1. Introduction

Refuse derived fuel (RDF) is the usable combustible components separated and collected from municipal solid waste (MSW). RDF is considered a renewable energy source and an effective alternative to fossil fuel [

1,

2]. Reusing RDF reduces the amount of waste sent to landfills [

3]. Thermochemical processes are most extensively used to harvest the energy from MSW/RDF, including combustion in an incinerator [

3,

4,

5], gasification in various gasifier types [

6,

7,

8], and pyrolysis technologies [

9,

10,

11,

12]. The selection of the process depends on the process efficiency, available technology, and choice of products. The combustion of MSW/RDF generates heat, which can be converted to electricity, while pyrolysis creates char, gas, and liquid oil, and product gas or syngas is generated from gasification [

6].

The gasification process has been realized as a promising technology to convert RDF and plastic waste into a usable gas or a product gas containing high heating value [

6,

7,

8]. In this research, the gasification technology used is the Dual Fluidised Bed (DFB) gasifier system, utilising superheated steam (H

2O) as a gasifying agent. The product gas produced from the DFB gasifier is of high quality, comprising primarily hydrogen (34–45 vol%), carbon monoxide (20–30 vol%), carbon dioxide (15–25 vol%), and methane (8–12 vol%) [

13]. The calorific value of the product gas is as high as 12–14 MJ/Nm

3. With the high quality of the product gas, it can be utilised directly in gas engines or gas turbines for power generation, and it can be further used for the production of hydrogen gas, synthetic natural gas, and transportation fuels (e.g., Fischer–Tropsch liquid fuel synthesis) [

14,

15,

16,

17,

18].

Studies of gasification of RDF and various plastic wastes have been performed in the lab-scale DFB gasifier, involving either mono-gasification of plastics or co-gasification with biomass [

19,

20,

21,

22,

23,

24,

25]. A few studies on plastic gasification on a large scale can be found involving the Chalmers DFB gasifier in Sweden [

26,

27,

28,

29]; nevertheless, none of these have reported the results of the product gas and gas cleaning for its utilisation in the entire process of electricity production.

In recent years, studies have been conducted in the lab-scale DFB gasifier using various plastic wastes as feedstocks [

19,

20,

21,

22,

30]. Two different types of plastic residues, namely, shredder light fraction (SLF) and a mixture of classified municipal solid waste (MSW), were gasified in a dual fluidised bed gasifier [

20]. SLF was produced from the end-of-life vehicles that were recycled, shredded, and graded. MSW were plastics from bio-mechanical treatment of waste and plastic packaging from selective collection. This study investigated the key gasification parameters using different mixtures with soft wood pellets ranging from 0–100%, as well as different steam-to-carbon ratios. It is discovered that increasing share of plastics in the fuel mixture resulted in higher concentrations of CH

4, C

2H

4, and other light hydrocarbons in the product gas [

20]. Therefore, the heating value of the product gas with a share of plastics was higher than pure wood. The tar and dust content of the product gas was found to be increased, whereas the amount of entrained char was decreased with increasing plastic share [

20]. Mixtures of plastics and wood changed the product gas composition in a non-linear relationship, indicating a synergistic effect of plastic and wood. With co-gasification of plastic and wood, an increasing demand of auxiliary fuel to the combustor of the DFB gasifier was required in order to maintain the gasifier temperatures, which was found to be due to the lower char content of plastic residues compared to wood [

20].

In the literature, tar in the product gas from the DFB gasifier was increased with the proportion of plastic wastes in co-gasification with wood pellets [

20,

21,

24]. However, the co-gasification of plastics and biomass significantly reduced the tar formation compared to mono-gasification of plastics [

21]. This was due to the presence of (1) wood char having a positive effect on polymer decomposition, steam reforming, and tar reduction, and (2) more radicals of different types available that interacted with each other and with the fluidization steam, enhancing the reforming reactions [

21,

22]. Due to lower tar formation, co-gasification of plastic waste with biomass is suggested as a suitable method for using plastic waste in the DFB gasifier [

21].

It was also found that the product gas composition was significantly affected by co-gasification, with the trend lines being nonlinear [

21]. This showed a synergistic effect of the binary feed mixtures. CO and CO

2 concentrations in the product gas were higher than predicted from linear interpolation of the pure material feedstocks, whereas H

2 production was either underestimated or overestimated depending on the plastic type. The tar content in the product gas generally increased with a greater share of plastics, however, it was lower than initially presumed [

21]. These changes were nonlinear, and therefore the gas composition could not be accurately predicted on the basis of mono-gasification of the materials only [

21].

From the literature, the inconsistency of the aforementioned results might be due to the heterogeneous properties of plastic wastes, MSW wastes, and RDF wastes. Therefore, the results from research work conducted in a small-scale DFB gasifier might not accurately predict the results of a commercial DFB gasifier. Due to the high tar content expected from RDF gasification, the RDF has to be mixed with wood chips to a degree in order to find the maximum allowable RDF in the particular design of Nong Bua plant. The Nong Bua DFB gasifier plant was designed to be versatile, and it can be fed with various biomass and waste resources, including wood chips, cassava rhizome, corncob, and RDF [

31,

32].

In the present research, therefore, the purpose was to investigate the influence of the RDF to fuel (R/F) mass ratio on the process operation conditions, product gas composition, and tar content from the co-gasification of RDF and wood chips in the Nong Bua plant. The local RDF pellets were physically mixed with wood chips with mass ratios of RDF pellets to fuel of 10%, 20%, and 30%. The experimental data of the binary feed are presented and compared with pure wood chips. The results obtained are crucial for the commercialisation of the DFB gasification process when using RDF as a binary feed.

2. Materials and Methods

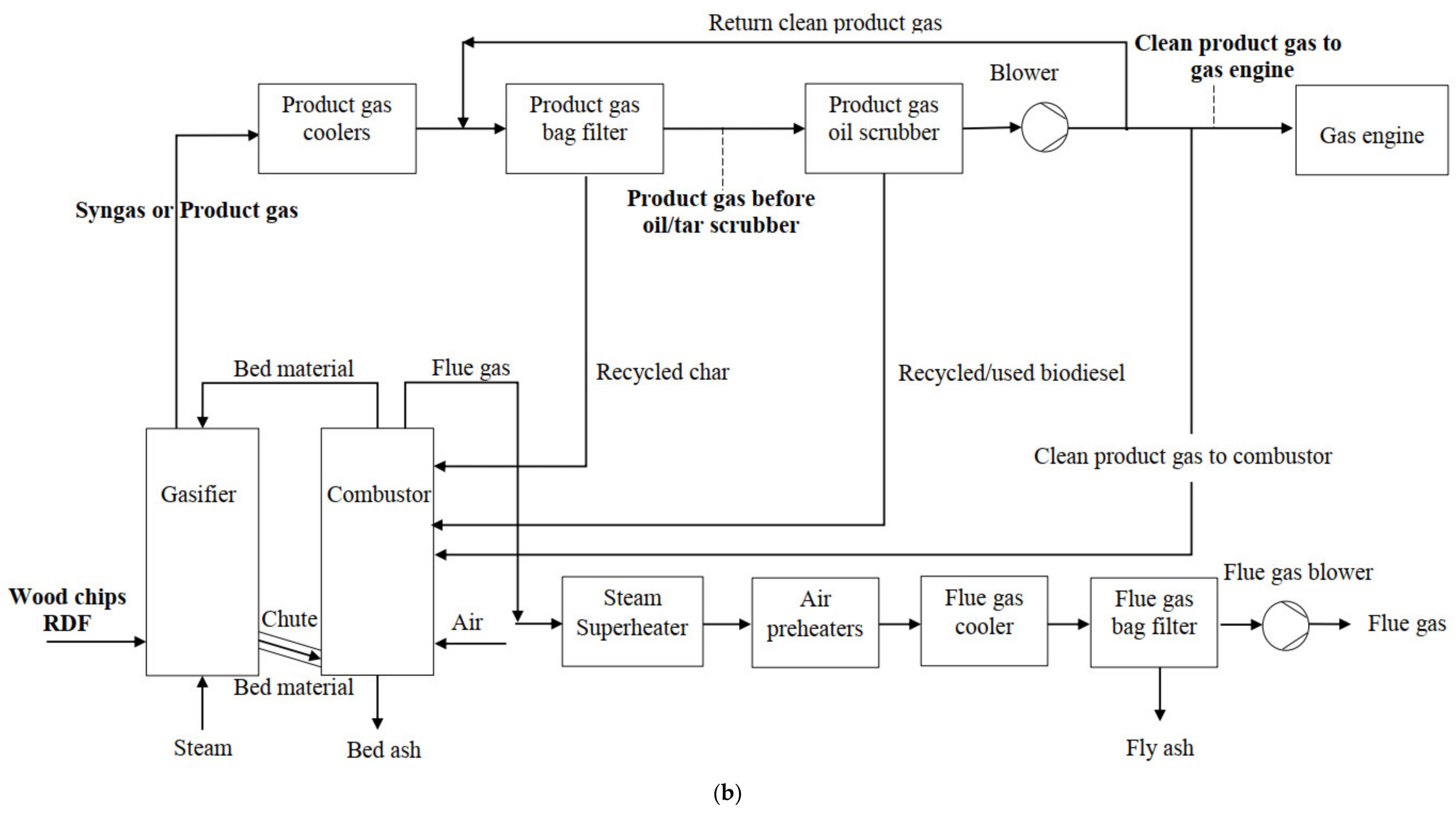

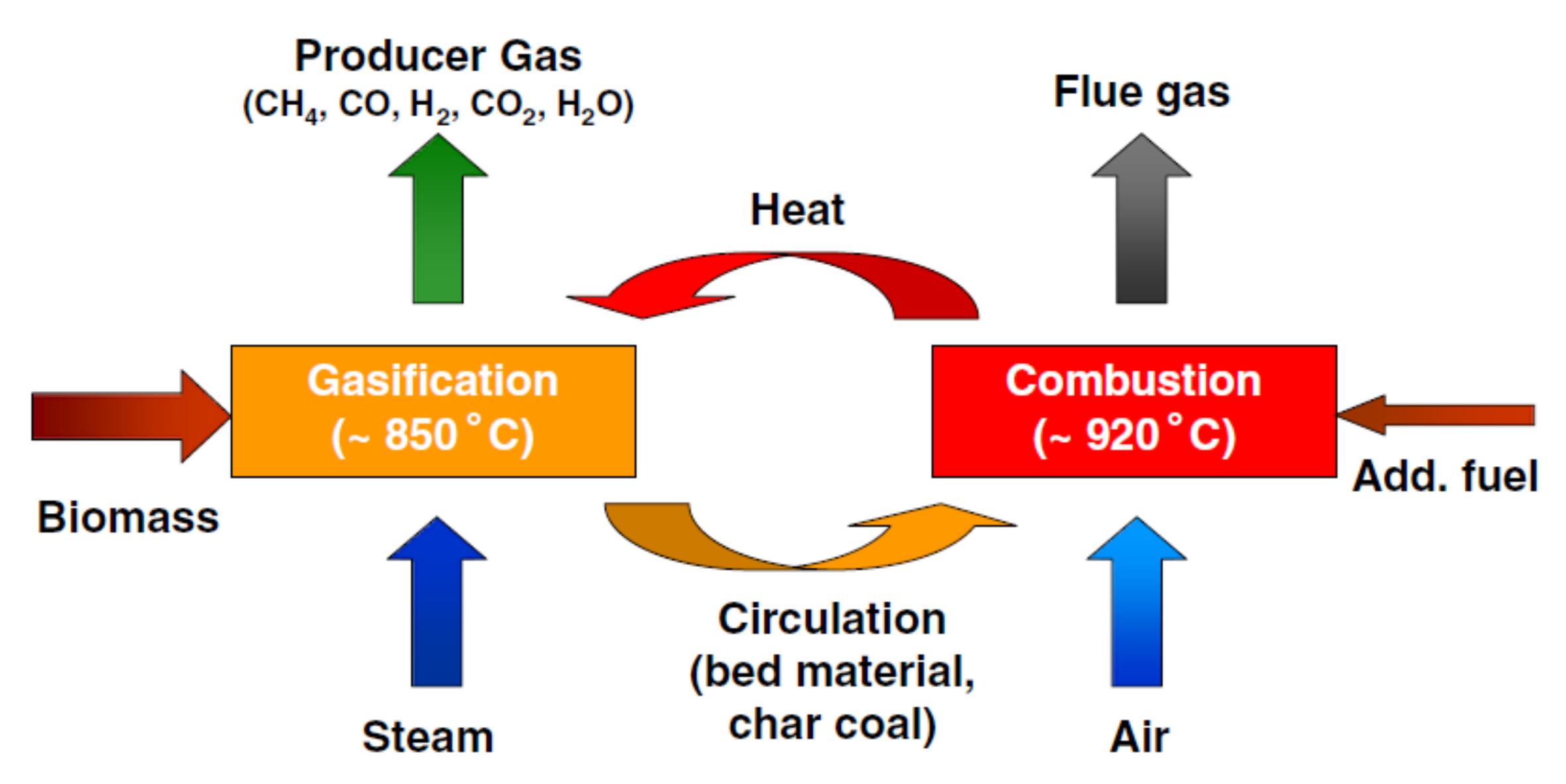

2.1. The DFB Gasifier and Its Principle

Figure 1 shows the principle of the DFB gasifier. The basic principle is to separate the product gas from the flue gas in order to obtain a nitrogen-free product gas. Therefore, the separation of the gasification reaction and the combustion reaction has to be fulfilled. The DFB steam gasifier is composed of two separated chambers: a bubbling fluidised bed (BFB) gasification reactor, and a fast fluidised bed (FFB) combustion reactor (

Figure 1 and

Figure 2).

The overall steam gasification reaction is endothermic, and hence it requires energy from the combustion reaction to supply to the gasification reaction via the bed material circulation. Feed fuel is fed into the bed of the gasification reactor using steam as a fluidising and gasifying agent. Residual fuel char from the gasification reactor is transported with the circulating bed material to the combustion reactor via an inclined chute (

Figure 2). The residual char provides added energy to the combustion chamber and thus to the overall DFB gasifier reactor. The BFB gasification reactor is operated at about 800–850 °C and atmospheric pressure. The heating rate in this reactor is fast, resulting in simultaneous pyrolysis and gasification reactions, which in turn provides low tar concentrations and high hydrogen and methane.

The combustion reactor Is fluidised with air and the combustion reaction takes place at about 900–950 °C and atmospheric pressure. The two connections between the gasification and combustion reactors are the loop seal and chute, which are fluidised with steam to prevent gas leakage between the two reactors. The steam injection at the loop seal and chute allows for a high solid circulation rate. The temperature difference between the gasification and combustion reactors is controlled by the bed material circulation rate, the residual char from the feed fuel, and the auxiliary fuel, i.e., product gas recirculation, diesel, and to a lesser degree, char from the product gas bag filter (

Figure 1 and

Figure 2).

2.2. The Nong Bua DFB Gasification Process

The facility used in this research was the Nong Bua DFB gasification power plant in Thailand, shown in

Figure 3. The main components of the DFB steam gasifier comprise a bubbling fluidised bed (BFB) gasification reactor and a fast fluidised bed (FFB) combustion reactor. The BFB gasification reactor is operated at about 820 °C and 1.053 bara (40 mbar gauge), whereas the FFB combustion reactor occurs at about 920 °C and 1.153 bara (140 mbar gauge). Both reactors run at slightly above atmospheric pressure in order to avoid air from the atmosphere entering the reactors. More details of the principle behind the DFB gasifier can be found in the literature [

22,

31,

32,

36,

37].

The process of converting the fuel feedstock into heat and power can be described as follows. Feedstocks are transported through a fuel handling system and then fed to the BFB gasification bed. The fuel handling system is designed for multi-fuel feeding and has two main hoppers, one for wood chips and another for RDF pellets, as displayed in

Figure 4 and

Figure 5. Wood chips with high moisture content of about 40% are transported via elevator 1 to the top of the dedicated dryer to reduce the moisture content to about 15–20%. The dried wood chips are subsequently mixed with RDF pellets at the belt conveyor connected to the bottom of the wood chip dryer, and the binary feed fuel is fed via elevator 2 to the two small hoppers, where mixing also occurs. The two small hoppers are equipped with flap gates, which are controlled automatically to open or close during the process of loading the binary fuels into the screw feeder, then to the BFB gasifier bed (

Figure 4 and

Figure 5).

The bed material used in the gasifier is calcined olivine sand (iron and magnesium orthosilicate, (Mg, Fe)

2SiO

4). The selection of calcined olivine is supported by its hardness, as required for the fast fluidization condition, and its high catalytic activity in biomass steam gasification reactions. During the plant start-up, the used calcined olivine from the previous run is reused because of its high calcium content on the outer layer of the used calcined olivine particles, which are incorporated from the interaction with biomass ash and additives (dolomite and calcium hydroxide) [

32,

38,

39].

The product gas from the DFB steam gasifier has the favourable characteristics of low nitrogen content and high hydrogen and methane content, resulting in a high calorific value of about 12–14 MJ/Nm3. The nitrogen content in the product gas is extremely low, as steam is used as a gasifying agent instead of air. The low nitrogen content in the product gas originates from the purge gas injected into the biomass feeder and into the product gas particle filter. The nitrogen purge gas is used to prevent air entering the feeder and filter, which could cause an explosion.

As shown in

Figure 3, the product gas from the gasifier is drawn by the product gas blower to pass through a cooling system, a fabric polytetrafluoroethylene (PTFE) bag filter, and a scrubber, sequentially. The product gas is cooled by two gas coolers installed in series to decrease the temperature of 800–820 °C to 280 °C. The bag filter is used to remove almost all of the particulates (char, ash, and fine bed material) from the product gas. The particulates from the bag filter, which contain primarily char (or called fly coke), are transported to the combustion chamber to be used as additional fuel. Then, the scrubber completely removes all the tars and particulates from the product gas using biodiesel (such as rapeseed methyl ester (RME) or palm methyl ester (PME)). The scrubber at the Nong Bua plant was designed specifically to deal with high tar content from various types of feedstocks. The height to diameter ratio of the tar scrubber, which is a design parameter, was increased for the Nong Bua plant compared to the Gussing plant in Gussing, Austria [

31]. This increases the contact time of the gas and biodiesel in the scrubber, thereby increasing the efficiency of tar removal and reducing the amount of fresh biodiesel required [

31]. PME has been used at the Nong Bua plant since 2019 to replace imported rapeseed methyl ester (RME) from Germany following the research work completed by the GRE group and partners [

40,

41,

42].

The scrubber further reduces the product gas temperature from 210 °C to about 40 °C, which is then compressed to 1.313 bara (300 mbar gauge) as required for the gas engine. Finally, the clean product gas is further cooled with an air cooler and drawn to: (1) the Caterpillar gas engine to generate electricity and heat; (2) the FFB combustor to control the DFB gasifier temperatures; (3) returned or recirculated product gas system to further mix and cool down the product gas after the coolers but before the bag filter; and lastly (4) flaring, if required.

As for the flue gas, it is generated from the FFB combustor and removed from calcined olivine and particles in the cyclone. The flue gas is drawn by the flue gas blower to pass through the steam super heater and air preheaters, where its sensible heat is recovered for steam superheating and air preheating, respectively. The flue gas is later cooled to 160–170 °C in the flue gas cooler and filtered in the flue gas filter, then released to the environment.

The heat recovered from the product gas and flue gas coolers is used for wood chip drying and steam production. The waste heat available from the entire process results from the product gas and flue gas coolers as well as from the gas engine flue gas and hot water. These heat sources are currently not recovered, and are cooled by air coolers or radiators. However, the waste heat can be recovered to use in various applications such as drying, the district heating system, electrical generation via the Organic Rankine Cycle (ORC) process, cold water generation via absorption chiller, etc.

2.3. Nong Bua DFB Gasifier Operation Conditions

The DFB steam gasifier operation conditions were set as shown in

Table 1. The total power of fuel input to the BFB gasifier was roughly 3800 kW

th. The bed material used was calcined olivine, its size range was 300–800 µm, and the particle density was 2800–2900 kg/m

3. The temperatures of the BFB and FFB reactors were measured at different heights and varied to a certain degree between the values of 795–880 °C and 870–950 °C, respectively.

In this test, the steam to fuel ratio, defined as the ratio of mass flow rate of the feeding steam and moisture in the fuel to mass flow rate of the dry fuel feedstock, was set at 0.5 kg/kg

dry. The superheated steam for the gasification reactions was produced from the condensed water of the wet product gas, which was separated from the recycled biodiesel in the sedimentation tank or scrubber basin placed below the tar scrubber column (see

Figure 3a). The condensed and separated water from the sedimentation tank was fed to an evaporator to generate saturated steam. This saturated steam was superheated by the recovered heat from the product gas and flue gas cooling system. Due to the reuse of water, the fresh soft water used for the entire process is extremely low. The soft water is mainly consumed to make up the cooling tower.

2.4. Materials

2.4.1. Feedstocks

The feedstocks tested for this research included local Thai wood chips and RDF pellets. The wood chips were supplied by the wood chip mill near the Nong Bua plant, while RDF pellets were prepared and supplied by the Center of Excellence in Biomass, Suranaree University of Technology (SUT). The wood chip sizes generally were between 5 mm to 32 mm long; the maximum allowable was 120 mm long.

Figure 6 displays the RDF pellets, known as RDF-5 in Thailand. Combustible wastes such as plastics, paper, textile, wood, food waste, etc., were separated from other non-combustible wastes of the MSW. The combustible waste, mainly plastic waste, was shredded by the shredder, underwent mechanical and biological treatment, and was screened by a trommel with a screen size of 80–120 mm to obtain coarse RDF, called RDF-3. The coarse RDF was subjected to an agglomerator and subsequently to a pelletizing machine to obtain RDF pellets. The size of the pellets was 4.5 mm diameter × 45–50 mm length [

43].

Before the experiments, proximate and ultimate analysis of the wood chips and RDF pellets was conducted by SGS (Thailand) Limited; the results are provided in

Table 2.

The total feed power input to the gasifier has to be approximately 3800 kWth. Therefore, the lower heating value from the analysis is essential, as it was used to calculate the mass input of RDF pellets and wood chips to the specified RDF to fuel (R/F) ratios. The four feedstocks used included (1) local Thai wood chips (0% R/F); (2) RDF mixed with wood chips at mass ratio of 10:90 (10% R/F); (3) RDF mixed with wood chips at mass ratio of 20:80 (20% R/F); and (4) RDF mixed with wood chips at mass ratio of 30:70 (30% R/F).

Table 3 and

Table 4 present the mass feed rate of raw wood chips (≈40% moisture content) to the dryer and RDF pellets to mix with the dried wood chips (15% moisture content). To control the feed of each mixture ratio, wood chips and RDF pellets were placed into two different hoppers and two main screw driver sets, where they were designed for this purpose of multi-fuel feeding (

Figure 4 and

Figure 5). The mass of either wood chips or RDF pellets was set and controlled by the screw driver speed controller. The screw driver speed was calibrated based on the fuel bulk density and was pretested beforehand. The wood chips as received with a moisture of 40% were used and dried in a dedicated wood chip dryer to 15% before mixing with the RDF. The mixture was then fed into the bed of the BFB gasifier.

2.4.2. Consumables

The consumables used were calcined olivine, dolomite, calcium hydroxide, palm methyl ester (PME), soft water, nitrogen gas, and diesel for heating up the gasifier. All of these consumables were locally purchased in Thailand except for calcined olivine, which was imported from Austria.

2.5. Sampling and Analysis

In this experiment, the product gas composition, tar concentrations, and electrical power output were measured during steady operating conditions. The operating conditions (temperature, pressure, etc.) from measurements were recorded using a SCADA system during steady operating mode. Temperature and pressure measurement of the presented data was conducted using Honeywell thermocouple K-type probes and transmitters (model STT3000 family of microprocessor based smart), Honeywell pressure sensors and transmitters (models: STG700 and STG800 smartline gauge pressure), and Honeywell differential pressure sensors and transmitters (models: STD700 and STD800 smartline differential pressure). The instrumental accuracies of the K-type thermocouple, gauge pressure measurement, and differential pressure measurement were +/−1.1 °C, 0.06%, and 0.05%, respectively.

2.5.1. Product Gas Sampling and Analysis

Automatic sampling was used to sample the clean product gas after the product gas blower. An ABB gas analyser (model ABB EL 3020) measured the product gas composition. ABB gas analyser calibration was conducted with the known gas concentrations. The composition of CO, CO2, CH4, and O2 was presented and stored in the SCADA system on site. The H2 composition was determined by calculation.

2.5.2. Tar Sampling and Analysis

Tar sampling and analysis in the clean product gas was modified from the European Standard CEN/TS 15439:2006 Biomass gasification—Tar and particles in product gases—Sampling and analysis.

Tar sampling and analysis procedures were prepared by the College of Advanced Manufacturing Innovation under King Mongkut’s Institute of Technology Ladkrabang (KMITL) and Gussing Renewable Energy (Thailand) company in Bangkok, Thailand, and by the support from Prof. Dr. Reinhard Rauch from Karlsruhe Institute of Technology in Karlsruhe, Germany. More details of sampling and analysis can be found in the literature [

32,

44].

3. Results and Discussion

In the experiments, the results of process operation conditions, product gas composition, and engine power were measured and recorded in the SCADA system for every second. The data of every minute over the test run of 60–90 min for each fuel feed ratio was used to calculate the average value and the standard deviation; these values are reported in this research. For the tar concentration, the results were averaged from two to four repeated measurements. The error bars shown in the graphical presentation represent the standard deviations.

3.1. Influence of R/F Ratio on the Gasification Process Operation Conditions

In the process control system of the Nong Bua plant, the temperatures of the FFB combustor relied on the amount of char carried from the BFB gasifier as well as the clean product gas recirculation and diesel injection. In the present study, the amount of recirculated clean product gas to the combustor was set stably at 200 Nm3/h and diesel injection was not needed; hence, these values did not affect the temperatures. The temperatures between the BFB gasifier and the FFB combustor were balanced by the bed material circulation rate to control heat from the combustor to the gasifier.

The results of the gasification process operation conditions including the BFB gasifier, FFB combustor, coolers, bag filter, and scrubber are presented in

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

Figure 11. In

Figure 7 and

Figure 8, gasifier and combustor temperatures slightly increased in a very small range with the addition of RDF into the feed. When the R/F ratio increased from 0% to 30%, the in-bed gasifier temperature increased from 857 °C to 876 °C (2.2% increase) while combustor temperatures at the bottom and middle height increased from about 915 °C to 945 °C (3.3% increase). The trends of the temperatures were expected, and were due to the much lower moisture content of RDF compared to wood chips and the higher volatile matter of RDF compared to wood chips. Less heat was required to heat up and vaporise water in the feed fuel, and thus temperatures were increased. It was expected that there would be less char or fixed carbon in the higher R/F ratio feed transported along with the calcined olivine from the gasifier to the combustor [

20], and that diesel would be required to supply the combustor. However, over all of the tests for the four R/F ratios, the required diesel supply remained at 0 L/h. This was due to the small mass percentage of RDF used, and its resulting similarity to the fixed carbon amount of the binary feed, i.e., 0% R/F (10.74%), 10% R/F (10.10%), 20% R/F (9.47%), and 30% R/F (8.83%).

In

Figure 7, the pressure drop over the gasifier was 100–120 mbar and its average freeboard pressure was between 2 and 20 mbar.

Figure 8 illustrates the pressure at the middle and the top of the combustor at about −7 to 15 mbar, and its two bottom pressures were 90–150 mbar. The absolute pressure and pressure drop of these main reactors fluctuated within a very narrow range as designed. In general, the changes of these temperatures and pressures with the incorporation of RDF were considered small and within the fluctuation level of the commercial-scale DFB gasifier plant.

Figure 9 shows the product gas temperatures in and out of the cooler unit. The product gas temperature was cooled down in the two coolers from about 800–820 °C (gasifier freeboard temperature) to 235–270 °C from a cooler 2, and finally down to 225–242 °C after mixing with the returned cold and clean product gas before passing through the fabric PTFE bag filter. The coolers must cool the product gas temperature below 240–250 °C due to the limit temperature of the PTFE material of the fabric bag filter. The pressure drop in the two coolers varied in a narrow range, as designed.

Figure 10 presents the product gas temperature in and out of the bag filter and the pressure drop across the bag filter, while

Figure 11 shows the product gas temperature out of the scrubber and the pressure drop across the scrubber. All values were fluctuated within a varied window, and the results show the good performance of the DFB gasifier process. The pressure drops need to be controlled to avoid high pressure build-up and blockages in the equipment.

Overall, the incorporation of RDF did not interrupt the gasification operation conditions, i.e., temperatures and pressures. The pressure was steady, and the fluidisation in the gasifier and combustor did not change. No diesel was added in any of the tests, showing that the char was sufficient to maintain the gasifier and combustor temperatures.

3.2. Influence of R/F Ratio on the Product Gas Composition and Heating Value

Table 5 and

Figure 12 present the measured clean product gas composition and the calculated lower heating value at standard conditions (1.013 bara and 0 °C). The experimental data show that the changes in all four main gas concentrations with the R/F ratio were rather insignificant and varied within small ranges. H

2, CO, CO

2, and CH

4 concentrations (vol%) were within 37.5–41.0%, 23.7–25.3%, 19.0–20.3%, and 9.8–11.1, respectively. The similar ranges of the product gas compositions were possible because of control of the constant feed input of 3800 kW

th. The lower heating value was calculated from the measured gas composition to be between 13.2 and 13.6 MJ/Nm

3. As shown in

Figure 12 a, these experimental results are consistent with the data obtained from the process simulation calculation using IPSEpro software (the trend lines in the graph). IPSEpro software was developed using experimental data obtained in the lab-scale and commercial-scale DFB gasifiers, and it is owned by the Institute of Chemical Engineering, Vienna University of Technology. The IPSEpro software uses an equation-oriented steady state modelling environment for simulation [

45,

46,

47]. Thermodynamic data were collected and the structure of the model framework and formulation of the model equations were formed during software development. Additional details of the principles of the IPSEpro software package are described elsewhere [

45,

46,

47]. Simulated data of 0% R/F and 100% R/F were received from the IPSEpro software, whereas the trend lines shown in

Figure 12 were simply calculated by the interpolation of the two sets of numbers from 0% R/F and 100% R/F.

From the simulation, it can be clearly seen that the H

2 concentration is reduced from 41% to 39% when the R/F ratio increases from 0% to 30%, and H

2 concentration is further reduced to 34% when the R/F is 100%. In contrast, CH

4 shows an opposite trend, which is in accordance with the literature [

20,

21]. CH

4 increases from 10% to 14% as the R/F ratio changes from 0% to 100%, as CH

4 is a typical decomposition product of polymers in steam gasification reactions [

20,

21]. CO and CO

2 concentrations are rather stable at 23% and 21% for 0–100% R/F ratios.

The experimental LHV of the product gas is as high as 13.2–13.6 MJ/Nm

3, which matches the simulation data and is comparable to previous studies [

32,

38]. From the values of the product gas composition, it is shown that the binary mixtures of wood chips and RDF with the mass percentage of RDF up to 30% are good feedstock in the DFB gasification process. These simulation data can probably be used for prediction of the composition and LHV of the product gas from the Nong Bua DFB gasifier plant for R/F ratios over 30%. More precise data nevertheless result from the experimental data.

3.3. Influence of R/F Ratio on the Tar Concentration

The tar concentration in the product gas after passing through the PME scrubber is presented in

Figure 13. The experimental tar concentration of 0% R/F was as low as 8.4 mg/Nm

3, increased to 105 mg/Nm

3 for 20% R/F, and dropped to 75 mg/Nm

3 for 30% R/F. Due to high amount of various types of plastics or long chain hydrocarbons in the RDF, the hydrocarbons were cracked in the steam decomposition reactions into shorter chains. Smaller hydrocarbons, not only CH

4, C

2H

4, etc., are produced from the cracking reactions of plastics, but also tars [

20,

21].

Tar concentration increased with the share of RDF from 0% R/F to 20% R/F, while the tar concentration decreased with increasing the RDF from 20% R/F to 30% R/F. This phenomenon could be due to the synergistic effect of the co-gasification of RDF and wood chips and/or the synergistic effect of the ash in the RDF and the ash in the wood chips. To confirm this observation, extra experiments involving feeding the RDF at mass ratios of 0% R/F, 10% R/F, 20% R/F, 30% R/F, 40% R/F, 50% R/F, and so forth, up to 100% R/F, must be conducted.

In this work, the inlet tar concentration to the scrubber could not be sampled due to the high vacuum state in the product gas line; a sampling pump does not have enough power to pull the product gas into the sampling solution bottles. A larger pump is required in order to draw the gas inlet of the scrubber. The inlet tar was therefore calculated using IPSEpro software. It was found that 4.19 g/Nm

3 tar was generated from 0% R/F and 5.60 g/Nm

3 was generated from 100% R/F. From the calculated tar inlet and the measured tar outlet, the removal efficiency can be calculated as shown in

Figure 13. The tar removal efficiency of the scrubber is extremely high, at more than 99.8% at 0% R/F and 98.8%, 97.7%, and 98.4% for 10, 20, and 30% R/F, respectively.

The influence of the R/F ratio on the tar results are consistent with other research works in lab-scale DFB steam gasification of plastic residues and wood pellets as a mixture feed, which found that tar increased with an increasing plastic ratio in the feed [

20,

21]. Tar concentrations from the RDF mixtures were high, and it must be removed further from the product gas before it can be used in the gas engine. Alternatively, more catalysts such as calcium hydroxide can be added into the gasifier for further cracking of the tar inside the gasifier. In addition, an additional scrubber or a fixed bed adsorber might be integrated in series into the current system to further reduce tar. Otherwise, a new design of the scrubber is necessary for the tar removal from RDF gasification.

3.4. Influence of R/F Ratio on Engine Power

It was intended to send the clean product gas from the binary feed to the Caterpillar (Cat) G3516C gas engine. However, due to the higher tar content in the product gas of the binary feed than that specified by the engine manufacturer, utilisation of the gas in the gas engine was limited. The product gas from the binary feed was not drawn into the gas engine to avoid blockage and knocking of the Cat engine. The current study, however, provides the data of engine power of the Cat gas engine with 0% R/F product gas, presented in

Figure 14. The product gas flow rate of about 600 Nm

3/h was required to feed into the engine to generate 600–620 kW electricity. This factual rating and engine efficiency is slightly lower than that calculated from the IPSEpro simulation data.