A Coal Seam Thickness Prediction Model Based on CPSAC and WOA–LS-SVM: A Case Study on the ZJ Mine in the Huainan Coalfield

Abstract

:1. Introduction

2. The CPSAC

3. The WOA–LS-SVM Coal Seam Thickness Prediction Model

3.1. The Whale Optimization Algorithm (WOA)

3.1.1. Surrounding the Prey

3.1.2. Bubble-Net Attacks

3.1.3. Random Search

3.2. The Least Squares Support Vector Machine (LS-SVM)

3.3. The Coal Thickness Prediction Model

4. Application Cases

4.1. Overview of the Study Area

4.2. Seismic Attribute Extraction and Preference

4.2.1. Seismic Attribute Extraction

4.2.2. Seismic Attribute Preference

4.3. Coal Thickness Prediction

5. Discussion

5.1. Comparison of the Results of Prediction Models

5.2. Prediction Accuracy

5.3. Analysis of the Factors Affecting Prediction Accuracy

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. The Main Implementation Steps of the CPSAC

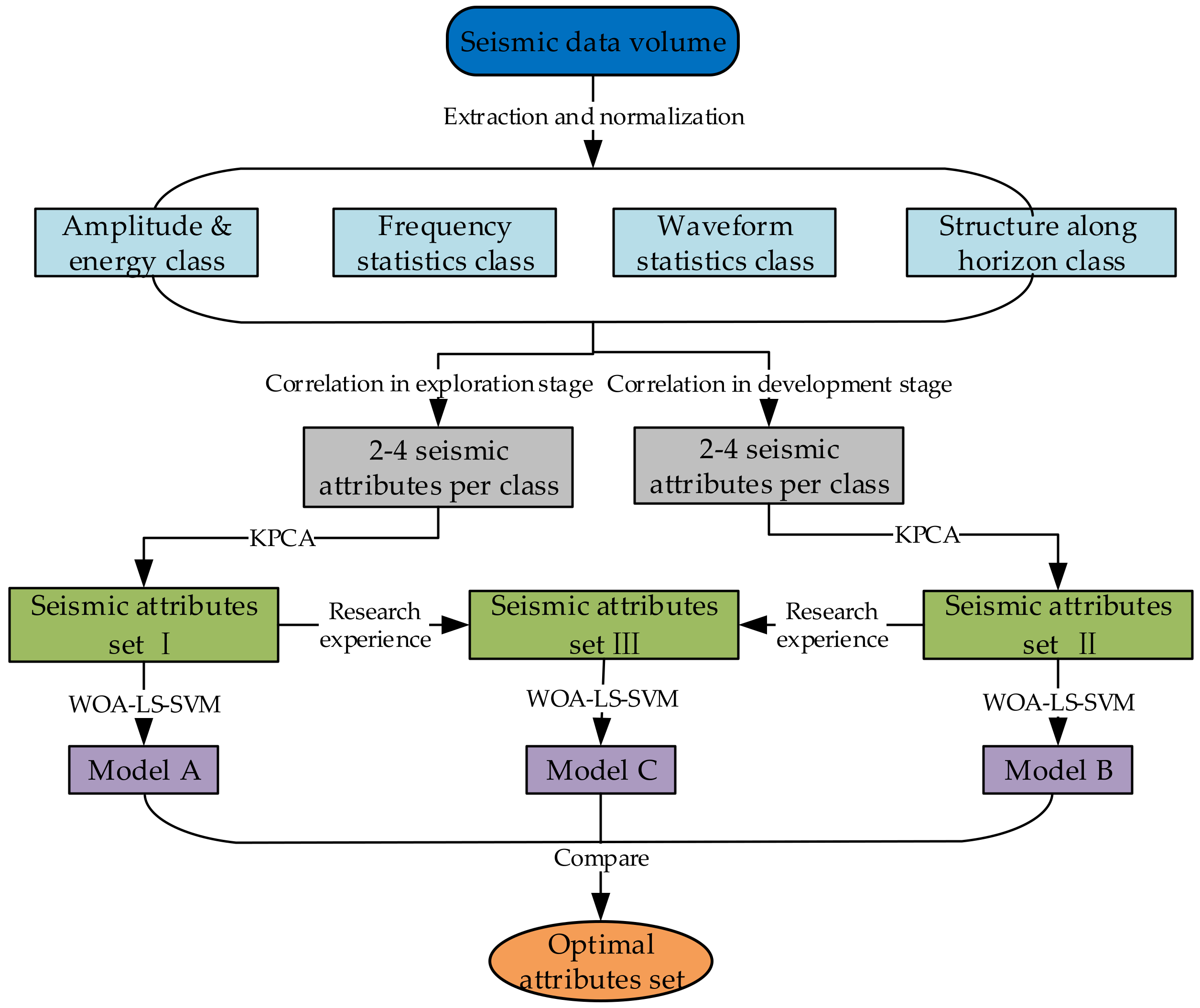

- Based on the amplitude and energy class, frequency statistics class, waveform statistics class, and structure along horizon class, multiple more commonly used seismic attributes were extracted from the seismic data volume and normalized to the 0–1 interval (i.e., the data were mapped to the [0, 1] interval uniformly). The purpose of normalization was to limit the preprocessed data to a certain range, thus eliminating the adverse effects caused by odd sample data to facilitate later data analysis.

- Coal thickness correlation analysis was separately performed for each major class of seismic attributes, and two to four seismic attributes with high correlation and relative independence of changes in the coal thickness data exposed in the coal exploration stage, were preferably selected to facilitate precise prediction of the coal seam thickness characteristics and improve the accuracy of their description.

- Because of the nonlinear relationship between coal thickness and multiple seismic attributes, a set of seismic attribute sets was developed using attribute dimension reduction algorithms, such as KPCA, to select the primary seismic attributes whose cumulative principal element variance contribution values exceeded a set threshold (95%) as a set of input parameters for the coal thickness prediction model.

- Moreover, the seismic attributes were preferentially selected by amplitude and energy and other major classes (i.e., the cumulative coal thickness data obtained in the exploration and development stages were used as samples), and two to four seismic attributes with high correlation and relative independence of the coal thickness variation were selected from each major category of seismic attributes. The novel seismic attribute combinations were reacquired using the dimension reduction algorithm for seismic attributes. Furthermore, based on the results of the two attribute preferences, a third set of seismic attribute combinations was obtained by combining seismic attribute selection experience and regional seismic attribute characteristics in similar previous studies.

- The coal thickness data and corresponding seismic attribute data obtained in the exploration and development stages of the study area were used as training samples, and a training model based on the prediction of coal thickness between coal thickness and multiple seismic attributes was established according to three different combinations of seismic attributes. The thickness of the coal seams at the geological sampling points in the first mining face in the mining stage was predicted.

- Comparing the thickness predicted by the three prediction models with the actual coal thickness data obtained for the first mining face, the seismic attribute combination with the highest prediction accuracy was selected as the base parameter for the prediction model of coal thickness in the working faces in the later mining stages.

Appendix B. Whale Optimization Algorithm Pseudocode

- Input: Fitness function, whale population

- Output: Optimal solution

- Step 1. Set the parameter values involved in the algorithm: the population size N, the maximum number of iterations Max_iter, the variation scale factor F, the constant coefficient b of the spiral formula, and the positions of all whale individuals within the population, and randomly generate the relevant parameter values of A, C, a, p and l.

- Step 2. Randomly generate the positions of all individuals in the population and calculate their fitness, then record the best whale positions and their fitness values.

- Step 3. while (t < Max_iter)

- Step 4. for j = 1:N

- Step 5. if p < 0.5

- Step 6. if abs(A) ≥ 1

- Step 7. Update the current whale position based on a random whale position

- Step 8. else abs(A) < 1

- Step 9. Update the current whale position based on the prey location

- Step 10. end

- Step 11. end

- Step 12. else p ≥ 0.5

- Step 13. Update the whale position according to Archimedes’ spiral formula

- Step 14. t = t + 1

- Step 15. end

- Step 16. Return the optimal solution

Appendix C. Construction Process of the WOA–LS-SVM Coal Thickness Prediction Model

- Preprocess the coal thickness data and seismic attribute data to obtain the input sample dataset.

- Initialize the whale population with the empirical values of γ and δ: set the population size N, spiral formula coefficient b, number of iterations t and Max_iter, variation scale factor F, spiral formula constant coefficient, and positions of all whale individuals in the population. Randomly produce the relevant parameter values of A, C, a, p, and l.

- Train the LS-SVM prediction models using the processed datasets.

- Calculate the fitness value of all individual whales in the population according to the fitness function (Equation (C1)), and record the current best fitness value and the best whale location:

- Update the values of parameters A, C, and a according to Equations (3) and (4), respectively, and generate the values of p and l.

- If p < 0.5 and |A| < 1, update the whale individual position according to the following equation:

- If p ≥ 0.5, update the whale position according to the following equation:

- Determine whether the maximum number of iterations has been reached. If so, the algorithm optimization is complete; otherwise, return to step (3) and continue the execution.

- The optimal whale individual positions are saved as two parameters of the LS-SVM, and then the WOA–LS-SVM prediction model is constructed.

Appendix D. Classes and Preliminary Data of Seismic Attributes

| Classes of Seismic Attributes | Seismic Attributes |

|---|---|

| Amplitude and energy class | Amplitudes, average energy, average magnitude, average peak value, average positive amplitude, average positive peak value, maximum amplitude, mean amplitude, median, minimum amplitude, rms amplitude, standard deviation of amplitude, sum of amplitudes, sum of magnitudes, sum of positive, ari poststack amplitude, geo poststack amplitude, ins poststack amplitude, std poststack amplitude, ins poststack amplitude, half energy, extract value, geometric mean, harmonic mean |

| Frequency class | Arc length, dominant frequency-rms amplitude, envelope-rms amplitude, instantaneous bandwidth rms amplitude, instantaneous frequency rms amplitude |

| Waveform statistics class | Interval average arithmetic, loop asymmetry, loop kurtosis, lower loop area, lower loop duration, upper loop area, upper loop duration, upper loop skewness |

| Structure along horizon class | Ins curvature, contour curvature, curvedness, dip, dip azimuth, edge preserving, filter mean irregular, edge preserving filter mean regular, edge preserving filter median irregular, edge preserving filter median regular, Gaussian curvature, Lambertian reflectance, local variability, max filter, maximum curvature, mean curvature, mean filter, median filter, min filter minimum curvature, most negative curvature, most positive curvature, Prewitt filter (crossline), Prewitt filter (inline), Roberts filter (A), Roberts filter (B), second-order derivative, shape index, Sobel filter (crossline), Sobel filter (inline), strike, strike curvature, throw |

| Borehole | Average Energy | Average Positive Peak Value | Maximum Amplitude | Rms Amplitude | Envelope Rms Amplitude | Arc Length | Upper Loop Area | Interval Average | Median Filter | Mean Filter | Mean Regular |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10-1 | 0.24734 | 0.37067 | 0.36099 | 0.36670 | 0.42314 | 0.59133 | 0.24158 | 0.31760 | 0.22788 | 0.22895 | 0.22243 |

| 10-2 | 0.25752 | 0.36265 | 0.37980 | 0.37841 | 0.44891 | 0.47926 | 0.32274 | 0.33318 | 0.36245 | 0.36397 | 0.37221 |

| 10-3 | 0.20610 | 0.28233 | 0.27068 | 0.31746 | 0.33184 | 0.42534 | 0.28182 | 0.35632 | 0.55390 | 0.55391 | 0.55196 |

| 10-4 | 0.74598 | 0.89622 | 0.90211 | 0.82138 | 0.89872 | 1.00000 | 0.70994 | 0.76017 | 0.63792 | 0.64508 | 0.63157 |

| 10-5 | 0.42886 | 0.55546 | 0.56641 | 0.55575 | 0.58881 | 0.64747 | 0.45856 | 0.54545 | 0.70260 | 0.70272 | 0.70139 |

| 11-1 | 0.16829 | 0.16914 | 0.17579 | 0.26946 | 0.24480 | 0.16039 | 0.22323 | 0.35534 | 0.12454 | 0.12336 | 0.12462 |

| 11-3 | 0.22555 | 0.25540 | 0.26370 | 0.34106 | 0.33155 | 0.27319 | 0.28182 | 0.39319 | 0.03346 | 0.03230 | 0.02867 |

| 12-1 | 0.00000 | 0.29877 | 0.03551 | 0.00000 | 0.00000 | 0.08401 | 0.01313 | 0.00000 | 0.08030 | 0.08595 | 0.00957 |

| 12-2 | 0.19545 | 0.25926 | 0.27772 | 0.30424 | 0.31036 | 0.32716 | 0.19933 | 0.32798 | 0.12639 | 0.12917 | 0.10967 |

| 12-3 | 0.51546 | 0.57705 | 0.56836 | 0.63463 | 0.62176 | 0.44945 | 0.62250 | 0.69112 | 0.55390 | 0.55391 | 0.55196 |

| 12-4 | 0.46744 | 0.57150 | 0.58822 | 0.59162 | 0.61842 | 0.56883 | 0.55263 | 0.62408 | 0.87435 | 0.87731 | 0.86077 |

| E2 | 0.13815 | 0.16231 | 0.15750 | 0.22885 | 0.22601 | 0.25856 | 0.14955 | 0.26073 | 0.75279 | 0.75883 | 0.74632 |

| 10 + 1 | 0.89419 | 0.95207 | 0.99029 | 0.92837 | 1.00000 | 0.98616 | 0.88321 | 0.84382 | 0.85502 | 0.85756 | 0.85221 |

| Borehole/Coal Spot | Std Poststack Amplitude | Ins Poststack Amplitude | Maximum Amplitude | Geo Poststack Amplitude | Average Energy | Envelope Rms Amplitude | Arc Length | Upper Loop Area | Interval Average Arithmetic | Shape Index | Strike |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10-1 | 0.54842 | 0.34390 | 0.36099 | 0.71213 | 0.24734 | 0.42313 | 0.59133 | 0.24158 | 0.31760 | 0.59496 | 0.81939 |

| 10-2 | 0.53605 | 0.21998 | 0.37980 | 0.69421 | 0.25752 | 0.44891 | 0.47926 | 0.32274 | 0.33318 | 0.09768 | 0.83471 |

| 10-3 | 0.37879 | 0.40940 | 0.27068 | 0.48431 | 0.20610 | 0.33184 | 0.42534 | 0.28182 | 0.35632 | 0.41322 | 0.51014 |

| 10-4 | 0.91780 | 0.95075 | 0.90211 | 0.78463 | 0.74598 | 0.89872 | 1.00000 | 0.70994 | 0.76017 | 0.11820 | 0.99252 |

| 10-5 | 0.62119 | 0.56842 | 0.56641 | 0.74925 | 0.42886 | 0.58881 | 0.64747 | 0.45856 | 0.54545 | 0.83656 | 0.00000 |

| 11-1 | 0.26955 | 0.30958 | 0.17579 | 0.51197 | 0.16829 | 0.24480 | 0.16039 | 0.22323 | 0.35534 | 0.79731 | 0.88172 |

| 11-3 | 0.39595 | 0.38564 | 0.26370 | 0.62988 | 0.22555 | 0.33155 | 0.27319 | 0.28182 | 0.39319 | 0.87353 | 0.00000 |

| 12-1 | 0.00000 | 0.05397 | 0.03551 | 0.25242 | 0.00000 | 0.00000 | 0.08401 | 0.01313 | 0.00000 | 0.43895 | 0.05751 |

| 12-2 | 0.30452 | 0.36591 | 0.27772 | 0.51804 | 0.19545 | 0.31036 | 0.32716 | 0.19933 | 0.32798 | 0.79078 | 0.00000 |

| 12-3 | 0.63974 | 0.66929 | 0.56836 | 0.57137 | 0.51546 | 0.62176 | 0.44945 | 0.62250 | 0.69112 | 0.41322 | 0.51014 |

| 12-4 | 0.61710 | 0.61462 | 0.58822 | 0.72638 | 0.46744 | 0.61842 | 0.56883 | 0.55262 | 0.62408 | 0.43858 | 0.59334 |

| E2 | 1.00000 | 0.13553 | 0.15750 | 0.51251 | 0.13815 | 0.22601 | 0.25856 | 0.14955 | 0.26073 | 0.00000 | 0.11328 |

| 10 + 1 | 0.39876 | 1.00000 | 0.99029 | 1.00000 | 0.89419 | 1.00000 | 0.98616 | 0.88321 | 0.84382 | 0.44032 | 0.63369 |

| W1-1 | 0.39876 | 0.35831 | 0.39245 | 0.62586 | 0.32261 | 0.44680 | 0.40307 | 0.38580 | 0.45960 | 0.86972 | 0.17550 |

| W1-2 | 0.27805 | 0.24600 | 0.21291 | 0.52301 | 0.14622 | 0.28860 | 0.35697 | 0.12085 | 0.25976 | 0.28588 | 0.89670 |

| W1-3 | 0.57620 | 0.45018 | 0.55041 | 0.70907 | 0.39877 | 0.57075 | 0.67339 | 0.42044 | 0.49710 | 0.44033 | 0.45652 |

| W1-4 | 0.48523 | 0.52223 | 0.41889 | 0.70337 | 0.37135 | 0.48071 | 0.34771 | 0.46731 | 0.57933 | 0.80177 | 0.81130 |

| W2-1 | 0.31599 | 0.32268 | 0.24520 | 0.59385 | 0.22042 | 0.33481 | 0.20709 | 0.30318 | 0.44153 | 0.67415 | 0.00000 |

| W2-2 | 0.38492 | 0.40285 | 0.27491 | 0.59570 | 0.19677 | 0.32801 | 0.38784 | 0.20355 | 0.32754 | 0.87353 | 0.00000 |

| W2-3 | 0.36987 | 0.39778 | 0.26916 | 0.55624 | 0.23926 | 0.33149 | 0.28930 | 0.35969 | 0.44366 | 1.00000 | 0.00000 |

| W2-4 | 0.55876 | 0.53061 | 0.41979 | 0.66016 | 0.31921 | 0.48405 | 0.54115 | 0.33366 | 0.45000 | 0.88065 | 0.00000 |

| W2-5 | 0.59536 | 0.62501 | 0.52684 | 0.70542 | 0.40291 | 0.55971 | 0.61882 | 0.44161 | 0.53119 | 0.19091 | 0.00000 |

| W3-1 | 0.13805 | 0.18505 | 0.02793 | 0.41660 | 0.10070 | 0.07847 | 0.00000 | 0.19635 | 0.30919 | 0.07820 | 0.61462 |

| W3-2 | 0.36125 | 0.49917 | 0.38414 | 0.57224 | 0.32219 | 0.11554 | 0.35702 | 0.43777 | 0.50724 | 0.80295 | 0.51014 |

| W3-3 | 0.44783 | 0.48956 | 0.37324 | 0.60231 | 0.33142 | 0.43313 | 0.31545 | 0.43624 | 0.53402 | 0.43986 | 0.25497 |

| W3-4 | 0.29966 | 0.28958 | 0.14646 | 0.59906 | 0.20922 | 0.25124 | 0.03203 | 0.37802 | 0.46103 | 0.43990 | 0.76522 |

| W3-5 | 0.44192 | 0.46799 | 0.34878 | 0.00000 | 0.26137 | 0.39780 | 0.44362 | 0.29271 | 0.39916 | 0.19091 | 0.00000 |

| W3-6 | 0.54881 | 0.58510 | 0.50970 | 0.63687 | 0.39213 | 0.56766 | 0.62586 | 0.40441 | 0.50923 | 0.80046 | 0.00000 |

| W3-7 | 0.43591 | 0.46214 | 0.34215 | 0.66711 | 0.22586 | 0.38099 | 0.49972 | 0.22175 | 0.33961 | 0.43969 | 0.15054 |

| J1 | 0.49506 | 0.55567 | 0.44821 | 0.67608 | 0.38304 | 0.83850 | 0.41770 | 0.50176 | 0.57390 | 0.80053 | 0.70112 |

| J2 | 0.82822 | 0.86613 | 0.87087 | 0.95329 | 0.83247 | 0.87722 | 0.66927 | 0.91078 | 0.96377 | 0.24916 | 0.32135 |

| J3 | 0.91387 | 0.78299 | 1.00000 | 0.92260 | 1.00000 | 0.99690 | 0.81193 | 1.00000 | 1.00000 | 0.12660 | 0.42329 |

| J4 | 0.81526 | 0.96673 | 0.91434 | 0.83196 | 0.81160 | 0.89318 | 0.84642 | 0.80772 | 0.84467 | 0.10279 | 0.51014 |

| No. | Principal Researchers | Extracted Seismic Attributes | Adopted Seismic Attributes | Year | Study Area |

|---|---|---|---|---|---|

| 1 | Cui, Wang | Amplitude, dominant frequency, dominant frequency amplitude, average frequency, low-frequency (5–35 Hz) bandwidth energy | Amplitude, dominant frequency, dominant frequency amplitude, average frequency, low-frequency (5–35 Hz) bandwidth energy | 1997 | Zhangxiaolou mine in Xuzhou, No. 2 coal seam |

| 2 | Han, Zhang, Li | Eight types of time domains, nine types of frequency domains, three types of fractal parameters | Peak and trough amplitude, average frequency, energy of dominant-frequency bandwidth, energy of low-frequency bandwidth, peak frequency | 2001 | Coalfield, No. 2 coal seam |

| 3 | Meng, Guo, Wang et al. | 15 types of amplitude class, five types of complex trace statistics, eight types of spectral statistics | Average instantaneous frequency, average peak amplitude, kurtosis of amplitude, maximum absolute amplitude, maximum peak amplitude, maximum trough amplitude, instantaneous frequency slope, amplitude variation | 2006 | Xieqiao mine in Huainan, 13-1 coal seam |

| 4 | Hu, Qian, Zhong | Peak and trough amplitude, average frequency, energy of dominant-frequency bandwidth, energy of low-frequency bandwidth, peak frequency | Peak and trough amplitude, average frequency, energy of dominant-frequency bandwidth, energy of low-frequency bandwidth, peak frequency | 2010 | Huainan coalfield |

| 5 | Wang, Cui, Chen | 18 types of seismic wave kinematics, dynamics, time domain and frequency domain | Average frequency phase, main frequency phase, dominant frequency, correlation coefficient, two-dimensional fractal parameters, broadband total energy, capacity dimension | 2010 | East 6 mining section, Liangjia coal mine in Longkou |

| 6 | Suo, Chang, Peng et al. | Maximum absolute amplitude, apparent time difference of reflection at the top–bottom interface of coal seam | Maximum absolute amplitude, apparent time difference of reflection at the top–bottom interface of coal seam | 2011 | A coalmine in Yangquan, No. 15 coal seam |

| 7 | Du | 63 types of instantaneous, wavelet, amplitude statistics and spectral attributes | Upper and lower limit frequencies, apparent polarity, dominant power spectrum, response frequency, root mean square amplitude, smoothing frequency, sum of autocorrelation, relative layer thickness | 2013 | Taoyuan coalmine in Huaibei |

| 8 | Chen, Yang, Zhang et al. | Maximum amplitude, maximum number, positive polarity amplitude, instantaneous phase, instantaneous frequency, average number, average wave crest number, root mean square amplitude, arc length, minimum amplitude | Maximum number, instantaneous frequency, average peak number, arc length | 2015 | First mining section, Shilawusu coal mine, 4-1 coal seam |

| 9 | Xu, Han, Zhang et al. | 17 types of amplitude classes, two types of complex trace statistics, one type of spectral statistics | Average energy, average negative phase amplitude, average trough amplitude, average zero crossing trough, instantaneous amplitude, relative acoustic impedance, standard deviation of amplitude, minimum amplitude | 2017 | West second mining section, coal mine in Huainan, A group coal seam |

| 10 | Shan | Amplitude, frequency, phase, spectrum statistics, etc. | Derivative instantaneous, amplitude phase, amplitude weighted cosine, dominant frequency, cosine instantaneous phase, quadrature trace, filter 5/10–15/20, filter 45/50–55/60 | 2021 | Coal mine in Xinjiang, A3 coal seam |

References

- Yuan, L. Scientific conception of precision coal mining. J. China Coal Soc. 2017, 42, 1–7. [Google Scholar] [CrossRef]

- Yuan, L.; Jiang, Y.D.; Wang, K.; Zhao, Y.X.; Hao, X.J.; Xu, C. Precision exploitation and utilization of closed/abandoned mine resources in China. J. China Coal Soc. 2018, 43, 14–20. [Google Scholar] [CrossRef]

- Shang, X.Q.; Yang, H.Y.; Ai, G.; Zhang, Y.G.; Zhu, G.A. Study on the evolution and impact of mining-induced stress in coal thickness variation area. China Min. Mag. 2020, 29, 148–151, 157. [Google Scholar] [CrossRef]

- Cui, W.X.; Wang, B.L.; Wang, Y.H. High-precision inversion method of coal seam thickness based on transmission channel wave. J. China Coal Soc. 2020, 45, 2482–2490. [Google Scholar] [CrossRef]

- Huang, Y.; Yan, L.; Cheng, Y.; Qi, X.; Li, Z. Coal Thickness Prediction Method Based on VMD and LSTM. Electronics 2022, 11, 232. [Google Scholar] [CrossRef]

- Ricker, N. The Form and Laws of Propagation of Seismic Wavelets. Geophysics 1953, 18, 10–40. [Google Scholar] [CrossRef]

- Widess, M.B. How thin is a thin bed. Geophysics 1973, 38, 1176–1180. [Google Scholar] [CrossRef]

- Ruter, H.; Schepers, R. Investigation of the seismic response of cyclically layered carboniferous rock by means of synthetic seismograms. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 92. [Google Scholar] [CrossRef]

- Koefoed, O.; De Voogd, N. The linear properties of thin layers, with an application to synthetic seismograms over coal seams. Geophysics 1980, 45, 1254–1268. [Google Scholar] [CrossRef]

- Cheng, Z.Q.; Wu, Y.F.; Zhao, Z.Q.; Zhang, S.S.; Wang, Z.R.; Ning, L. Quantitative interpretating method of coal using seismic reflected wave. Acta Geophys. Sin. 1991, 34, 657–662. [Google Scholar]

- Dong, S.H. Seismic Data on Coal Seam Lateral Prediction and Evaluation Methods; China University of Mining and Technology Press: Xuzhou, China, 2004; pp. 23–95. [Google Scholar]

- Suo, C.H.; Chang, S.L.; Peng, S.M.; Duan, R.T.; Wang, G.M. Study and Application of Seismic Attributes on Coal Seam Thickness Prediction. Sci. Technol. Eng. 2011, 11, 8429–8433. [Google Scholar] [CrossRef]

- Meng, F.B. Numerical Simulation and Seismic Response Analysis of coal seam thickness variation. Chin. J. Eng. Geophys. 2018, 15, 677–685. [Google Scholar] [CrossRef]

- Liu, T.F.; Chen, B.; Fu, J.S. Spectral moment method for seismic inversion of coal seam thickness and its application. In A Collection of Technical Papers on Geophysical Lithology Exploration in Coalfield; Coal Industry Press: Beijing, China, 1996; pp. 135–146. [Google Scholar]

- Liu, J.H.; Liu, T.F. Study of the trace integration method for predicting coal seam thickness. J. China Univ. Min. Technol. 1996, 25, 73–76. [Google Scholar]

- Peng, S.P.; Zou, G.G.; Li, Q.L. Seam Thickness Prediction Methods Based on the Logging Constrained Seismic Inversion. J. China Univ. Min. Technol. 2008, 37, 729–733. [Google Scholar] [CrossRef]

- Cui, R.F.; Zhong, Q.T.; Li, J.P. Coal thickness interpretation prediction using seismic data. Coal Geol. Explor. 2002, 30, 54–57. [Google Scholar]

- Meng, Z.P.; Guo, Y.S.; Wang, Y.; Pan, J.N.; Lu, J. Prediction models of coal thickness based on seismic attributions and their applications. Chin. J. Geophys. 2006, 49, 512–517. [Google Scholar] [CrossRef]

- Wang, X.; Chen, T. Quantitative Prediction of Tectonic Coal Thickness Based on FNN and Seismic Attributes. J. Inf. Comput. Sci. 2014, 11, 3653–3662. [Google Scholar] [CrossRef]

- Wang, X.; Chen, T.J.; Xu, H. Thickness distribution prediction for tectonically deformed coal with a deep belief network: A case study. Energies 2020, 13, 1169. [Google Scholar] [CrossRef] [Green Version]

- Shan, R. Application of Multi-group Seam Thickness Prediction in CJT Coal Mine. IOP Conf. Ser. Earth Environ. Sci. 2020, 525, 012091. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Chen, T.J.; Yan, Q.Y.; Li, M. Quantitative thickness prediction of tectonically deformed coal using Extreme Learning Machine and Principal Component Analysis: A case study. Comput. Geosci. 2017, 101, 38–47. [Google Scholar] [CrossRef]

- Li, Z.W.; Xia, S.X.; Niu, Q.; Xia, Z.G. Coal Thickness Prediction Based on Support Vector Machine Regression. In Proceedings of the Eighth Acis International Conference on Software Engineering, Qingdao, China, 30 July 2007; IEEE: Qingdao, China, 2007. [Google Scholar] [CrossRef]

- Qi, A.L.; Kang, W.H.; Zhang, G.M.; Lei, H.J. Coal seam thickness prediction based on transition probability of structural elements. Appl. Sci. 2019, 9, 1144. [Google Scholar] [CrossRef] [Green Version]

- Zeng, A.P.; Zhang, J.W.; Ren, E.M.; Liu, T.; Jiang, F.; Liu, X.J.; Jiang, F. Research on coal thickness prediction method based on VMD and SVM. Coal Geol. Explor. 2021, 49, 243–250. [Google Scholar] [CrossRef]

- Zheng, H.Z.; Wei, C.J.; Wang, S.H. Seismic attribute optimization research based on principal component analysis and kernel principal component analysis. J. Qingdao Univ. 2017, 30, 76–80. [Google Scholar] [CrossRef]

- Li, H.X.; Wu, S.Y. Attribute reduction and optimization for massive seismic data based on principal component analysis. China Earthq. Eng. J. 2019, 41, 757–762. [Google Scholar] [CrossRef]

- Chen, Y.K.; Yang, Y.G.; Zhang, X.; Zhang, H. Forecasting of coal thickness based on rough set and LS-SVM. Prog. Geophys. 2015, 30, 2136–2141. [Google Scholar] [CrossRef]

- Fan, J.; Wang, X.; Xu, H. Prediction method of tectonic coal thickness based on particle swarm optimized hybrid kernel extreme learning machine. J. Comput. Appl. 2018, 38, 1820. [Google Scholar] [CrossRef]

- Zhou, X.J.; Gao, F.; Fang, X.; Lan, Z.H. Improved bat algorithm for UAV path planning in three-dimensional space. IEEE Access 2021, 9, 20100–20116. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Mirjalili, S. How effective is the Grey Wolf optimizer in training multi-layer perceptron. Appl. Intell. 2015, 43, 150–161. [Google Scholar] [CrossRef]

- Houssein, E.H.; Ahmed, M.M.; Elaziz, M.A.; Ewees, A.A.; Ghoniem, R.M. Solving Multi-Objective Problems Using Bird Swarm Algorithm. IEEE Access 2021, 9, 36382–36398. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Kaur, G.; Arora, S. Chaotic Whale Optimization Algorithm. J. Comput. Des. Eng. 2018, 5, 275–284. [Google Scholar] [CrossRef]

- Mafarja, M.M.; Mirjalili, S. Hybrid Whale Optimization Algorithm with simulated annealing for feature selection. Neurocomputing 2017, 260, 302–312. [Google Scholar] [CrossRef]

- Suykens, J.A.K.; Vangestel, T.; Debrabanter, J. Least Squares Support Vector Machines; World Scientific: Singapore, 2002; pp. 1–26. [Google Scholar]

| Classes of Seismic Attributes | Seismic Attributes | Correlation Coefficient with Coal Thickness |

|---|---|---|

| Amplitude and energy class | Average energy | −0.69775 |

| Average positive peak value | −0.66054 | |

| Maximum amplitude | −0.64955 | |

| Rms amplitude | −0.63253 | |

| Frequency class | Envelope-rms amplitude | −0.63126 |

| Arc length | −0.57008 | |

| Waveform statistics class | Upper loop area | −0.65711 |

| Interval average–arithmetic | −0.57268 | |

| Structure along horizon class | Median filter | −0.28807 |

| Mean filter | −0.28726 | |

| Mean regular | −0.28664 |

| Class of Seismic Attributes | Seismic Attributes | Correlation Coefficient with Coal Thickness |

|---|---|---|

| Amplitude and energy class | Std poststack amplitude | −0.46954 |

| Ins poststack amplitude | −0.45588 | |

| Maximum amplitude | −0.44909 | |

| Geo poststack amplitude | −0.44728 | |

| Average energy | −0.44292 | |

| Frequency class | Envelope-rms amplitude | −0.45009 |

| Arc length | −0.44547 | |

| Waveform statistics class | Upper loop area | −0.38463 |

| Interval average–arithmetic | −0.34505 | |

| Structure along horizon class | Shape index | −0.12820 |

| Strike | 0.11526 |

| Coal Thickness Prediction Models | Seismic Attribute Set | Penalty Factor γ | Kernel Function Parameter σ2 |

|---|---|---|---|

| Model A | Set I | 26.35 | 48.24 |

| Model B | Set II | 67.19 | 257.05 |

| Model C | Set III | 76.67 | 330.56 |

| No. | Actual Thickness (m) | Predicted Thickness (m) | Absolute Error (m) | Relative Error (%) |

|---|---|---|---|---|

| cc102 | 3.4 | 3.1 | 0.3 | 8.82 |

| cc107 | 3.6 | 3.8 | 0.2 | 5.56 |

| cc108 | 3.8 | 3.8 | 0 | 0.00 |

| cc116 | 4.0 | 4.1 | 0.1 | 2.50 |

| cc122 | 3.7 | 3.8 | 0.1 | 2.70 |

| cc127 | 4.3 | 4.0 | 0.3 | 6.98 |

| cc131 | 4.2 | 3.9 | 0.3 | 7.14 |

| cc201 | 3.4 | 3.3 | 0.1 | 2.94 |

| cc204 | 3.7 | 3.9 | 0.2 | 5.41 |

| cc207 | 2.6 | 3.1 | 0.5 | 19.23 |

| cc212 | 3.6 | 3.5 | 0.1 | 2.78 |

| cc303 | 3.7 | 3.6 | 0.1 | 2.70 |

| cc308 | 3.5 | 3.5 | 0 | 0.00 |

| cc314 | 3.7 | 3.9 | 0.2 | 5.41 |

| cc319 | 3.9 | 4.2 | 0.3 | 7.69 |

| cc324 | 3.9 | 3.8 | 0.1 | 2.56 |

| cc328 | 3.7 | 3.7 | 0 | 0.00 |

| cc401 | 3.4 | 3.4 | 0 | 0.00 |

| cc406 | 3 | 3.2 | 0.2 | 6.67 |

| cc412 | 2.3 | 2.8 | 0.5 | 21.74 |

| cc413 | 2.3 | 3.0 | 0.7 | 30.43 |

| cc417 | 3.8 | 3.7 | 0.1 | 2.63 |

| cc421 | 3.9 | 4.0 | 0.1 | 2.56 |

| cc425 | 3.2 | 3.6 | 0.4 | 12.50 |

| cc430 | 3.9 | 3.9 | 0 | 0.00 |

| cc435 | 3.7 | 3.6 | 0.1 | 2.70 |

| cc501 | 3.5 | 3.5 | 0 | 0.00 |

| cc507 | 3.8 | 3.9 | 0.1 | 2.63 |

| cc510 | 3.0 | 3.2 | 0.2 | 6.67 |

| cc515 | 3.5 | 3.6 | 0.1 | 2.86 |

| cc521 | 4.0 | 3.8 | 0.2 | 5.00 |

| cc525 | 4.0 | 4.0 | 0 | 0.00 |

| cc528 | 4.2 | 4.3 | 0.1 | 2.38 |

| cc531 | 3.7 | 4 | 0.3 | 8.11 |

| cc534 | 4.2 | 3.9 | 0.3 | 7.14 |

| cc536 | 3.8 | 3.7 | 0.1 | 2.63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, X.; Zhang, P.; Meng, F.; Liu, C. A Coal Seam Thickness Prediction Model Based on CPSAC and WOA–LS-SVM: A Case Study on the ZJ Mine in the Huainan Coalfield. Energies 2022, 15, 7324. https://doi.org/10.3390/en15197324

Lin X, Zhang P, Meng F, Liu C. A Coal Seam Thickness Prediction Model Based on CPSAC and WOA–LS-SVM: A Case Study on the ZJ Mine in the Huainan Coalfield. Energies. 2022; 15(19):7324. https://doi.org/10.3390/en15197324

Chicago/Turabian StyleLin, Xiaobo, Pingsong Zhang, Fanbin Meng, and Chang Liu. 2022. "A Coal Seam Thickness Prediction Model Based on CPSAC and WOA–LS-SVM: A Case Study on the ZJ Mine in the Huainan Coalfield" Energies 15, no. 19: 7324. https://doi.org/10.3390/en15197324