Sustainable Value Chain of Industrial Biocomposite Consumption: Influence of COVID-19 and Consumer Behavior

Abstract

:1. Introduction

- Opportunities for the development of new sustainable business models and creation of revenue streams [18]

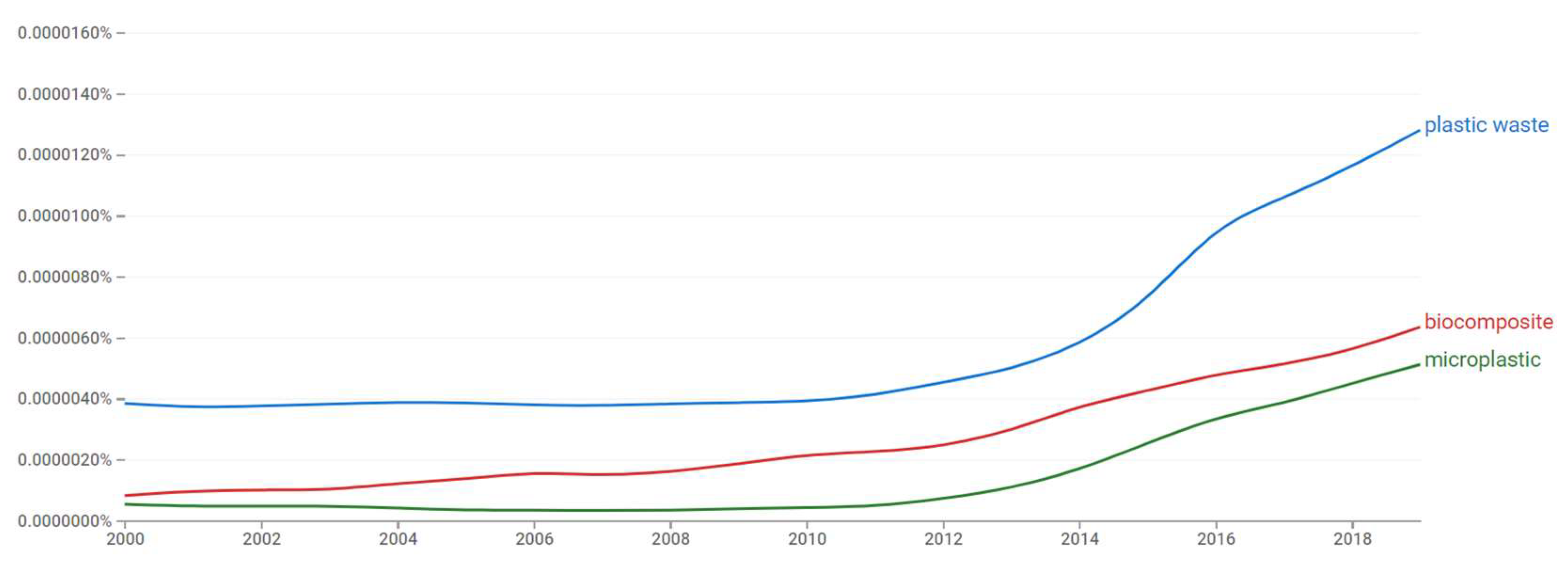

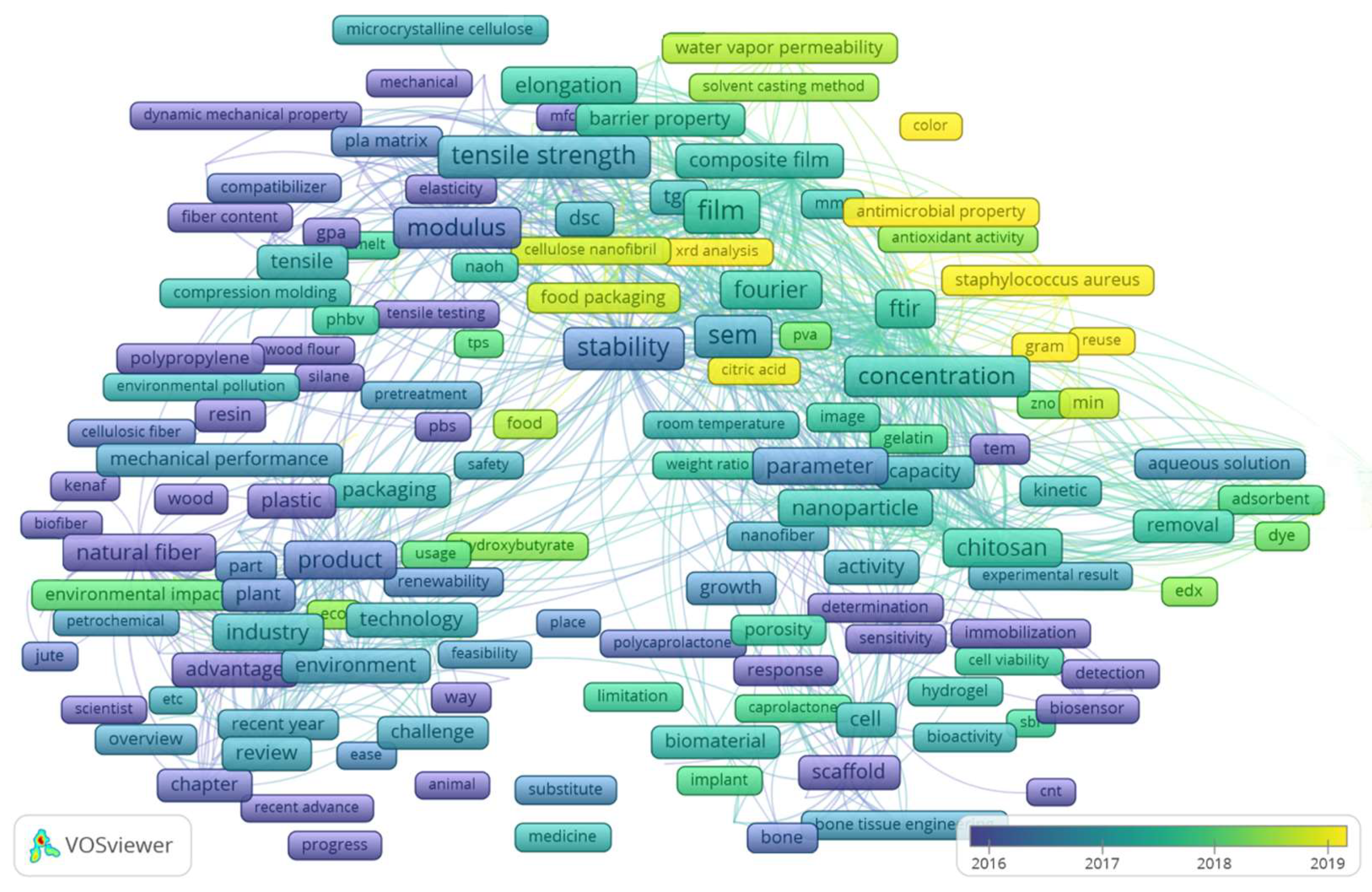

2. Literature Review

2.1. Sustainable Industrial Consumption

2.2. The Sustainable Industrial Consumption of Biocomposite Materials

- Beneficial, safe, and healthy for all individuals and communities throughout their life cycle;

- Meets market criteria for performance and costs;

- Obtained, produced, transported, and processed using renewable energy;

- Produced using renewable or recycled raw materials and clean production technologies;

- Made of harmless materials in all possible end-of-life scenarios;

- Designed to optimize used materials and energy consumption;

- Recovered and utilized in industrial and/or biological cradle-to-cradle or closed-loop cycles.

- The materials must be optimized to improve the shelf life of the product;

- The packaging should be intended for recycling;

- Bio-based materials should be efficiently produced from the second-generation feedstock.

2.3. Role of Biocomposites in Industrial Consumption

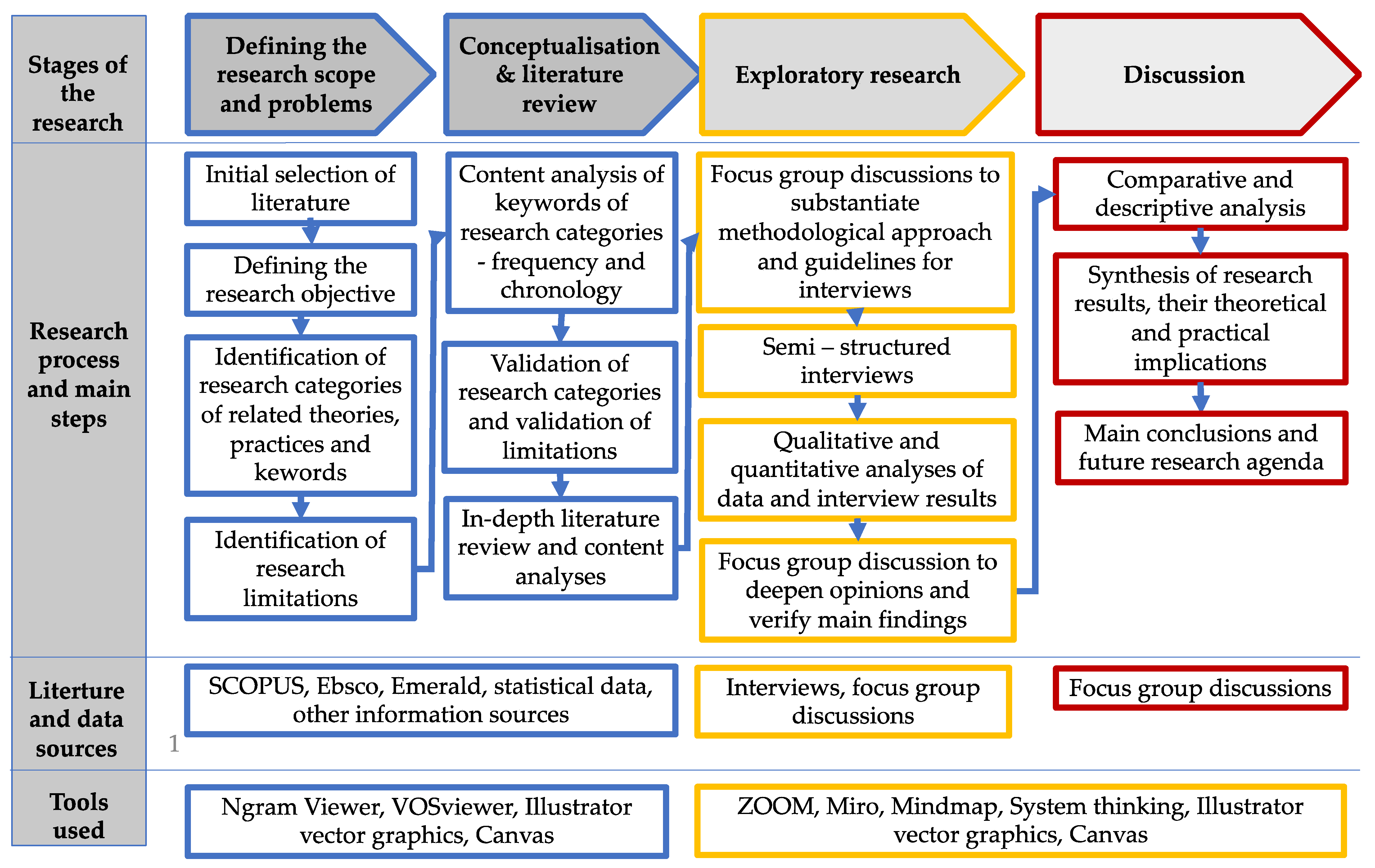

3. Materials and Methods

- T1: To develop the cognitive model of main stakeholders and processes of the value chain of the sustainable industrial consumption of biocomposite materials;

- T2: To investigate the influence of the COVID-19 pandemic on the sustainable industrial consumption of biocomposite materials;

- T3: To substantiate the research based on the integration of economic, business management, and natural-science perspectives and justify the interdisciplinary conceptual basis for further research.

4. Results

4.1. Feedstock Production and Pre-Treatment

4.2. Raw Material Processing and Refining

“Maybe in some extent, we are much prepared for pandemic time and new customer trends—healthy, natural, and with traceable or local materials than other entrepreneurs that are currently dependent on limited supplies of specific materials”(an interviewee—I8)

4.3. Packaging Manufacturers

4.4. Product Manufacturers

“We continue to work with eco and sustainability issues as we did it before. It may take 3 or 4 years from the idea of the new product to the production and sales requiring more time than prior to COVID-19”(an interviewee—I5)

4.5. Retailers

5. Discussion and Conclusions

- The role of waste recycling policy in facilitating sustainable industrial consumption.

- More detailed investigations of hindering factors of the introduction of biocomposites and recycling, in particular, related to the economic interests of stakeholders and technological factors.

- Promoting the competitiveness of sustainable industrial consumption partners by eliminating greenwashing.

- Difficulties in the introduction of biocomposites in the industry and overcoming them.

- The impact of the actualization of microplastic pollution problems on the production of non-degradable bioplastics.

- The end of the life cycle of conventional plastics after recycling, when they have lost their properties for further use.

- Industrial consumer difficulties within the EU green transition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| No | Field of Expertise of Interviewee | Role in the Sustainable Production Chain | Industry or Field of the Operation of the Organization Represented (Part of the Value Chain) | Size of the Company (Turnover EUR in 2020) | Duration of Interview | The Time Period of the Interview |

|---|---|---|---|---|---|---|

| I1 | Corporate Social Responsibility, Sustainability | Retailer (BE) | FMCG Retail | 36 bn | 1 h | 2nd quarter of 2021 |

| I2 | Country Manager | Retailer (LV, LT) | Furniture Manufacturing and Retail | 39 bn | 60 min | 3rd quarter of 2020 |

| I3 | Head of Store Development Department | Retailer (IT) | Clothing Retail | 17 bn | 90 min | 3rd quarter of 2020 |

| I4 | Manufacturing, Lead of R&D | Product manufacturer (LV) | Cosmetics | 16 M | 60 min | 3rd quarter of 2020 |

| I5 | General Manager | Product manufacturer (LV) | Food | 1 M | 60 min | 2nd quarter of 2021 |

| I6 | Regional Head of R&D | Packaging manufacturer (DE) | Cosmetics, Consumer Goods | 102 M | 120 min | 3rd quarter of 2020 |

| I7 | Head of R&D | Packaging manufacturer (IL) | Food | 60 min | 2nd quarter of 2021 | |

| I8 | CEO | Raw material (SE) | Starch Producer | 1 M | 60 min | 2nd quarter of 2021 |

| I9 | CEO | Raw material (DE) | Fiber Producer | 1 M | 60 min | 2nd quarter of 2021 |

| I10 | Board Member | Feedstock (LV) | Hemp Raw Materials | 60 min | 2nd quarter of 2021 |

References

- United Nations. The Sustainable Development Goals Report 2021. New York: United Nations.Halkos, G.; Gkampoura, E.-Ch.; 2021. Where do we stand on the 17 Sustainable Development Goals? An overview on progress. Econ. Anal. Policy 2021, 70, 94–122. [Google Scholar] [CrossRef]

- Fischer, D.; Reinermann, J.L.; Guillen-Mandujano, G.; DesRoches, C.T.; Diddi, S.; Vergragt, P.J. Sustainable consumption communication: A review of an emerging field of research. J. Clean. Prod. 2021, 300, 126880. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Uvarova, I.; Atstaja, D.; Korpa, V. Challenges of the introduction of circular business models within rural SMEs of EU. Int. J. Econ. Sci. 2020, 9, 128–149. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Circular Economy Stakeholder Platform. 2021. Available online: https://circulareconomy.europa.eu/platform/en/commitments/hm-groups-vision-become-100-circular (accessed on 20 July 2021).

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Borowski, G.; Szczypiński, M.; Klepka, T.; Thakur, V.K. Recent progress in biodegradable polymers and nanocomposite-based packaging materials for sustainable environment. Int. J. Polym. Anal. Charact. 2018, 23, 383–395. [Google Scholar] [CrossRef]

- Cohen, M.J. Does the COVID-19 outbreak mark the onset of a sustainable consumption transition? Sustain. Sci. Pract. Policy 2020, 16, 1–3. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics Market Development Update 2020. 2020. Available online: https://docs.european-bioplastics.org/conference/Report_Bioplastics_Market_Data_2020_short_version.pdf (accessed on 20 July 2021).

- OECD. Business Models for the Circular Economy: Opportunities and Challenges from a Policy Perspective. In Recircle Resource Efficient & Circular Economy Project; OECD Publishing: Paris, France, 2018. [Google Scholar]

- Melnyk, S.A.; Handfield, R.B.; Catalogne, R.J. Integrating Environmental Concerns into the Design Process: The Gap between Theory and Practice. IEEE Trans. Eng. Manag. 2001, 48, 189–208. [Google Scholar]

- Porter, M.E. America’s green strategy. Sci. Am. 1991, 264, 168. [Google Scholar] [CrossRef]

- Porter, M.E.; Van der Linde, C. Toward a New Conception of Environment-Competitiveness Relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef] [Green Version]

- De Jesus, A.; Mendonça, S. Lost in transition? Drivers and barriers in the eco-innovation road to the circular economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Ranta, V.; Aarikka-Stenroos, L.; Mäkinen, S.J. Creating value in the circular economy: A structured multiple-case analysis of business models. J. Clin. Prod. 2018, 201, 988–1000. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Publishers: The Hague, The Netherlands, 2017. [Google Scholar]

- Bocken, N.; van Bogaert, A. Sustainable business model innovation for positive societal and environmental impact. In Sustainable Development Research at ICIS: Taking Stock and Looking Ahead; ICIS; Maastricht University: Maastricht, Netherlands, 2016; pp. 107–119. [Google Scholar]

- Funk, K. Sustainability and performance. MIT Sloan Manag. Rev. 2003, 44, 65–70. [Google Scholar]

- Lo, S.F.; Sheu, H.J. Is corporate sustainability a value-increasing strategy for business? Corp. Gov. Int. Rev. 2007, 15, 345–358. [Google Scholar] [CrossRef]

- Laufer, W.S. Social accountability and corporate greenwashing. J. Bus. Ethics 2003, 43, 253–261. [Google Scholar] [CrossRef]

- Torelli, R.; Balluchi, F.; Lazzini, A. Greenwashing and environmental communication: Effects on stakeholder’’ perceptions. Bus. Strategy Environ. 2020, 29, 407–421. [Google Scholar] [CrossRef] [Green Version]

- Nekmahmud, M.; Fekete-Farkas, M. Why not green marketing? Determinates of consumers’ intention to green purchase decision in a new developing nation. Sustainability 2020, 12, 7880. [Google Scholar] [CrossRef]

- Wang, Z.; Hsieh, T.S.; Sarkis, J. CSR performance and the readability of CSR reports: Too good to be true? Corp. Soc. Responsib. Environ. Manag. 2018, 25, 66–79. [Google Scholar] [CrossRef]

- Walker, K.; Wan, F. The harm of symbolic actions and green-washing: Corporate actions and communications on environmental performance and their financial implications. J. Bus. Ethics 2012, 109, 227–242. [Google Scholar] [CrossRef] [Green Version]

- Loučanová, E.; Šupín, M.; Čorejová, T.; Repková-Štofková, K.; Šupínová, M.; Štofková, Z.; Olšiaková, M. Sustainability and Branding: An Integrated Perspective of Eco-innovation and Brand. Sustainability 2021, 13, 732. [Google Scholar] [CrossRef]

- Delmas, M.A.; Burbano, V.C. The drivers of greenwashing. Calif. Manag. Rev. 2011, 54, 64–87. [Google Scholar] [CrossRef] [Green Version]

- Massaro, M.; Secinaro, S.; Dal Mas, F.; Brescia, V.; Calandra, D. Industry 4.0 and circular economy: An exploratory analysis of academic and practitioners’ perspectives. Bus. Strategy Environ. 2021, 30, 1213–1231. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Avdiushchenko, A. Circular economy indicators in relation to eco-innovation in European regions. Clean Technol. Environ. Policy 2017, 19, 669–678. [Google Scholar] [CrossRef] [Green Version]

- Scarpellini, S. Social indicators for businesses’ circular economy: Multi-faceted analysis of employment as an indicator for sustainability reporting. Eur. J. Soc. Impact Circ. Econ. 2021, 2, 17–44. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Nordin, N.; Selke, S. Social aspect of sustainable packaging. Packag. Technol. Sci. 2010, 23, 317–326. [Google Scholar] [CrossRef]

- Pournader, M.; Sauer, P.C.; Fahimnia, B.; Seuring, S. Behavioral studies in sustainable supply chain management. Int. J. Prod. Econ. 2022, 243, 108344. [Google Scholar] [CrossRef]

- Uvarova, I.; Mavlutova, I.; Atstaja, D. Development of the green entrepreneurial mindset through modern entrepreneurship education. IOP Conf. Ser. Earth Environ. Sci. 2020, 628, 012034. [Google Scholar] [CrossRef]

- Dwivedi, A.; Agrawal, D.; Jha, A.; Gastaldi, M.; Paul, S.K.; D’Adamo, I. Addressing the challenges to sustainable initiatives in value chain flexibility: Implications for Sustainable Development Goals. Glob. J. Flex. Syst. Manag. 2021, 22, 179–197. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Mustapha, K.B.; Godsell, J.M.; Adamu, Z.; Babatunde, K.A.; Akintade, D.D.; Koh, S.C.L. A critical review of the impacts of COVID-19 on the global economy and ecosystems and opportunities for circular economy strategies. Resour. Conserv. Recycl. 2020, 164, 105169. [Google Scholar] [CrossRef]

- Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Vazquez-Brust, D.; Yakovleva, N. Circular economy, degrowth and green growth as pathways for research on sustainable development goals: A global analysis and future agenda. Ecol. Econ. 2021, 185, 107050. [Google Scholar] [CrossRef]

- Fratila, D. 8.09-Environmentally friendly manufacturing processes in the context of transition to sustainable production”. Compr. Mater. Process. 2014, 8, 163–175. [Google Scholar]

- Pereira, C.J. Environmentally friendly processes. Chem. Eng. Sci. 1999, 54, 1959–1973. [Google Scholar] [CrossRef] [Green Version]

- Jawahir, I.S.; Wanigarathne, P.C.; Wang, X. Product design and manufacturing processes for sustainability. In Chapter 12—Mechanical Engineers’ Handbook; John Wiley and Sons: Hoboken, NJ, USA, 2006; pp. 414–443. [Google Scholar]

- Brunner, P.H.; Rechberger, H. Handbook of Material Flow Analysis: For Environmental, Resource, and Waste Engineers; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Laner, D.; Rechberger, H.; Astrup, T. Systematic evaluation of uncertainty in material flow analysis. J. Ind. Ecol. 2014, 18, 859–870. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Delmas, M.A.; Pekovic, S. Resource efficiency strategies and market conditions. Long Range Plan. 2015, 48, 80–94. [Google Scholar] [CrossRef] [Green Version]

- Thiede, S.; Bogdanski, G.; Herrmann, C. A systematic method for increasing the energy and resource efficiency in manufacturing companies. Procedia CIRP 2012, 2, 28–33. [Google Scholar] [CrossRef]

- Rennings, K.; Christian, R. Increasing Energy and Resource Efficiency through Innovation: An Explorative Analysis Using Innovation Survey Data. 2009. Available online: https://madoc.bib.uni-mannheim.de/2479/ (accessed on 30 June 2021).

- Nakamura, S.; Kondo, Y. Input-output analysis of waste management. J. Ind. Ecol. 2002, 6, 39–63. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Oliveira, C.; Coelho, D.; Antunes, C.H. Coupling input–output analysis with multiobjective linear programming models for the study of economy–energy–environment–social (E3S) trade-offs: A review. Ann. Oper. Res. 2016, 247, 471–502. [Google Scholar] [CrossRef]

- Minx, J.C.; Wiedmann, T.; Wood, R.; Peters, G.P.; Lenzen, M.; Owen, A.; Scott, K.; Barrett, J.; Hubacek, K.; Baiocchi, G.; et al. Input–output analysis and carbon footprinting: An overview of applications. Econ. Syst. Res. 2009, 21, 187–216. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C.; Baldé, K.; Polder, M. Measuring resource efficiency and circular economy: A market value approach. Resour. Conserv. Recycl. 2017, 122, 163–171. [Google Scholar] [CrossRef]

- Evans, S.; Vladimirova, D.; Holgado, M.; Van Fossen, K.; Yang, M.; Silva, E.A.; Barlow, C.Y. Business model innovation for sustainability: Towards a unified perspective for creation of sustainable business models. Bus. Strategy Environ. 2017, 26, 597–608. [Google Scholar] [CrossRef]

- Veleva, V.; Ellenbecker, M. Indicators of sustainable production: Framework and methodology. J. Clin. Prod. 2001, 9, 519–549. [Google Scholar] [CrossRef]

- Bocken, N.M.; Geradts, T.H. Barriers and drivers to sustainable business model innovation: Organization design and dynamic capabilities. Long Range Plan. 2020, 53, 101950. [Google Scholar] [CrossRef]

- Veleva, V.; Bodkin, G. Corporate-entrepreneur collaborations to advance a circular economy. J. Clin. Prod. 2018, 188, 20–37. [Google Scholar] [CrossRef]

- Bocken, N.; Boons, F.; Baldassarre, B. Sustainable business model experimentation by understanding ecologies of business models. J. Clin. Prod. 2019, 208, 1498–1512. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Circular ecosystem innovation: An initial set of principles. J. Clin. Prod. 2020, 253, 119942. [Google Scholar] [CrossRef]

- Brown, P.; Baldassarre, B.; Konietzko, J.; Bocken, N.; Balkenende, R. A tool for collaborative circular proposition design. J. Clin. Prod. 2021, 297, 126354. [Google Scholar] [CrossRef]

- Uvarova, I.; Platonova, I.; Rascevska, Z.; Volkova, T.; Atstaja, D. The value co-creation in circular business models: Quadruplex Helix perspective. In Proceedings of the 6th International Conference on New Business Models: New Business Models in a Decade of Action: Sustainable, Evidence-based, Impactful, Halmstad, Sweden, 9–11 June 2021; pp. 382–389, ISBN 978-91-88749-68-0. [Google Scholar]

- Lüdeke-Freund, F.; Carroux, S.; Joyce, A.; Massa, L.; Breuer, H. The sustainable business model pattern taxonomy—45 patterns to support sustainability-oriented business model innovation. Sustain. Prod. Consum. 2018, 15, 145–162. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clin. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Bocken, N.M.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clin. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef] [Green Version]

- Young, W.; Hwang, K.; McDonald, S.; Oates, C.J. Sustainable consumption: Green consumer behaviour when purchasing products. Sustain. Dev. 2010, 18, 20–31. [Google Scholar] [CrossRef]

- Hargreaves, T. Practice-ing behaviour change: Applying social practice theory to pro-environmental behaviour change. J. Consum. Cult. 2011, 11, 79–99. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clin. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Mont, O. Institutionalisation of sustainable consumption patterns based on shared use. Ecol. Econ. 2004, 50, 135–153. [Google Scholar] [CrossRef]

- Mavlutova, I.; Kuzmina, J.; Uvarova, I.; Atstaja, D.; Lesinskis, K.; Mikelsone, E.; Brizga, J. Does Car Sharing Contribute to Urban Sustainability from User-Motivation Perspectives? Sustainability 2021, 13, 10588. [Google Scholar] [CrossRef]

- Armstrong, C.M.J. Fashion and the Buddha: What Buddhist Economics and Mindfulness Have to Offer Sustainable Consumption. Cloth. Text. Res. J. 2021, 39, 91–105. [Google Scholar] [CrossRef]

- Dimante, D.; Tambovceva, T.; Atstaja, D. Raising environmental awareness through education. Int. J. Contin. Eng. Educ. Life-Long Learn. 2016, 26, 259–272. [Google Scholar] [CrossRef]

- Henry, M.; Schraven, D.; Bocken, N.; Frenken, K.; Hekkert, M.; Kirchherr, J. The battle of the buzzwords: A comparative review of the circular economy and the sharing economy concepts. Environ. Innov. Soc. Transit. 2021, 38, 1–21. [Google Scholar] [CrossRef]

- Wang, P.; McCarthy, B.; Kapetanaki, A.B. To be ethical or to be good? The impact of ‘Good Provider’ and moral norms on food waste decisions in two countries. Glob. Environ. Change 2021, 69, 102300. [Google Scholar] [CrossRef]

- Armstrong, C.M.; Niinimäki, K.; Kujala, S.; Karell, E.; Lang, C. Sustainable product-service systems for clothing: Exploring consumer perceptions of consumption alternatives in Finland. J. Clin. Prod. 2015, 97, 30–39. [Google Scholar] [CrossRef]

- Reijonen, H.; Bellman, S.; Murphy, J.; Kokkonen, H. Factors related to recycling plastic packaging in Finland’s new waste management scheme. Waste Manag. 2021, 131, 88–97. [Google Scholar] [CrossRef] [PubMed]

- Tanner, C.; Kast, W.S. Promoting sustainable consumption: Determinants of green purchases by Swiss consumers. Psychol. Mark. 2003, 20, 883–902. [Google Scholar] [CrossRef]

- Ahir, R.K.; Chakraborty, B. A meta-analytic approach for determining the success factors for energy conservation. Energy 2021, 230, 120821. [Google Scholar] [CrossRef]

- De las Heras, A.; Relinque-Medina, F.; Zamora-Polo, F.; Luque-Sendra, A. Analysis of the evolution of the sharing economy towards sustainability. Trends and transformations of the concept. J. Clin. Prod. 2020, 291, 125227. [Google Scholar] [CrossRef]

- Costa, N.; Patrício, L.; Morelli, N.; Magee, C.L. Bringing service design to manufacturing companies: Integrating PSS and service design approaches. Des. Stud. 2018, 55, 112–145. [Google Scholar] [CrossRef]

- Fuentes, C.; Cegrell, O.; Vesterinen, J. Digitally enabling sustainable food shopping: App glitches, practice conflicts, and digital failure. J. Retail. Consum. Serv. 2021, 61, 102546. [Google Scholar] [CrossRef]

- Porter, M. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Koval, V.; Duginets, G.; Plekhanova, O.; Antonov, A.; Petrova, M. On the supranational and national level of global value chain management. Entrep. Sustain. Issues 2019, 6, 1922. [Google Scholar] [CrossRef] [Green Version]

- Nasr, A.K.; Kashan, M.K.; Maleki, A.; Jafari, N.; Hashemi, H. Assessment of barriers to renewable energy development using stakeholders approach. Entrep. Sustain. Issues 2020, 7, 2526. [Google Scholar] [CrossRef] [Green Version]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clin. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Beske, P.; Land, A.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Costa, C.; Antonucci, F.; Pallottino, F.; Aguzzi, J.; Sarriá, D.; Menesatti, P. A Review on Agri-Food Supply Chain Traceability by Means of RFID Technology. Food Bioprocess Technol. 2013, 6, 353–366. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clin. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Chumtong, J.; Kaldewey, D. Beyond the Google ngram viewer. Forum Internationale Wissenschaft. 2017. Available online: https://bonndoc.ulb.uni-bonn.de/xmlui/bitstream/handle/20.500.11811/1150/FIW_Working_Paper_08.pdf?sequence=1 (accessed on 30 June 2021).

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066. [Google Scholar] [CrossRef]

- Raddadi, N.; Fava, F. Biodegradation of oil-based plastics in the environment: Existing knowledge and needs of research and innovation. Sci. Total Environ. 2019, 679, 148–158. [Google Scholar] [CrossRef]

- Amulya, K.; Katakojwala, R.; Ramakrishna, S.; Mohan, S.V. Low carbon biodegradable polymer matrices for sustainable future. Compos. Part C Open Access 2021, 4, 100111. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iwata, T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angew. Chem. Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef]

- SPC. Definition of Sustainable Packaging. Sustainable Packaging Coalition, A Project of Greenblue. 2011. Available online: https://sustainablepackaging.org/wp-content/uploads/2017/09/Definition-of-Sustainable-Packaging.pdf (accessed on 24 July 2021).

- Verghese, K.; Lewis, H.; Lockrey, S.; Williams, H. Packaging’s role in minimizing food loss and waste across the supply chain. Packag. Technol. Sci. 2015, 28, 603–620. [Google Scholar] [CrossRef]

- Wikström, F.; Williams, H.; Trischler, J.; Rowe, Z. The importance of packaging functions for food waste of different products in households. Sustainability 2019, 11, 2641. [Google Scholar] [CrossRef] [Green Version]

- De Mello Soares, C.T.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios. Resour. Conserv. Recycl. 2022, 176, 105905. [Google Scholar] [CrossRef]

- Boz, Z.; Korhonen, V.; Sand, C.K. Consumer considerations for the implementation of sustainable packaging: A review. Sustainability 2020, 12, 2192. [Google Scholar] [CrossRef] [Green Version]

- Kolybaba, M.; Tabil, L.G.; Panigrahi, S.; Crerar, W.J.; Powell, T.; Wang, B. Biodegradable polymers: Past, present, and future. In ASABE/CSBE North Central Intersectional Meeting; American Society of Agricultural and Biological Engineers: Avenue North Fargo, ND, USA, 2006; p. 1. [Google Scholar]

- Abu Ghalia, M.; Dahman, Y. Synthesis and utilization of 15 natural fibre-reinforced poly (lactic acid) bionanocomposites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Woodhead Publishing: Sawston, UK, 2017; pp. 313–345. [Google Scholar] [CrossRef]

- Rai, P.; Mehrotra, S.; Priya, S.; Gnansounou, E.; Sharma, S.K. Recent advances in the sustainable design and applications of biodegradable polymers. Bioresour. Technol. 2021, 325, 124739. [Google Scholar] [CrossRef] [PubMed]

- Meixner, O.; Katt, F. Assessing the impact of COVID-19 on consumer food safety perceptions—A choice-based willingness to pay study. Sustainability 2020, 12, 7270. [Google Scholar] [CrossRef]

- Kitz, R.; Walker, T.; Charlebois, S.; Music, J. Food packaging during the COVID-19 pandemic: Consumer perceptions. Int. J. Consum. Stud. 2021. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, V.; Rocculi, P.; Romani, S.; Dalla Rosa, M. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Vikhareva, I.N.; Buylova, E.A.; Yarmuhametova, G.U.; Aminova, G.K.; Mazitova, A.K. An overview of the main trends in the creation of biodegradable polymer materials. J. Chem. 2021, 2021, 5099705. [Google Scholar] [CrossRef]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Stäbler, A.; Lazzeri, A. Thermal and mechanical properties of biocomposites made of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and potato pulp powder. Polymers 2019, 11, 308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prajapati, S.K.; Jain, A.; Jain, A.; Jain, S. Biodegradable polymers and constructs: A novel approach in drug delivery. Eur. Polym. J. 2019, 120, 109191. [Google Scholar] [CrossRef]

- George, A.; Shah, P.A.; Shrivastav, P.S. Natural biodegradable polymers based nano-formulations for drug delivery: A review. Int. J. Pharm. 2019, 561, 244–264. [Google Scholar] [CrossRef]

- Cohn, D.; Zarek, M.; Elyashiv, A.; Sbitan, M.A.; Sharma, V.; Ramanujan, R.V. Remotely triggered morphing behavior of additively manufactured thermoset polymer-magnetic nanoparticle composite structures. Smart Mater. Struct. 2021, 30, 045022. [Google Scholar] [CrossRef]

- Kumar, A.; Jyske, T.; Möttönen, V. Properties of injection molded biocomposites reinforced with wood particles of short-rotation aspen and willow. Polymers 2020, 12, 257. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-mechanical and thermodynamic properties of mycelium-based biocomposites: A review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef] [Green Version]

- Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, Á.; Addy, C.; Xu, Q.; Jiang, L.; Neisiany, R.E.; Singha, S.; et al. Circular economy in biocomposite development: State-of-the-art, challenges and emerging trends. Compos. Part C Open Access 2021, 5, 100138. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fibre composites environmentally superior to glass fibre reinforced composites? Compos. Part A 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Sheldon, R.A.; Norton, M. Green chemistry and the plastic pollution challenge: Towards a circular economy. Green Chem. 2020, 22, 6310–6322. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C.; Maheshwari, M.K.; Sharma, R.K. Bagasse fibre composites: A review. J. Mater. Environ. Sci. 2012, 3, 1079–1092. [Google Scholar]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fibre reinforced composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Dungani, R.; Karina, M.; Subyakto; Sulaeman, A.; Hermawan, D.; Hadiyane, A. Agricultural waste fibres towards sustainability and advanced utilization: A review. Asian J. Plant Sci. 2016, 15, 42–55. [Google Scholar] [CrossRef] [Green Version]

- Aigbodion, V.S. Bean pod ash nanoparticles a promising reinforcement for aluminium matrix biocomposites. J. Mater. Res. Technol. 2019, 8, 6011–6020. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Sanjay, K.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Smoca, A.; Kukle, S.; Zelca, Z. Properties of hemp fibres reinforced PLA composites. Key Engineering Materials. Key Eng. Mater. 2019, 800, 205–209. [Google Scholar] [CrossRef]

- Rafiee, K.; Schritt, H.; Pleissner, D.; Kaur, G.; Brar, S.K. Biodegradable green composites: It’s never too late to mend. Curr. Opin. Green Sustain. Chem. 2021, 30, 100482. [Google Scholar] [CrossRef]

- EIHA. Hemp a Real Green Deal. European Industrial Hemp Association. 2020. Available online: https://eiha.org/wp-content/uploads/2020/09/Hemp-a-real-green-deal_EN.pdf (accessed on 25 July 2021).

- Mohan, S.V.; Katakojwala, R. Circular Chemistry Conceptual Framework: A way forward to Sustainability in Industry 4.0. Curr. Opin. Green Sustain. Chem. 2020, 28, 100434. [Google Scholar] [CrossRef]

- Kobayashi, T.; Nakajima, L. Sustainable development goals for advanced materials provided from industry wastes and biomass sources. Curr. Opin. Green Sustain. Chem. 2021, 28, 100439. [Google Scholar] [CrossRef]

- Dicker, M.P.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Ravi, H.K. Towards petroleum-free with plant-based chemistry. Curr. Opin. Green Sustain. Chem. 2021, 28, 100450. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Uddin, M.J. How the agent-based banking model might facilitate financial inclusion and sustainability via economic circularity?–A Bangladesh perspective. Eur. J. Soc. Impact Circ. Econ. 2020, 1, 76–94. [Google Scholar] [CrossRef]

- Geng, Y.; Zhu, Q.; Doberstein, B.; Fujita, T. Implementing China’s circular economy concept at the regional level: A review of progress in Dalian, China. Waste Manag. 2009, 29, 996–1002. [Google Scholar] [CrossRef]

- Tongco, M.D.C. Purposive sampling as a tool for informant selection. Ethnobot. Res. Appl. 2007, 5, 147–158. [Google Scholar] [CrossRef] [Green Version]

- Biernacki, P.; Waldorf, D. Snowball sampling: Problems and techniques of chain referral sampling. Sociol. Methods Res. 1981, 10, 141–163. [Google Scholar] [CrossRef]

- Salzmann, O.; Ionescu-Somers, A.; Steger, U. The business case for corporate sustainability: Literature review and research options. Eur. Manag. J. 2005, 23, 27–36. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Dal Mas, F.; Massaro, M.; Lombardi, R.; Garlatti, A. From output to outcome measures in the public sector: A structured literature review. Int. J. Organ. Anal. 2019, 27, 1631–1656. [Google Scholar] [CrossRef]

- Alhawari, O.; Awan, U.; Bhutta, M.K.S.; Ülkü, M.A. Insights from circular economy literature: A review of extant definitions and unravelling paths to future research. Sustainability 2021, 13, 859. [Google Scholar] [CrossRef]

- Vurro, C.; Russo, A.; Perrini, F. Shaping sustainable value chains: Network determinants of supply chain governance models. J. Bus. Ethics 2009, 90, 607–621. [Google Scholar] [CrossRef]

- Durán-Romero, G.; López, A.M.; Beliaeva, T.; Ferasso, M.; Garonne, C.; Jones, P. Bridging the gap between circular economy and climate change mitigation policies through eco-innovations and Quintuple Helix Model. Technol. Forecast. Soc. Chang. 2020, 160, 120246. [Google Scholar] [CrossRef]

- Scarpellini, S.; Marín-Vinuesa, L.M.; Aranda-Usón, A.; Portillo-Tarragona, P. Dynamic capabilities and environmental accounting for the circular economy in businesses. Sustain. Accounting, Manag. Policy J. 2020, 11, 1129–1158. [Google Scholar] [CrossRef] [Green Version]

- Radavičius, T.; van der Heide, A.; Palitzsch, W.; Rommens, T.; Denafas, J.; Tvaronavičienė, M. Circular solar industry supply chain through product technological design changes. Insights Reg. Dev. 2021, 3, 10–30. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Nonino, F.; Pompei, A. Which are the determinants of green purchase behaviour? A study of Italian consumers. Bus. Strategy Environ. 2021, 30, 2600–2620. [Google Scholar] [CrossRef]

- Global Price Increase of Polypropylene (PP) from January 2020 to March 2021. Available online: https://www.statista.com/statistics/1239058/bi-monthly-polypropylene-price-worldwide/ (accessed on 25 July 2021).

- Siltaloppi, J.; Jähi, M. Toward a sustainable plastics value chain: Core conundrums and emerging solution mechanisms for a systemic transition. J. Clean. Prod. 2021, 315, 128113. [Google Scholar] [CrossRef]

- Barone, A.S.; Matheus, J.R.V.; de Souza, T.S.P.; Moreira, R.F.A.; Fai, A.E.C. Green-based active packaging: Opportunities beyond COVID-19, food applications, and perspectives in circular economy—A brief review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4881–4905. [Google Scholar] [CrossRef]

- Zhao, L.; Kim, K. Responding to the COVID-19 Pandemic: Practices and strategies of the global clothing and Textile value chain. Cloth. Text. Res. J. 2021, 39, 157–172. [Google Scholar] [CrossRef]

- Koval, V.; Olczak, P.; Vdovenko, N.; Boiko, O.; Matuszewska, D.; Mikhno, I. Ecosystem of environmentally sustainable municipal infrastructure in the Ukraine. Sustainability 2021, 13, 10223. [Google Scholar] [CrossRef]

- Stankevičius, A.; Novikovas, A.; Bakaveckas, A.; Petryshyn, O. EU waste regulation in the context of the circular economy: Peculiarities of interaction. Entrep. Sustain. Issues 2020, 8, 533–545. [Google Scholar] [CrossRef]

- Koval, V.; Mikhno, I.; Udovychenko, I.; Gordiichuk, Y.; Kalina, I. Sustainable natural resource management to ensure strategic environmental development. TEM J. 2021, 10, 1022–1030. [Google Scholar] [CrossRef]

| Fiber Type | Flax | Hemp | Jute | Sisal |

|---|---|---|---|---|

| Density (g/cm3) | 1.4–1.5 | 1.4–1.5 | 1.3–1.5 | 1.3–1.5 |

| Tensile Strength (Mpa) | 343–2000 | 270–900 | 320–800 | 363–700 |

| Tensile Modulus (Gpa) | 27.6–103 | 23.5–90 | 8–78 | 9–38 |

| Specific Modulus | 45 | 40 | 30 | 17 |

| Elongation to Break (%) | 1.2–3.3 | 1–3.5 | 1–1.8 | 2–7 |

| Cellulose (wt %) | 62–72 | 68–74.4 | 59–71.5 | 60–78 |

| Hemicellulose (wt %) | 18.6–20.6 | 15–22.4 | 13.6–20.4 | 10–14.2 |

| Lignin (wt %) | 2.3 | 3.7–10 | 11.8–13 | 8–14 |

| Moisture content (wt %) | 8–12 | 6.2–12 | 12.5–13.7 | 10–22 |

| Cost per weight (EUR/kg) | 8.0 | 1.1 | 0.3 | 0.9 |

| Label Codes | Questions | Types of Responses |

|---|---|---|

| A-IQ1 | Represented sector/industry/field | Open |

| A-IQ2 | Size of the company | Open: turnover in EUR |

| A-IQ3 | Role in the sustainable production chain | Closed: #1 Feedstock production & pre-treatment; #2 Raw material processing and refining; #3 Packaging manufacturing, #4 Product manufacturing, #4 Retailer |

| A-IQ4 | Field of expertise/position | Open |

| Label Codes | Questions | Types of Responses |

|---|---|---|

| B-IQ1 | The general perception of the EU Green Deal Strategy and the sustainability goals within the industry | Open |

| B-IQ2 | The general perception of the sustainability principles within the company of the interviewee and its value chain | Open |

| B-IQ3 | The adoption/introduction of the sustainability principles into the practice of the company of the interviewee and its value chain | Open |

| B-IQ4 | If and how consumer behavior affects industrial consumption during COVID-19 | Open |

| B-IQ5 | The general intention and the practice regarding the use of biocomposite materials | Open |

| B-IQ6 | The opinion about the functionality, technological feasibility, environmental, and economic aspects of the sustainable packaging and, particularly, the use of biocomposite materials | Open |

| B-IQ7 | Any changes observed within the use of biocomposite materials during COVID-19 | Open |

| B-IQ8 | Possible impact of COVID-19 on the use of biocomposite materials at each stage of the value chain (stages: #1 Feedstock production & pre-treatment; #2 Raw material processing and refining; #3 Packaging manufacturing; #4 Product manufacturing, #4 Retailer) | Closed: Positive, neutral, negative |

| Criteria for Sustainable Packaging | Dimensions of Sustainable Packaging | |||

|---|---|---|---|---|

| Functional | Technologically Feasible | Environmental | Economic | |

| 1. Safe and healthy for all individuals throughout their life cycle | X | X | X | |

| 2. Meets market criteria in terms of its performance and costs | X | |||

| 3. Obtained, produced, transported, and processed using renewable energy | X | X | X | |

| 4. Produced using renewable or recycled raw materials and clean production technologies | X | X | X | |

| 5. Made of harmless materials in all possible end-of-life scenarios | X | X | ||

| 6. Physically designed and validated to optimize used materials and energy consumption | X | X | X | |

| 7. Fully recovered and utilized in industrial and/or biological cradle-to-cradle cycles | X | X | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rutitis, D.; Smoca, A.; Uvarova, I.; Brizga, J.; Atstaja, D.; Mavlutova, I. Sustainable Value Chain of Industrial Biocomposite Consumption: Influence of COVID-19 and Consumer Behavior. Energies 2022, 15, 466. https://doi.org/10.3390/en15020466

Rutitis D, Smoca A, Uvarova I, Brizga J, Atstaja D, Mavlutova I. Sustainable Value Chain of Industrial Biocomposite Consumption: Influence of COVID-19 and Consumer Behavior. Energies. 2022; 15(2):466. https://doi.org/10.3390/en15020466

Chicago/Turabian StyleRutitis, Didzis, Anete Smoca, Inga Uvarova, Janis Brizga, Dzintra Atstaja, and Inese Mavlutova. 2022. "Sustainable Value Chain of Industrial Biocomposite Consumption: Influence of COVID-19 and Consumer Behavior" Energies 15, no. 2: 466. https://doi.org/10.3390/en15020466

APA StyleRutitis, D., Smoca, A., Uvarova, I., Brizga, J., Atstaja, D., & Mavlutova, I. (2022). Sustainable Value Chain of Industrial Biocomposite Consumption: Influence of COVID-19 and Consumer Behavior. Energies, 15(2), 466. https://doi.org/10.3390/en15020466