Aspects Regarding the Optimization of Cross Geometry in Traction Asynchronous Motors Using the Theory of Nonlinear Circuits

Abstract

:1. Introduction

- -

- Electrical tractionmotors should be placed so that they are easily accessible for verifications, revisions, and repairs;

- -

- The transmission should enable the rotor to rotate faster than the motor axle is driven, ensuring the optimum speed of the electrical tractionmotor.

2. Analysis of Stator and Rotor Slot Geometry

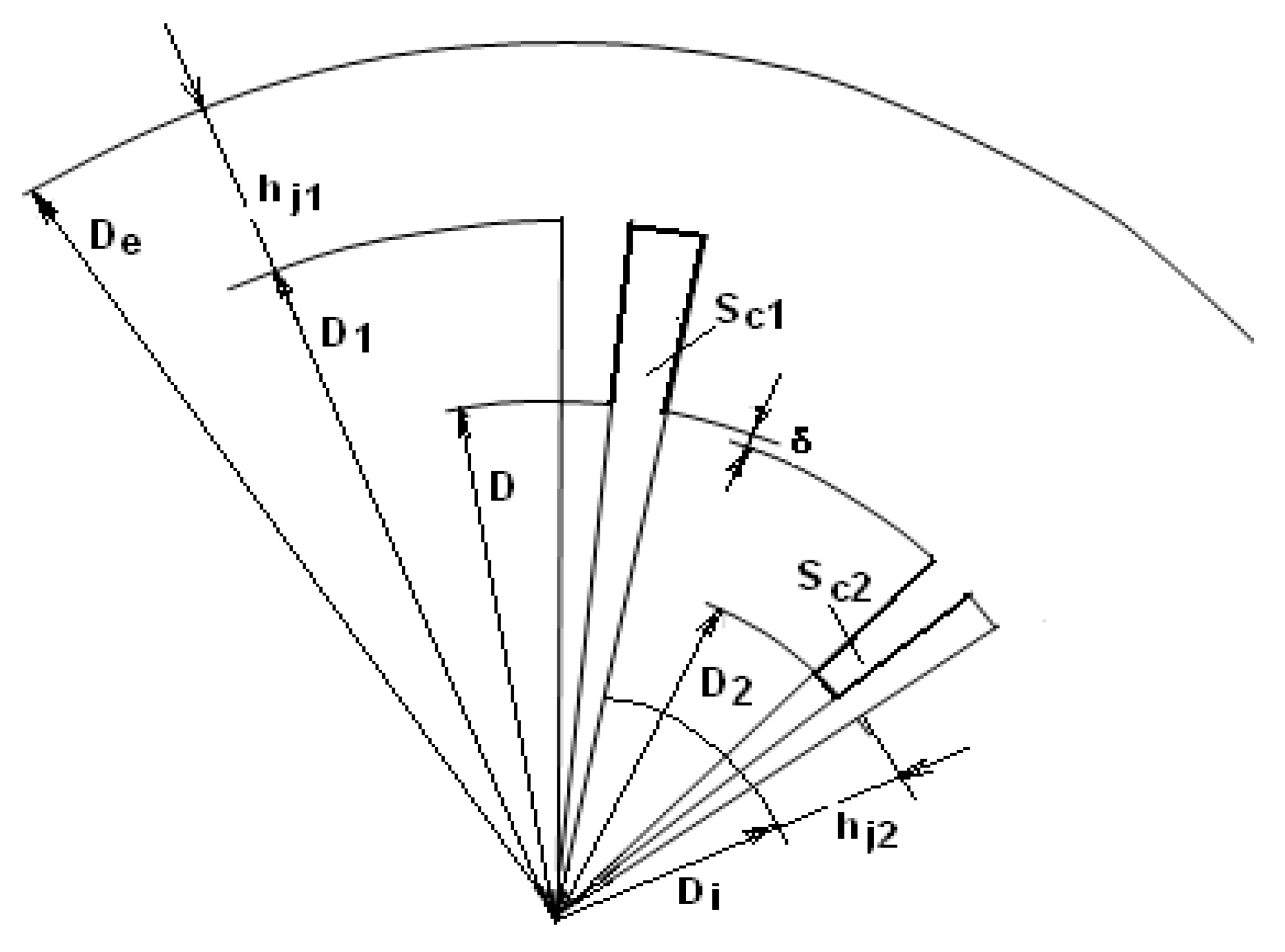

Variables Defining the Cross Geometry of an Asynchronous Motor

- De, D—outer and inner diameter, respectively, ofthe stator lamination;

- D-2*δ, Di—outer and inner diameter, respectively, ofthe rotor lamination;

- D1, D2—diameters of the slot base, for the stator and rotor slot, respectively;

- Sc1, Sc2—areas of the geometric surfaces, for the stator and rotor slot, respectively;δ—machine air-gap.

3. The Simplified Mathematical Model Used to Optimize the Transverse Geometry of the Asynchronous Motor

- -

- The outer diameter of the stator plate is kept for the analyzed motor;

- -

- The solenacy corresponding to the magnetizing current (the magnetomotive voltage on a pair of poles), in the study being done, will be an imposed quantity (the reference solenacy);

- -

- The same electrical stresses are preserved;

- -

- The constant air-gap is preserved, the same one as in the analyzed motor;

- -

- The geometric dimensions in the cross geometry and the magnetic stresses in all parts of the magnetic circuit are modified so that the total ampere-turn, for a pole pair, is minimized;

- -

- For these dimensions of the magnetic circuit, the air-gap magnetic induction is progressively increased (so the inductances in the teeth and yokes also increase, etc.), and as a result, solenacy on the pair of poles increases until the imposed value of “reference solenacy” is reached.

3.1. Objective Function

3.2. Variables and Restrictions of the Objective Function

4. Simulated Results

4.1. Necessary Steps for Local Optimization in Relation to Each Variable

- -

- The relation for the resultant ampere-turn total(magneto-motive force for a pole pair) is considered, as known in literature:

- -

- t.m.m. to the “reference motor” (the classically designed one) is calculated, and the obtained value will be kept constant during the optimization Umm.i = const.;

- -

- Each variable corresponds to at least one term of this sum, for example:

- *

- For the variable D—théinner stator diameter, Umj1, Umd1,Umd2, and Umj2 changes;

- *

- For the variable Di—the rotor lamination inner diameter, Umj2 changes;

- *

- For the variable βc1—the stator slot shape factor, Umd1 and Umj1 changes;

- *

- For the variable βc2—rotor slot shape factor, Umd2 and Umj2, changes.

- -

- The geometrical dimensions modify in the cross-section of the magnetic circuit; consequently, the afferent magnetic stresses are changed (magnetic field induction and intensity) for the established variable;

- -

- The established variable is changed by ±15% compared to the known reference value, and the minimum value for Umm—t.m.m. (rel. 12) is sought;

- -

- B—the air-gap magnetic induction is progressively increased; consequently, all terms in the relation (12) increase, until the imposed value Umm.i = cont. is reached;

- -

- Thus, the optimum value of the analyzed variable is established.

4.1.1. Optimization Relative to Variable D (Motor Diameter)

4.1.2. Optimization Relative to the Variable Dir (Rotor Inner Diameter)

4.1.3. Optimization Relative to the Variable βc1 = hc1/bc1(Stator Slot Shape Factor)

4.1.4. Optimization Relative to the Variable βc2 = hc2/bc2(Rotor Slot Shape Factor)

4.1.5. The Final Optimal Solution for the Transversal Geometry of the Motor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kreuawan, S.; Gillon, F.; Moussouni, F.; Brisset, S.; Brochet, P. Optimal design of traction motor in railway propulsion system. In Proceedings of the International Aegean Conference on Electric Machines, Power Electronics and Electromotion Joint Conference, Bodrum Turkey, 10–12 September 2007; pp. 343–348. [Google Scholar]

- Abouzeid, A.F.; Guerrero, J.M.; Endemaño, A. Control strategies for induction motors in railway traction applications. Energies 2020, 13, 700. [Google Scholar] [CrossRef]

- Finch, J.W.; Gsaoris, D. Contolled AC Electrical Drives. IEEE Trans. Ind. Electron. 2008, 2, 481–491. [Google Scholar] [CrossRef]

- Fabrini, B.; Boldea, I. Electric Machinery and Adjustable Speed Motor Drives. Part I-Guest Editorial. IEEE Trans. Ind. Electron. 2007, 5, 2363–2364. [Google Scholar]

- Chefneux, M.; Livadaru, L. Solutions of Integrated Design of Electrical Machines for a Rational Use of the Natural and Artificial Resources; CIT-TE-ICPE Publishing House: Bucharest, Romania, 2008. [Google Scholar]

- Nigim, K.A.; DeLyser, R.R. Using MathCad in understanding the induction motor characteristics. IEEE Trans. Educ. 2011, 44, 165–169. [Google Scholar] [CrossRef]

- Vlad, I.; Campeanu, A.; Enache, S. Computer-Aided Design of Asynchronous Motors. Optimization Problems; Universitaria Publishing House: Craiova, Romania, 2011. [Google Scholar]

- IEC 60034-2-1:2014; Rotating Electrical Machines-Part 2-1. Standard Methods for Determining Losses and Efficiency from Tests. IEC: Geneva, Switzerland, 2014.

- Boglietti, A.; Cavagnino, A.; Lazzari, M.; Pastorelli, M. International standards for the induction motor efficiency determination: A critical analysis of the stray load loss determination. IEEE-IAS Trans. Ind. Appl. 2004, 40, 1294–1301. [Google Scholar] [CrossRef]

- Fasquelle, A.; Saury, D.; Harmand, S.; Randria, A. Numerical study of convective heat transfer in end region of enclosed induction motor of railway traction. IJEET Int. J. Electr. Eng. Transp. 2006, 2, 39–44. [Google Scholar]

- Necula, D.; Vasile, N.; Stan, M.F. The Electrical Machines Impact on the Environment and Solution to reduce its. In Scientific Bulletin of the Electrical Engineering Faculty; Bibliotheca Publishing House: Târgovişte, Romania, 2011; pp. 37–42. [Google Scholar]

- Maksay, S.T.; Stoica, D. Computer-Aided Mathematics; Politechnical Timisoara Publishing House: Timișoara, Romania, 2006. (In Romanian) [Google Scholar]

- Campeanu, A.; Cautil, I.; Vlad, I.; Enache, S. Modelling and Simulation of Alternating Current Machines; Romanian Academy Publishing House: Bucharest, Romania, 2012. [Google Scholar]

- Roux, P.F.; Ngwenyama, M.K. Static and Dynamic simulation of an induction motor using Matlab/Simulink. Energies 2022, 15, 3564. [Google Scholar] [CrossRef]

- Samarkanov, D.; Gillon, F.; Brochet, P.; Laloy, D. Techno-economic optimization of induction machines: An industrial application. In Proceedings of the ACEMP—Electromotion 2011, Istanbul, Turkey, 8–10 September 2011; pp. 825–830. [Google Scholar]

- Ta, C.M.; Chakraborthy, C.; Hori, Y. Efficiency maximization of induction motor drives for electric vehicles based on actual measurement of input power. Proc. IECON (IEEE-IES) 2011, 3, 1692–1697. [Google Scholar]

| Criterion | Ct (€) | Cf (€) | Ce (€) | η | cosφ | mm (r.u.) | |

|---|---|---|---|---|---|---|---|

| Variant | |||||||

| Values imposed | - | - | - | ≥0.94 | ≥0.92 | ≥2.40 | |

| Vm—Real var. | 346,700 | 29,750 | 317,000 | 0.951 | 0.923 | 2.648 | |

| Vo.—Opt. var. | 312,700 | 28,930 | 283,800 | 0.956 | 0.926 | 2.807 | |

| Criterion | Ct (€) | Cf (€) | Ce (€) | η | cosφ | mm (r.u.) | |

|---|---|---|---|---|---|---|---|

| Variant | |||||||

| Values imposed | - | - | - | ≥0.94 | ≥0.92 | ≥2.40 | |

| Vm—Real var. | 346,700 | 29,750 | 317,000 | 0.951 | 0.923 | 2.648 | |

| Vo.—Opt. var. | 346,300 | 29,060 | 317,200 | 0.951 | 0.920 | 2.682 | |

| Criterion | Ct (€) | Cf (€) | Ce (€) | η | cosφ | mm (r.u.) | |

|---|---|---|---|---|---|---|---|

| Variant | |||||||

| Values imposed | - | - | - | ≥0.94 | ≥0.92 | ≥2.40 | |

| Vm—Real var. | 346,700 | 29,750 | 317,000 | 0.951 | 0.923 | 2.648 | |

| Vo.—Opt. var. | 337,700 | 29,440 | 308,300 | 0.953 | 0.922 | 2.652 | |

| Criterion | Ct (€) | Cf (€) | Ce (€) | η | cosφ | mm (r.u.) | |

|---|---|---|---|---|---|---|---|

| Variant | |||||||

| Values imposed | - | - | - | ≥0.94 | ≥0.92 | ≥2.40 | |

| Vm—Real var. | 346,700 | 29,750 | 317,000 | 0.951 | 0.923 | 2.648 | |

| Vo.—Opt. var. | 353,900 | 30,180 | 323,700 | 0.950 | 0.917 | 2.402 | |

| Criterion | Ct (€) | Cf (€) | Ce (€) | η | cosφ | mm (r.u.) | |

|---|---|---|---|---|---|---|---|

| Variant | |||||||

| Values imposed | - | - | - | ≥0.94 | ≥0.92 | ≥2.40 | |

| Vm—Real var. | 346,700 | 29,750 | 317,000 | 0.951 | 0.923 | 2.648 | |

| Vo.—Opt. var. | 304,100 | 27,930 | 276,200 | 0.957 | 0.920 | 2.934 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enache, S.; Vlad, I.; Enache, M.A. Aspects Regarding the Optimization of Cross Geometry in Traction Asynchronous Motors Using the Theory of Nonlinear Circuits. Energies 2022, 15, 6648. https://doi.org/10.3390/en15186648

Enache S, Vlad I, Enache MA. Aspects Regarding the Optimization of Cross Geometry in Traction Asynchronous Motors Using the Theory of Nonlinear Circuits. Energies. 2022; 15(18):6648. https://doi.org/10.3390/en15186648

Chicago/Turabian StyleEnache, Sorin, Ion Vlad, and Monica Adela Enache. 2022. "Aspects Regarding the Optimization of Cross Geometry in Traction Asynchronous Motors Using the Theory of Nonlinear Circuits" Energies 15, no. 18: 6648. https://doi.org/10.3390/en15186648