Salt Deposits and Brine Blowout: Development of a Cross-Linking Composition for Blocking Formations and Methodology for Its Testing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Methodology

2.2. Study of Formation Fluid Samples from Developing Intervals

2.3. Study of the Compatibility of Drilling Fluids and Brine and Brine and Polymer Components of Blocking Compositions

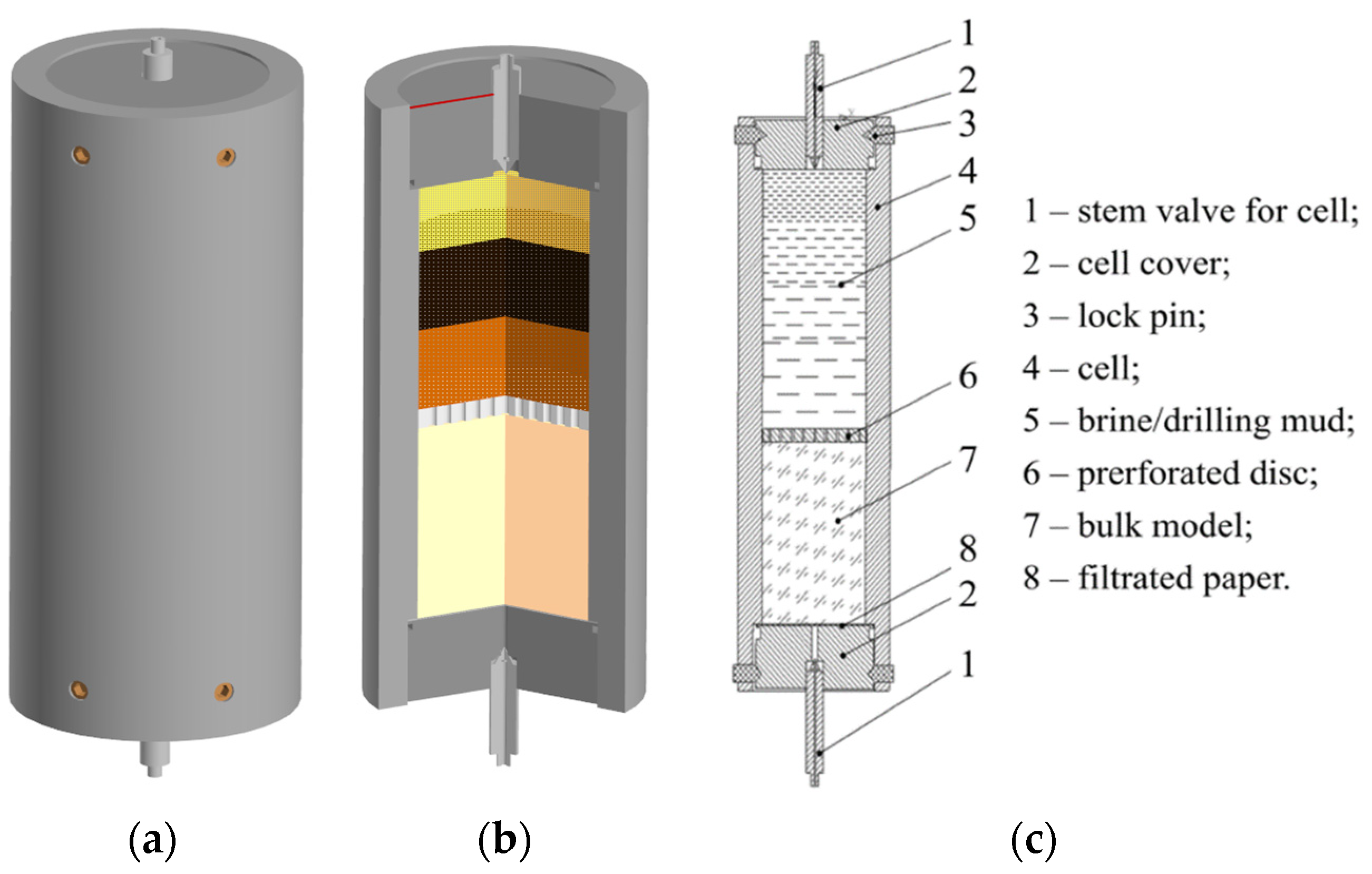

2.4. Filtration Study of Blocking Compounds

3. Results

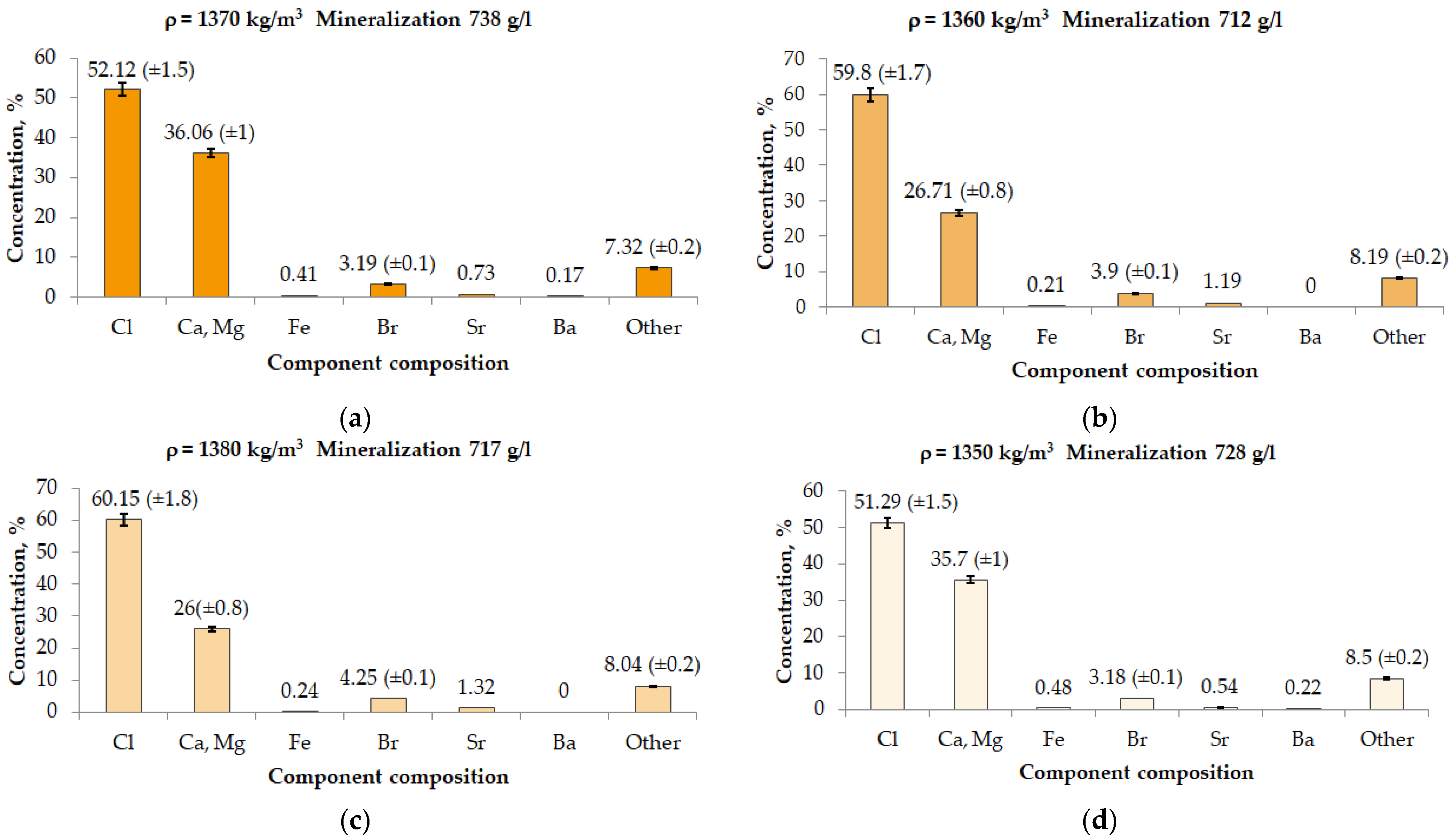

3.1. Chemical Analysis of the Component Composition of Formation Fluid

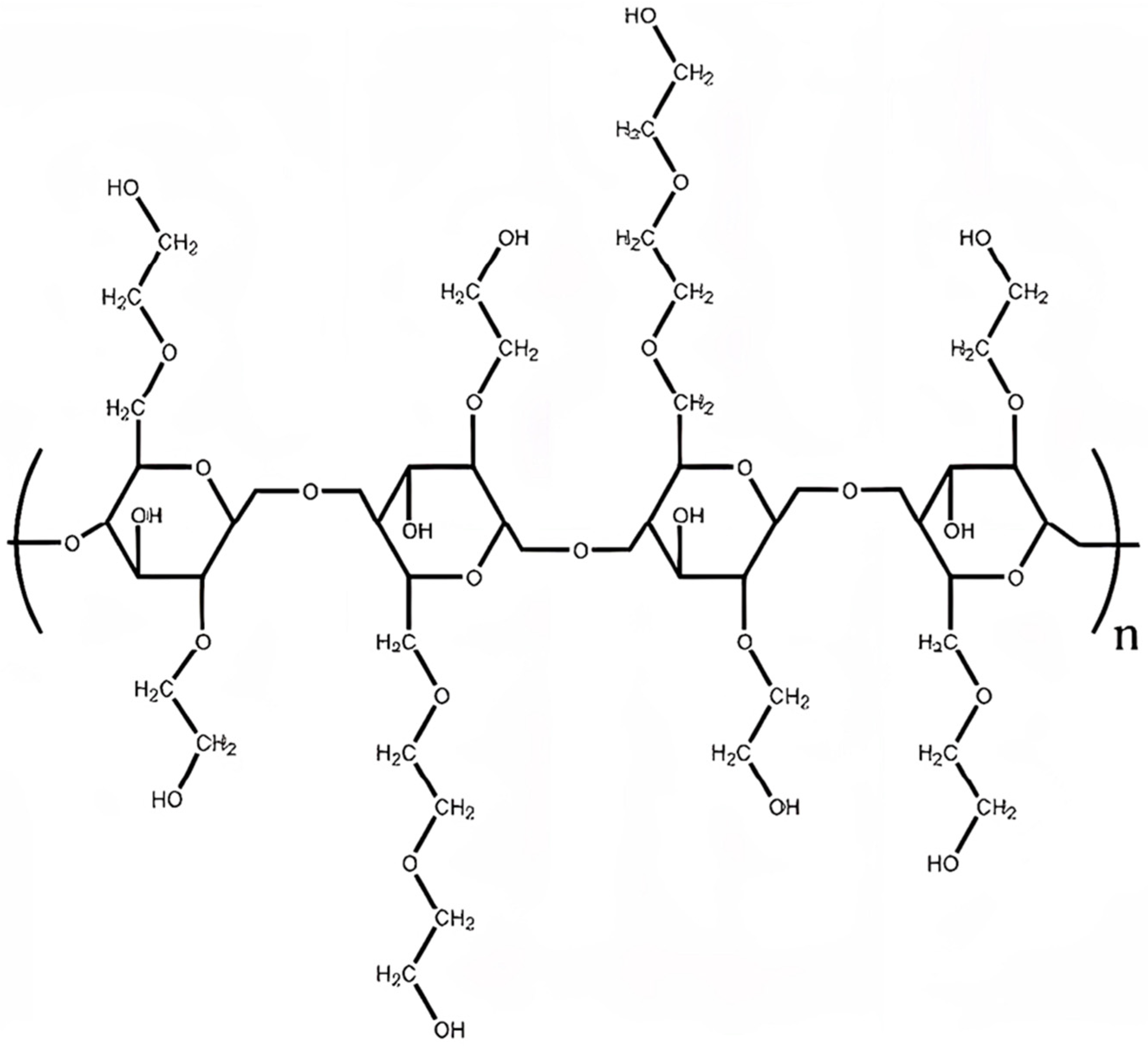

3.2. Selection of a Polymer Base for a Blocking Compound

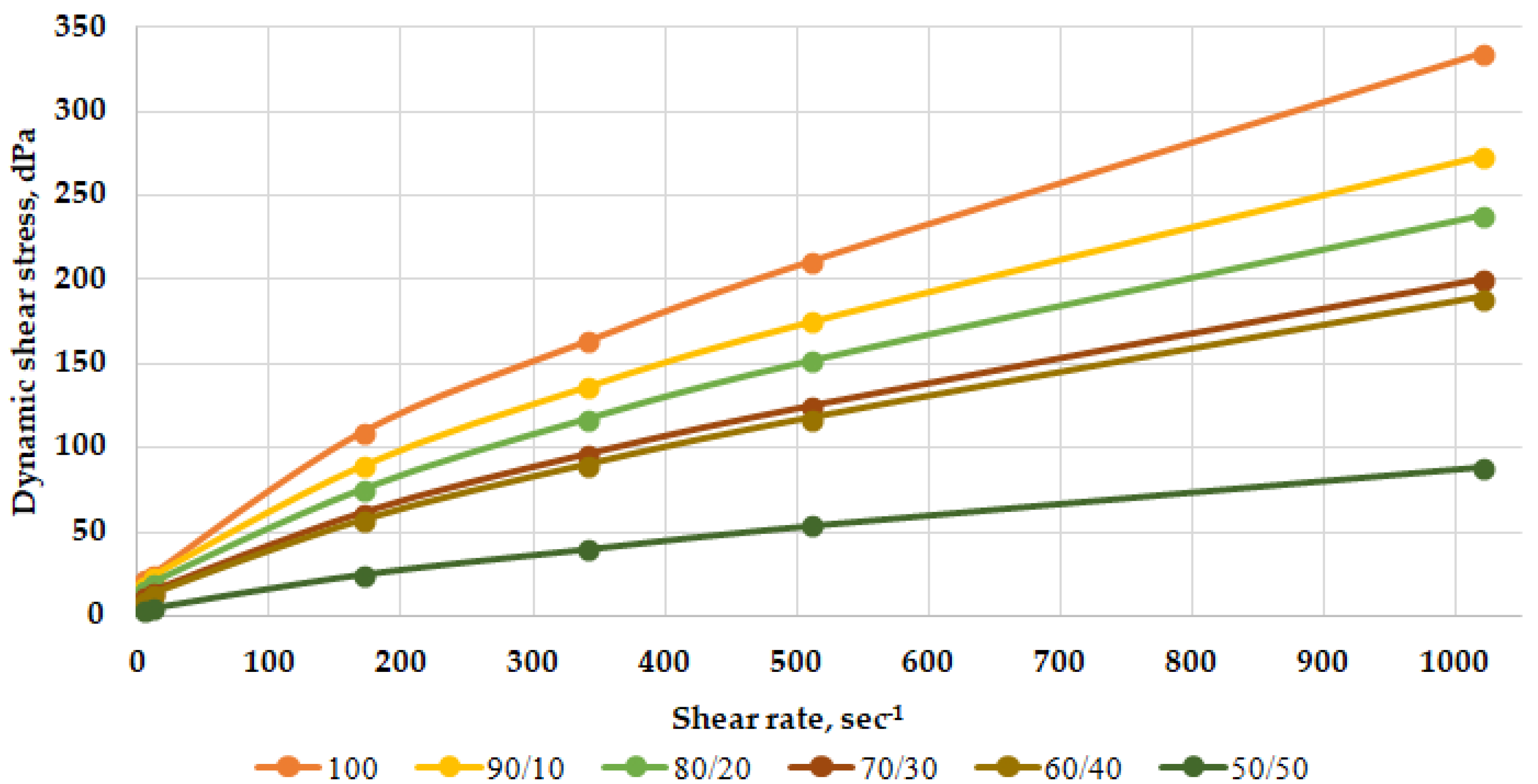

3.3. Studies of the Influence of Brine on the Structural–Rheological and Filtration Characteristics of Drilling Fluids

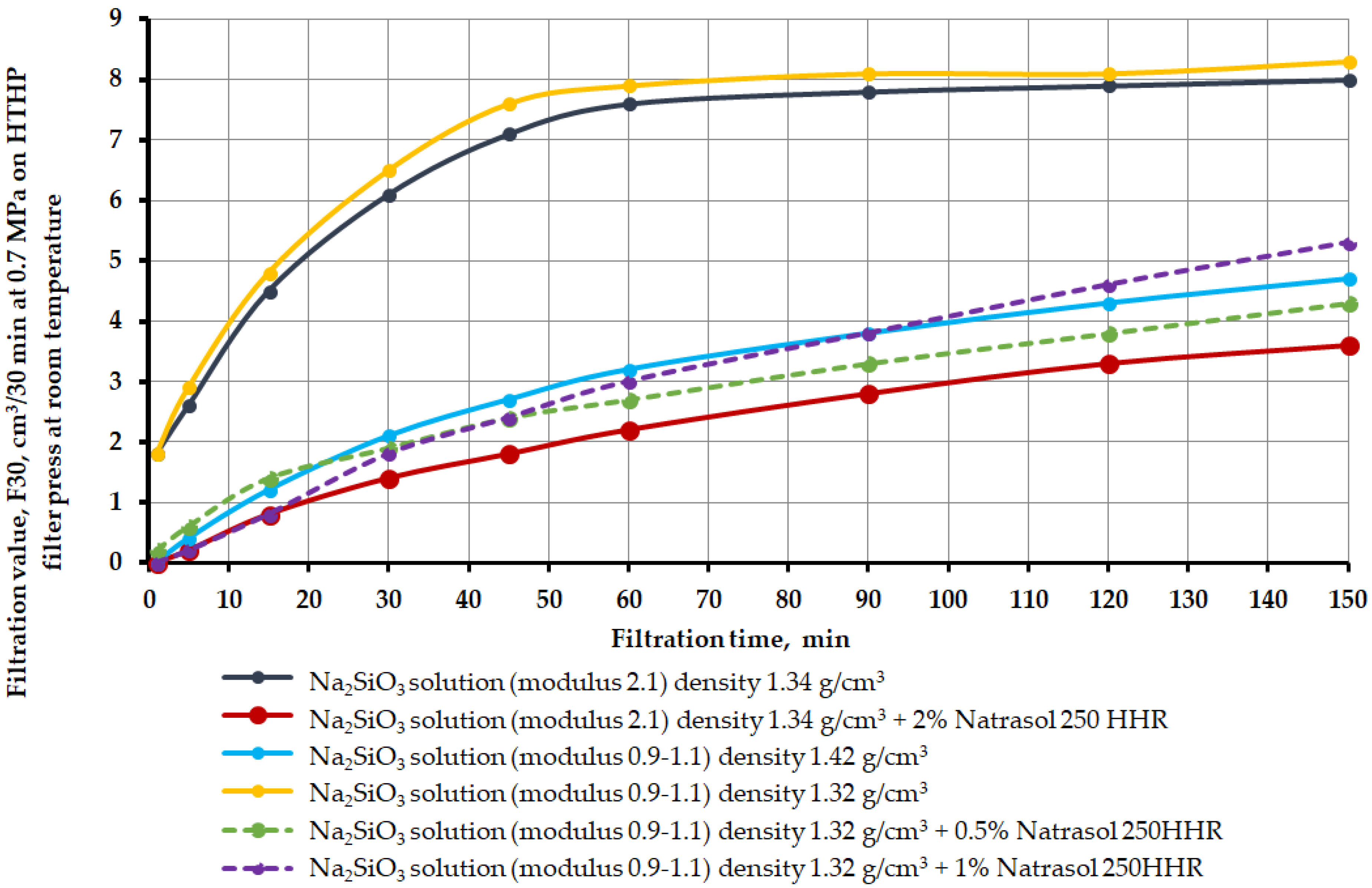

3.4. The Study of the Filtration Characteristics of the Blocking Composition under Normal Conditions

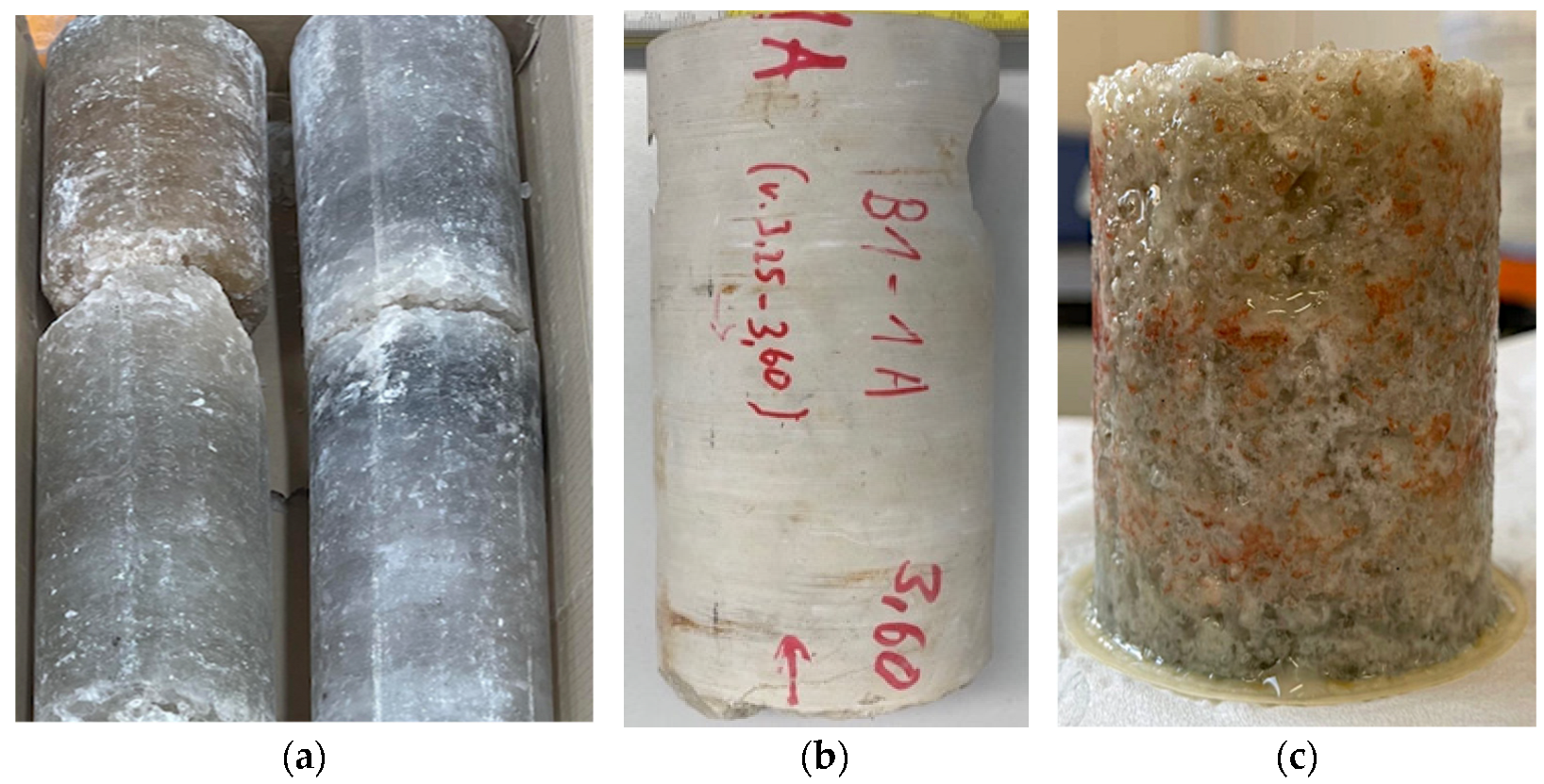

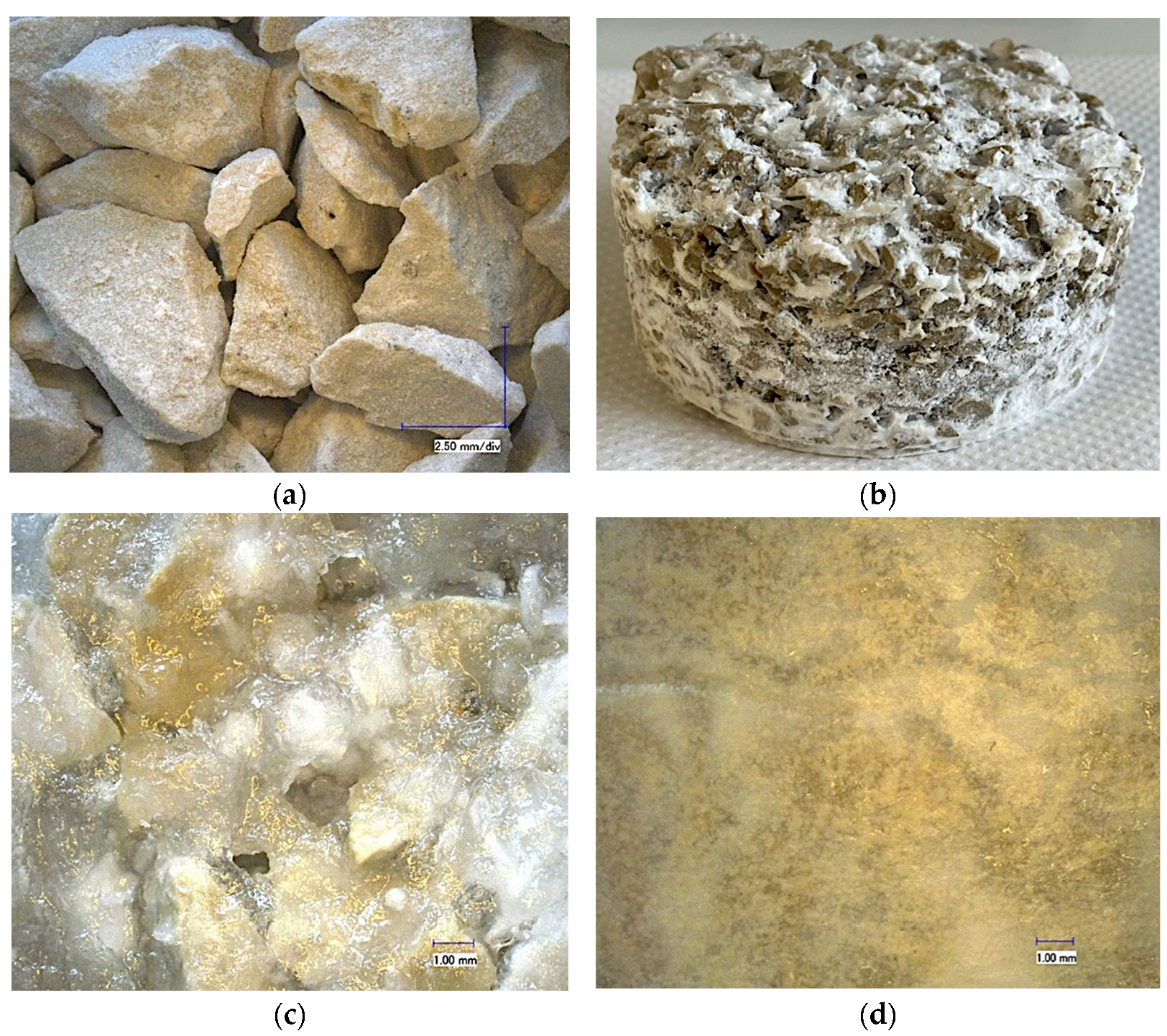

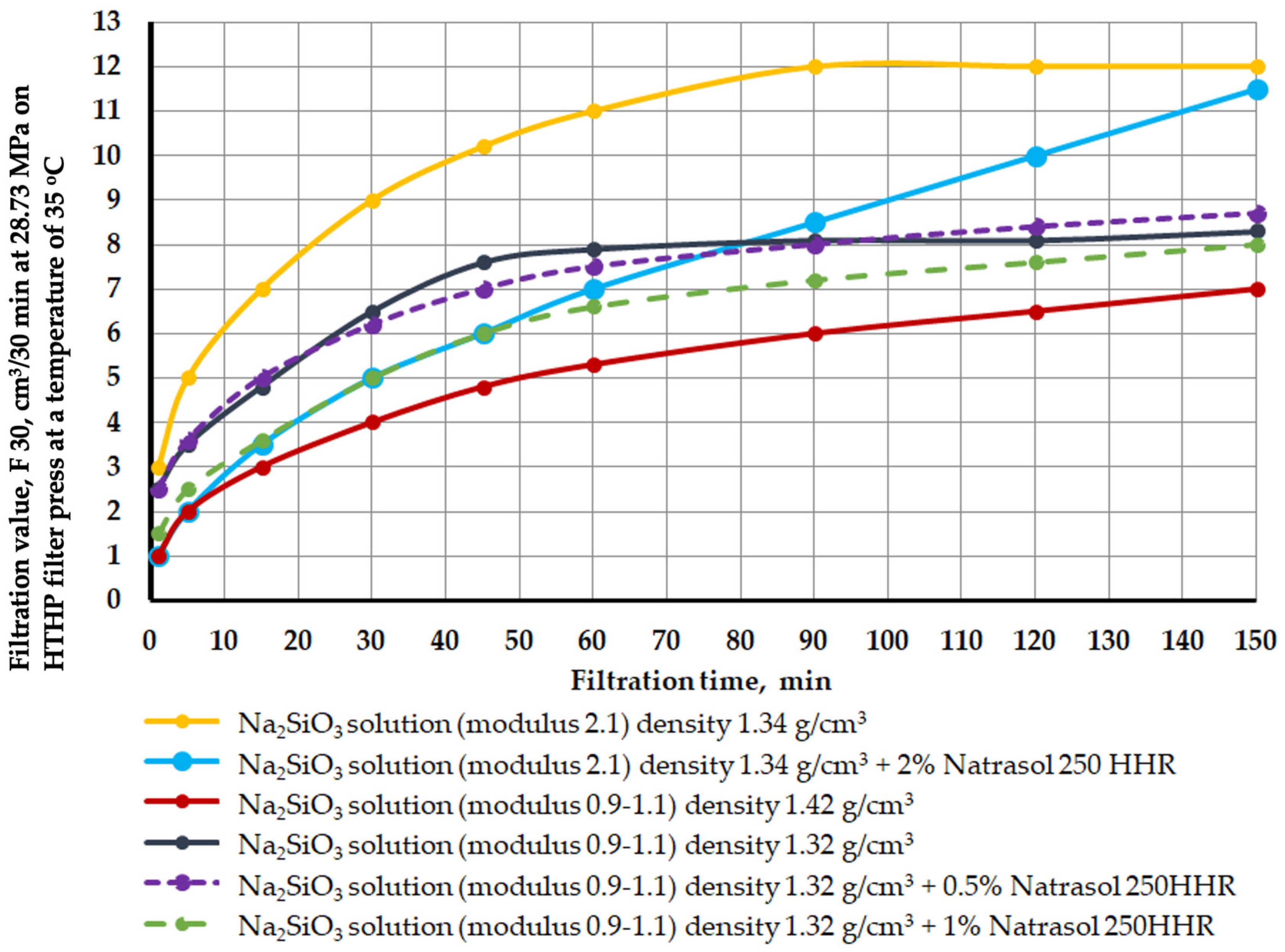

3.5. Study of Filtration Characteristics and Plugging Ability of Blocking Composition under Thermobaric Conditions

4. Experimental Stand Design

- Creation of a reservoir model saturated with fluid;

- Creation of a well model filled with drilling fluid;

- Creation of a model of the drill string, through which the hardening composition will be injected.

5. Discussion

6. Conclusions

- The choice of a method for isolating formations without stopping the drilling process and changing the borehole assembly to minimize non-productive time is justified.

- Based on the methods of atomic emission spectrometry, spectrophotometry, and titrimetry, the composition of the reservoir fluid was studied in detail. The concentration of chlorides reaches 60%, and divalent salts of calcium chloride (CaCl2) and magnesium (MgCl2) 26% and 35.7%. The identification of these components made it possible to put forward and experimentally confirm the idea of the possibility of crystallization of metal cations upon interaction with Na2SiO3 with the formation of an insoluble precipitate.

- Based on the study of the compatibility of polymers of different groups, it was found that the most suitable additive for thickening the gel and increasing the hardening time of the composition is HEC. Successful combination with brine is explained by a more flexible macromolecule and the nonionic nature of the functional groups: -CH2OCH2CH2OH and -HC-OCH2CH2OH. The explanation of the interaction process by means of hydrogen bonds, the subsequent intermolecular interweaving of molecules, and the alignment of an ordered structure around the HEC molecule with an increase in viscosity confirmed the effectiveness of the selected additive.

- Filtration of the polymer composition through a bulk model from the core of developing formations saturated with brine at a pressure of 28.73 MPa and 35 °C made it possible to establish the optimal concentration of the polymer at 2%, dissolved in sodium metasilicate with a silicate modulus of 2.1 and a total density of the composition of 1.34 g/cm3. After filtering the composition, the bulk model had the highest strength with the formation of a hard crust on the upper part of the sample.

- Based on tomographic studies, it was found that the depth of penetration of the filtrate during the injection of the developed blocking composition into the core of developing layers was 74 mm.

- For subsequent tests, an experimental stand was developed to simulate the process of isolation of layers under conditions of back pressure from the side of the layer. Laboratory tests on the stand will allow not only testing of various compositions to resist losses and blowout, but also allow exploration of other technical methods for isolating problem horizons.

- The use of the developed method of blocking formations will allow oil and gas companies to reduce non-productive time associated with the elimination of brine manifestations and accelerate the transition to further development of productive hydrocarbon deposits.

- The developed research methodology will allow scientists and oil engineers to select and develop new types of blocking compositions based on the study of physical and chemical interaction with formation fluid components.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AHFP | Abnormally high formation pressure |

| BOP | Blowout preventer |

| DSS | Dynamic shear stress |

| FHLS | Ferrochrome lignosulfonate |

| HEC | Hydroxyethylcellulose |

| HPHT | High pressure and high temperature |

| LCM | Loss circulation materials |

| PAC | Polyanionic cellulose |

References

- Vakhromeev, A.G.; Sverkunov, S.A.; Ilin, A.I. Mining and Geological Conditions of Drilling Brine Productive Zones with Abnormally High Reservoir Pres-sure in Natural Cambrian Reservoirs of the Kovykta Gas Condensate Field. Proc. Sib. Dep. Sect. Earth Sci. Russ. Acad. Nat. Sci. 2016, 2, 74–78. [Google Scholar] [CrossRef]

- Dvoynikov, M.; Kuchin, V.; Mintzaev, M. Development of viscoelastic systems and technologies for isolating water-bearing horizons with abnormal formation pressures during oil and gas wells drilling. J. Min Inst. 2021, 247, 57–65. [Google Scholar] [CrossRef]

- Ageev, S.A.; Rakhimov, N.V.; Kiryakov, G.A. Strategic Aspects, Technical and Technological Solutions for Improving Well Workover Efficiency. Bull. Assoc. Drill. Contractors 2016, 4, 13–20. [Google Scholar]

- Goronovich, S.N. Genesis of brine collectors and conditions of their plugging during well construction in the Orenburg region. Environ. Prot. Oil Gas Ind. 2007, 6, 39–43. [Google Scholar]

- Vakhromeev, A.G.; Gorlov, I.V. Fountain manifestations of extremely saturated lithium-bearing brines in wells in the south of the Siberian Platform: Drilling, testing, forecasting of fluid systems with AHFP. In Proceedings of the All-Russian Conference on Groundwater of the East of Russia XII, Novosibirsk, Russia, 18–22 June 2018; pp. 27–33. [Google Scholar]

- Ushivtseva, L.F. Geological risks and environmental safety of well drilling in regions with the development of salt dome tectonics. Geoecological problems of our time and ways to solve them. In Proceedings of the II All-Russian Scientific and Practical Conference, Oryol, Russia, 6 October 2020; pp. 103–113. [Google Scholar]

- Feng, Y.; Gray, K. Review of fundamental studies on lost circulation and wellbore strengthening. J. Pet. Sci. Eng. 2017, 152, 511–522. [Google Scholar] [CrossRef]

- Al-salali, Y.Z.; Al-Bader, H.; Vidyasagar, D.; Manimaran, A.; Packirisamy, S.; Al-Ibrahim, A. Paradigm Shift in Reducing Formation Damage: Application of Potassium Formate Water Based Mud in Deep HPHT Exploratory Well. In Proceedings of the SPE Kuwait International Petroleum Conference and Exhibition, Kuwait City, Kuwait, 10–12 December 2012. [Google Scholar] [CrossRef]

- Amir, Z.; Saaid, M. The retardation of polyacrylamide by ammonium chloride in high-salinity and high-temperature conditions: Molecular analysis. Polym. Bull. 2020, 77, 5469–5487. [Google Scholar] [CrossRef]

- Skokov, V.V. Genesis and chemical composition of brines of the Astrakhan gas condensate field, factors of occurrence and methods of combating brine manifestation. Izv. Vuzov. Min. Mag. 2017, 2, 44–49. [Google Scholar]

- Batyrov, M.I.; Savenok, O.V. Development of measures for the prevention and timely elimination of geological complications in the form of brine during drilling of well No. 9 of the Vikanskaya area. Nauka. Technique. Technol. 2020, 1, 44–73. [Google Scholar]

- Ma, J.; Yu, P.; Xia, B. Effect of salt and temperature on molecular aggregation behavior of acrylamide polymer. e-Polymers 2019, 19, 594–606. [Google Scholar] [CrossRef]

- Ghalambor, A.; Salehi, S.; Shahri, M.P.; Karimi, M. Integrated workflow for lost circulation prediction. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014. [Google Scholar]

- Mirabbasi, S.; Ameri, M.; Alsaba, M.; Karami, M.; Zargarbashi, A. The evolution of lost circulation prevention and mitigation based on wellbore strengthening theory: A review on experimental issues. J. Pet. Sci. Eng. 2022, 211. [Google Scholar] [CrossRef]

- Ushivtseva, L.F. Hydrogeological characteristics of the zones of brine manifestations of the Astrakhan arch. Geol. Geogr. Glob. Energy 2019, 4, 106–115. [Google Scholar]

- Khurshudov, V.A.; Khurshudov, D.V. Characteristic features of the struggle with deposits in the salt deposits of the Upper Jurassic when drilling super-deep wells in the areas of the Eastern Ciscaucasia (Combating the manifestations of brine). Constr. Oil Gas Wells Land Sea 2010, 1, 11–14. [Google Scholar]

- Zhu, D.; Bai, B.; Hou, J. Polymer Gel Systems for Water Management in High-Temperature Petroleum Reservoirs: A Chemical Review. Energy Fuels 2017, 31, 13063–13087. [Google Scholar] [CrossRef]

- Seright, R. Gel propagation through fractures. SPE Prod. Facil. 2001, 16, 225–231. [Google Scholar] [CrossRef]

- Khamityanov, N.K. Technology of isolation of the complication zone by a column of expandable pipes. Onshore Offshore Oil Gas Well Constr. 2011, 1, 19–21. [Google Scholar]

- Averkina, E.V.; Shakirova, E.V. Features of the preparation of drilling fluids based on formation water of the Znamenskoye field. Probl. Collect. Prep. Transp. Oil Oil Prod. 2019, 4, 38–46. [Google Scholar]

- Khailovsky, V.N. Analysis of geological complications in overproductive deposits at the Astrakhan GCF. Int. Sci. Res. J. 2015, 1, 79–83. [Google Scholar]

- Wang, J.; Yan, L.; Liu, F.; Yang, H.; Yin, D. Treatment Technology of Brine Contamination and Barite Settlement for the High Temperature and High Density OBM for Ultra-Deep Well Drilling in Western China. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar] [CrossRef]

- Kovyktinskoe Field. Available online: https://www.gazprom.com/projects/kovyktinskoye/ (accessed on 26 September 2022).

- Averkina, E.V. Analysis of brine-producing wells in gas condensate fields of the Irkutsk region. Proc. Sib. Branch Sect. Earth Sci. Russ. Acad. Nat. Sciences. Geol. Prospect. Explor. Ore Depos. 2009, 2, 152–157. [Google Scholar]

- Buglov, E.N.; Vaseneva, E.G. Well drilling under conditions of hydrogen sulfide aggression. Bull. ISTU 2013, 12, 121–123. [Google Scholar]

- Environmental Regulation 14.1:2:4.261-10; Quantitative Chemical Analysis of Waters. Methodology for Measuring the Mass Concentration of Dry and Calcined Residues in Samples of Drinking, Natural and Waste Water by the Gravimetric Method. RussianGost: Moscow, Russia, 2015.

- GOST 18164-72; Drinking Water. Method for Determining the Content of Dry Residue. Introduction 01/01/1974; RussianGost: Moscow, Russia, 1974.

- API RP 13I: Laboratory Testing of Drilling Fluids, 9th ed.; American Petroleum Institute: Washington, DC, USA, December 2020.

- P1-01.05 M-0044; Guidelines of Rosneft Oil Company PJSC Uniform Technical Requirements for the Main Classes of Chemical Reagents. Rosneft Oil Company: Moscow, Russia, 2016.

- Petrov, N.A. Study of salt-resistant polymeric reagents. Electron. J. Oil Gas Bus. 2016, 2, 38–54. [Google Scholar] [CrossRef] [Green Version]

- Babajide, A.; Adebowale, O.; Adesina, F.; Churchill, A.; Ifechukwu, M. Effects of Temperature and Pressure on Shale Cuttings Dispersion in Water Based Mud WBM Using NACL, CACL2, KCL Salts as Primary Inhibiting Agents and Polymer XCD Xanthan Gum as Secondary Inhibiting Agent. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 2–4 August 2016. [Google Scholar] [CrossRef] [Green Version]

- Howard, S.; Kaminski, L.; Downs, J. Xanthan Stability in Formate Brines-Formulating Non-Damaging Fluids for High Temperature Applications. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar] [CrossRef]

- Magzoub, M.; Salehi, S.; Hussein, I.; Nasser, M. Development of a Polyacrylamide-Based Mud Formulation for Loss Circulation Treatments. ASME J. Energy Resour. Technol. 2021, 143, 073001. [Google Scholar] [CrossRef]

- Ulyasheva, N.; Leusheva, E.; Galishin, R. Development of the drilling mud composition for directional wellbore drilling considering rheological parameters of the fluid. J. Min. Inst. 2020, 244, 454–461. [Google Scholar] [CrossRef]

- Karsani, K.; Al-Muntasheri, G.; Sultan Hussein, I. Impact of salts on polyacrylamide hydrolysis and gelation: New insights. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Islamov, S.R.; Bondarenko, A.V.; Mardashov, D.V. A selection of emulsifiers for preparation of invert emulsion drilling fluids. In Topical Issues of Rational Use of Natural Resources; Taylor & Francis: London, UK, 2020; pp. 487–494. [Google Scholar] [CrossRef]

- Zulhelmi, A.; Said, I. In situ organically cross-linked polymer gel for high-temperature reservoir conformance control: A review. Polym. Adv. Technol. 2018, 30, 13–39. [Google Scholar] [CrossRef] [Green Version]

- Islamov, S.R.; Bondarenko, A.V.; Mardashov, D.V. Substantiation of a well killing technology for fractured carbonate reservoirs. In Youth Technical Sessions Proceedings: VI Youth Forum of the World Petroleum Council–Future Leaders Forum; Taylor & Francis: London, UK, 2019; pp. 256–264. [Google Scholar] [CrossRef]

- Koshelev, V.N. Cleanout of Oil and Gas Wells; Nedra Publishers: Moscow, Russia, 2019; p. 687. [Google Scholar]

- Morenov, V.; Leusheva, E.; Liu, T. Development of a Weighted Barite-Free Formate Drilling Mud for Well Construction under Complicated Conditions. Polymers 2021, 13, 4457. [Google Scholar] [CrossRef]

- Mao, H.; Yang, Y.; Zhang, H.; Zheng, J.; Zhong, Y. Conceptual Design and Methodology for Rheological Control of Water-Based Drilling Fluids in Ultra-High Temperature and Ultra-High Pressure Drilling Applications. J. Pet. Sci. Eng. 2020, 188, 106884. [Google Scholar] [CrossRef]

- Zhou, H.; Deville, J.P.; Davis, C.L. Novel High Density Brine-Based Drill-In Fluids Significantly Increased Temperature Limit for HP/HT Applications; SPE: London, UK, 17 March 2015. [Google Scholar] [CrossRef]

- Liu, T.; Leusheva, E.L.; Morenov, V.A.; Li, L.; Jiang, G.; Fang, C.; Zhang, L.; Zheng, S.; Yu, Y. Influence of polymer reagents in the drilling fluids on the efficiency of deviated and horizontal wells drilling. Energies 2020, 18, 4704. [Google Scholar] [CrossRef]

- Nikolaev, N.I.; Leusheva, E.L. low-density cement compositions for well cementing under abnormally low reservoir pressure conditions. J. Min. Inst. 2019, 236, 194. [Google Scholar] [CrossRef] [Green Version]

- Mardashov, D.V.; Bondarenko, A.V.; Raupov, I.R. Technique for calculating technological parameters of non-Newtonian liquids injection into oil well during workover. J. Min. Inst. 2022, 253, 41–48. [Google Scholar] [CrossRef]

- Mohamed, A.; Salehi, S.; Ahmed, R. Significance and Complications of Drilling Fluid Rheology in Geothermal Drilling: A Review. Geothermics 2021, 93, 102066. [Google Scholar] [CrossRef]

- Abbas, A.; Bashikh, A.; Hayder, A.; Haider, M. Intelligent decisions to stop or mitigate lost circulation based on machine learning. Energy 2019, 183, 1104–1113. [Google Scholar] [CrossRef]

- Yang, G.; Liu, T.; Blinov, P.A.; Wang, Y.; Feng, Y. Temperature regulation effect of low melting point phase change microcapsules for cement slurry in nature gas hydrate-bearing sediments. Energy 2022, 253, 124115. [Google Scholar] [CrossRef]

- Ali, A.; Si, Q.; Yuan, J. Investigation of energy performance, internal flow and noise characteristics of miniature drainage pump under water–air multiphase flow: Design and part load conditions. Int. J. Environ. Sci. Technol. 2022, 19, 7661–7678. [Google Scholar] [CrossRef]

- Koteleva, N.; Buslaev, G.; Valnev, V.; Kunshin, A. Augmented Reality System and Maintenance of Oil Pumps. Int. J. Eng. 2020, 33, 1620–1628. [Google Scholar] [CrossRef]

| No. | Mass Concentration of a Chemical Element | Research Results, mg/dm3 | Research Method | |||

|---|---|---|---|---|---|---|

| Sample No. 1 | Sample No. 2 | Sample No. 3 | Sample No. 4 | |||

| 1 | Lithium | 740 ± 96 | 645 ± 84 | 655 ± 85 | 760 ± 99 | Atomic emission spectrometry |

| 2 | Bor | 81 ± 11 | 126 ± 16 | 121 ± 16 | 47 ± 6 | |

| 3 | Barium | 114 ± 15 | 104 ± 14 | 122 ± 16 | 110 ± 14 | |

| 4 | Calcium | 166,000 ± 28,220 | 99,400 ± 16,898 | 103,000 ± 17,510 | 163,000 ± 27,710 | |

| 5 | Magnesium | 34,800 ± 4524 | 76,300 ± 9919 | 77,600 ± 10,088 | 33,000 ± 4290 | |

| 6 | Potassium | 3360 ± 437 | 967 ± 126 | 1150 ± 150 | 2830 ± 368 | |

| 7 | Sodium | 1510 ± 196 | 961 ± 125 | 1140 ± 148 | 1490 ± 194 | |

| 8 | Iron | 1150 ± 127 | 503 ± 55 | 546 ± 60 | 1220 ± 134 | |

| 9 | Manganese | 227 ± 30 | 87 ± 11 | 99 ± 13 | 234 ± 30 | |

| 10 | Strontium | 2730 ± 340 | 3011 ± 422 | 4520 ± 633 | 1640 ± 230 | |

| 11 | Phosphate-ion | 20 ± 4 | 45 ± 9 | 45 ± 9 | 50 ± 10 | Spectrophotometry |

| 12 | Sulfate-ion | 2882 ± 259 | 2209 ± 199 | 2305 ± 207 | 2882 ± 259 | Titrimetry |

| 13 | Chloride-ion | 388,275± 58,241 | 386,300 ± 57,945 | 396,500± 59,475 | 387,750± 58,163 | |

| 14 | Bicarbonate-ion | 1373 ± 165 | 1525 ± 183 | 1068 ± 128 | 1373 ± 165 | |

| Rheological Characteristics | Units | Material Name | |||||

|---|---|---|---|---|---|---|---|

| Brine | Aqua PAC L 2% | Aqua PAC R 2% | Natrosol 2% | Biosin 2% | Starch Poly KR 2% | ||

| Torsion angles: ϴ600 | degree | 23 | 25 | 28 | 33 | 29 | 25 |

| ϴ300 | degree | 12 | 13 | 16 | 20 | 17 | 13 |

| ϴ200 | degree | 8 | 9 | 11 | 14 | 9 | 9 |

| ϴ100 | degree | 4 | 5 | 5 | 9 | 5 | 5 |

| ϴ66 | degree | 1 | 1 | 2 | 6 | 1 | 1 |

| ϴ3 | degree | 1 | 1 | 1 | 3 | 1 | 1 |

| Plastic viscosity, ηp | mPa·s | 11 | 12 | 12 | 13 | 12 | 12 |

| DSS | dPa | 5 | 5 | 20 | 35 | 25 | 5 |

| Gels 10 s | dPa | 1 | 1 | 1 | 1 | 1 | 1 |

| Gels 10 min | dPa | 1 | 1 | 1 | 2 | 2 | 1 |

| Density | kg/m3 | 1390 | 1390 | 1390 | 1390 | 1390 | 1390 |

| Rheological Characteristics | Units | Material Name and Concentration | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Natrosol 250 HHR, % | Biosin, % | ||||||||||||

| 1 | 2 | 3 | 5 | 7 | 10 | 1 | 2 | 3 | 5 | 7 | 10 | ||

| Torsion angles: ϴ600 | degree | 25 | 25 | 29 | 60 | 230 | >300 | 24 | 25 | 25 | 27 | 29 | 32 |

| ϴ300 | degree | 13 | 13 | 15 | 32 | 130 | – | 12 | 13 | 13 | 14 | 15 | 17 |

| ϴ200 | degree | 8 | 9 | 10 | 22 | 89 | – | 8 | 8 | 9 | 9 | 9 | 11 |

| ϴ100 | degree | 5 | 5 | 5 | 11 | 48 | – | 4 | 4 | 5 | 5 | 5 | 6 |

| ϴ6 | degree | 1 | 1 | 1 | 1 | 2 | – | 1 | 1 | 1 | 1 | 2 | 2 |

| ϴ3 | degree | 1 | 1 | 1 | 1 | 2 | – | 1 | 1 | 1 | 1 | 2 | 2 |

| Plastic viscosity, ηp | mPa·s | 12 | 12 | 14 | 28 | 30 | – | 12 | 12 | 12 | 13 | 14 | 15 |

| DSS | dPa | 5 | 5 | 15 | 20 | 146 | – | 0 | 5 | 5 | 5 | 5 | 5 |

| Gels 10 s | dPa | 1 | 1 | 2 | 2 | 2 | – | 1 | 1 | 1 | 2 | 2 | 2 |

| Gels 10 min | dPa | 2 | 2 | 2 | 2 | 4 | – | 1 | 1 | 1 | 2 | 2 | 2 |

| Rheological Characteristics | Units | Material Name and Concentration | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Natrosol 250 HHR, % | Biosin, % | ||||||||||||

| 1 | 2 | 3 | 5 | 7 | 10 | 1 | 2 | 3 | 5 | 7 | 10 | ||

| Torsion angles: ϴ600 | degree | 26 | 25 | 29 | 55 | 226 | >300 | 22 | 25 | 23 | 25 | 30 | 31 |

| ϴ300 | degree | 15 | 14 | 16 | 33 | 133 | – | 11 | 10 | 13 | 14 | 16 | 15 |

| ϴ200 | degree | 7 | 8 | 11 | 21 | 87 | – | 10 | 6 | 7 | 8 | 7 | 11 |

| ϴ100 | degree | 6 | 7 | 7 | 12 | 51 | – | 6 | 7 | 6 | 4 | 5 | 4 |

| ϴ6 | degree | 1 | 2 | 1 | 1 | 2 | – | 1 | 1 | 1 | 1 | 2 | 2 |

| ϴ3 | degree | 1 | 2 | 1 | 1 | 2 | – | 1 | 1 | 1 | 1 | 2 | 2 |

| Plastic viscosity, ηпл | mPa·s | 13 | 13 | 12 | 29 | 32 | – | 14 | 12 | 10 | 12 | 13 | 15 |

| DSS | dPa | 4 | 5 | 13 | 18 | 148 | – | 1 | 4 | 5 | 4 | 4 | 5 |

| Gels 10 s | dPa | 2 | 2 | 2 | 2 | 2 | – | 2 | 1 | 1 | 2 | 2 | 2 |

| Gels 10 min | dPa | 2 | 2 | 2 | 2 | 3 | – | 1 | 1 | 1 | 2 | 2 | 2 |

| No. | Compound | Penetration Zone, Rf, mm |

|---|---|---|

| 1 | Na2SiO3 solution (modulus 2.1) density 1340 kg/m3 250 HHR | 56 |

| 2 | Na2SiO3 solution (modulus 2.1) density 1340 kg/m3 + 2% Natrosol 250 HHR | 74 |

| 3 | Na2SiO3 solution (modulus 0.9–1.1) density 1420 kg/m3 | 43 |

| 4 | Na2SiO3 solution (modulus 0.9–1.1) density 1320 kg/m3 | 52 |

| 5 | Na2SiO3 solution (modulus 0.9–1.1) density 1320 kg/m3 + 0.5% Natrosol 250 HHR | 63 |

| 6 | Na2SiO3 solution (modulus 0.9–1.1) density 1320 kg/m3 + 1.0% Natrosol 250 HHR | 65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvoynikov, M.; Sidorov, D.; Kambulov, E.; Rose, F.; Ahiyarov, R. Salt Deposits and Brine Blowout: Development of a Cross-Linking Composition for Blocking Formations and Methodology for Its Testing. Energies 2022, 15, 7415. https://doi.org/10.3390/en15197415

Dvoynikov M, Sidorov D, Kambulov E, Rose F, Ahiyarov R. Salt Deposits and Brine Blowout: Development of a Cross-Linking Composition for Blocking Formations and Methodology for Its Testing. Energies. 2022; 15(19):7415. https://doi.org/10.3390/en15197415

Chicago/Turabian StyleDvoynikov, Mikhail, Dmitry Sidorov, Evgeniy Kambulov, Frederick Rose, and Rustem Ahiyarov. 2022. "Salt Deposits and Brine Blowout: Development of a Cross-Linking Composition for Blocking Formations and Methodology for Its Testing" Energies 15, no. 19: 7415. https://doi.org/10.3390/en15197415

APA StyleDvoynikov, M., Sidorov, D., Kambulov, E., Rose, F., & Ahiyarov, R. (2022). Salt Deposits and Brine Blowout: Development of a Cross-Linking Composition for Blocking Formations and Methodology for Its Testing. Energies, 15(19), 7415. https://doi.org/10.3390/en15197415