Theoretical and Numerical Study on Thermal Insulation Performance of Thermal Barrier Coatings

Abstract

:1. Introduction

- At present, the temperature-drop of the coating itself is used to evaluate the thermal insulation effect alone, and the temperature of the blade substrate is more concerned about the design and use of the engine, that is, the temperature-drop of the blade substrate caused by the spray coating, so the coating effect after actual application often fails to meet expectations.

- The related research on the thermal insulation mechanism of the coating is insufficient. The coating relies on its high thermal resistance, but the heat conduction of the coating is just one part of the heat transfer between the inside and outside of the blade. The influence of layer thickness, thermal conductivity, and other factors on the thermal insulation effect cannot be combined with the internal and external heat transfer of the blade.

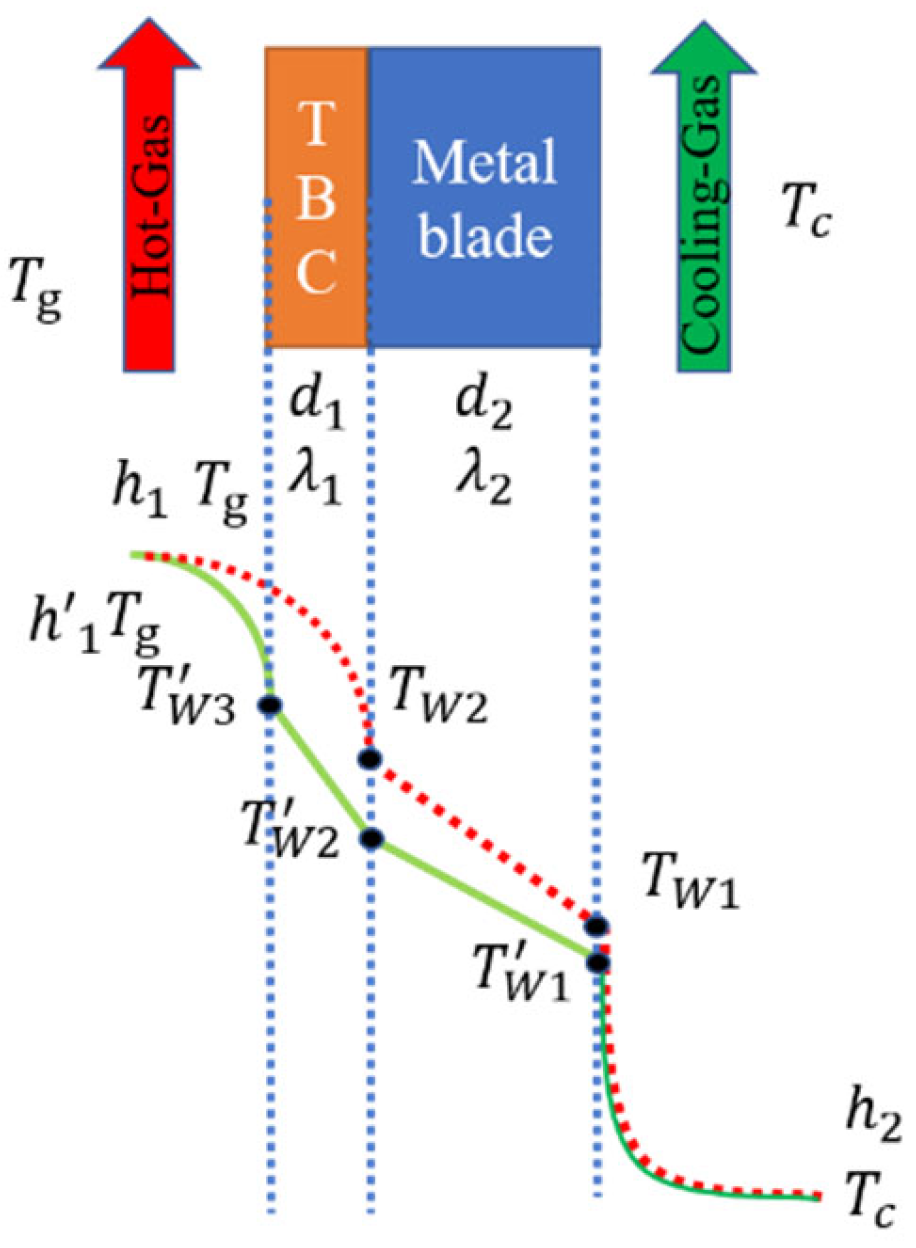

2. One-Dimensional Theoretical Heat Transfer Model and Mechanism Analysis of TBCs

3. Numerical Calculation

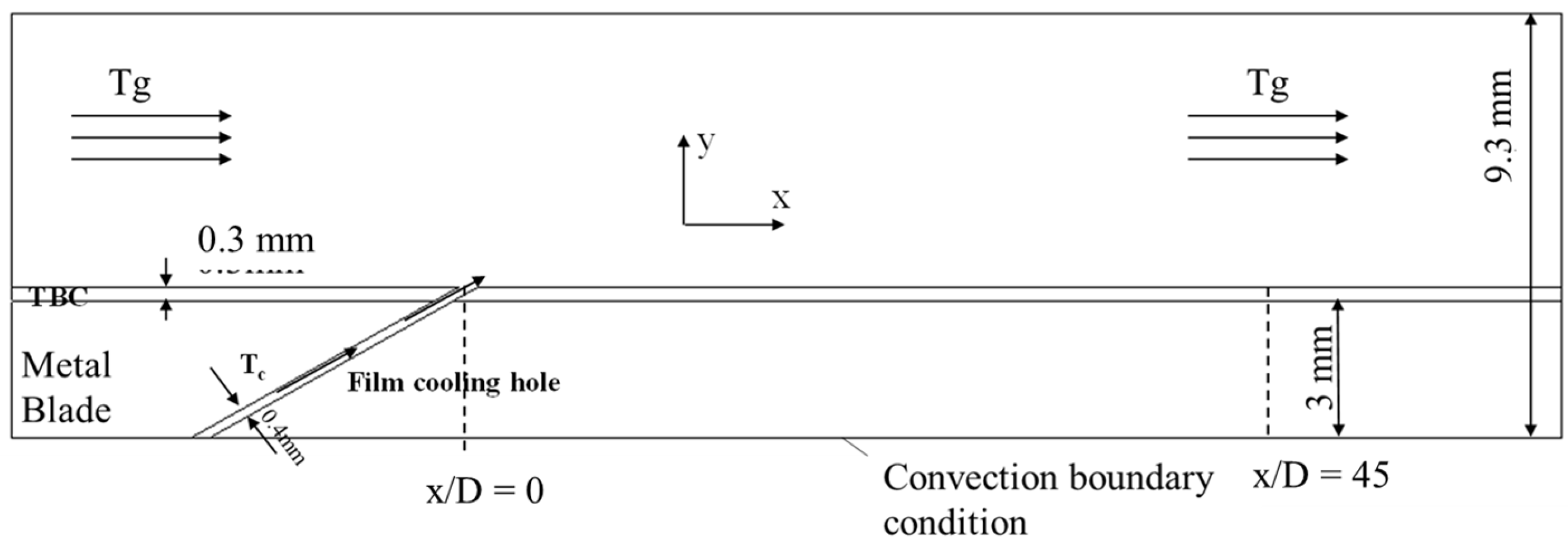

3.1. Computation Model

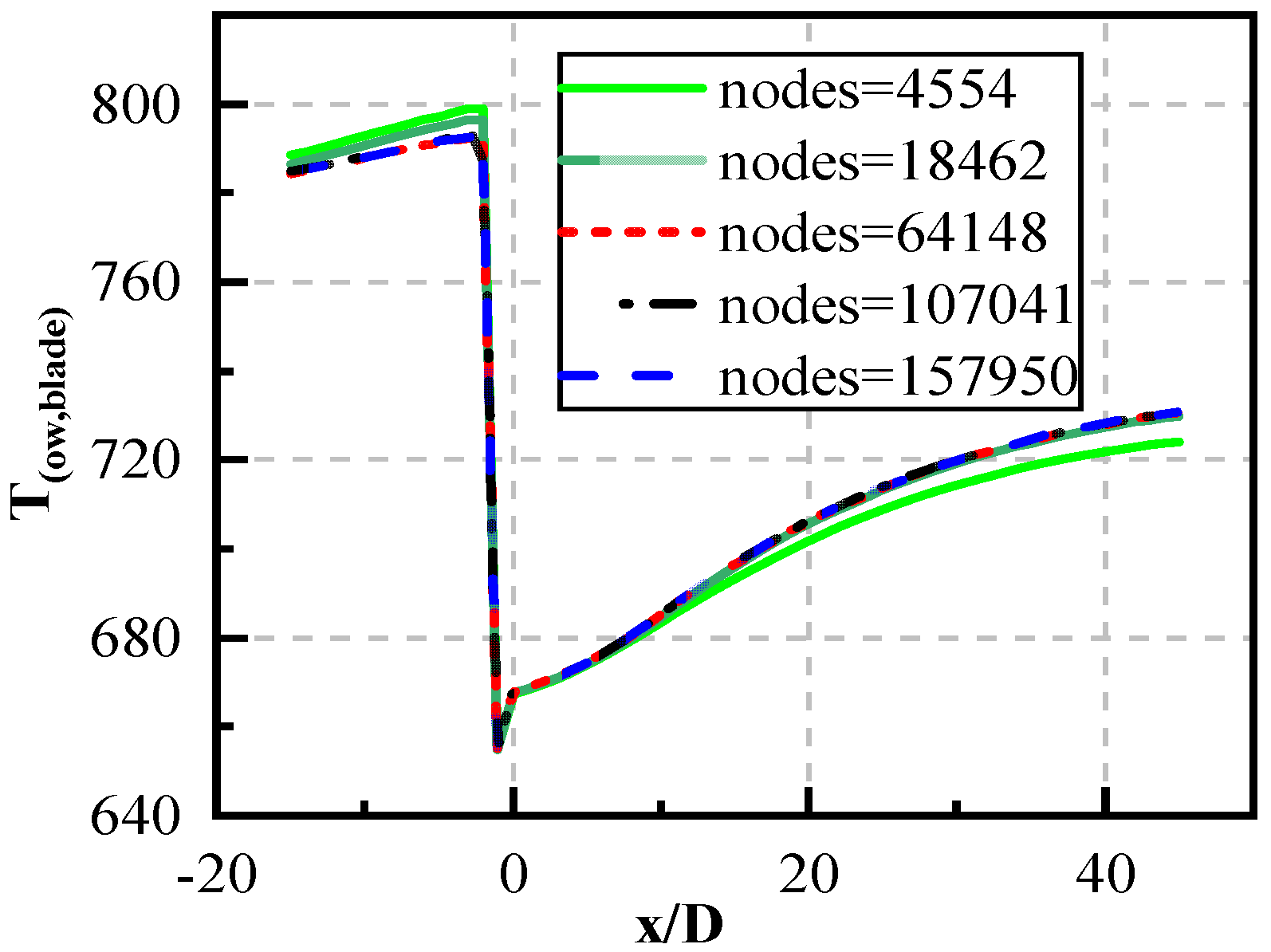

3.2. Computational Technique

3.3. Parameters Setting

4. Results

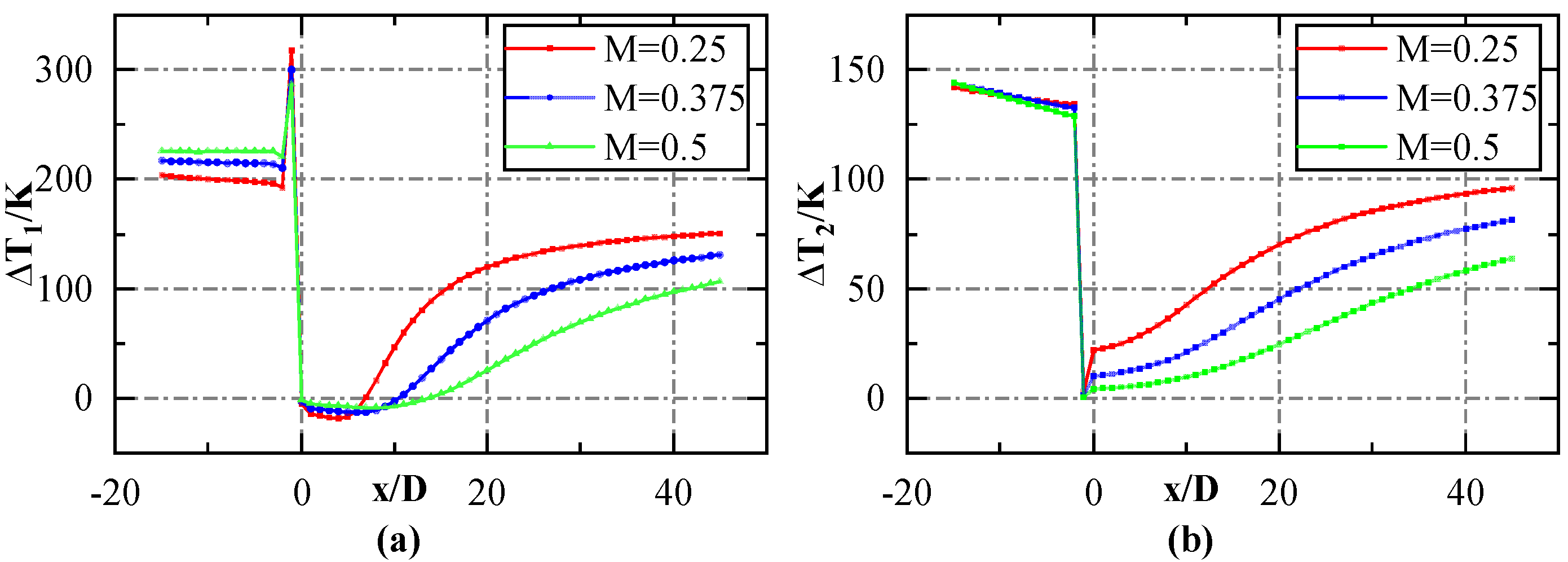

4.1. Numerical Verification of Temperature-Drop Equation

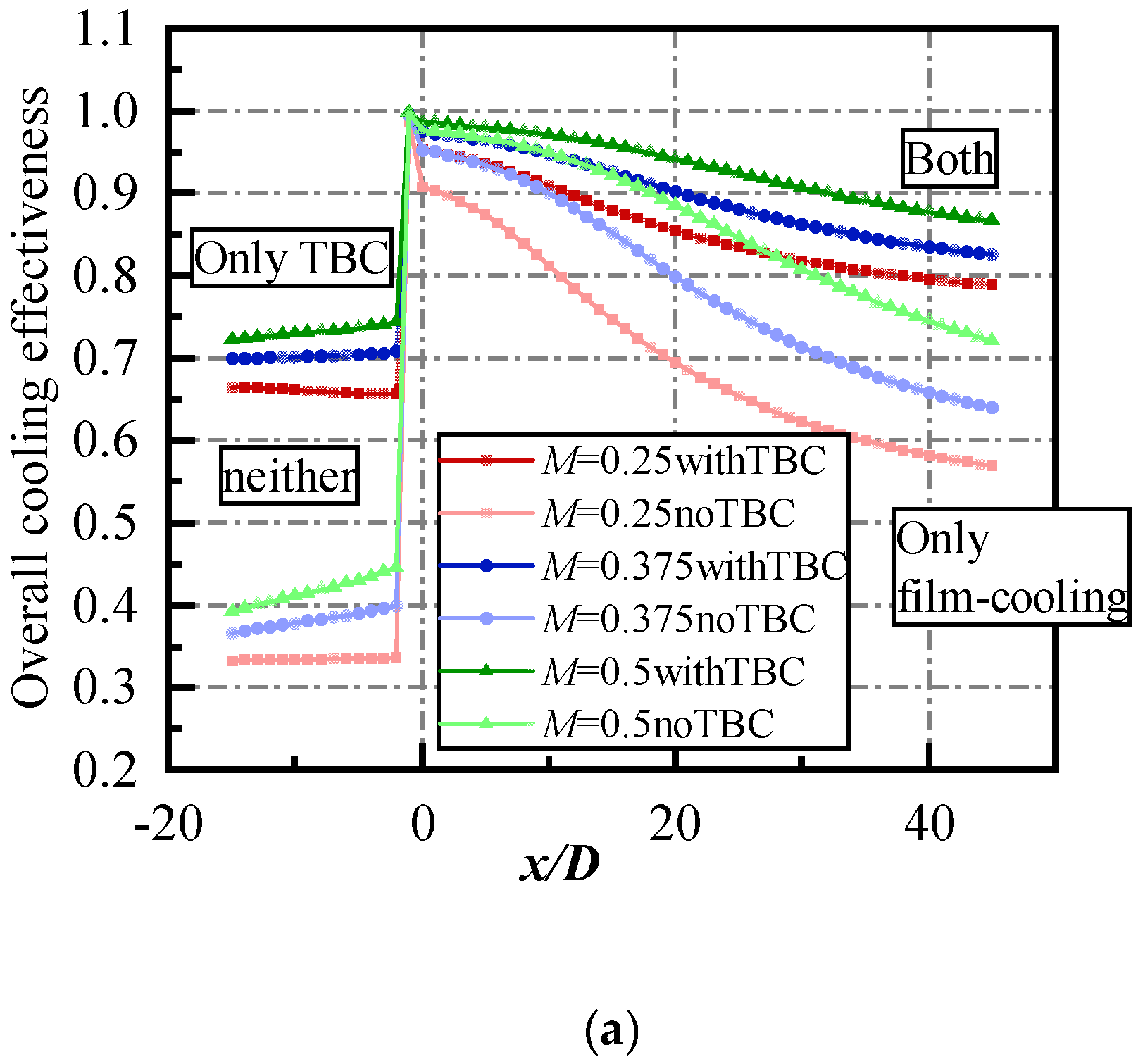

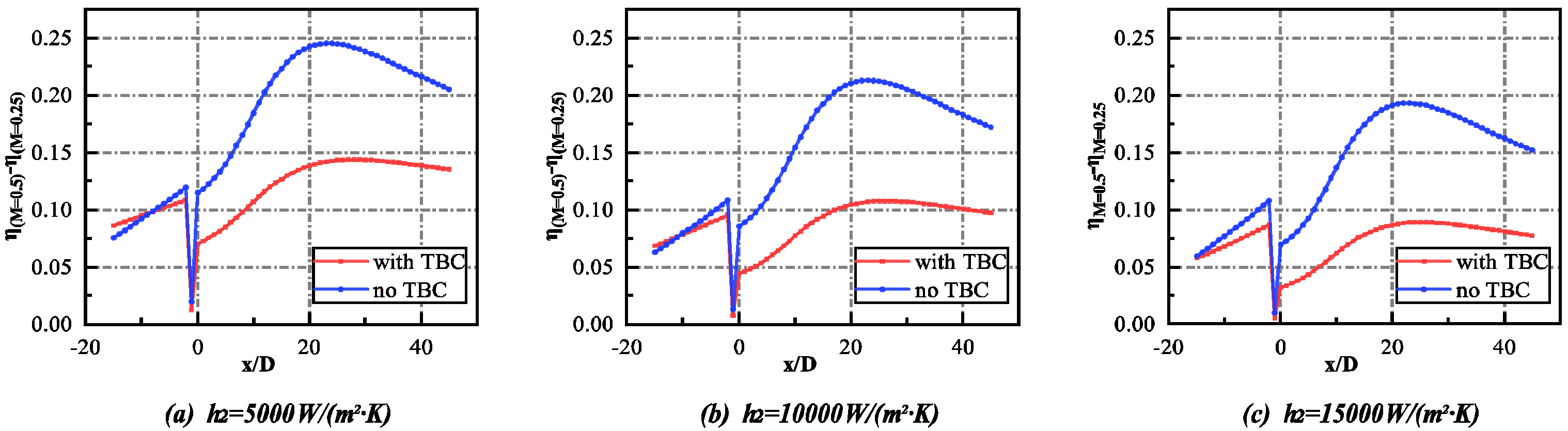

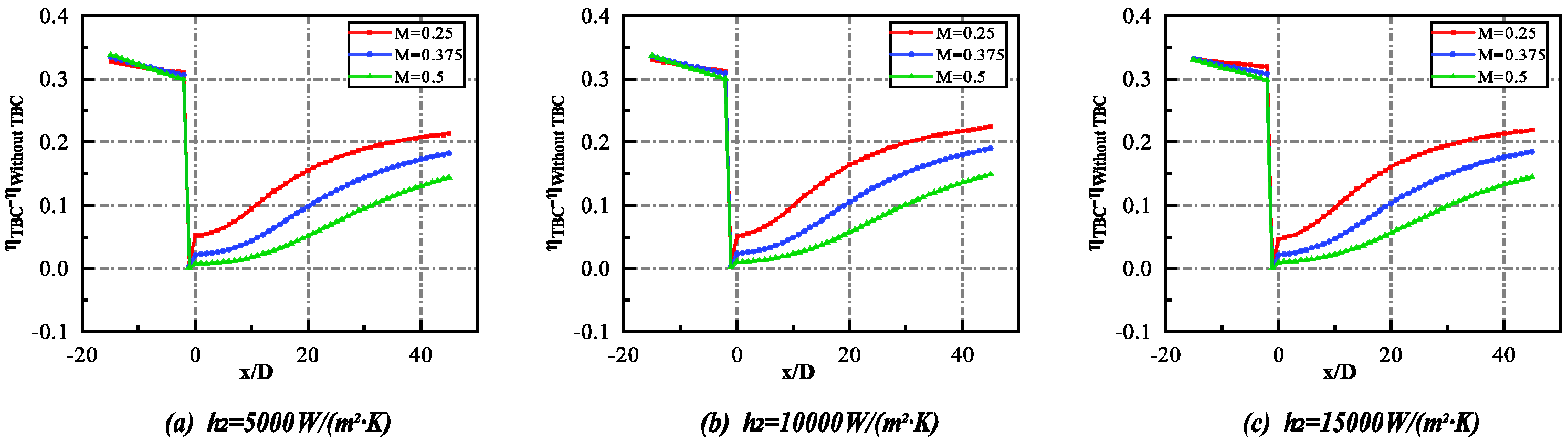

4.2. TBC–Film Cooling Combined Effect and Factor Analysis

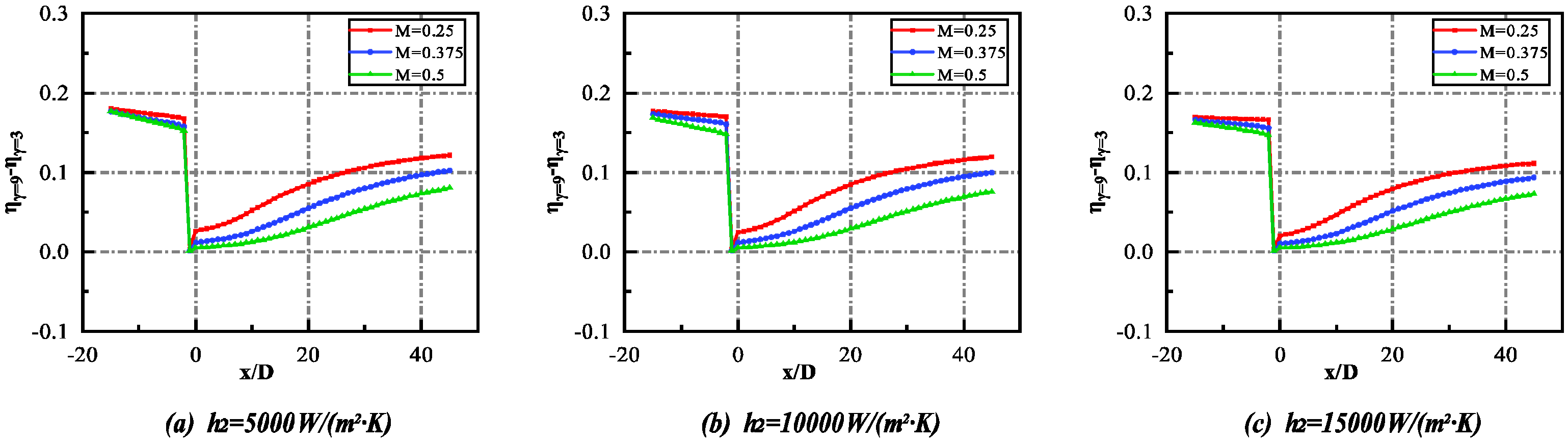

4.3. TBC–Film Cooling Combined Effect and Multiple Factors Sensitivity Analysis

5. Conclusions

- (1)

- We theoretically obtained and numerically verified the relationship between the temperature-drop of the coating itself (). This is a current evaluation of the TBC effect and temperature-drop difference between the external surface of the metal blade with or without coating (), of which aero-engines really consider. Further, we obtained the corresponding increase in turbine inlet temperature. This has a certain reference value to understand the thermal insulation mechanism of the TBC, and can help to further establish a more reasonable evaluation of the TBC effect.

- (2)

- TBC and film cooling can be integrated to have a better cooling effect than each alone, but they can only play an effect of . However, the gap with TBC is smaller than the one without TBC, which means that TBC weakens the effect of BR on the overall cooling effectiveness , that is, TBC weakens the effect of film cooling on the overall cooling effectiveness. Meanwhile, the gap between the overall cooling effectiveness with and without TBC becomes smaller, with BR increasing under a different internal heat transfer coefficient; thus, meaning that the increase in BR will weaken the effect of TBC on the overall cooling effectiveness , that is, the improved effect of film cooling will weaken the effect of TBC on the overall cooling effectiveness. These two points further prove that TBC and film cooling can only play an effect of .

- (3)

- The overall cooling effectiveness improves as the thermal resistance ratio increases. In addition, when the thermal resistance ratio becomes larger, the effect on the overall cooling effectiveness of the same increases as the thermal resistance ratio becomes smaller. Furthermore, by comparing the effect of on under different BRs, it illustrates that with the BR increasing, the improvement caused by an increase in the same results in it becoming smaller; thus, indicating that the increase in BR will weaken the influence of the variation of the thermal resistance ratio on the overall cooling effectiveness. Meanwhile, the gap is basically the same at the same BR with the variation of h2, which means that the increase in the internal heat transfer coefficient will basically not affect the improvement of on the overall cooling effectiveness.

- (4)

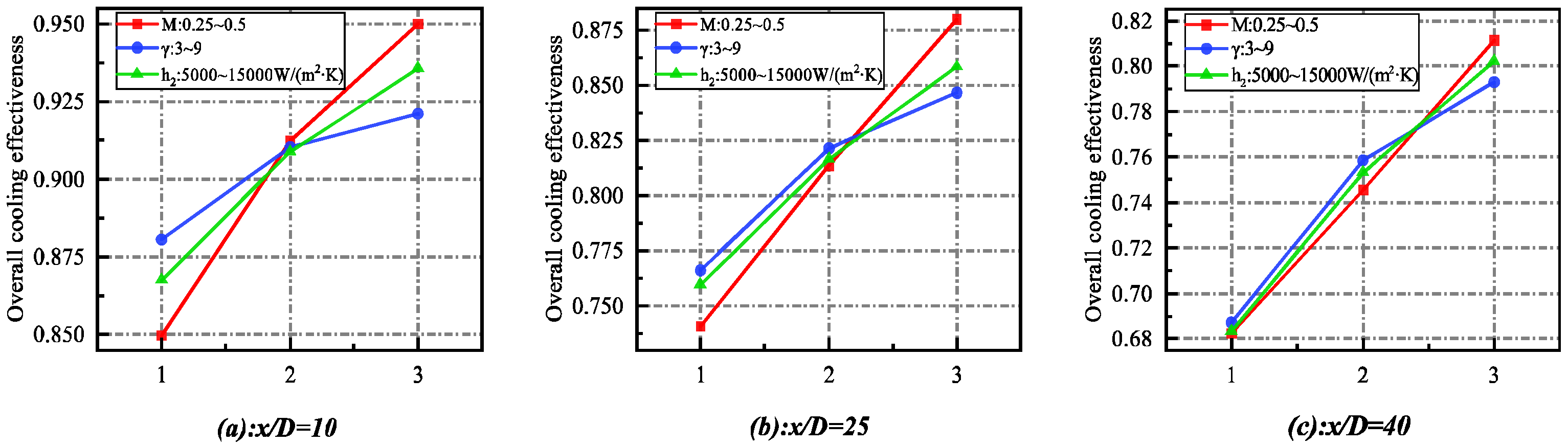

- We chose the overall cooling effect at three different dimensionless distances x/D as the evaluation index to analyze the sensitivity of the variation of the blowing ratio , the thermal resistance ratio , and the internal heat transfer coefficient to represent the effect of external film cooling, thermal insulation of TBCs, and the effect of internal heat transfer, respectively. We analyzed the sensitivity of the above influencing factors on overall cooling effectiveness. It was found that film cooling plays a major role in the contribution of the overall cooling effectiveness near the exit of the film-hole, at x/D = 10, while the contribution of TBC is small. However, it was found that the contribution of TBC and internal heat transfer coefficient to overall cooling effectiveness gradually improves as the x/D increases, among which the contribution of TBC improves significantly.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, M. The development of Aero-engine technology. Sci. Chin. 2015, 28, 10–19. [Google Scholar]

- Deng, H. Experimental Study on the Heat Transfer Characteristics of the Cooling System in the Middle of a Turbine Blade; Beihang University: Beijing, China, 2004. [Google Scholar]

- Matsumoto, K.; Itoh, Y.; Kameda, T. EB-PVD Process and Thermal Properties of Hafnia-Based Thermal Barrier Coating. Sci. Technol. Adv. Mater. 2003, 4, 153. [Google Scholar] [CrossRef]

- Qin, J.; Chen, G.; Du, Z.M.; Jin, Y.H. Study on Performance of 8YSZ Thick Gradient TBC. Appl. Mech. Mater. 2014, 607, 43–46. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Liu, H.; Weng, Y. Study on Thermal Resistance Performance of 8YSZ Thermal Barrier Coatings. Int. J. Therm. Sci. 2017, 122, 12–25. [Google Scholar] [CrossRef]

- Demasi-Marcin, J.T.; Gupta, D.K. Protective Coatings in the Gas Turbine Engine. Surf. Coat. Technol. 1994, 68, 1–9. [Google Scholar] [CrossRef]

- Guo, H.; Gong, S.; Xu, H. Progress in Thermal Barrier Coatings for Advanced Aeroengines. Mater. China 2009, 9, 18–26. [Google Scholar]

- Meier, S.M.; Gupta, D.K. The Evolution of Thermal Barrier Coatings in Gas Turbine Engine Applications. J. Eng. Gas Turbines Power 1994, 116, 250–257. [Google Scholar] [CrossRef]

- Davidson, F.T.; Dees, J.E.; Bogard, D.G. An Experimental Study of Thermal Barrier Coatings and Film Cooling on an Internally Cooled Simulated Turbine Vane. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011. [Google Scholar]

- Padture, N.P.; Gell, M.; Jordan, E.H. Materials Science—Thermal Barrier Coatings for Gas-Turbine Engine Apptications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Prapamonthon, P.; Xu, H.; Yang, W.; Wang, J. Numerical Study of the Effects of Thermal Barrier Coating and Turbulence Intensity on Cooling Performances of a Nozzle Guide Vane. Energies 2017, 10, 362. [Google Scholar] [CrossRef]

- Lawson, S.A.; Thole, K.A.; Okita, Y.; Nakamata, C. Simulations of Multi-Phase Particle Deposition on a Showerhead with Staggered Film-Cooling Holes. J. Turbomach. 2012, 134, 051041.1–051041.12. [Google Scholar] [CrossRef]

- Albert, J.E.; Bogard, D.G. Experimental Simulation of Contaminant Deposition on a Film Cooled Turbine Vane Pressure Side with a Trench. J. Turbomach. 2013, 135, 051008.1–051008.11. [Google Scholar] [CrossRef]

- Ekkad, S.V.; Han, J.C. Heat Transfer Distributions on a Cylinder with Simulated Thermal Barrier Coating Spallation. J. Thermophys. Heat Transf. 2015, 13, 76–81. [Google Scholar] [CrossRef]

- Maikell, J.; Bogard, D.; Piggush, J.; Kohli, A. Experimental Simulation of a Film Cooled Turbine Blade Leading Edge Including Thermal Barrier Coating Effects. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Han, Z.X.; Dennis, B.H.; Dulikravich, G.S. Simultaneous Prediction of External Flow-Field and Temperature in Internally Cooled 3-D Turbine Blade Material. Int. J. Turbo Jet Engines 2001, 18, 47–58. [Google Scholar] [CrossRef]

- Zhu, W.; Wang, J.W.; Yang, L.; Zhou, Y.C.; Wei, Y.G.; Wu, R.T. Modeling and Simulation of the Temperature and Stress Fields in a 3D Turbine Blade Coated with Thermal Barrier Coatings. Surf. Coat. Technol. 2017, 315, 443–453. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Zhu, W.; Yang, L.; Zhou, Y.C. Numerical Prediction of Thermal Insulation Performance and Stress Distribution of Thermal Barrier Coatings Coated on a Turbine Vane. Int. J. Therm. Sci. 2020, 158, 106552. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P. The Influence of Quantity and Distribution of Cooling Channels of Turbine Elements on Level of Stresses in the Protective Layer TBC and the Efficiency of Cooling. Comput. Mater. Sci. 2012, 52, 293–297. [Google Scholar] [CrossRef]

- Shih, I.P. Biot-Number Analogy for Design of Experiments in Turbine Cooling. J. Turbomach. 2015, 137, 061002. [Google Scholar]

- Mensch, A.; Thole, K.A.; Craven, B.A. Conjugate Heat Transfer Measurements and Predictions of a Blade Endwall with a Thermal Barrier Coating. J. Turbomach. 2014, 136, 121003.1–121003.11. [Google Scholar] [CrossRef]

- Eifel, M.; Caspary, V.; Hönen, H.; Jeschke, P. Experimental and Numerical Analysis of Gas Turbine Blades with Different Internal Cooling Geometries. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Ke, Z.; Wang, J. Numerical Investigations of Pulsed Film Cooling on an Entire Turbine Vane. Appl. Therm. Eng. 2015, 87, 117–126. [Google Scholar] [CrossRef]

- Du, K.; Li, J. Numerical Study on the Effects of Slot Injection Configuration and Endwall Alignment Mode on the Film Cooling Performance of Vane Endwall. Int. J. Heat Mass Transf. 2016, 98, 768–777. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, P.; Du, Q.; Xu, Q.; Liu, J.; Zhu, J. Numerical Investigations of Film Cooling Characteristics of Interrupted Slot and Trench Holes on a Vane Endwall. J. Therm. Sci. 2021, 30, 1010–1024. [Google Scholar] [CrossRef]

- Lynch, S.P.; Thole, K.A.; Kohli, A.; Lehane, C. Computational Predictions of Heat Transfer and Film-Cooling for a Turbine Blade with Nonaxisymmetric Endwall Contouring. J. Turbomach. 2011, 133, 041003.1–041003.10. [Google Scholar] [CrossRef]

- Alizadeh, M.; Izadi, A.; Fathi, A. Sensitivity Analysis on Turbine Blade Temperature Distribution Using Conjugate Heat Transfer Simulation. J. Turbomach. 2014, 136, 011001. [Google Scholar] [CrossRef]

- Williams, R.P.; Dyson, T.E.; Bogard, D.G.; Bradshaw, S.D. Sensitivity of the Overall Effectiveness to Film Cooling and Internal Cooling on a Turbine Vane Suction Side. J. Turbomach. 2014, 136, 031006.1–031006.7. [Google Scholar] [CrossRef]

- Prapamonthon, P.; Yin, B.; Yang, G.; Zhang, M. Separate and Combined Effects of Surface Roughness and Thermal Barrier Coating on Vane Cooling Performance. J. Therm. Sci. Eng. Appl. 2020, 12, 051017. [Google Scholar] [CrossRef]

- Wang, C.; Sun, X.; Zhang, J. Uncertainty analysis of trench film cooling on flat plate. Appl. Therm. Eng. 2019, 156, 562–575. [Google Scholar] [CrossRef]

- Huang, X.; Pu, J.; Wang, J.H.; Qu, Y.F.; He, J.H. Sensitivity analysis of internal layout and coating thickness to overall cooling performances of laminated cooling configurations with surface thermal barrier coatings. Appl. Therm. Eng. 2020, 181, 116020. [Google Scholar] [CrossRef]

- Shi, Y. Probability Theory and Mathematical Statistics, 4th ed.; Northwestern Polytechnical University Press: Xi’an, China, 2012. [Google Scholar]

- Yang, D. Experimental Design and Analysis; China Agricultural Press: Beijing, China, 2002; pp. 1–14. [Google Scholar]

- Li, Y.; Hu, C. Experimental Design and Data Processing; Chemical Industry Press: Beijing, China, 2005; pp. 79–83. [Google Scholar]

| Boundary | Condition |

|---|---|

| Mainstream inlet | |

| Mainstream | |

| Coolant film inlet | |

| Inner surface |

| Case (x/D = 30) | Computation | Theoretical |

|---|---|---|

| Case1: H2 = 5000 M = 0.25 | 1.01 | 1.47 |

| Case2: H2 = 10,000 M = 0.5 | 1.28 | 1.65 |

| Case3: H2 = 15,000 M = 0.375 | 1.49 | 1.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.; Liu, Y.; You, R.; Li, H. Theoretical and Numerical Study on Thermal Insulation Performance of Thermal Barrier Coatings. Energies 2022, 15, 6880. https://doi.org/10.3390/en15196880

Gao C, Liu Y, You R, Li H. Theoretical and Numerical Study on Thermal Insulation Performance of Thermal Barrier Coatings. Energies. 2022; 15(19):6880. https://doi.org/10.3390/en15196880

Chicago/Turabian StyleGao, Chao, Yang Liu, Ruquan You, and Haiwang Li. 2022. "Theoretical and Numerical Study on Thermal Insulation Performance of Thermal Barrier Coatings" Energies 15, no. 19: 6880. https://doi.org/10.3390/en15196880

APA StyleGao, C., Liu, Y., You, R., & Li, H. (2022). Theoretical and Numerical Study on Thermal Insulation Performance of Thermal Barrier Coatings. Energies, 15(19), 6880. https://doi.org/10.3390/en15196880