Hemp Biocomposite Boards Using Improved Magnesium Oxychloride Cement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used

2.2. Mixing Technology

2.3. Curing Conditions and Testing of the Samples

3. Results and Discussion

3.1. Binder Properties

3.1.1. Workability and Setting Time

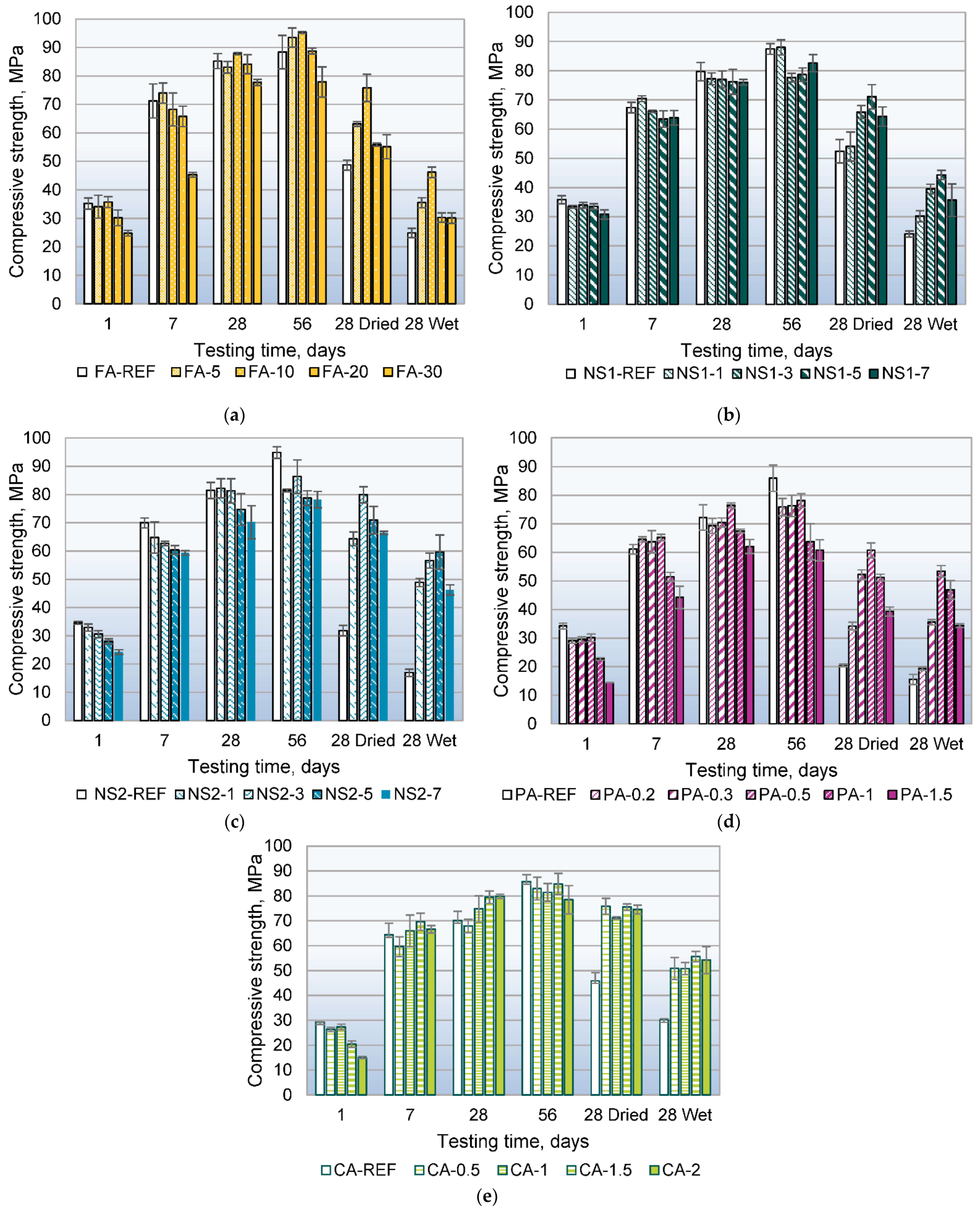

3.1.2. Compressive Strength and Softening Coefficient

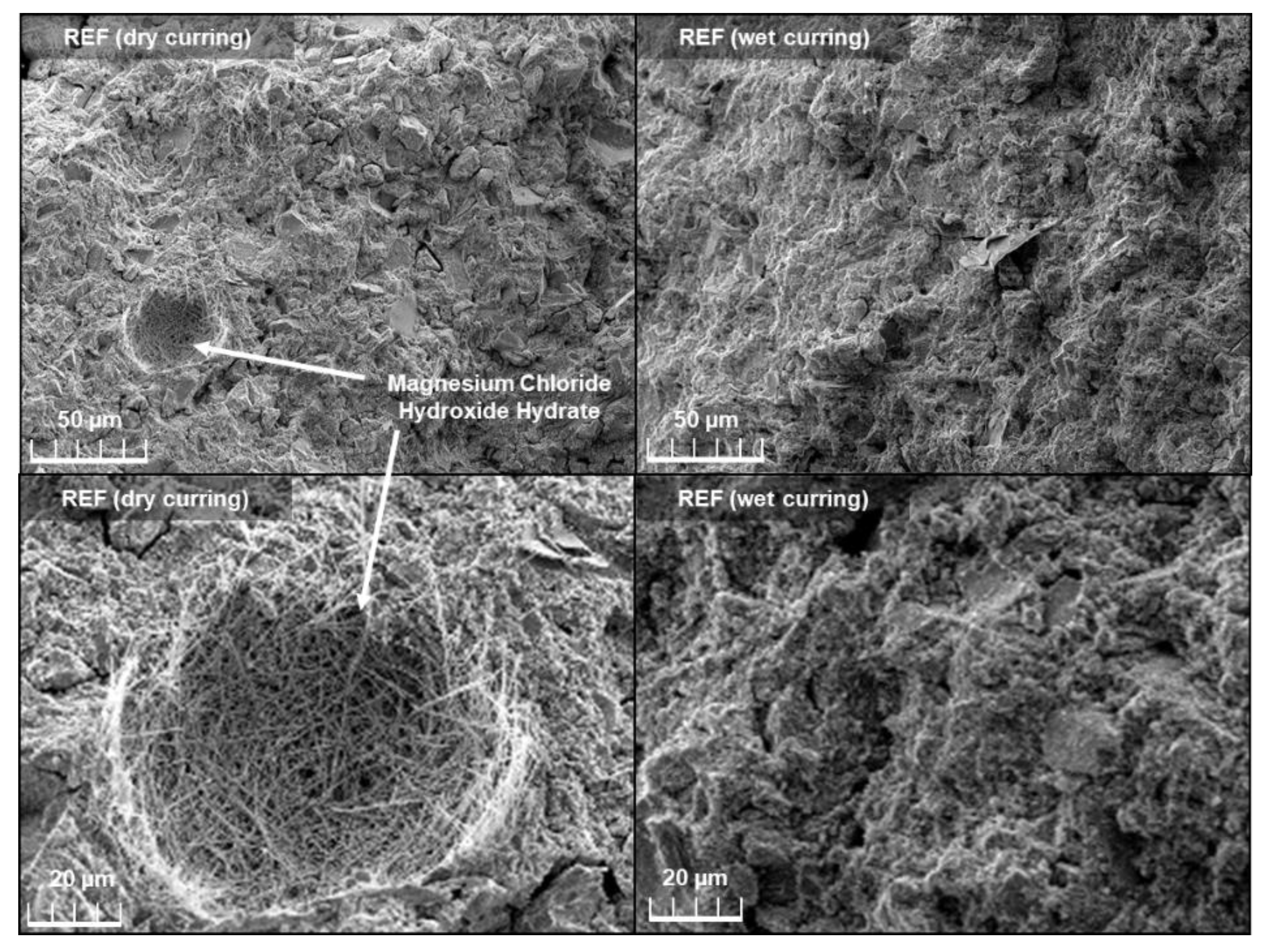

3.1.3. XRD and SEM Analysis

3.2. Biocomposite Properties

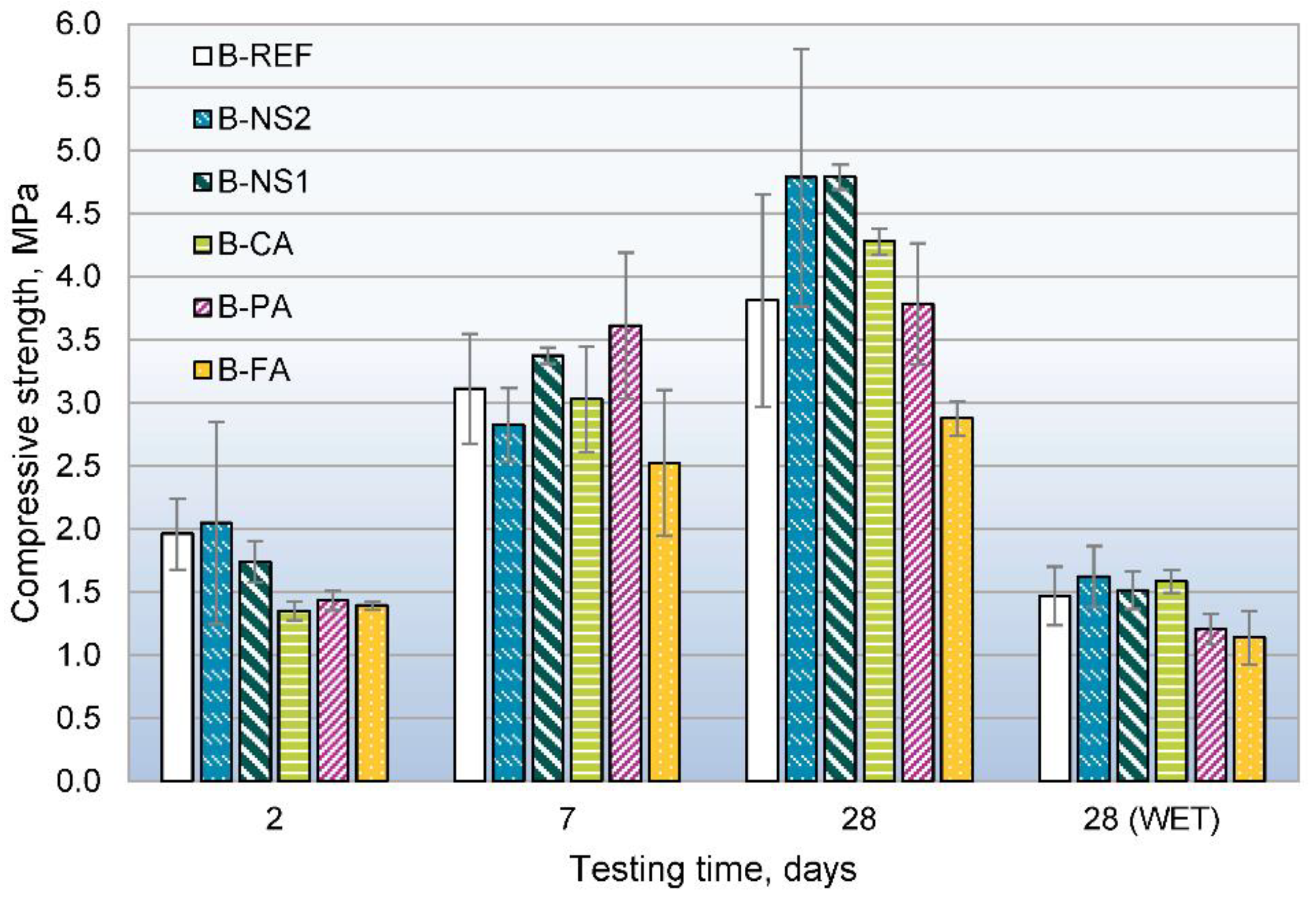

3.2.1. Compressive Strength and Softening Coefficient

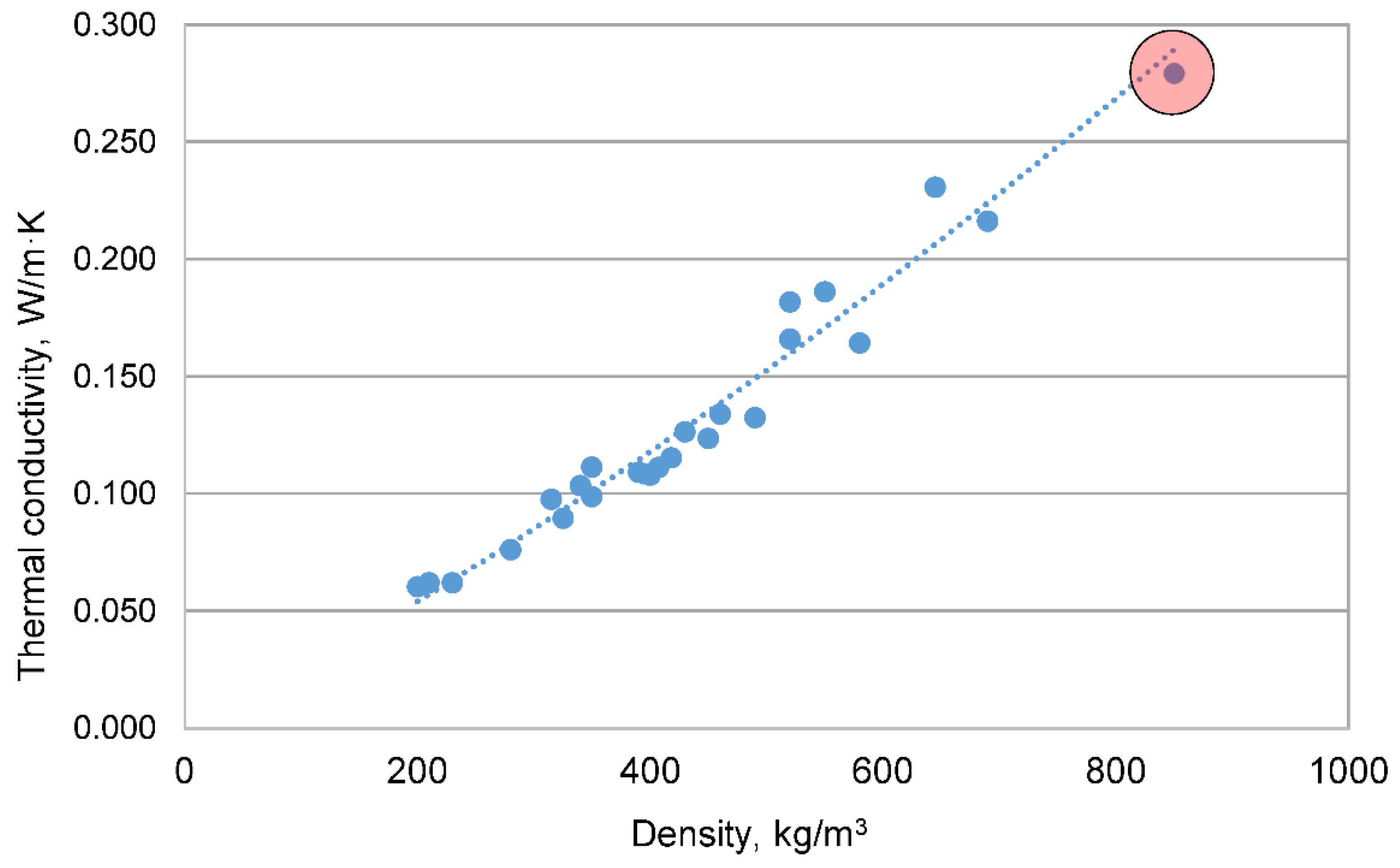

3.2.2. Thermal Conductivity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ripple, W.J.; Wolf, C.; Newsome, T.M.; Barnard, P.; Moomaw, W.R. World Scientists’ Warning of a Climate Emergency. Bioscience 2020, 70, 8–12. [Google Scholar] [CrossRef]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council Establishing the Framework for Achieving Climate Neutrality and Amending REGULATION (EU) 2018/1999 (European Climate Law); EN: Brussels, Belgium, 2020; pp. 1–58. [Google Scholar]

- Zlaugotne, B.; Ievina, L.; Azis, R.; Baranenko, D.; Blumberga, D. GHG Performance Evaluation in Green Deal Context. Environ. Clim. Technol. 2020, 24, 431–441. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Hu, F.; Wang, Y. Comparison of evaluation standards for green building in China, Britain, United States. Renew. Sustain. Energy Rev. 2017, 68, 262–271. [Google Scholar] [CrossRef]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Brümmer, M.; Durán-Suárez, J.A. A review of the factors affecting the properties and performance of hemp aggregate concretes. J. Build. Eng. 2020, 31, 101323. [Google Scholar] [CrossRef]

- Wang, L.; Lenormand, H.; Zmamou, H.; Leblanc, N. Effect of variability of hemp shiv on the setting of lime hemp concrete. Ind. Crop. Prod. 2021, 171, 113915. [Google Scholar] [CrossRef]

- Shang, Y.; Tariku, F. Hempcrete building performance in mild and cold climates: Integrated analysis of carbon footprint, energy, and indoor thermal and moisture buffering. Build. Environ. 2021, 206, 108377. [Google Scholar] [CrossRef]

- Arehart, J.H.; Nelson, W.S.; Srubar, W.V. On the theoretical carbon storage and carbon sequestration potential of hempcrete. J. Clean. Prod. 2020, 266, 121846. [Google Scholar] [CrossRef]

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and thermal properties of lime and hemp concrete (“hempcrete”) manufactured by a projection process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Kidalova, L.; Terpakova, E.; Stevulova, N. MgO cement as suitable conventional binders replacement in hemp concrete. Pollack Period. 2011, 6, 115–122. [Google Scholar] [CrossRef]

- Sinka, M.; van den Heede, P.; de Belie, N.; Bajare, D.; Sahmenko, G.; Korjakins, A. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resour. Conserv. Recycl. 2018, 133C, 288–299. [Google Scholar] [CrossRef]

- Qiao, H.; Cheng, Q.; Wang, J.; Shi, Y. The application review of magnesium oxychloride cement. J. Chem. Pharm. Res. 2014, 6, 180–185. [Google Scholar]

- Walling, S.A.; Provis, J.L. Magnesia-Based Cements: A Journey of 150 Years, and Cements for the Future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Yu, Y.; Li, J.; Wang, Y.; Liu, H. Experimental study on urban refuse/magnesium oxychloride cement compound floor tile. Cem. Concr. Res. 2003, 33, 1663–1668. [Google Scholar] [CrossRef]

- Gong, W.; Wang, N.; Zhang, N.; Han, W.; Qiao, H. Water resistance and a comprehensive evaluation model of magnesium oxychloride cement concrete based on Taguchi and entropy weight method. Constr. Build. Mater. 2020, 260, 119817. [Google Scholar] [CrossRef]

- He, P.; Poon, C.S.; Tsang, D.C.W. Water resistance of magnesium oxychloride cement wood board with the incorporation of supplementary cementitious materials. Constr. Build. Mater. 2020, 255, 119145. [Google Scholar] [CrossRef]

- Chen, F. Study on preparation and properties of modified magnesium oxysulfate cements. Chem. Eng. Trans. 2017, 62, 973–978. [Google Scholar]

- Xu, K.; Xi, J.; Guo, Y.; Dong, S. Effects of a new modifier on the water-resistance of magnesite cement tiles. Solid State Sci. 2012, 14, 10–14. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Hu, C.; Yang, S.; Li, Z. Influence of curing regimes on mechanical properties of magnesium oxychloride cement-based composites. Constr. Build. Mater. 2016, 102, 613–619. [Google Scholar] [CrossRef]

- Chau, C.K.; Chan, J.; Li, Z. Influences of fly ash on magnesium oxychloride mortar. Cem. Concr. Compos. 2009, 31, 250–254. [Google Scholar] [CrossRef]

- Jin, Y.; Xiao, L.; Luo, F. Influence of fly ash on the properties of magnesium oxychloride cement. Adv. Mater. Res. 2013, 662, 406–408. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H.; Zheng, L.; Wen, J.; Wu, C.; Tan, Y. Compressive strength of fly ash magnesium oxychloride cement containing granite wastes. Constr. Build. Mater. 2013, 38, 1–7. [Google Scholar] [CrossRef]

- Sikora, P.; Rucinska, T.; Stephan, D.; Chung, S.Y.; Elrahman, M.A. Evaluating the effects of nanosilica on the material properties of lightweight and ultra-lightweight concrete using image-based approaches. Constr. Build. Mater. 2020, 264, 120241. [Google Scholar] [CrossRef]

- Yuan, Z.Y.; Liu, X.L.; Jia, Y.F.; Liu, P.; Li, M.C. Modification research on the water-resistance of magnesium oxychloride cement. Appl. Mech. Mater. 2013, 423–426, 1027–1030. [Google Scholar] [CrossRef]

- Guan, B.; Tian, H.; Ding, D.; Wu, J.; Xiong, R.; Xu, A.; Chen, H. Effect of Citric Acid on the Time-Dependent Rheological Properties of Magnesium Oxychloride Cement. J. Mater. Civ. Eng. 2018, 30, 4018275. [Google Scholar] [CrossRef]

- Zhang, N.; Yu, H.; Gong, W.; Liu, T.; Wang, N.; Tan, Y.; Wu, C. Effects of low- and high-calcium fly ash on the water resistance of magnesium oxysulfate cement. Constr. Build. Mater. 2020, 230, 116951. [Google Scholar] [CrossRef]

- Huang, J.; Ge, S.; Wang, H.; Chen, R. Study on the improvement of water resistance and water absorption of magnesium oxychloride cement using long-chain organosilane-nonionic surfactants. Constr. Build. Mater. 2021, 306, 124872. [Google Scholar] [CrossRef]

- Li, M.; Gu, K.; Chen, B. Effects of flue gas desulfurisation gypsum incorporation and curing temperatures on magnesium oxysulfate cement. Constr. Build. Mater. 2022, 349, 128718. [Google Scholar] [CrossRef]

- Guan, H.; Lu, J.F.; Ba, H.J. On the volume stability of Magnesium oxychloride cement-based materials. J. Shenzhen Univ. Sci. Eng. 2009, 26, 296–300. [Google Scholar]

- Kastiukas, G.; Zhou, X.; Neyazi, B.; Wan, K.T. Sustainable Calcination of Magnesium Hydroxide for Magnesium Oxychloride Cement Production. J. Mater. Civ. Eng. 2019, 31, 04019110. [Google Scholar] [CrossRef] [Green Version]

- Ye, Q.; Wang, W.; Zhang, W.; Li, J.; Chen, H. Tuning the phase structure and mechanical performance of magnesium oxychloride cements by curing temperature and H2O/MgCl2 ratio. Constr. Build. Mater. 2018, 179, 413–419. [Google Scholar] [CrossRef]

- Kumari, L.; Li, W.Z.; Vannoy, C.H.; Leblanc, R.M.; Wang, D.Z. Synthesis, characterisation and optical properties of Mg(OH)2 micro-/nanostructure and its conversion to MgO. Ceram. Int. 2009, 35, 3355–3364. [Google Scholar] [CrossRef]

- Góchez, R.; Wambaugh, J.; Rochner, B.; Kitchens, C.L. Kinetic study of the magnesium oxychloride cement cure reaction. J. Mater. Sci. 2017, 52, 7637–7646. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, Y.; Grover, L. Effect of phosphoric acid on the properties of magnesium oxychloride cement as a biomaterial. Cem. Concr. Res. 2014, 56, 69–74. [Google Scholar] [CrossRef]

- Aiken, T.A.; Russell, M.; McPolin, D.; Bagnall, L. Magnesium oxychloride boards: Understanding a novel building material. Mater. Struct. Constr. 2020, 53, 1–16. [Google Scholar] [CrossRef]

- Vitola, L.; Sinka, M.; Korjakins, A.; Bajare, D. Impact of Organic Compounds Extracted from Hemp-Origin Aggregates on the Hardening Process and Compressive Strength of Different Types of Mineral Binders. J. Mater. Civ. Eng. 2020, 32, 04020386. [Google Scholar] [CrossRef]

- Barbieri, V.; Gualtieri, M.L.; Manfredini, T.; Siligardi, C. Lightweight concretes based on wheat husk and hemp hurd as bio-aggregates and modified magnesium oxysulfate binder: Microstructure and technological performances. Constr. Build. Mater. 2021, 284, 122751. [Google Scholar] [CrossRef]

- Terpáková, E.; Kidalová, L.; Eštoková, A.; Čigášová, J.; Števulová, N. Chemical modification of hemp shives and their characterisation. Procedia Eng. 2012, 42, 931–941. [Google Scholar] [CrossRef] [Green Version]

- Sinka, M.; Sahmenko, G. Sustainable thermal insulation biocomposites from locally available hemp and lime. Vide. Tehnologija. Resur.-Environ. Technol. Resour. 2013, 1, 73–77. [Google Scholar] [CrossRef] [Green Version]

- Sinka, M.; Korjakins, A.; Bajare, D.; Zimele, Z.; Sahmenko, G. Bio-based construction panels for low carbon development. Energy Procedia 2018, 147, 220–226. [Google Scholar] [CrossRef]

| Name | MgO, % | SiO2, % | Al2O3, % | CaO, % | K2O, % | SO3, % | Fe2O3, % | Na2O, % | Density, g/cm3 |

|---|---|---|---|---|---|---|---|---|---|

| Magnesia | 73.0 | 4.0 | 1.0 | 4.0 | - | - | 3.0 | - | 0.8 |

| Fly ash | 1.33 | 50.77 | 27.51 | 2.89 | 2.22 | 0.65 | 6.43 | 0.6 | - |

| CB8 | - | 50 | - | - | - | - | - | - | 1.4 |

| CB50 | - | 15 | - | - | - | - | - | - | 1.1 |

| Fibres, % | Skins/ leaves, % | Part. < 1 mm, % | Shives | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1–5 mm,% | 5–10 mm, % | 10–15 mm, % | 15–20 mm, % | 20–25 mm, % | 25–30 mm, % | 30–35 mm, % | 35–40 mm, % | |||

| 2.49 | 11.18 | 2.00 | 13.57 | 21.95 | 15.47 | 12.77 | 4.58 | 5.64 | 4.19 | 6.15 |

| Name | MgO | MgCl2 1:1 | Add. Water | FA | NS1 | NS2 | PA | CA |

|---|---|---|---|---|---|---|---|---|

| FA-REF | 1 | 0.60 | - | - | - | - | - | - |

| FA-5 | 0.95 | 0.57 | - | 0.05 | - | - | - | - |

| FA-10 | 0.90 | 0.54 | - | 0.10 | - | - | - | - |

| FA-20 | 0.80 | 0.48 | 0.025 | 0.20 | - | - | - | - |

| FA-30 | 0.70 | 0.42 | 0.050 | 0.30 | - | - | - | - |

| NS1-REF | 1 | 0.6 | - | - | - | - | - | - |

| NS1-1 | 1 | 0.6 | - | - | 0.01 | - | - | - |

| NS1-3 | 1 | 0.6 | - | - | 0.03 | - | - | - |

| NS1-5 | 1 | 0.6 | - | - | 0.05 | - | - | - |

| NS1-7 | 1 | 0.6 | - | - | 0.07 | - | - | - |

| NS2-REF | 1 | 0.6 | - | - | - | - | - | - |

| NS2-1 | 1 | 0.6 | - | - | - | 0.01 | - | - |

| NS2-3 | 1 | 0.6 | - | - | - | 0.03 | - | - |

| NS2-5 | 1 | 0.6 | - | - | - | 0.05 | - | - |

| NS2-7 | 1 | 0.6 | - | - | - | 0.07 | - | - |

| PA-REF | 1 | 0.6 | - | - | - | - | - | - |

| PA-0.2 | 1 | 0.6 | - | - | - | - | 0.002 | - |

| PA-0.3 | 1 | 0.6 | - | - | - | - | 0.003 | - |

| PA-0.5 | 1 | 0.6 | - | - | - | - | 0.005 | - |

| PA-1 | 1 | 0.6 | - | - | - | - | 0.010 | - |

| PA-1.5 | 1 | 0.6 | - | - | - | - | 0.015 | - |

| CA-REF | 1 | 0.6 | - | - | - | - | - | - |

| CA-0.5 | 1 | 0.6 | - | - | - | - | - | 0.005 |

| CA-1 | 1 | 0.6 | - | - | - | - | - | 0.010 |

| CA-1.5 | 1 | 0.6 | - | - | - | - | - | 0.015 |

| CA-2 | 1 | 0.6 | - | - | - | - | - | 0.020 |

| Name | MgO | MgCl2 1:1 Solution | Additive | Hemp Shives | H2O for Hemp Shives |

|---|---|---|---|---|---|

| B-REF | 1 | 0.6 | - | 0.25 | 0.25 |

| B-FA | 0.95 | 0.57 | 0.05 | 0.25 | 0.25 |

| B-NS1 | 1 | 0.6 | 0.05 | 0.25 | 0.25 |

| B-NS2 | 1 | 0.6 | 0.05 | 0.25 | 0.25 |

| B-PA | 1 | 0.6 | 0.005 | 0.25 | 0.25 |

| B-CA | 1 | 0.6 | 0.005 | 0.25 | 0.25 |

| Name | Initial Flow Diameter, mm | Diameter After Jolting 15 Times, mm | Setting Time, min | |

|---|---|---|---|---|

| tinitial | tfinal | |||

| FA-REF | 115 | 230 | 58 | 118 |

| FA-5 | 100 | 210 | 71 | 120 |

| FA-10 | 100 | 205 | 62 | 140 |

| FA-20 | 100 | 195 | 55 | 138 |

| FA-30 | 100 | 185 | 50 | 150 |

| NS1-REF | 105 | 225 | 57 | 112 |

| NS1-1 | 110 | 225 | 70 | 135 |

| NS1-3 | 120 | 235 | 63 | 127 |

| NS1-5 | 145 | 247 | 64 | 123 |

| NS1-7 | 160 | 260 | 65 | 114 |

| NS2-REF | 115 | 235 | 62 | 118 |

| NS2-1 | 115 | 245 | 50 | 133 |

| NS2-3 | 115 | 250 | 54 | 126 |

| NS2-5 | 115 | 245 | 72 | 126 |

| NS2-7 | 120 | 245 | 80 | 125 |

| PA-REF | 125 | 245 | 60 | 130 |

| PA-0.2 | 150 | 270 | 122 | 212 |

| PA-0.3 | 135 | 255 | 108 | 213 |

| PA-0.5 | 125 | 250 | 120 | 203 |

| PA-1 | 105 | 190 | 113 | 243 |

| PA-1.5 | 100 | 170 | 95 | 225 |

| CA-REF | 165 | 265 | 60 | 120 |

| CA-0.5 | 170 | 290 | 130 | 190 |

| CA-1 | 145 | 255 | 223 | 318 |

| CA-1.5 | 155 | 250 | 233 | 352 |

| CA-2 | 165 | 260 | 267 | 380 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zorica, J.; Sinka, M.; Sahmenko, G.; Vitola, L.; Korjakins, A.; Bajare, D. Hemp Biocomposite Boards Using Improved Magnesium Oxychloride Cement. Energies 2022, 15, 7320. https://doi.org/10.3390/en15197320

Zorica J, Sinka M, Sahmenko G, Vitola L, Korjakins A, Bajare D. Hemp Biocomposite Boards Using Improved Magnesium Oxychloride Cement. Energies. 2022; 15(19):7320. https://doi.org/10.3390/en15197320

Chicago/Turabian StyleZorica, Jelizaveta, Maris Sinka, Genadijs Sahmenko, Laura Vitola, Aleksandrs Korjakins, and Diana Bajare. 2022. "Hemp Biocomposite Boards Using Improved Magnesium Oxychloride Cement" Energies 15, no. 19: 7320. https://doi.org/10.3390/en15197320

APA StyleZorica, J., Sinka, M., Sahmenko, G., Vitola, L., Korjakins, A., & Bajare, D. (2022). Hemp Biocomposite Boards Using Improved Magnesium Oxychloride Cement. Energies, 15(19), 7320. https://doi.org/10.3390/en15197320