Abstract

Changes in modern technologies have led to a decrease in the role of oil and threaten the well-being of oil-exporting countries. The oil and gas industry is the leading one in the economy of Kazakhstan, and the future of the country depends on its development. The purpose of the presented research is to determine the long-term image of the future oil and gas industry and develop a strategy for the government and national companies in different spheres for actions in conditions of increasing uncertainty. The article presents the materials of an expert survey using the Delphi method (211 industry experts) and a group discussion during a foresight session (75 participants), in which the authors provided methodological support and practical participation. The top nine development trends have been identified, the majority of experts (about 90%) see the future of the industry as the development of unmanned production based on digital management and an increase in environmental requirements (85%). The author’s methodology is based on a pragmatic approach to conducting an industry technological foresight in the medium term. The visionary image of the development of the oil and gas industry is built on the basis of the possibilities of technological breakthroughs. The refined image was formed as a response to the challenges of the external environment on the principle of the “Most Advanced, Yet Acceptable”. The main characteristic of the future of the oil and gas industry in Kazakhstan is a deserted production, where the production process is fully automated and robotic. Risks of oil and gas industry development are critical for the entire economy of Kazakhstan, so plans based on industry foresight projections to prevent them are a national priority.

1. Introduction

Kazakhstan is one of the most mineral-rich countries and therefore the mining and processing of minerals is particularly important for the economy. According to the authors of [1], the country possesses about 3% of the world’s reserves and is among the top 15 oil-producing countries that provide 60% of the world’s consumption of hydrocarbons. The oil and gas industry is the largest taxpayer of the state and provides 44% of the tax revenues to the budget of the republic. An important peculiarity of the industry is the remoteness of its production from the main oil consumption markets. More than 80% of the oil produced in Kazakhstan is exported, which requires an effective system of pipelines and other transport.

The global oil and gas industry employs more than five million people. Just over seventy-one thousand people are employed in the oil and gas enterprises of the republic, of which 96.6% are citizens of Kazakhstan. The attractiveness of the oil and gas sector is high because of the high level of wages in the industry, which on average is one and a half times higher than the average monthly wage in the industry.

The oil and gas industry is actively taking steps to integrate into the new digital economy, as well as seeking to make production more nature-friendly. In recent decades, the practice of creating geological computer three-dimensional models using modern computer programs of Landmark, Roxar, and Schlumberger has become widespread in Kazakhstan, which makes the work more efficient.

At the same time, traditional oil, gas, and other resource deposits are being depleted, and production companies are being forced to move to increasingly complex fields, as well as new types of resources, such as oil sands, shale gas, and offshore and deep-water deposits, so companies in Kazakhstan need specialists.

Human resources in the main segment—oil production—is underdeveloped, there is a need to improve its level. This problem is urgent for the republic due to the growing share of foreign workers with high unemployment in the oil-producing regions. The need for new qualifications is due to the widespread transition from comprehensive automation of technological processes to the informatization of these processes, i.e., the implementation of computer systems in the management of technological, logistical, financial, and other processes. The study on which we relied was devoted to the development of the atlas of new, transforming, and disappearing professions, as well as the definition of future competencies in the oil and gas industry.

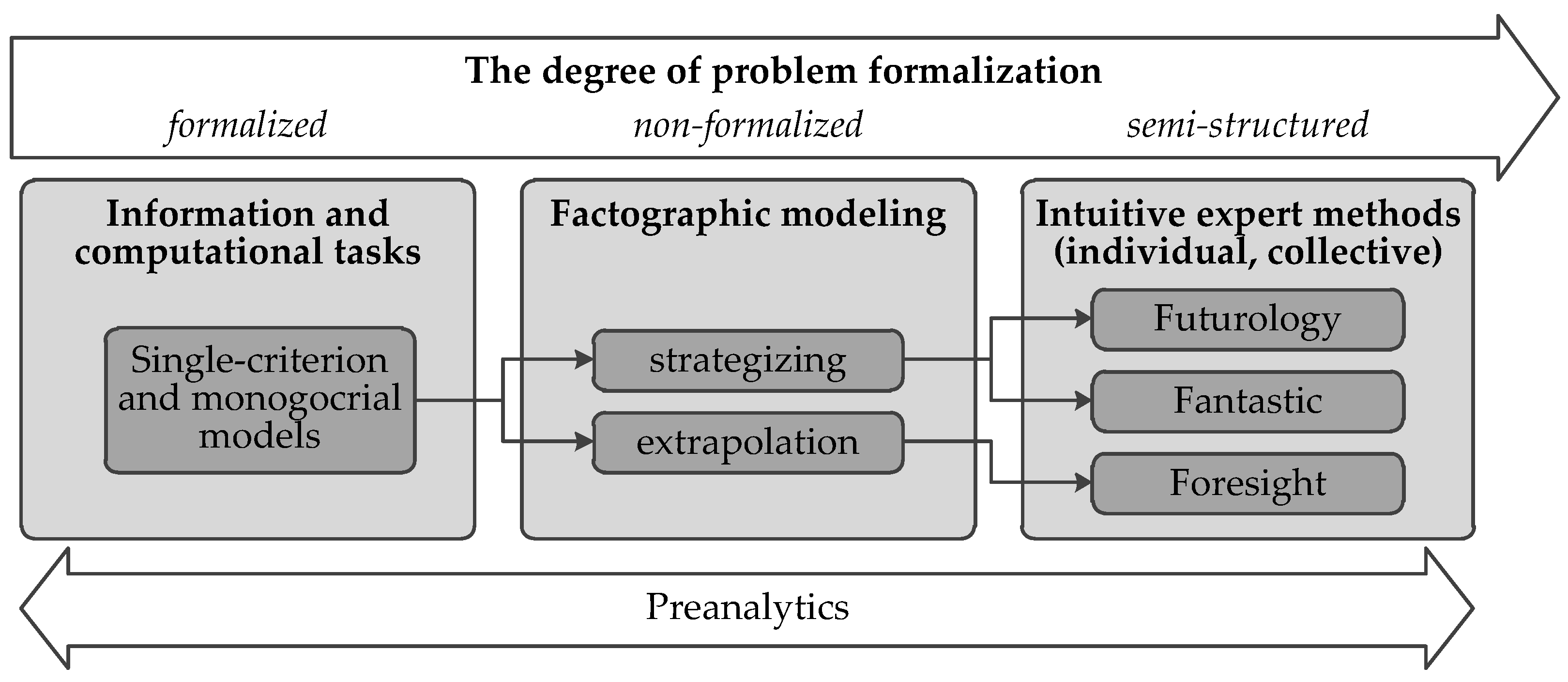

In modern management there is no single approach to forecasting; general scientific methods and specific techniques are used. Scientific forecasting methodology includes several principles and rules, a set of research methods, and procedures for interaction with experts. The degree of detail and reliability of forecasts depends on the tasks set and the methods used (see Figure 1).

Figure 1.

Methods of foresight for predicting the future.

It contains methods of working with the future. Conventionally, we can divide the methods of designing the future into two groups. The one, based on quantitative analysis, is in the slide to the left. This is extrapolation and strategy. We can effectively use these methods if we have accumulated quantitative data about the current and past situations. If we can accumulate enough facts for correct conclusions, we use creative methods—futurology and science fiction—a method that allows you to combine quantitative and cognitive methods is foresight.

A change in forecasting methods occurs as the degree of uncertainty of the problems being solved increases. Well-structured problems are predicted by mathematical models. Stochastic and deterministic, cognitive, and logical-probabilistic models are applied [2]. For semi-structured problems, combined methods are used using experts and information. If the task of the forecast is to provide a strategy, then the object domain is modeled and the state variables (cross-sectional data) are studied. In another case, based on the study of intensity variables (time-series data), time-series modeling is performed to extrapolate the intensity of object change.

Foresight as a combined method of forecasting the future includes previous methods. Fractographic models form the basis of foresight pre-analytics. Strategy also precedes foresight, since it reflects the response to the oncoming stream of factors and forms the context of responsibility for the future.

Foresight pre-analytics in the oil and gas and energy industries included the presented methods. Several hundred analytical sources were processed, models of retrospective analysis of employment in industries were built, and a comparative analysis of the development of commodity markets was carried out. The content of the preliminary analysis made it possible to study trends, evaluate alternatives, and provide the foresight participants with reliable and objective information. The broader and more thorough the preliminary analysis is performed, the more reliable the results of the entire foresight are. The conducted pre-analytics made it possible to identify and describe the main trends (more than 20) in the development of the industry, to identify key technologies that have an impact on the oil and gas and energy industries at present and/or soon.

The purpose of our article is to determine the image of the future of Kazakhstan’s oil and gas complex based on foresight methodology.

The research methodology is based on the Technology Skills Foresight (STF) developed by the International Labor Organization (ILO), the Agency for Strategic Initiatives of Russia, and Skolkovo Moscow School of Management (Russia) and adapted to the realities of the Kazakhstan economy, as well as the MAYA principle (an acronym for “Most Advanced, Yet Acceptable”).

2. State of the Art

2.1. Foresight: Definition and History of Development

Strategic foresight involves understanding future activities and making appropriate decisions. J. Berger′s early work emphasized the need for the management team to share the creation of perspectives for the future [3]. This vision can clarify ultimate goals and facilitate the selection of means and planning [4].

Rohrbeck et al. [5] provide a historical framework for foresight studies from its inception in the mid-20th century to scenario building in the second half of the 20th century and organizational integration in the early 21st century. Hamel and Prahalad [6] contrast increasing competitiveness through restructuring and cost reduction, which can be used to create a new competitive advantage with industry foresight as a deep understanding of trends. They also argue that the ability to overcome crises by fighting for the future allows for high profitability.

Slaughter [7] uses the conflation of strategic management techniques with future method development to refer to the term “strategic foresight”. Ahuja et al. [8] use the personal ability to anticipate as a characteristic of foresight. They define foresight ability as the actions of managers that can create a competitive advantage. Rohrbeck et al. [5] describe practices that allow an organization to form the foundation of future competitive advantage by creating value to describe the term corporate foresight.

Nevertheless, excessive focus on foresight may not always be helpful. Day and Shoemaker [9] make the case for a condition in a company whose peripheral vision exceeds its needs, which they call “neurotic”. Burt et al. [10] argue that foresight can cause a condition in top managers, which they call “managerial hypermetropia”, or over-focusing on managing the long-term prospects while not paying enough attention to current affairs. Coates et al. [4] used the French notion of “perspective” as a basic concept to introduce the concept of strategic foresight. “La prospective is foresight when we add in English the adjective strategic, i.e., strategic foresight.” “The reason for considering the French approach to foresight is the emphasis placed on human decisions, the consequences of future states and the participation of the decision-maker in the whole process of foresight” [11].

Strategic foresight seeks the dual goal of observing, perceiving, and controlling factors that may cause future change, and coping with those changes through appropriate organizational responses. These two processes, according to the foresight approach, should not be considered separately; here the decision-maker does the strategic part, and the futurologist does the foresight part. In this integrated process, the decision-maker and the foresight process themselves are mutually influential.

Foresight and technology foresight originally emerged as an attempt to determine the future development of technology and science. Technology foresight can be seen as “a process involving systematic attempts to look into the long-term future of science, technology, economics, and society in order to identify areas of strategic research and emerging new technologies that can yield the greatest economic and social benefits” [12].

The large-scale national studies of technology and science foresight conducted in Japan, and two decades later in the United States, Great Britain, and Germany, were designed to provide more acceptable information for the development and implementation of national technology and science policies.

Although in the beginning, the process of institutional learning took place mainly through the analysis of the development of the internal dynamics of technologies (first-generation foresight) by Georgiou et al. [13], later more attention began to be paid to social aspects and markets.

The foresight programs have also been influenced by a comprehensive policy aimed at improving coordination among the initiating institutions, which are more deeply integrated into the strategic decision-making process among other government agencies.

In different countries, the structure and direction of national research in the field of technology forecasting differ significantly from country to country. The learning economy is neither a pure market economy nor a pure planned economy; it is a mixed economy in a fundamental sense [14]. Better integration of corporate strategy and public policy is a key issue. Often new strategies are developed in parallel with foresight research, or even earlier. As a result, the current political agenda can sometimes outpace the results of predictive analysis [15].

2.2. Foresight: Technology Foresight

The nature of technological foresight stems from the need for long-term defense planning and stems from the industrial age [16]. Martin’s [12] (p. 142) definition of technological foresight is as follows: “Technology foresight is the process involved in systematically attempting to look into the longerterm future of science, technology, the economy and society with the aim of identifying the areas of strategic research and emerging generic technologies likely to yield the greatest economic and social benefits”.

Technology foresight has some disadvantages. For example, foresight practitioners are often encouraged to present “success stories” in their work to improve the evaluation of the quality of their work [17,18,19]. Researchers are encouraged to make further contributions to conceptual and methodological progress to provide a clearer understanding of foresight′s predictive capabilities [20,21]. There are several ways to classify and organize foresight methods [13,22,23,24]. Saritas and Aylen [24] divided foresight methods into five groups: understanding; models and synthesis; selection and analysis; transformation, and action. The classification of technology foresight methods developed by Magruk [22] on the basis of cluster analysis suggests 10 types: strategic, overview, prescriptive, advisory, multi-criteria, creative, radar, diagnostic, simulation, and analytical.

Georghiou introduced the “Foresight Diamond” which has four sides, such as experience, evidence, creativity, and interaction [13]. “Interactive” methods are defined as fully quantitative, including surveys, and voting. Examples of “creative” methods involve simulation and play, presented as semi-quantitative groups, wildcards. Examples of “expert” methods include roadmaps, interviews presented as qualitative methods, and expert panels. “Evidence-based” methods are also defined as semi-quantitative methods, including methods such as scanning, modeling, extrapolation, and literature reviews. Georghiou notes that road planning refers to the “expert knowledge” of the diamond, while scenario planning covers the area between “experience” and “creativity” [13].

Porter et al. [23] presented technology foresight as a set of thirteen groups of methods, including both quantitative and qualitative methods and their combination to compensate for the weaknesses of each individually. Putting the technology roadmap and scenario planning used in combination in perspective within the broader set of available technology foresight methods, scenario planning belongs to the “scenario” family, and the technology roadmap belongs to both “matrix” and “descriptive”.

2.3. Foresight: Regional Foresight

Foresight has evolved as both a forward-looking technological analysis and a regional policy direction. Foresight analysis quite often draws on various traditions of future research with the intention of informing regional policy-makers [25,26]. Foresight in terms of evolution and implementation coincides with the intensification of research and the further spread of the concept of innovation systems [27]. A flurry of research on national innovation systems has created the foundation for the development of more elaborate policy instruments that require substantial information not only about the current situation but also about future trends in science and technology. This concept emerged in the 1980s and has since become widespread [28]. It focuses on the role of innovation (of various types) and learning processes in economic progress, taking into account organizational, social, and political factors that evolve over time.

Institutions are seen as a key component of the national innovation systems; institutional learning is seen as driving the process of knowledge production and dissemination [29].

When analyzing the emergence and development of forward-looking activities in a particular country, it is important to take into account the relevant institutional conditions related to economic development, knowledge production, and dissemination. This is because the historical transformation of the NIS encompasses the production structure, technology, and institutions [30].

Over the past few decades, foresight and science and technology policy have evolved in tandem. The evolution of foresight can be seen as a process of institutional learning.

The most appropriate formulation of this is innovation systems or industry foresight, where the emphasis is on predicting the development and growth of a sector or industry, often to develop interventions to address the “system failures” that impede such development [31,32,33]. Thus, innovation systems foresight has established itself as a framework for understanding the challenges and dynamics of innovative change [32,33,34,35].

In this case, the practical problem is that there is a dependence of the predicted outcome on how the participants are defined and what their perceptions are. This is supported by the fact that six of the top ten foresight methods are based on soliciting opinions and insights from experts (discussion forums, literature reviews, brainstorming, workshops, interviews, and the Delphi method) [36].

3. Materials and Methods

3.1. Rapid Foresight

The methodology of the study is based on the recommendations of the International Labor Organization.

In general, on the basis of foresight, long-term, for 25–30 years, strategies for the development of the economy, science, and technology, aimed at improving competitiveness and the most efficient development of the socio-economic sphere are developed. The authors use their own methodology based on the Skills Technology Foresight (STF) approach.

A distinctive feature of STF is that it allows participants to coordinate actions in the context of the expected future, along with the solution of other tasks of foresight. The use of STF implies the support of the discussion by an experienced moderator, who leads the discussion by the participants of the group according to a preset methodology. This allows going through all the necessary steps to obtain the desired result.

3.2. Delphi Method: Interviewing Industry Experts Using In-Depth Interviewing, Questionnaires, and a Foresight Session

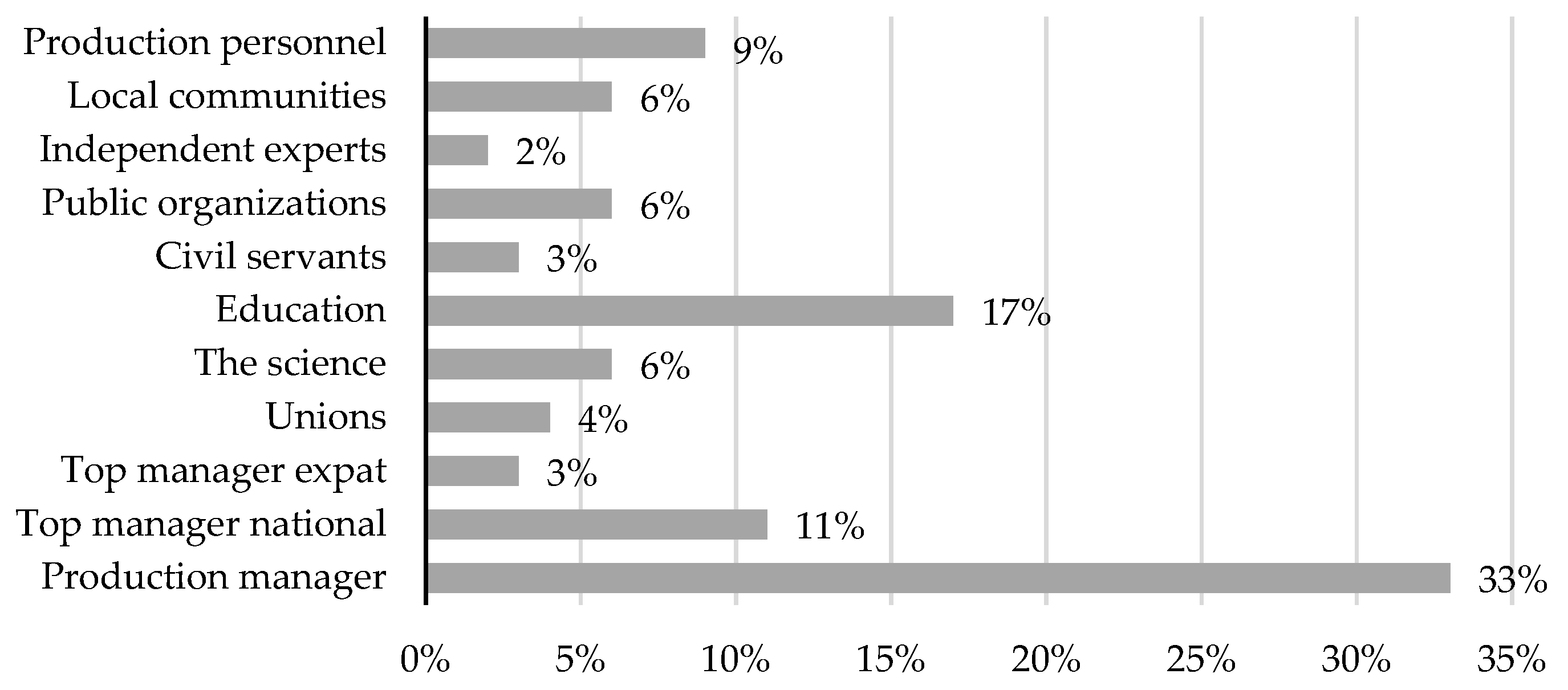

The Delphi method involves 20 or more experts in the evaluation. About 71 thousand people were employed in the oil and gas industry in the period before the pandemic. According to qualification indicators, 10% of the employed are experts, thus, the general population of experts is 7 thousand people. The survey involved 211 experts [1]; the confidence interval of the population of selected experts is 95% at the sampling error of 6.52% which is a sufficient indicator for the verification of the obtained data. The experts included representatives of industry, trade unions, the state, local communities, teachers, scientists, and other stakeholders influencing the development of the industry (see Figure 2).

Figure 2.

Expert categories by fields of activity.

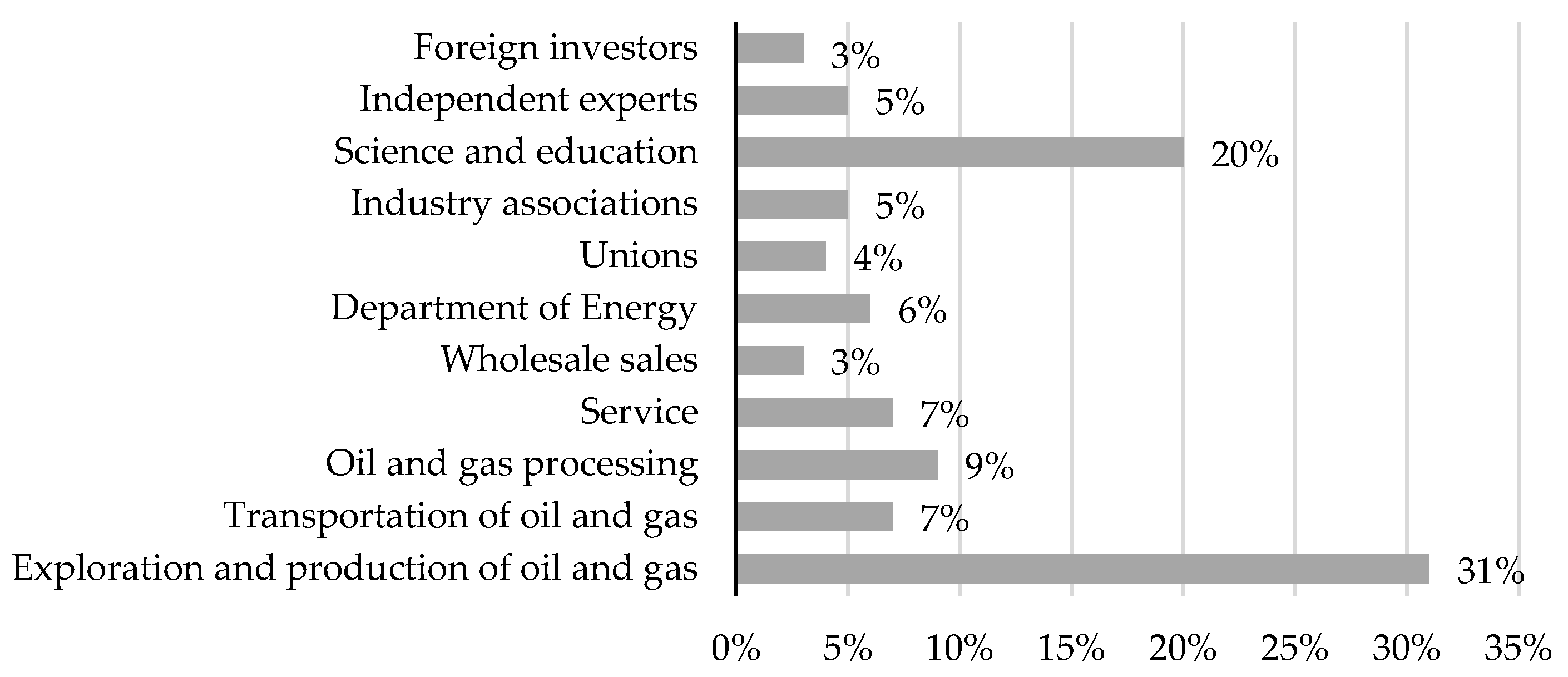

The experts interviewed are highly qualified specialists—41% of them have been working in the branch for more than 15 years, another 21% have 10 to 15 years of experience. The average length of service of the interviewed experts was 11 years, which is optimal for understanding the current problems and the prospects of the industry’s development. To obtain the most reliable results, the sectoral composition of experts was formed from representatives of all sectors of the industry (see Figure 3).

Figure 3.

Expert affiliations by sectors of the oil and gas industry.

The forecasts made by the experts combined knowledge of technological innovations with an understanding of the specifics of the real situation in the country and in the industry.

The in-depth interview is a method of qualitative research, representing an individual conversation between the moderator and the respondent. This type of research is the most effective in technological foresight, as it allows obtaining not only expert evaluations but also knowledge of a forward-looking nature, generated on the basis of disclosure of profound professional motivation. In this study, the methodology of “expert interviews” is applied, which belongs to the category of “B2B interviews”. The duration of the interview ranges from 30 min to 1.5 h (depending on the characteristics of the topic under study). The interviewer conducts the conversation according to a predetermined plan, and the wording or order of questions can vary depending on the answers of the respondent.

The fundamental difference between foresight is the formation of a special environment and the creation of a community aimed at obtaining a picture of the desired future; personal participation in its construction; interaction with stakeholders; constant clarification, and continuous improvement of the contours of the future. The set tasks were solved through the involvement of competent and interested participants—industry experts—in the co-design of the future. The primary stage of involvement was based on participation in an absentee expert survey, based on a questionnaire using a web resource.

A total of 211 experts participated in the questionnaire survey “Study of the image of the future of the oil and gas industry of the Republic of Kazakhstan and the target industry competencies”.

The industry foresight session of the oil and gas industry on the topic “Atlas of new professions and competencies of the oil and gas industry of the Republic of Kazakhstan” was held on 14–17 July 2020. A total of 75 industry experts took part in the foresight session [1]. As a result of the foresight session, the participants, together with a group of researchers, proposed a vision of trends.

3.3. Applying the MAYA Methodology

Kazakhstan’s national foresight methodology combines a system of methods of expert evaluation of strategic directions of socio-economic and innovative development with the construction of networks of like-minded people who share a common vision and participate in its practical implementation. Kazakhstan’s foresight methodology is based on a pragmatic approach in conducting sectoral technological foresight, aimed at identifying technological breakthroughs that can have an impact on the economy and society of the country in the medium term and move from catch-up to innovative development.

The authors believe that the viability of foresight projects can be increased if the MAYA methodology is applied at the stage of transition from the image of the ideal future to its realization. This approach was first formulated by Raymond Loewy (1893–1986), who designed innovative products according to the principle design for the future but balance it with the present of your users. The authors consider the methodological principles of choosing the “Most Acceptable, Yet Advanced” as a methodology for promoting innovation. The problem with promoting innovations is their dissimilarity, making them difficult to understand and causing rejection. An incomprehensible image in foresight can seem unattractive, alien, and even hostile, and therefore will not be understood or accepted.

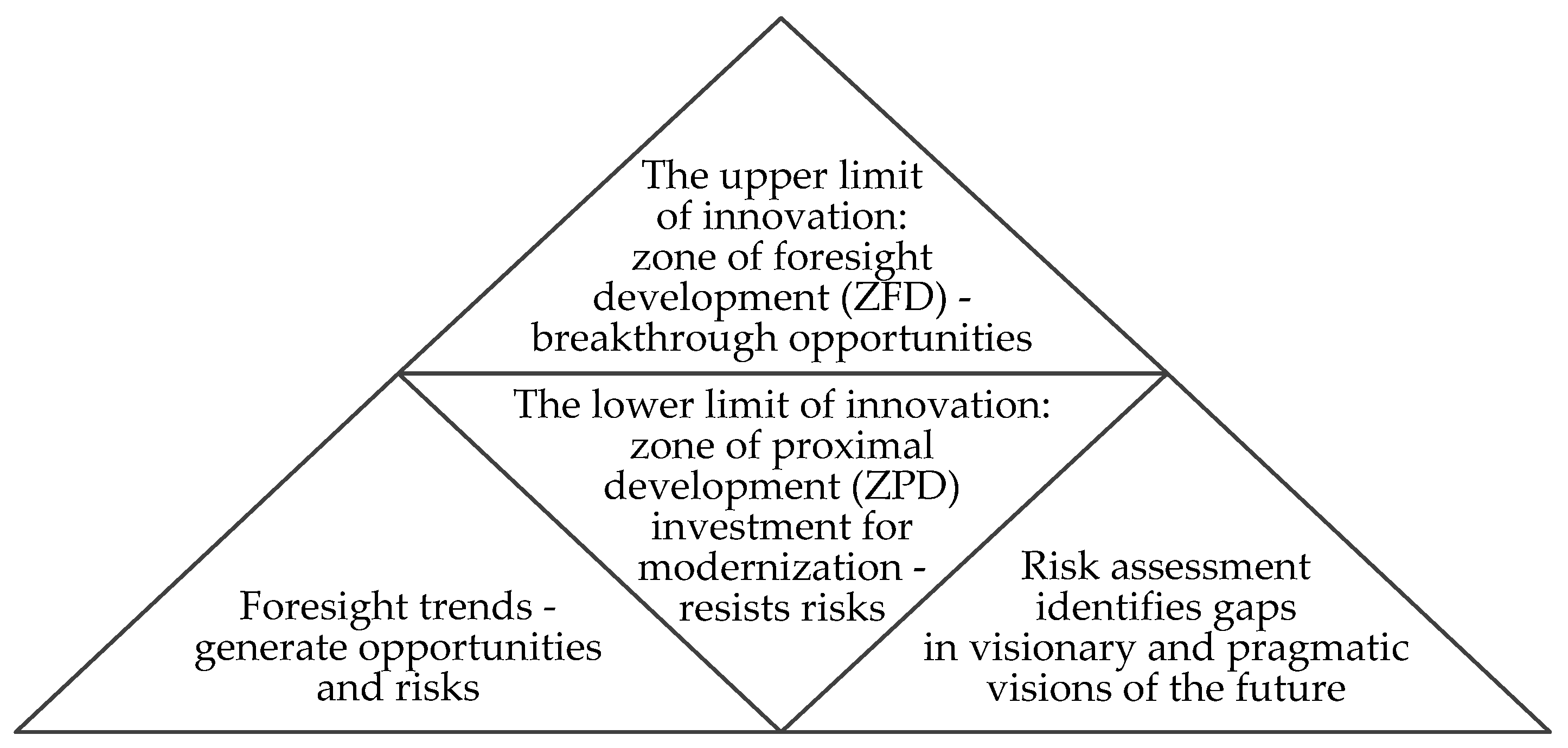

The MAYA principle involves a step-by-step transition in mastering the future. To promote the new, you have to make it somewhat similar to the old, partly recognizable, and therefore not intimidating. To change the old, you need to give it something new and inspiring. We need to create a foresight of the oil and gas industry based on new products and processes that already inspire, but do not yet cause rejection. The forecast of the oil and gas sector development should be understandable and perceived without difficulties at the expense of connection with something familiar and habitual. The authors expanded the MAYA method by applying an assessment of the industry’s problems from the standpoint of the “degree of crisis” and the development of problems into risks. Foresight trends shape opportunities for future development but can pose threats to the industry. The problematic trends identified by the experts were assessed according to the likelihood of their manifestation and the degree of adverse impact. Classification of problems by the degree of risk generation allows us to adjust the vision of the future development of the industry based on a pragmatic approach and to determine the boundaries of innovation (see Figure 4).

Figure 4.

The pyramid of boundaries of innovation in foresight in the MAYA methodology.

The pragmatic school of Kazakh foresight considers innovative development not as alternative thinking, but as a rethinking of the current framework of production and management processes. In the foresight of industry development, we gradually expand the innovative framework, highlighting the zones of near and far development.

4. Results and Comparision: What Awaits the Oil and Gas Industry in Kazakhstan?

4.1. Forecast of Changes in the Oil and Gas Industry

Experts assess the industry’s prospects pragmatically: they see opportunities for improvement (38.7%) and hope for a stable situation (29.3%). Kazakhstan is expected to increase oil production to 110–115 million tons by 2030 and keep it at this level until 2050.

In today’s oil and gas industry, there is a decrease in easily accessible oil reserves on land and shallow offshore shelf to a depth of 130 m. Reduction of easily accessible reserves requires an increase in oil recovery since the current efficiency is in the region of 30%. Oil reserves at great depth, in hard-to-recover formations, oil sands, and shales imply high costs.

It will no longer be possible to make a profit by increasing oil production. The peak of oil production will be passed in the next 5–7 years, after which a decline will begin, which will continue at least until 2050.

Kazakhstani oil companies are aware of the need to accelerate the use of innovation in production. The largest oil and gas companies declare their desire to become advanced innovative companies. Most experts (71.7%) believe that industrial enterprises are ready to support the implementation of innovations. The main breakthrough is expected in the sphere of monitoring and data processing.

It is especially important for the oil and gas industry to maintain a balance between economic development and social consequences. Increasing environmental requirements to reduce the load on the environment, increasing responsibility for the full development of territories, the need to reduce the gap in the income of personnel force the management of oil and gas companies to pursue a policy of balancing interests [37]. The relevance of this problem was noted by the experts in the first place.

Experts mark as the most dangerous and influential external events:

- the presence and strengthening of trade barriers between countries (76.2% of respondents);

- political instability in producing countries (76.8%);

- major environmental disasters in the oil industry (69.2%).

Even though improvements in technology and attention to environmental issues are changing the structure of demand for primary energy resources, oil, and gas, along with coal, will remain the main sources of energy in the period up to 2035 [38].

Experts link the future of the industry primarily with the introduction of new exploration and production technologies (90.4%), based on digitalization, and the collection and analysis of big data (87%).

The “smart” well operates independently in the mode set by the technological model of the surface infrastructure and can adjust to changing conditions on its own. A digital take of the well is created in the control center, which records the set parameters of the object (pressure, temperature, gassiness) and allows the operator to control the well from a distance. The number of well or pipeline parameters can be increased up to dozens and data collection frequency can be set on a second-by-second basis. By automating processes and controlling remote facilities, management personnel can see at any time what is happening at the facility, respond to abnormal situations, and predict how the results will change.

Experts believe that smart wells (20.1% of estimates), sensor devices/smart sensors (19.2%), and real-time eco-monitoring (12.5%) will be implemented in the extremely near future and will become the basis for unmanned operation technologies.

The introduction of digitalization will bring comprehensive benefits to the development of the oil and gas industry. There will be a “digital” field—a supercomputer constantly updated geological and hydrodynamic model of the field.

The key elements of the digital field are sensor devices, smart devices; drones for surveillance; an integrated operations control center; real-time oilfield services; 3D printing of spare parts, and waste management.

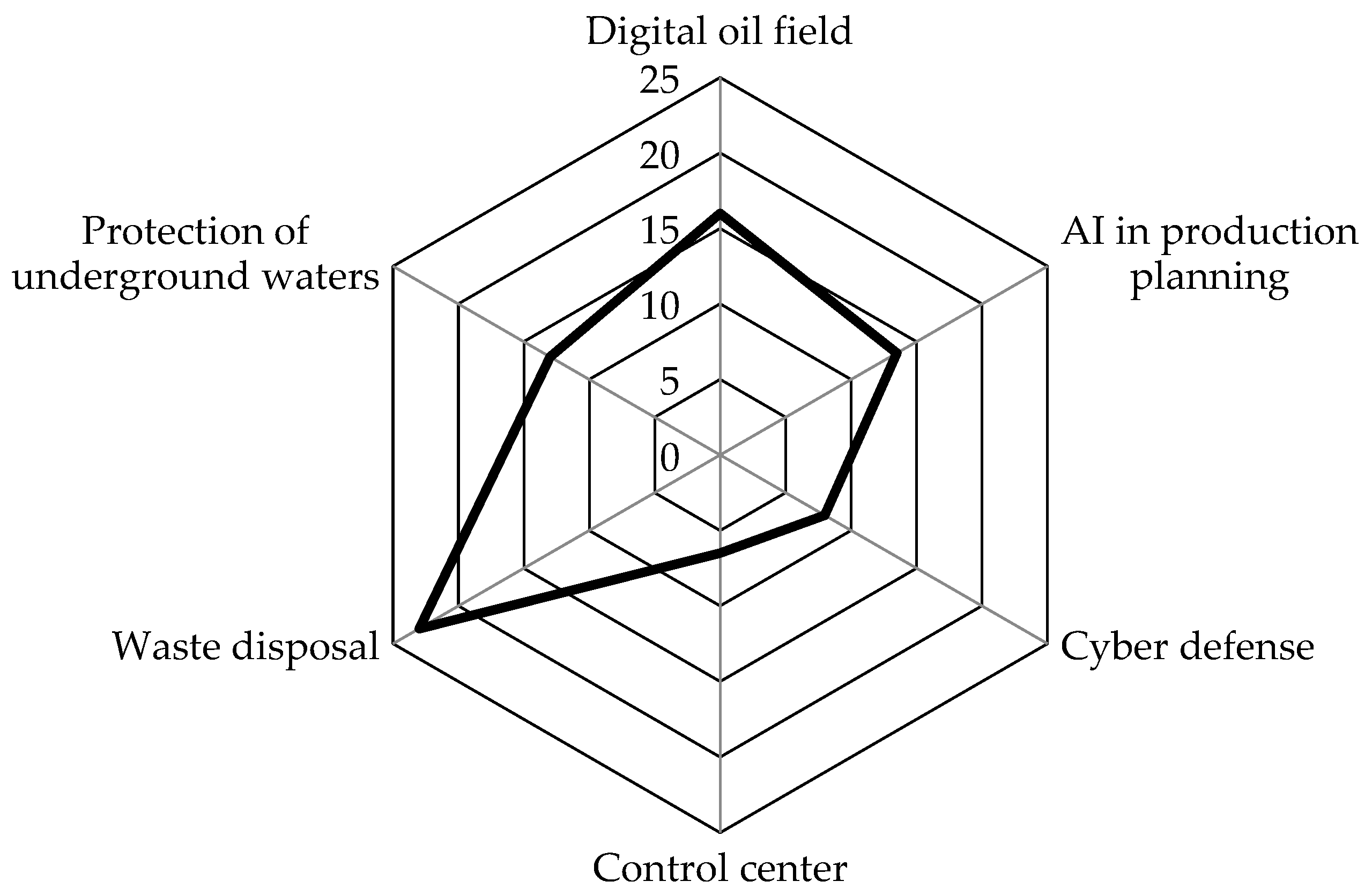

In the future, the oil and gas industry will become not only “smarter” but also “cleaner”. Artificial intelligence and digital technologies will be used to organize production in such a way that resources will be used more economically, waste will be better disposed of, and control over groundwater protection and protection of valuable data will be carried out in a continuous digital mode [39]. Experts’ opinions on the relevance of each area as a percentage of the entire expert panel (see Figure 5).

Figure 5.

Actual directions of future development of the oil and gas industry.

More than a third of professions in the oil and gas industry will be replaced by robotic or cyber–physical systems by 2025.

The labor market of the oil and gas industry is changing rapidly and dramatically. While the demand for some activities is dropping, technological advances are creating demand for others. The large-scale digitalization of the oilfield service industry has already created a shortage of personnel with oilfield service education and experience with digital systems.

4.2. Trends Shaping the Future of Kazakhstan′s Oil and Gas Industry

Experts have identified about two dozen trends affecting the development of the oil and gas industry. Below are the most significant ones, under the influence of which the future of the industry and, eventually, the economy of the whole country will be boosted.

Trend 1. Depletion of old fields, deterioration of the quality of hydrocarbons in them, a drop in profitability, a decrease in the city-forming potential of the industry. The years of big profits are being pumped up. The profitability of late fields is gradually falling. In late fields, oil quality decreases, which leads to increased corrosive wear of oil and gas equipment. The main way to increase profitability is to increase the oil recovery factor. Late third-generation oil recovery technologies, i.e., increase of oil recovery through pumping of technical gases and drilling fluids into the wells, are already being used in the world. In addition, optimization of mechanized production, selection, and adaptation of oil production technologies should be carried out. Since Soviet times, oil production has played a city-forming role. Soon it will be necessary to transform the economy of “oil” cities.

Trend 2. Reduction of explored oil reserves in Kazakhstan. There is practically no replenishment of reserves in Kazakhstan. At the same rate of production, the explored reserves will last approximately 30–35 years. The moratorium on exploration of new fields has been lifted, but this is not a one-time process; it requires a long time and large capital expenditures. It is practically impossible to discover new reserves in known areas using old technologies.

Trend 3. Growth of production of hydrocarbons from light oil fractions, in particular propane, for the synthesis of polymers. Kazakhstan’s oil and gas industry is diversifying. Instead of the production and export of crude oil, production of other petroleum products, including those from alternative sources, is increasing. The nomenclature of production of products from oil, in particular propane, polymers, etc., is increasing. The use of unconventional sources of hydrocarbon production and the expansion of the range of products produced from them requires a global logistic transformation of logistics routes.

Trend 4. Strengthening the integration of production process management. The number of decision-making points for field management is reduced and will be reduced to the Integrated Operations Control Center (IOCC), which will be like the control room at the airport, which controls the order of landing and takeoff of aircraft.

The concept of building a hierarchical management system for the oil and gas complex distinguishes four levels of management:

- instrumental level—application of fiber-optic sensors, sensors for continuous data collection of underground, underwater, and surface equipment operation, wells in the main technological processes;

- information level—the analysis of a large volume of geological and field information (Big Data);

- operational level—application of oil and gas production process control systems of SCADA type, MES type systems for smart energy systems, smart transportation systems, water management and management level—the use of integrated intelligent information systems such as ERP for operational and strategic management of the oil and gas industry as a whole.

Changes in the oil and gas industry are leading to the creation of real-time control centers for the exploration, drilling, development, operation, treatment, transportation, refining, and marketing of oil, gas, and petroleum products. At BP, for example, their number has reached 10 and they control up to 42% of all hydrocarbon production [40].

Trend 5. Expansion of computer modeling sphere, increase of autonomy of industrial equipment, level of drilling processes autonomy. By 2025–2035 the transition to fully automated and unmanned technologies at new offshore oil and gas fields is expected. Computer modeling of objects (reservoirs and other natural objects, industrial facilities, and equipment), business processes, well conditions, and production processes are being introduced in the oil and gas industry. This trend is embodied in the following solutions: giga-cell simulation: high-precision reservoir simulator; three-dimensional model of wells and fields, simulation of a reservoir near-wellbore zone, simulation of business processes in the fields, etc. The equipment has more and more variability in responding to different situations, learning to recognize different production situations, choosing the right algorithm of action, and even building these algorithms independently.

The industrial internet of things of the oil and gas industry is implemented in the following solutions:

- oil and gas platforms of industrial internet of things, equipped with sensors, actuators, sensors, information transmission channels;

- systems for intelligent monitoring of the object’s condition;

- tracking the health of machines and mechanisms;

- monitoring of hazardous areas and production results.

Trend 6. Expanding the scope of sensor devices and sensors, the use of drones. Devices help detect abnormal changes in temperature, pressure, etc., on drilling rigs, wells, etc. The first generation of smart wells contains about 100 downhole sensors and transmits about 106 megabytes of data per year.

The second generation of smart wells already contains more than 10,000 downhole sensors, which are spirally spaced 1 cm apart and record all pipe stresses, temperature, and pressure. The second-generation smart well will allow monitoring and controlling the production of reserves throughout the life cycle of an oil and gas field. Second-generation smart wells transmit about 109 gigabytes of data per year. Third-generation smart wells contain about 100,000 downhole sensors and transmit about 1012terabytes of data per year [41].

Drones monitor oil and gas production workflows: performing critical site inspections, geostationary and aerial mapping, safety and surveillance, and progress monitoring. Compared to traditional methods, drones can provide automation to speed up the data collection process with added speed and accuracy during routine risky industrial inspections. Drones can be equipped with multiple payloads and sensors, depending on mission requirements, or intended targets. Similarly, drones are used to deliver spare parts from depots directly to the fields.

Trend 7. Accelerating information flows and increasing their transparency. Data collection, analysis, and control commands are carried out in real time. For 2015 it is quarterly, for 2025—monthly, for 2035—weekly, for 2045—daily data latency [41]. The speed of data transmission is also increasing. For example, data rates for first-generation smart fields were typically 10 Gbps. Construction of bottom antenna complexes will require even higher data rates. Further growth is expected in the amount of data transmitted to extremely high volumes. This will require the use of higher data rate systems—40 and possibly 100 Gbps [40].

Nowadays, the consumer is actively involved in the process of creating a product, being its co-author, tester, and source of feedback. In this regard, transparency of information flows is increasingly in demand around the world.

Trend 8. Increasing demands on the quality of the workplace. The development of communications and digital technologies leads to the fact that the boundary between work and personal space is gradually erased. This is reflected in the demands of a new generation of employees. They stop perceiving work as a place where a person spends 8 h, then returns home and continues to live their private life there. For them, work is part of life. Consequently, they want to see elements of their everyday life at work.

The first is the desire to improve general working conditions. Progressive companies, especially those in the high-tech sector, are creating designer rooms for workers with reclining seats, relaxation rooms, etc. They are also starting to improve the work environment in industrial companies.

Another requirement of the new generation is involvement in the information environment. Life is gradually moving to the global information network [40]. Communication takes place in a social network, so the presence of a professional community with interesting content in the next 10–15 years will be an important factor in choosing this enterprise as a workplace.

The third factor for a comfortable work environment is flexible working hours. New citizens want to manage their own working time. For example, Dell plans to move 50% of its employees around the world to a flexible schedule by 2020. Intel, Volkswagen, and Apple offer their employees a variety of work schedules from which they can choose the most suitable: floating start and finish times, working from home, a “compressed work week” (4 days but 10 h each), and the ability to allocate a predetermined number of working hours at their own discretion. For Kazakhstan’s oil and gas industry, this trend will not be critical in the next 5–7 years, but every year it will become more and more relevant. The danger is increased social tension in several oil-bearing regions of Kazakhstan, which may develop into demands not only to give people jobs and provide a certain level of wages but also to provide at enterprises clubs on interests, organized leisure time, and comfortable conditions in living quarters and shift camps.

Trend 9. Growing demand for intensive retraining in the oil and gas industry of Kazakhstan (new skills for current equipment). Technological and social changes in the country have formed requirements to the qualification profile of the oil and gas industry worker. There is a growing need for retraining in the gas industry of Kazakhstan (equipment repair and maintenance, remote control and maintenance, IT skills, data analysis and processing, technology of polypropylene production). The oil and gas industry in Kazakhstan is increasing the depth of oil refining and, accordingly, the requirements for knowledge of the technology of production of products from oil are increasing. Global automation of the economy leads to the production of equipment controlled remotely without human involvement. Digitalization allows using unprecedented amounts of data for organization and production. For oil and gas workers, there are new tasks that have not been solved before, which require new skills and competencies. The increasing share of software-controlled equipment requires operators to know the basics of programming and other IT skills to set up and operate the equipment. The oil and gas industry in Kazakhstan has a growing demand for workers who speak Russian and English. Equipment purchased by companies in most cases has instruction manuals written in English and Russian. Young workers replacing the older generation do not speak these languages sufficiently and are not always able to read and understand the instructions.

4.3. MAYA: Analysis and Evaluation of Industry Experts’ Opinions

The authors of this article were part of the team that developed the industry foresight methodology and were directly involved in conducting foresight sessions and interviewing experts. Over the course of a year, the image of the future of the industry was discussed and agreed upon. During the research, we managed to collect the material necessary for the further development of the methodology.

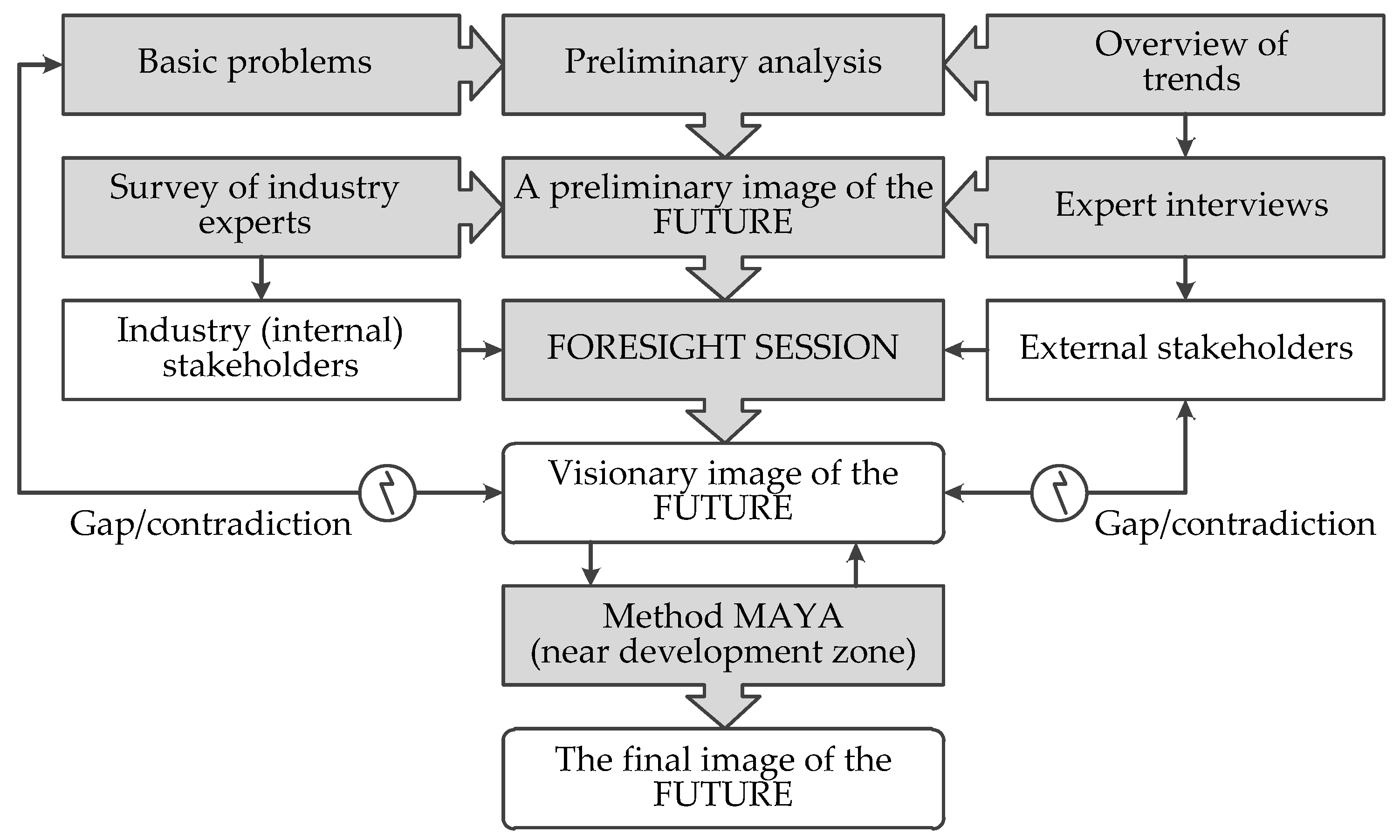

At the initial stage of the pre-analysis, the established global trends of the oil and gas sector development on a global scale were investigated and the problem areas of the Kazakhstani industry were identified. To form a preliminary image, the results of a mass anonymous survey of industry experts were used. The survey was based on the Delphi methodology. The method consists in structuring the process of group communication, aimed at creating the conditions for the team to work effectively on a complex problem (see Figure 6).

Figure 6.

Algorithm of oil and gas industry foresight in Kazakhstan.

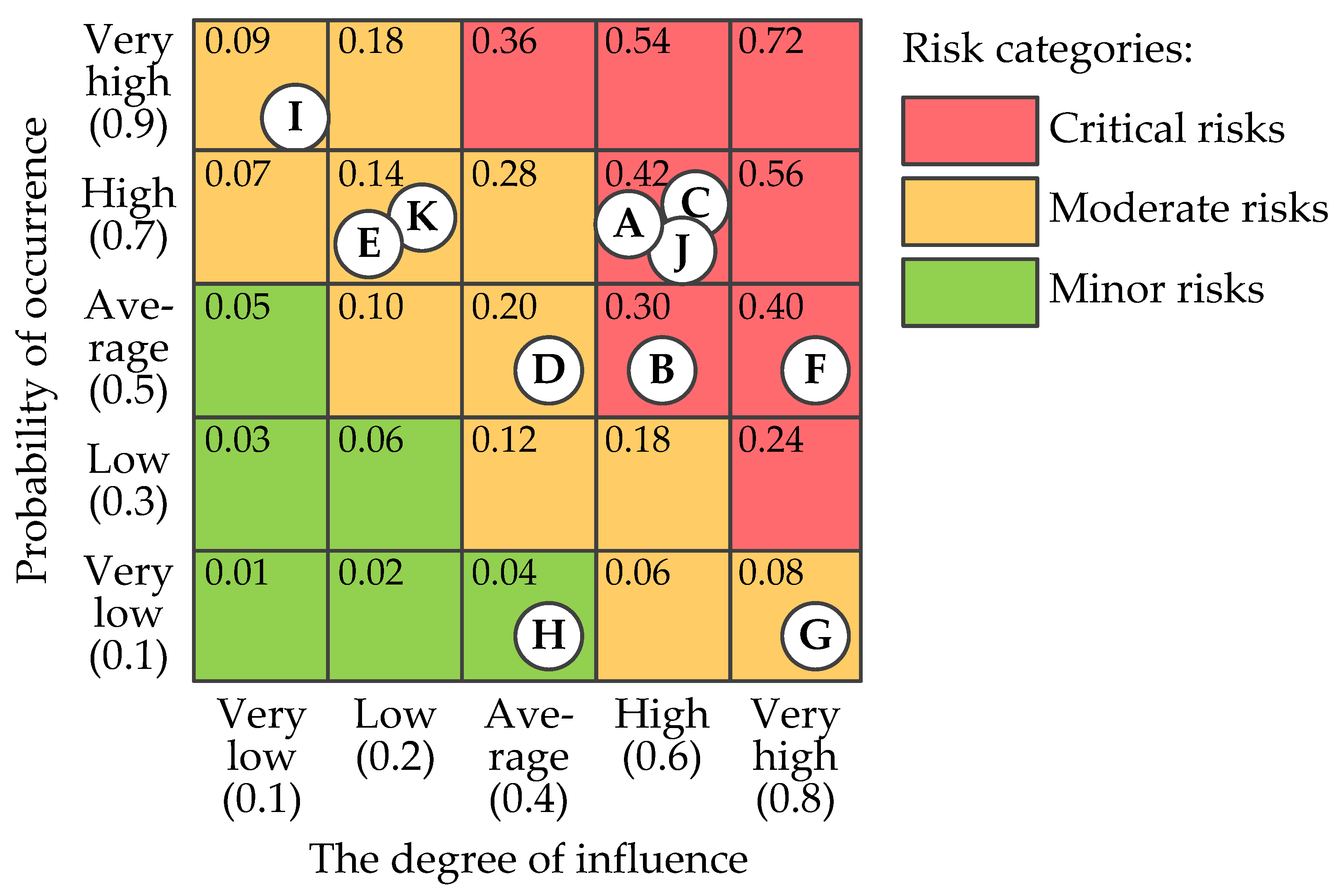

The experts involved in the survey about the prospects of the oil and gas industry gave an assessment of the future, according to a number of indicators. Problems were identified, the development of which can lead to risks of varying degrees of criticality. The authors quantified and introduced a risk severity scale (Table 1).

Table 1.

Assessment of the problems of the oil and gas industry of Kazakhstan.

Each expert noted the likelihood of the risk and the strength of its impact. The table shows the weighted average estimates of all responses for each risk group.

The problem was assessed using the formula:

Ap = Po × Wi.

The product of numbers of the probability of manifestations and the degree of impact of the problem form its aggregate value, which can reflect different degrees of crisis. Figure 7 shows a matrix for classifying problems according to the severity of risks in the future. About half of the problems noted by experts may in the future give rise to serious risks for the development of the industry.

Figure 7.

Matrix the transition of problems into risks of the oil and gas industry in Kazakhstan.

The greatest risks arise due to insufficient active development of new technologies (A), contradictions between the interests of national companies and the local community (B, C, J), and increased environmental requirements (F). The results of the assessment of the occurrence of risks are used to agree on the vision of the future of the industry, which was put forward by various experts.

In particular, there were answers to the questions:

- Specify in what areas should be directed the main investments for the modernization and renewal of technology?

- Can you predict in which area a qualitative technological breakthrough is expected?

The era of cheap oil is coming to an end and the net profit of oil companies is inevitably decreasing. Companies will need to introduce new technologies that reduce costs as much as possible. It will no longer be possible to make a profit by increasing oil production. The peak of oil production will be passed in the next 5–7 years, after which a decline will begin, which will continue at least until 2050.

Experts assess the prospects of the industry pragmatically: they see opportunities for improvement (38.7%) and hope for a stable situation (29.3%). Every third expert notes a high level of uncertainty in the market and the possibility of deterioration of the situation. According to the opinion of experts, the following risks are most probable in the future: instability of prices (63%), technological backwardness (55.2%), irreplaceable loss of stocks (54.1%), and growth of expenses (51.9%). The pragmatic view of Kazakhstani experts means the search for new ways of development while continuously improving existing processes.

The expert Delphi survey was supplemented by an in-depth interview with the Vice Minister of Energy of the Republic of Kazakhstan, Director of the Oil and Gas Production Department of JSC NC KazMunayGas, General Director of KAZENERGY Association, CEO of JSC Kaztransgaz, KMG International, Petroleum Engineering Manager, experts of NGO “Veterans of the Oil and Gas Complex of the RK”, and other stakeholders [1].

Based on the expert discussion, a visionary image of the future development of the oil and gas industry of Kazakhstan was formed. The future of the oil and gas industry of Kazakhstan will be built around solving the problems of the natural reduction of economic efficiency of fields and wells. Much attention is paid to methods of improving oil recovery using methods such as gas reinjection, steam injection, iREX microbiological technology, etc.

Population growth and increasing demands for environmental friendliness in cities will lead to the active use of gas as a fuel. HBO vehicles and electric cars will change the transport picture Kazakhstan’s cities will become environmentally friendly, and oil refineries in Pavlodar, Atyrau, Taraz, and Shymkent will be reoriented to produce new petrochemical products of complete processing. In the “smart” unmanned production, the entire process from pumping and storage of oil and gas to the production of new materials based on petrochemicals is fully automated and robotic.

Oil production is carried out at digital wells, which are serviced by a single service cluster [42]. National research centers of open innovations—R&D centers—adapt the best innovative developments for the conditions of local production. Based on digital platforms, universities and R&D centers are integrated into unified scientific and educational complexes of continuous training of oil and gas industry personnel. Kazakhstan’s oil and gas industry is becoming a center of innovation development and production of materials and products with new, unique properties, competitive in the world market. The industry is developing in accordance with the goals of sustainable development and supports an authentic ecosystem.

The image formed has a visionary character, defining common goals and inspiring participants to achieve the desired future. However, the visionary image needs the recognition and perception of interested participants and in the implementation, there are gaps in the content and emotional presentation of the image and the real problems that industry employees solve every day. The gap is observed both at the expense of a significant difference between the current state and the desired state, and at the expense of the difference between the perceptions of the collective image and the individual evaluation of the stakeholders.

The presence of such gaps is a common methodological problem in the management of Kazakhstan. The country has adopted many innovative programs representing the country’s entry into the ranks of the most developed countries, the transition to a digital economy, and the industrialization of a new technological level. However, the weakness of these programs is their full implementation and achievement of planned performance indicators, which is largely due to the lack of understanding of the sequence of transition from the current problem state to the ideal future.

The lower limit of the perception of innovation is the ZPD—zone of the nearest development (Table 2). This zone reflects the identified problems with perceived directions for solutions. The upper limit is the zone of ZFD foresight development when through the gradual expansion of the framework of innovative thinking, it is ensured that the collective thinking approaches the visionary image of the future.

Table 2.

Zones of perception of innovations in the formation of the foresight of the oil and gas industry of Kazakhstan.

Breakthrough opportunities for technology development are the broadest frame of perception of innovations—the “Most Advanced, Yet Acceptable” methodology [43]. The ranks for development areas indicate recognition of the priority of this area in terms of the strength of influence on the future of the industry, while the percentages indicate the proportion of experts who have prioritized this area. In the ZFD area, the greatest impact is the ability to digitally monitor and analyze a large flow of data in real time to get big results in all parts of the process chain. Because of digital management, the management system (rank 2) will be completely rebuilt in the future and the technological process will be changed. Health and safety will also be ensured by removing personnel from hazardous production areas and switching to a digital safety system.

However, when determining the direction of near-term innovations, there is a gap between the potential of the future and the perception of current problems. Investments in basic production come first, with a higher number of expert responses. Modernization of management systems comes down to rank #4. We consider this assessment to be a zone of proximal development (ZPD).

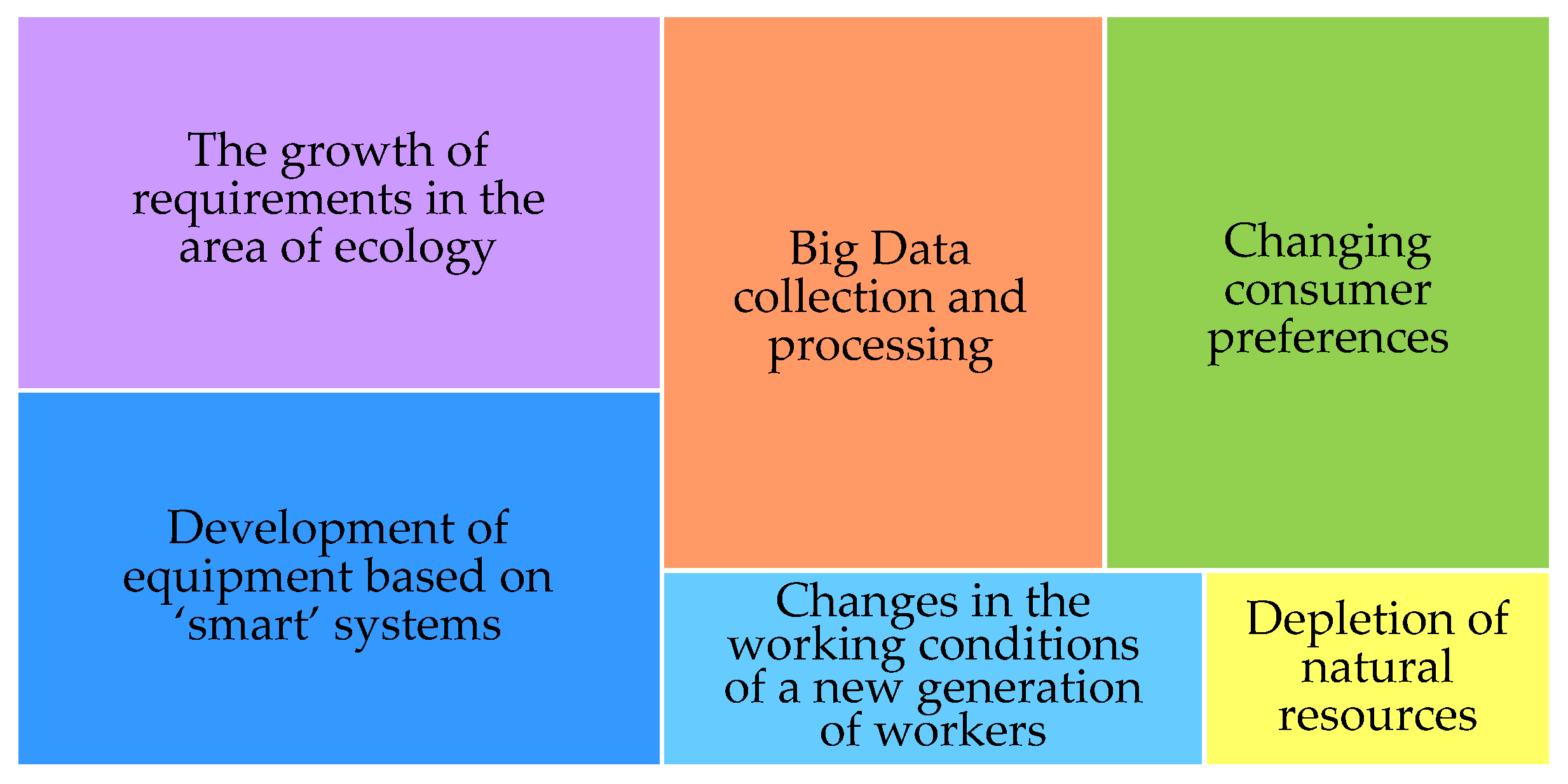

Visionary image of the oil and gas industry development was based on the possibilities of technological breakthroughs. The refined foresight was formed as a response to the challenges of the external environment under the influence of global and national trends (Figure 8).

Figure 8.

A refined image of the future of Kazakhstan’s oil and gas industry.

Experts see new opportunities in the industry in the sphere of company consolidation, optimization of processes and costs (35.7%), and discovery of new fields (28.6%). The influence of the trends has been clarified:

- 85% of experts consider the growth of environmental requirements to be important;

- development of basic technological equipment based on ‘smart systems’—84% of experts;

- influence of digitalization, big data collection, and analytics—82%;

- changing consumption patterns of oil and gas products—81%;

- complicating the demands of a new generation of employees—36%;

- depletion of raw material reserves—23%.

It should be noted that at the time of the foresight forecast, experts did not consider the abandonment of internal combustion engines in the production of car bombs to be a sufficient threat. Such a position poses a threat to the country, as more and more states declare such a refusal by 2035–2040.

4.4. Comparision the Results of the Analyzes with Similar Results

The results of the presented forecast correlate with the estimates obtained in other studies. So, for the oil and gas sector, there is an increase in the share of hard-to-recover natural resources, in Russia, 75% of oil reserves are in this category [44].

Forecasting the development of the oil and gas sector in most researchers is based on the recognition of the crucial role of technological innovation. Karasev et al.: “The key role in the development of the industry plays a technological component” [45]. However, scientists specializing in sectoral problems of foresight argue for the limited impact of technological innovation “among companies of the oil and gas sector the most workable model will be exactly–innovative development through continuous innovative changes that meets the requirements of stakeholders in terms of dividend income, return on investment, as well as the unacceptability of misuse of funds by supervisory and regulatory authorities” [46]. This position is closest to the Kazakhstan foresight methodology, based on a pragmatic approach to the choice of innovations to be introduced, which is reflected in the presented material by applying the principle “Most Advanced, Yet Acceptable”.

The first in Russia foresight forum “Neftegaz-2020. Innovations. Ecology. Climate” was held in March 2020 at the center of Russian oil production—in Nizhnevartovsk. The event was held in the format of public discussions. Previously, Russian scientists conducted separate studies based on assessing the opinions of stakeholders in the oil and gas industry using the trend-based foresight method, which involves the synthesis of knowledge about current, emerging, and future development trends based on different sources of information and identified general trends similar to those noted in the world and in Kazakhstan [45].

In the near future, the energy industry will be managed by artificial intelligence, planning production. The forecast of Kazakh experts considers the main directions of its use to be the organization of unmanned and safe production, personnel training, as well as accounting on the principles of blockchain. However, experts focus on the transfer of global technology, and it is necessary to consider the risks of adapting foreign solutions to the national language and institutional environment. The problems of using artificial intelligence in the oil and gas industry should be discussed in the broader context of state innovation policy. Risks of oil and gas industry development are critical for the entire economy of Kazakhstan, so plans to prevent them are a national priority, based on industry foresight projections.

5. Conclusions

The study used the foresight method, which improves decision-making and creates alternative directions for future development. Conducting foresight increases preparedness for unforeseen circumstances and motivates participants to make and implement decisions to achieve the desired future. Foresight is a system of methods of expert evaluation of strategic directions of socio-economic and innovative development, identification of technological breakthroughs that can have an impact on the economy and society in the medium and long term.

Foresight refers to foresight processes that identify opportunities and threats arising in the medium- and long-term versions of the future. As a way of thinking, foresight develops innovation, strategic assessment, and proactive shaping of the future. While traditional planning focuses on risk prevention, foresight prioritizes resilience. Foresight studies are a development of strategic planning that considers different alternatives to the future. In this regard, foresight and futures analysis are long-term planning methods for anticipating and preparing for a possible, likely, and desirable future.

There is a fundamental difference between “forecasting the future” and “foresight”. Foresight is based on modeling and evaluating possible, probable, and preferable variants of the future. Foresight consists of developing a strategy of action in the future in the face of uncertainty. Both approaches include a set of methods that consider the future as the object and purpose of strategic planning.

The main characteristic of the future of Kazakhstan’s oil and gas industry is manless production, where the process of pumping and storing oil and gas is fully automated and robotic. There are no fitters, linemen, shift supervisors, or other grassroots personnel. A versatile pipeline section manager, who has the competencies of a software engineer, a big-data analyst, a petrochemistry, monitors the operation of instruments. His main task is to monitor and evaluate instrument readings and timely update the software, ensure compliance with the pumping process with the planned one and, if necessary, correct the programs laid down.

The work of oil fields and refineries is the unified work of tens of thousands of workers and engineers who debug and operate a large amount of complex and ‘smart’ equipment. Oil production centers will become a catalyst for the development of service and repair enterprises and enterprises outsourcing narrow types of work. They will be the basis for the creation of a new generation of service enterprises integrated with oil-producing companies based on digital platforms. Service enterprises will implement 4PL concepts for logistics and supply of inventories, as well as use digital twins for equipment diagnostics and repair.

The authors have already addressed the problems of energy in Kazakhstan in their research [47,48], but the topic turned out to be so large-scale that apparently there are still several articles to be written. Some of the possible research concerns the study of risks in the oil and gas industry. It may also be worth identifying short- and medium-term foresight and forecasts. Additionally, the study of AI capabilities is an area of separate research. Alternative energy was underestimated by experts in the foresight conducted. Preparations for the next foresight are underway and the impact of alternative energy is taken into account as significant.

Author Contributions

Conceptualization, I.D. and Y.P.; methodology, I.D. and Y.P.; software, I.D.; validation, Y.P.; formal analysis, Y.P.; investigation, Y.P.; resources, I.D.; data curation, I.D. and Y.P., and O.M.; writing, I.D.; visualization, O.M.; supervision, Y.P.; project administration, O.M.; funding acquisition, Y.P. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed by a grant from the Plekhanov Russian University of Economics.

Institutional Review Board Statement

The study was conducted according to the guidelines of the Declaration of Helsinki.

Data Availability Statement

Informed consent was obtained from all subjects involved in the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Atlas of New Professions and Competencies in the Republic of Kazakhstan. Available online: https://www.enbek.kz/atlas/en (accessed on 9 December 2021).

- Tikhanychev, O. Forecasting in dynamic system control. Softw. Syst. 2017, 30, 40–44. [Google Scholar] [CrossRef]

- Berger, G. Phénoménologie du Temps et Prospective; Presses Universitaires de France: Paris, France, 1964. [Google Scholar]

- Coates, J.; Durance, P.; Godet, M. Strategic Foresight Issue: Introduction. Technol. Forecast. Soc. Change 2010, 77, 1423–1425. [Google Scholar] [CrossRef]

- Rohrbeck, R.; Battistella, C.; Huizingh, E. Corporate Foresight: An Emerging Field with a Rich Tradition. Technol. Forecast. Soc. Change 2015, 101, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Prahalad, C.K.; Hamel, G.P.; Mehrotra, L.C. Competing for the future. Int. J. Res. Found. Hosp. Healthc. Adm. 2014, 2, 133–135. [Google Scholar] [CrossRef]

- Slaughter, R.A. A Foresight Strategy for Future Generations. Futures 1997, 29, 723–730. [Google Scholar] [CrossRef]

- Ahuja, G.; Coff, R.W.; Lee, P.M. Managerial Foresight and Attempted Rent Appropriation: Insider Trading on Knowledge of Imminent Breakthroughs. Strateg. Manag. J. 2005, 26, 791–808. [Google Scholar] [CrossRef] [Green Version]

- Day, G.S.; Schoemaker, P.J. Scanning the periphery. Harv. Bus. Rev. 2005, 83, 135. [Google Scholar] [PubMed]

- Mackay, D.; Burt, G. Strategic Learning, Foresight and Hyperopia. Manag. Learn. 2014, 46, 546–564. [Google Scholar] [CrossRef]

- Vecchiato, R. Strategic Foresight: Matching Environmental Uncertainty. Technol. Anal. Strateg. Manag. 2012, 24, 783–796. [Google Scholar] [CrossRef]

- Martin, B.R. Foresight in Science and Technology. Technol. Anal. Strateg. Manag. 1995, 7, 139–168. [Google Scholar] [CrossRef]

- Forge, S. The Handbook of Technology Foresight: Concepts and practice 2008. Edited by Luke Georghiou, Jennfer Cassingena Harper, Michael Keenan, Ian Miles, and Rafael Popper. The Handbook of Technology Foresight: Concepts and Practice. Cheltenham, UK: Edward Elgar 2008. Foresight 2008, 10, 65–66. [Google Scholar]

- Lundvall, B.; Johnson, B. The Learning Economy. J. Ind. Stud. 1994, 1, 23–42. [Google Scholar] [CrossRef]

- Gokhberg, L.; Sokolov, A. Summary—Targeting STI Policy Interventions—Future Challenges for Foresight. Sci. Technol. Innov. Policy Future 2013, 289–292. [Google Scholar] [CrossRef]

- Linstone, H.A. Three Eras of Technology Foresight. Technovation 2011, 31, 69–76. [Google Scholar] [CrossRef]

- Costanzo, L.A. Strategic Foresight in a High-Speed Environment. Futures 2004, 36, 219–235. [Google Scholar] [CrossRef]

- Cuhls, K. From Forecasting to Foresight Processes?New Participative Foresight Activities in Germany. J. Forecast. 2003, 22, 93–111. [Google Scholar] [CrossRef]

- Hond, F.D.; Groenewegen, P. Environmental Technology Foresight: New Horizons for Technology Management. Technol. Anal. Strateg. Manag. 1996, 8, 33–46. [Google Scholar] [CrossRef]

- Rohrbeck, R.; Gemünden, H.G. Corporate Foresight: Its Three Roles in Enhancing the Innovation Capacity of a Firm. Technol. Forecast. Soc. Change 2011, 78, 231–243. [Google Scholar] [CrossRef]

- Salo, A.; Cuhls, K. Technology Foresight? Past and Future. J. Forecast. 2003, 22, 79–82. [Google Scholar] [CrossRef]

- Magruk, A. Innovative Classification of Technology Foresight Methods. Technol. Econ. Dev. Econ. 2012, 17, 700–715. [Google Scholar] [CrossRef]

- Porter, A.L.; Ashton, W.B.; Clar, G.; Coates, J.F.; Cuhls, K.; Cunningham, S.W.; Ducatel, K.; van der Duin, P.; Georghiou, L.; Gordon, T.; et al. Technology Futures Analysis: Toward Integration of the Field and New Methods. Technol. Forecast. Soc. Change 2004, 71, 287–303. [Google Scholar]

- Saritas, O.; Aylen, J. Using Scenarios for Roadmapping: The Case of Clean Production. Technol. Forecast. Soc. Change 2010, 77, 1061–1075. [Google Scholar] [CrossRef]

- Martin, B.R. The Origins of the Concept of ‘Foresight’ in Science and Technology: An Insider’s Perspective. Technol. Forecast. Soc. Change 2010, 77, 1438–1447. [Google Scholar] [CrossRef]

- Miles, I. The Development of Technology Foresight: A Review. Technol. Forecast. Soc. Change 2010, 77, 1448–1456. [Google Scholar] [CrossRef]

- Cariola, M.; Rolfo, S. Evolution in the Rationales of Foresight in Europe. Futures 2004, 36, 1063–1075. [Google Scholar] [CrossRef]

- National Systems of Innovation. Towards a Theory of Innovation and Interactive Learning; Lundvall, B.A. (Ed.) Pinter Publishers: London, UK, 1992; p. 317. ISBN 1-85567-063-1. [Google Scholar]

- Edquist, C. Systems of Innovation: Perspectives and Challenges. Oxf. Handb. Online 2006, 2, 14–45. [Google Scholar]

- Lundvall, B.Å. National Innovation Systems—Analytical Concept and Development Tool. Ind. Innov. 2007, 14, 95–119. [Google Scholar] [CrossRef]

- Dufva, M.; Könnölä, T.; Koivisto, R. Multi-Layered Foresight: Lessons from Regional Foresight in Chile. Futures 2015, 73, 100–111. [Google Scholar] [CrossRef]

- Alkemade, F.; Kleinschmidt, C.; Hekkert, M. Analysing Emerging Innovation Systems: A Functions Approach to Foresight. Int. J. Foresight Innov. Policy 2007, 3, 139. [Google Scholar] [CrossRef]

- Andersen, A.D.; Andersen, P.D. Innovation System Foresight. Technol. Forecast. Soc. Change 2014, 88, 276–286. [Google Scholar] [CrossRef]

- Breukers, S.; Hisschemöller, M.; Cuppen, E.; Suurs, R. Analysing the Past and Exploring the Future of Sustainable Biomass. Participatory Stakeholder Dialogue and Technological Innovation Systems Research. Technol. Forecast. Soc. Change 2014, 81, 227–235. [Google Scholar] [CrossRef]

- Keller, J.; Markmann, C.; von der Gracht, H.A. Foresight Support Systems to Facilitate Regional Innovations: A Conceptualization Case for a German Logistics Cluster. Technol. Forecast. Soc. Change 2015, 97, 15–28. [Google Scholar] [CrossRef]

- Popper, R. How Are Foresight Methods Selected? Foresight 2008, 10, 62–89. [Google Scholar] [CrossRef]

- Sansyzbayev, A. Influence of Social Partnership to the Development of Enterprise: On the Example of Oil Industry. Entrep. Sustain. Issues 2019, 7, 1613–1627. [Google Scholar] [CrossRef]

- Karaev, A.K.; Ponkratov, V.V.; Masterov, A.I.; Pozdnyaev, A.S.; Kuznetsov, N.V. The Analysis of the Comparative Efficiency of State Support for Natural Gas Production: The Case of Some OECD and BRICS Countries. Entrep. Sustain. Issues 2020, 7, 1778–1789. [Google Scholar] [CrossRef] [Green Version]

- Plenkina, V.; Andronova, I.; Deberdieva, E.; Lenkova, O.; Osinovskaya, I. Specifics of Strategic Managerial Decisions-Making in Russian Oil Companies. Entrep. Sustain. Issues 2018, 5, 858–874. [Google Scholar] [CrossRef] [Green Version]

- Dmitrievsky, A.N.; Eremin, N.A.; Shabalin, N.A. Innovative Approaches to Development of The Middle Kuril Offshore Oil and Gas Bearing Region. Actual Probl. Oil Gas 2018, 21. [Google Scholar] [CrossRef] [Green Version]

- Dmitrievsky, A.N.; Kamaeva, S.S.; Chernikov, A.D.; Eremin, N.A. Contactless Diagnostics of Oil and Gas Pipelines: Status and Prospects of Development. Actual Probl. Oil Gas 2018, 20. [Google Scholar] [CrossRef] [Green Version]

- Ivanová, E.; Žárská, V.; Masárová, J. Digitalization and human capital development. Entrepreneur. Sustain. Issues 2021, 9, 402–415. [Google Scholar] [CrossRef]

- Nasr, A.K.; Kashan, M.K.; Maleki, A.; Jafari, N.; Hashemi, H. Assessment of Barriers to Renewable Energy Development Using Stakeholders Approach. Entrepreneur. Sustain. Issues 2020, 7, 2526–2541. [Google Scholar] [CrossRef] [Green Version]

- Iskrickaya, N.I.; Makarevich, V.N.; Schepochkina, A.A. Izmenenie struktury trudnoizvlekaemyh zapasov nefti v svyazi s perekhodom na novuyu klassifikaciyu. Neftegazov. Geol. 2016, 11, 8. [Google Scholar]

- Karasev, O.I.; Mukanina, E.I.; Trostyanskij, S.S.; Beloshickij, A.V. Forsajt kak instrument opredeleniya strategicheskih prioritetov razvitiya neftegazovoj otrasli v Rossii. Vestnik Voronezhskogo gosudarstvennogo universiteta. Ekon. Upr. 2019, 4, 44–49. [Google Scholar]

- Martynov, V.G.; Golunov, N.N.; Makarova, E.D. Forsajt innovacij. Izmeneniya tekhnologij i instrumentov upravleniya innovaciyami v neftegazovom komplekse. Delovoj Zhurnal Neftegaz RU 2020, 6, 16–26. [Google Scholar]

- Vechkinzova, E.; Denisov, I.; Ochoa Siguencia, L.; Gródek-Szostak, Z. “Leaky Bucket” of Kazakhstan’s Power Grid: Losses and Inefficient Distribution of Electric Power. Energies 2020, 13, 2947. [Google Scholar]

- Petrenko, Y.; Denisov, I.; Koshebayeva, G.; Biryukov, V. Energy Efficiency of Kazakhstan Enterprises: Unexpected Findings. Energies 2020, 13, 1055. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).