A Study of Control Methodologies for the Trade-Off between Battery Aging and Energy Consumption on Electric Vehicles with Hybrid Energy Storage Systems

Abstract

:1. Introduction

2. Modeling

2.1. Vehicle Modeling

2.1.1. Vehicle Dynamics

2.1.2. Transmission

2.1.3. Motor and Power Electronics

2.1.4. Battery

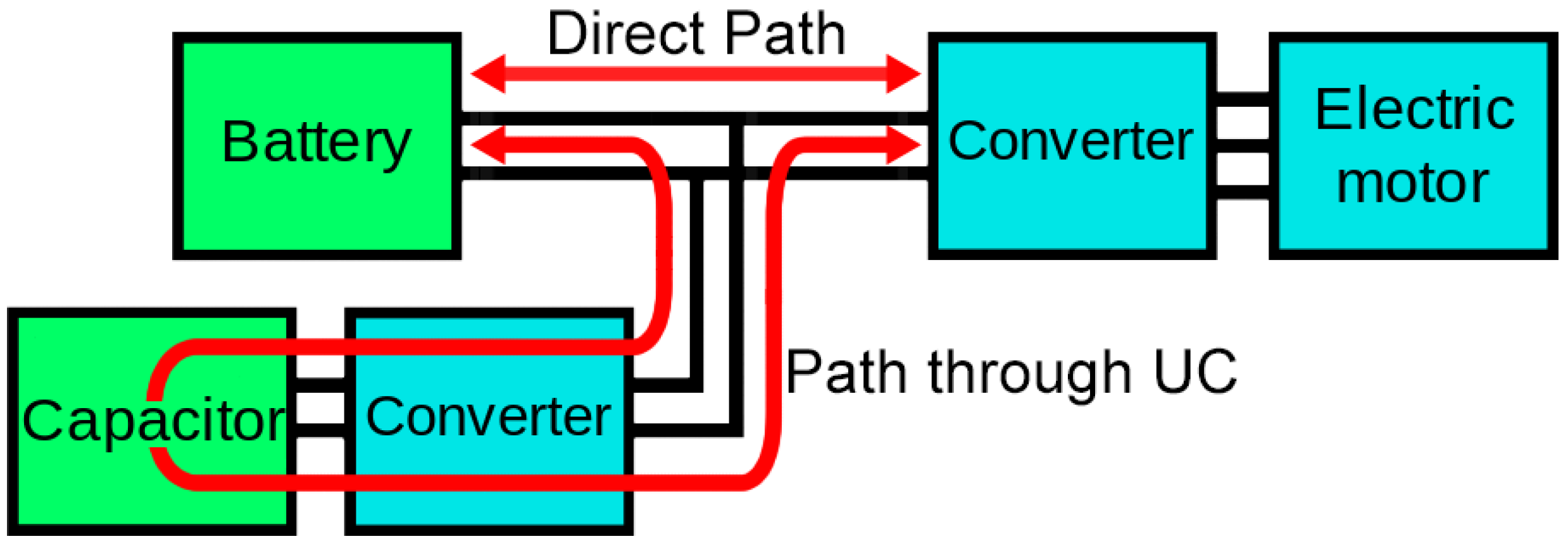

2.1.5. Ultracapacitor

2.2. Battery Aging Model

2.3. Ultracapacitor Aging

2.4. Aging and Fuel Economy Trade-Off

3. Control

- DDP with Battery Aging Penalty, denoted DDP-B;

- DDP with Energy Loss Penalty and Battery and Capacitor Aging Penalties, denoted DDP-EC;

- DDP with Battery Power Penalty, denoted DDP-P;

- SDP with Battery Aging Penalty, denoted SDP-B;

- SDP with Energy Loss Penalty and Battery and Capacitor Aging Penalties, denoted SDP-EC;

- SDP with Battery Power Penalty, denoted SDP-P;

- Load Leveling, denoted LL.

3.1. Dynamic Programming

3.2. Load-Leveling

4. Case Study

- DDP-B and SDP-B had the parameter varied from to ;

- DDP-EC and SDP-EC had the parameter varied from to ;

- DDP-P and SDP-P had the parameter varied from to ;

- LL has the parameter varied from 2 C to 0.8 C.

5. Results

5.1. Verification of DP Controllers

5.2. Effect of Aging-Aware Control

5.3. Ultracapacitor Overuse

5.4. Cost-Benefit Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| APV | Alternative Powertrain Vehicle |

| EV | Electric Vehicle |

| HEV | Hybrid Electric Vehicle |

| UC | Ultracapacitor |

| HESS | Hybrid Energy Storage System |

| EMS | Energy Management Strategy |

| DP | Dynamic Programming |

| DDP | Deterministic Dynamic Programming |

| SDP | Stochastic Dynamic Programming |

| SOC | State of Charge |

| DOD | Depth of Discharge |

| SOA | State of Aging |

| PM | Palmgren-Miner |

| MPGe | Miles per Gallon Equivalent |

| BCPM | Battery Cost per Mile |

| UCCPM | Ultracapacitor Cost per Mile |

| ECPM | Energy Cost per Mile |

| GGE | Gasoline Gallon Equivalent |

| BPM | Benefit per Mile |

References

- Lee, T.K.; Filipi, Z. Impact of Model-Based Lithium-Ion Battery Control Strategy on Battery Sizing and Fuel Economy in Heavy-Duty HEVs. SAE Int. J. Commer. Veh. 2011, 4, 198–209. [Google Scholar] [CrossRef]

- Moura, S.J.; Stein, J.L.; Fathy, H.K. Battery-Health Conscious Power Management in Plug-In Hybrid Electric Vehicles via Electrochemical Modeling and Stochastic Control. IEEE Trans. Control Syst. Technol. 2013, 21, 679–694. [Google Scholar] [CrossRef]

- Suri, G.; Onori, S. A control-oriented cycle-life model for hybrid electric vehicle lithium-ion batteries. Energy 2016, 96, 644–653. [Google Scholar] [CrossRef]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Williamson, S.S. Energy Management Strategies for Electric and Plug-in Hybrid Electric Vehicles; Springer: New York, NY, USA, 2013. [Google Scholar]

- Kovaltchouk, T.; Multon, B.; Ahmed, H.B.; Aubry, J.; Venet, P. Enhanced Aging Model for Supercapacitors Taking Into Account Power Cycling: Application to the Sizing of an Energy Storage System in a Direct Wave Energy Converter. IEEE Trans. Ind. Appl. 2015, 51, 2405–2414. [Google Scholar] [CrossRef] [Green Version]

- Kovaltchouk, T.; Ahmed, H.B.; Multon, B.; Aubry, J.; Venet, P. An aging-aware life cycle cost comparison between supercapacitors and Li-ion batteries to smooth Direct Wave Energy Converter production. In Proceedings of the 2015 IEEE Eindhoven PowerTech, Eindhoven, The Netherlands, 29 June–2 July 2015; pp. 1–6. [Google Scholar] [CrossRef] [Green Version]

- Hammar, A.; Venet, P.; Lallemand, R.; Coquery, G.; Rojat, G. Study of Accelerated Aging of Supercapacitors for Transport Applications. IEEE Trans. Ind. Electron. 2010, 57, 3972–3979. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Deng, J.; Dorrell, D.G. Multiobjective Optimal Sizing of Hybrid Energy Storage System for Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 1027–1035. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, X.; Li, J.; Hofmann, H.; Ouyang, M.; Du, J. Component sizing optimization of plug-in hybrid electric vehicles with the hybrid energy storage system. Energy 2018, 144, 393–403. [Google Scholar] [CrossRef]

- Eldeeb, H.H.; Elsayed, A.T.; Lashway, C.R.; Mohammed, O. Hybrid Energy Storage Sizing and Power Splitting Optimization for Plug-In Electric Vehicles. IEEE Trans. Ind. Appl. 2019, 55, 2252–2262. [Google Scholar] [CrossRef]

- Song, Z.; Li, J.; Hou, J.; Hofmann, H.; Ouyang, M.; Du, J. The battery-supercapacitor hybrid energy storage system in electric vehicle applications: A case study. Energy 2018, 154, 433–441. [Google Scholar] [CrossRef]

- Wieczorek, M.; Lewandowski, M. A mathematical representation of an energy management strategy for hybrid energy storage system in electric vehicle and real time optimization using a genetic algorithm. Appl. Energy 2017, 192, 222–233. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Li, M.; Chen, Z. A review of key issues for control and management in battery and ultra-capacitor hybrid energy storage systems. eTransportation 2020, 4, 100064. [Google Scholar] [CrossRef]

- Song, Z.; Li, J.; Han, X.; Xu, L.; Lu, L.; Ouyang, M.; Hofmann, H. Multi-objective optimization of a semi-active battery/supercapacitor energy storage system for electric vehicles. Appl. Energy 2014, 135, 212–224. [Google Scholar] [CrossRef]

- Shen, J.; Dusmez, S.; Khaligh, A. Optimization of Sizing and Battery Cycle Life in Battery/Ultracapacitor Hybrid Energy Storage Systems for Electric Vehicle Applications. IEEE Trans. Ind. Inform. 2014, 10, 2112–2121. [Google Scholar] [CrossRef]

- Akar, F.; Tavlasoglu, Y.; Vural, B. An Energy Management Strategy for a Concept Battery/Ultracapacitor Electric Vehicle With Improved Battery Life. IEEE Trans. Transp. Electrif. 2017, 3, 191–200. [Google Scholar] [CrossRef]

- Carter, R.; Cruden, A.; Hall, P.J. Optimizing for Efficiency or Battery Life in a Battery/Supercapacitor Electric Vehicle. IEEE Trans. Veh. Technol. 2012, 61, 1526–1533. [Google Scholar] [CrossRef]

- Zhao, C.; Yin, H.; Ma, C. Quantitative Evaluation of LiFePO Battery Cycle Life Improvement Using Ultracapacitors. IEEE Trans. Power Electron. 2016, 31, 3989–3993. [Google Scholar] [CrossRef]

- Du, J.; Zhang, X.; Wang, T.; Song, Z.; Yang, X.; Wang, H.; Ouyang, M.; Wu, X. Battery degradation minimization oriented energy management strategy for plug-in hybrid electric bus with multi-energy storage system. Energy 2018, 165, 153–163. [Google Scholar] [CrossRef]

- Hou, J.; Song, Z. A hierarchical energy management strategy for hybrid energy storage via vehicle-to-cloud connectivity. Appl. Energy 2020, 257, 113900. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, X.; Xie, S.; Song, Z.; Hu, L.; Hou, C. Adaptively coordinated optimization of battery aging and energy management in plug-in hybrid electric buses. Appl. Energy 2019, 256, 113891. [Google Scholar] [CrossRef]

- Cordoba-Arenas, A.; Onori, S.; Guezennec, Y.; Rizzoni, G. Capacity and power fade cycle-life model for plug-in hybrid electric vehicle lithium-ion battery cells containing blended spinel and layered-oxide positive electrodes. J. Power Sources 2015, 278, 473–483. [Google Scholar] [CrossRef] [Green Version]

- Tang, L.; Rizzoni, G. Energy management strategy including battery life optimization for a HEV with a CVT. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Busan, Korea, 1–4 June 2016; pp. 549–554. [Google Scholar]

- Mohan, G.; Assadian, F.; Longo, S. Comparative analysis of forward-facing models vs backwardfacing models in powertrain component sizing. In Proceedings of the IET Hybrid and Electric Vehicles Conference 2013 (HEVC 2013), London, UK, 6–7 November 2013; pp. 1–6. [Google Scholar] [CrossRef] [Green Version]

- Zeng, X.; Yang, N.; Wang, J.; Song, D.; Zhang, N.; Shang, M.; Liu, J. Predictive-model-based dynamic coordination control strategy for power-split hybrid electric bus. Mech. Syst. Signal Process. 2015, 60–61, 785–798. [Google Scholar] [CrossRef]

- Sangtarash, F.; Esfahanian, V.; Nehzati, H.; Haddadi, S.; Bavanpour, M.A.; Haghpanah, B. Effect of Different Regenerative Braking Strategies on Braking Performance and Fuel Economy in a Hybrid Electric Bus Employing CRUISE Vehicle Simulation. SAE Int. J. Fuels Lubr. 2008, 1, 828–837. [Google Scholar] [CrossRef]

- Wang, B.H.; Luo, Y.G.; Zhang, J.W. Simulation of city bus performance based on actual urban driving cycle in China. Int. J. Automot. Technol. 2008, 9, 501–507. [Google Scholar] [CrossRef]

- Markel, T.; Brooker, A.; Hendricks, T.; Johnson, V.; Kelly, K.; Kramer, B.; O’Keefe, M.; Sprik, S.; Wipke, K. ADVISOR: A systems analysis tool for advanced vehicle modeling. J. Power Sources 2002, 110, 255–266. [Google Scholar] [CrossRef]

- Erdinc, O.; Vural, B.; Uzunoglu, M. A dynamic lithium-ion battery model considering the effects of temperature and capacity fading. In Proceedings of the 2009 International Conference on Clean Electrical Power, Capri, Italy, 9–11 June 2009; pp. 383–386. [Google Scholar]

- Nelson, R.F. Power requirements for batteries in hybrid electric vehicles. J. Power Sources 2000, 91, 2–26. [Google Scholar] [CrossRef]

- Fauvel, C.; Vikesh, N.; Aymeric, R. Medium and Heavy Duty Hybrid Electric Vehicle Sizing to Maximize Fuel Consumption Displacement on Real World Drive Cycles; Power (W): Los Angeles, CA, USA, 2012. [Google Scholar]

- Dougal, R.; Gao, L.; Liu, S. Ultracapacitor model with automatic order selection and capacity scaling for dynamic system simulation. J. Power Sources 2004, 126, 250–257. [Google Scholar] [CrossRef]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; Van den Bossche, P.; Coosemans, T.; et al. Lithium iron phosphate based battery—Assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Safari, M.; Morcrette, M.; Teyssot, A.; Delacourt, C. Life-Prediction Methods for Lithium-Ion Batteries Derived from a Fatigue Approach I. Introduction: Capacity-Loss Prediction Based on Damage Accumulation. J. Electrochem. Soc. 2010, 157, A713–A720. [Google Scholar] [CrossRef]

- Zhou, C.; Qian, K.; Allan, M.; Zhou, W. Modeling of the Cost of EV Battery Wear Due to V2G Application in Power Systems. IEEE Trans. Energy Convers. 2011, 26, 1041–1050. [Google Scholar] [CrossRef]

- Mallon, K.R.; Assadian, F.; Fu, B. Analysis of On-Board Photovoltaics for a Battery Electric Bus and Their Impact on Battery Lifespan. Energies 2017, 10, 943. [Google Scholar] [CrossRef]

- Xu, B.; Oudalov, A.; Ulbig, A.; Andersson, G.; Kirschen, D.S. Modeling of lithium-ion battery degradation for cell life assessment. IEEE Trans. Smart Grid 2016, 9, 1131–1140. [Google Scholar] [CrossRef]

- Lee, D.H.; Kim, U.S.; Shin, C.B.; Lee, B.H.; Kim, B.W.; Kim, Y.H. Modelling of the thermal behaviour of an ultracapacitor for a 42-V automotive electrical system. J. Power Sources 2008, 175, 664–668. [Google Scholar] [CrossRef]

- Mallon, K.; Assadian, F. Robustification and its Implication for Hybrid Electric Vehicle Energy Management Strategies. J. Dyn. Syst. Control. 2020, 143, 091001. [Google Scholar] [CrossRef]

- Tate, E.D.; Grizzle, J.W.; Peng, H. Shortest path stochastic control for hybrid electric vehicles. Int. J. Robust Nonlinear Control 2008, 18, 1409–1429. [Google Scholar] [CrossRef]

- Lin, C.C.; Peng, H.; Grizzle, J.W. A stochastic control strategy for hybrid electric vehicles. In Proceedings of the 2004 American Control Conference, Boston, MA, USA, 30 June–2 July 2004; Volume 5, pp. 4710–4715. [Google Scholar]

- Johannesson, L.; Asbogard, M.; Egardt, B. Assessing the Potential of Predictive Control for Hybrid Vehicle Powertrains Using Stochastic Dynamic Programming. IEEE Trans. Intell. Transp. Syst. 2007, 8, 71–83. [Google Scholar] [CrossRef]

- Vagg, C.; Akehurst, S.; Brace, C.J.; Ash, L. Stochastic dynamic programming in the real-world control of hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2015, 24, 853–866. [Google Scholar] [CrossRef] [Green Version]

- Opila, D.F.; Wang, X.; McGee, R.; Grizzle, J. Real-time implementation and hardware testing of a hybrid vehicle energy management controller based on stochastic dynamic programming. J. Dyn. Syst. Meas. Control 2013, 135, 021002. [Google Scholar] [CrossRef] [Green Version]

- Zhu, T.; Wills, R.G.A.; Lot, R.; Kong, X.; Yan, X. Optimal sizing and sensitivity analysis of a battery-supercapacitor energy storage system for electric vehicles. Energy 2021, 221, 119851. [Google Scholar] [CrossRef]

- US Energy Information Administration. July 2021 Monthly Energy Review; Technical Report; U.S. Energy Information Administration: Washington, DC, USA, 2021.

- Barlow, T.J.; Latham, S.; Mccrae, I.S.; Boulter, P.G. A Reference Book of Driving Cycles for Use in the Measurement of Road Vehicle Emissions; TRL Published Project Report; Transport Research Laboratory: Crothorne, UK, 2009. [Google Scholar]

- Hughes-Cromwick, M. 2019 Public Transportation Fact Book; World Transit Research; American Public Transportation Association: Chicago, IL, USA, 2019. [Google Scholar]

- Min, H.; Lai, C.; Yu, Y.; Zhu, T.; Zhang, C. Comparison Study of Two Semi-Active Hybrid Energy Storage Systems for Hybrid Electric Vehicle Applications and Their Experimental Validation. Energies 2017, 10, 279. [Google Scholar] [CrossRef]

- Mongird, K.; Viswanathan, V.V.; Balducci, P.J.; Alam, M.J.E.; Fotedar, V.; Koritarov, V.S.; Hadjerioua, B. Energy Storage Technology and Cost Characterization Report; Technical Report; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2019.

- Wang, J.; Liu, P.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Cycle-life model for graphite-LiFePO4 cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Serrao, L.; Onori, S.; Sciarretta, A.; Guezennec, Y.; Rizzoni, G. Optimal energy management of hybrid electric vehicles including battery aging. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011; pp. 2125–2130. [Google Scholar] [CrossRef]

- Lin, X.; Hao, X.; Liu, Z.; Jia, W. Health conscious fast charging of Li-ion batteries via a single particle model with aging mechanisms. J. Power Sources 2018, 400, 305–316. [Google Scholar] [CrossRef]

- Laver, R.; Schneck, D.; Skorupski, D.; Brady, S.; Cham, L. Useful Life of Transit Buses and Vans; Number: FTA-VA-26-7229-07.1; National Academy of Sciences: Washington, DC, USA, 2007. [Google Scholar]

| Parameter | Variable | Value |

|---|---|---|

| Vehicle Mass | 18,181 kg | |

| Frontal Area | 8.02 m | |

| Drag Coefficient | 0.55 | |

| Roll Resistance Coefficient | 0.008 | |

| Wheel Inertia | 20.52 kg-m | |

| Motor Inertia | 0.277 kg-m | |

| Wheel Radius | 0.48 m | |

| Final Drive Ratio | 5.1:1 | |

| Gearbox Ratio | 5:1 | |

| Transmission Efficiency | 96% |

| Parameter | Variable | Value |

|---|---|---|

| Battery Cells in Parallel | 400 cells | |

| Parallel Sets in Series | 100 sets | |

| Total Charge Capacity | 340 Ah | |

| Nominal Open Circuit Voltage | 3.8 v | |

| Nominal Equivalent Resistance | 7.5 m |

| Parameter | Variable | Value |

|---|---|---|

| UC modules in Parallel | variable | |

| UC Parallel Sets in Series | 100 sets | |

| Resistance | 44.3 m | |

| Capacitance | 105.9 F |

| Type | DDP Max | MPGe at | SDP Lifespan | Difference | Mean Life |

|---|---|---|---|---|---|

| Lifespan | DDP Peak | at DDP Peak | at Peak | Difference | |

| (Years) | (MPGe) | (Years) | (%) | (%) | |

| DP-B | 5.47 | 9.54 | 5.46 | −0.27 | −0.45 |

| DP-EC | 5.76 | 9.65 | 5.73 | −0.51 | −0.95 |

| DP-P | 5.20 | 9.49 | 5.04 | −3.11 | −1.67 |

| Type | Peak | MPGe | Lifespan | MPGe vs. | UC |

|---|---|---|---|---|---|

| Lifespan | at Peak | vs. Nominal | Nominal | Per Year | |

| (Years) | (MPGe) | (%) | (%) | at Peak | |

| Nominal | 4.47 | 10.43 | – | – | 4.064 |

| SDP-B | 4.68 | 9.81 | 4.7 | –5.9 | 6.633 |

| SDP-EC | 4.69 | 10.14 | 5.1 | –2.8 | 4.587 |

| SDP-P | 4.58 | 10.18 | 2.5 | –2.4 | 4.105 |

| LL | 4.47 | 10.43 | – | – | 4.064 |

| Type | Peak | MPGe | Lifespan | MPGe vs. | UC |

|---|---|---|---|---|---|

| Lifespan | at Peak | vs. Nominal | Nominal | Per Year | |

| (Years) | (MPGe) | (%) | (%) | at Peak | |

| Nominal | 4.47 | 10.43 | – | – | 4.064 |

| SDP-B | 5.12 | 9.62 | 14.7 | –7.8 | 4.138 |

| SDP-EC | 5.16 | 9.81 | 15.6 | –6.0 | 4.091 |

| SDP-P | 4.87 | 9.71 | 9.0 | –6.9 | 4.093 |

| LL | 4.48 | 10.40 | 0.4 | –0.3 | 4.063 |

| Type | Peak | MPGe | Lifespan | MPGe vs. | UC |

|---|---|---|---|---|---|

| Lifespan | at Peak | vs. Nominal | Nominal | Per Year | |

| (Years) | (MPGe) | (%) | (%) | at Peak | |

| Nominal | 4.47 | 10.43 | – | – | 4.064 |

| SDP-B | 5.48 | 9.51 | 22.6 | –8.9 | 4.100 |

| SDP-EC | 5.73 | 9.71 | 28.2 | –7.0 | 4.060 |

| SDP-P | 5.07 | 9.32 | 13.4 | –10.7 | 4.057 |

| LL | 4.58 | 10.09 | 2.6 | –3.3 | 4.046 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mallon, K.; Assadian, F. A Study of Control Methodologies for the Trade-Off between Battery Aging and Energy Consumption on Electric Vehicles with Hybrid Energy Storage Systems. Energies 2022, 15, 600. https://doi.org/10.3390/en15020600

Mallon K, Assadian F. A Study of Control Methodologies for the Trade-Off between Battery Aging and Energy Consumption on Electric Vehicles with Hybrid Energy Storage Systems. Energies. 2022; 15(2):600. https://doi.org/10.3390/en15020600

Chicago/Turabian StyleMallon, Kevin, and Francis Assadian. 2022. "A Study of Control Methodologies for the Trade-Off between Battery Aging and Energy Consumption on Electric Vehicles with Hybrid Energy Storage Systems" Energies 15, no. 2: 600. https://doi.org/10.3390/en15020600