Experimental Characterization of Hydrodynamic Properties of a Deformable Rock Fracture

Abstract

:1. Introduction

2. Theoretical Background

2.1. Intact Rock and Fracture Deformation

2.2. Intact Rock and Fracture Porosity and Permeability Relations

2.3. Two-Phase Flow

3. Materials and Methods

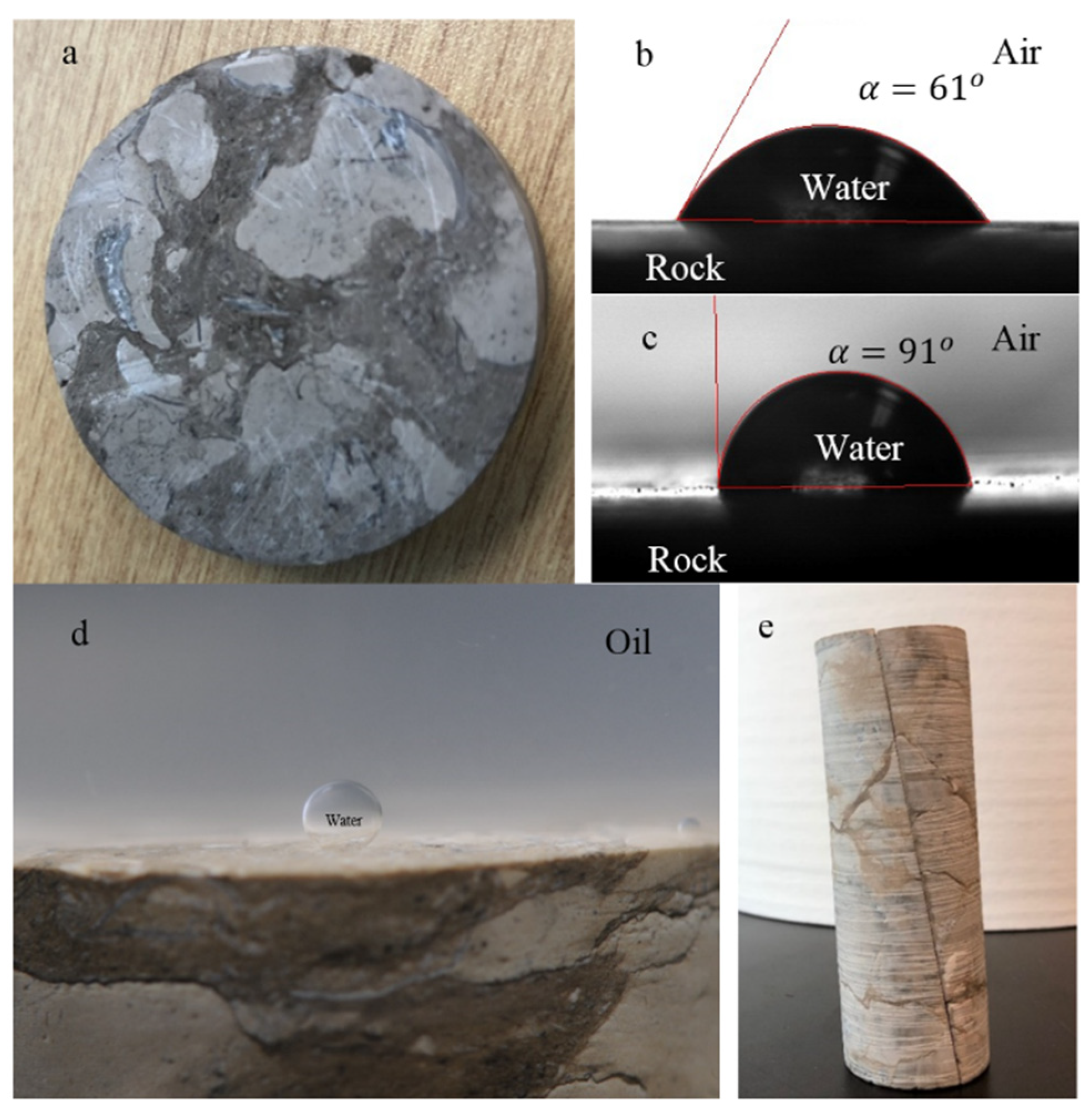

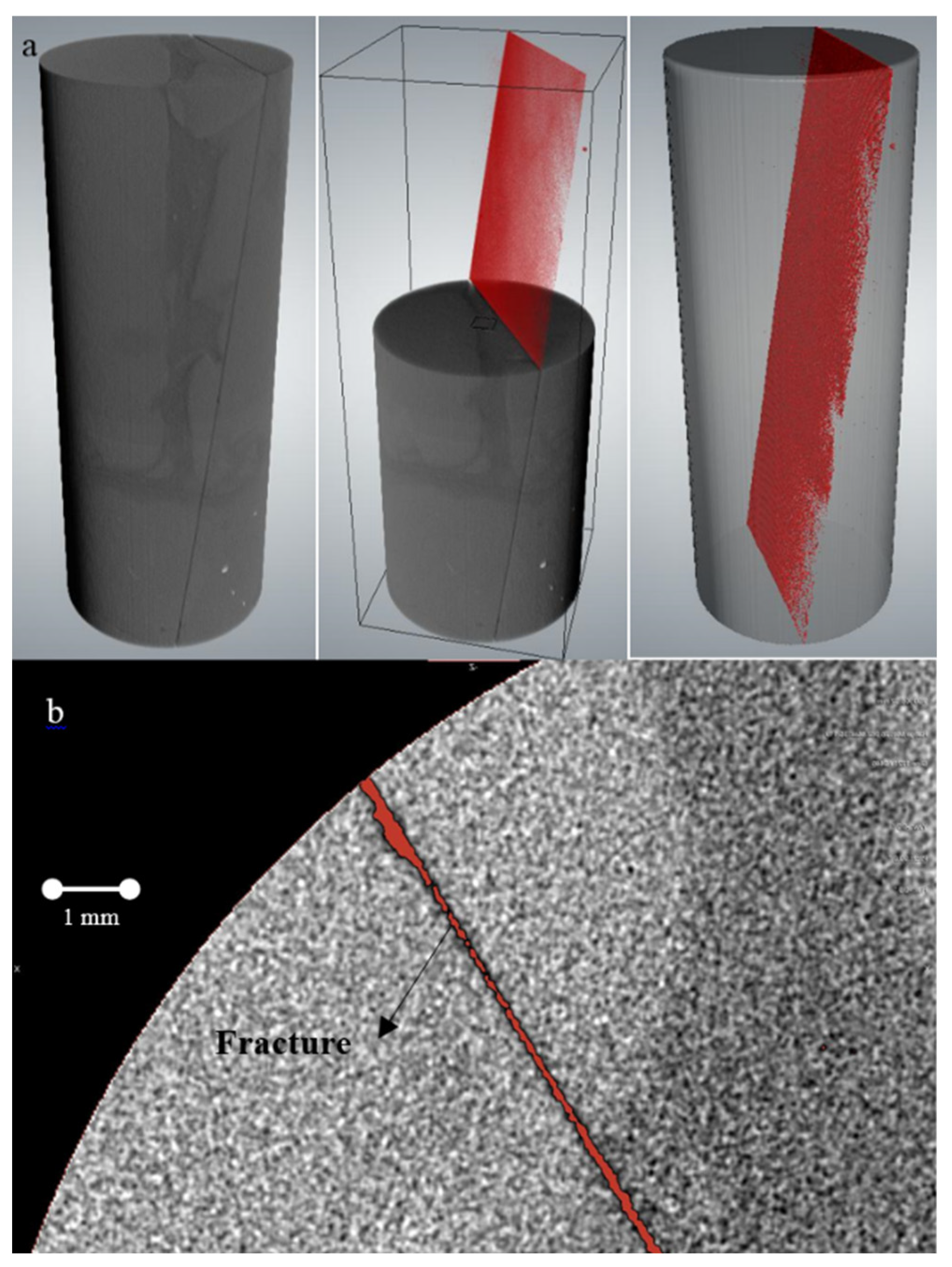

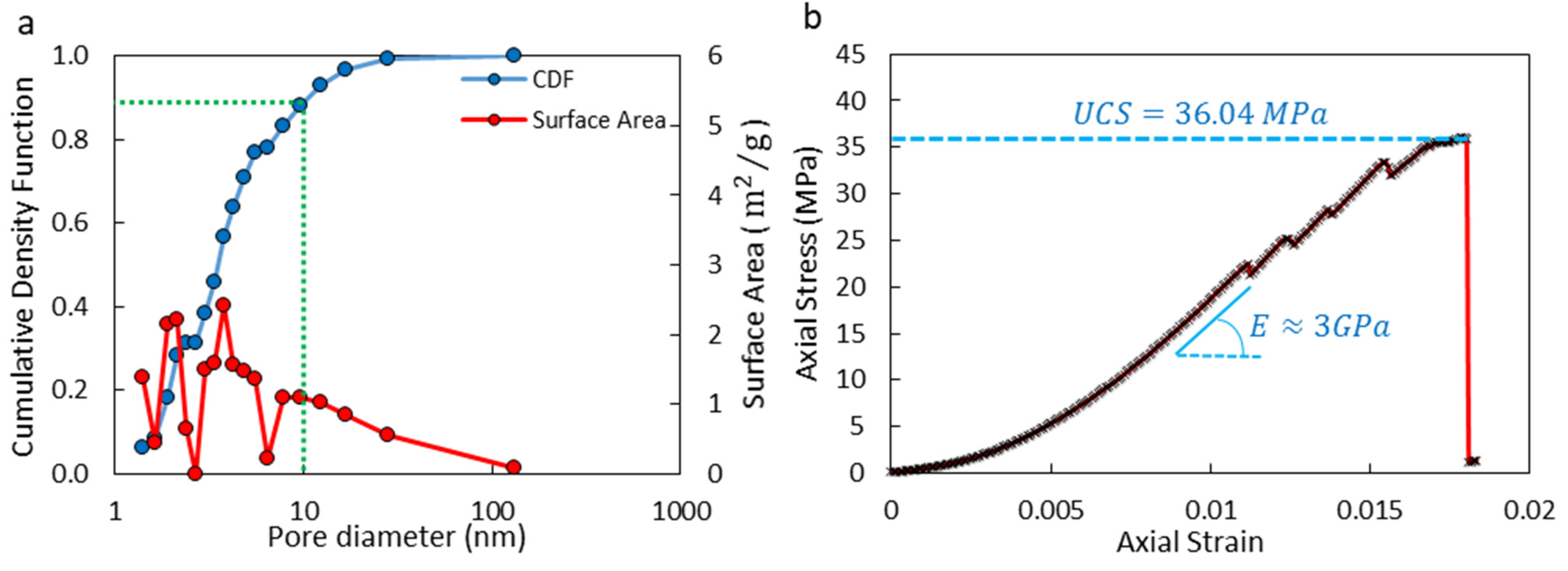

3.1. Rock Sample

3.2. Fluids

3.3. Core-Flooding Apparatus

3.4. Experimental Process

4. Results and Discussion

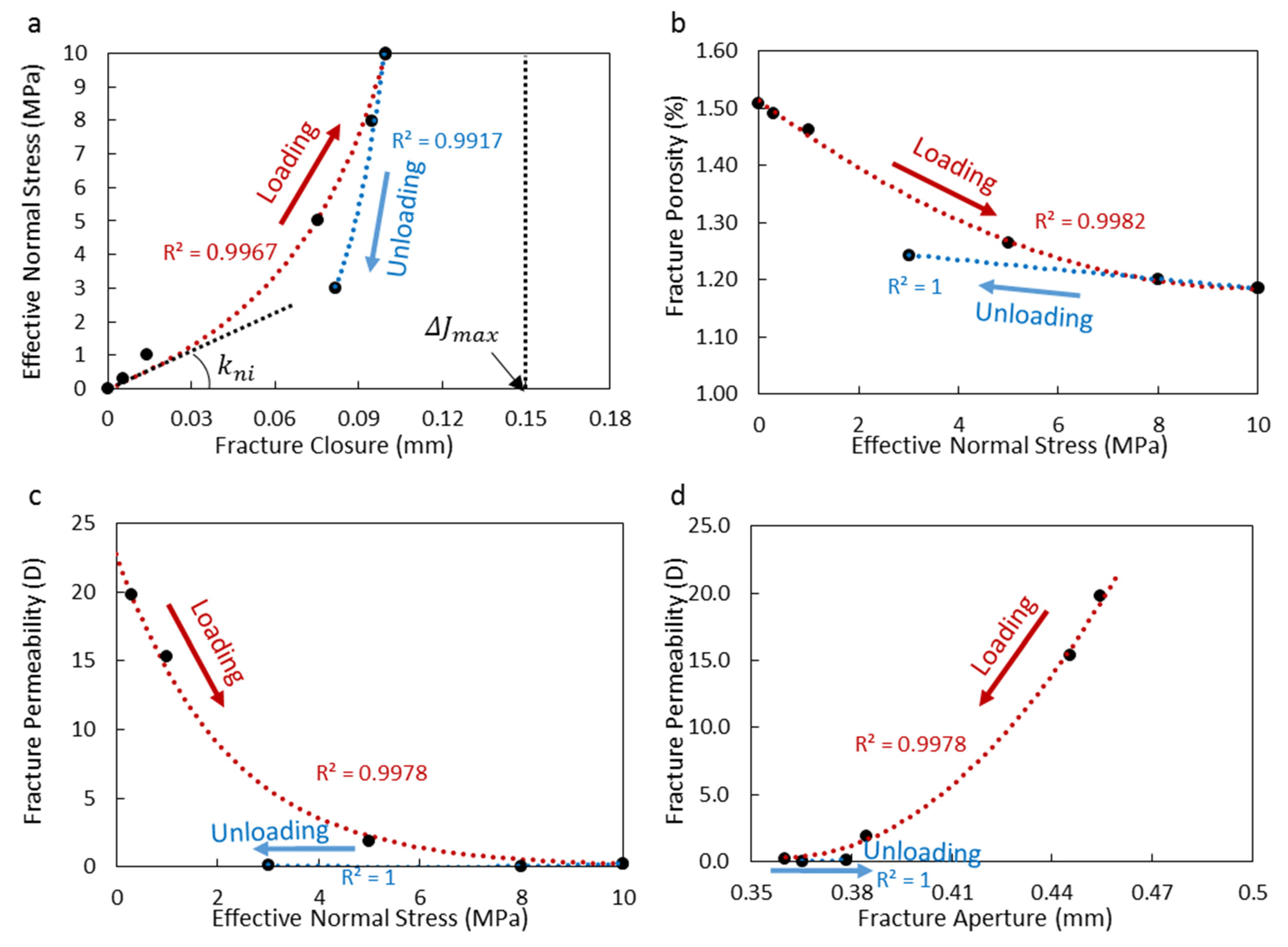

4.1. Intact Rock Porosity and Absolute Permeability with Stress

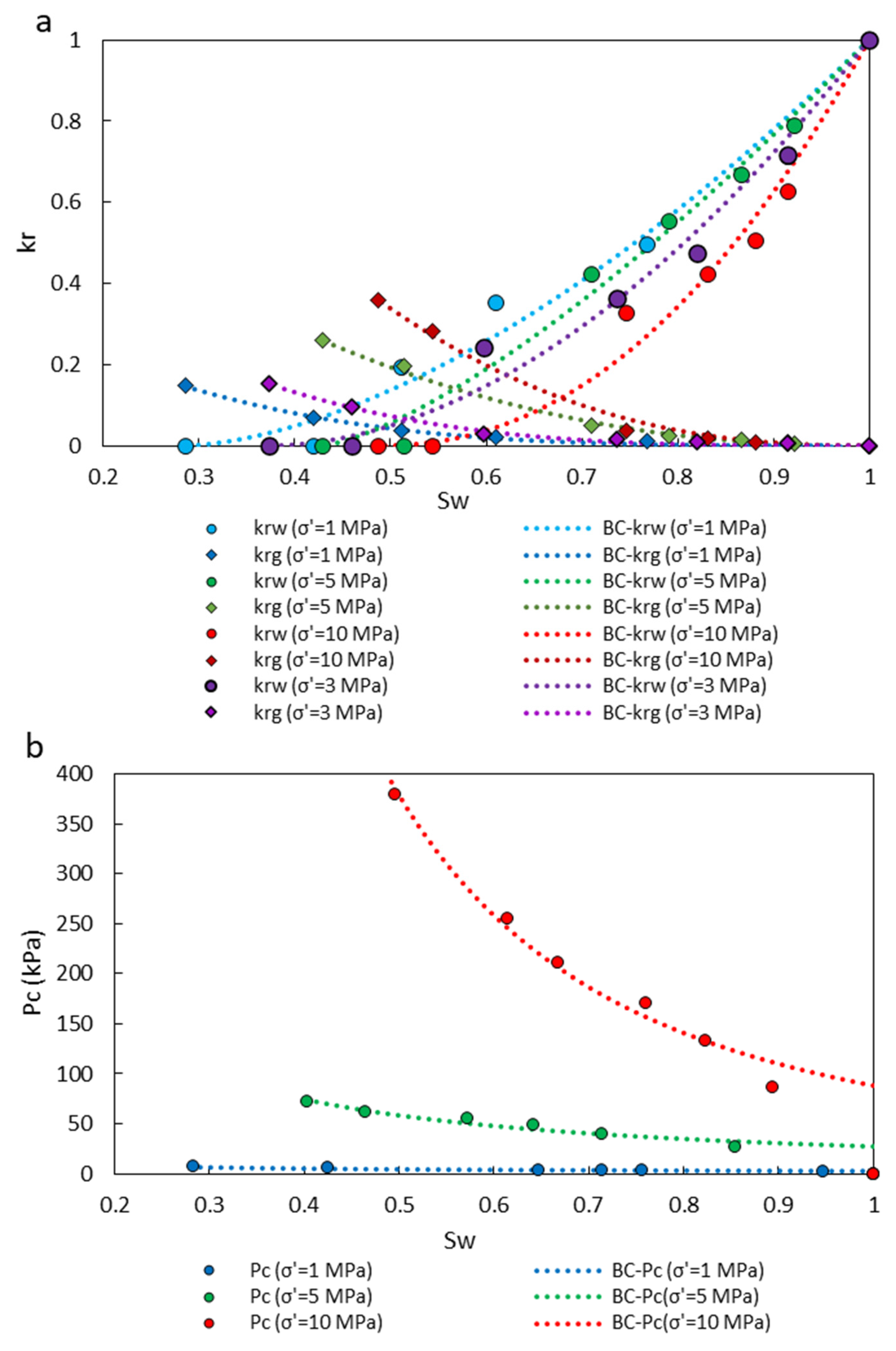

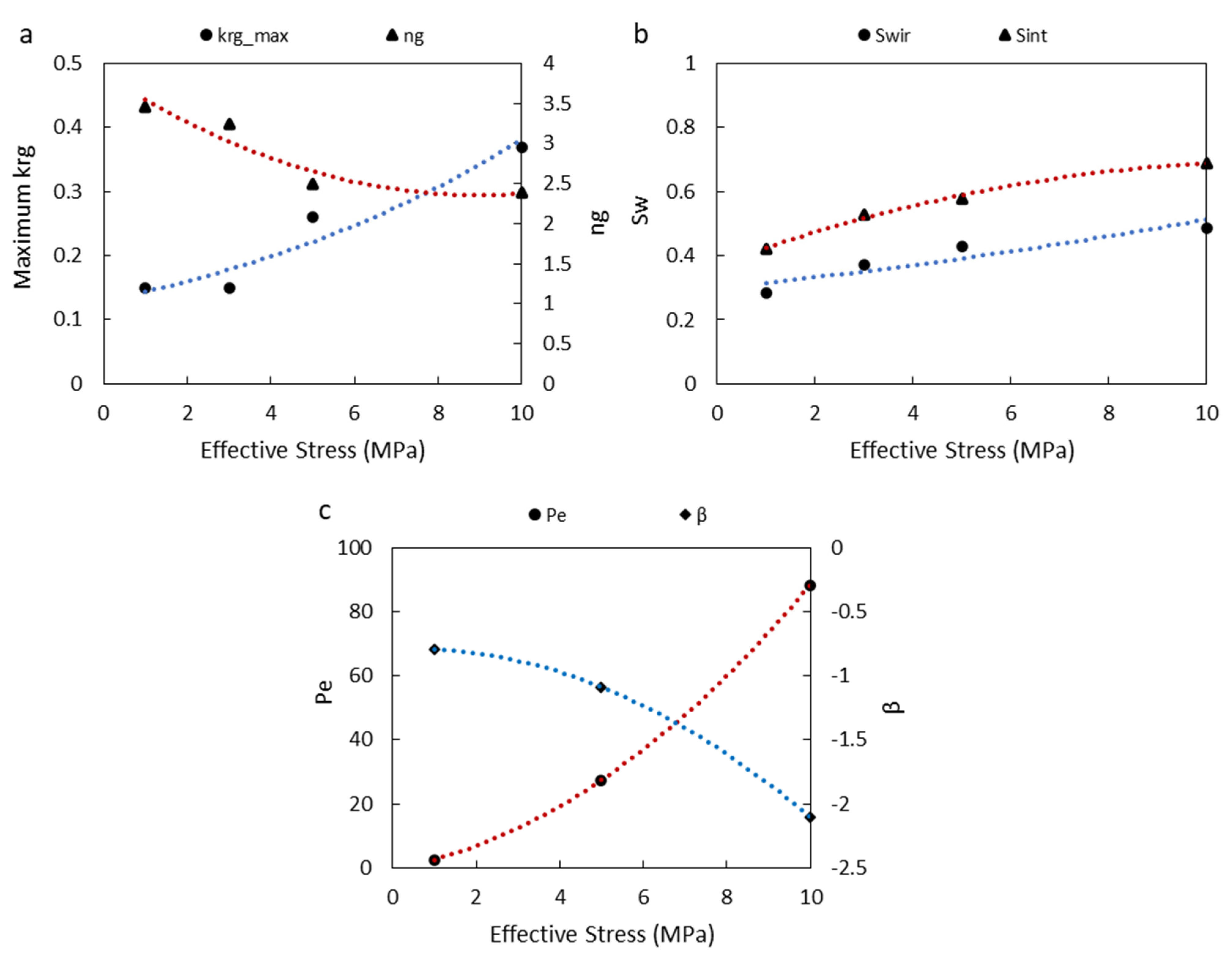

4.2. Stress-Dependent Drainage Relative Permeability and Capillary Pressure of Fracture

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, T.; McKinney, P. Advanced Reservoir Engineering; Elsevier/Gulf Professional Pub: Burlington, MA, USA, 2011. [Google Scholar]

- Rahman, M.J.; Jamilur, M.F.; Nazmul, H.M. 3D Field-Scale Geomechanical Modeling of Potential CO2 Storage Site Smeaheia, Offshore Norway. Energies 2022, 15, 1407. [Google Scholar] [CrossRef]

- Cueto-Felgueroso, L.; Juanes, R. Nonlocal interface dynamics and pattern formation in gravity-driven unsaturated flow through porous media. Phys. Rev. Lett. 2008, 101, 244504. [Google Scholar] [CrossRef] [PubMed]

- Berre, I.; Doster, F.; Keilegavlen, E. Flow in fractured porous media: A review of conceptual models and discretization approaches. Transp. Porous Media 2019, 130, 215–236. [Google Scholar] [CrossRef]

- Huo, D.; Benson, S.M. Experimental Investigation of Stress-Dependency of Relative Permeability in Rock Fractures. Transp. Porous Media 2016, 113, 567–590. [Google Scholar] [CrossRef]

- Lian, P.; Cheng, L.; Ma, C.Y. The characteristics of relative permeability curves in naturally fractured carbonate reservoirs. J. Can. Pet. Technol. 2012, 51, 137–142. [Google Scholar] [CrossRef]

- McDonald, A.E.; Beckner, B.L.; Chan, H.M.; Jones, T.A.; Wooten, S.O. Some important considerations in the simulation of naturally fractured reservoirs. In Low Permeability Reservoirs Symposium; Society of Petroleum Engineers: Richardson, TX, USA, 1991. [Google Scholar]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Lund Snee, J.E.; Zoback, M.D. Multiscale variations of the crustal stress field throughout North America. Nat. Commun. 2020, 11, 1951. [Google Scholar] [CrossRef] [PubMed]

- Haghi, A.H.; Kharrat, R.; Asef, M.R.; Rezazadegan, H. Present-day stress of the central Persian Gulf: Implications for drilling and well performance. Tectonophysics 2013, 608, 1429–1441. [Google Scholar] [CrossRef]

- Haghi, A.H.; Chalaturnyk, R.; Ghobadi, H. The state of stress in SW Iran and implications for hydraulic fracturing of a naturally fractured carbonate reservoir. Int. J. Rock Mech. Min. Sci. 2018, 105, 28–43. [Google Scholar] [CrossRef]

- Heidbach, O.; Rajabi, M.; Cui, X.; Fuchs, K.; Müller, B.; Reinecker, J.; Ziegler, M.O. The World Stress Map database release 2016: Crustal stress pattern across scales. Tectonophysics 2018, 744, 484–498. [Google Scholar] [CrossRef]

- Haghi, A.H.; Kharrat, R.; Asef, M.R. A case study for HCL-based fracturing and stress determination: A Deformation/Diffusion/Thermal approach. J. Pet. Sci. Eng. 2013, 112, 105–116. [Google Scholar] [CrossRef]

- Kohli, A.; Zoback, M. Stratigraphically Controlled Stress Variations at the Hydraulic Fracture Test Site-1 in the Midland Basin, TX. Energies 2021, 14, 8328. [Google Scholar] [CrossRef]

- Zimmerman, R.W.; Somerton, W.H.; King, M.S. Compressibility of porous rocks. J. Geophys. Res. 1986, 91, 12765–12777. [Google Scholar] [CrossRef]

- Zhu, W.; Wong, T.F. The transition from brittle faulting to cataclastic flow: Permeability evolution. J. Geophys. Res. Solid Earth 1997, 102, 3027–3041. [Google Scholar] [CrossRef]

- Haghi, A.H.; Chalaturnyk, R.; Geiger, S. New semi-analytical insights into stress-dependent imbibition in naturally fractured carbonate reservoirs. Water Resour. Res. 2018, 54, 9605–9622. [Google Scholar] [CrossRef]

- Xu, D.; Chen, S.; Chen, J.; Xue, J.; Yang, H. Study on the Imbibition Damage Mechanisms of Fracturing Fluid for the Whole Fracturing Process in a Tight Sandstone Gas Reservoir. Energies 2022, 15, 4463. [Google Scholar] [CrossRef]

- Barton, N.; Bandis, S.; Bakhtar, K. Strength, deformation and conductivity coupling of rock joints. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1985, 22, 121–140. [Google Scholar] [CrossRef]

- Stokes, G.G. On the theories of the internal friction of fluids in motion, and of the equilibrium and motion of elastic solids. Trans. Camb. Philos. Soc. 1845, 8, 287–305. [Google Scholar]

- Boussinesq, J. Mémoire sur l’influencedes frottments dans les mouvements reguliers des fluids (Thesis about the influence of friction within the steady flow of fluids). Louisville 1868, 13, 377–424. [Google Scholar]

- Witherspoon, P.A.; Wang, J.S.; Iwai, K.; Gale, J.E. Validity of cubic law for fluid flow in a deformable rock fracture. Water Resour. Res. 1980, 16, 1016–1024. [Google Scholar] [CrossRef]

- Zimmerman, R.W.; Bodvarsson, G.S. Hydraulic conductivity of rock fractures. Transp. Porous Media 1996, 23, 1–30. [Google Scholar] [CrossRef]

- Bisdom, K.; Bertotti, G.; Nick, H.M. The impact of different aperture distribution models and critical stress criteria on equivalent permeability in fractured rocks. J. Geophys. Res. Solid Earth 2016, 121, 4045–4063. [Google Scholar] [CrossRef]

- Babadagli, T.; Ren, X.; Develi, K. Effects of fractal surface roughness and lithology on single and multiphase flow in a single fracture: An experimental investigation. Int. J. Multiph. Flow 2015, 68, 40–58. [Google Scholar] [CrossRef]

- Martin, V.; Jaffré, J.; Roberts, J.E. Modeling fractures and barriers as interfaces for flow in porous media. SIAM J. Sci. Comput. 2005, 26, 1667–1691. [Google Scholar] [CrossRef]

- Moinfar, A.; Narr, W.; Hui, M.H.; Mallison, B.; Lee, S.H. Comparison of discrete-fracture and dual-permeability models for multiphase flow in naturally fractured reservoirs. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 21–23 February 2011; OnePetro: Richardson, TX, USA, 2011. [Google Scholar]

- Haghi, A.H.; Chalaturnyk, R.; Talman, S. Stress-Dependent Pore Deformation Effects on Multiphase Flow Properties of Porous Media. Sci. Rep. 2019, 9, 15004. [Google Scholar] [CrossRef] [PubMed]

- Haghi, A.H.; Talman, S.; Chalaturnyk, R. Consecutive Experimental Determination of Stress-dependent Fluid Flow Properties of Berea Sandstone and Implications for Two-phase Flow Modelling. Water Resour. Res. 2020, 56, e2018WR024245. [Google Scholar] [CrossRef]

- Haghi, A.H.; Chalaturnyk, R.; Blunt, M.J.; Hodder, K.; Geiger, S. Poromechanical controls on spontaneous imbibition in earth materials. Sci. Rep. 2021, 11, 3328. [Google Scholar] [CrossRef]

- Peters, E.J. Advanced Petrophysics: Dispersion, Interfacial Phenomena; Greenleaf Book Group: Austin, TX, USA, 2012; Volume 2. [Google Scholar]

- Detournay, E.; Cheng, A.H.D. Comprehensive rock engineering: Principles, practice and projects. Analysis and design method. Fundam. Poroelasticity 1993, 2, 113–171. [Google Scholar]

- Liu, H.H.; Rutqvist, J.; Berryman, J.G. On the relationship between stress and elastic strain for porous and fractured rock. Int. J. Rock Mech. Min. Sci. 2009, 46, 289–296. [Google Scholar] [CrossRef]

- Bagheri, M.; Settari, A. Modeling Fluid Flow in Deformable Fractured Reservoirs using Full Tensor permeability. In Proceedings of the EAGE Annual Conference and Exhibition, Rome, Italy, 9–12 June 2008; pp. 9–12. [Google Scholar]

- Pariseau, W.G. Design Analysis in Rock Mechanics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Hudson, J.A.; Harrison, J.P. Engineering Rock Mechanics: An Introduction to the Principles; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Cundall, P.A.; Lemos, J.V. Numerical simulation of fault instabilities with a continuously-yielding joint model. In Rockbursts and Seismicity in Mines; Balkema, S., Ed.; CRC Press: Boca Raton, FL, USA, 1990; pp. 147–152. [Google Scholar]

- Bandis, S.C.; Lumsden, A.C.; Barton, N.R. Fundamentals of rock joint deformation. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1983, 20, 249–268. [Google Scholar] [CrossRef]

- Kozeny, J. Uber kapillare leitung der wasser in boden. R. Acad. Sci. Vienna Proc. Cl. I 1927, 136, 271–306. [Google Scholar]

- Carman, P.C. Permeability of saturated sands, soils and clays. J. Agric. Sci. 1939, 29, 262–273. [Google Scholar] [CrossRef]

- Batchelor, G.K. An Introduction to Fluid Dynamics. Cambridge Mathematical Library; Cambridge University Press: Cambridge, UK, 1967. [Google Scholar]

- Elrod, H.G. A general theory for laminar lubrication with Reynolds roughness. J. Lubr. Technol. 1979, 101, 8–14. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Electrodynamics of Continuous Media; F’ergamon Press: New York, NY, USA, 1960. [Google Scholar]

- Zimmerman, R.W.; Kumar, S.; Bodvarsson, G.S. Lubrication theory analysis of the permeability of rough-walled fractures. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1991, 28, 325–331. [Google Scholar] [CrossRef]

- Purcell, W.R. Capillary pressures-their measurement using mercury and the calculation of permeability therefrom. J. Pet. Technol. 1949, 1, 39–48. [Google Scholar] [CrossRef]

- Burdine, N. Relative permeability calculations from pore size distribution data. J. Pet. Technol. 1953, 5, 71–78. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Properties of porous media affecting fluid flow. J. Irrig. Drain. Div. 1966, 92, 61–90. [Google Scholar] [CrossRef]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils 1. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Lawrence, M.; Jiang, Y. Porosity, pore size distribution, micro-structure. In Bio-Aggregates Based Building Materials; Springer: Dordrecht, The Netherlands, 2017; pp. 39–71. [Google Scholar]

- Niu, Y.; Mostaghimi, P.; Shabaninejad, M.; Swietojanski, P.; Armstrong, R.T. Digital rock segmentation for petrophysical analysis with reduced user bias using convolutional neural networks. Water Resour. Res. 2020, 56, e2019WR026597. [Google Scholar] [CrossRef]

- Rouquerol, J.; Llewellyn, P.; Rouquerol, F. Is the BET equation applicable to microporous adsorbents. Stud. Surf. Sci. Catal 2007, 160, 49–56. [Google Scholar]

- Cooper, J.R.; Dooley, R.B. Release of the IAPWS Formulation 2008 for the Viscosity of Ordinary Water Substance. The International Association for the Properties of Water and Steam. 2008. Available online: http://www.iapws.org (accessed on 17 January 2019).

- Lemmon, E.W.; Jacobsen, R.T. Viscosity and thermal conductivity equations for nitrogen, oxygen, argon, and air. Int. J. Thermophys. 2004, 25, 21–69. [Google Scholar] [CrossRef]

- Yan, W.; Zhao, G.Y.; Chen, G.J.; Guo, T.M. Interfacial tension of (methane+ nitrogen)+ water and (carbon dioxide+ nitrogen)+ water systems. J. Chem. Eng. Data 2001, 46, 1544–1548. [Google Scholar] [CrossRef]

- Richardson, J.G.; Kerver, J.K.; Hafford, J.A.; Osoba, J.S. Laboratory determination of relative permeability. J. Pet. Technol. 1952, 4, 187–196. [Google Scholar] [CrossRef]

- Leas, W.J.; Jenks, J.H.; Russell, C.D. Relative permeability to gas. J. Pet. Technol. 1950, 2, 65–72. [Google Scholar] [CrossRef]

- Pini, R.; Benson, S.M. Simultaneous determination of capillary pressure and relative permeability curves from core-flooding experiments with various fluid pairs. Water Resour. Res. 2013, 49, 3516–3530. [Google Scholar] [CrossRef]

- NRCS. Chapter 4—Engineering Classification of Rock Materials. In National Engineering Handbook (NEH), Part 631-Geology; 631.0401 Rock Material Properties, Section (c); NRCS: Washington, DC, USA, 2012. [Google Scholar]

- Pyrak-Nolte, L.J.; Morris, J.P. Single fractures under normal stress: The relation between fracture specific stiffness and fluid flow. Int. J. Rock Mech. Min. Sci. 2000, 37, 245–262. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haghi, A.H.; Chalaturnyk, R. Experimental Characterization of Hydrodynamic Properties of a Deformable Rock Fracture. Energies 2022, 15, 6769. https://doi.org/10.3390/en15186769

Haghi AH, Chalaturnyk R. Experimental Characterization of Hydrodynamic Properties of a Deformable Rock Fracture. Energies. 2022; 15(18):6769. https://doi.org/10.3390/en15186769

Chicago/Turabian StyleHaghi, Amir H., and Richard Chalaturnyk. 2022. "Experimental Characterization of Hydrodynamic Properties of a Deformable Rock Fracture" Energies 15, no. 18: 6769. https://doi.org/10.3390/en15186769