Study and Application of Ultrafine Temperature-Resistant and Salt-Tolerant Swellable Particles in Low Permeability Reservoirs

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Materials and Equipment

2.2. Experimental Method

2.2.1. Particle Suspension Preparation Method

2.2.2. Experiment Flow for Determination of Swelling Property

- A total of 0.2 g of swellable particles DS-1 was weighed;

- Particle suspensions with mineralization degrees of 1, 5, 10, 15, and 20 × 104 mg/L, respectively, were prepared;

- Twenty (20) mL of suspension was pipetted into a 30 mL ampule by a large pipette;

- The ampule was sealed with an alcohol blast burner and a pair of tweezers, and then placed into a 500 mL aging tank;

- The aging tank was placed into an oven at 50, 80, 120, and 150 °C;

- After 1, 3, 5, 7, 9, 11, 13, and 15 days, the aging tank was taken out and cooled naturally to 50 °C first and then cooled by water;

- The swelling ratio was determined. The aged particle suspension was filtered until no water drop seeped, and then it was weighed. The swelling ratio is as follows:

2.2.3. Test of Plugging Property

2.2.4. Test of Oil Displacement Effect of Two Parallel Pipes

3. Experimental Results and Discussion

3.1. Synthesis and Characterization of Particles

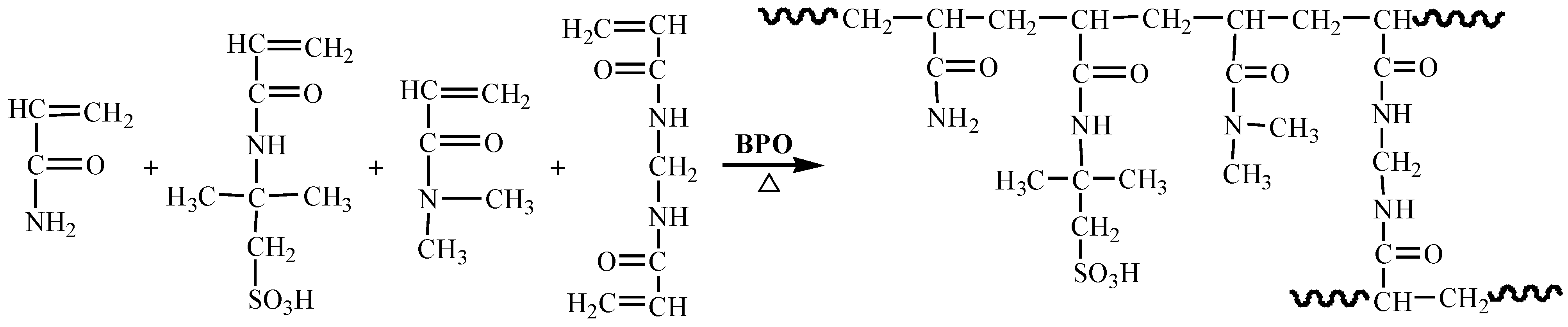

3.1.1. Synthesis Path

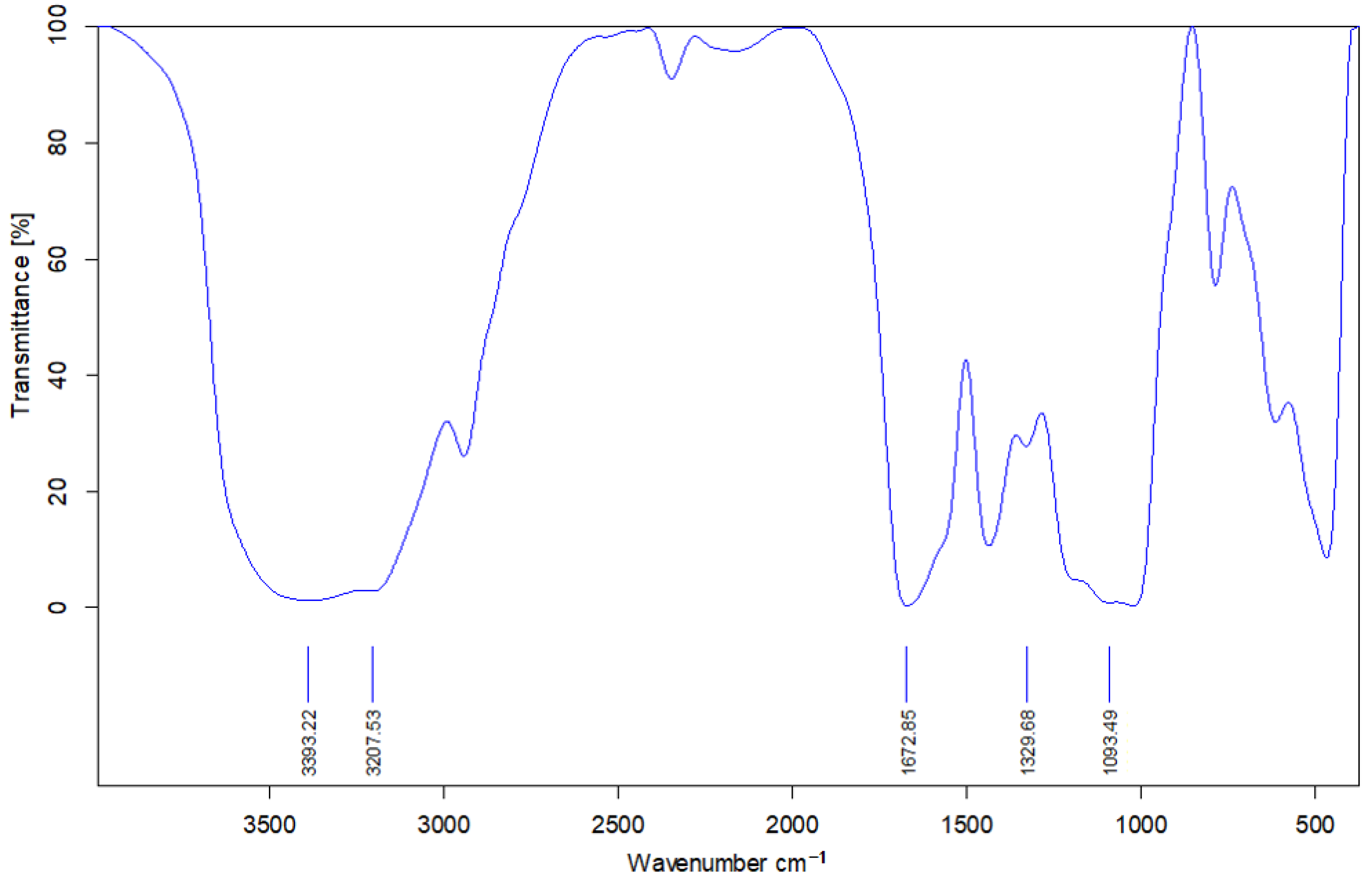

3.1.2. Infrared Spectra

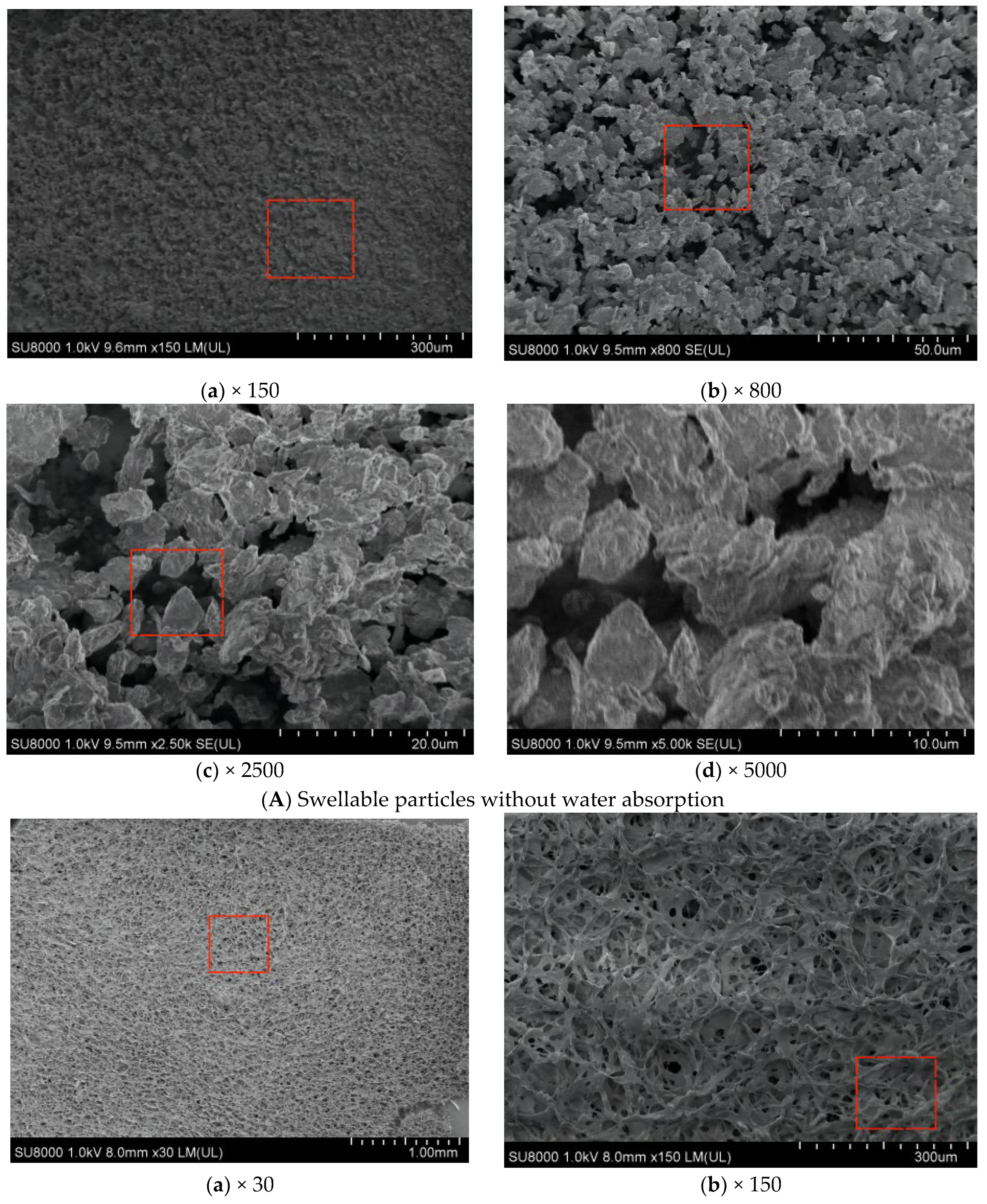

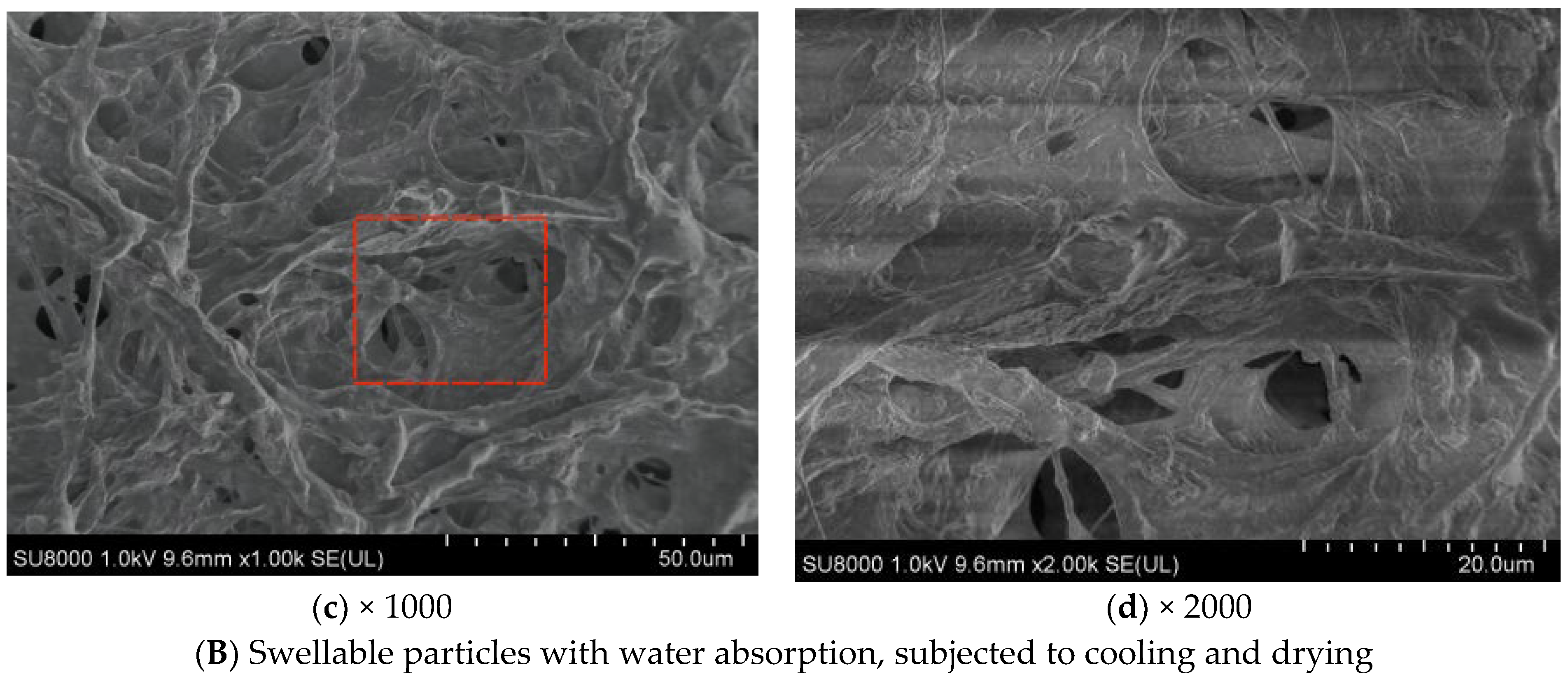

3.1.3. Scanning Electron Microscope

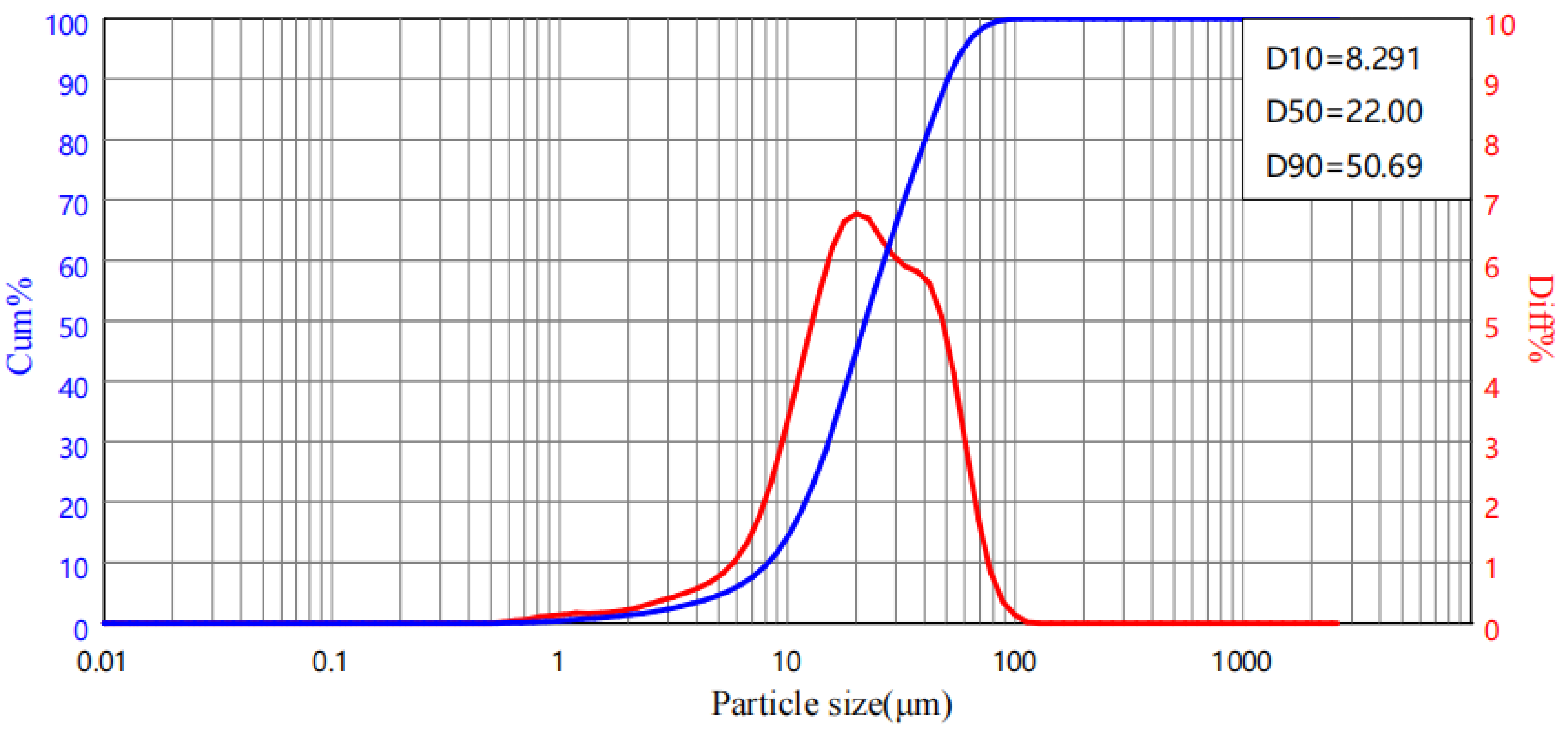

3.1.4. Test of Particle Size

3.2. Test of Swelling Property

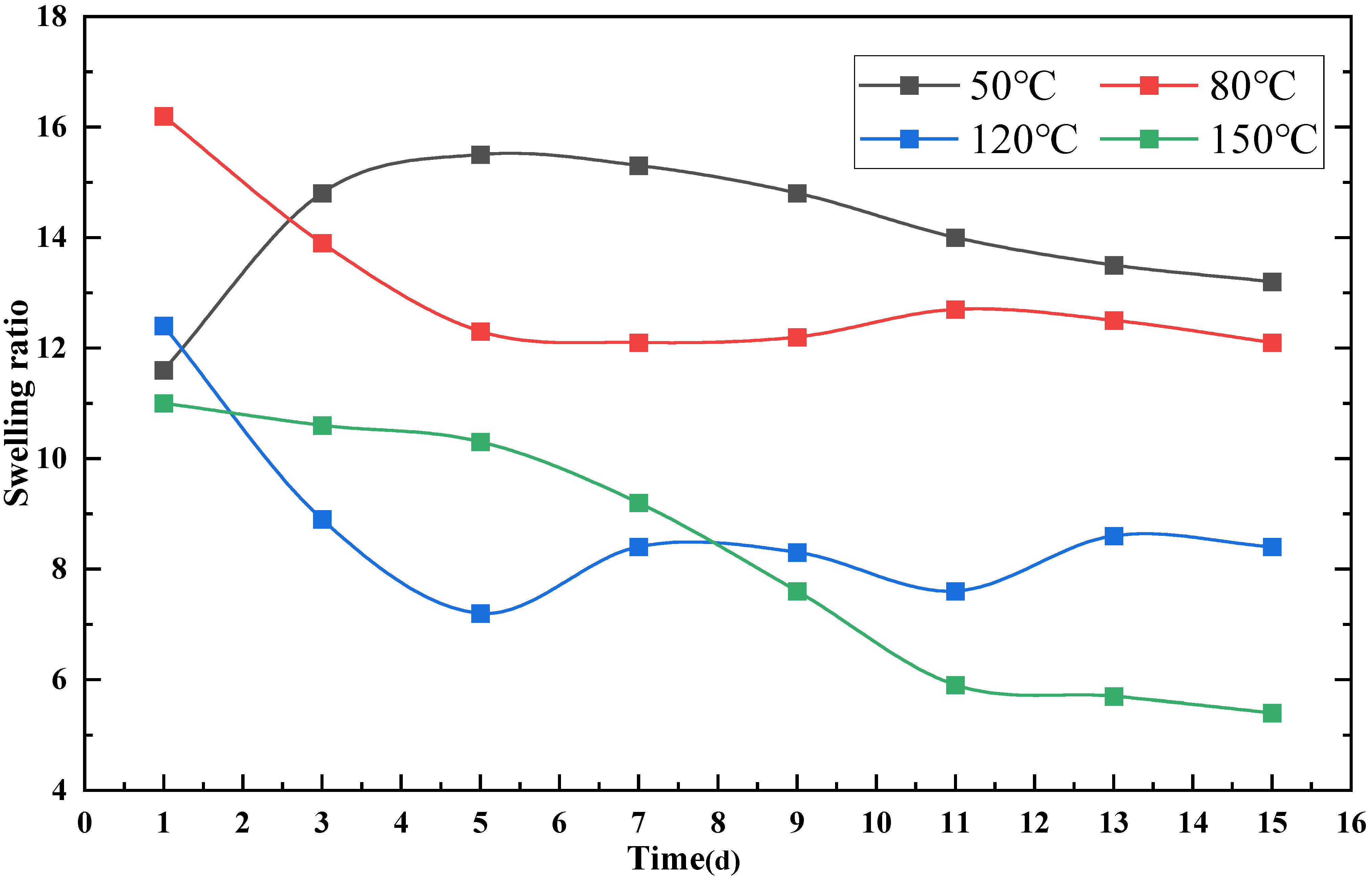

3.2.1. Influence of Temperature on Swelling Property

3.2.2. Influence of Mineralization Degree on Swelling Property

3.3. Physical Modeling Experiment of Flow of Swellable Particle Core

3.3.1. Test of Plugging Property

3.3.2. Experiment of Oil Displacement Effect of Two Parallel Pipes

4. Field Experiment

4.1. Geological Exploitation Situations in Experimental Well

4.2. Construction Process

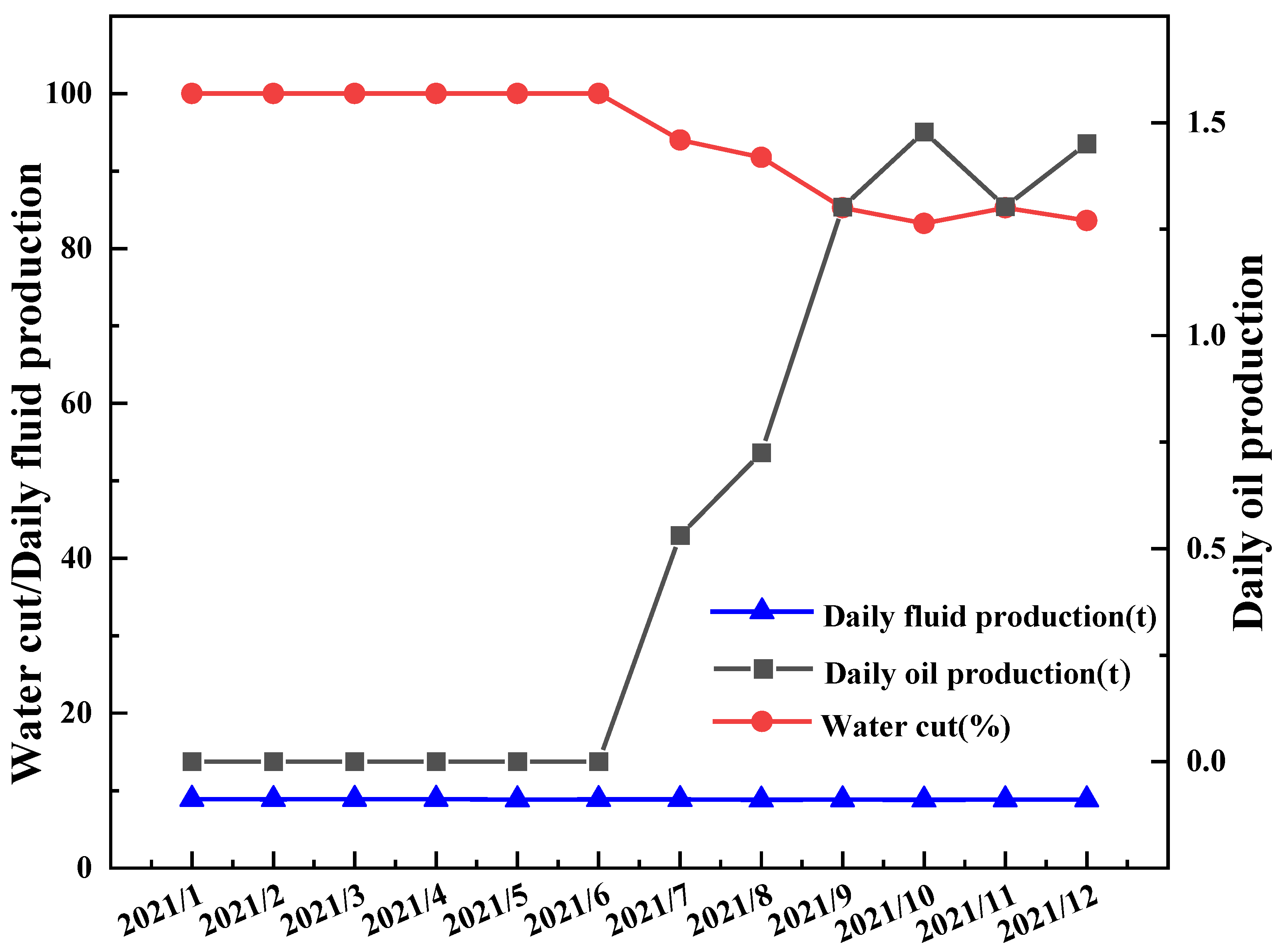

4.3. Construction Effect

5. Conclusions

- (1)

- Temperature-resistant and salt-tolerant gel particles DS-1 with a three-dimensional reticular structure were synthesized by introducing DMAA monomer into an AMPS/AM/N,N-dimethylbisacrylamide ternary crosslinking system. The median of the initial particle size of the particles is 20.00 μm, where 90% of the particles have particle sizes less than 50.69 μm, and the ratio of particle size above 82.28% to pore throat diameter is 1.4–1.5, which is compatible with the requirements for injection, transport, and plugging in low-permeability reservoirs. The particle surface without water absorption is porous, where each pore has a rough inside surface, and there are good connectivity and thick walls between adjacent pores. The particle surface after water absorption exhibits a reticular structure with dense pores—without the gel failure phenomenon seen at high temperatures salt content—thereby confirming that the particles have a strong water absorption capability and excellent stability.

- (2)

- Static experimental results show that both an increase in temperature and increase in mineralization degree can influence the swelling property of the particles, but the particles can still maintain a considerable swelling ratio and excellent stability for a long time. The dynamic displacement experiment confirmed that the particles can effectively plug the dominant channels of waterflooding, thereby causing the reversal of fluid flow and increasing the sweep efficiency by controlling the water absorption profiles to enhance the intralayer (interlayer) oil recovery.

- (3)

- The swellable particles DS-1 had a good water cut decrease and oil production increase effect in the field experiment. In Oil Well G42, the daily oil production increased by 1.45 t and the water cut decreased by 16.41%. The successful use of DS-1 expanded the application scope of swellable particles, providing a new choice for water plugging and profile control agents in low-permeability reservoirs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, L.H.; Feng, C.; Sun, L.H.; Feng, C.; Wang, L.; Lang, X.M.; Li, B.W.; Sun, D.M. Prospect of a new technology to improve the recovery of low permeability reservoirs: Supramolecular polymer flooding. Appl. Chem. Ind. 2021, 50, 3396–3401. [Google Scholar] [CrossRef]

- Zhang, C.B. Study on theoretical model for recovery evaluation of CO2 flooding in low permeability reservoirs. Pet. Geol. Recovery Effic. 2021, 28, 131–139. [Google Scholar] [CrossRef]

- Han, X.Q.; Shi, L.H.; Liu, C.Y.; Zhao, S.Y.; Zhou, X.; Feng, T.T. Optimization study and application of staged fracturing production parameters for horizontal wells in ultra-low permeability reservoirs of Yanchang Oilfield. Drill. Prod. Technol. 2018, 41, 8, 9, 61–64. [Google Scholar]

- He, X.M.; Liu, H.X.; Chen, J.M.; Jing, F.T. Acidizing technology for low permeability sandstone reservoir in Xinli Oilfield. Fault-Block Oil Gas Field 2009, 16, 110–111. [Google Scholar]

- Lv, P.; Liu, Y.G.; Zhang, Y.B.; Gao, J.C.; Xia, H. Research on the performance of body-expanding particles and their oil drive mechanism based on reservoir microstructure improvement. Chem. Eng. 2019, 33, 80–83. [Google Scholar] [CrossRef]

- Li, G.; Fu, M.; Li, X.; Hu, J.N. A Study of the Thin Film-Coated Swelling Retarding Particles in Fractured Carbonate Reservoirs for Water Plugging and Profile Control. Energies 2022, 15, 1085. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, C.Q.; Wang, W.Z.; Zhou, Y.F.; Lu, Y.T.; Zhang, P.; Jia, Z.F.; Zhou, C.Y.; Chen, S.L. Preparation and application of polyalkylene-based cross-linking agents with “pulley” effect in bulk particle-type modifiers. Chem. J. Chin. Univ. 2018, 39, 2098–2104. [Google Scholar]

- Li, L.; Zhang, R.S.; Liu, J.X.; Wu, Y.J.; Wu, J.W. Analysis on mechanism of plugging and profile control with swelling retarding particles for fracture-vuggy reservoirs in Tahe Oilfield. Oilfield Chem. 2020, 37, 245–249. [Google Scholar] [CrossRef]

- Zhang, J.S. Preparation of swelling retarding and high strength particles for profile control and flooding in deep part and evaluation of its performance. J. Xi’an Shiyou Univ. 2013, 28, 3, 50–53. [Google Scholar]

- Zhao, X.T.; Chen, Z.H.; Chen, W.X.; Ma, H.Q.; Zhai, D.Q.; Ren, Z.L. Current research situation and development trend of particle profile control and water plugging agents. Oil Drill. Prod. Technol. 2015, 37, 105–112. [Google Scholar] [CrossRef]

- Zhao, J.; Kang, W.L.; Liu, J.; Zhang, B. Study on compatibility between pre-crosslinking gel particles and formation. China Sci. 2015, 10, 1818–1821. [Google Scholar]

- James, P.; Harry, F.; Joe, B.; Steve, C.; Jim, M.; Chang, K.; Dennis, W.; James, G.; Pritchett, J.; Frampton, H. Field Application of a New In-Depth Waterflood Conformance Improvement Tool. In Proceedings of the SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 20–21 October 2003. [Google Scholar]

- Lei, G.L.; Li, W.Z.; Jia, X.F.; Yao, C.J.; Sun, W.K. Influence of pore throat scale elastic microspheres on drive regulation. Oil Gas Geol. Recovery 2012, 19, 41–43, 113–114. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, J.H.; Sun, H.Q.; Cao, Z.Q.; Song, D.F. Size influencing factors and plugging properties of polymer microspheres. Pet. Geol. Recovery Effic. 2006, 4, 80–82, 110–111. [Google Scholar]

| No. | Length × Diameter (mm × mm) | Permeability (mD) | Porosity (%) | Pore Volume (cm3) |

|---|---|---|---|---|

| F1 | 200 × 25 | 21.30 | 25.78 | 25.30 |

| R1 | 21.20 | 23.84 | 23.39 | |

| R2 | 5.30 | 15% | 14.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, M.; Zhang, J.; Li, G.; Hu, J.; Chen, P.; Chen, L.; He, H. Study and Application of Ultrafine Temperature-Resistant and Salt-Tolerant Swellable Particles in Low Permeability Reservoirs. Energies 2022, 15, 6619. https://doi.org/10.3390/en15186619

Fu M, Zhang J, Li G, Hu J, Chen P, Chen L, He H. Study and Application of Ultrafine Temperature-Resistant and Salt-Tolerant Swellable Particles in Low Permeability Reservoirs. Energies. 2022; 15(18):6619. https://doi.org/10.3390/en15186619

Chicago/Turabian StyleFu, Meilong, Junbo Zhang, Guojun Li, Jiani Hu, Peng Chen, Lifeng Chen, and Honglin He. 2022. "Study and Application of Ultrafine Temperature-Resistant and Salt-Tolerant Swellable Particles in Low Permeability Reservoirs" Energies 15, no. 18: 6619. https://doi.org/10.3390/en15186619