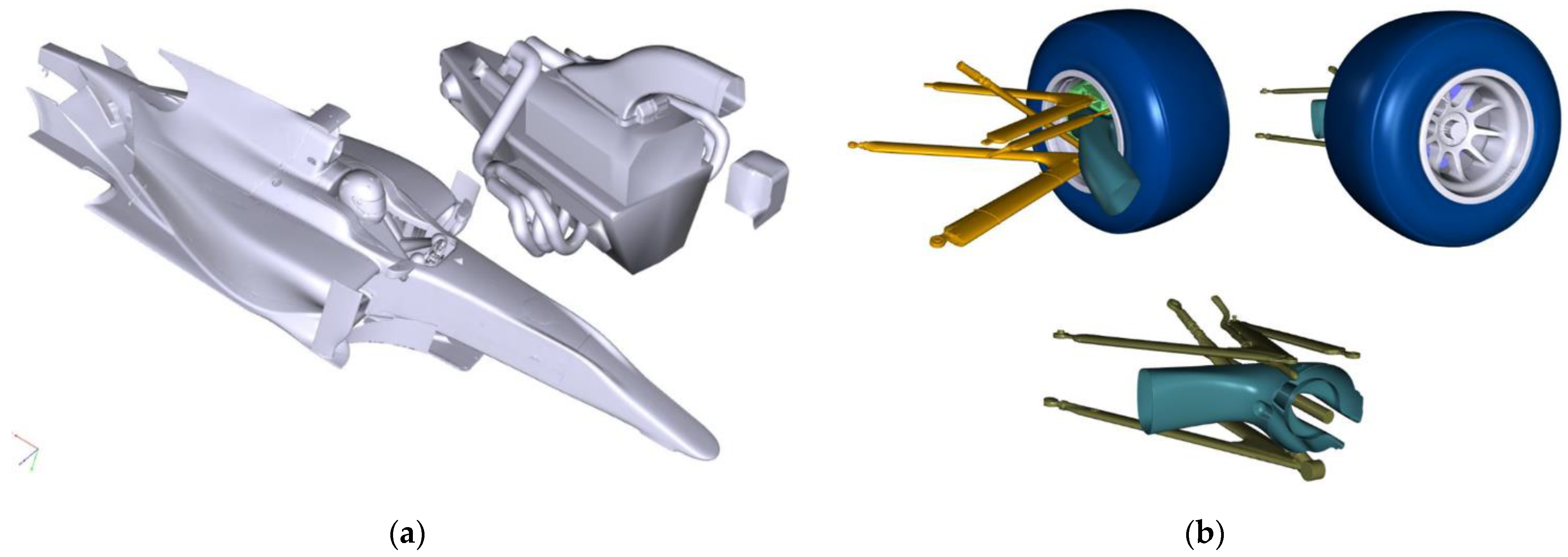

Figure 1.

Vehicle 3D scans: (a) Scan of main vehicle body and engine-gearbox unit; (b) Scan of suspension and wheel assemblies with fully detailed brake cooling ducts.

Figure 1.

Vehicle 3D scans: (a) Scan of main vehicle body and engine-gearbox unit; (b) Scan of suspension and wheel assemblies with fully detailed brake cooling ducts.

Figure 2.

Final 3D model assembly: (a) Full vehicle model ready for CFD analysis; (b) Adjustable front flap and rear wing and movable suspension kinematics allowed for CFD analysis to be performed as a sweep of aerodynamic device settings and ride heights.

Figure 2.

Final 3D model assembly: (a) Full vehicle model ready for CFD analysis; (b) Adjustable front flap and rear wing and movable suspension kinematics allowed for CFD analysis to be performed as a sweep of aerodynamic device settings and ride heights.

Figure 3.

Plots of pressure coefficient Cp and vertical component alone CpZ: (a) pressure distribution over the entire car body; (b) downforce/lift contributions on upper surfaces.

Figure 3.

Plots of pressure coefficient Cp and vertical component alone CpZ: (a) pressure distribution over the entire car body; (b) downforce/lift contributions on upper surfaces.

Figure 4.

Pressure coefficient Cp in front and rear view: (a) front view showing stagnation pressure areas; (b) rear view showing low pressure areas under rear wing and in underbody Venturi ducts.

Figure 4.

Pressure coefficient Cp in front and rear view: (a) front view showing stagnation pressure areas; (b) rear view showing low pressure areas under rear wing and in underbody Venturi ducts.

Figure 5.

Pressure coefficient Cp under the car, showing main downforce contributions through ground effect.

Figure 5.

Pressure coefficient Cp under the car, showing main downforce contributions through ground effect.

Figure 6.

Drag coefficient CDS vs. Front Ride Height FRH and Rear Ride Height RRH. Actual figures are not shown for confidentiality reasons. The percentage variation is computed with reference to maximum drag. Also shown are the ride height ranges: the front one is lower on average and narrower than the rear. Cells with values in red are the areas less likely to tap into: high nose and low tail (high FRH/low RRH, bottom left) and very low nose, high tail (low FRH/high RRH, top right). Background colors highlight the CDS trend: red is the worst (highest) drag zone, while green is the lowest.

Figure 6.

Drag coefficient CDS vs. Front Ride Height FRH and Rear Ride Height RRH. Actual figures are not shown for confidentiality reasons. The percentage variation is computed with reference to maximum drag. Also shown are the ride height ranges: the front one is lower on average and narrower than the rear. Cells with values in red are the areas less likely to tap into: high nose and low tail (high FRH/low RRH, bottom left) and very low nose, high tail (low FRH/high RRH, top right). Background colors highlight the CDS trend: red is the worst (highest) drag zone, while green is the lowest.

Figure 7.

Downforce coefficient CZS vs. FRH and RRH. The percentage variation is computed with reference to maximum downforce, corresponding to FRH = 0 mm, RRH = 30 mm. Background colors highlight the CZS trend: in this case green is the best (highest) downforce zone, while red is the lowest.

Figure 7.

Downforce coefficient CZS vs. FRH and RRH. The percentage variation is computed with reference to maximum downforce, corresponding to FRH = 0 mm, RRH = 30 mm. Background colors highlight the CZS trend: in this case green is the best (highest) downforce zone, while red is the lowest.

Figure 8.

Aero balance AB vs. FRH and RRH. The variation is computed with reference to the average AB within the map domain, corresponding to FRH = 15 mm, RRH = 40 mm for a pitch angle of 0.46° over a wheelbase of 3.12 m. Background colors in this case highlight the trend of the fore/aft downforce distribution or aero balance with reference to the average value: blue is forward, green is rearward.

Figure 8.

Aero balance AB vs. FRH and RRH. The variation is computed with reference to the average AB within the map domain, corresponding to FRH = 15 mm, RRH = 40 mm for a pitch angle of 0.46° over a wheelbase of 3.12 m. Background colors in this case highlight the trend of the fore/aft downforce distribution or aero balance with reference to the average value: blue is forward, green is rearward.

Figure 9.

Efficiency vs. FRH and RRH, 3D map.

Figure 9.

Efficiency vs. FRH and RRH, 3D map.

Figure 10.

Typical bump stop force vs. deflection curve with “progressive” characteristics.

Figure 10.

Typical bump stop force vs. deflection curve with “progressive” characteristics.

Figure 11.

Evolution of Front vs. Rear Ride Heights for increasing speed, starting from static RH values: (a) speed increases along yellow arrow and the area inside the yellow dotted line is the aero map domain; (b) this is the most significant graph for trackside engineering activities. Vertical red and yellow lines are references for the relevant speed range on a given circuit; yellow markers show where bump stops come into play.

Figure 11.

Evolution of Front vs. Rear Ride Heights for increasing speed, starting from static RH values: (a) speed increases along yellow arrow and the area inside the yellow dotted line is the aero map domain; (b) this is the most significant graph for trackside engineering activities. Vertical red and yellow lines are references for the relevant speed range on a given circuit; yellow markers show where bump stops come into play.

Figure 12.

Efficiency vs. Aero Balance and Downforce vs. Drag for the 100–300 kph speed range. Yellow arrows show increasing speed. Dotted lines on the second graph are iso-efficiency levels: (a) Efficiency vs. Aero Balance (b) Downforce vs. Drag. Yellow dots are speed references relevant to a specific circuit.

Figure 12.

Efficiency vs. Aero Balance and Downforce vs. Drag for the 100–300 kph speed range. Yellow arrows show increasing speed. Dotted lines on the second graph are iso-efficiency levels: (a) Efficiency vs. Aero Balance (b) Downforce vs. Drag. Yellow dots are speed references relevant to a specific circuit.

Figure 13.

Aero maps plotted as: (a) Downforce vs. Rear Ride height; (b) Aero Balance vs. Rear Ride Height, for various Front Ride Heights. These graphs highlight non-linear sensitivity to both front and rear ride heights hence to heave and pitch. The evolution in the 0–300 kph range is shown in red. Yellow arrows indicate increasing speed.

Figure 13.

Aero maps plotted as: (a) Downforce vs. Rear Ride height; (b) Aero Balance vs. Rear Ride Height, for various Front Ride Heights. These graphs highlight non-linear sensitivity to both front and rear ride heights hence to heave and pitch. The evolution in the 0–300 kph range is shown in red. Yellow arrows indicate increasing speed.

Figure 14.

Front and rear decay functions starting from static ride heights: (

a) RH vs. RH sensitivity; (

b) FRH and RRH vs. Speed. Dots and lines as in

Figure 11.

Figure 14.

Front and rear decay functions starting from static ride heights: (

a) RH vs. RH sensitivity; (

b) FRH and RRH vs. Speed. Dots and lines as in

Figure 11.

Figure 15.

Decay effect on ride heights as a function of vehicle speed: (a) efficiency vs. aero balance; (b) downforce vs. drag. Yellow dots are speed references relevant to a specific circuit.

Figure 15.

Decay effect on ride heights as a function of vehicle speed: (a) efficiency vs. aero balance; (b) downforce vs. drag. Yellow dots are speed references relevant to a specific circuit.

Figure 16.

Plots showing vehicle motion with baseline aero maps (#1, blue) and with the application of decay functions (#2, red) along a quasi-static straight-line maneuver with increasing speed. Porpoising is triggered at around 210 kph, with the rear axle coming first and dominating in terms of amplitude. Pitch oscillates with an amplitude above 1 degree and a consistent frequency around 6 Hz.

Figure 16.

Plots showing vehicle motion with baseline aero maps (#1, blue) and with the application of decay functions (#2, red) along a quasi-static straight-line maneuver with increasing speed. Porpoising is triggered at around 210 kph, with the rear axle coming first and dominating in terms of amplitude. Pitch oscillates with an amplitude above 1 degree and a consistent frequency around 6 Hz.

Figure 17.

Comparison of aerodynamic vertical forces with baseline maps (blue) and with decay functions (red). Apart from the oscillations, the average downforce is massively reduced either at the front (top plot) and at the rear (middle plot). Vertical acceleration at the center of gravity (bottom plot) oscillates with an amplitude of +/− 0.6 g.

Figure 17.

Comparison of aerodynamic vertical forces with baseline maps (blue) and with decay functions (red). Apart from the oscillations, the average downforce is massively reduced either at the front (top plot) and at the rear (middle plot). Vertical acceleration at the center of gravity (bottom plot) oscillates with an amplitude of +/− 0.6 g.

Figure 18.

Comparing amplitudes of front and rear suspension jounce (left) and tire radial deflection (right). The latter is around an order of magnitude larger than the first one: the porpoising phenomenon appears to be dominated by underdamped bouncing on the tires.

Figure 18.

Comparing amplitudes of front and rear suspension jounce (left) and tire radial deflection (right). The latter is around an order of magnitude larger than the first one: the porpoising phenomenon appears to be dominated by underdamped bouncing on the tires.

Figure 19.

Increased front damping (blue plot) results in a slightly reduced amplitude at the rear end (center plot), showing that front and rear axles are strongly coupled through body pitch oscillations (bottom plot). In addition, the modified car can reach a higher speed in the same simulation time: this is due to increased aerodynamic efficiency in terms of drag reduction.

Figure 19.

Increased front damping (blue plot) results in a slightly reduced amplitude at the rear end (center plot), showing that front and rear axles are strongly coupled through body pitch oscillations (bottom plot). In addition, the modified car can reach a higher speed in the same simulation time: this is due to increased aerodynamic efficiency in terms of drag reduction.

Figure 20.

Increased front damping (blue plot) also reduces the amplitude of front suspension jounce (left plots for front and rear axle), the tire deflection is however increased (right plots for front and rear axle). Both amplitudes are reduced at the rear end. Frequencies are basically unaltered.

Figure 20.

Increased front damping (blue plot) also reduces the amplitude of front suspension jounce (left plots for front and rear axle), the tire deflection is however increased (right plots for front and rear axle). Both amplitudes are reduced at the rear end. Frequencies are basically unaltered.

Figure 21.

A stiffer bump stop at the rear axle (blue) basically delays the onset of porpoising from 210 to 220 kph for FRH (top), RRH (center), and pitch oscillation (bottom). Aero efficiency is also affected by a higher rear ride height on average.

Figure 21.

A stiffer bump stop at the rear axle (blue) basically delays the onset of porpoising from 210 to 220 kph for FRH (top), RRH (center), and pitch oscillation (bottom). Aero efficiency is also affected by a higher rear ride height on average.

Figure 22.

Once porpoising oscillations are triggered, average downforce levels are not affected by bump stop stiffness. In this plot front downforce (top), rear downforce (center), and vertical acceleration (bottom) are shown.

Figure 22.

Once porpoising oscillations are triggered, average downforce levels are not affected by bump stop stiffness. In this plot front downforce (top), rear downforce (center), and vertical acceleration (bottom) are shown.

Figure 23.

Rear suspension jounce amplitude (on the left for front and rear axle) and the delay in terms of speed are the only significant effects of a stiffer bump stop at the rear end (blue plot as always).

Figure 23.

Rear suspension jounce amplitude (on the left for front and rear axle) and the delay in terms of speed are the only significant effects of a stiffer bump stop at the rear end (blue plot as always).

Figure 24.

Front ride height +10 mm (blue): porpoising is partially mitigated mainly because bouncing is reduced at the front end in terms of amplitude. In this plot FRH (top), RRH (center) and pitch variation (bottom) are shown.

Figure 24.

Front ride height +10 mm (blue): porpoising is partially mitigated mainly because bouncing is reduced at the front end in terms of amplitude. In this plot FRH (top), RRH (center) and pitch variation (bottom) are shown.

Figure 25.

Rear ride height +20 mm (blue): bouncing is significantly reduced at the rear axle and at the front end as well. In this plot FRH (top), RRH (center), and pitch variation (bottom) are shown.

Figure 25.

Rear ride height +20 mm (blue): bouncing is significantly reduced at the rear axle and at the front end as well. In this plot FRH (top), RRH (center), and pitch variation (bottom) are shown.

Figure 26.

Static ride height variations FRHS +5 mm, RRHS +10 mm (#3, blue): porpoising is remarkably delayed. In this plot FRH (top), RRH (center), and pitch variation (bottom) are shown.

Figure 26.

Static ride height variations FRHS +5 mm, RRHS +10 mm (#3, blue): porpoising is remarkably delayed. In this plot FRH (top), RRH (center), and pitch variation (bottom) are shown.

Figure 27.

Static ride height variations FRHS +5 mm, RRHS +10 mm (#3, blue): downforce is stable until porpoising is triggered, and higher on average. Efficiency is also improved, and the final simulation speed is higher as well. In this plot front downforce (top), rear downforce (center) and vertical acceleration (bottom) are shown.

Figure 27.

Static ride height variations FRHS +5 mm, RRHS +10 mm (#3, blue): downforce is stable until porpoising is triggered, and higher on average. Efficiency is also improved, and the final simulation speed is higher as well. In this plot front downforce (top), rear downforce (center) and vertical acceleration (bottom) are shown.

Figure 28.

Vehicle body motion with static ride height variations FRHS +10 mm, RRHS +20 mm (#4, green) vs. baseline configuration plus decay functions (#2, red) and without (#1, blue). Changes to ride heights and their effects are clearly visible: porpoising is fully removed. In this plot FRH (top), RRH (center), and pitch variation (bottom) are shown.

Figure 28.

Vehicle body motion with static ride height variations FRHS +10 mm, RRHS +20 mm (#4, green) vs. baseline configuration plus decay functions (#2, red) and without (#1, blue). Changes to ride heights and their effects are clearly visible: porpoising is fully removed. In this plot FRH (top), RRH (center), and pitch variation (bottom) are shown.

Figure 29.

With the final static ride height variations FRHS +10 mm, RRHS +20 mm (#4, green) the downforce is reduced compared to the original configuration (#1, blue) but porpoising is no longer there. In this plot front downforce (top), rear downforce (center), and vertical acceleration (bottom) are shown.

Figure 29.

With the final static ride height variations FRHS +10 mm, RRHS +20 mm (#4, green) the downforce is reduced compared to the original configuration (#1, blue) but porpoising is no longer there. In this plot front downforce (top), rear downforce (center), and vertical acceleration (bottom) are shown.

Figure 30.

Porpoising is fully removed with Setup #4 (green), in terms of suspension motion (left plots for front and rear axle) and of tire deflection (right plots for front and rear axle).

Figure 30.

Porpoising is fully removed with Setup #4 (green), in terms of suspension motion (left plots for front and rear axle) and of tire deflection (right plots for front and rear axle).

Figure 31.

Map of the F1 Sakhir circuit in Bahrain, with official corner numbering.

Figure 31.

Map of the F1 Sakhir circuit in Bahrain, with official corner numbering.

Figure 32.

Baseline setup (blue, #1) vs. model with decay functions/porpoising (red, #2). Top plot is the speed profile vs. lap distance, mid and bottom plots are the front and rear ride heights.

Figure 32.

Baseline setup (blue, #1) vs. model with decay functions/porpoising (red, #2). Top plot is the speed profile vs. lap distance, mid and bottom plots are the front and rear ride heights.

Figure 33.

Baseline setup (blue, #1) vs. model with decay functions/porpoising (red, #2). Top and mid plot are the front and rear downforce vs. lap distance, bottom plot is the vertical acceleration at the center of gravity.

Figure 33.

Baseline setup (blue, #1) vs. model with decay functions/porpoising (red, #2). Top and mid plot are the front and rear downforce vs. lap distance, bottom plot is the vertical acceleration at the center of gravity.

Figure 34.

Setup #3 (purple) vs. #4 (green). Setup #3 is a reasonable tradeoff between the reduction of porpoising (and of driver discomfort as well) and performance in terms of average downforce. Top plot is the speed profile vs. lap distance, mid and bottom plots are the front and rear ride heights.

Figure 34.

Setup #3 (purple) vs. #4 (green). Setup #3 is a reasonable tradeoff between the reduction of porpoising (and of driver discomfort as well) and performance in terms of average downforce. Top plot is the speed profile vs. lap distance, mid and bottom plots are the front and rear ride heights.

Figure 35.

With Setup #3 porpoising is triggered just at the end of the straight, the downforce level however is higher on average. Top and mid plot are the front and rear downforce vs. lap distance, bottom plot is the vertical acceleration at the center of gravity.

Figure 35.

With Setup #3 porpoising is triggered just at the end of the straight, the downforce level however is higher on average. Top and mid plot are the front and rear downforce vs. lap distance, bottom plot is the vertical acceleration at the center of gravity.

Figure 36.

Setup #2 (baseline with porpoising induced by means of the decay functions, red) vs. Setup #3 (FRHS +5 mm, RRHS +10 mm, purple). By raising the ride heights in the correct proportion front to rear porpoising can be reduced without damaging performance too much. Top plot is the speed profile vs. lap distance, mid and bottom plots are the front and rear ride heights.

Figure 36.

Setup #2 (baseline with porpoising induced by means of the decay functions, red) vs. Setup #3 (FRHS +5 mm, RRHS +10 mm, purple). By raising the ride heights in the correct proportion front to rear porpoising can be reduced without damaging performance too much. Top plot is the speed profile vs. lap distance, mid and bottom plots are the front and rear ride heights.

Table 1.

Configurations tested with related lap time. Faster lap time gaps in green, slower in red.

Table 1.

Configurations tested with related lap time. Faster lap time gaps in green, slower in red.

| Car Setups and Configuration | Lap Time | Gap from (#1) Baseline | Gap from (#2) Porpoising |

|---|

| (#0) Real-world GP2 car, 4th position in 2013 Qualifying session (Bahrain circuit) | 1:40.58 | +0.8% | |

| (#1) Full model, Baseline setup | 1:39.79 | = | −1.03 |

| (#2) Baseline with porpoising | 1:40.82 | +1.03 | = |

| (#3) FRHS +5 mm/RRHS +10 mm | 1:40.32 | +0.53 | −0.50 |

| (#4) FRHS +10 mm/RRHS +20 mm | 1:40.71 | +0.92 | −0.11 |