Liquid–Gas Jet Pump: A Review

Abstract

:1. Introduction

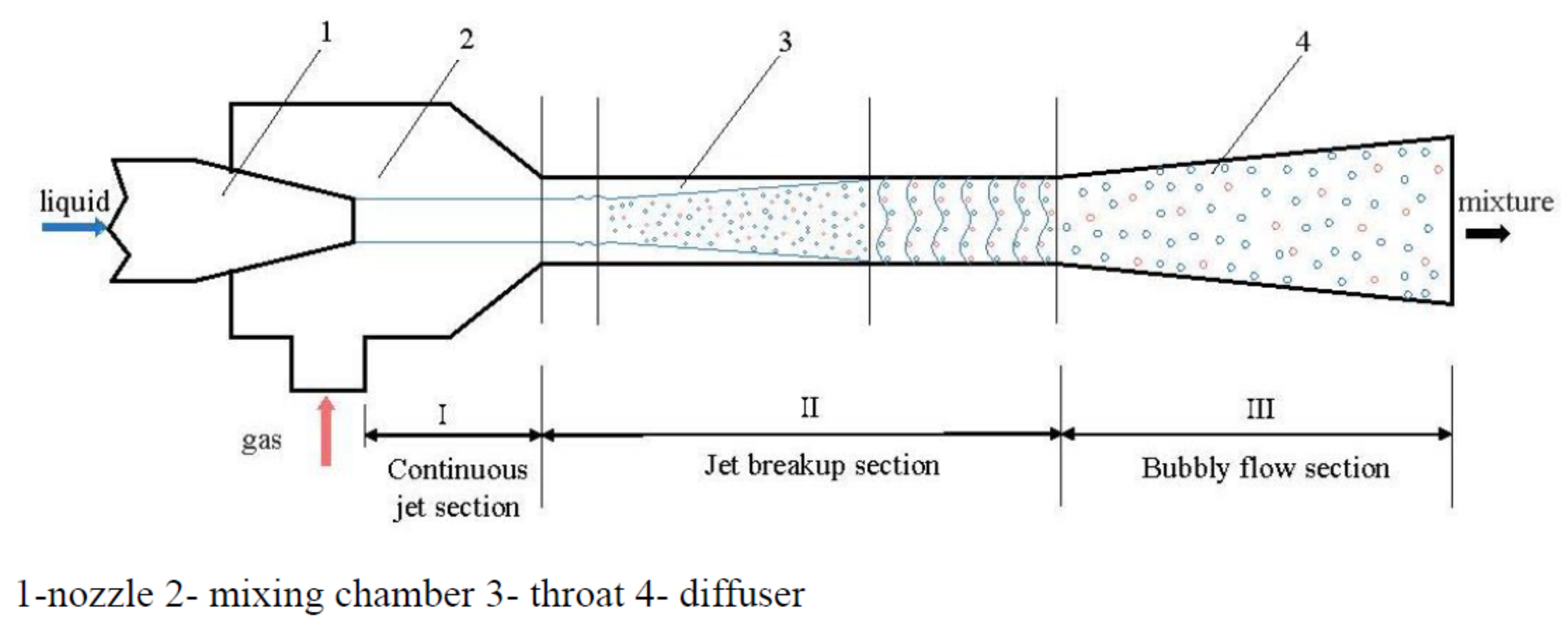

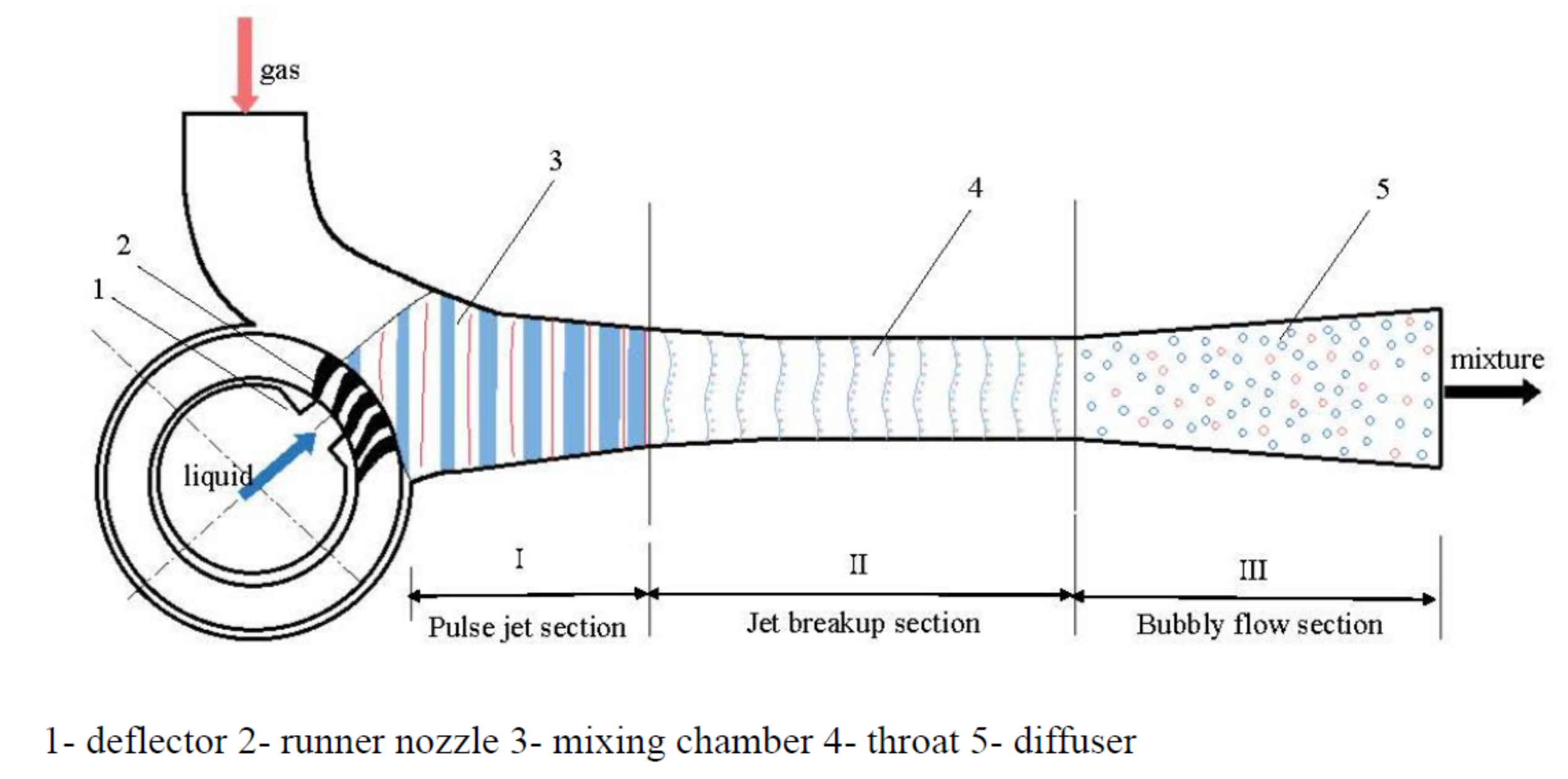

2. Structure and Principle

3. Research Status

3.1. Research Status of the LGJP

3.2. Research Status of the PLGJP

4. Application Research Status

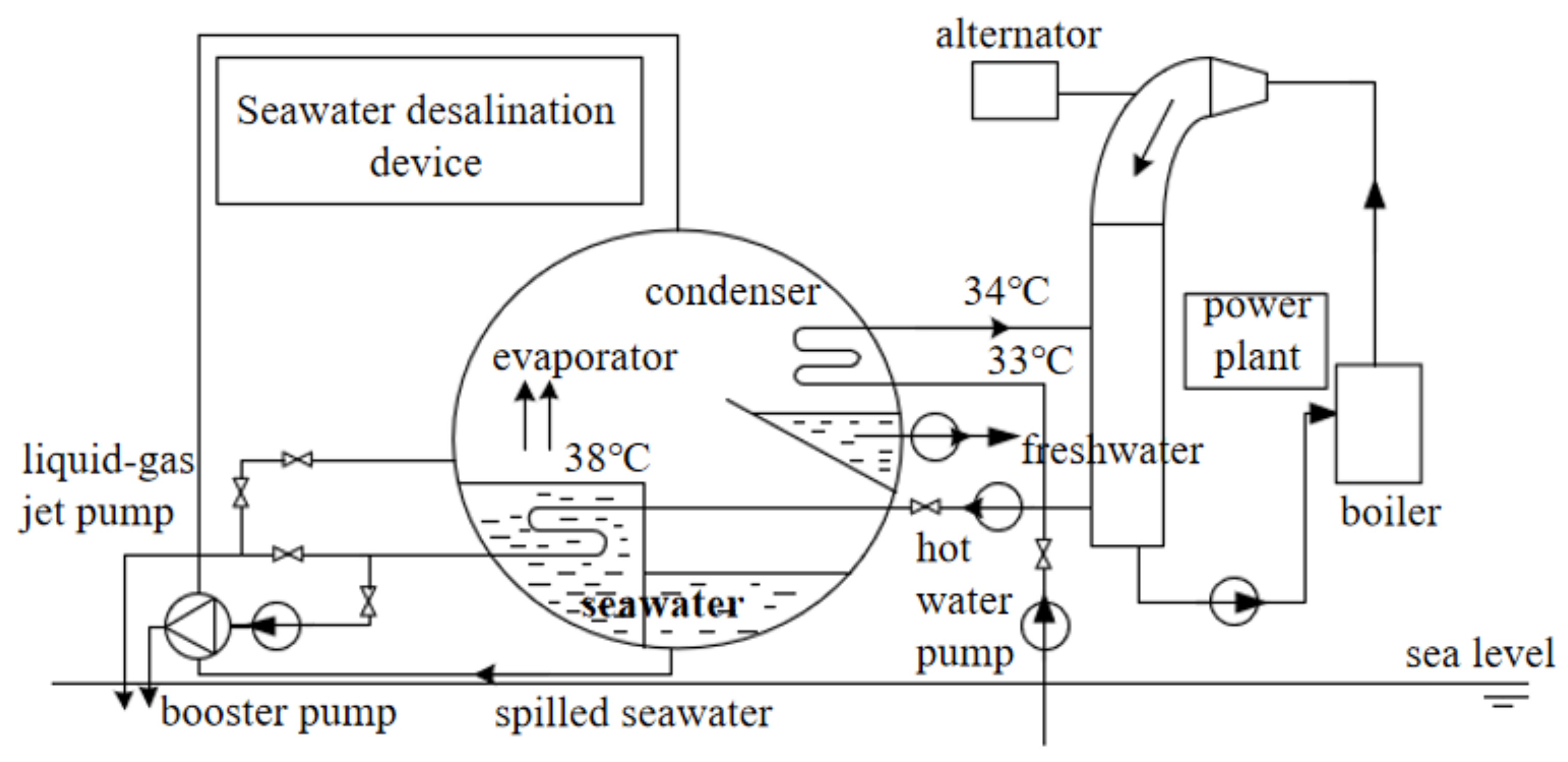

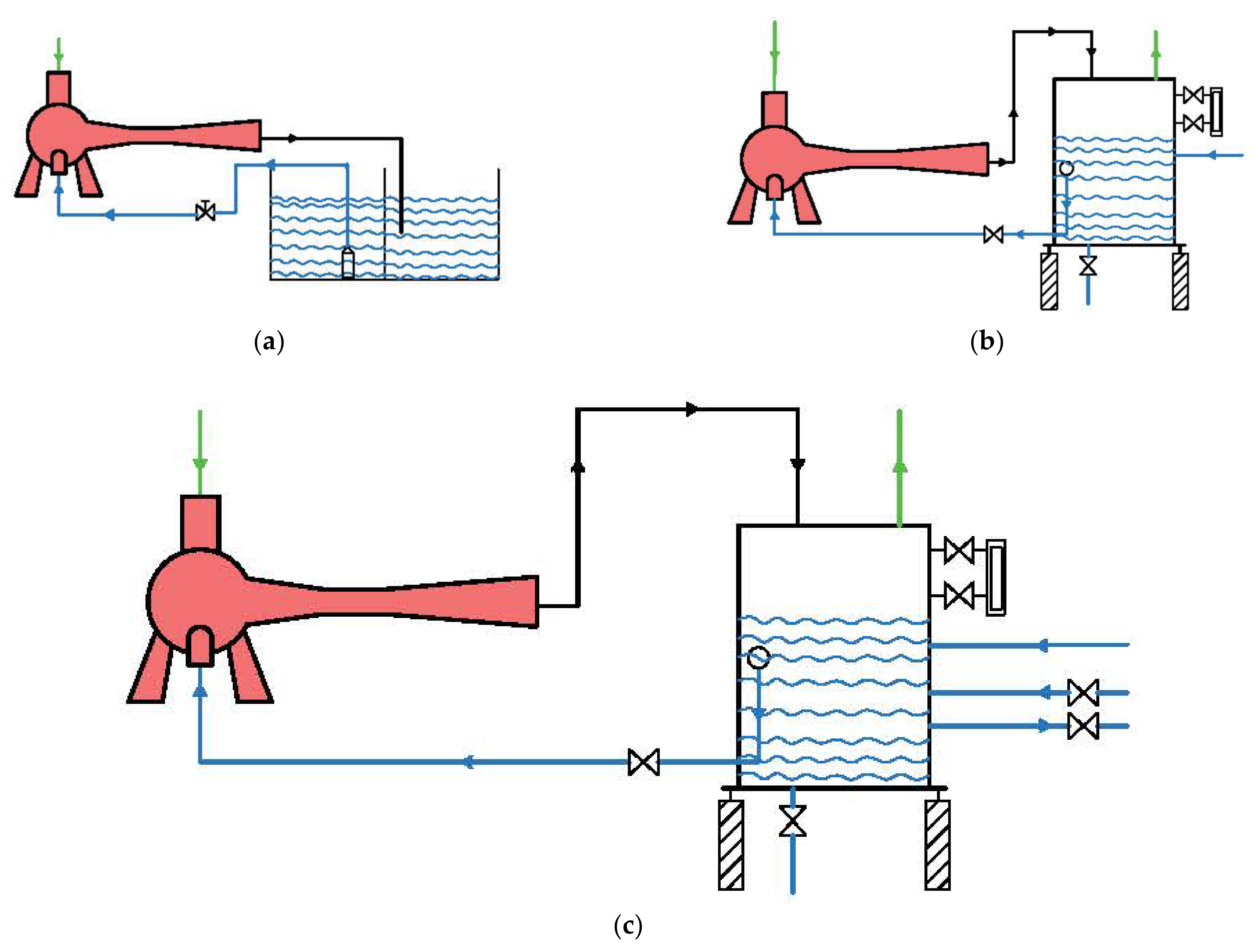

4.1. Application Research Status of the LGJP

4.2. Application Research Status of the CJVP

5. Conclusions

- (1)

- CFD will be more deeply applied to the mechanism research and performance improvement of the LGJP. The theoretical research of the LGJP has been in-depth, and combined with CFD technology, the mechanism analysis of the LGJP is also progressing. At present, the research of the LGJP tends to combine simulation analysis with practical application fields to analyze the flow and suction mechanism to carry out targeted structural optimization, reduce research and development and application costs, and improve reliability.

- (2)

- The diversity and multiphase of the fluid medium and its influence on the internal flow mechanism are the research directions of the LGJP. The application of the LGJP is no longer limited to liquid–gas two-phase flow, and it is not uncommon for the working fluid or the aspirated fluid to be a liquid–gas mixture or non-Newtonian fluid. At present, there are few studies on the internal flow mechanism of the LGJP in the case of multiphase mixed flow medium, which needs further attention.

- (3)

- The PLGJP provides more energy-saving options. Today, when energy saving and consumption reduction are required, the PLGJP provides a new idea for energy-saving transformation in various industries, and the research on related mechanisms can expand the application scope of the LGJP in the future. However, there are few studies on the relevant mechanism of the PLGJP, and these are needed to improve the theoretical and experimental research.

- (4)

- The application prospect of the CJVP is broad. The characteristics of the high efficiency and low consumption of the CJVP results in its broad application in the market today, as it advocates energy conservation and emission reduction. It is precisely because of the high market demand that the related theoretical and experimental research on CJVPs is very urgent and needs more attention.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Witte, J.H. Mixing Shocks and Their Influence on the Design of Liquid-Gas Ejectors. Master’s Thesis, Delft University, Delft, The Netherlands, 1962. [Google Scholar]

- Cunningham, R.G. Liquid jet pumps for two-phase flows. J. Fluids Eng. 1995, 117, 309–316. [Google Scholar] [CrossRef]

- Sherif, S.; Lear, W.; Steadham, J.; Hunt, P.; Holladay, J. Analysis and modeling of a two-phase jet pump of a thermal management system for aerospace applications. Int. J. Mech. Sci. 2000, 42, 185–198. [Google Scholar] [CrossRef]

- Kumar, R.S.; Mani, A.; Kumaraswamy, S. Analysis of a jet-pump-assisted vacuum desalination system using power plant waste heat. Desalination 2005, 179, 345–354. [Google Scholar] [CrossRef]

- Neve, R.S. The performance and modeling of liquid jet gas pumps. Int. J. Heat Fluid Flow 1988, 9, 156–164. [Google Scholar] [CrossRef]

- Carvalho, P.M. Modeling the Electrical Submersible Jet Pump Producing High Gas-Liquid-Ratio Petroleum Wells. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 1998. [Google Scholar]

- Neve, R.S. Diffuser performance in two-phase jet pumps. Int. J. Multiph. Flow 1991, 17, 267–272. [Google Scholar] [CrossRef]

- Lu, H. Theory and Application of Jet Pump Technology; Water Conservancy and Electric Power Press: Beijing, China, 1989. [Google Scholar]

- Lu, H. Theory and Application of Jet Technology; Wuhan University Press: Wuhan, China, 2004. [Google Scholar]

- Liao, D.; Lu, H. Research on basic performance and correction coefficients of liquid-liquid gas jet pump. Chin. J. Hydrodyn. 1996, 12, 610–617. [Google Scholar]

- Haidl, J.; Mařík, K.; Moucha, T.; Rejl, F.J.; Valenz, L.; Zednikova, M. Hydraulic characteristics of liquid–gas ejector pump with a coherent liquid jet. Chem. Eng. Res. Des. 2021, 168, 435–442. [Google Scholar] [CrossRef]

- Rahman, F.; Umesh, D.; Subbarao, D.; Ramasamy, M. Enhancement of entrainment rates in liquid–gas ejectors. Chem. Eng. Process. Process Intensif. 2010, 49, 1128–1135. [Google Scholar] [CrossRef]

- Opletal, M.; Novotný, P.; Linek, V.; Moucha, T.; Kordač, M. Gas suction and mass transfer in gas-liquid up-flow ejector loop reactors. Effect of nozzle and ejector geometry. Chem. Eng. J. 2018, 353, 436–452. [Google Scholar] [CrossRef]

- Kim, M.I.; Kim, O.S.; Lee, D.H.; Kim, S.D. Numerical and experimental investigations of gas–liquid dispersion in an ejector. Chem. Eng. Sci. 2007, 62, 7133–7139. [Google Scholar] [CrossRef]

- Sharma, V.P.; Kumaraswamy, S.; Mani, A. Effect of various nozzle profiles on performance of a two-phase flow jet pump. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2012, 1, 173–179. [Google Scholar] [CrossRef]

- Liu, J. Experimental Research on performance of liquid-air jet pump. J. Wuhan Inst. Water Conserv. Electr. Power 1982, 3, 105–114. [Google Scholar]

- Liao, D.; Lu, H. Study on basic performance and correction coefficients of liquid-liquid gas jet pump. Fluid Mach. 1997, 4, 26–29. [Google Scholar]

- Gao, C.; Wang, Y. Research and application progress of liquid-gas jet pump. China Pet. Mach. 2008, 2, 67–70. [Google Scholar]

- Zhang, J.; Gao, C.; Yan, Y.; Wang, X. Pulsed liquid-air jet pump energy balance. J. Drain. Irrig. Mach. 2012, 30, 422–427. [Google Scholar] [CrossRef]

- Ge, Y.; Ge, Q.; Yang, J. Numerical simulation of throat distance of liquid-gas jet pump and its optimal range determination. Fluid Mach. 2012, 40, 21–24. [Google Scholar] [CrossRef]

- Bhatkar, V.; Sur, A. An experimental analysis of liquid air jet pump. Front. Heat Mass Transf. (FHMT) 2021, 17, 12. [Google Scholar] [CrossRef]

- Wu, Y.L.; Xiang, Q.J.; Li, H.; Chen, S.X. Study on bubble sizes in a down-flow liquid jet gas pump. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 052017. [Google Scholar] [CrossRef]

- Eisallak, M.; Hefny, M.M. Experimental investigation of the performance of liquid gas jet pumps with inlet swirling. Proc. Inst. Mech. Eng. Part A J. Power Energy 2010, 224, 363–372. [Google Scholar] [CrossRef]

- Mikheev, N.I.; Davletshin, I.A.; Mikheev, A.N.; Kratirov, D.V.; Fafurin, V.A. Efficiency of liquid-jet high-pressure booster compressors. J. Phys. Conf. Ser. 2017, 891, 012202. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, J.; Liu, Z.; Zuo, P.; Kwabena, A.R. Numerical simulation and parameter study of ejector in casing gas recovery system. J. Mech. Sci. Technol. 2021, 35, 2689–2696. [Google Scholar] [CrossRef]

- Choi, S.H.; Ji, H.S.; Kim, K.C. Comparative study of hydrodynamic characteristics with respect to direction of installation of gas-liquid ejector system. J. Mech. Sci. Technol. 2015, 29, 3267–3276. [Google Scholar] [CrossRef]

- Jiao, B.; Blais, R.N.; Schmidt, Z. Efficiency and pressure recovery in hydraulic jet pumping of two-phase gas/liquid mixtures. SPE Prod. Eng. 1990, 5, 361–364. [Google Scholar] [CrossRef]

- Ismagilov, A.R.; Spiridonov, E.K. Operational process and characteristics of liquid-gas jet pumps with the ejected vapor-gas medium. Procedia Eng. 2016, 150, 247–253. [Google Scholar] [CrossRef] [Green Version]

- Sharma, D.; Patwardhan, A.; Ranade, V. Effect of turbulent dispersion on hydrodynamic characteristics in a liquid jet ejector. Energy 2018, 164, 10–20. [Google Scholar] [CrossRef]

- Chen, L.; Liu, S. Numerical simulation of internal flow field of pulsed liquid-gas jet pump. Machinery 2013, 8, 29–31. [Google Scholar] [CrossRef]

- Semlitsch, B. Large Eddy Simulation of Turbulent Compressible Jets. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2014. [Google Scholar]

- Zheng, P.; Qin, J.; Chen, X. Numerical simulation and optimization of gas-liquid ejector ejection performance. J. Jiangsu Univ. (Nat. Sci. Ed.) 2017, 38, 30–36. [Google Scholar] [CrossRef]

- Qin, J.; Zheng, P.; Chen, X. Numerical simulation of gas-liquid ejector jet performance under different inlet and outlet conditions. Chin. J. Process Eng. 2017, 17, 469–476. [Google Scholar] [CrossRef]

- Gao, G.; Xing, Y.; Wang, Y. Numerical study on the influence of the constriction half angle of the throat segment on the flow field characteristics of a liquid-air jet pump. Chin. J. Vac. Sci. Technol. 2020, 40, 174–179. [Google Scholar]

- Wang, X.; Li, H.; Dong, J.; Wu, J.; Tu, J. Numerical study on mixing flow behavior in gas-liquid ejector. Exp. Comput. Multiph. Flow 2021, 3, 108–112. [Google Scholar] [CrossRef]

- Yang, X.; Long, X.; Kang, Y.; Xiao, L. Application of constant rate of velocity or pressure change method to improve annular jet pump performance. Int. J. Fluid Mach. Syst. 2013, 6, 137–143. [Google Scholar] [CrossRef]

- Wang, X.; Yang, X.; Long, X.; Zhou, D. Application of constant rate of velocity change method to improve dust cleaning performance. Disaster Adv. 2013, 6, 459–468. [Google Scholar]

- Xiao, J.; Wu, Q.; Chen, L.; Ke, W.; Wu, C.; Yang, X.; Yu, L.; Jiang, H. Assessment of different CFD modeling and solving approaches for a supersonic steam ejector simulation. Atmosphere 2022, 13, 144. [Google Scholar] [CrossRef]

- Yang, X.; Long, X.; Kang, Y.; Xiao, L. Effect of diffuser structure and throat length on jet pump performance. J. Harbin Inst. Technol. 2014, 46, 111–115. [Google Scholar] [CrossRef]

- Sato, K.; Hachino, K.; Saito, Y. Inception and dynamics of traveling-bubble-type cavitation in a venturi. In Proceedings of the ASME/JSME 2003 4th Joint Fluids Summer Engineering Conference, Honolulu, HI, USA, 6–10 July 2003; Volume 36967, pp. 279–285. [Google Scholar]

- Stutz, B.; Legoupil, S. X-ray measurements within unsteady cavitation. Exp. Fluids 2003, 35, 130–138. [Google Scholar] [CrossRef]

- Coutier Delgosha, O.; Reboud, J.; Delannoy, Y. Numerical simulation of the unsteady behaviour of cavitating flows. Int. J. Numer. Methods Fluids 2003, 42, 527–548. [Google Scholar] [CrossRef]

- Coutier Delgosha, O.; Fortes Patella, R.; Reboud, J.L. Evaluation of the turbulence model influence on the numerical simulations of unsteady cavitation. J. Fluids Eng. 2003, 125, 38–45. [Google Scholar] [CrossRef]

- Gu, Y.; Ma, L.; Yan, M.; He, C.; Zhang, J.; Mou, J.; Wu, D.; Ren, Y. Strategies for improving friction behavior based on carbon nanotube additive materials: A review. Tribol. Int. 2022, 228, 107490. [Google Scholar] [CrossRef]

- He, C.; Gu, Y.; Zhang, J.; Ma, L.; Yan, M.; Mou, J.; Ren, Y. Preparation and modification technology analysis of Ionic Polymer-Metal Composites (IPMCs). Int. J. Mol. Sci. 2022, 23, 3522. [Google Scholar] [CrossRef]

- Gu, Y.; Zhang, J.; Yu, S.; Mou, C.; Li, Z.; He, C.; Wu, D.; Mou, J.; Ren, Y. Unsteady numerical simulation method of hydrofoil surface cavitation. Int. J. Mech. Sci. 2022, 228, 107490. [Google Scholar] [CrossRef]

- Yazici, B.; Tuncer, I.; Ak, M. Numerical & experimental investigation of flow through a cavitating venturi. In Proceedings of the 2007 3rd International Conference on Recent Advances in Space Technologies, Istanbul, Turkey, 14–16 June 2007; pp. 236–241. [Google Scholar]

- Sayyaadi, H. Instability of the cavitating flow in a venturi reactor. Fluid Dyn. Res. 2010, 42, 055503. [Google Scholar] [CrossRef]

- Xu, C.; Huang, Y. Experimental characteristics of pneumatic pulse jet pumping systems with a Venturi-like reverse flow diverter. Int. J. Chem. React. Eng. 2011, 9, A34. [Google Scholar] [CrossRef]

- Long, X.; Wang, J.; Zuo, D.; Zhang, J.; Ji, B. Experimental Investigation of the instability of cavitation in veturi tube under different cavitation Stage. J. Mech. Eng. 2018, 54, 209–215. [Google Scholar] [CrossRef]

- Wang, J.; Xu, S.; Cheng, H.; Ji, B.; Zhang, J.; Long, X. Experimental investigation of cavity length pulsation characteristics of jet pumps during limited operation stage. Energy 2018, 163, 61–73. [Google Scholar] [CrossRef]

- Yan, H.; Wang, Z.; Chen, Y. High-speed photography analysis on cavitation of Venturi injector. J. Drain. Irrig. Mach. Eng. 2014, 32, 901–905. [Google Scholar] [CrossRef]

- Hu, B.; Musculus, M.P.B.; Oefelein, J.C. The influence of large-scale structures on entrainment in a decelerating transient turbulent jet revealed by large eddy simulation. Phys. Fluids 2012, 24, 045106. [Google Scholar] [CrossRef]

- Xu, M.; Yang, X.; Long, X.; Lyu, Q. Large eddy simulation of turbulent flow structure and characteristics in an annular jet pump. J. Hydrodyn. 2017, 29, 702–715. [Google Scholar] [CrossRef]

- Xu, M.; Yang, X.; Long, X.; Lyu, Q.; Ji, B. Numerical investigation of turbulent flow coherent structures in annular jet pumps using the LES method. Sci. China Technol. Sci. 2018, 61, 86–97. [Google Scholar] [CrossRef]

- Yang, X.; Long, X. Numerical investigation on the jet pump performance based on different turbulence models. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 052019. [Google Scholar] [CrossRef]

- Yang, X.; Long, X.; Yao, X. Numerical investigation on the mixing process in a steam ejector with different nozzle structures. Int. J. Therm. Sci. 2012, 56, 95–106. [Google Scholar] [CrossRef]

- Kolář, J. Error analysis of supersonic air-to-air ejector schlieren pictures. EPJ Web Conf. 2013, 45, 01004. [Google Scholar] [CrossRef]

- Gagan, J.; Smierciew, K.; Butrymowicz, D.; Karwacki, J. Comparative study of turbulence models in application to gas ejectors. Int. J. Therm. Sci. 2014, 78, 9–15. [Google Scholar] [CrossRef]

- El-Behery, S.M.; Hamed, M.H. A comparative study of turbulence models performance for separating flow in a planar asymmetric diffuser. Comput. Fluids 2011, 44, 248–257. [Google Scholar] [CrossRef]

- Kolář, J.; Dvořák, V. Verification of K-ω SST turbulence model for supersonic internal flows. Int. J. Mech. Mechatron. Eng. 2011, 5, 1715–1719. [Google Scholar] [CrossRef]

- Semlitsch, B.; Laurendeau, E.; Mihăescu, M. Steady-State and unsteady simulations of a high velocity jet into a venturi shaped pipe. In Proceedings of the Fluids Engineering Division Summer Meeting, Chicago, IL, USA, 3–7 August 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 46230, p. V01CT16A023. [Google Scholar] [CrossRef]

- Liang, Y.Z.; Long, Y.; Long, X.; Cheng, H. Verification and validation of large eddy simulation of cavitating flow in Venturi. Chin. J. Ship Res. 2022, 17, 196–204. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, C.; Dong, Y.; He, Q.; Wan, F.; Friedrich, T.; Bi, X.; Tian, Y. Flue gas fine treatment by ejecting technology. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4311–4318. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, X.; Zou, J.; Zhang, Y.; Sun, J.; Liu, Z. Research on performance optimization of gas–liquid ejector in multiphase mixed transportation device. J. Mech. 2022, 38, 22–31. [Google Scholar] [CrossRef]

- Sliusenko, A.; Ponomarenko, V.; Forostiuk, I. Water-air ejector with conical-cylindrical mixing chamber. Acta Polytech. 2021, 61, 768–776. [Google Scholar] [CrossRef]

- Kumar, R.S.; Kumaraswamy, S.; Mani, A. Experimental investigations on a two-phase jet pump used in desalination systems. Desalination 2007, 204, 437–447. [Google Scholar] [CrossRef]

- Drozdov, A.N.; Malyavko, E.A.; Alekseev, Y.L.; Shashel, O.V. Stand research and analysis of liquid-gas jet-pump’s operation characteristics for oil and gas production. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar] [CrossRef]

- Asuaje, M.; Toteff, J.; Noguera, R. Evaluation of a jet-pump for the improvement of oil-water flow in pipeline loops using CFD tools. E3S Web Conf. 2021, 321, 02012. [Google Scholar] [CrossRef]

- Asfora, L.; dos Santos, A.; Duarte, L.J.N. Modeling multiphase jet pumps for gas compression. J. Pet. Sci. Eng. 2019, 173, 844–852. [Google Scholar] [CrossRef]

- Kolla, S.S.; Mohan, R.S.; Shoham, O. Numerical analysis of flow behavior in Gas–Liquid Cylindrical Cyclone (GLCC©) separators with inlet design modifications. J. Energy Resour. Technol. 2021, 143, 093005. [Google Scholar] [CrossRef]

- Bazaluk, O.; Dubei, O.; Ropyak, L.; Shovkoplias, M.; Pryhorovska, T.; Lozynskyi, V. Strategy of compatible use of jet and plunger pump with chrome parts in oil well. Energies 2021, 15, 83. [Google Scholar] [CrossRef]

- Toteff, J.; Asuaje, M.; Noguera, R. New design and optimization of a jet pump to boost heavy oil production. Computation 2022, 10, 11. [Google Scholar] [CrossRef]

- Tang, J.; Zhou, Y.; Liu, J.; Wang, J.; Zhu, W. Liquid metal actuated ejector vacuum system. Appl. Phys. Lett. 2015, 106, 031901. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, Z.; Li, L.; Wang, J.; Liu, J.; Zhou, Y. Influence of driving fluid properties on the performance of liquid-driving ejector. Int. J. Heat Mass Transf. 2016, 101, 20–26. [Google Scholar] [CrossRef]

- Wang, L.; Gao, C. Study progress of pulse jet pump. Integr. Intell. Energy 2006, 28, 33–35. [Google Scholar] [CrossRef]

- Long, X.; Lu, H. Derivation of performance equation of unsteady jet pump. Fluid Mach. 1997, 25, 26–29. [Google Scholar]

- Lu, H.; Gao, C.; Long, X.; Wang, S.; Cheng, M. Research on design theory of gas liquid piston pulsed liquid jet pump. Fluid Mach. 1996, 10, 3–6. [Google Scholar]

- Lu, H.; Gao, C. Theoretical study on the efficiency of gas-liquid piston pulsed liquid jet pump. Mech. Electr. Eng. Technol. 2000, 4, 33–36. [Google Scholar] [CrossRef]

- Gao, C.; Lu, H.J. Theoretical study on the performance of gas-liquid piston pulsed liquid jet pump. Mech. Electr. Eng. Technol. 2000, 4, 52–56. [Google Scholar] [CrossRef]

- Gao, C.; Lu, H.; Liao, D. Theoretical study on stability of gas liquid piston pulsed liquid jet pump. Chin. J. Appl. Mech. 2001, 18, 129–134. [Google Scholar] [CrossRef]

- Gao, C.; Wang, Y.; Chen, H.; Lei, T.; Chen, X.; Wang, X. Basic performance test of pulsed liquid-air jet pump. Nucl. Power Eng. 2010, 31, 133–137. [Google Scholar]

- Guo, Y.; Jing, S.; Zhang, J.; Wu, Q.; Song, C. Experimental study on performance of pneumatic pulsed liquid jet pump. Nucl. Sci. Eng. 2004, 24, 65–71. [Google Scholar] [CrossRef]

- Wang, L.H.; Gan, C.; Ning, P.H. Numerical Study on throat tube inlet function of Pulsed Liquid Jet Pump. Adv. Mater. Res. 2012, 354, 650–654. [Google Scholar] [CrossRef]

- Nygård, A.; Altimira, M.; Semlitsch, B.; Wittberg, L.; Fuchs, L. Analysis of vortical structures in intermittent jets. In Proceedings of the 5th International Conference on Jets, Wakes and Separated Flows (ICJWSF2015), Stockholm, Sweden, 15–18 June 2015; Springer: Cham, Switzerland, 2016; pp. 3–10. [Google Scholar] [CrossRef]

- Lu, H.; Gui, Z.; Sun, M. Mechanism analysis and experimental research of centrifugal jet vacuum pump. Fluid Mach. 1988, 9, 18–25. [Google Scholar]

- Wu, Y.; Ge, L.; Chen, N. Large eddy simulation of silt-liquid two-phase flow through a centrifugal pump impeller. J. Tsinghua Univ. (Sci. Technol.) 2001, 41, 93–96. [Google Scholar] [CrossRef]

- Guo, R.; Li, R.; Zhang, R.; Song, Q. Characteristic analysis of interior hydrodynamic noise in jetting centrifugal pump. Trans. Chin. Soc. Agric. Mach. 2018, 49, 156–164. [Google Scholar] [CrossRef]

- Sun, M. Analysis of power consumption of liebrand vacuum pump. Electr. Power 1981, 6, 30–33. [Google Scholar]

- Shen, X. Comparison and analysis of technical performance of ZBK21 water jet vacuum pump, SZ water ring vacuum pump and hydraulic ejector. China Pap. 1984, 3, 38–41. [Google Scholar]

- Electric Power Science and Technology Network. Available online: http://www.eptchina.com/video/record202012243857.html (accessed on 16 June 2022).

- Luo, H.; Zhou, P.; Shu, L.; Mou, J.; Zheng, H.; Jiang, C.; Wang, Y. Energy performance curves prediction of centrifugal pumps based on constrained PSO-SVR model. Energies 2022, 15, 3309. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, R.; Jiang, L.; Guo, G. DMD analysis on the unsteady flow in a centrifugal pump impeller. J. Vib. Shock. 2022, 41, 33–40+57. [Google Scholar]

- Wu, B. Performance Research and Numerical Simulation of Liquid-Gas Jet Pump. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2017. [Google Scholar]

- Yuan, G.; Zhang, L.; Zhang, H.; Wang, Z. Numerical and experimental investigation of performance of the liquid–gas and liquid jet pumps in desalination systems. Desalination 2011, 276, 89–95. [Google Scholar] [CrossRef]

- Sarshar, S. The recent applications of jet pump technology to enhance production from tight oil and gas fields. In Proceedings of the SPE Middle East Unconventional Gas Conference and Exhibition, Abu Dhabi, United Arab Emirates, 23–25 March 2012. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zou, D.; Yang, X.; Mou, J.; Zhou, Q.; Xu, M. Liquid–Gas Jet Pump: A Review. Energies 2022, 15, 6978. https://doi.org/10.3390/en15196978

Zhang H, Zou D, Yang X, Mou J, Zhou Q, Xu M. Liquid–Gas Jet Pump: A Review. Energies. 2022; 15(19):6978. https://doi.org/10.3390/en15196978

Chicago/Turabian StyleZhang, Huiyan, Daohang Zou, Xuelong Yang, Jiegang Mou, Qiwei Zhou, and Maosen Xu. 2022. "Liquid–Gas Jet Pump: A Review" Energies 15, no. 19: 6978. https://doi.org/10.3390/en15196978