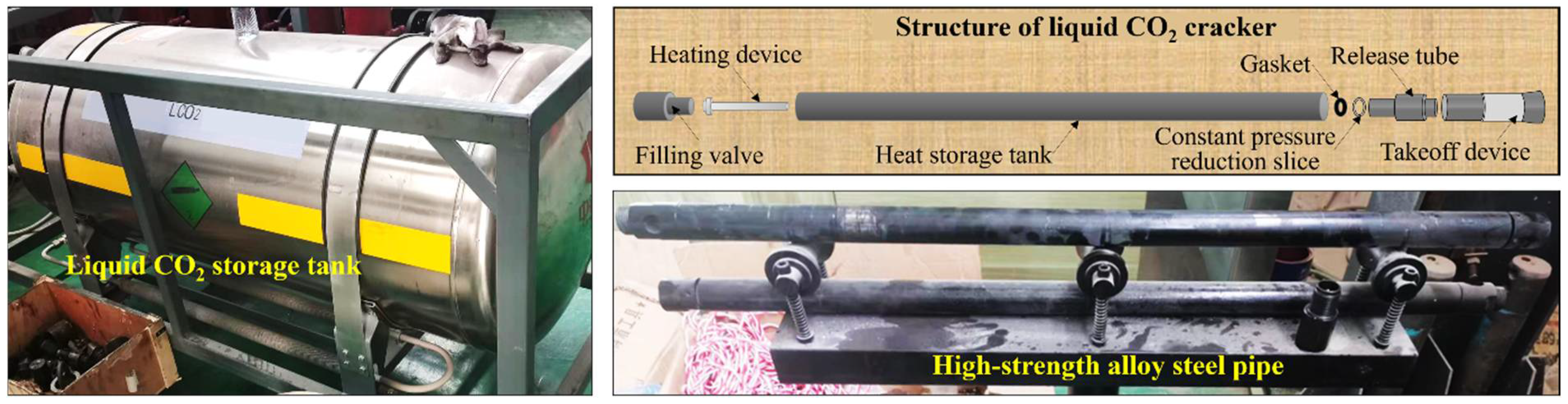

2.3. Liquid CO2 Gas Pre-Splitting Roof Technology

2.4. Mechanized Directional Roof-Cutting Technology

2.4.1. Continuous Cutting Technology of Chain Arm Saw Machine

2.4.2. Application of Directional Cutting Roof Rig

3. Pre-Splitting and Roof-Cutting Technology for Non-Pillar Mining

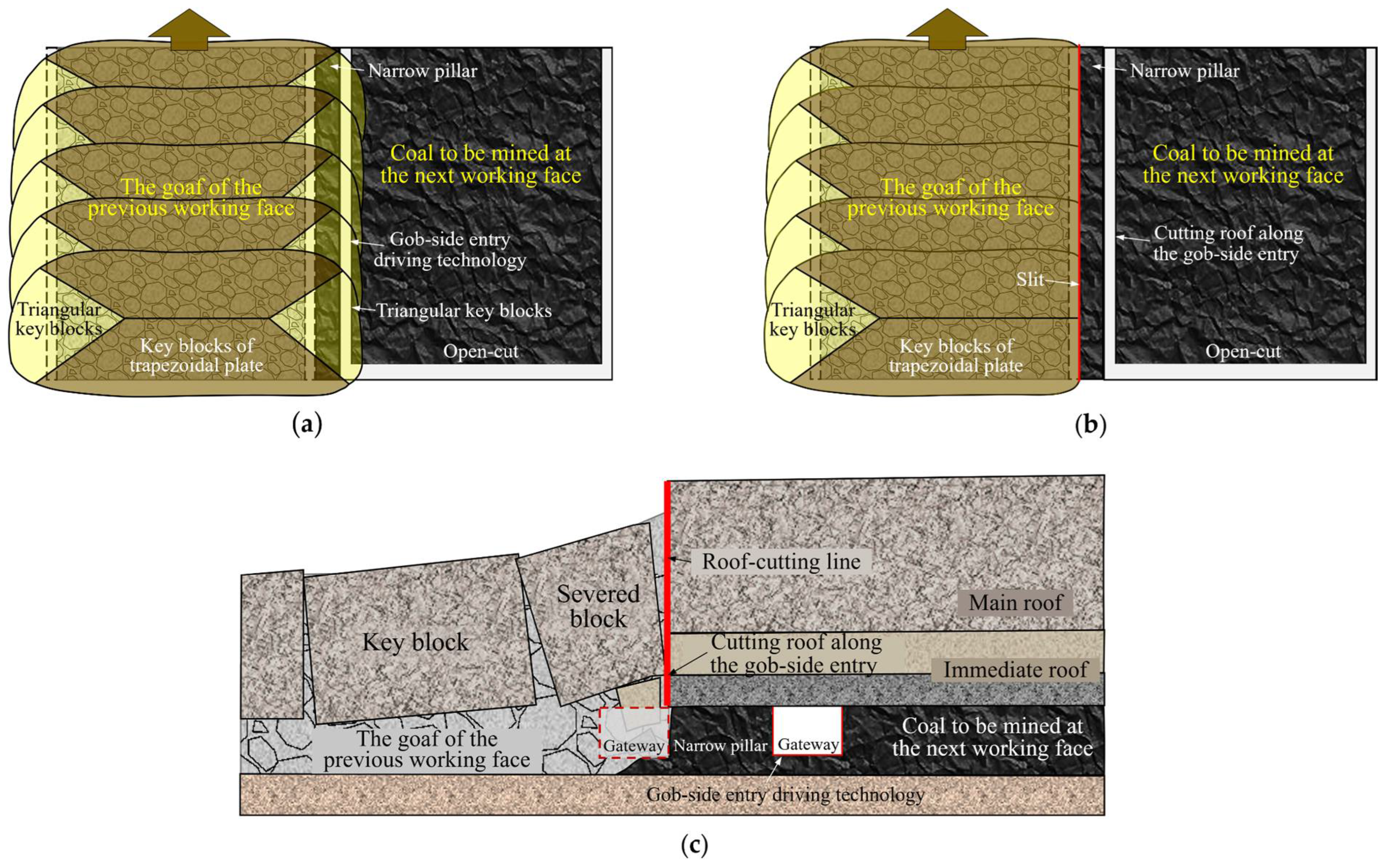

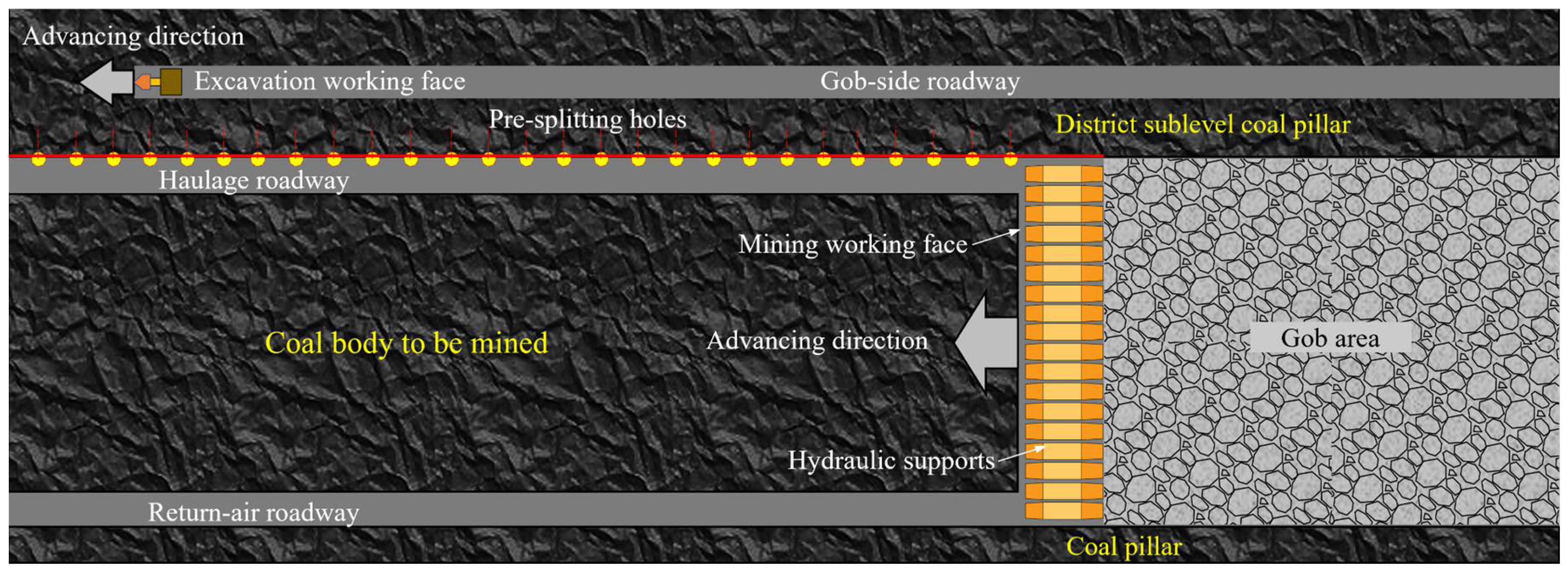

3.1. Application in Gob-Side Entry Driving

3.2. Application in Gob-Side Entry Retaining

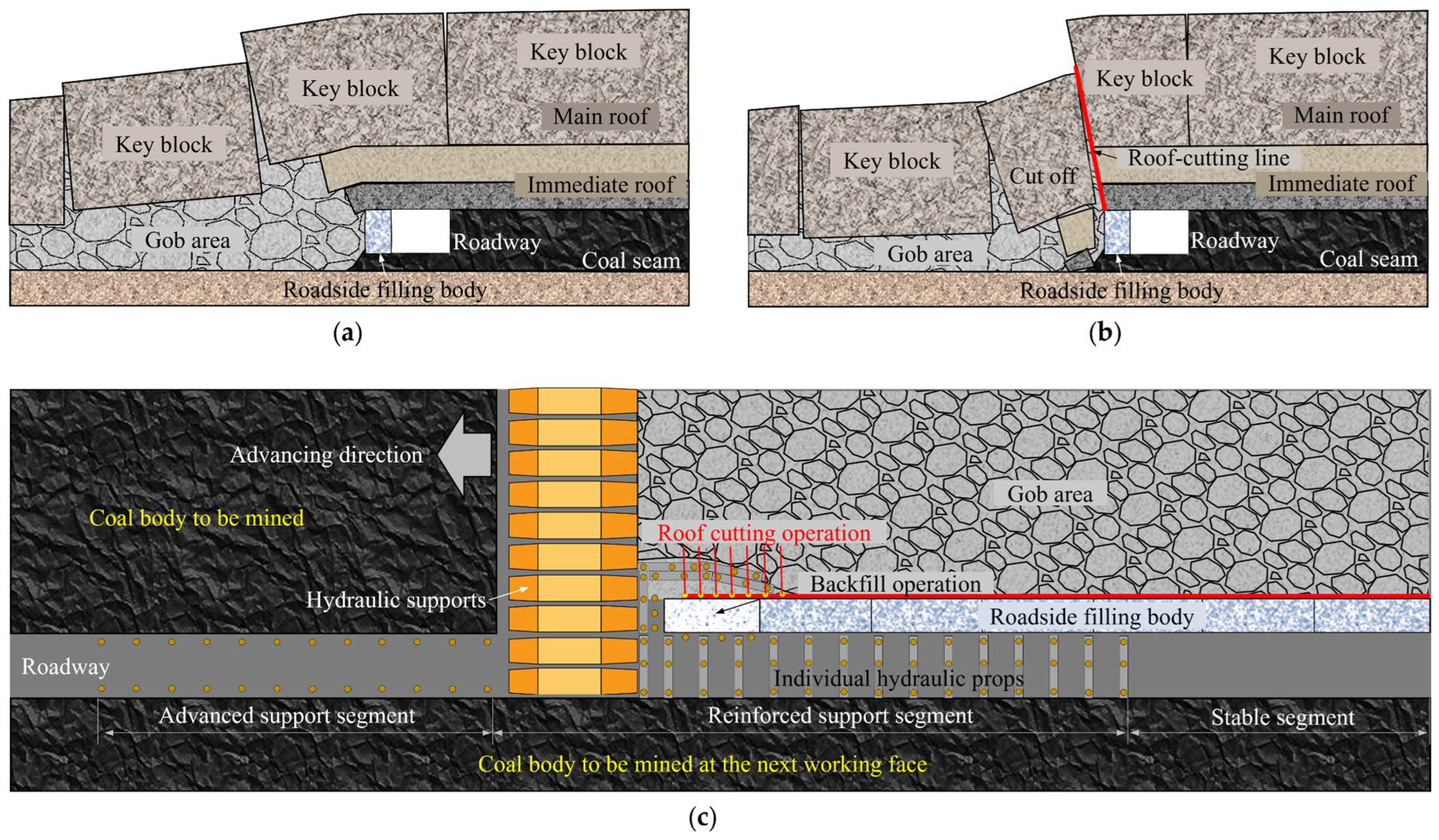

3.2.1. Gob-Side Entry Retaining with the Filling Body

- (1)

- Delayed pre-splitting and cutting roof

- (2)

- Advance pre-splitting and cutting roof

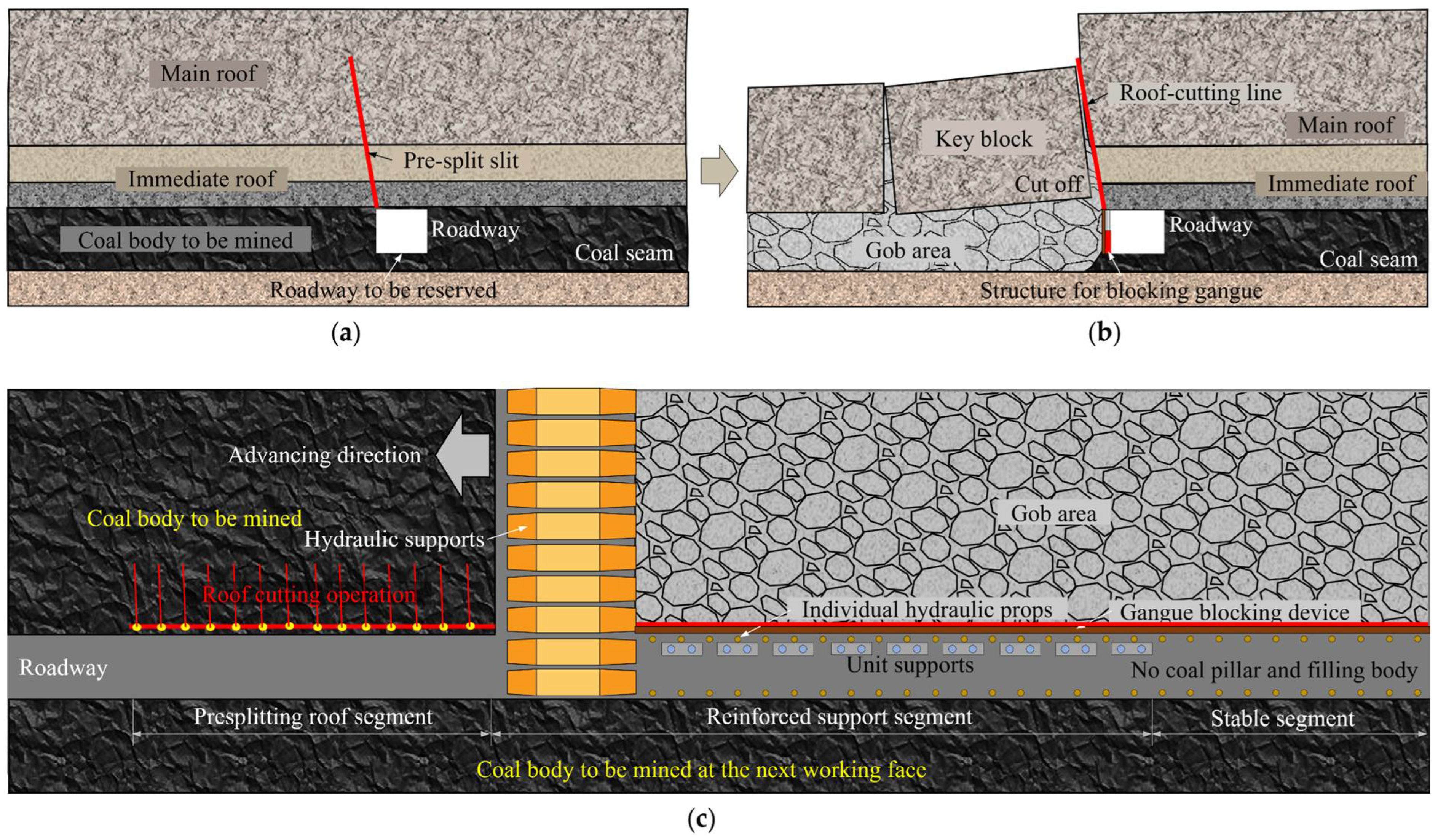

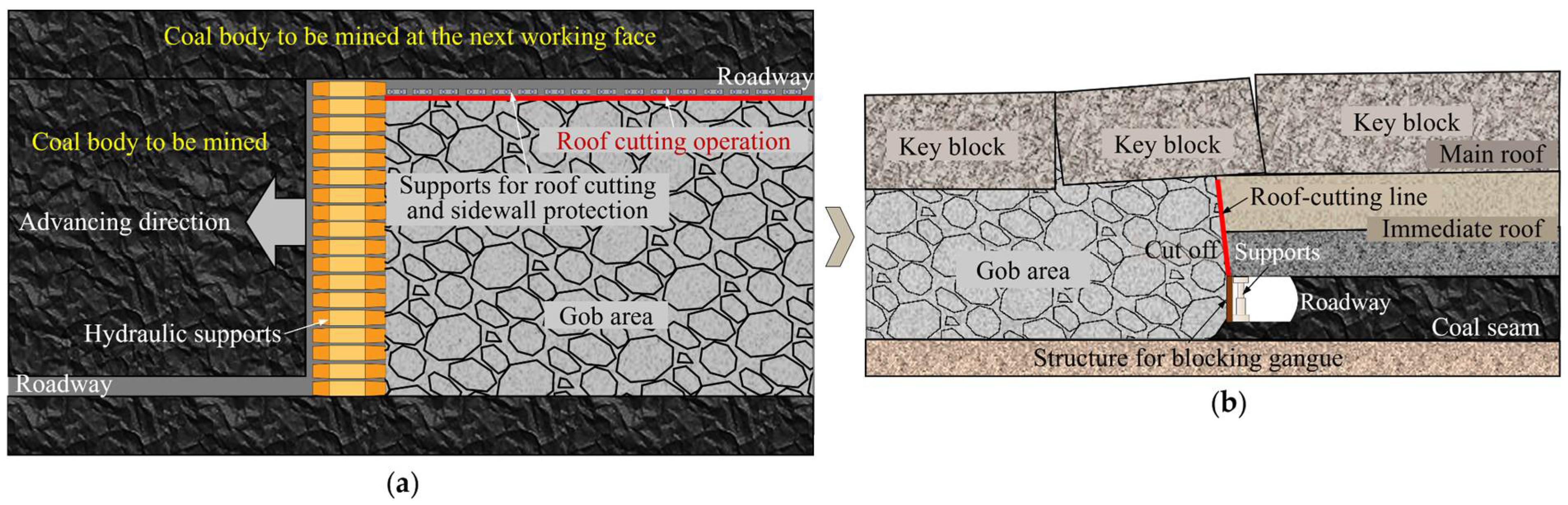

3.2.2. Completely Gob-Side Entry Retaining

- (1)

- Cutting roof for retaining roadway with advance pre-splitting

- (2)

- Combined support for cutting roof retaining roadway

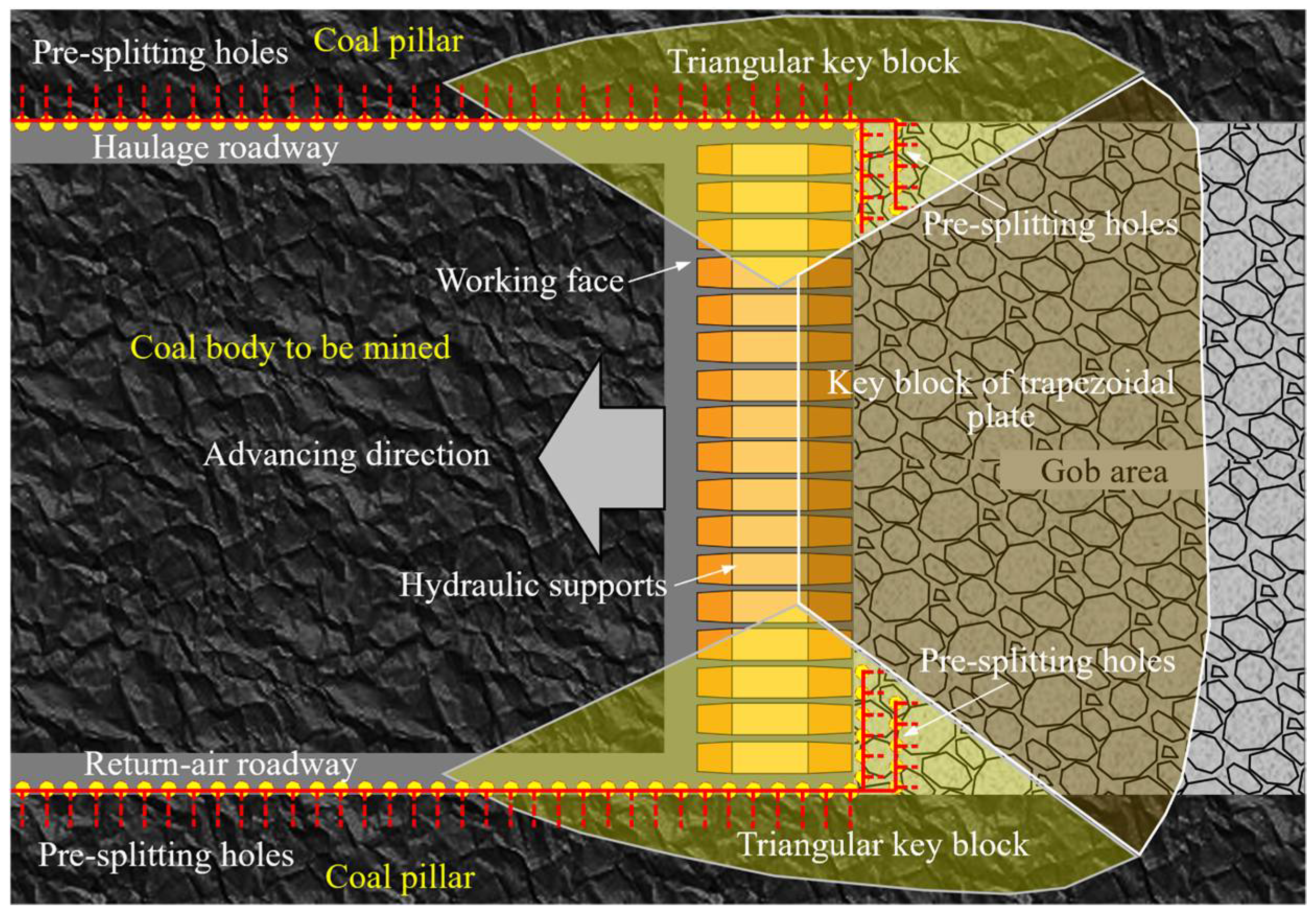

3.3. “N00” Construction Method

4. Pre-Splitting and Roof-Cutting Technology for Pressure Relief Mining of Working Face

4.1. Fracturing Operation of Thick and Hard Main Roof

4.2. Fracturing Operation of Hard Roof at the End of the Working Face

5. Pre-Splitting and Roof-Cutting Technology for Roadway’s Pressure Relief

5.1. Large Deformation of Roadway along Goaf

5.2. Blasting Pressure Relief Technology for Roadways

6. Discussion

- (1)

- The pre-splitting method of explosive blasting has gradually developed to low pollution, low dust, high precision, and high safety. The methods of water-filled pressure blasting, liquid explosive blasting, and liquid CO2 gas phase blasting improve environmental protection and safety significantly. The composite blasting form is committed to establishing a continuous fracture surface to achieve precise roof cutting.

- (2)

- Hydraulic fracturing technology is gradually becoming more and more widespread in the application of hard-roof fracturing, especially in roof pre-splitting near the working face and the goaf; this method does not produce toxic gas and dust, which has high application safety for gas mines.

- (3)

- The research hotspots of pre-splitting and roof cutting focus on pressure relief technology and gob-side entry retaining technology. For deep high-stress mining environments, applying roof pre-splitting technology will be more widely, including the safe replacement of deep coal seam working face, deep hard roof cracking, and deep roadway pressure relief.

- (4)

- As an essential step of non-pillar mining, pre-splitting and roof cutting technology is also developing towards mechanized roof cutting, while the mining method is mechanization and automation. The research, development, and application of the chain arm saw machine and directional cutting roof rig are representative; it is anticipated that the future pre-splitting and roof-cutting technology will balance precision, automation, and greening, which will help the development of intelligent and unmanned mining.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, M.; Wang, Q.; Wu, Q. Innovation and future of mining rock mechanics. J. Rock Mech. Geotech. Eng. 2021, 13, 1–21. [Google Scholar] [CrossRef]

- Yu, B.; Tai, Y.; Gao, R.; Yao, Q.; Li, Z.; Xia, H. The sustainable development of coal mines by new cutting roof technology. R. Soc. Open Sci. 2020, 7, 191913. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Wang, J.; He, M.; Gao, Y.; Hu, J.; Wang, Q. Key Technologies and Application Test of an Innovative Noncoal Pillar Mining Approach: A Case Study. Energies 2018, 11, 2853. [Google Scholar] [CrossRef]

- Wang, E.; Xie, S. Determination of coal pillar width for gob-side entry driving in isolated coal face and its control in deep soft-broken coal seam: A case study. Energy Sci. Eng. 2022, 10, 2305–2316. [Google Scholar] [CrossRef]

- Xie, S.; Gao, M.; Chen, D.; Sun, Y.; Pan, H.; Su, H.; Lan, S. Stability influence factors analysis and construction of a deep beam anchorage structure in roadway roof. Int. J. Min. Sci. Technol. 2017, 28, 445–451. [Google Scholar]

- Xie, S.; Pan, H.; Zeng, J.; Wang, E.; Chen, D.; Zhang, T.; Peng, X.; Yang, J.; Chen, F.; Qiao, S. A case study on control technology of surrounding rock of a large section chamber under a 1200-m deep goaf in Xingdong coal mine, China. Eng. Fail. Anal. 2019, 104, 112–125. [Google Scholar] [CrossRef]

- Chen, D.; Wang, E.; Xie, S.; He, F.; Wang, L.; Zhang, Q.; Wu, X.; Jiang, Z.; Li, Y.; Shi, S. Roadway surrounding-rock under multi-coal seam mining: Deviatoric stress evolution and control technology. Adv. Civil Eng. 2020, 2020, 9891825. [Google Scholar] [CrossRef]

- Kang, H.; Zhang, X.; Wang, D.; Tian, J.; Yi, Z.; Jiang, W. Strata control technology and applications of non-pillar coal mining. J. China Coal Soc. 2022, 47, 16–44. [Google Scholar]

- Qian, M.; Miao, X.; Xu, J. Theoretical Study of Key Sratum in Ground Conrol. J. China Coal Soc. 1996, 21, 2–7. [Google Scholar]

- He, S.S.; Xie, S.R.; Song, B.H.; Zhou, D.Q.; Sun, Y.D.; Han, S. Breaking laws and stability analysis of damage main roof in close distance hypogynous seams. J. China Coal Soc. 2016, 41, 2596–2605. [Google Scholar]

- He, F.L.; Chen, D.D.; Xie, S.R. The kDL effect on the first fracture of main roof with elastic foundation boundary. Chin. J. Rock Mech. Eng. 2017, 36, 1384–1399. [Google Scholar]

- Chen, D.D.; Guo, F.F.; Wu, Y.Y. Study on the first fracture of the main roof plate structure with one side goaf and elastic-plastic foundation boundary. J. China Coal Soc. 2021, 46, 3090–3105. [Google Scholar]

- Chen, D.D.; He, F.L.; Xie, S.R.; Zeng, J.C. Time-space relationship between periodic fracture of plate structure of main roof and rebound in whole region with elastic foundation boundary. Chin. J. Rock Mech. Eng. 2019, 38, 1172–1187. [Google Scholar]

- Xie, S.; Cheng, D.; Ceng, J.; Gao, M.; Zhang, T.; Liu, J. First fracturing characteristics of main roof plate structure considering coal pillars and elastic coal foundation on both sides of stope. J. China Coal Soc. 2019, 44, 115–126. [Google Scholar]

- He, F.; He, W.R.; Chen, D.D.; Xie, S.R.; Li, H.; He, C.X. First fracture structure characteristics of main roof plate considering elastic-plastic deformation of coal. J. China Coal Soc. 2020, 45, 2704–2717. [Google Scholar]

- Li, Z.; Changzhi, Z.; Xie, H.; Yang, F. Similar simulation test for breakage law of working face floor in coal mining above aquifer. Chin. J. Rock Mech. Eng. 2011, 30, 1571–1578. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, N.; Guo, X.; Zhao, X.; Fan, L. Falling principle and support design of butterfly-failure roof in large deformation mining roadways. J. China Coal Soc. 2016, 41, 2932–2939. [Google Scholar]

- Guo, X.F.; Guo, L.F.; Ma, N.J.; Zhao, Z.Q.; Li, C. Applicability analysis of the roadway butterfly failure theory. J. China Univ. Min. Technol. 2020, 49, 646–653. [Google Scholar]

- Tao, Z.; Zheng, X.; Zhu, C.; Zhang, H.; Zhang, X. Framework and engineering application of large data monitoring system for a non-pillar mining method with gob-side entry formed automatically. J. China Univ. Min. Technol. 2021, 50, 983–991. [Google Scholar]

- Xie, S.; Guo, F.; Wu, Y. Control Techniques for Gob-Side Entry Driving in an Extra-Thick Coal Seam with the Inflence of Upper Residual Coal Pillar: A Case Study. Energies 2022, 15, 3620. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Xin, Z.X.; He, M.C.; Li, S.C.; Zhang, P.; Wang, Y.; Jiang, Z.H. Development of a 3D geomechanical model test system for non-pillar mining with automatically formed roadway and its engineering application. Chin. J. Rock Mech. Eng. 2020, 39, 1582–1594. [Google Scholar]

- Xie, S.; Wu, Y.; Chen, D.; Liu, R.; Han, X.; Ye, Q. Failure analysis and control technology of intersections of large-scale variable cross-section roadways in deep soft rock. Int. J. Coal Sci. Technol. 2022, 9, 19. [Google Scholar] [CrossRef]

- Liu, X.; He, M.; Wang, J.; Ma, Z. Research on non-pillar coal mining for thick and hard conglomerate roof. Energies 2021, 14, 299. [Google Scholar] [CrossRef]

- Chen, X.; Li, L.; Guo, Z.; Chang, T. Evolution characteristics of spontaneous combustion in three zones of the goaf when using the cutting roof and release pressure technique. Energy Sci. Eng. 2019, 7, 710–720. [Google Scholar] [CrossRef]

- Wang, Q.; Qin, Q.; Jiang, B.; Jiang, Z.; He, M.; Li, S.; Wang, Y. Geomechanics model test research on automatically formed roadway by roof cutting and pressure releasing. Int. J. Rock Mech. Min. Sci. 2020, 135, 104506. [Google Scholar] [CrossRef]

- Chen, X.; Du, Y.; Wang, L.; Zhao, S. Evolution and application of airflow permeability characteristics of gob in roof cutting and pressure releasing mining method. Energy Sci. Eng. 2020, 8, 2073–2085. [Google Scholar] [CrossRef]

- Wu, Y.; Xie, S.; Zhang, Y. Research on stability control of roadway intersections with nested variable cross-section in deep mine. J. Min. Sci. Technol. 2022, 7, 720–729. [Google Scholar]

- Li, G.; Yang, S.; Sun, Y.; Xu, J.; Li, J. Research progress of roadway surrounding strata rock control technologies under complex conditions. Coal Sci. Technol. 2022, 50, 29–45. [Google Scholar]

- Yang, S.; Li, G.; Bi, R.; Yao, B.; Feng, R.; Sun, Y. The Stability of Roadway Groups under Rheology Coupling Mining Disturbance. Sustainability 2021, 13, 12300. [Google Scholar] [CrossRef]

- Sun, Y.; Bi, R.; Sun, J.; Zhang, J.; Taherdangkoo, R.; Huang, J.; Li, G. Stability of roadway along hard roof goaf by stress relief technique in deep mines: A theoretical, numerical and field study. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 45. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; He, M.; Jiang, B.; Li, S.; Jiang, Z.; Wang, Y.; Xu, S. Experimental research and application of automatically formed roadway without advance tunneling. Tunn. Undergr. Space Technol. 2021, 114, 103999. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.; Guo, S.; Qi, J.; Yang, J.; Wang, C.; Xia, M.; Li, L. Investigation on the key techniques and application of the new-generation automatically formed roadway without coal pillars by roof cutting. Int. J. Rock Mech. Min. Sci. 2022, 152, 105058. [Google Scholar] [CrossRef]

- Wang, Y.; He, M.; Yang, J.; Wang, Q.; Liu, J.; Tian, X.; Gao, Y. Case study on pressure-relief mining technology without advance tunneling and coal pillars in longwall mining. Tunn. Undergr. Space Technol. 2020, 97, 103236. [Google Scholar] [CrossRef]

- Li, Z.; Tao, Z.; Meng, Z.; He, M. Longwall mining method with roof-cutting unloading and numerical investigation of ground pressure and roof stability. Arab. J. Geosci. 2018, 11, 697. [Google Scholar] [CrossRef]

- Yang, J.; Liu, B.; Bian, W.; Chen, K.; Wang, H.; Cao, C. Application Cumulative Tensile Explosions for Roof Cutting in Chinese Underground Coal Mines. Arch. Min. Sci. 2021, 66, 421–435. [Google Scholar]

- Xie, S.R.; Pan, H.; Chen, D.D.; Zeng, J.C.; Song, H.Z.; Cheng, Q.; Xiao, H.B.; Yan, Z.Q.; Li, Y.H. Stability analysis of integral load-bearing structure of surrounding rock of gob-side entry retention with flexible concrete formwork. Tunn. Undergr. Space Technol. 2020, 103, 103492. [Google Scholar] [CrossRef]

- Wang, Q.; He, M.; Yang, J.; Gao, H.; Jiang, B.; Yu, H. Study of a no-pillar mining technique with automatically formed gob-side entry retaining for longwall mining in coal mines. Int. J. Rock Mech. Min. Sci. 2018, 110, 1–8. [Google Scholar] [CrossRef]

- Tao, Z.; Song, Z.; He, M.; Meng, Z.; Pang, S. Principles of the roof cut short-arm beam mining method (110 method) and its mining-induced stress distribution. Int. J. Min. Sci. Technol. 2018, 28, 391–396. [Google Scholar] [CrossRef]

- Fan, D.; Liu, X.; Tan, Y.; Yan, L.; Song, S.; Ning, J. An innovative approach for gob-side entry retaining in deep coal mines: A case study. Energy Sci. Eng. 2019, 7, 2321–2335. [Google Scholar] [CrossRef]

- Wang, Q.; He, M.; Li, S.; Jiang, Z.; Wang, Y.; Qin, Q.; Jiang, B. Comparative study of model tests on automatically formed roadway and gob-side entry driving in deep coal mines. Int. J. Min. Sci. Technol. 2021, 31, 591–601. [Google Scholar] [CrossRef]

- Tu, M.; Zhao, G.; Zhang, X.; Bu, Q.; Dang, J. Fracture Evolution between Blasting Roof Cutting Holes in a Mining Stress Environment. Minerals 2022, 12, 418. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.; Wang, J.; Guo, S.; Guo, Z.; Liu, X.; Hu, J.; Ma, Z.; Fan, L.; Guo, P. Instantaneous expansion with a single fracture: A new directional rock-breaking technology for roof cutting. Int. J. Rock Mech. Min. Sci. 2020, 132, 104399. [Google Scholar] [CrossRef]

- Hua, X.Z.; Liu, X.; Huang, Z.G.; Yang, P.; Ma, Y. Stability mechanism of non-pillar gob-side entry retaining by roof cutting under the coupled static-dynamic loading. J. China Coal Soc. 2020, 45, 3696–3708. [Google Scholar]

- Ma, X.; He, M.; Sun, J.; Wang, H.; Liu, X.; Zhen, E. Neural Network of Roof Cutting Blasting Parameters Based on Mines with Different Roof Conditions. Energies 2018, 11, 3468. [Google Scholar] [CrossRef]

- Fan, D.; Liu, X.; Tan, Y.; Song, S.; Gu, Q.; Yan, L.; Xu, Q. Roof Cutting Parameters Design for Gob-Side Entry in Deep Coal Mine: A Case Study. Energies 2019, 12, 2032. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Guo, S.; Gong, W.; Feng, L.; Wang, H.; Ming, C.; Ma, Z. Shaped Charge Hydraulic Blasting: An Environmental, Safe, and Economical Method of Directional Roof Cutting. Geofluids 2021, 2021, 5511081. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, Z.; Jiang, B.; Gao, H.; Huang, Y.; Zhang, P. Research on an automatic roadway formation method in deep mining areas by roof cutting with high-strength bolt-grouting. Int. J. Rock Mech. Min. Sci. 2020, 128, 104264. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, J.; Xue, H.; Mao, W.; Gao, Y.; Yang, J.; He, M. Innovative approach based on roof cutting by energy-gathering blasting for protecting roadways in coal mines. Tunn. Undergr. Space Technol. 2020, 99, 103387. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; He, M.; Tian, X.; Liu, J.; Xue, H.; Huang, R. Test of a liquid directional roof-cutting technology for pressure-relief entry retaining mining. J. Geophys. Eng. 2019, 16, 620–638. [Google Scholar] [CrossRef]

- Yang, T. 3D Breaking Characteristics of Overlying Strata and Stress Field Evolution Law in Stope with Directional Hard Roof Cutting; China University of Mining and Technology: Xuzhou, China, 2021. [Google Scholar]

- Wang, Q.; Zhang, P.; Jiang, Z.; He, M.; Li, S.; Wang, Y.; Jiang, B. Automatic roadway formation method by roof cutting with high strength bolt-grouting in deep coal mine and its validation. J. China Coal Soc. 2021, 46, 382–397. [Google Scholar]

- Pan, J.F.; Ma, W.T.; Liu, S.H.; Jiaming, G. A prevention technology of rock burst based on directional presplitting of water jet prefabricated slot in hard roof. Chin. J. Rock Mech. Eng. 2021, 40, 1591–1602. [Google Scholar]

- Tang, T.; Liu, D.; Cui, Z.; Han, Z.; Liu, B.; Wang, Z. Initiation pressure evaluation of coal mine roof hydraulic fracturing based on fracture mechanics. J. China Coal Soc. 2020, 45, 727–735. [Google Scholar]

- Lin, J.; Guo, K.; Sun, Z.; Wang, T. Study on fracturing timing of hydraulic fracturing top-cutting and pressure relief in roadway with strong dynamic pressure. J. China Coal Soc. 2021, 46, 140–148. [Google Scholar]

- Huang, B.; Chen, S.; Zhao, X. Hydraulic fracturing stress transfer methods to control the strong strata behaviours in gob-side gateroads of longwall mines. Arab. J. Geosci. 2017, 10, 236. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, Q.; He, M.; Wang, J.; Liu, J.; Ming, C.; Guo, L.; Fan, L. Numerical investigation on rock fracture induced by a new directional rock-breaking technology. Eng. Fract. Mech. 2022, 268, 108473. [Google Scholar] [CrossRef]

- Wu, Y. Study on De-Stressing Mechanism of Directional Hydraulic Fracturing to Control Deformation of Reused Roadway in Longwall Mining with Two Gateroad Layout and Its Onsite Practices; China Coal Research Institute: Beijing, China, 2018. [Google Scholar]

- Zhang, J.; Gao, Z.; Zhang, H. Parameters determination of coal-rock HJC model and research on blasting characteristics by liquid CO2. Chin. J. Rock Mech. Eng. 2021, 40 (Suppl. 1), 2633–2642. [Google Scholar]

- Kuang, T. Research on Overlying Rock Structure and Near-Far Roof Control Technology in Extra Thick Coal Seam; China University of Mining and Technology: Xuzhou, China, 2021. [Google Scholar]

- Tai, Y.; Yu, B.; Xia, B.; Li, Z.; Xia, H. Research on stress release for the gob-side roadway using the roof-cutting technology with a chainsaw arm. R. Soc. Open Sci. 2020, 7, 191663. [Google Scholar] [CrossRef]

- Wang, Q.; Feng, H.; Tang, P.; Peng, Y.; Li, C.; Jiang, L.; Mitri, H.S. The structure characteristics and deformation of “short cantilever beam” using a non-pillar mining method with gob-side entry formed automatically. J. China Univ. Min. Technol. 2019, 48, 718–726. [Google Scholar]

- Sun, X.; Liu, Y.; Wang, J.; Li, J.; Sun, S.; Cui, X. Study on three-dimensional stress field of gob-side entry retaining by roof cutting without pillar under near-group coal seam mining. Processes 2019, 7, 552. [Google Scholar] [CrossRef]

- Yang, J.; Wang, H.; Gao, Y.; Wang, J.; Liu, H. Fracture characteristics of the roof in gob-side entry retaining with roof cutting and pressure release. J. Min. Saf. Eng. 2019, 36, 1137–1144. [Google Scholar]

- Tian, C.; Wang, A.; Liu, Y.; Jia, T. Study on the migration law of overlying strata of gob-side entry retaining formed by roof cutting and pressure releasing in the shallow seam. Shock Vib. 2020, 2020, 8821160. [Google Scholar] [CrossRef]

- Chen, D.; Guo, F.; Xie, S.; Wang, E.; Wu, Y.; Jiang, Z.; Wang, L.; Cui, J.; Zhang, X.; Liu, R. Mining-induced failure characteristics and surrounding rock control of gob-side entry driving adjacent to filling working face in the deep coal mine. Energy Sci. Eng. 2022, 10, 2593–2611. [Google Scholar] [CrossRef]

- Zhang, B.S.; Wang, P.F.; Cui, S.Q.; Fan, M.Z.; Qiu, Y.M. Mechanism and surrounding rock control of roadway driving along gob in shallow-buried, large mining height and small coal pillars by roof cutting. J. China Coal Soc. 2021, 46, 2254–2267. [Google Scholar]

- Song, X. Pressure Relief at Cutting Top of Mining Face Study on the Regularity of Mine Pressure in Retaining Small Coal Pillar; Taiyuan University of Technology: Taiyuan, China, 2021. [Google Scholar]

- Wang, F.; Shang, J.; Zhao, B.; Cao, Q. Surrounding rock structural characteristics and anchor-cable strengthened support technology of the gob-side entry retaining with roof cutting and pressure releasing. Chin. J. Rock Mech. Eng. 2021, 40, 2296–2305. [Google Scholar]

- Zhang, Y.; Xu, H.; Song, P.; Sun, X.; He, M.; Guo, Z. Stress evolution law of surrounding rock with gob-side entry retaining by roof cutting and pressure release in composite roof. Adv. Mate. Sci. Eng. 2020, 2020, 1961680. [Google Scholar] [CrossRef]

- Wang, K. Study on Surrounding Rock Control of Gob-Side Entry Filling in Lingzhida Hard Top Plate Working Face; China University of Mining and Technology: Xuzhou, China, 2020. [Google Scholar]

- Zhen, E.; Gao, Y.; Wang, Y.; Wang, S. Comparative study on two types of non-pillar mining techniques by roof cutting and by filling artificial materials. Adv. Civil Eng. 2019, 2019, 5267240. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zu, H.; Zhang, K.; Qian, J. Study on filling support design and ground pressure monitoring scheme for gob-side entry retention by roof cutting and pressure relief in high-gas thin coal seam. Int. J. Environ. Res. Public Health 2022, 19, 3913. [Google Scholar] [CrossRef]

- Xie, S.; Wang, E.; Chen, D.; Li, H.; Jiang, Z.; Yang, H. Stability analysis and control technology of gob-side entry retaining with double roadways by filling with high-water material in gently inclined coal seam. Int. J. Coal Sci. Technol. 2022, 9, 52. [Google Scholar] [CrossRef]

- Xie, S.; Wang, E.; Chen, D.; Sun, Y.; Cheng, Q.; Ji, C.; Yan, Z.; Xiao, H. Failure analysis and control mechanism of gob-side entry retention with a 1.7-m flexible-formwork concrete wall: A case study. Eng. Fail. Anal. 2020, 117, 104816. [Google Scholar] [CrossRef]

- Liu, X.; Hua, X.; Yang, P.; Huang, Z. A study of the mechanical structure of the direct roof during the whole process of non-pillar gob-side entry retaining by roof cutting. Energ. Explor. Exploit. 2020, 38, 1706–1724. [Google Scholar] [CrossRef]

- He, M.; Ma, X.; Yu, B. Analysis of strata behavior process characteristics of gob-side entry retaining with roof cutting and pressure releasing based on composite roof structure. Shock Vib. 2019, 2019, 2380342. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, J.; Gao, H.; Yang, J.; Zhang, Y.; He, M. Mine pressure distribution and surrounding rock control of gob-side entry formed by roof cutting and pressure release under the influence of faults. Chin. J. Rock Mech. Eng. 2019, 38, 2182–2193. [Google Scholar]

- Liu, H.; Zhao, Y.; Ren, T.; Wang, F.; Li, Z. Characteristics of overburden failure and fracture development in gob of mining with gob-side entry formed by cutting roof. J. China Univ. Min. Technol. 2022, 51, 77–89. [Google Scholar]

- Li, L.; Li, G.; Gong, W.; Wang, J.; Deng, H. Energy evolution pattern and roof control strategy in non-pillar mining method of goaf-side entry retaining by roof cutting—A case study. Sustainability 2019, 11, 7029. [Google Scholar] [CrossRef]

- Wang, Q.; Guo, Z.; Ouyang, Z.; Yin, S.; Peng, R. The influence of crushed rock size on bearing-deformation performance of gangue rib of gob-side entry retaining formed by roof fracturing. J. China Univ. Min. Technol. 2022, 51, 100–106. [Google Scholar]

- Xie, S.; Wu, X.; Chen, D.; Sun, Y.; Zeng, J.; Zhang, Q.; Ji, C.; Cheng, Q.; Wang, E.; Ren, Y. Automatic roadway backfilling of caving gangue for cutting roofs by combined support on gob-side entry retaining with no-pillars: A case study. Adv. Mater. Sci. Eng. 2019, 2019, 8736103. [Google Scholar] [CrossRef]

- Chen, D.D.; He, F.L.; Xie, S.; Gao, M.M.; Song, H.Z. First fracture of the thin plate of main roof with three sides elastic foundation boundary and one side coal pillar. J. China Coal Soc. 2017, 42, 2528–2536. [Google Scholar]

- Wang, Y.; He, M.; Wang, Q.; Yang, J.; Wang, J.; Liu, H.; Chen, F. Design of equipment system and surrounding rock control for N00 mining method without coal pillar left and roadway excavation. J. China Coal Soc. 2022. [Google Scholar] [CrossRef]

- Wang, J.; Gao, R.; Yu, G.; Gong, W.; Zhu, D. Experimental study on infrared radiation characteristics of overburden movement of self-forming roadway under pressure relief. J. China Coal Soc. 2020, 45, 119–127. [Google Scholar]

- He, H.; Dou, L.; Fan, J.; Du, T.; Sun, X. Deep-hole directional fracturing of thick hard roof for rockburst prevention. Tunn. Undergr. Space Technol. 2012, 32, 34–43. [Google Scholar] [CrossRef]

- Yan, S.; Liu, T.; Bai, J.; Wu, W. Key Parameters of Gob-Side Entry Retaining in A Gassy and Thin Coal Seam with Hard Roof. Processes 2018, 6, 51. [Google Scholar]

- Liu, H.; Dai, J.; Jiang, J.; Wang, P.; Yang, J. Analysis of Overburden Structure and Pressure-Relief Effect of Hard Roof Blasting and Cutting. Adv. Civ. Eng. 2019, 2019, 1354652. [Google Scholar]

- Zhang, L.; Zhao, J.; Zang, C.; Wang, S. An Innovative Approach for Gob-Side Entry Retaining by Roof Cutting in Steeply Pitching Seam Longwall Mining with Hard Roof: A Case Study. Min. Metall. Explor. 2020, 37, 1079–1091. [Google Scholar]

- Yang, H.; Liu, Y.; Cao, S.; Pan, R.; Wang, H.; Li, Y.; Luo, F. A caving self-stabilization bearing structure of advancing cutting roof for gob-side entry retaining with hard roof stratum. Geomech. Eng. 2020, 21, 23–33. [Google Scholar]

- Gao, K.; Huang, P.; Liu, Z.G.; Liu, J.; Wang, F.; Shu, C.M. Pressure Relief by Blasting Roof Cutting in Close Seam Group Mining under Thick Sandstone to Enhance Gas Extraction for Mining Safety. Processes 2021, 9, 693. [Google Scholar]

- Hu, J.; He, M.; Wang, J.; Ma, Z.; Wang, Y.; Zhang, X. Key Parameters of Roof Cutting of Gob-Side Entry Retaining in a Deep Inclined Thick Coal Seam with Hard Roof. Energies 2019, 12, 934. [Google Scholar]

- Ma, X.; He, M.; Wang, J.; Gao, Y.; Zhu, D.; Liu, Y. Mine Strata Pressure Characteristics and Mechanisms in Gob-Side Entry Retention by Roof Cutting under Medium-Thick Coal Seam and Compound Roof Conditions. Energies 2018, 11, 2539. [Google Scholar]

- Chen, D.D.; Guo, F.F.; Wu, Y.Y. Study on the first fracture of the main roof plate structure with the long side goaf and elastic-plastic softening foundation boundary. J. China Coal Soc. 2022, 47, 1473–1489. [Google Scholar]

- Chen, D.D.; Xie, S.R.; He, F.L.; Zeng, J.C.; Xie, F.X.; Cheng, Q. First fracturing of thin plate of main roof with elastic foundation boundary on both sides of the long side of goaf (coal pillars). J. China Coal Soc. 2018, 43, 3273–3285. [Google Scholar]

- Guo, Z.; Wang, H.; Ma, Z.; Wang, P.; Kuai, X.; Zhang, X. Research on the transmission of stresses by roof cutting near gob rocks. Energies 2021, 14, 1237. [Google Scholar]

- Li, P.; Lai, X.; Gong, P.; Su, C.; Suo, Y. Mechanisms and applications of pressure relief by roof cutting of a deep-buried roadway near Goafs. Energies 2020, 13, 5732. [Google Scholar] [CrossRef]

- Yang, X.; Liu, C.; Sun, H.; Yue, S.; Ji, Y.; Zhang, X.; Hou, L. Research on the deformation mechanism and directional blasting roof cutting control measures of a deep buried high-stress roadway. Shock Vib. 2020, 2020, 6742504. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; He, M.; Wang, Q.; Qiao, Y.; Yang, J. Mine pressure behavior characteristics and control methods of a reused entry that was formed by roof cutting: A case study. Shock Vib. 2020, 2020, 4276730. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Wang, L.; Liu, B.; Li, S.; Gao, H.; Wang, Y. Control mechanism of roof fracture in no-pillar roadways automatically formed by roof cutting and pressure releasing. Arab. J. Geosci. 2020, 13, 274. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Y.; Wang, E.; He, M.; Yang, J. Roof deformation characteristics and preventive techniques using a novel non-pillar mining method of gob-side entry retaining by roof cutting. Energies 2018, 11, 627. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.; Zhao, Z.; Xu, Q.; Wang, J.; Ding, K. Roadside support schemes numerical simulation and field monitoring of gob-side entry retaining in soft floor and hard roof. Arab. J. Geosci. 2018, 11, 563. [Google Scholar] [CrossRef]

- Sun, B.J.; Hua, X.Z.; Zhang, Y.; Yin, J.; He, K.; Zhao, C.; Li, Y. Analysis of roof deformation mechanism and control measures with roof cutting and pressure releasing in gob-side entry retaining. Shock Vib. 2021, 2021, 6677407. [Google Scholar] [CrossRef]

- Guo, J.G.; Li, Y.H.; Shi, S.H.; Jiang, Z.S.; Chen, D.D.; He, F.L.; Xie, S.R. Self-forming roadway of roof cutting and surrounding rock control technology under thick and hard basic roof. J. China Coal Soc. 2021, 46, 2853–2864. [Google Scholar]

- Zhao, S.K.; Deng, Z.G.; Qi, Q.X.; Li, H.Y. Theory and application of deep hole floor-break blasting in floor rock burst coal mine. J. Min. Saf. Eng. 2016, 33, 636–642. [Google Scholar]

- Liu, S.; Feng, M.; Pan, J.; Wang, S. Experimental analysis on vibration of roadway with strong probability of rock burst subjected to pressure relief blasting. Chin. J. Rock Mech. Eng. 2016, 35, 906–918. [Google Scholar]

- Xie, S.R.; Wang, E.; Chen, D.D.; Jiang, Z.S.; Li, H.; Liu, R.P. Collaborative control technology of external anchor-internal unloading of surrounding rock in deep large-section coal roadway under strong mining influence. J. China Coal Soc. 2022, 47, 1946–1957. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, S.; Wu, Y.; Guo, F.; Zou, H.; Chen, D.; Zhang, X.; Ma, X.; Liu, R.; Wu, C. Application of Pre-Splitting and Roof-Cutting Control Technology in Coal Mining: A Review of Technology. Energies 2022, 15, 6489. https://doi.org/10.3390/en15176489

Xie S, Wu Y, Guo F, Zou H, Chen D, Zhang X, Ma X, Liu R, Wu C. Application of Pre-Splitting and Roof-Cutting Control Technology in Coal Mining: A Review of Technology. Energies. 2022; 15(17):6489. https://doi.org/10.3390/en15176489

Chicago/Turabian StyleXie, Shengrong, Yiyi Wu, Fangfang Guo, Hang Zou, Dongdong Chen, Xiao Zhang, Xiang Ma, Ruipeng Liu, and Chaowen Wu. 2022. "Application of Pre-Splitting and Roof-Cutting Control Technology in Coal Mining: A Review of Technology" Energies 15, no. 17: 6489. https://doi.org/10.3390/en15176489

APA StyleXie, S., Wu, Y., Guo, F., Zou, H., Chen, D., Zhang, X., Ma, X., Liu, R., & Wu, C. (2022). Application of Pre-Splitting and Roof-Cutting Control Technology in Coal Mining: A Review of Technology. Energies, 15(17), 6489. https://doi.org/10.3390/en15176489