Review of Recent Offshore Photovoltaics Development

Abstract

:1. Introduction

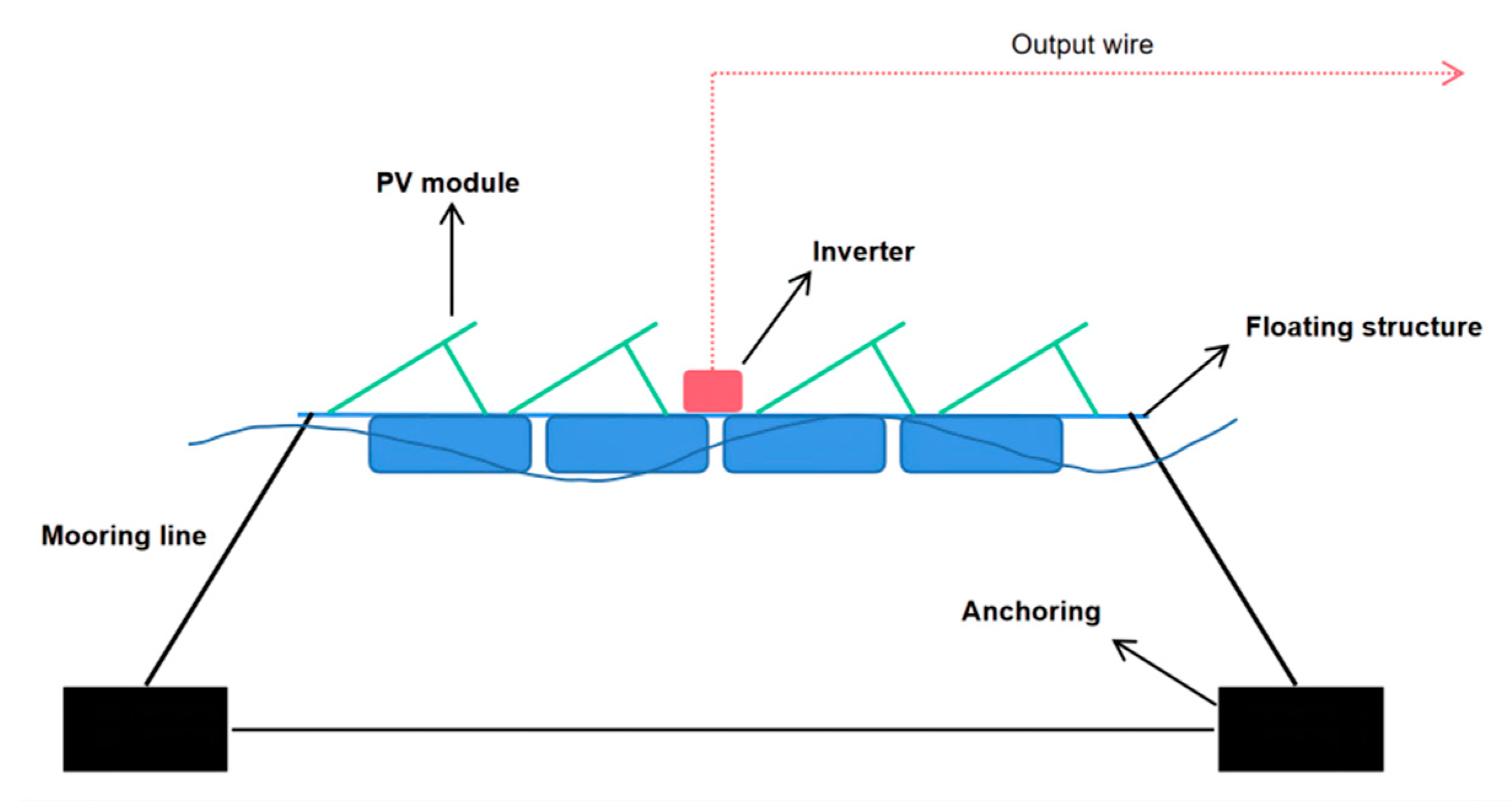

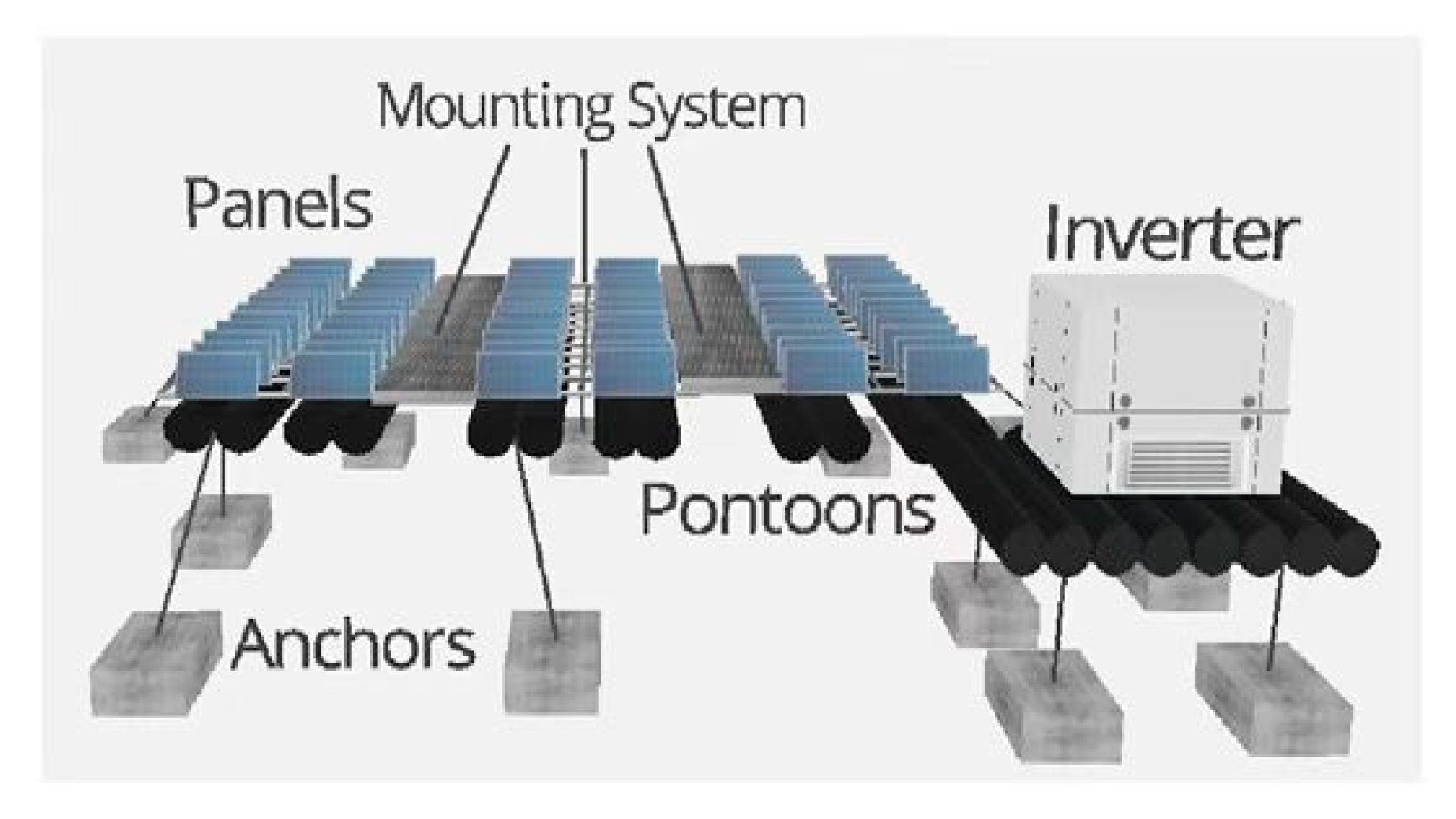

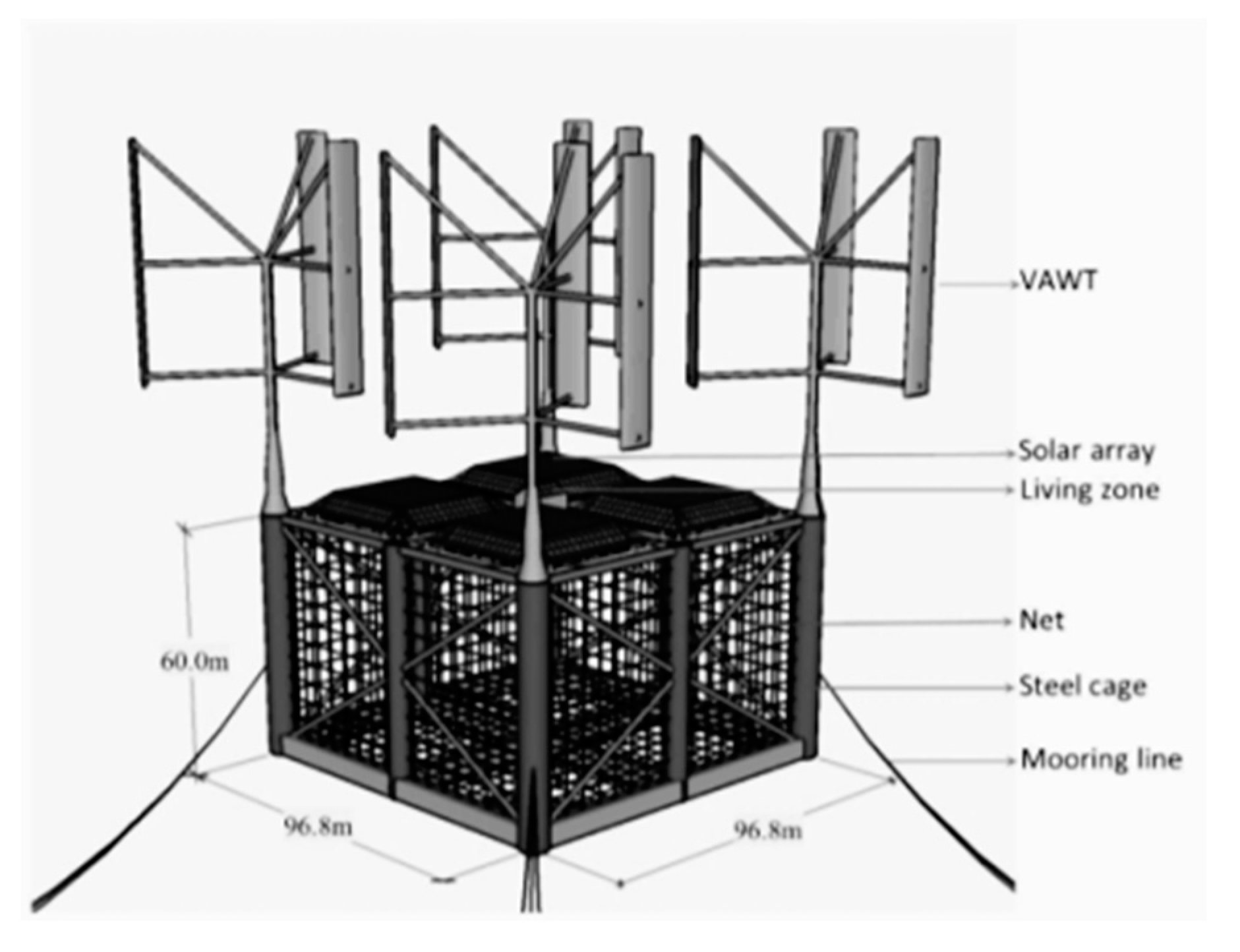

2. Floating PV Systems

2.1. Fixed Pile-Based Photovoltaic Systems

- (1)

- The need for better anti-corrosion protection, especially for electrical equipment (C5 rating);

- (2)

- The need to build wave protection facilities (permeable, slope, and floating dikes);

- (3)

- The need to consider the impact of sea ice;

- (4)

- The need for a detailed demonstration of the impact of storm surges.

2.2. Wave-Proof Floating Photovoltaic

2.3. Floating Platform Photovoltaic Systems

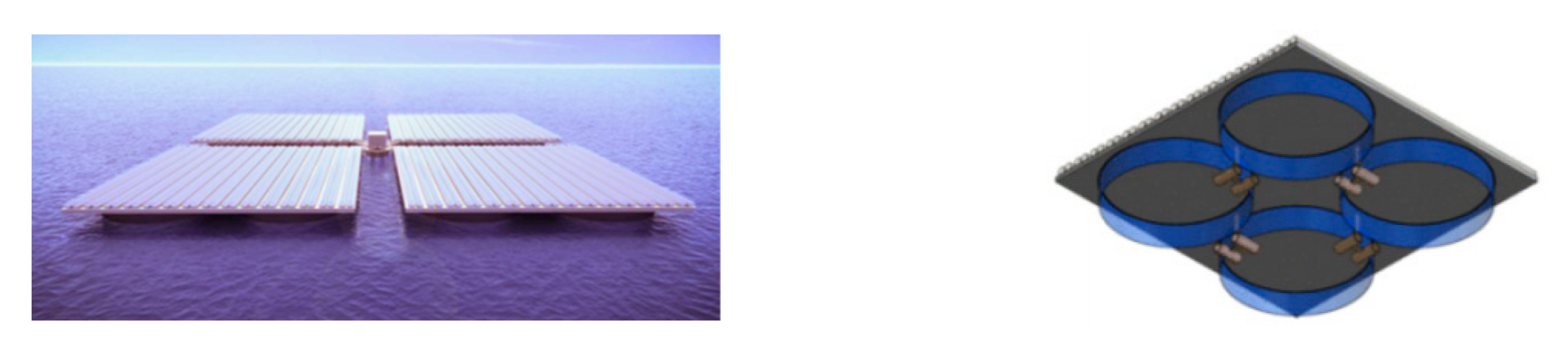

2.4. Floating Thin-Film Photovoltaic Systems

2.4.1. Low Theoretical Cost of a Floating PV Installation

2.4.2. Simple, Fast, and Safe Maritime Installation

2.4.3. Enhanced Efficiency from Direct Water Cooling

2.4.4. Robustness against Wind, Waves, and Currents

3. Shortcomings and Challenges

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cosemans, V. Expert Consortium Including DEME Explores Pioneering High-Wave Offshore Solar Technology. 18 July 2019. Available online: https://www.deme-group.com/news/expert-consortium-including-deme-explores-pioneering-high-wave-offshore-solar-technology (accessed on 4 August 2022).

- Micheli, L.; Talavera, D.L.; Tina, G.M.; Almonacid, F.; Fernández, E.F. Techno-economic potential and perspectives of floating photovoltaics in Europe. Sol. Energy 2022, 243, 203–214. [Google Scholar] [CrossRef]

- Gorjian, S.; Minaei, S.; MalehMirchegini, L.; Trommsdorff, M.; Shamshiri, R.R. Applications of Solar PV Systems in Agricultural Automation and Robotics. In Photovoltaic Solar Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2020; pp. 191–235. [Google Scholar]

- Crago, C.L.; Koegler, E. Drivers of growth in commercial-scale solar PV capacity. Energy Policy 2018, 120, 481–491. [Google Scholar] [CrossRef]

- Garanovic, A. EU Targets 40 GW of Ocean Energy and Other Emerging Technologies by 2050; Offshore Energy: Rotterdam, The Netherlands, 2020. [Google Scholar]

- Wang, Z.; Carriveau, R.; Ting, D.S.-K.; Xiong, W.; Wang, Z. A review of marine renewable energy storage. Int. J. Energy Res. 2019, 43, 6108–6150. [Google Scholar] [CrossRef]

- Joo, H.J.; Lee, N.H.; Lee, S.W. Floating photovoltaic power generation system. Korean Soc. Adv. Compos. Struct. 2013, 4, 31–39. [Google Scholar]

- Smyth, M.; Russell, J.; Milanowski, T. Solar Energy in the Winemaking Industry; Springer: London, UK, 2011. [Google Scholar]

- Vo, T.T.E.; Ko, H.; Huh, J.; Park, N. Overview of Possibilities of Solar Floating Photovoltaic Systems in the OffShore Industry. Energies 2021, 14, 6988. [Google Scholar] [CrossRef]

- Emiliano, B. Off-Shore PV Project with LCOE of €0.15/kWh Off the Belgian Coast. PV Mag. 2021. Available online: https://www.pv-magazine.com/2021/09/03/off-shore-pv-project-with-lcoe-of-e0-15-kwh-off-the-belgian-coast/ (accessed on 4 August 2022).

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating photovoltaic power plant: A review. Renew. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Gorjian, S.; Sharon, H.; Ebadi, H.; Kant, K.; Scavo, F.B.; Tina, G.M. Recent technical advancements, economics and environmental impacts of floating photovoltaic solar energy conversion systems. J. Clean. Prod. 2021, 278, 124285. [Google Scholar] [CrossRef]

- Huadong Engineering Corporation Limited; Nanjing Parrott Solar Energy Co.; Southeast University. Floating Photovoltaic Power Generation System. CN202111226822.8, 10 December 2021. [Google Scholar]

- Wen, J.B. Shandong: Support offshore wind power, photovoltaic and hydrogen energy development is expected to form a hundred billion investment scale. New Energy Technol. 2022, 4, 19–20. [Google Scholar]

- Xu, Z.; Lin, X.Y. Wenzhou Taihan 550 MW fishery and solar power project connected to the grid. Wenzhou Daily, 27 December 2021. [Google Scholar]

- Tina, G.M.; Scavo, F.B.; Merlo, L.; Bizzarri, F. Analysis of water environment on the performances of floating photovoltaic plants. Renew. Energy 2021, 175, 281–295. [Google Scholar] [CrossRef]

- Oliveira-Pinto, S.; Stokkermans, J. Marine Floating Solar Plants: An overview of potential, challenges and feasibility. Proc. Inst. Civ. Eng.-Marit. Eng. 2020, 173, 120–135. [Google Scholar] [CrossRef]

- Solar Energy Research Institute of Singapore; World Bank Group; Energy Sector Management Assistance Program. Where Sun Meets Water: Floating Solar Market Report. 30 October 2018. Available online: https://openknowledge.worldbank.org/handle/10986/31880 (accessed on 4 August 2022).

- Bjørneklett, G. Offshore floating solar—A technical perspective. PV Tech Power 2018, 16, 6–9. [Google Scholar]

- Boersma, T.; van der Laan, J.; Noorduyn, O.; Mesbahi, M. A Comprehensive Overview of 200+ Global Floating Solar Plants. Available online: https://www.solarplaza.com/channels/future-grid/12067/200-global-floating-solar-plants/ (accessed on 4 August 2022).

- Prouvost, B. Hydrelio® Technology Catalog. 5 May 2018. Available online: https://issuu.com/cieletterre/docs/c_t_catalog_hydrelio__technology_20 (accessed on 4 August 2022).

- Trapani, K.; Millar, D.L. Proposing offshore photovoltaic (PV) technology to the energy mix of the Maltese islands. Energy Convers. Manag. 2013, 67, 18–26. [Google Scholar] [CrossRef]

- Grech, M.; Stagno, L.M.; Aquilina, M.; Cadamuro, M.; Witzke, U. Floating photovoltaic installations in Maltese sea waters. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016; pp. 1965–1968. [Google Scholar]

- Zhang, T.F.; Zhang, H.; Sun, L. Analysis of the influence of the shape of floating breakwater on the effect of wave stopping and wave dissipation. Pearl River Water Transp. 2022, 08, 90–94. [Google Scholar]

- Wu, X.H. A brief discussion on the design of permeable breakwater pile foundation. Pearl River Water Transp. 2021, 15, 90–91. [Google Scholar]

- Sheng, Y.S.; Zhou, Y.R.; Pan, J.N.; Wang, X.G. Research progress and application of floating breakwater. Hydro-Sci. Eng. 2016, 5, 124–132. [Google Scholar]

- Sheng, Y.S.; Zhou, Y.R.; Pan, J.N.; Wang, X.G. Experimental study on wave dissipation effect of double floating tank type floating breakwater under different connection methods. In Proceedings of the 18th China Ocean (Shore) Engineering Symposium (Below), Zhoushan, China, 22–25 September 2017; pp. 259–263. [Google Scholar]

- Liu, W.J.; Sun, Z.L. A Kind of Circular Floating Breakwater. CN104912028A, 16 September 2015. [Google Scholar]

- Rosa-Clot, M.; Tina, G. Submerged and Floating Photovoltaic Systems: Modelling, Design and Case Studies; Elsevier: Amsterdam, The Netherlands; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- International Finance Group, Utility-Scale Solar Photovoltaic Power Plants: A Project Developer’s Guide. 4 August 2022. Available online: https://www.ifc.org/wps/wcm/connect/a1b3dbd3-983e-4ee3-a67b-cdc29ef900cb/IFC+Solar+Report_Web+_08+05.pdf?MOD=AJPERES&CVID=kZePDPG (accessed on 4 August 2022).

- Walker, A. Best Practices for Operation and Maintenance of Photovoltaic and Energy Storage Systems, 3rd ed.; 4 August 2022. Available online: https://www.nrel.gov/docs/fy19osti/73822.pdf (accessed on 4 August 2022).

- Clemons, S.K.C.; Salloum, C.R.; Herdegen, K.G.; Kamens, R.M.; Gheewala, S.H. Life cycle assessment of a floating photovoltaic system and feasibility for application in Thailand. Renew. Energy 2021, 168, 448–462. [Google Scholar] [CrossRef]

- Daroen, I. Risk Assessment of Offshore Floating Photovoltaic Systems: Methodology for Technological Risks. Master’s Thesis, Delft University of Technology, Delft, The Netherland, 2021. [Google Scholar]

- Eisl, R. HELIOFLOAT—A Floating Lightweight Platform. Institute for Energy Systems and Thermodynamics. 4 August 2022. Available online: https://www.tuwien.at/fileadmin/Assets/dienstleister/forschungsmarketing/messe/Messe_Rueckblick/HM2016/HELIOFLOAT_platform_EN.pdf (accessed on 5 August 2022).

- SOLARDUCK. Flexibly Interconnected Semi-Sub Triangular Structures. Artificulated Floating Structure. PCT/EP2020/087842, 2020. [Google Scholar]

- Tiong, Y.K.; Zahari, M.A.; Wong, S.F. The Feasibility of Wind and Solar Energy Application for Oil and Gas Offshore Platform. IOP Conf. Ser. Mater. Sci. Eng. 2015, 78, 012042. [Google Scholar] [CrossRef]

- Rosebro, J.; Fossil-Fuel Platform Runs on Renewable Energy. 20 April 2006. Available online: http://www.greencarcongress.com/2006/04/fossilfuel_plat.html (accessed on 5 August 2022).

- Zhang, J.H.; Liu, X.G.; Gu, Z.J.; Cheng, G.F.; Zhu, H. The ecological economic characteristics of fishery and light complementary and its development direction. J. Fish. China 2022, 46, 1525–1535. [Google Scholar]

- Zheng, X.; Zheng, H.; Lei, Y.; Li, Y.; Li, W. An offshore floating wind-solar-aquaculture system: Concept design and extreme response in survival conditions. Energies 2020, 13, 604. [Google Scholar] [CrossRef] [Green Version]

- Ravichandran, N.; Ravichandran, N.; Panneerselvam, B. Comparative assessment of offshore floating photovoltaic systems using thin film modules for Maldives islands. Sustain. Energy Technol. Assess. 2022, 53 Pt A, 102490. [Google Scholar] [CrossRef]

- Zaini, N.H.; Ab-Kadir, M.Z.A.; Izadi, M. On the effect of lightning on a solar photovoltaic system. In Proceedings of the 2016 33rd International Conference on Lightning Protection (ICLP), Estoril, Portugal, 25–30 September 2016; pp. 1–4. [Google Scholar]

- El-Reedy, M.A. Offshore Structure Platform Design. In Offshore Structures; Elsevier BV: Amsterdam, The Netherlands, 2012; pp. 93–211. [Google Scholar]

- Fallah, N.; Gomes, C.; Ab Kadir, M.Z.A. Lightning protection techniques for roof-top PV systems. In Proceedings of the 2013 IEEE 7th International Power Engineering and Optimization Conference (PEOCO), Langkawi, Malaysia, 3–4 June 2013; pp. 417–421. [Google Scholar]

- Kaymak, M.K.; Şahin, A.D. Problems encountered with floating photovoltaic systems under real conditions: A new FPV concept and novel solutions. Sustain. Energy Technol. Assess. 2021, 47, 101504. [Google Scholar] [CrossRef]

- Kougias, I.; Taylor, N.; Kakoulaki, G.; Jäger-Waldau, A. The role of photovoltaics for the European Green Deal and the recovery plan. Renew. Sustain. Energy Rev. 2021, 144, 111017. [Google Scholar] [CrossRef]

| Diameter 73 m | Diameter 51 m | |

|---|---|---|

| Capacity (Module dep.) | 525–640 kWp | 230–260 kWp |

| # of Modules | 1944 | 848 |

| Smart string inverters | 3 × 185 kWp 1500 V DC/800 V AC | 3 × 100 kWp 1500 V DC/400 V AC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Lund, P.D. Review of Recent Offshore Photovoltaics Development. Energies 2022, 15, 7462. https://doi.org/10.3390/en15207462

Wang J, Lund PD. Review of Recent Offshore Photovoltaics Development. Energies. 2022; 15(20):7462. https://doi.org/10.3390/en15207462

Chicago/Turabian StyleWang, Jun, and Peter D. Lund. 2022. "Review of Recent Offshore Photovoltaics Development" Energies 15, no. 20: 7462. https://doi.org/10.3390/en15207462

APA StyleWang, J., & Lund, P. D. (2022). Review of Recent Offshore Photovoltaics Development. Energies, 15(20), 7462. https://doi.org/10.3390/en15207462