A Review on the Effects of Pretreatment and Process Parameters on Properties of Pellets

Abstract

1. Introduction

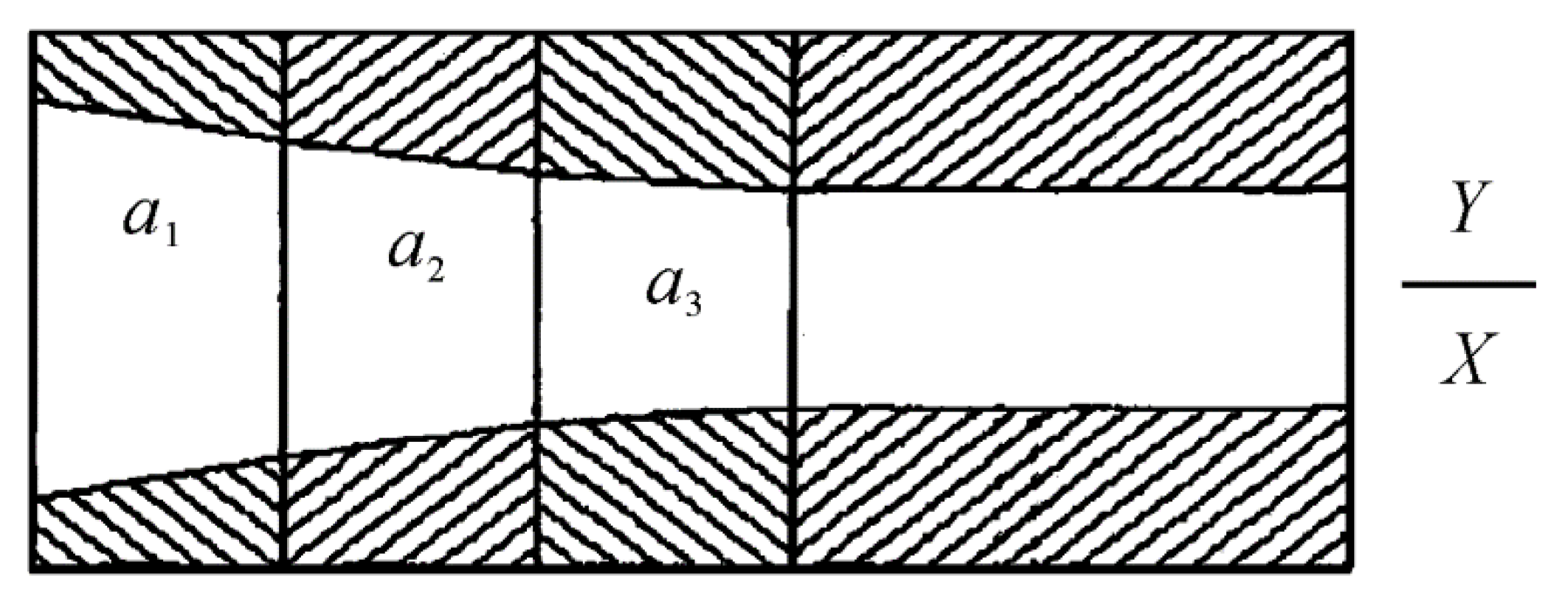

2. Integrating Pretreatment Approaches with Pelletization

2.1. Thermal Pretreatment Integrated with Pelletization

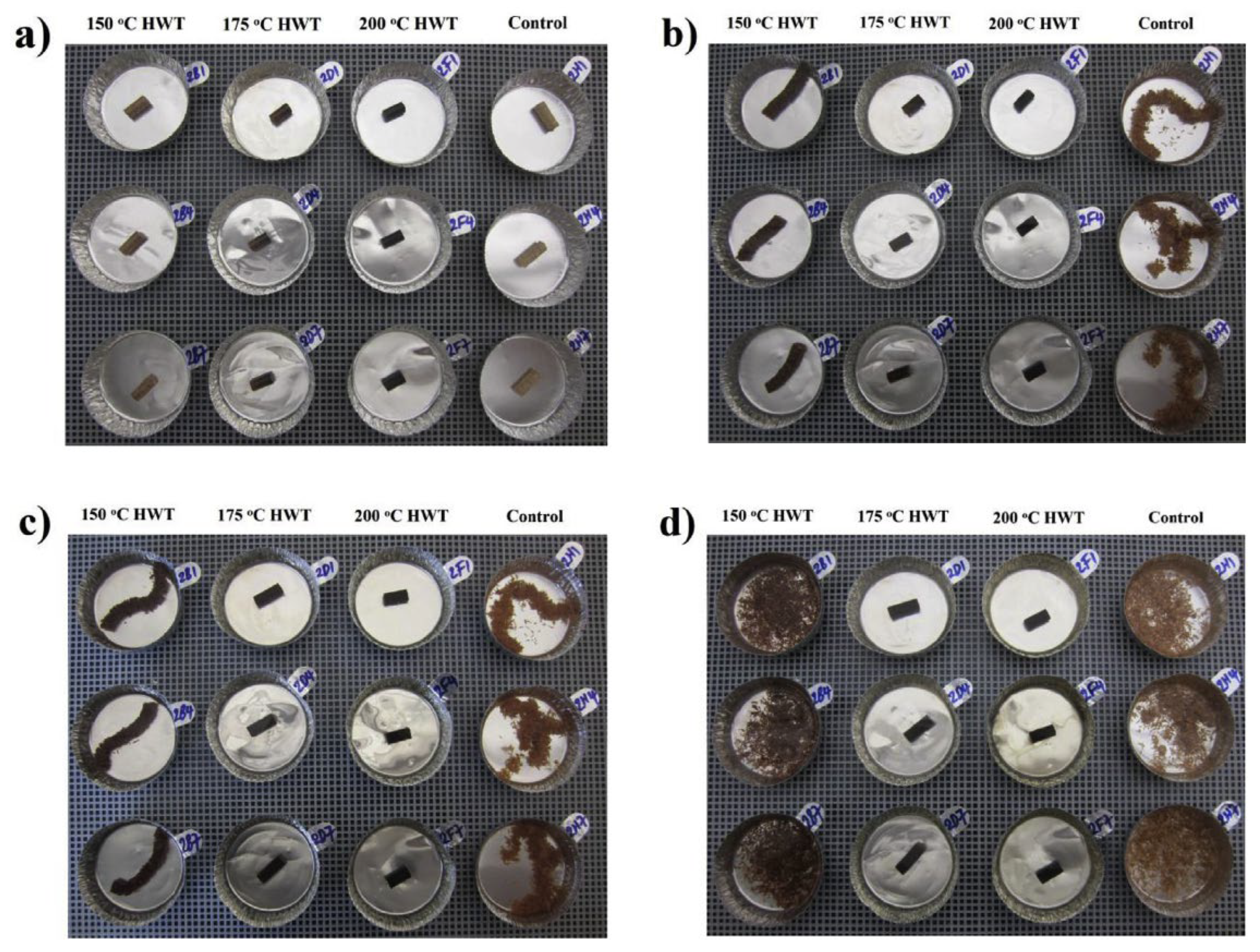

2.2. Hydrothermal Treatment before Pelletization

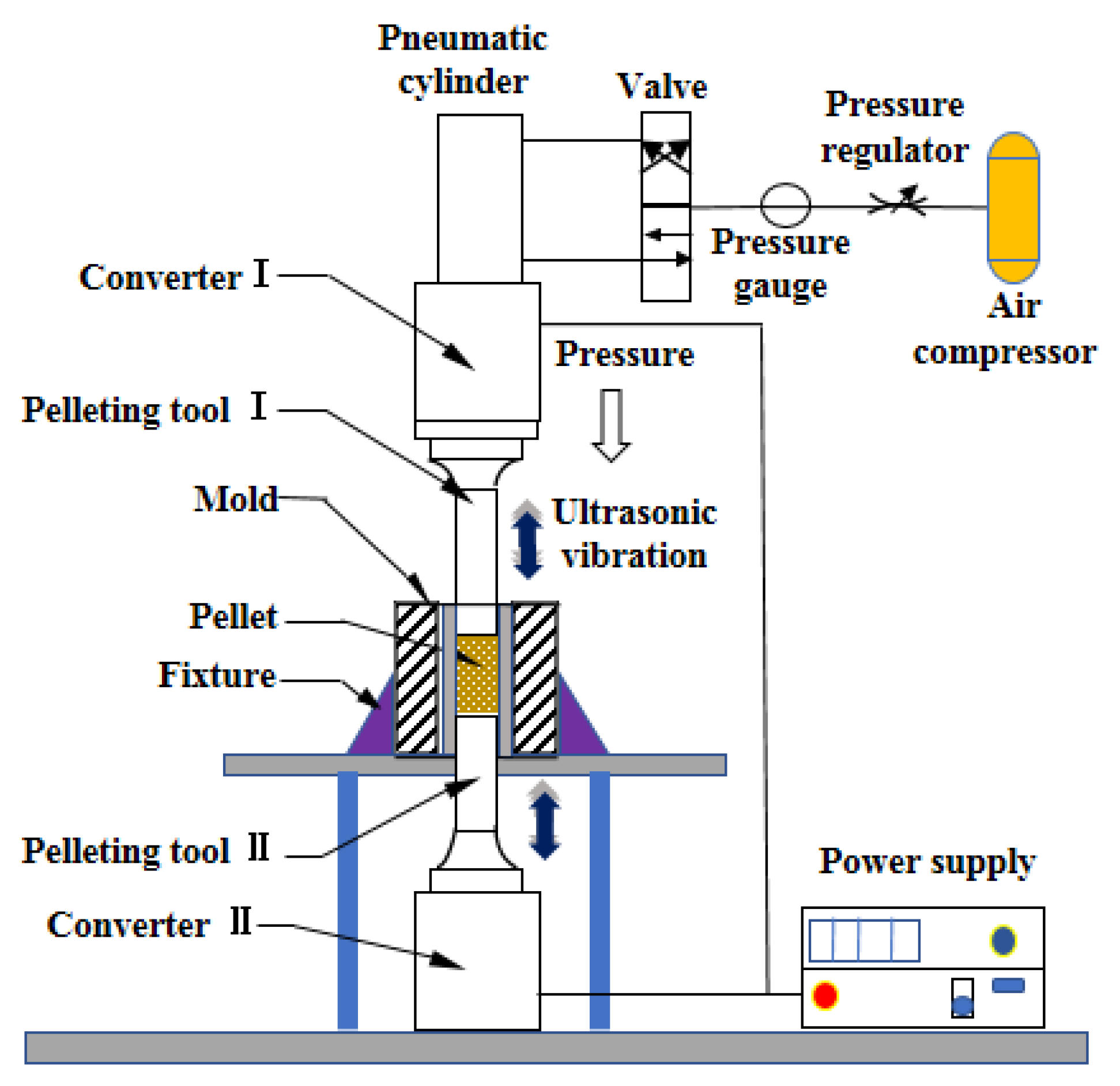

2.3. Ultrasonic Vibration-Assisted Pelleting

2.4. Supercritical Fluid Extraction

3. Effects of Process Parameters (PPs) and Characteristics of Raw Materials on the Quality of Pellets

3.1. Effects of Biomass Types

3.2. Effects of Moisture Contents

3.3. Effects of Particle Size

3.4. Effects of Pressure and Temperature

3.5. Effects of Additives

3.6. Effects of Holding Time

3.7. Effects of Pelleting Parameters

4. Summary and Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. FAOSTAT. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 29 May 2021).

- Shinde, R.; Shahi, D.K.; Mahapatra, P.; Singh, C.S.; Naik, S.K.; Thombare, N.; Singh, A.K. Management of crop residues with special reference to the on-farm utilization methods: A review. Ind. Crops Prod. 2022, 181, 114772. [Google Scholar] [CrossRef]

- Černiauskienė, Ž.; Raila, A.J.; Zvicevičius, E.; Kadžiulienė, Ž.; Tilvikienė, V. Analysis of Artemisia dubia Wall. growth, preparation for biofuel and thermal conversion properties. Renew. Energy 2018, 118, 468–476. [Google Scholar] [CrossRef]

- Bhattacharjya, S.; Sahu, A.; Manna, M.; Patra, A. Potential of surplus crop residues, horticultural waste and animal excreta as a nutrient source in the central and western regions of India. Curr. Sci. 2019, 116, 1314–1323. [Google Scholar] [CrossRef]

- Zhang, X. Present Situation Analysis and Development Suggestions of Straw Comprehensive Utilization in China in 2020. Available online: https://www.huaon.com/channel/trend/770418.html (accessed on 16 December 2021).

- Venkatramanan, V.; Shah, S.; Rai, A.K.; Prasad, R. Nexus Between Crop Residue Burning, Bioeconomy and Sustainable Development Goals Over North-Western India. Front. Energy Res. 2021, 8, 614212. [Google Scholar] [CrossRef]

- Cong, H.; Meng, H.; Yu, J.; Yao, Z.; Feng, J.; Zhao, L. Analysis of long-term mechanism for development of straw industry in northeast China under guidance of “Green-concept”. Trans. Chin. Soc. Agric. Eng. 2021, 37, 314–321. [Google Scholar] [CrossRef]

- Lohan, S.K.; Jat, H.S.; Yadav, A.K.; Sidhu, H.S.; Jat, M.L.; Choudhary, M.; Peter, J.K.; Sharma, P.C. Burning issues of paddy residue management in north-west states of India. Renew. Sustain. Energy Rev. 2018, 81, 693–706. [Google Scholar] [CrossRef]

- National Policy on Biofuel; Government of India: New Delhi, India, 2018.

- Zdzisław, W.; Beata, M.; Krzysztof, P.; Sonia, K. Biomass as the Main Source of Renewable Energy in Poland; Report: Biogas and Biofuel Production Technologies; Renewable Energy and Energy Efficiency Partnership (REEP): Vienna, Austria, 2012. [Google Scholar]

- Sun, N.; Wang, F.; Sun, R.; Wang, Y.; Wang, H.; Wang, L.; Bi, Y. Comprehensive Utilization and Experience Reference of Crop Straw in Foreign Countried. China Popul. Resour. Environ. 2016, 26, 469–474. [Google Scholar]

- Alternative Energy Development Plan: AEDP 2015; Ministry of Energy: Bangkok, Thailand, 2015.

- Wang, W.; Porninta, K.; Aggarangsi, P.; Leksawasdi, N.; Li, L.; Chen, X.; Zhuang, X.; Yuan, Z.; Qi, W. Bioenergy development in Thailand based on the potential estimation from crop residues and livestock manures. Biomass Bioenergy 2021, 144, 105914. [Google Scholar] [CrossRef]

- Huo, L.; Yao, Z.; Zhao, L.; Luo, J.; Zhang, P. Contribution and Potential of Comprehensive Utilization of Straw in GHG Emission and Carbon Sequestration. Trans. Chin. Soc. Agric. Mach. 2022, 53, 349–359. [Google Scholar] [CrossRef]

- Kulokas, M.; Praspaliauskas, M.; Pedišius, N. Investigation of Buckwheat Hulls as Additives in the Production of Solid Biomass Fuel from Straw. Energies 2021, 14, 265. [Google Scholar] [CrossRef]

- Nosek, R.; Werle, S.; Borsukiewicz, A.; Żelazna, A.; Łagód, G. Investigation of Pellet Properties Produced from a Mix of Straw and Paper Sludge. Appl. Sci. 2020, 10, 5450. [Google Scholar] [CrossRef]

- Frodeson, S.; Henriksson, G.; Berghel, J. Effects of moisture content during densification of biomass pellets, focusing on polysaccharide substances. Biomass Bioenergy 2019, 122, 322–330. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Meda, V. Characteristics of torrefied fuel pellets obtained from co-pelletization of agriculture residues with pyrolysis oil. Biomass Bioenergy 2021, 150, 106139. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Styks, J.; Wróbel, M.; Frączek, J.; Knapczyk, A. Effect of Compaction Pressure and Moisture Content on Quality Parameters of Perennial Biomass Pellets. Energies 2020, 13, 1859. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of cold densified rice straw briquettes and the potential use of sawdust as binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Sirous, R.; da Silva, F.J.N.; da Cruz Tarelho, L.A.; Martins, N.A.D. Mixed biomass pelleting potential for Portugal, step forward to circular use of biomass residues. Energy Rep. 2020, 6, 940–945. [Google Scholar] [CrossRef]

- Ríos-Badrán, I.M.; Luzardo-Ocampo, I.; García-Trejo, J.F.; Santos-Cruz, J.; Gutiérrez-Antonio, C. Production and characterization of fuel pellets from rice husk and wheat straw. Renew. Energy 2020, 145, 500–507. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Kachel-Jakubowska, M.; Niedziółka, I.; Zaklika, B.; Zawiślak, K. Impact of Various Kinds of Straw and Other Raw Materials on Physical Characteristics of Pellets. Annu. Set Environ. Prot. Rocz. Ochr. Sr. 2017, 19, 270–287. [Google Scholar]

- Minajeva, A.; Jasinskas, A.; Domeika, R.; Vaiciukevičius, E.; Lemanas, E.; Bielski, S. The Study of the Faba Bean Waste and Potato Peels Recycling for Pellet Production and Usage for Energy Conversion. Energies 2021, 14, 2954. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Warmiński, K.; Krzyżaniak, M.; Olba–Zięty, E. Cascaded use of perennial industrial crop biomass: The effect of biomass type and pre-treatment method on pellet properties. Ind. Crops Prod. 2022, 185, 115104. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Z.; Wang, Z.; Kong, W.; Feng, S.; Shen, B.; Mu, L. Integration of torrefaction and in-situ pelletization for biodried products derived from municipal organic wastes: The influences of temperature on fuel properties and combustion behaviours. Fuel 2022, 313, 122845. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Jiang, L.; Huang, B.; Xiao, Z.; Chen, X.; Wang, H.; et al. Complementary effects of torrefaction and co-pelletization: Energy consumption and characteristics of pellets. Bioresour. Technol. 2015, 185, 254–262. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Dalai, A.K.; Venkatesh, M. Physicochemical and Fuel Characteristics of Torrefied Agricultural Residues for Sustainable Fuel Production. Energy Fuels 2020, 34, 14169–14181. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Biomass energy and the environmental impacts associated with its production and utilization. Renew. Sustain. Energy Rev. 2010, 14, 919–937. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Pelletier, C.; Rogaume, Y.; Dieckhoff, L.; Bardeau, G.; Pons, M.-N.; Dufour, A. Effect of combustion technology and biogenic CO2 impact factor on global warming potential of wood-to-heat chains. Appl. Energy 2019, 235, 1381–1388. [Google Scholar] [CrossRef]

- Jiang, L.; Xue, B.; Ma, Z.; Yu, L.; Huang, B.; Chen, X. A life-cycle based co-benefits analysis of biomass pellet production in China. Renew. Energy 2020, 154, 445–452. [Google Scholar] [CrossRef]

- Saletnik, A.; Saletnik, B.; Puchalski, C. Modification of Energy Parameters in Wood Pellets with the Use of Waste Cooking Oil. Energies 2021, 14, 6486. [Google Scholar] [CrossRef]

- Huo, L.; Zhao, L.; Hao, Y.; Meng, H.; Yao, Z.; Liu, Z.; Liu, T.; Yuan, Y. Quality standard system of densified biomass fuels at home and abroad. Trans. Chin. Soc. Agric. Eng. 2020, 36, 245–254. [Google Scholar] [CrossRef]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Environmental externalities of wood pellets from fast-growing and para-rubber trees for sustainable energy production: A case in Thailand. Energy Convers. Manag. X 2022, 14, 100183. [Google Scholar] [CrossRef]

- Cutz, L.; Tiringer, U.; Gilvari, H.; Schott, D.; Mol, A.; de Jong, W. Microstructural degradation during the storage of biomass pellets. Commun. Mater. 2021, 2, 2. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statistics 2021; World Bioenergy Association (WBA): Stockholm, Sweden, 2021; pp. 1–50. [Google Scholar]

- Cui, X.; Yang, J.; Wang, Z.; Shi, X. Better use of bioenergy: A critical review of co-pelletizing for biofuel manufacturing. Carbon Capture Sci. Technol. 2021, 1, 100005. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Wang, Z. A multi-parameter optimization of the bio-pellet manufacturing process: Effect of different parameters and different feedstocks on pellet characteristics. Biomass Bioenergy 2021, 155, 106299. [Google Scholar] [CrossRef]

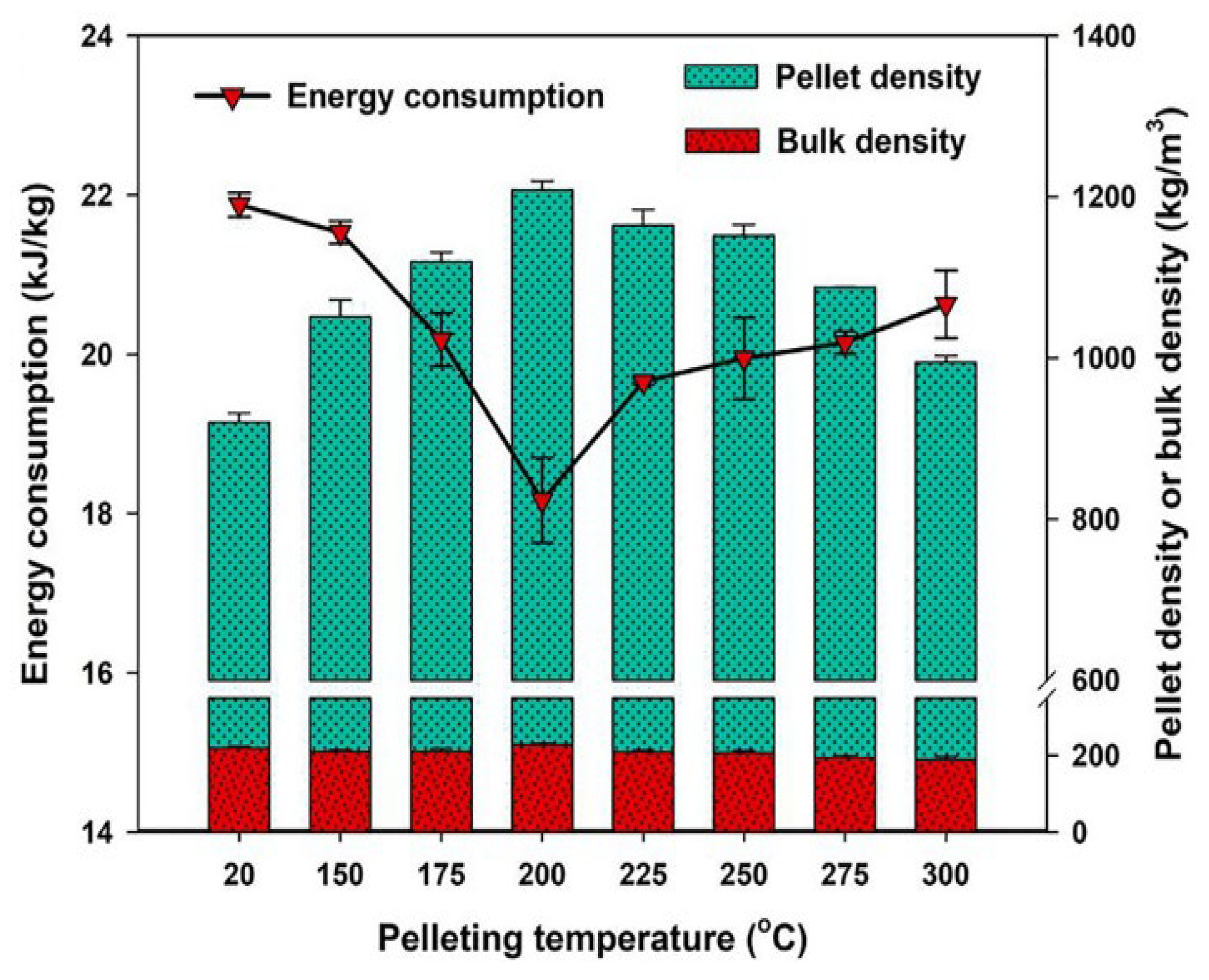

- Zhang, Q.; Zhang, P.; Pei, Z.; Rys, M.; Wang, D.; Zhou, J. Ultrasonic vibration-assisted pelleting of cellulosic biomass for ethanol manufacturing: An investigation on pelleting temperature. Renew. Energy 2016, 86, 895–908. [Google Scholar] [CrossRef]

- Zhang, Q.; Heng, L.; Zhang, P.; Pei, Z.J.; Wang, D.; Wilson, J.; Zhou, J. Comparison of two pelleting methods for cellulosic ethanol manufacturing: Ultrasonic vibration-assisted pelleting vs. ring-die pelleting. Biomass Convers. Biorefin. 2015, 6, 13–23. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Bi, X.; Zaini, P.; Tabil, L. Binderless Pelletization of Biomass. In Proceedings of the 2005 ASAE Annual International Meeting, Tampa, FL, USA, 17–20 July 2005. [Google Scholar]

- Wang, T.; Tang, L.; Feng, X.a.; Xu, J.; Ding, L.; Chen, X. Influence of organic binders on the pyrolysis performance of rice straw pellets. J. Anal. Appl. Pyrolysis 2022, 161, 105366. [Google Scholar] [CrossRef]

- Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies 2021, 14, 6529. [Google Scholar] [CrossRef]

- Gong, C.; Thomsen, S.T.; Meng, X.; Pu, Y.; Puig-Arnavat, M.; Bryant, N.; Bhagia, S.; Felby, C.; Ragauskas, A.J.; Thygesen, L.G. Effects of different pelleting technologies and parameters on pretreatment and enzymatic saccharification of lignocellulosic biomass. Renew. Energy 2021, 179, 2147–2157. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for Pretreatment of Lignocellulosic Biomass for Efficient Hydrolysis and Biofuel Production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Khan, M.F.S.; Akbar, M.; Xu, Z.; Wang, H. A review on the role of pretreatment technologies in the hydrolysis of lignocellulosic biomass of corn stover. Biomass Bioenergy 2021, 155, 106276. [Google Scholar] [CrossRef]

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol production from agricultural wastes: An overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- Gao, W.; Tabil, L.G.; Dumonceaux, T.; Ríos, S.E.; Zhao, R. Optimization of biological pretreatment to enhance the quality of wheat straw pellets. Biomass Bioenergy 2017, 97, 77–89. [Google Scholar] [CrossRef]

- Canam, T.; Town, J.R.; Tsang, A.; McAllister, T.A.; Dumonceaux, T.J. Biological pretreatment with a cellobiose dehydrogenase-deficient strain of Trametes versicolor enhances the biofuel potential of canola straw. Bioresour. Technol. 2011, 102, 10020–10027. [Google Scholar] [CrossRef]

- Guo, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Xiao, Z.; Jiang, L.; Zeng, G. Effect of pretreatment by solid-state fermentation of sawdust on the pelletization and pellet’s properties. Chin. J. Biotechnol. 2015, 31, 1449–1458. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. Comparative evaluation of torrefaction and hydrothermal carbonization of lignocellulosic biomass for the production of solid biofuel. Energy Convers. Manag. 2015, 105, 746–755. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Daniyanto; Sutidjan; Deendarlianto; Budiman, A. Torrefaction of Indonesian Sugar-cane Bagasse to Improve Bio-syngas Quality for Gasification Process. Energy Procedia 2015, 68, 157–166. [Google Scholar] [CrossRef]

- Song, X.; Yang, Y.; Zhang, M.; Zhang, K.; Wang, D. Ultrasonic pelleting of torrefied lignocellulosic biomass for bioenergy production. Renew. Energy 2018, 129, 56–62. [Google Scholar] [CrossRef]

- Abedi, A.; Dalai, A.K. Study on the quality of oat hull fuel pellets using bio-additives. Biomass Bioenergy 2017, 106, 166–175. [Google Scholar] [CrossRef]

- Sarker, T.R.; Azargohar, R.; Stobbs, J.; Karunakaran, C.; Meda, V.; Dalai, A.K. Complementary effects of torrefaction and pelletization for the production of fuel pellets from agricultural residues: A comparative study. Ind. Crops Prod. 2022, 181, 114740. [Google Scholar] [CrossRef]

- Chen, C.; Yang, R.; Wang, X.; Qu, B.; Zhang, M.; Ji, G.; Li, A. Effect of in-situ torrefaction and densification on the properties of pellets from rice husk and rice straw. Chemosphere 2022, 289, 133009. [Google Scholar] [CrossRef]

- Xia, X.; Xiao, H.; Xiao, S.; Li, B.; Song, Z.; Li, G. Research on the raw materials pretreatment technology of biomass densification process. J. Chin. Agric. Mech. 2018, 39, 61–66. [Google Scholar] [CrossRef]

- Azargohar, R.; Soleimani, M.; Nosran, S.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Tabil, L.G. Thermo-physical characterization of torrefied fuel pellet from co-pelletization of canola hulls and meal. Ind. Crops Prod. 2019, 128, 424–435. [Google Scholar] [CrossRef]

- Sarker, T.R.; Nanda, S.; Meda, V.; Dalai, A.K. Pelletization of torrefied canola residue: Effects of microwave power, residence time and bio-additives on fuel pellet quality. Fuel 2022, 312, 122728. [Google Scholar] [CrossRef]

- Siyal, A.A.; Mao, X.; Liu, Y.; Ran, C.; Fu, J.; Kang, Q.; Ao, W.; Zhang, R.; Dai, J.; Liu, G. Torrefaction subsequent to pelletization: Characterization and analysis of furfural residue and sawdust pellets. Waste Manag. 2020, 113, 210–224. [Google Scholar] [CrossRef]

- Cheng, W.; Shao, J.A.; Zhu, Y.; Zhang, W.; Jiang, H.; Hu, J.; Zhang, X.; Yang, H.; Chen, H. Effect of oxidative torrefaction on particulate matter emission from agricultural biomass pellet combustion in comparison with non-oxidative torrefaction. Renew. Energy 2022, 189, 39–51. [Google Scholar] [CrossRef]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Kim, C.S.; Sokhansanj, S. Densified biocoal from woodchips: Is it better to do torrefaction before or after densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Siyal, A.A.; Liu, Y.; Ali, B.; Mao, X.; Hussain, S.; Fu, J.; Ao, W.; Zhou, C.; Wang, L.; Liu, G.; et al. Pyrolysis of pellets prepared from pure and blended biomass feedstocks: Characterization and analysis of pellets quality. J. Anal. Appl. Pyrolysis 2022, 161, 105422. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Z.; Sun, Y.; Yang, G. One-pot pyrolysis route to Fe-N-Doped carbon nanosheets with outstanding electrochemical performance as cathode materials for microbial fuel cell. Int. J. Agric. Biol. Eng. 2020, 13, 207–214. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Borén, E.; Pommer, L.; Nordin, A.; Lestander, T.A. Combined effects of torrefaction and pelletization parameters on the quality of pellets produced from torrefied biomass. Appl. Energy 2017, 191, 414–424. [Google Scholar] [CrossRef]

- Sarker, T.R.; Pattnaik, F.; Nanda, S.; Dalai, A.K.; Meda, V.; Naik, S. Hydrothermal pretreatment technologies for lignocellulosic biomass: A review of steam explosion and subcritical water hydrolysis. Chemosphere 2021, 284, 131372. [Google Scholar] [CrossRef]

- Anukam, A.; Berghel, J.; Henrikson, G.; Frodeson, S.; Ståhl, M. A review of the mechanism of bonding in densified biomass pellets. Renew. Sustain. Energy Rev. 2021, 148, 111249. [Google Scholar] [CrossRef]

- Anukam, A.I.; Berghel, J.; Famewo, E.B.; Frodeson, S. Improving the Understanding of the Bonding Mechanism of Primary Components of Biomass Pellets through the Use of Advanced Analytical Instruments. J. Wood Chem. Technol. 2019, 40, 15–32. [Google Scholar] [CrossRef]

- Anukam, A.I.; Berghel, J.; Frodeson, S.; Famewo, E.B.; Nyamukamba, P. Characterization of Pure and Blended Pellets Made from Norway Spruce and Pea Starch: A Comparative Study of Bonding Mechanism Relevant to Quality. Energies 2019, 12, 4415. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- Larsson, S.H.; Agar, D.A.; Rudolfsson, M.; da Silva Perez, D.; Campargue, M.; Kalén, G.; Thyrel, M. Using the macromolecular composition to predict process settings that give high pellet durability in ring-die biomass pellet production. Fuel 2021, 283, 119267. [Google Scholar] [CrossRef]

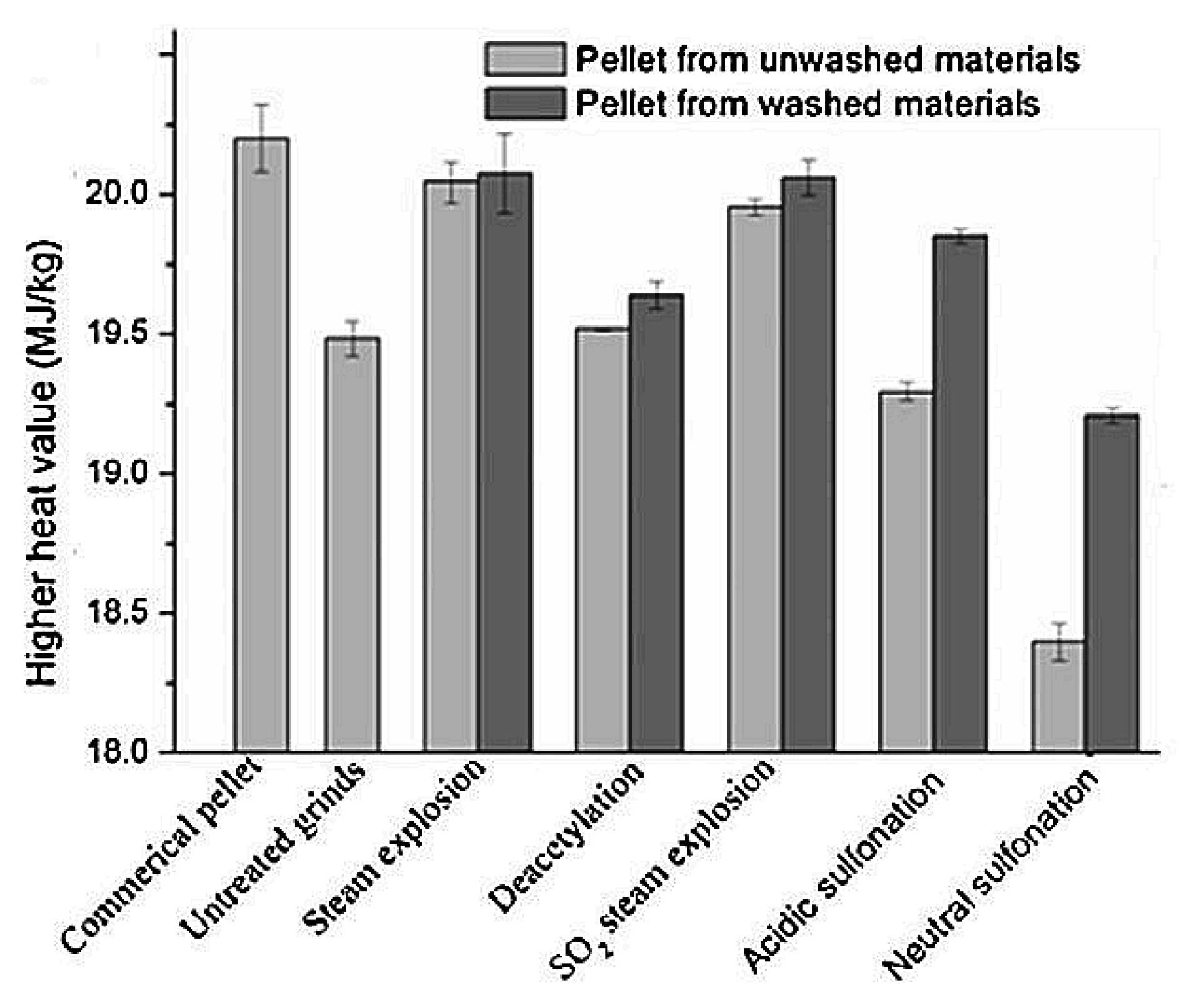

- Yu, Y.; Lau, A.; Sokhansanj, S. Improvement of the pellet quality and fuel characteristics of agricultural residues through mild hydrothermal treatment. Ind. Crops Prod. 2021, 169, 113654. [Google Scholar] [CrossRef]

- Song, X.; Zhang, S.; Wu, S.; Zhang, Y.; Cao, Z.; Wu, Y. Effect of hydrothermal treantment on physical and combustion properties of charcoal briquette prepared from biomass waste. Acta Energ. Sol. Sin. 2021, 42, 348–354. [Google Scholar] [CrossRef]

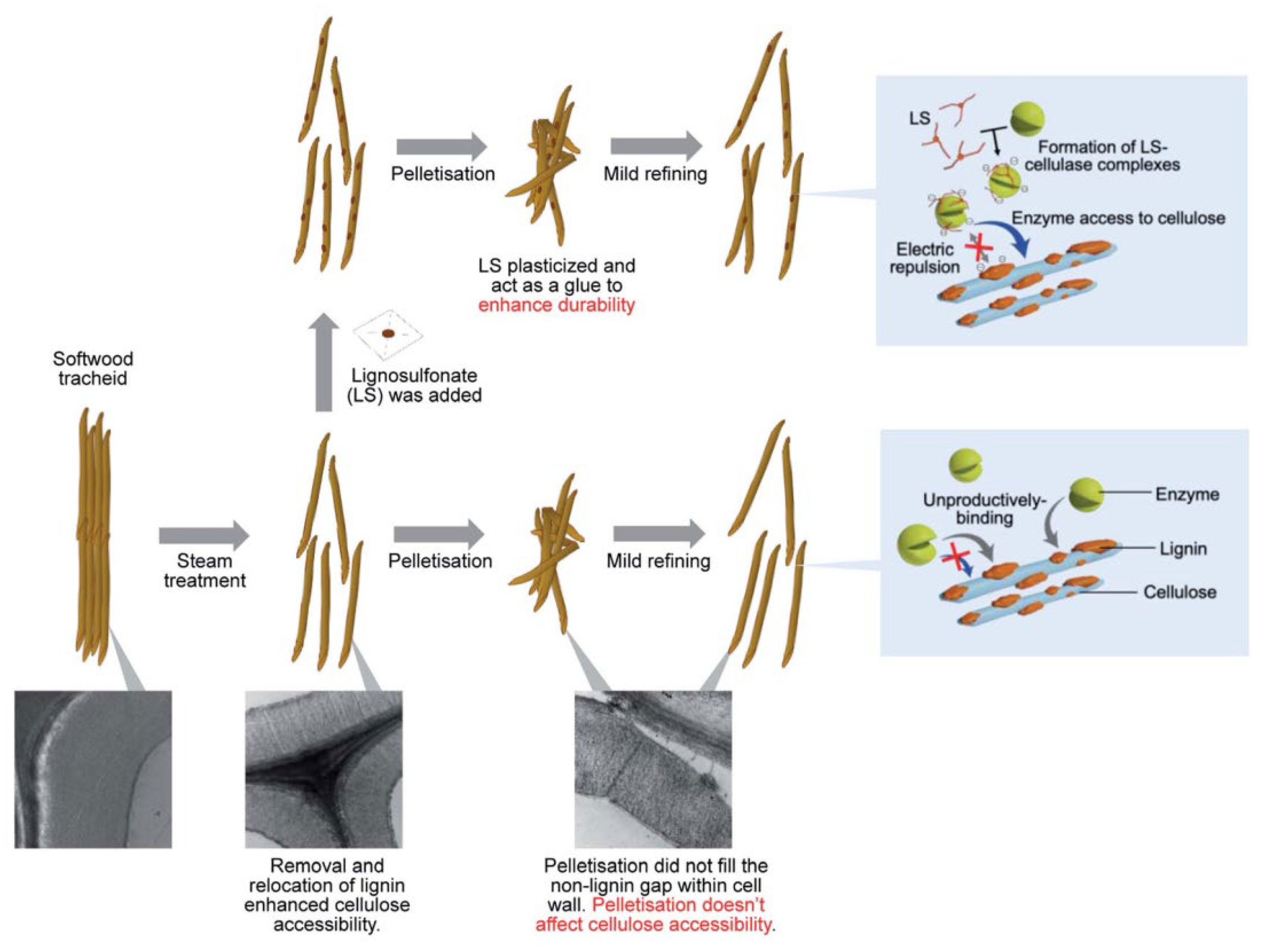

- Wu, J.; Ebadian, M.; Kim, K.H.; Kim, C.S.; Saddler, J. The use of steam pretreatment to enhance pellet durability and the enzyme-mediated hydrolysis of pellets to fermentable sugars. Bioresour. Technol. 2022, 347, 126731. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. The Role of Biomass Composition and Steam Treatment on Durability of Pellets. BioEnergy Res. 2018, 11, 341–350. [Google Scholar] [CrossRef]

- Takada, M.; Saddler, J.N. The influence of pre-steaming and lignin distribution on wood pellet robustness and ease of subsequent enzyme-mediated cellulose hydrolysis. Sustain. Energy Fuels 2021, 5, 424–429. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Kang, K.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Kozinski, J.A. Effects of bio-additives on the physicochemical properties and mechanical behavior of canola hull fuel pellets. Renew. Energy 2019, 132, 296–307. [Google Scholar] [CrossRef]

- Phani, K.A.; Lope, G.T.; Schoenau, G.J. Factors affecting the quality of biomass pellet for biofuel and energy analysis of pelleting process. Int. J. Agric. Biol. Eng. 2013, 6, 1–12. [Google Scholar] [CrossRef]

- Tang, Y.; Chandra, R.P.; Sokhansanj, S.; Saddler, J.N. Influence of steam explosion processes on the durability and enzymatic digestibility of wood pellets. Fuel 2018, 211, 87–94. [Google Scholar] [CrossRef]

- Fan, K.Q.; Tang, Y.J.; Fang, Y. Ultrasonic Vibration-Assisted Pelleting of Cellulosic Biomass: A Review. Adv. Mater. Res. 2013, 805–806, 151–155. [Google Scholar] [CrossRef]

- Song, X.; Zhang, M.; Pei, Z.J.; Wang, D. Ultrasonic vibration-assisted (UV-A) pelleting of wheat straw: A constitutive model for pellet density. Ultrasonics 2015, 60, 117–125. [Google Scholar] [CrossRef]

- Li, Y.; Ning, F.; Cong, W.; Zhang, M.; Tang, Y. Investigating pellet charring and temperature in ultrasonic vibration-assisted pelleting of wheat straw for cellulosic biofuel manufacturing. Renew. Energy 2016, 92, 312–320. [Google Scholar] [CrossRef]

- Tang, Y.; Cong, W.; Xu, J.; Zhang, P.; Liu, D. Ultrasonic vibration-assisted pelleting for cellulosic biofuels manufacturing: A study on in-pellet temperatures. Renew. Energy 2015, 76, 296–302. [Google Scholar] [CrossRef]

- Cong, W.; Pei, Z.; Zhang, P.; Qin, N.; Deines, T.W.; Lin, B. Ultrasonic-vibration-assisted pelleting of switchgrass: Effects of ultrasonic vibration. Trans. Tianjin Univ. 2011, 17, 313–319. [Google Scholar] [CrossRef]

- Song, X.; Yu, X.; Zhang, M.; Pei, Z.J.; Wang, D. A physics-based temperature model for ultrasonic vibration-assisted pelleting of cellulosic biomass. Ultrasonics 2014, 54, 2042–2049. [Google Scholar] [CrossRef]

- Zhang, Q.; Shi, Z.; Zhang, P.; Zhang, M.; Li, Z.; Chen, X.; Zhou, J. Ultrasonic-Assisted Pelleting of Sorghum Stalk: Predictive Models for Pellet Density and Durability Using Multiple Response Surface Methodology. Energies 2018, 11, 1214. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, P.; Pei, Z.J. Ultrasonic vibration-assisted pelleting of wheat straw: A predictive model for pellet density using response surface methodology. Biofuels 2014, 3, 259–267. [Google Scholar] [CrossRef]

- Xu, J.; Tang, Y.; Hu, H.; Zhang, Y. Study on the influencing factors to pellet density during dual ultrasonic vibration-assisted pelleting of sawdust. Renew. Energy Resour. 2015, 33, 143–148. [Google Scholar] [CrossRef]

- Wen, K.; Zhang, Y.; Yao, Z.; Zhang, J. Study on factors affecting pellet drop resistance during dual ultrasonic vibration-assisted pelletizing of biomass. Electromach. Mould. 2016, 1, 47–50. [Google Scholar]

- Attard, T.M.; Arshadi, M.; Nilsson, C.; Budarin, V.L.; Valencia-Reyes, E.; Clark, J.H.; Hunt, A.J. Impact of supercritical extraction on solid fuel wood pellet properties and off-gassing during storage. Green Chem. 2016, 18, 2682–2690. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Volk, T.A.; Amidon, T.E.; Shi, S. Influence of blending and hot water extraction on the quality of wood pellets. Fuel 2019, 241, 1058–1067. [Google Scholar] [CrossRef]

- Nguyen, Q.N.; Cloutier, A.; Stevanovic, T.; Achim, A. Pressurized hot water treatment of sugar maple and yellow birch wood particles for high quality fuel pellet production. Biomass Bioenergy 2017, 98, 206–213. [Google Scholar] [CrossRef]

- Zhang, Q.; Shi, Z.; Zhang, P.; Li, Z.; Jaberi-Douraki, M. Predictive temperature modeling and experimental investigation of ultrasonic vibration-assisted pelleting of wheat straw. Appl. Energy 2017, 205, 511–528. [Google Scholar] [CrossRef]

- Tumuluru, J. Pelleting of Pine and Switchgrass Blends: Effect of Process Variables and Blend Ratio on the Pellet Quality and Energy Consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

- Ma, L.; Sha, L.; Liu, X.; Zhang, S. Study of Molding and Drying Characteristics of Compressed Municipal Sludge-Corn Stalk Fuel Pellets. Energies 2021, 14, 3116. [Google Scholar] [CrossRef]

- Brand, M.A.; Rodrigues, T.M.; da Silva, J.P.; de Oliveira, J. Recovery of agricultural and wood wastes: The effect of biomass blends on the quality of pellets. Fuel 2021, 284, 118881. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The use of lignocellulosic waste in the production of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Atay, O.A.; Ekinci, K. Characterization of pellets made from rose oil processing solid wastes/coal powder/pine bark. Renew. Energy 2020, 149, 933–939. [Google Scholar] [CrossRef]

- Nosek, R.; Tun, M.M.; Juchelkova, D. Energy Utilization of Spent Coffee Grounds in the Form of Pellets. Energies 2020, 13, 1235. [Google Scholar] [CrossRef]

- Harun, N.Y.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Chojnacki, J.; Zdanowicz, A.; Ondruška, J.; Šooš, Ľ.; Smuga-Kogut, M. The Influence of Apple, Carrot and Red Beet Pomace Content on the Properties of Pellet from Barley Straw. Energies 2021, 14, 405. [Google Scholar] [CrossRef]

- Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. [Google Scholar] [CrossRef]

- Acampora, A.; Civitarese, V.; Sperandio, G.; Rezaei, N. Qualitative Characterization of the Pellet Obtained from Hazelnut and Olive Tree Pruning. Energies 2021, 14, 4083. [Google Scholar] [CrossRef]

- Lisowski, A.; Matkowski, P.; Dąbrowska, M.; Piątek, M.; Świętochowski, A.; Klonowski, J.; Mieszkalski, L.; Reshetiuk, V. Particle Size Distribution and Physicochemical Properties of Pellets Made of Straw, Hay, and Their Blends. Waste Biomass Valorization 2018, 11, 63–75. [Google Scholar] [CrossRef]

- Hettiarachchi, L.; Jayathilake, N.; Fernando, S.; Gunawardena, S. Effects of compost particle size, moisture content and binding agents on co-compost pellet properties. Int. J. Agric. Biol. Eng. 2019, 12, 184–191. [Google Scholar] [CrossRef]

- Križan, P.; Svátek, M.; Matúš, M.; Beniak, J.; Lisý, M. Determination of Compacting Pressure and Pressing Temperature Impact on Biomass Briquettes Density and Their Mutual Interactions. In Proceedings of the 4thSGEM GeoConference on Energy and Clean Technologies, Albena, Bulgaria, 17–26 June 2014; SGEM: Sofia, Bulgaria, 2014; pp. 133–140. [Google Scholar]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.-A.; Lestander, T. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Filbakk, T.; Skjevrak, G.; Høibø, O.; Dibdiakova, J.; Jirjis, R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011, 92, 871–878. [Google Scholar] [CrossRef]

- Yılmaz, H.; Çanakcı, M.; Topakcı, M.; Karayel, D. The effect of raw material moisture and particle size on agri-pellet production parameters and physical properties: A case study for greenhouse melon residues. Biomass Bioenergy 2021, 150, 106125. [Google Scholar] [CrossRef]

- Lavergne, S.; Larsson, S.H.; Da Silva Perez, D.; Marchand, M.; Campargue, M.; Dupont, C. Effect of process parameters and biomass composition on flat-die pellet production from underexploited forest and agricultural biomass. Fuel 2021, 302, 121076. [Google Scholar] [CrossRef]

- Lee, J.S.; Sokhansanj, S.; Lau, A.K.; Lim, C.J. Physical properties of wood pellets exposed to liquid water. Biomass Bioenergy 2020, 142, 105748. [Google Scholar] [CrossRef]

- Deng, T.; Alzahrani, A.M.; Bradley, M.S. Influences of environmental humidity on physical properties and attrition of wood pellets. Fuel Process. Technol. 2019, 185, 126–138. [Google Scholar] [CrossRef]

- Siyal, A.A.; Mao, X.; Liu, Y.; Ao, W.; Jiang, Z.; Wahab, N.; Ran, C.; Zhang, R.; Liu, G.; Dai, J. Pellet production from furfural residue and sawdust: Evaluating the characteristics and quality of pellets and their dependency on process parameters. Biomass Bioenergy 2021, 149, 106087. [Google Scholar] [CrossRef]

- Labbé, R.; Paczkowski, S.; Knappe, V.; Russ, M.; Wöhler, M.; Pelz, S. Effect of feedstock particle size distribution and feedstock moisture content on pellet production efficiency, pellet quality, transport and combustion emissions. Fuel 2020, 263, 116662. [Google Scholar] [CrossRef]

- Harun, N.Y.; Saeed, A.A.H.; Ramachandran, V.A.L.A. Abundant nipa palm waste as Bio-pellet fuel. Mater. Today: Proc. 2021, 42, 436–443. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Pilot scale production of fuel pellets from waste biomass leaves: Effect of milling size on pelletization process and pellet quality. Fuel 2021, 285, 119145. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Styks, J.; Knapczyk, A.; Lapczynska-Kordon, B. Effect of Compaction Pressure and Moisture Content on Post-Agglomeration Elastic Springback of Pellets. Materials 2021, 14, 879. [Google Scholar] [CrossRef]

- Frodeson, S.; Lindén, P.; Henriksson, G.; Berghel, J. Compression of Biomass Substances—A Study on Springback Effects and Color Formation in Pellet Manufacture. Appl. Sci. 2019, 9, 4302. [Google Scholar] [CrossRef]

- Li, H.; Jiang, L.-B.; Li, C.-Z.; Liang, J.; Yuan, X.-Z.; Xiao, Z.-H.; Wang, H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness, and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Jewiarz, M.; Mudryk, K.; Wróbel, M.; Frączek, J.; Dziedzic, K. Parameters Affecting RDF-Based Pellet Quality. Energies 2020, 13, 910. [Google Scholar] [CrossRef]

- Chen, X.; Liang, J.; Liao, P.; Huang, W.; He, J.; Chen, J. Effect of process parameters and raw material characteristics on the physical and mechanical quality of sugarcane bagasse pellets. Biomass Bioenergy 2021, 154, 106242. [Google Scholar] [CrossRef]

- García, R.; Gil, M.V.; Fanjul, A.; González, A.; Majada, J.; Rubiera, F.; Pevida, C. Residual pyrolysis biochar as additive to enhance wood pellets quality. Renew. Energy 2021, 180, 850–859. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, J.; Liu, Z.; Li, Y.; Xu, C. Effect of CaO and MgO additives on the compressive strength of pellets: Exploration on the decisive stage during induration. Powder Technol. 2021, 390, 496–503. [Google Scholar] [CrossRef]

- Zhao, H.X.; Zhou, F.S.; Evelina, A.L.M.; Liu, J.L.; Zhou, Y. A review on the industrial solid waste application in pelletizing additives: Composition, mechanism and process characteristics. J. Hazard Mater. 2022, 423, 127056. [Google Scholar] [CrossRef]

- Ji, S.; Qi, Y.; Wang, M.; Ma, R.; Ge, P. Effect of Additives on Combustion Characteristics of Straw Briquette Fuel. Biomass Chem. Eng. 2019, 53, 47–53. [Google Scholar] [CrossRef]

- Li, Y.; Tan, Z.; Zhu, Y.; Zhang, W.; Du, Z.; Shao, J.; Jiang, L.; Yang, H.; Chen, H. Effects of P-based additives on agricultural biomass torrefaction and particulate matter emissions from fuel combustion. Renew. Energy 2022, 190, 66–77. [Google Scholar] [CrossRef]

- Wang, Q.; Han, K.; Gao, J.; Wang, J.; Lu, C. Investigation of Maize Straw Char Briquette Ash Fusion Characteristics and the Influence of Phosphorus Additives. Energy Fuels 2017, 31, 2822–2830. [Google Scholar] [CrossRef]

- Han, K.; Gao, J.; Qi, J. The study of sulphur retention characteristics of biomass briquettes during combustion. Energy 2019, 186, 115788. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, B.; Su, Y. Advanced control of NO emission from algal biomass combustion using loaded iron-based additives. Energy 2019, 185, 229–238. [Google Scholar] [CrossRef]

- Han, J.; Yu, D.; Wu, J.; Yu, X.; Liu, F.; Wang, J.; Xu, M. Fine Ash Formation and Slagging Deposition during Combustion of Silicon-Rich Biomasses and Their Blends with a Low-Rank Coal. Energy Fuels 2019, 33, 5875–5882. [Google Scholar] [CrossRef]

- Roberts, L.J.; Mason, P.E.; Jones, J.M.; Gale, W.F.; Williams, A.; Hunt, A.; Ashman, J. The impact of aluminosilicate-based additives upon the sintering and melting behaviour of biomass ash. Biomass Bioenergy 2019, 127, 105284. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H. High-pressure densication of wood residues to form an upgraded fuel. Biomass Bioenergy 2000, 19, 177–186. [Google Scholar] [CrossRef]

- Xu, G.; Wang, S.; Yu, S.; Zhou, G.; Wang, C.; Wei, H.; Wang, C. Progress in Finite Element Analysis of Solidification Forming of Biomass Materials. J. Chongqing Univ. Technol. Nat. Sci. 2020, 34, 205–218. [Google Scholar] [CrossRef]

- Choi, J.-H.; Lee, H.-W.; Lee, J.-W. Effects of chemical composition of Miscanthus sacchariflorus var. No. 1 on pelletizing, focusing on optimal pressure and compression ratio. Ind. Crops Prod. 2021, 161, 113189. [Google Scholar] [CrossRef]

- Segerström, M.; Larsson, S.H. Clarifying sub-processes in continuous ring die pelletizing through die temperature control. Fuel Process. Technol. 2014, 123, 122–126. [Google Scholar] [CrossRef]

- Liu, X.; Feng, X.; Huang, L.; He, Y. Rapid Determination of Wood and Rice Husk Pellets’ Proximate Analysis and Heating Value. Energies 2020, 13, 3741. [Google Scholar] [CrossRef]

| Quality Parameters | Temperature (°C) | |||||

|---|---|---|---|---|---|---|

| 200 | 250 | 300 | 450 | 650 | 850 | |

| Particle density (g/cm3) | ||||||

| Raw FRPs 1.38 ± 0.01 | PYFRPs | |||||

| aRT-15 min | 1.309 ± 0.01 | 1.25 ± 0.01 | 1.16 ± 0.01 | 1.188 ± 0.01 | 1.141 ± 0.00 | 1.119 ± 0.00 |

| RT-30 min | 1.29 ± 0.02 | 1.248 ± 0.01 | 1.166 ± 0.01 | 1.172 ± 0.01 | 1.146 ± 0.01 | 1.128 ± 0.01 |

| RT-45 min | 1.279 ± 0.01 | 1.24 ± 0.02 | 1.169 ± 0.02 | 1.169 ± 0.01 | 1.154 ± 0.01 | 1.146 ± 0.02 |

| Raw SSPs 1.517 ± 0.02 | PYSSPs | |||||

| aRT-15 min | 1.459 ± 0.01 | 1.409 ± 0.02 | 1.354 ± 0.01 | 1.259 ± 0.01 | 1.209 ± 0.01 | 1.181 ± 0.07 |

| RT-30 min | 1.448 ± 0.02 | 1.406 ± 0.02 | 1.349 ± 0.01 | 1.254 ± 0.01 | 1.201 ± 0.02 | 1.178 ± 0.07 |

| RT-45 min | 1.446 ± 0.01 | 1.4 ± 0.02 | 1.334 ± 0.01 | 1.25 ± 0.01 | 1.193 ± 0.01 | 1.167 ± 0.01 |

| Raw FRSSPs 1.296 ± 0.02 | PYFRSSPs | |||||

| aRT-15 min | 1.237 ± 0.02 | 1.221 ± 0.01 | 1.08 ± 0.01 | 1.043 ± 0.01 | 1.007 ± 0.01 | 1.004 ± 0.01 |

| RT-30 min | 1.222 ± 0.01 | 1.198 ± 0.02 | 1.071 ± 0.02 | 1.041 ± 0.01 | 1.006 ± 0.01 | 0.993 ± 0.01 |

| RT-45 min | 1.219 ± 0.01 | 1.194 ± 0.01 | 1.064 ± 0.01 | 1.039 ± 0.01 | 0.998 ± 0.01 | 0.989 ± 0.02 |

| Volumetric energy density (kJ/m3) | ||||||

| Raw FRPs 29.3 ± 0.00 | PYFRPs | |||||

| RT-30 min | 28.66 ± 0.17 | 29.66 ± 0.23 | 29.86 ± 0.16 | 30.35 ± 0.15 | 30.12 ± 0.17 | 30.18 ± 0.16 |

| Raw SSPs 12.38 ± 0.00 | PYSSPs | |||||

| RT-30 min | 12.26 ± 0.24 | 11.36 ± 0.13 | 10.17 ± 0.14 | 8.92 ± 0.15 | 8.34 ± 0.11 | 7.88 ± 0.15 |

| Raw FRSSPs 26.56 ± 0.00 | PYFRSSPs | |||||

| RT-30 min | 25.17 ± 0.13 | 25.08 ± 0.14 | 24.14 ± 0.17 | 23.85 ± 0.14 | 23.84 ± 0.17 | 23.56 ± 0.10 |

| Strength (N/mm2) | ||||||

| Raw FRPs 5.92 ± 0.79 | PYFRPs | |||||

| RT-15 min | 5.435 ± 0.90 | 5.147 ± 0.46 | 3.81 ± 0.86 | 1.891 ± 0.25 | 1.394 ± 0.08 | 1.267 ± 0.03 |

| RT-30 min | 5.238 ± 0.78 | 4.542 ± 0.59 | 3.35 ± 0.76 | 1.751 ± 0.41 | 1.197 ± 0.24 | 1.025 ± 0.05 |

| RT-45 min | 4.892 ± 0.64 | 4.368 ± 0.82 | 3.04 ± 0.48 | 1.63 ± 0.45 | 1.101 ± 0.07 | 0.859 ± 0.11 |

| Raw SSPs 5.238 ± 0.22 | PYSSPs | |||||

| RT-15 min | 4.297 ± 0.06 | 3.263 ± 0.14 | 2.085 ± 0.13 | 1.114 ± 0.05 | 1.012 ± 0.05 | 0.837 ± 0.03 |

| RT-30 min | 3.804 ± 0.12 | 3.104 ± 0.08 | 1.926 ± 0.07 | 1.038 ± 0.06 | 0.99 ± 0.07 | 0.805 ± 0.04 |

| RT-45 min | 3.785 ± 0.28 | 3.059 ± 0.55 | 1.795 ± 0.24 | 0.945 ± 0.04 | 0.95 ± 0.05 | 0.719 ± 0.04 |

| Raw FRSSPs 5.68 ± 0.18 | PYFRSSPs | |||||

| RT-15 min | 5.465 ± 0.34 | 4.985 ± 0.02 | 3.711 ± 0.07 | 2.218 ± 0.09 | 1.909 ± 0.23 | 1.798 ± 0.1 |

| RT-30 min | 5.159 ± 0.65 | 4.94 ± 0.21 | 3.403 ± 0.04 | 2.145 ± 0.06 | 1.836 ± 0.08 | 1.655 ± 0.03 |

| RT-45 min | 5.013 ± 0.32 | 4.833 ± 0.09 | 3.23 ± 0.04 | 2.104 ± 0.11 | 1.821 ± 0.04 | 1.566 ± 0.04 |

| Feedstock | Additives | Effects | Ref. |

|---|---|---|---|

| Jack pine, balsam fir and black spruce | Starch, lignosulphonate, and pyrolytic lignin | Starch and lignosulphonate could not link torrefied fibers, making pellets easy to crush by hand. Only 15% of pyrolytic lignin produced pellets with good durability. | [45] |

| Oat hull | Proline, lignin and sunflower oil | Pellets with lignin content ≥15% and proline content ≥5% had the highest density, durability, and hardness. Adding sunflower oil increased the HHV, and decreased the ash content, density, durability, and hardness of the pellets. | [58] |

| Canola residue | Mustard meal, lignin and Pyrolysis-derived bio-oil | Mustard meal significantly improved the physical and mechanical properties of the pellets. A combination of lignin, mustard meal, and bio-oil produced the best quality pellet from torrefied biomass, with 100% durability and 1.2 MPa tensile strength. | [63] |

| Furfural residue and sawdust | Synthetic resin | The particle density of the wood pellets was increased and, after storage time of 2 weeks, remained the same as the initial particle density. Die temperature and specific energy consumption were decreased. | [117] |

| Cornstalk | Phosphorus-based additive (NH4H2PO4) | Enhanced the removal of O and the tension of C; effectively reduced the mass and energy losses during torrefaction; decreased the absolute content of Cl and S in the torrefied fuel. | [132] |

| Maize straw | Calcium phosphate monobasic and ammonium dihydrogen phosphate | Ash fusion temperatures and fusion phenomena were greatly improved by adding NH4H2PO4 and Ca(H2PO4)2. | [134] |

| Cotton straw, rice straw, maize straw, pine sawdust, and poplar wood | Fugu coal (bituminous coal) and inorganic additives (CaCO3, CaO, K2CO3) | Fugu coal improved the calorific value, and the potassium-based additives had a higher improvement than the calcium-based ones. | [135] |

| Algal biomass | Iron-based additives (Fe, Fe2+ and Fe3+) | The inhibitory effects of Fe2+ and Fe3+ were comparable, but better than those of Fe. Increased the concentration of the iron-based additive load, which had a significant inhibitory effect. | [136] |

| Corn stalk, rice husks and their blends | Low-rank coal | Promoted the release of alkali chlorides while inhibiting the vaporization of Ca, Mg, and Fe. The slagging was efficiently inhibited. | [137] |

| Olive-cake and white-wood | Coal pulverized fuel ash and kaolin powder | Increased the flow temperature of the ash compositions. Significantly reduced sintering and clearly inhibited KCl release. Al–Si additive use should be restricted to high K, high Cl biomass. | [138] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Wang, M.; Meng, F.; Zhang, Y.; Zhang, B. A Review on the Effects of Pretreatment and Process Parameters on Properties of Pellets. Energies 2022, 15, 7303. https://doi.org/10.3390/en15197303

Li W, Wang M, Meng F, Zhang Y, Zhang B. A Review on the Effects of Pretreatment and Process Parameters on Properties of Pellets. Energies. 2022; 15(19):7303. https://doi.org/10.3390/en15197303

Chicago/Turabian StyleLi, Wentao, Mingfeng Wang, Fanbin Meng, Yifei Zhang, and Bo Zhang. 2022. "A Review on the Effects of Pretreatment and Process Parameters on Properties of Pellets" Energies 15, no. 19: 7303. https://doi.org/10.3390/en15197303

APA StyleLi, W., Wang, M., Meng, F., Zhang, Y., & Zhang, B. (2022). A Review on the Effects of Pretreatment and Process Parameters on Properties of Pellets. Energies, 15(19), 7303. https://doi.org/10.3390/en15197303