An Analytical Hierarchy-Based Method for Quantifying Hydraulic Fracturing Stimulation to Improve Geothermal Well Productivity

Abstract

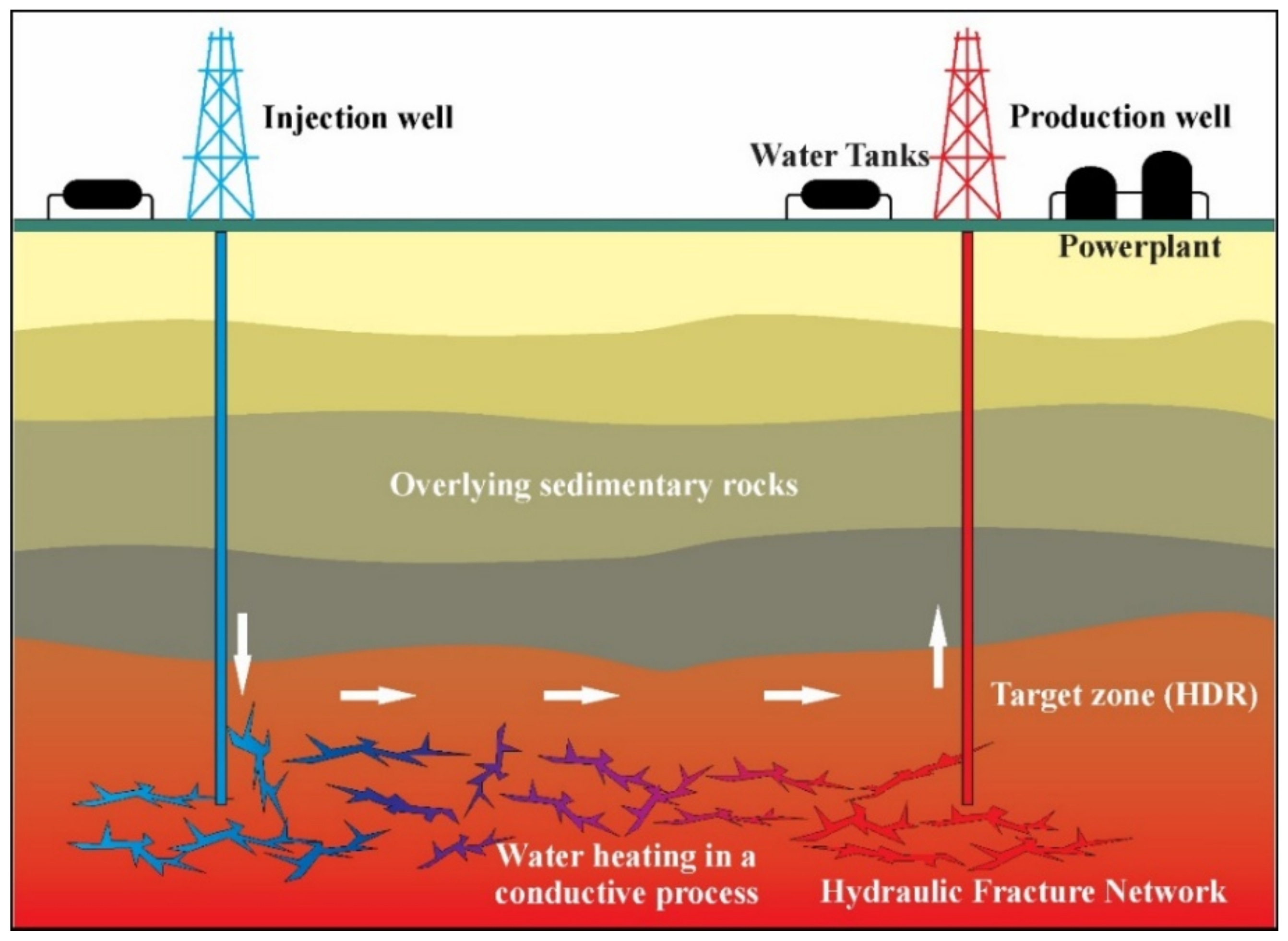

:1. Introduction

2. A Review of Hydraulic Fracturing in the Global Geothermal Fields

3. Theory and Method

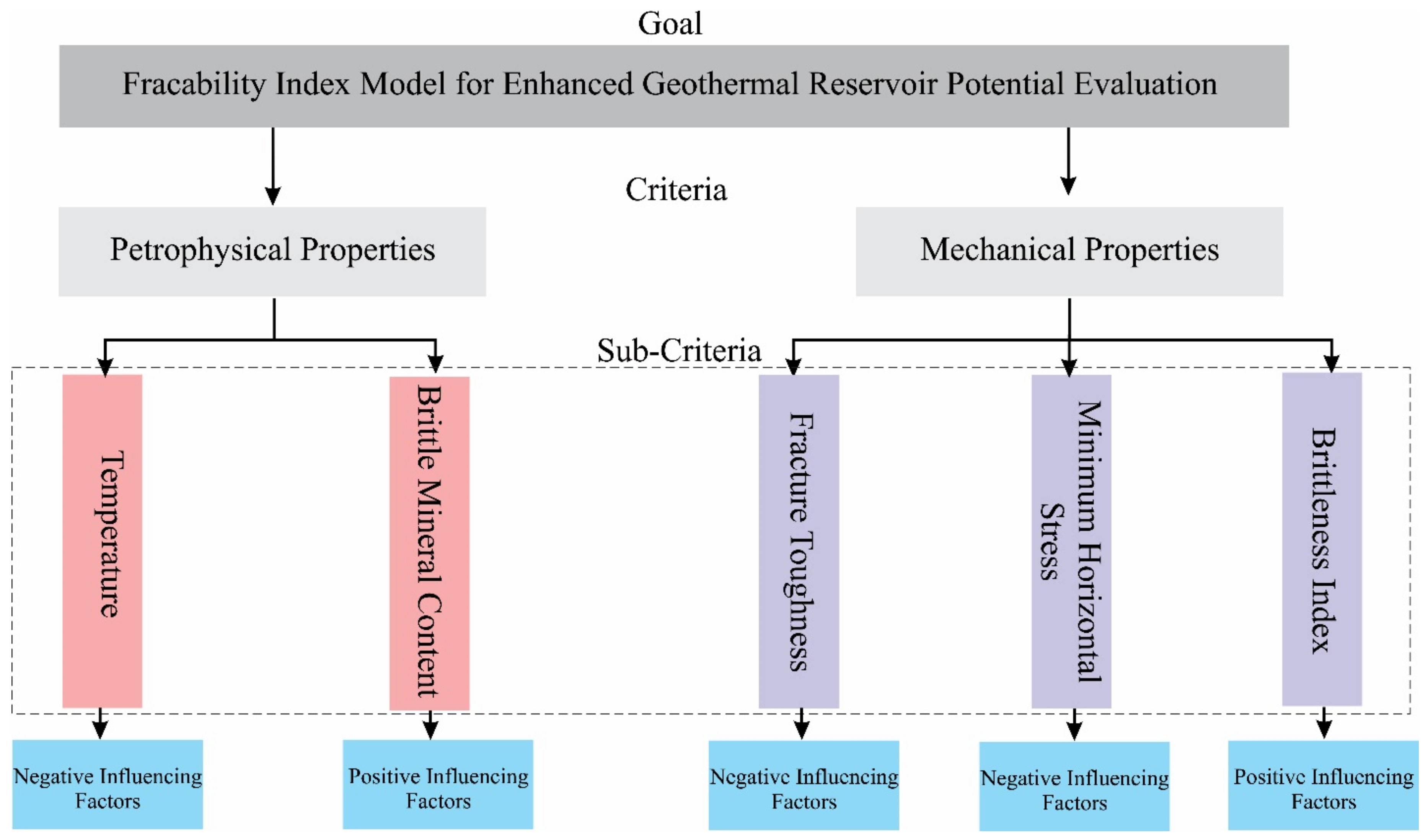

3.1. Rock Fracability Influencing Factors

3.1.1. Fracture Toughness

3.1.2. Brittleness Index

3.1.3. Minimum Horizontal In-Situ Stress

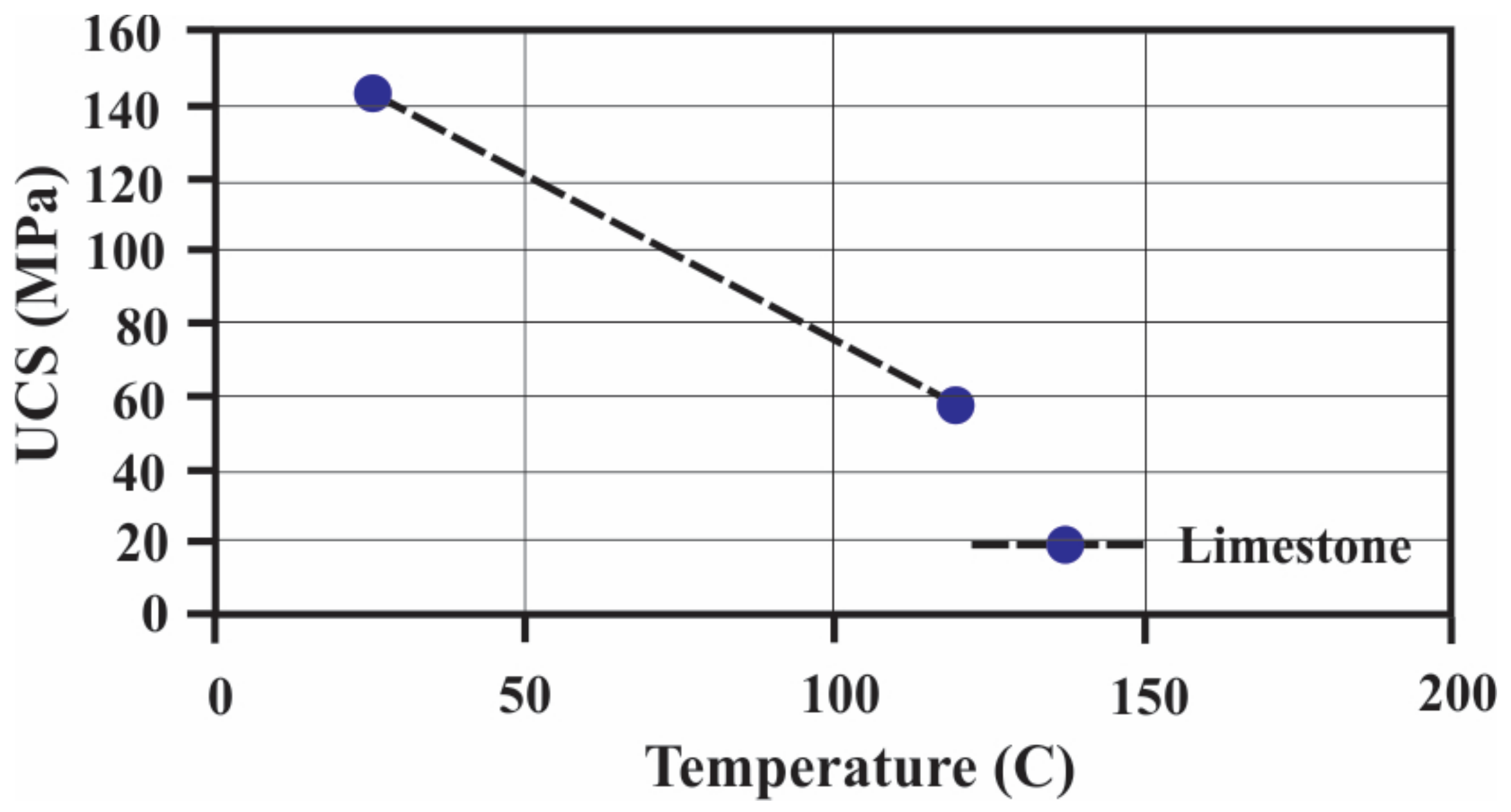

3.1.4. Temperature

3.1.5. Other Influencing Factors

3.2. Quantification of Analytical Hierarchy-Based FI Model

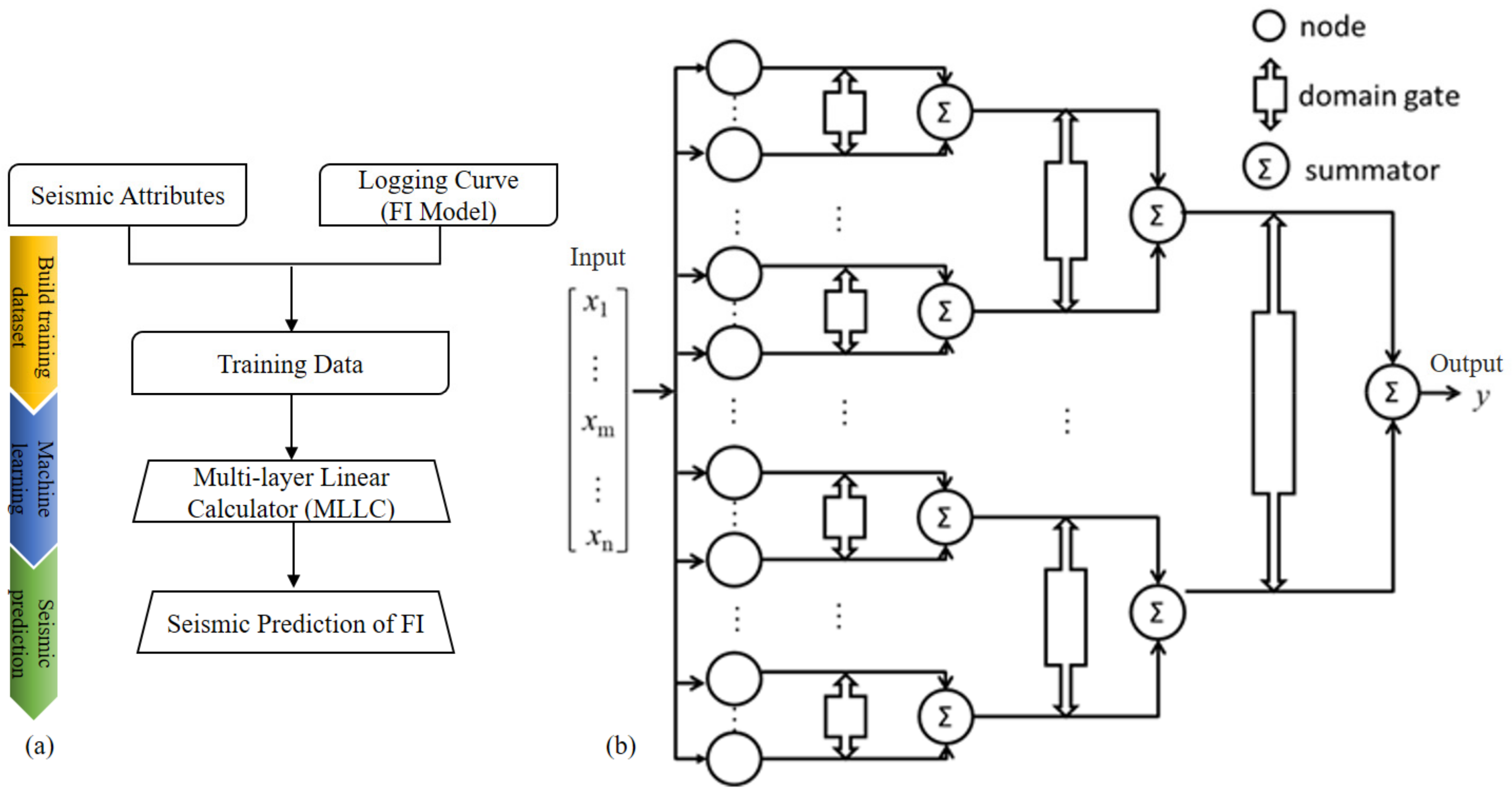

3.3. Workflow for Seismic Prediction of FI with Multi-Layer Linear Calculator

4. Results and Discussion

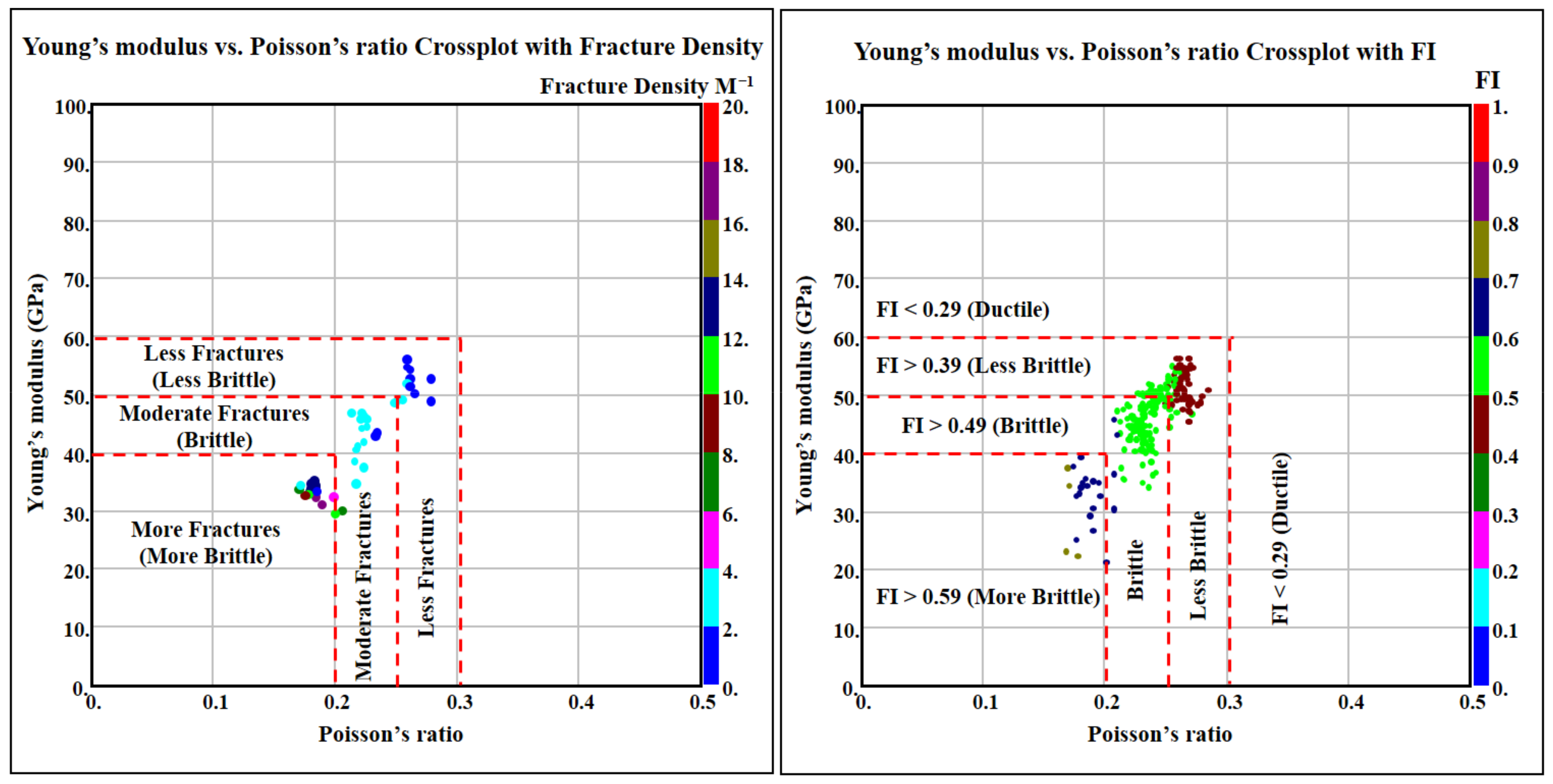

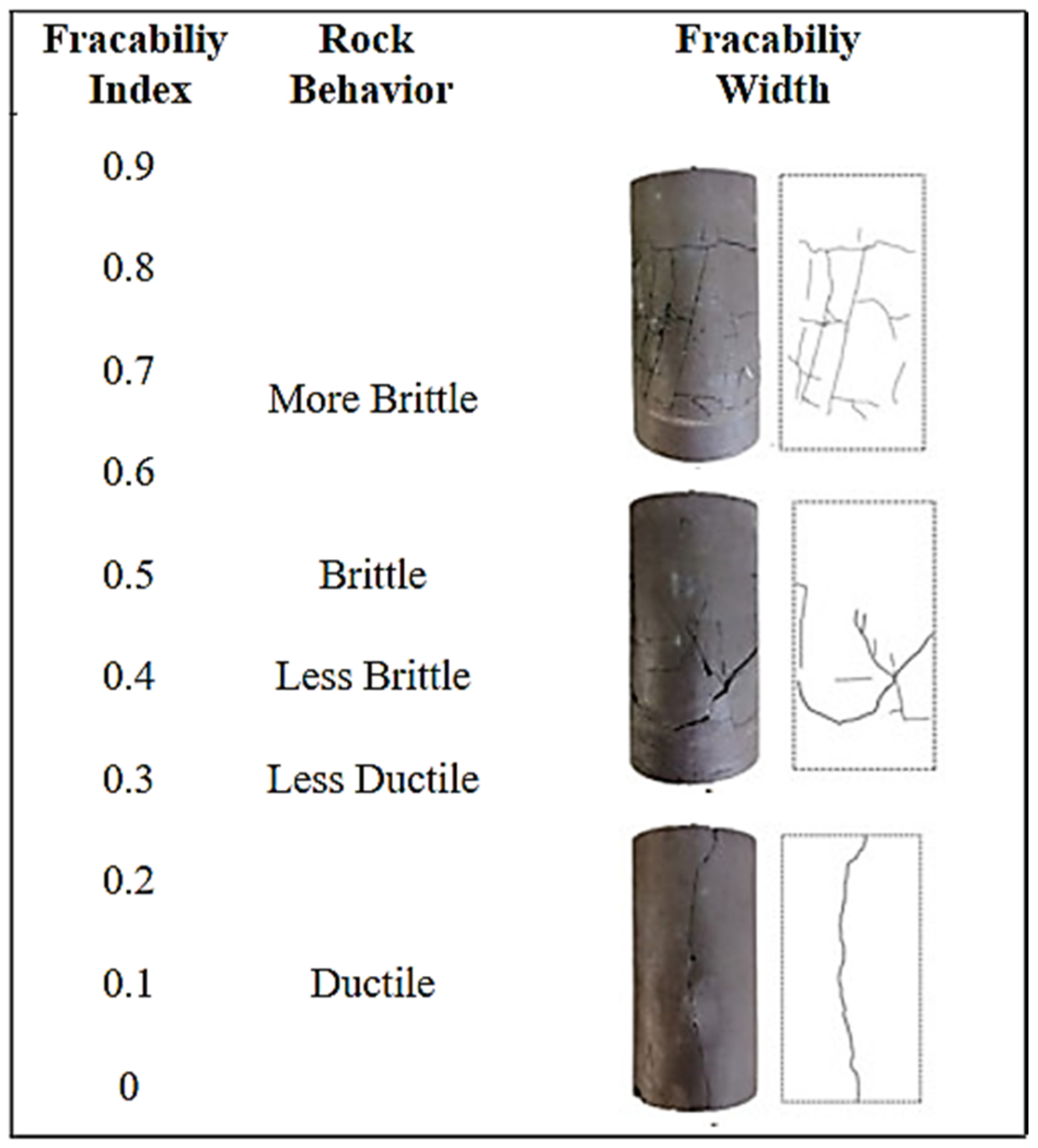

4.1. Fracability Index Classification

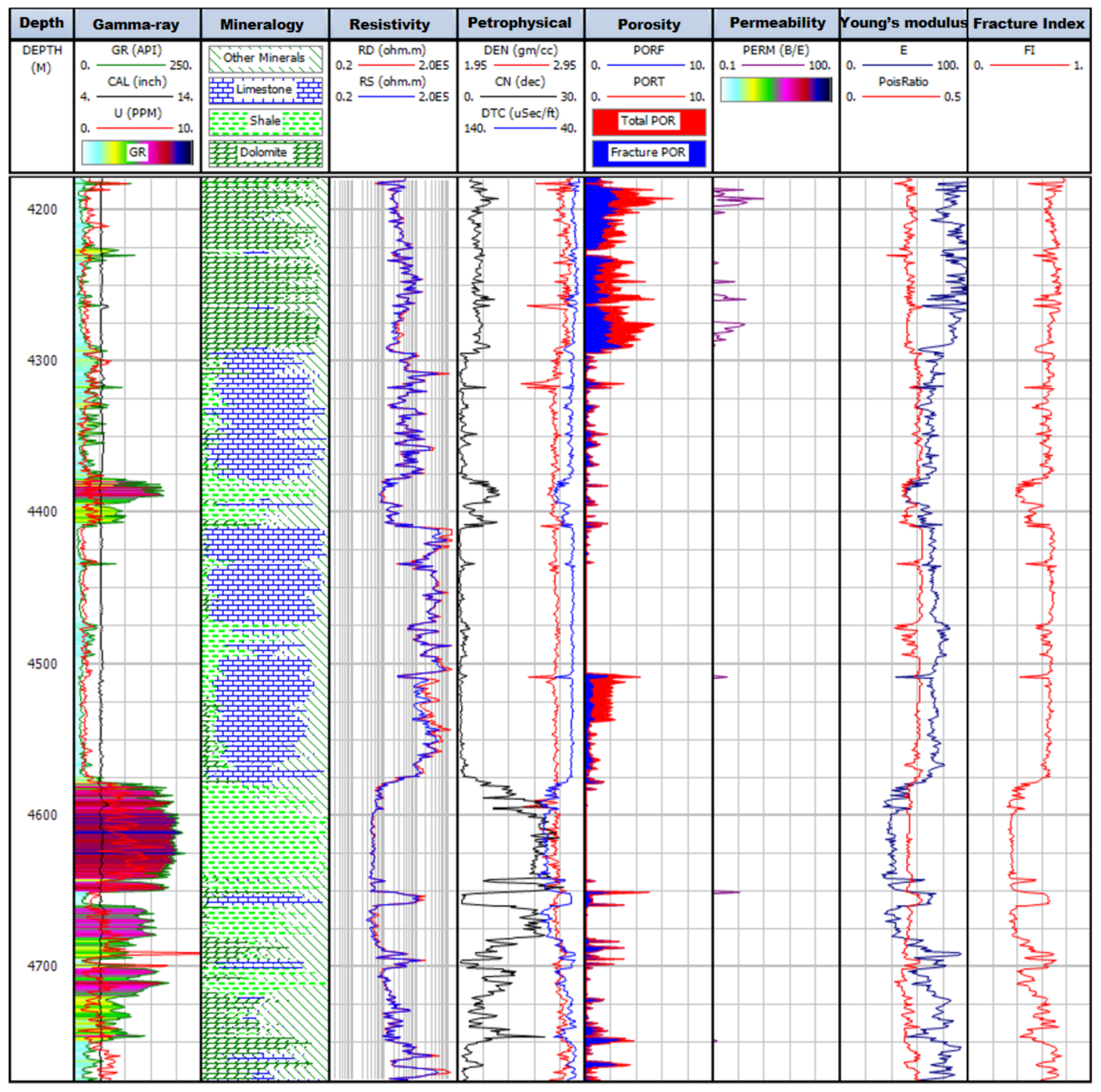

4.2. Hydraulic Fracturing in Geothermal Reservoirs

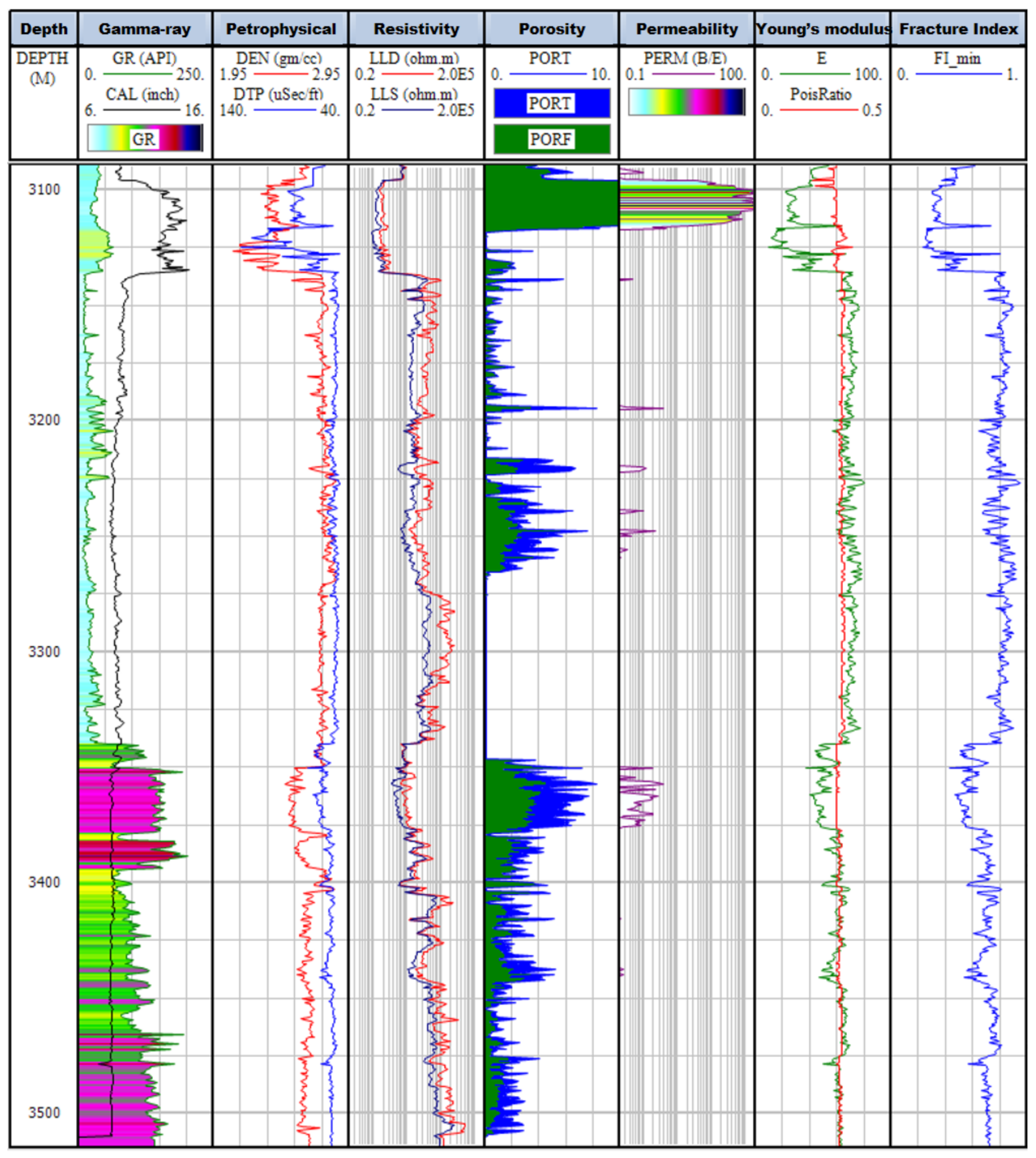

4.3. Hydraulic Fracturing in Shale Gas Well

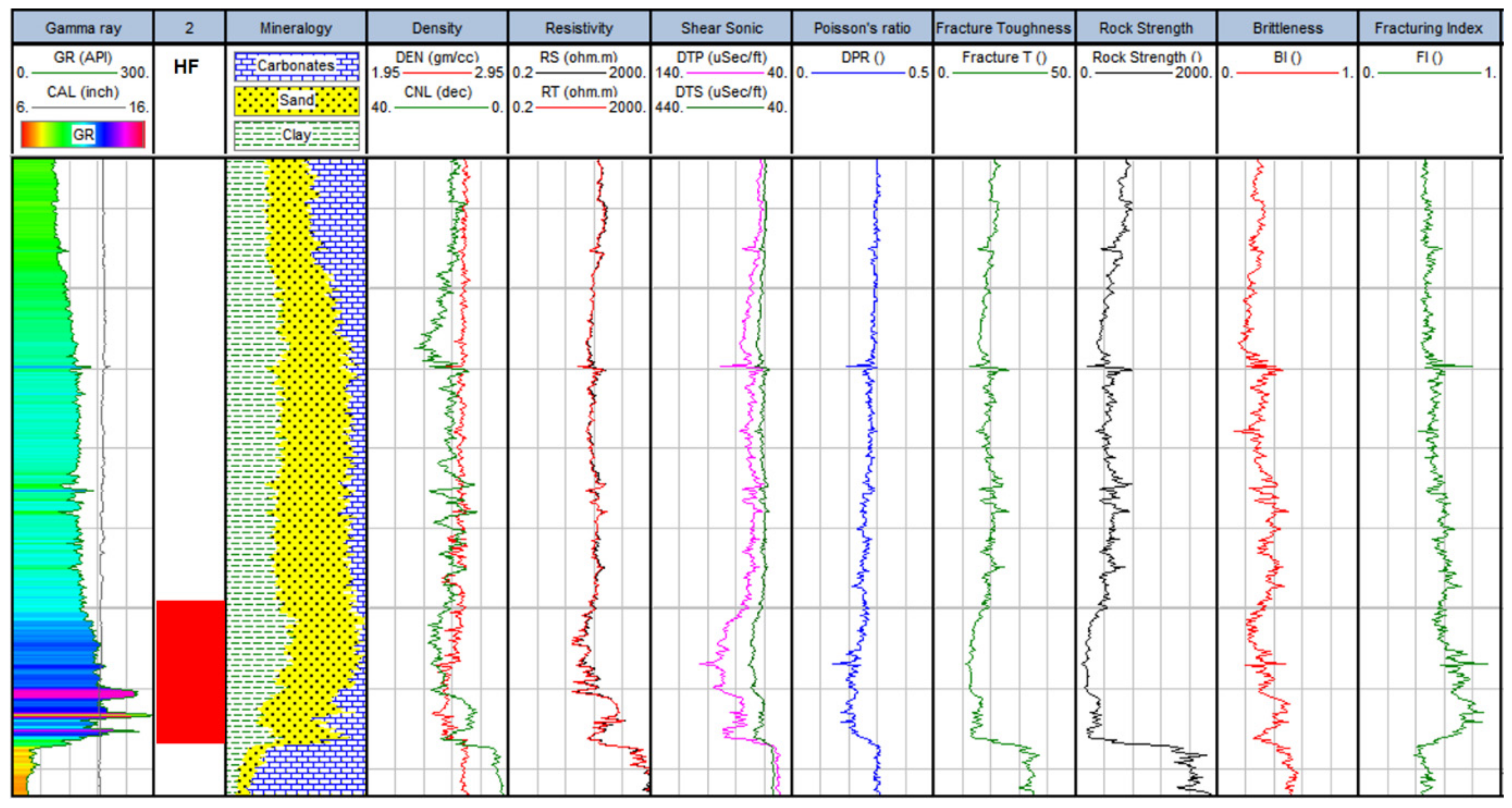

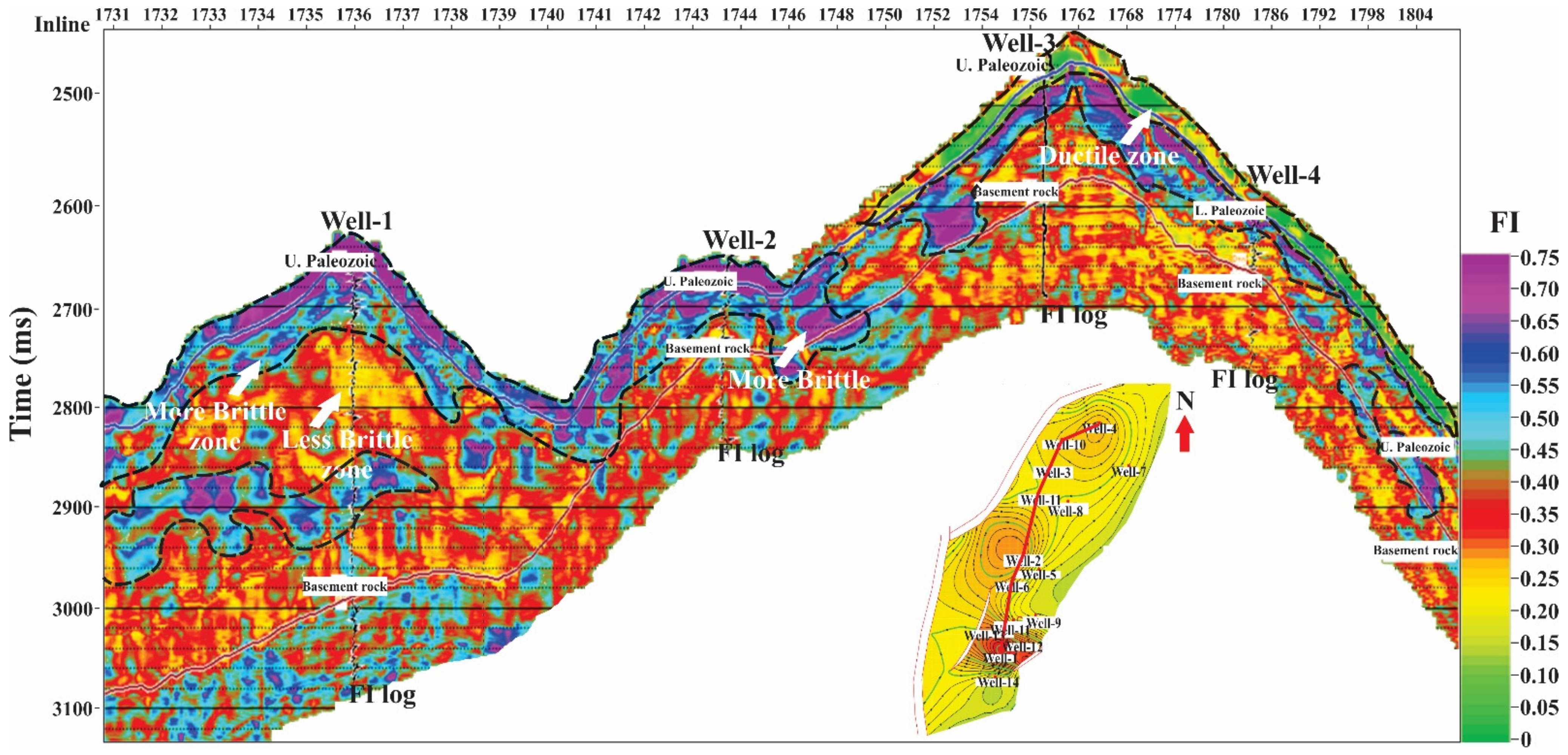

4.4. Quantitative Seismic Prediction of FI

4.5. Analysis of Hydraulic Fracturing

5. Conclusions

- Rock fracability in HDR is primarily controlled by the temperature, brittleness index, brittle mineral composition, fracture toughness, and the magnitude of stresses. The analytical hierarchy process was used to develop a continuous fracability evaluation mathematical model by integrating qualitative and quantitative approaches. The model quantifies the strength of low permeability carbonate geothermal reservoirs and horizontal sections of shale fracability.

- The improved fracability index model demonstrates a high-quality geothermal reservoir section along low permeability zones and can be utilized confidently to generate a complex fracture network system during hydraulic fracturing for EGS. Seismic inversion profiles indicate high FI and brittle behavior on top of the Paleozoic formation in the low parts of Well-1 and Well-2. Meanwhile, the top of the Paleozoic formation around Well-3 and Well-4 is ductile and difficult to fracture during hydraulic fracturing for EGS.

- The field case study for low permeability geothermal reservoirs shows that the carbonate rocks are prone to fracture and have high heat and flow exchange efficiency. The rock has the highest potential for EGS.

- The study took into account a wide range of geomechanical and petrophysical properties as well as temperature effects to quantify rock fracability. Still, it has some limitations that need improvement in future studies. Furthermore, acid dissolution, pore structure, and fluid type can enhance geothermal rock permeability in addition to its geomechanical properties. This is especially true of carbonate reservoir exploration since it is an incredibly effective method to fracture the reservoirs.

- We believe that the improved fracability index and case studies will serve as practical examples for future research in similar areas, particularly in carbonate geothermal reservoirs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yasin, Q.; Du, Q.; Sohail, G.M.; Ismail, A. Fracturing index-based brittleness prediction from geophysical logging data: Application to Longmaxi shale. Geomech. Geophys. Geo-Energ. Geo-Resour. 2018, 4, 301–325. [Google Scholar] [CrossRef]

- Li, Z.; Li, L.; Li, M.; Zhang, L.; Zhang, Z.; Huang, B.; Tang, C.A. A numerical investigation on the effects of rock brittleness on the hydraulic fractures in the shale reservoir. J. Nat. Gas Sci. Eng. 2018, 50, 22–32. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.; Petre, E.; Grieser, B.; Kundert, D. A Practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the barnett shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008; p. SPE-115258-MS. [Google Scholar]

- Sone, H.; Zoback, M. Mechanical properties of shale-gas reservoir rocks—Part 1: Static and dynamic elastic properties and anisotropy. Geophysics 2013, 78, 381–392. [Google Scholar] [CrossRef] [Green Version]

- Yuan, J.; Zhou, J.; Liu, S.; Feng, Y.; Deng, J.; Xie, Q.; Lu, Z. An Improved Fracability-Evaluation Method for Shale Reservoirs Based on New Fracture Toughness-Prediction Models. SPE J. 2017, 22, 1704–1713. [Google Scholar] [CrossRef]

- Yasin, Q.; Sohail, G.M.; Liu, K.-Y.; Du, Q.-Z.; Boateng, C.D. Study on brittleness templates for shale gas reservoirs-A case study of Longmaxi shale in Sichuan Basin, southern China. Pet. Sci. 2021, 18, 1370–1389. [Google Scholar] [CrossRef]

- Bai, M. Why are brittleness and fracability not equivalent in designing hydraulic fracturing in tight shale gas reservoirs. Petroleum 2016, 2, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Guo, T.; Zhang, S.C.; Ge, H. A new method for evaluating ability of forming fracture network in shale reservoir. Rock Soil Mech. 2013, 34, 947–954. [Google Scholar]

- Hou, B.; Chen, M.; Li, Z.; Wang, Y.; Diao, C. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 2014, 41, 833–838. [Google Scholar] [CrossRef]

- Jin, X.; Shah, S.N.; Roegiers, J.-C.; Zhang, B. An Integrated Petrophysics and Geomechanics Approach for Fracability Evaluation in Shale Reservoirs. SPE J. 2015, 20, 518–526. [Google Scholar] [CrossRef]

- Sui, L.; Ju, Y.; Yang, Y.; Yang, Y.; Li, A. A quantification method for shale fracability based on analytic hierarchy process. Energy 2016, 115, 637–645. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, S.; Cao, H.; Zheng, M.; Sun, P.; Luo, X. Fracability evaluation of shale gas reservoir-A case study in the Lower Cambrian Niutitang formation, northwestern Hunan, China. J. Pet. Sci. Eng. 2018, 164, 675–684. [Google Scholar] [CrossRef]

- Fan, Z.; Parashar, R. Analytical Solutions for a Wellbore Subjected to a Non-isothermal Fluid Flux: Implications for Optimizing Injection Rates, Fracture Reactivation, and EGS Hydraulic Stimulation. Rock Mech. Rock Eng. 2019, 52, 4715–4729. [Google Scholar] [CrossRef]

- McClure, M.W.; Horne, R.N. An investigation of stimulation mechanisms in Enhanced Geothermal Systems. Int. J. Rock Mech. Min. Sci. 2014, 72, 242–260. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Pan, Y.; Liu, B.; Shi, Y.; Wei, J.; Li, W. Study on CO2 foam fracturing model and fracture propagation simulation. Energy 2022, 238, 121778. [Google Scholar] [CrossRef]

- Mulyadi. Case study: ‘Hydraulic fracturing experience in the wayang windu geothermal field’. In Proceedings of the World Geothermal Congress 2010, Bali, Indonesia, 25–29 April 2010. [Google Scholar]

- Tester, J.; Anderson, B.; Batchelor, A.; Blackwell, D.; DiPippo, R.; Drake, M.; Garnish, J.; Livesay, B.; Moore, M. The Future of Geothermal Energy—Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; Massachusetts Institute of Technology: Cambridge, MA, USA; Idaho National Laboratory: Idaho Falls, ID, USA, 2006. [Google Scholar]

- Moska, R.; Labus, K.; Kasza, P. Hydraulic Fracturing in Enhanced Geothermal Systems—Field, Tectonic and Rock Mechanics Conditions—A Review. Energies 2021, 14, 5725. [Google Scholar] [CrossRef]

- Zhou, L.; Zhu, Z.; Xie, X.; Hu, Y. Coupled thermal–hydraulic–mechanical model for an enhanced geothermal system and numerical analysis of its heat mining performance. Renew. Energy 2022, 181, 1440–1458. [Google Scholar] [CrossRef]

- Ai, K.; Duan, L.; Gao, H.; Jia, G. Hydraulic Fracturing Treatment Optimization for Low Permeability Reservoirs Based on Unified Fracture Design. Energies 2018, 11, 1720. [Google Scholar] [CrossRef] [Green Version]

- Amiri, H.; Ramezanzadeh, A.; Parhizgar, M. Candidate well selection for hydraulic fracturing treatment—New fracability index based on a case study in a fractured carbonate reservoir in Iran. In Proceedings of the 79th EAGE Conference and Exhibition, Paris, France, 12–15 June 2017. [Google Scholar]

- Gandossi, L. An Overview of Hydraulic Fracturing and Other Formation Stimulation Technologies for Shale Gas Production; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar]

- Britt, L. Fracture stimulation fundamentals. J. Nat. Gas Sci. Eng. 2012, 8, 34–51. [Google Scholar] [CrossRef]

- Casini, M.; Ciuffi, S.; Fiordelisi, A.; Mazzotti, A.; Stucchi, E. Results of a 3D seismic survey at the Travale (Italy) test site. Geothermics 2010, 39, 4–12. [Google Scholar] [CrossRef]

- Baujard, C.; Genter, A.; Dalmais, E.; Maurer, V.; Hehn, R.; Rosillette, R.; Vidal, J.; Schmittbuhl, J. Hydrothermal characterization of wells GRT-1 and GRT-2 in Rittershoffen, France: Implications on the understanding of natural flow systems in the rhine graben. Geothermics 2017, 65, 255–268. [Google Scholar] [CrossRef] [Green Version]

- Lengliné, O.; Boubacar, M.; Schmittbuhl, J. Seismicity related to the hydraulic stimulation of GRT1, Rittershoffen, France. Geophys. J. Int. 2017, 208, 1704–1715. [Google Scholar] [CrossRef]

- Morris, C.W.; Sinclair, A.R. Evaluation Of Bottomhole Treatment Pressure for Geothermal Well Hydraulic Fracture Stimulation. J. Pet. Technol. 1984, 36, 829–836. [Google Scholar] [CrossRef]

- Siler, D.L.; Faulds, J.E.; Hinz, N.H.; Dering, G.M.; Edwards, J.H.; Mayhew, B. Three-dimensional geologic mapping to assess geothermal potential: Examples from Nevada and Oregon. Geotherm. Energy 2019, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Legarth, B.; Huenges, E.; Zimmermann, G. Hydraulic fracturing in a sedimentary geothermal reservoir: Results and implications. Int. J. Rock Mech. Min. Sci. 2005, 42, 1028–1041. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Y.; Yu, Z.; Hu, Z.; Li, L.; Zhang, S.; Fu, L.; Zhou, L.; Xie, Y. Exploratory research into the enhanced geothermal system power generation project: The Qiabuqia geothermal field, Northwest China. Renew. Energy 2019, 139, 52–70. [Google Scholar] [CrossRef]

- Norbeck, J.H.; McClure, M.W.; Horne, R.N. Field observations at the Fenton Hill enhanced geothermal system test site support mixed-mechanism stimulation. Geothermics 2018, 74, 135–149. [Google Scholar] [CrossRef]

- Wyborn, D.; de Graaf, L.; Davidson, S.; Hann, S. Development of Australia’s first hot Fractured Rock (HFR) underground heat exchanger, Cooper Basin, South Australia. In Proceedings of the World Geothermal Congress 2005, Antalya, Turkey, 24–29 April 2005. [Google Scholar]

- Holl, H.-G.; Barton, C. Habanero field—Structure and state of stress. In Proceedings of the World Geothermal Congress, Melbourne, Australia, 19–25April 2015. [Google Scholar]

- Holl, H.-G. What Did we Learn about EGS in the Cooper Basin? Geodynamics Limited: London, UK, 2015. [Google Scholar]

- Vidal, J.; Genter, A. Overview of naturally permeable fractured reservoirs in the central and southern Upper Rhine Graben: Insights from geothermal wells. Geothermics 2018, 74, 57–73. [Google Scholar] [CrossRef]

- Schindler, M.; Nami, P.; Schellschmidt, R.; Teza, D.; Tischner, T. Summary of Hydraulic Stimulation Operations in the 5 km Deep Crystalline HDR/EGS Reservoir at Soultz-Sous-Forêts. In Proceedings of the Thirty-Third Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 28–30 January 2008. SGP-TR-185. [Google Scholar]

- Moeck, I.; Schandelmeier, H.; Holl, H.-G. The stress regime in a Rotliegend reservoir of the Northeast German Basin. Int. J. Earth Sci. 2009, 98, 1643–1654. [Google Scholar] [CrossRef] [Green Version]

- Moeck, I.S. Catalog of geothermal play types based on geologic controls. Renew. Sustain. Energy Rev. 2014, 37, 867–882. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Kim, K.-I.; Xie, L.; Yoo, H.; Min, K.-B.; Kim, M.; Yoon, B.; Kim, K.Y.; Zimmermann, G.; Guinot, F.; et al. Observations and analyses of the first two hydraulic stimulations in the Pohang geothermal development site, South Korea. Geothermics 2020, 88, 101905. [Google Scholar] [CrossRef]

- Kwon, S.; Xie, L.; Park, S.; Kim, K.-I.; Min, K.-B.; Kim, K.Y.; Zhuang, L.; Choi, J.; Kim, H.; Lee, T.J. Characterization of 4.2-km-Deep Fractured Granodiorite Cores from Pohang Geothermal Reservoir, Korea. Rock Mech. Rock Eng. 2019, 52, 771–782. [Google Scholar] [CrossRef]

- Sowiżdżał, A.; Gładysz, P.; Pająk, L. Sustainable Use of Petrothermal Resources—A Review of the Geological Conditions in Poland. Resources 2021, 10, 8. [Google Scholar] [CrossRef]

- Wójcicki, A.; Sowiżdżał, A.; Bujakowski, W. Ocena Potencjału, Bilansu Cieplnego i Perspektywicznych Struktur Geologicznych dla Potrzeb Zamkniętych Systemów Geotermicznych (Hot Dry Rocks) w Polsce; Ministerstwo Środowiska: Warsaw, Poland, 2013.

- Zuchiewicz, W.; Badura, J.; Jarosinski, M. Neotectonics of Poland: Selected examples. Biul. Panstw. Inst. Geol. 2007, 425, 105–128. [Google Scholar]

- Zhang, H.; Wan, Z.; Elsworth, D. Failure Behavior of Hot-Dry-Rock (HDR) in Enhanced Geothermal Systems: Macro to Micro Scale Effects. Geofluids 2020, 2020, 8878179. [Google Scholar] [CrossRef]

- Zimmermann, G.; Blöcher, G.; Reinicke, A.; Brandt, W. Rock specific hydraulic fracturing and matrix acidizing to enhance a geothermal system—Concepts and field results. Tectonophysics 2011, 503, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Zhang, D.; Ranjith, P.G.; Perera, M.S.A. The brittleness indices used in rock mechanics and their application in shale hydraulic fracturing: A review. J. Pet. Sci. Eng. 2016, 143, 158–170. [Google Scholar] [CrossRef]

- Jin, Y.; Yuan, J.; Chen, M.; Chen, K.; Lu, Y.; Wang, H. Determination of Rock Fracture Toughness K IIC and its Relationship with Tensile Strength. Rock Mech. Rock Eng. 2011, 44, 621–627. [Google Scholar] [CrossRef]

- Yasin, Q.; Baklouti, S.; Khalid, P.; Ali, S.H.; Boateng, C.D.; Du, Q. Evaluation of shale gas reservoirs in complex structural enclosures: A case study from Patala Formation in the Kohat-Potwar Plateau, Pakistan. J. Pet. Sci. Eng. 2021, 198, 108225. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, K.; Chen, Z.; Zhang, K.; Ji, D.; Zhong, H.; Gonzalez Perdomo, M. A Novel Model of Brittleness Index for Shale Gas Reservoirs: Confining Pressure Effect. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 9–11 November 2015. [Google Scholar]

- Waters, G.A.; Lewis, R.E.; Bentley, D.C. The Effect of Mechanical Properties Anisotropy in the Generation of Hydraulic Fractures in Organic Shales. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011; p. SPE-146776-MS. [Google Scholar]

- Zhang, L.-Y.; Ma, L.-C.; Zhuo, X.-Z.; Dong, M.; Li, B.-W.; Liu, S.-X.; Sun, D.-S.; Wu, D.; Zhou, X.-G. Mesozoic–Cenozoic stress field magnitude in Sichuan Basin, China and its adjacent areas and the implication on shale gas reservoir: Determination by acoustic emission in rocks. China Geol. 2020, 3, 591–601. [Google Scholar] [CrossRef]

- Pinińska, J. Wpływ podwyższonej temperatury na właściwości mechaniczne skał. Prace Naukowe Instytutu Geotechniki i Hydrotechniki Politechniki Wrocławskiej. Konferencje 2007, 76, 527–534. [Google Scholar]

- Wan, Z.-J.; Zhao, Y.-S.; Zhang, Y.; Wang, C. Research status quo and prospection of mechanical characteristics of rock under high temperature and high pressure. Procedia Earth Planet. Sci. 2009, 1, 565–570. [Google Scholar] [CrossRef] [Green Version]

- Fan, Z.Q.; Jin, Z.H.; Johnson, S.E. Modelling petroleum migration through microcrack propagation in transversely isotropic source rocks. Geophys. J. Int. 2012, 190, 179–187. [Google Scholar] [CrossRef] [Green Version]

- Jin, Z.H.; Johnson, S.E.; Fan, Z.Q. Subcritical propagation and coalescence of oil-filled cracks: Getting the oil out of low-permeability source rocks. Geophys. Res. Lett. 2010, 37, 1. [Google Scholar] [CrossRef]

- Yasin, Q.; Ding, Y.; Baklouti, S.; Boateng, C.D.; Du, Q.; Golsanami, N. An integrated fracture parameter prediction and characterization method in deeply-buried carbonate reservoirs based on deep neural network. J. Pet. Sci. Eng. 2022, 208, 109346. [Google Scholar] [CrossRef]

- Sharma, R.; Chopra, S.; Nemati, M.; Keay, J.; Lines, L. Integration of geomechanical and mineralogical data for fracability evaluation in Utica Shale play. In SEG Technical Program Expanded Abstracts 2017; Society of Exploration Geophysicists: Houston, TX, USA, 2017; pp. 3189–3193. [Google Scholar]

- Sohail, G.M.; Hawkes, C.D.; Yasin, Q. An integrated petrophysical and geomechanical characterization of Sembar Shale in the Lower Indus Basin, Pakistan, using well logs and seismic data. J. Nat. Gas Sci. Eng. 2020, 78, 103327. [Google Scholar] [CrossRef]

- Yasin, Q.; Sohail, G.M.; Ding, Y.; Ismail, A.; Du, Q. Estimation of Petrophysical Parameters from Seismic Inversion by Combining Particle Swarm Optimization and Multilayer Linear Calculator. Nat. Resour. Res. 2020, 29, 3291–3317. [Google Scholar] [CrossRef]

- Ding, Y.; Cui, M.; Zhao, F.; Shi, X.; Huang, K.; Yasin, Q. A Novel Neural Network for Seismic Anisotropy and Fracture Porosity Measurements in Carbonate Reservoirs. Arab. J. Sci. Eng. 2022, 47, 7219–7241. [Google Scholar] [CrossRef]

- Sui, H.; Gao, W.; Hu, R. A New Evaluation Method for the Fracability of a Shale Reservoir Based on the Structural Properties. Geofluids 2019, 2019, 2079458. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim Mohamed, M.; Mohamed, M.; Coskuner, Y.; Ibrahim, M.; Pieprzica, C.; Ozkan, E. Integrated approach to evaluate rock brittleness and fracability for hydraulic fracturing optimization in shale gas. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium, Oklahoma City, OK, USA, 9–10 April 2019. [Google Scholar]

- Sun, Z.; Lin, C.; Zhu, P.; Chen, J. Analysis and modeling of fluvial-reservoir petrophysical heterogeneity based on sealed coring wells and their test data, Guantao Formation, Shengli oilfield. J. Pet. Sci. Eng. 2018, 162, 785–800. [Google Scholar] [CrossRef]

- Xing, L.; Wang, W.; Xia, Z.; Chai, B.; Wang, Y. Evaluation of the Modification Potential for Carbonate Geothermal Rocks by considering Multiple Mechanics Properties and Acid Dissolution in the Jizhong Depression, China. Lithosphere 2022, 2021, 6289799. [Google Scholar] [CrossRef]

- Yao, T.Y.; Li, J.S.; Huang, Y.Z. Effects of temperature and stress on porosity and permeability of low permeability reservoir. J. Shenzhen Univ. Sci. Eng. 2012, 29, 154–158. [Google Scholar] [CrossRef]

- Li, Q.; Xing, H.; Liu, J.; Liu, X. A review on hydraulic fracturing of unconventional reservoir. Petroleum 2015, 1, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Warpinski, N.R.; Mayerhofer, M.J.; Vincent, M.C.; Cipolla, C.L.; Lolon, E.P. Stimulating Unconventional Reservoirs: Maximizing Network Growth While Optimizing Fracture Conductivity. J. Can. Pet. Technol. 2009, 48, 39–51. [Google Scholar] [CrossRef]

| EGS Site | Time Duration | Target Depth (m) | Zone Temp. (°C) | Lithofacies | Fault Regimes | Principal Stresses (MPa) | Ultrasonic Velocities | Fracturing Fluid |

|---|---|---|---|---|---|---|---|---|

| Qiabuqia (China) | 2016/17-present | 3700 [30] | 236 [30] | Middle triassic granite, Anisian | Normal | σv = 96, σH = 88, σh = 70 | E = 48, v = 0.28, E = 42, v = 0.23 [30] | HSP 20/40 cross-linked gel [30] |

| Fenton Hill (USA) | 1974–1995 | 4400 (EE-2 well) [17] | 327 at 4390 m [17] | granodiorite, gneiss | strike-slip/normal [31] | σH = 25 σh = 16.2 PP = 10.1 [31] | E = 18, v = 0.15 (3916 m). 4102 m depth: E= 33 v = 0.16 (4102 m) [17] | MHF—fresh water [31] |

| Habanero Cooper Basin (Australia) | 2003–2016 | 4400 [32] | 248.5 [32] | syenogranite, medium and coarse-grained [33] | strike-slip, reverse, and over-thrust [34] | σv = 98 σH = 151 σh = 123 PP = 73 [33] | E = 65, v = 0.25 (3657 m) | Fresh water [32] |

| Rhine Graben (Western Europe) | 2005-present | Soultz 5200 [35] | 200 [35] | Porphyric granites MFK, two-mica granites. Carboniferous [36] | Mixed, normal and strike-slip [25] | σv = 54.8 σh = 29.6 PP = 22.5; [26] | E (granite) = 80 GPa (Hydraulic conductivity zones) | Brine, then MHF—fresh water [36] |

| GeneSys Hannover (Germany) | 2005–2013 | 3834 [37] | 168 [37] | Buntsandstein sediments with low permeability (Permian) | Normal | σh = 77 [37] | E = 55, v = 0.21 E = 49, v = 0.23 (For clays) | Fresh water |

| Groß Schönebeck (Germany) | 2006-present | 4100 [37] | 149 | Clastic and volcanic Rock (Permian) | Normal & strike-slip (Moeck [38] | σv = 100, σH = 91, σh = 55, PP = 44 [37] | E = 55 v = 0.20 (For volcanic rocks) E = 55 v = 0.18 (For sediments) | MHF—fresh water or quartz sand 20/40 mesh, cross-linked gel with high strength in HTU linear gel |

| Pohang (South Korea) | 2010–2017 | 4200 [39] | 140 | Laminated Granodiorite, Permian | Reverse strike-slip | σv = 108, σH = 143, σh = 109, σv = 111, σH = 126, σh = 92 | VP = 4346, VS = 2676 Ed = 45 [40] | Fresh water [39] |

| Poland (Karkonosze Mountains, Gorzów Block, Mogilno-Łód’z Trough, Szczecin Trough, Upper Silesian Block | The site has not yet been fractured | 4000 to 5700 m [41] | 165 to 175 [42] 150 to 170 [41] | upper Carboniferous Granite at lower Permian low-permeable Triassic sediments [42] Permian or Carboniferous sediments (Sowiz˙dz˙ał et al., 2021) | normal with strike-slip component (Western Poland) [43] strike-slip (Upper Silesian Block) | σv = 96 (Karkonosze Mount), σv = 103 (Gorzów Block) σv = 136 (Mogilno-Łód’z Trough); σv = 120 (Szczecin Trough); σv = 120 (Upper Silesian Block). (Jarosi´nski et al., 2005) | The site has not yet been fractured |

| Numerical Scale | Description |

|---|---|

| 1 | i and j equally contribute to the factors |

| 3 | i and j are slightly more important |

| 5 | i and j are more important |

| 7 | i and j are strongly important |

| 9 | i and j are extremely important |

| 2, 4, 6, 8 Final preparation | values indicate an intermediate level of significance analyze the two targets in reverse order |

| Brittleness Index | Brittle Mineral Content | Fracture Toughness | Min. Horizontal Stress | Temperature | |

|---|---|---|---|---|---|

| Brittleness index | 1.00 | 2.00 | 3.00 | 5.00 | 7.00 |

| Brittle mineral content | 0.50 | 1.00 | 2.00 | 3.00 | 4.00 |

| Fracture toughness | 0.33 | 0.50 | 1.00 | 2.00 | 3.00 |

| Min. horizontal stress | 0.25 | 0.14 | 0.33 | 1.00 | 2.00 |

| Temperature | 0.15 | 0.12 | 0.28 | 0.50 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yasin, Q.; Majdański, M.; Awan, R.S.; Golsanami, N. An Analytical Hierarchy-Based Method for Quantifying Hydraulic Fracturing Stimulation to Improve Geothermal Well Productivity. Energies 2022, 15, 7368. https://doi.org/10.3390/en15197368

Yasin Q, Majdański M, Awan RS, Golsanami N. An Analytical Hierarchy-Based Method for Quantifying Hydraulic Fracturing Stimulation to Improve Geothermal Well Productivity. Energies. 2022; 15(19):7368. https://doi.org/10.3390/en15197368

Chicago/Turabian StyleYasin, Qamar, Mariusz Majdański, Rizwan Sarwar Awan, and Naser Golsanami. 2022. "An Analytical Hierarchy-Based Method for Quantifying Hydraulic Fracturing Stimulation to Improve Geothermal Well Productivity" Energies 15, no. 19: 7368. https://doi.org/10.3390/en15197368