Abstract

Modern healthcare is transforming from hospital-centric to individual-centric systems. Emerging implantable and wearable medical (IWM) devices are integral parts of enabling affordable and accessible healthcare. Early disease diagnosis and preventive measures are possible by continuously monitoring clinically significant physiological parameters. However, most IWM devices are battery-operated, requiring replacement, which interrupts the proper functioning of these devices. For the continuous operation of medical devices for an extended period of time, supplying uninterrupted energy is crucial. A sustainable and health-compatible energy supply will ensure the high-performance real-time functioning of IWM devices and prolong their lifetime. Therefore, harvesting energy from the human body and ambient environment is necessary for enduring precision healthcare and maximizing user comfort. Energy harvesters convert energy from various sources into an equivalent electrical form. This paper presents a state-of-the-art comprehensive review of energy harvesting techniques focusing on medical applications. Various energy harvesting approaches, working principles, and the current state are discussed. In addition, the advantages and limitations of different methods are analyzed and existing challenges and prospects for improvement are outlined. This paper will help with understanding the energy harvesting technologies for the development of high-efficiency, reliable, robust, and battery-free portable medical devices.

1. Introduction

Precision medicine enables individual-centric healthcare with flexibility, portability, and reduced cost in clinical decision support systems [1]. The accurate measurements of physiological parameters define the current health condition of the individual and aid medical professionals in a timely clinical decision-making process. Implantable and wearable medical (IWM) devices are a crucial part of nursing, physical activity monitoring, rehabilitation, and clinical early diagnosis of diseases, as well as monitoring of disease progression [2,3,4]. Besides extensive usage in precision medicine, IWM devices are useful in physical and mental condition assessment in the military [5,6]. For example, wearable photoplethysmography (PPG) sensors presented in [7] can measure the human heartbeat extracted from the blood flow in the cardiovascular system. Smart textiles allow the integration of wearable medical devices (WMDs) in dresses to record vital signs and electrocardiogram (ECG) signals [8,9].

The demand for incorporating portable medical devices in healthcare is rapidly growing due to: (i) the prevalence of chronic diseases, (ii) the increase in the number of elderly people, (iii) enabling easy accessibility to the personal health record, (iv) real-time monitoring of health conditions, and (v) cost-effectiveness. In addition, recent advances in integrated circuits, sensor technologies, and improved interfacing of biology and electronics have enabled the widespread adoption of IWM devices [10,11,12,13]. The improvement in front-end electronics and wireless communications for bio-signal acquisition facilitates continuous monitoring, quantitative measurements, and recording of high-quality clinical data.

Uninterrupted operation of IWM devices is contingent upon continuous powering, which is critical for many applications such as fall detection of sick people, heart activity monitoring to prevent myocardial infarction, etc. [14]. However, energy remains the major constraint, and most IWM devices are still battery-operated. Although significant improvement in designing miniaturized and high-storage-capacity batteries have been made over the past few years, the limited lifetime of batteries remains a burden. Other limitations of powering IWM devices using batteries are (i) the requirement of recharge or replacement often through surgery in the case of implantable medical devices (IMDs), (ii) the increased size and weight of the IWM devices to accommodate high-capacity batteries, resulting in user discomfort, and (iii) the requirement of manual human intervention for continuous operation [15]. The next generation of IWM devices should include improved functionality, ensure user comfort, and longer uninterrupted lifetime. Harvesting sufficient energy from the human body and the environment is the most viable solution [16,17]. Integrating energy harvesting in IWM devices will reduce the device sizes and ensure uninterrupted operation with minimal manual intervention and maintenance.

Energy harvesting is the conversion of available energy from the human body and ambient environment into a usable electrical form to facilitate a maintenance-less, long-lasting, and green energy supply in IWM devices. Electrical energy can be generated from biochemical reactions and motions associated with the human body. Solar light, radio frequency (RF) signals, etc., are a few significant environmental energy sources. The recent advancement in energy harvesting techniques has paved the way for full or partial power support for IWM devices.

There are a few review papers available providing detailed studies on discrete technologies such as extracting kinetic energy from body motion [18,19], wireless power transfer [20,21,22], and scavenging energy from the environment [23,24,25]. However, due to the rapid growth of energy harvesting technologies and radical paradigm shifts in implants and wearables, a state-of-the-art review is crucial. This paper presents a comprehensive review of the latest improvements in energy harvesting research focusing on implantable and wearable medical devices to achieve sustainable, robust, reliable, and enduring precision healthcare.

The rest of the paper is organized into different sections. Section 2 provides an overview of the implantable and wearable medical devices and discusses their role in precision medicine and healthcare. Section 3 discusses various energy harvesting techniques, energy sources, wireless power transfer, and an analysis of the advantages and limitations of each approach. Section 4 presents maximum power extraction methods from the energy harvesters. Recently, there has been a boost in adopting machine learning (ML) techniques in energy-harvesting-enabled IWM devices, which are included in Section 5. Section 6 discusses a few use cases and in vivo experiments of energy harvesters. The interaction of energy harvesters with the human body and potential biological effects are explained in Section 7. Existing challenges and future research directions are provided in Section 8. An overall discussion is presented in Section 9, and conclusions are drawn in Section 10.

2. Implantable and Wearable Medical Devices in Precision Healthcare

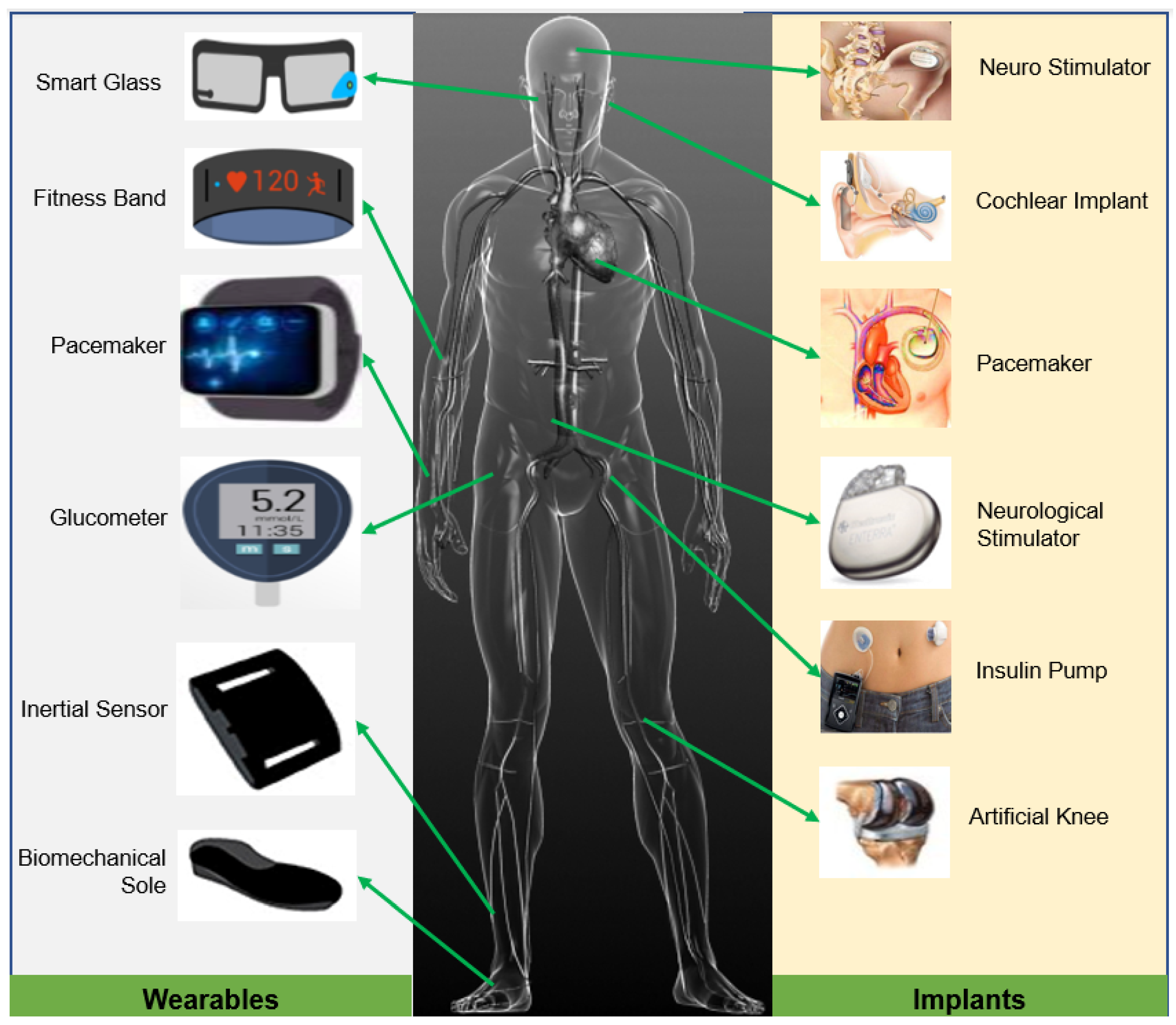

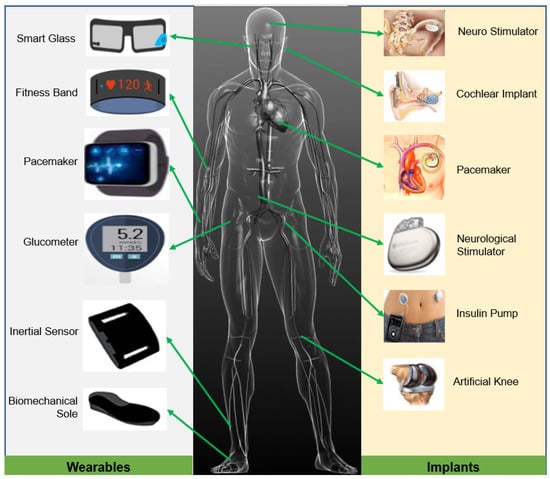

Recent progress in micro-fabrication has stimulated the miniaturization of implantable devices [26]. The pacemaker, insulin pump, neurostimulator, cochlear implant, cardiac defibrillator, and retinal implants are a few examples of clinically well-established IMDs used in precision healthcare [27]. An overview of different implantable and wearable medical devices and their usual placement in the human body are presented in Figure 1. In general, the energy system of the IMDs has three parts: energy source, storage, and power management unit (PMU) [28]. Depending on the application, the power requirement of implants varies from a few microwatts to milliwatts. The continuity and longevity of the operations of IMDs largely depend on an uninterrupted energy supply. Although the severity of the consequences of power interruption in implants varies, sometimes, it could lead to life-threatening events in the case of total artificial hearts, pacemakers, etc.

Figure 1.

Different wearable and implantable medical devices typically used in precision healthcare.

Although wearable devices are used in daily life events and fitness tracking, the adoption of wearables in healthcare is relatively slow. There are enormous opportunities to bring wearable devices to stimulate real-time, robust, reliable, and accurate monitoring of personalized health conditions. Driven by the increasing elderly population, increased economic burden, and prevalence of chronic diseases, a cost-effective, portable, and easily accessible personalized healthcare system is immensely important [2,29,30]. Therefore, the idea of care and treatment in hospitals is transferring towards more individual-centric healthcare services enabling early diagnosis and treatment initiatives [31,32]. Wearable medical devices (WMDs) are the key enabling technologies of individual-centric precision healthcare systems [33,34]. Different WMDs have been successfully implemented over the last few years such as non-invasive monitoring of the ECG, blood pressure, oxygen saturation, and respiratory rate for the prediction and prevention of diseases. Accelerometers and gyroscopes can monitor body motion and activities for ambient assistive living [4,35,36,37]. Different body fluids (blood, sweat, etc.) are also actively studied using wearable sensors to detect diabetes [38] and other metabolic disorders [39,40]. The wearables are commonly body-worn and often integrated into gloves, textiles, headsets, and patches. Appropriate management and control of many neurological and cardiovascular diseases such as Parkinson’s disease, heart failure, etc., require early detection and continuous monitoring of different clinical symptoms to maintain health in a stable condition. The wearable medical devices can mitigate the risk of catastrophic events from happening by (i) predicting disease through health monitoring, (ii) real-time diagnosis using on-site data processing, and (iii) informing concerned caregivers through telemedicine [41,42].

3. Energy Harvesting Techniques

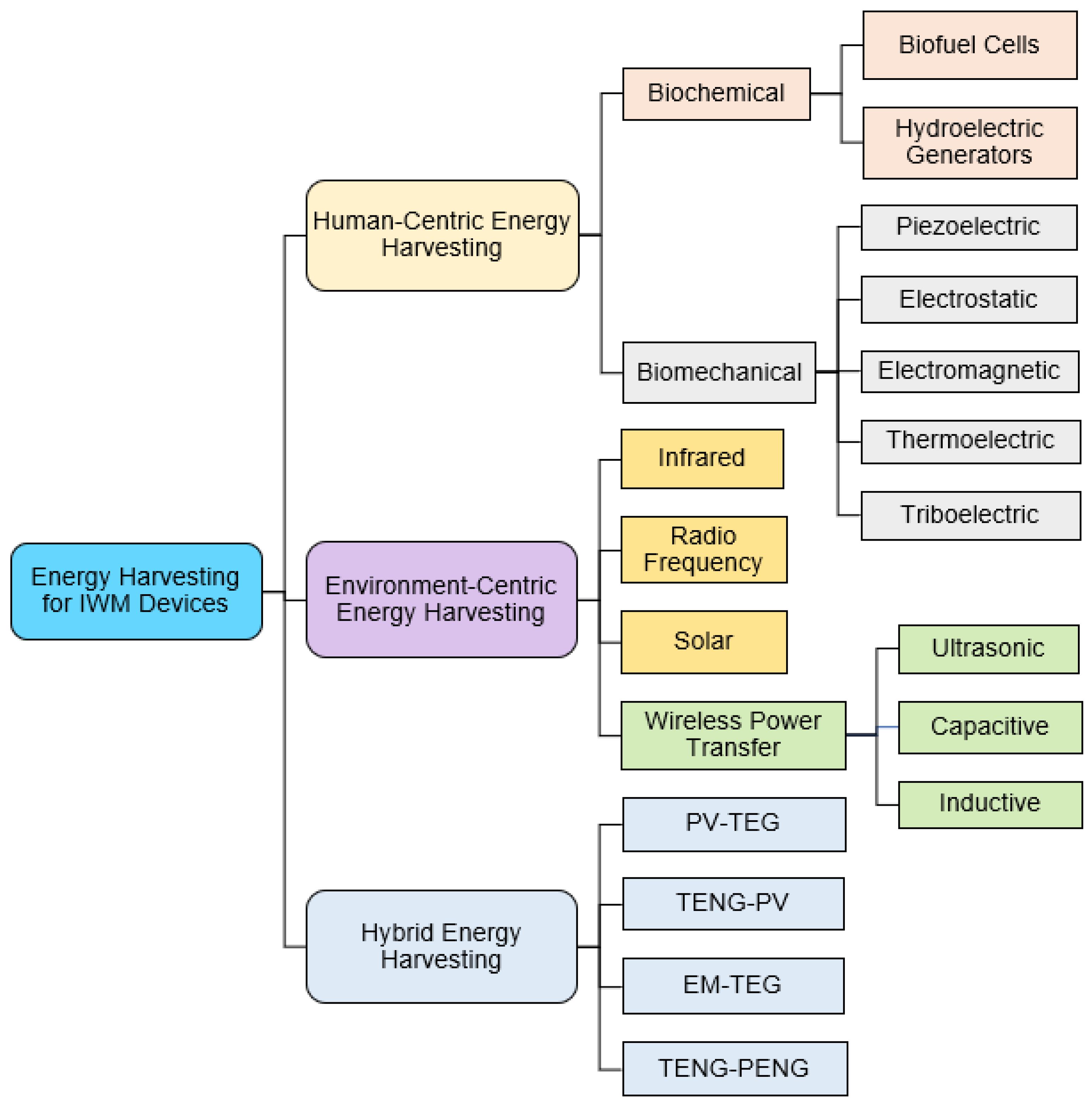

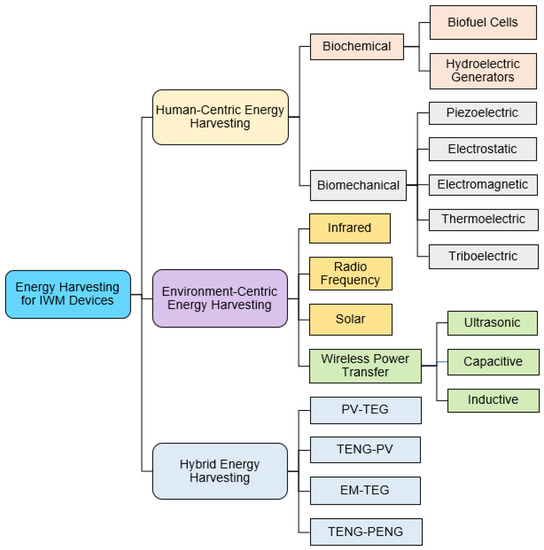

This review focuses on energy harvesting for IWM devices from two sources: (i) the human body and (ii) the environment. Human body motion and heat are a few examples of human-centric energy sources exploited for energy harvesting. A general classification of different energy harvesting techniques is presented in Figure 2. Thermoelectric energy generators (TEGs) use the temperature gradient between the human body and the surrounding environment to scavenge energy [43]. In addition, the heat dissipated from the human body has also demonstrated potential in energy harvesting using photovoltaic (PV) cells [44]. Various vibrations associated with the human body such as walking, running, and breathing are other sources of energy [45]. Researchers effectively transduced these body vibrations into electrical energy by electrostatic, triboelectric, electromagnetic (EM), and piezoelectric processes [46]. In addition, energy sources from the environment such as infrared radiation, solar energy, and radio frequency (RF) signals have shown promise as excellent sources of energy [47]. However, the reliability of environment-centric energy sources is often contingent upon their availability and requires additional storage to facilitate the continuous operation of IWM devices. Energy harvesting techniques can combine sources from the human body and the environment to obtain more robust energy solutions. Such hybrid energy harvesters are also briefly discussed in this section.

Figure 2.

Classification of human- and environment-centric energy harvesting techniques exploited in implantable and wearable medical devices.

3.1. Human-Centric Energy Harvesting

Human-centric energy harvesting has received significant attention in recent years. Researchers have shown that the human body can generate more energy than a battery cell, self-sufficient to operate IWM devices [14,48]. Harvesting this energy can minimize the burden of individuals undergoing repeated invasive procedures to replace the batteries in IWM devices and operate without any batteries. Human-centric energy harvesters often convert external body motion, temperature, and internal chemical reactions into electrical energy. While motion, vibration, temperature gradients, and enzymatic reactions can be excellent sources of energy, there is an increasing challenge because of the size constraints of the harvester in the human scenario. However, it has been shown as a proof-of-concept that even regular daily life activities are sources of different amounts of energy. For example, approximately 81 mW and 1630 mW of power can be harnessed from the human body while sleeping and walking, respectively [49]. In addition, the biofluids in the human body can act as a source of sustainable energy through their natural operation [50]. Major efforts have thus been put forward to harvest these human-centric energy, be it from the chemical reactions inside the human body or its mechanical motion. In this review, human-centric energy harvesting techniques are categorized into biochemical and biomechanical processes.

3.1.1. Biochemical Energy Harvesting

The human body contains numerous enzymes and agents to maintain the proper balance of biofluids [51]. Due to internal chemical reactions in the human body, the formation and breaking of chemical bonds generate an enormous amount of energy. This level of energy is sufficient to some extent to operate low-power implantable devices. The amount of harvested energy depends on many factors such as age, health, and food intake. In addition, the interaction of water with novel materials can generate usable energy using the hydro-voltaic effect. Biochemical energy harvesting is discussed in the following two categories: biofuel cells and hydroelectric generators (HEGs).

Biofuel Cells

Glucose in body fluid is an excellent source of energy. It releases a decent amount of energy through redox reactions in the metabolism process. Recently, the glucose biofuel (GBF) cell has garnered attention as an alternative energy source due to biocompatibility and abundance in the human body [52,53]. The GBF cell can store more energy compared to conventional lithium-ion batteries. For instance, a GBF cell implanted in the abdomen of a rat demonstrated 38.7 W of power at the output with a power density of 193.5 W/cm [54]. Experiments demonstrated that up to 100 W/cm can be generated from the GBF in the human body [55,56]. Recently, a significant improvement of the GBF cell was achieved in [57], obtaining 3.7 mW/cm of power density coating a metallic cotton fiber in glucose oxidase (GOx). However, there has been ongoing research to increase the power density of a biofuel cells (BFCs) [58]. Researchers have loaded an oxidizing enzyme and glucose dehydrogenase into a coating. The coating is made of redox polymers and polyethyleneimine, which act as a supercapacitor. Charges stored in the supercapacitor provide high-energy bursts when needed [50]. Besides, BFCs are implanted inside the body for extracting body fuel to produce electricity [59,60,61,62]. The bio-implantable fuel cell reported in [56] is powered by extracellular glucose in the cerebrospinal fluid surrounding the brain. Studies have shown the conceivability of using GOx for BFCs [63,64]. For these BFCs, the use of nanomaterial-modified electrodes with a large electrochemically active surface area (ECSA) enables a high loading and promotes power generation. Reduced graphene oxide (rGO) films, nickel microstructures, and Meldola’s blue-tetrathiafulvalene-modified carbon nanotubes (MDB-TTF-CNT) for the enzymatic anode have been reported to increase the ECSA by 3000× [65]. However, there are some limitations to the use of this enzyme due to safety concerns. Most of the concerns include the generation of hydrogen peroxide by GOx affecting the stability of the enzyme, which deteriorates the performance of the system, and most importantly, long-term use of these enzymes may be harmful to the body [66]. A few limitations of glucose as a biofuel include: (i) temperature and pH variation can disrupt glucose metabolism and (ii) potential chances of bacterial infection. In addition, biofouling often occurs in GBF cells, leading to biohazards [54]. Due to safety concerns, GBF cells are not yet usable in medical implants.

Lactates such as sweat and saliva are another energy source available in body fluids. For instance, in [50], a tattoo was designed to harvest energy from lactate during physical activity, generating 70 W/cm. Besides, pH differences can also act as a source of electrostatic energy [67]. The soft e-skin-based BFC reported in [68] extracts chemical energy from human sweat. This wearable e-skin-based BFC produces a power density of 1.2 mW/cm at 0.2 V by using sweat lactate from the human body. An extensive study on biosensor and biofuel cells is reported in [69]. This research team developed a BFC using passive sweat from the fingertips to continuously supply energy without requiring physical motion. In a recent attempt, researchers showed that 13 W of power can be achieved by a textile-based enzymatic BFC [70]. A “wearable microgrid” shirt has also been demonstrated, which incorporates sweat-powered BFCs, motion-powered triboelectric nanogenerators (TENGs), and supercapacitors to store the converted electric energy [71]. Apart from the fluids, the endocochlear potential (EP) in the inner ear can generate low power ranging between 1.1 and 6.3 nW [72].

EP found in the mammalian inner ear is a battery-like electrochemical gradient that can be used as an energy harvester. The EP occurs due to the ionic concentration difference between endolymph and perilymph. A CMOS integrated energy harvester was designed in [72] that can extract a minimum of 1.12 nW of power from the EP of a guinea pig for 5 h and also sense the change in EP.

A yarn-based biobattery utilizes the bacterial respiration system to generate green electricity [73]. The biobattery comprises polystyrene-sulfonate-based anodic and one cathodic yarn, which ensures maximum electron transfer from the microorganism to the electrode. Multiple yarns are arranged in parallel, making the biobattery easily scalable. The maximum current densities for typical 3-series, 2-parallel, and single biobatteries are 22.10 W/m, 19.14 W/m, and 2.12 W/m, respectively.

Hydroelectric Generators

The use of the hydro-voltaic effect for energy harvesting is an emerging area that falls into the biochemical category. The hydroelectric generator (HEG) uses the interaction between the water molecules and nanomaterials [74,75]. Low-dimensional materials such as carbon nanotubes and graphene can generate electricity at the solid–liquid interface while interacting with the water molecules.

Electricity generation by water evaporation and humidity does not require any additional mechanical force [76,77]. For instance, the flow of water molecules in nanomaterials’ gaps in the evaporation process induce electrical voltage and current. An electrical double-layer is formed at the channel wall surface due to the attraction between hydronium ions and negatively charged nanocarbon layers. During evaporation, the channel hydronium ion moves in the water flow direction, generating a potential difference and a resultant output current flow [75]. For example, up to 1.0 V and 150 nA of current can be generated using the water evaporation process on the annealed and plasma-treated carbon black film surface [78]. Another electricity generator using the water evaporation process was presented in [79], which uses silicon nanowire arrays. An output power density, current density, and voltage of 6 Wcm, 55 A cm, and 400 mV, respectively, were achieved while the ambient temperature was 65 °C and the relative humidity was 45%. The device used silicon nanowires as the active layer, graphite as the cathode, and silver as the anode.

The concept of humidity-induced electricity is the reversible process of hydration and dehydration. The free hydrated ion in this process migrates due to a concentration gradient triggered by moisture, creating an electrical output [77,80]. An output power density of 0.246 mW cm is achieved in a moisture-enabled HEG utilizing humidity variation from 5% to 95% [81]. A porous membrane captures the moisture, triggering the hydration and ion transport, and an electric potential is generated by the movement of the cations and anions. In an HEG using an arrangement of silver wire, graphene oxide can achieve a 0.21 Wcm output power density under a 70% humidity change [81].

A wearable perspiration analyzer was presented in [82], which uses the coupling of enzyme reactions and an HEG. The system consists of ZnO nanowire arrays modified by lactate oxidase and a flexible PDMS substrate. While attached to the skin, sweat flows through the microchannels to the ZnO array, producing an electrical current using the HEG principle. An electronic sensor using moisture-induced electricity was presented in [83]. The protein films of gelatin molecules serve as the active materials and generate considerable electrical output while the humidity level exceeds 55%. This device demonstrates potential application in wearable masks to monitor users’ breathing conditions. In addition, it finds application in evaluating the finger wound healing condition [83], detecting alcohol consumption [84], etc.

3.1.2. Biomechanical Energy Harvesting

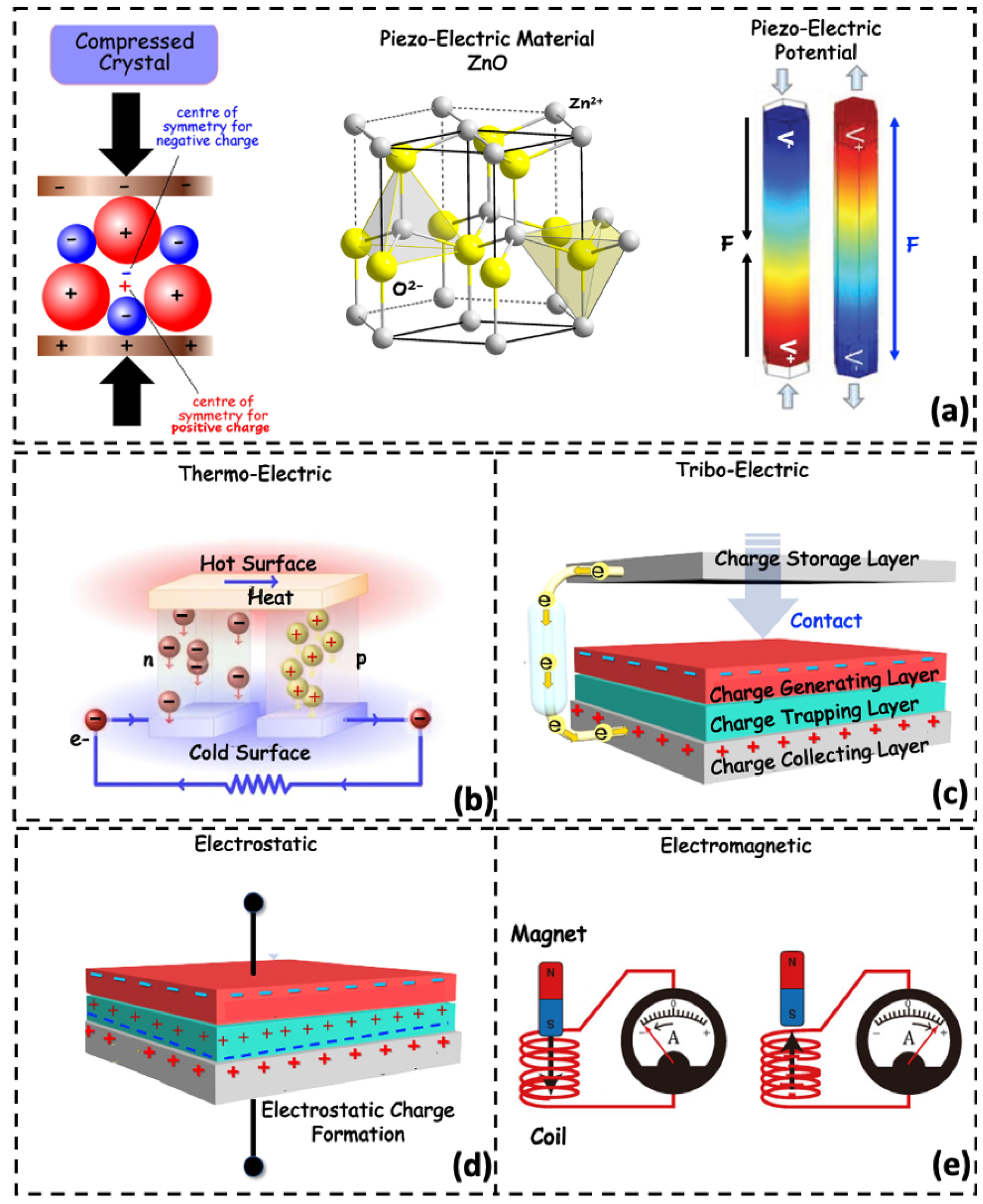

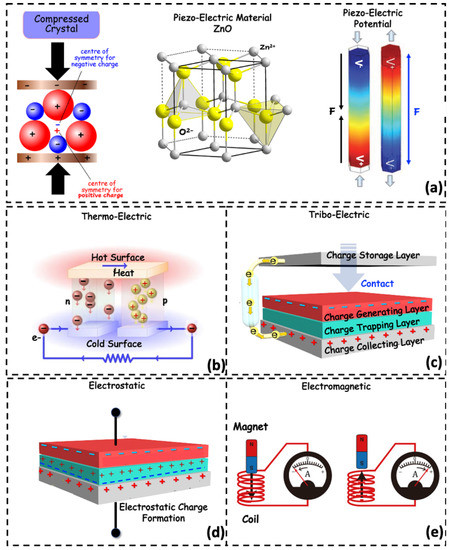

Human body motion can generate electrical energy. For instance, foot strikes, muscle movements, etc., can be converted to an electrical form, sufficient to operate wearable devices [85]. In addition, involuntary periodic activities such as cyclic breathing and rhythmic heart motion can generate electric energy for implantable devices and can be enhanced to operate on wearables. A low-power cardiac pacemaker was presented in [86], which achieves 11.1 J of electrical energy from a 90 bpm heart rhythm. The air pressure gradient due to breathing cycles develops a miniaturized wind turbine to operate wearables placed in face masks [87]. Human-centric energy harvesting from kinetic energy is discussed in this section identifying five techniques: piezoelectric, electrostatic, electromagnetic, thermoelectric, and triboelectric energy generators [88,89]. The energy conversion principles of different biomechanical energy harvesting processes are illustrated in Figure 3 and discussed in the subsequent sections.

Figure 3.

Schematic illustration for working principle of various types of biomechanical energy harvesting schemes. (a) Development of electric potential while the piezoelectric crystals are compressed/strained. (b) The temperature gradient between a hot and a cold surface on a thermoelectric material develops an electric potential and a resultant current flow. (c) Charge generation at the interface of triboelectric pair materials by contact friction. (d) Charge storage on the dielectric material inside two metal contacts by electrostatic action. The charges deposited in the triboelectric and electrostatic scheme store energy by capacitive coupling. (e) A moving magnet inside a coil produces a potential difference by Faraday action.

Piezoelectric Energy Generators

Advancements in microelectronics led to the development of implantable electronics (IMEs). Besides, emerging materials helped revolutionize the energy harvesting applications for IWM devices. One such material is piezoelectric materials, which directly convert mechanical energy into electricity without requiring conversion. An electric field, thus voltage, is generated while the piezoelectric materials experience mechanical stress, which is used in energy harvesting [90]. A schematic illustration of the piezoelectric energy harvesting principle is shown in Figure 3a. For instance, while running, the piezoelectric materials integrated with the sole and heel can produce 2 mW and 8 mW of electrical power, respectively [91,92]. In a broad sense, piezoelectric materials are classified as crystals and ceramics [93]. The ceramic polycrystalline lead zirconate titanate (PZT) is one of the popular materials due to its high piezoelectric coefficient and low fabrication cost [93].

Researchers have demonstrated that a magnetic microgenerator placed on the heel can generate around 1 W of power [91]. This system is appropriate only for users capable of walking, and the placement in shoes might induce user discomfort. An energy harvester for a total knee replacement (TKR) implant was presented in [94], generating 4.8 mW of power with an excitation load of 900 N using three PZT stacks. The sensitivity of ceramic piezoelectric materials degrades over time. In recent studies, single-crystal materials such as lead magnesium niobate–lead titanate (PMN-PT) and lead–zinc niobate–lead titanate (PZN-PT) have demonstrated promising results [95,96]. The lead-integrated piezoelectric materials are toxic and may stimulate health risks. Because of that, single-crystal zinc oxide (ZnO) materials have gained attention for their non-toxic and biocompatible behavior. In [97], ZnO-based nanogenerators harvests energy from rat heartbeat. However, the amount of energy is insufficient to operate IMDs, and an array arrangement of ZnO nanowires is necessary to obtain enough energy, which increases the cost [98].

It is to be noted that IWM devices need flexible, extremely slim, and lightweight media for successful attachment and operation. Researchers have been developing high-performance piezoelectric energy harvesters using organic and inorganic materials such as polymers, ceramics, and single crystals for attaining such features. Polyvinylidene difluoride (PVDF) is a flexible piezoelectric polymer, suitable for energy harvesting. The limitations of piezoelectric polymers are the low power density and coupling coefficient [93]. A hybrid material using both ceramics and polymer piezoelectric materials resulted in improved performance showing an output of 3.8 W/mm from the movement of a hand [99]. To this date, flexible thin film piezoelectric materials remain an appropriate choice for energy harvesting due to their soft nature and adaptability to human organ shapes [93,100].

Mechanical-pressure-induced piezoelectricity due to blood pressure variations was demonstrated in [101], generating 2.3 W of power. Similar experiments were carried out in [102] using PVDF transducers to generate energy from blood pressure gradients. Piezoelectric ceramics embedded into orthopedic implants at different body locations have shown promising results of 4.8 mW [103], 1.2 mW [104], and 1.81 mW [105], respectively, depending on the size and thickness of the piezoelectric materials. In [106,107], 40 W and 60 W piezoelectric generators were presented using zirconate titanate and aluminum nitride, respectively.

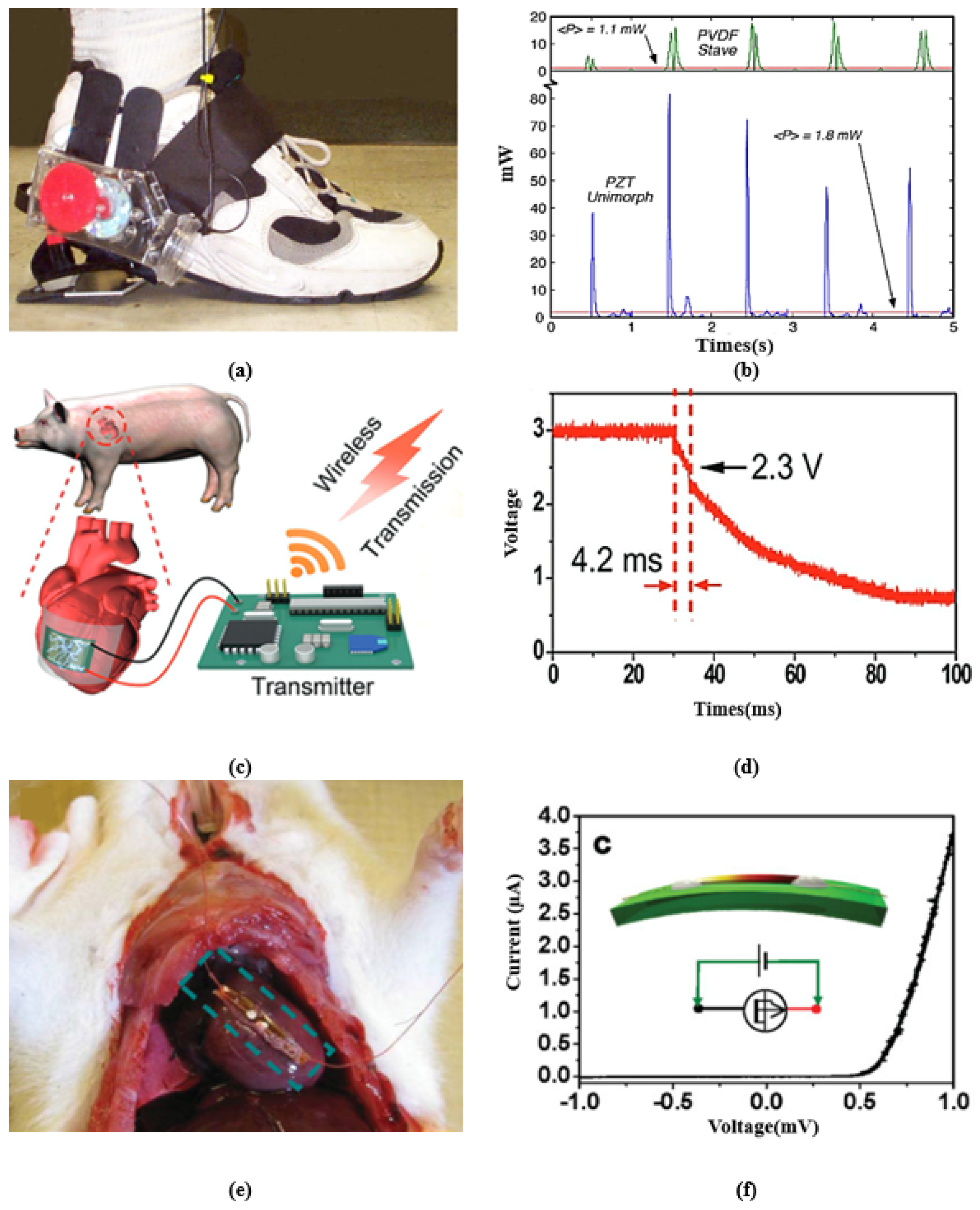

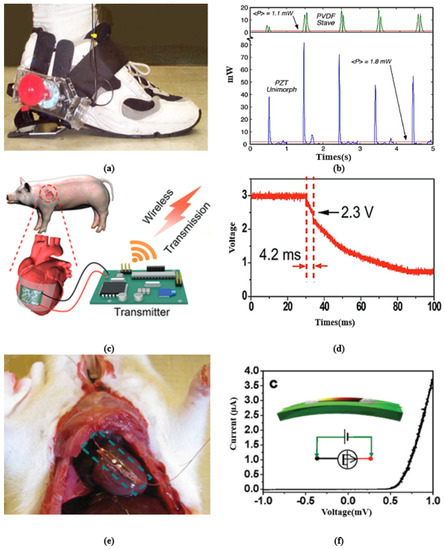

A single-wire nanogenerator driven by heart muscles’ motion was designed in [97], producing an average voltage of 3 mV and a current of 30 pA. A wearable PVDF-array-based device developed in [108] can harvest energy during running with 8.6 mW of output power. A belt-type piezoelectric energy harvester was presented in [109], which generates an output from the waist movement, producing an open-circuit voltage in the range of 1.5–1.8 V for normal and fast respiration processes. A flexible PEH-based sensor was developed in [110], which scavenges energy from respiration or shouting and the movement of muscles. Figure 4 presents some remarkable examples of piezoelectric energy harvesting in IWM devices from walking, cardiac motion, and breathing with their output characteristics. Figure 4a presents a system to harvest parasitic power in shoes. The system holds a generator in such a way as to give full pressure to the lever at the hinged heel plate. Figure 4b presents the resulting power delivered to the load by these systems. A flexible energy harvester is presented in Figure 4c, which is attached to a porcine heart, generating power from cardiac contraction and relaxation motions. The capacitor stores energy obtained from cardiac motion, finally transmitting the data to the receiver wirelessly. Figure 4d depicts the change in voltage activated by wireless data transmission where the steep slope in time from 29.8 to 34 ms implies the successful transmission of data. Figure 4e demonstrates the implantation of a single-wire generator (SWG) in a live rat to scavenge energy generated by its breath and heartbeat. This study illustrates that harvesting low-frequency dynamic muscle motion drives nanogenerators to bend periodically and generate an AC power output. Figure 4f gives the I-V characteristics of the nanogenerator.

Figure 4.

(a) A shoe-mounted rotary energy generator. (b) Output power from shoe-mounted rotary energy generator. Reprinted with permission from [91]. Copyright 1998 IEEE. (c) Flexible energy harvester using cardiac motions with storage capacitor and wireless transmission. (d) The resultant output voltage from the generator reported in [95]. Adapted with permission from [95]. Copyright 2017 WILEY-VCH Verlag GmbH & Co. (e) Single-wire energy generator from the beating heart of a living rat’s diaphragm. (f) I-V characteristic of the generator. Adapted with permission from [97]. Copyright 2010 WILEY-VCH Verlag GmbH & Co.

Being one of the most popular choices in biomechanical energy harvesting, the piezoelectric nanogenerator (PENG) drew much attention in recent times. In a broad sense, the four-circuit category has been discussed and incrementally improved over the last two decades for coupling interfaces of PENG. These are standard energy harvesting (SEH), synchronized charge extraction (SCE), parallel synchronized switch harvesting on inductor (P-SSHI), and series synchronized switch harvesting on inductor (S-SSHI) circuits. Different electro-mechanical coupling conditions can alter the charging of the energy storage element. A numerical study was performed considering numerous design space factors [111]. Recently, a self-powered array interface circuit based on synchronized switching and discharging a storage capacitor through an inductive coupling technique (SSDCI) was presented [112]. The SSDCI array circuit achieves an efficiency of 82.3% and allows a gain of up to 300% in comparison to the maximum output power generated by the full-bridge rectifier. Furthermore, a self-adapting synchronized switching interface circuit using a 180 nm CMOS process node [113] has been reported, which could achieve 500% more power compared to an ideal full-bridge rectifier. In principle, the piezo-electronic energy harvester uses inductive coupling techniques for power transfer, which is discussed later in this review.

Overall, the piezoelectric-based energy harvesters produce the highest power densities among the energy harvesters that use human vibrations. The limitations of piezoelectric energy harvesters are their frequency-dependent nature and inefficiency at low-frequency human motion.

Electrostatic Transduction

Mechanical vibration can generate electrical energy by transducing electrostatic energy suitable for implantable biosensors requiring ultra-low power. Electrostatic-transduction-based energy harvesters follow the fundamental principle of Coulomb’s Law. The capacitance changes between two parallel plates, typically electrically separated by air, a vacuum, or a dielectric. The forces of attraction between these oppositely charged plates vary with gap distance or area modulation. Therefore, by changing the capacitance of these vibration-dependent conductors, the mechanical energy from the vibrations can be converted into electrical energy. This principle is illustrated in Figure 3d. Typically, the power efficiency of electrostatic devices is improved by lowering the surface region or volume of the plate. Hence, the electrostatic generators are efficient at smaller scales and well suited to microelectromechanical systems’ (MEMS) fabrication. For example, a MEMS sensor with a parallel plate capacitor can generate 8 W of power through electrostatic induction [114]. Various comb structures have been explored such as finger teeth in an interdigitated shape [115] or a symmetrical three-port structure to increase the power output density up to 270.22 Wcm [116].

The limitations of a capacitor-based system are the requirement of recharging, low energy efficiency, and being suitable only for low-power implants. Integrating a MEMS with a variable capacitor ranging from 32 nF to 200 nF demonstrated 58 W of power generation from cardiac motion [117]. Another MEMS-based electrostatic inducer for energy harvesting in biomedical IWM devices was presented in [118], generating 80 W of power. Electrostatic generators/transducers have shown promise and commercial usability in numerous biomedical applications.

Recently, electrostatic energy harvesting has gained attention for delivering energy to implantable medical devices. For instance, ventricular motion and heartbeat energy can produce 36 and 58 W of power, respectively, to operate cardiac pacemakers using a variable capacitor electrostatic generator [117]. However, the variable-capacitor-type resonant structure is ineffective in generating energy from low-frequency human motion. A non-resonant MEMS structure was studied in [118], producing 80 W of power from nonperiodic human motion. In [119], generators using microfluidics were demonstrated to obtain 230 mW of power using the electrostatic harvesting approach from chest diaphragm motion.

Apart from MEMS, inexpensive, high-performance variable capacitance mechanism devices are an option. Such devices use printed dielectric ink made of nanocomposite materials in combination with commercially available conductive elastomers. These elastomers utilize a dielectric membrane with flexible electrodes. The deformation of this uniform membrane can act like a dielectric elastomer generator system (DEGS) [120]. Low leakage current and high cycling stability have been reported for such flexible electrostatic energy harvester prototypes. One provided a power density of 160 Wcm, over 1000 cycles at a low frequency of 0.5 Hz, making the device feasible for practical wearable applications [121]. Liquid metals were recently explored to use as the electrode material in addition to a dielectric layer. The upper limit for the relative permittivity MEMS and elastomer harvesters is 1–3, respectively, whereas liquid metals can easily accommodate the high efficiency of the device by using high-dielectric-constant (high-k) materials. The harvester electrodes have been developed with mercury [122] and, subsequently, with room temperature liquid metal alloys (Galinstan) [123]. However, mercury is a toxic material having a potential risk of oxidation of liquid metals. Researchers are looking into replacing the droplet electrode with an electrically conducting elastomer. Currently, with revolutionary advancements in printed electronics, it is even possible to print complex nanocomposite formulations for electrode structures in applications of IWM devices.

Another cutting-edge research is the electrostatic rotational energy harvester. A stochastic model of a rotational energy harvester based on arm swing was presented in [124]. Similar works for harvesting energy from human motion was demonstrated in [125,126] by using metal ball bearings. The system can scavenge up to 80 W of power from the arm swing while walking at a speed of 1.45 m/s. One of the main disadvantages of using this technology is the requirement of some seed input of energy. The addition of an electret layer, which acts as a permanent charge buried within a dielectric layer made of CYTOP polymer material, has been shown to overcome this challenge [127].

The advantages of electrostatic energy harvesters include (i) compatibility with micro-scale IMDs, (ii) high efficiency in ultra-low-power IMDs, and (iii) high efficiency in low-frequency human-centric (heartbeat, ankle, hip, knee, etc.) kinetic energy harvesting [26,28]. The necessity of pre-charging, the high output impedance, and the low output current are the challenges of using electrostatic energy harvesting for IWM devices.

Electromagnetic Induction

Oscillating magnetic fluxes induce an electric field in a winding based on Faraday’s Law, which is the working principle of electromagnetic induction. The electrical output is dependent on the strength of the magnetic field, the relative motion, and the number of turns in the winding [128]. The basic working principle is shown in Figure 3e. For instance, an electromagnetic generator was presented in [129], where a permanent magnet in the abdomen oscillates relative to the conductive coil due to motion. The system can generate 1.1 mW of power utilizing 0.3 Hz human motion. An electromagnetic generator using heart motion was presented in [130], producing 6 W of power. There has been another demonstration of an electromagnetic generator utilizing heartbeat, sewn into a sheep’s heart, producing 16.7 W by the electromagnetic oscillation [86]. Blood flow and pressure were also demonstrated to be effectively converted to 3.4 mW of power in [131] using an electromagnetic generator. Using the heart movement to design an energy harvester can minimize life threats, avoiding multiple replacements of cardiac pacemakers. Energy harvester for endocardial implantation was presented in [132,133,134]. The device operates on the electromagnetic induction principle, containing a microgenerator producing 4.2 W of output power. Furthermore, the same group proposed an energy harvester, in which an eccentric oscillating mass captures external heart excitation and converts it into the rotation of an electromagnetic generator, harvesting an output power of 6W. A curved electromagnetic energy harvesting system that can capture energy through human oscillatory walking motion was presented in [135]. The experimental results showed that the harvester can produce 5.185 mW of power. An energy harvester is placed in a backpack to utilize low-frequency and high-amplitude vibrations, which leads to an output peak power of up to 32 mW while walking at a speed of 3.58 m/s [136]. The significant weight and flexibility of the electromagnetic energy harvester are the main challenges for proper energy supply to IWM devices without causing damage. For the benefit of size, research efforts have been devoted to utilizing MEMS in electromagnetic energy harvesting [137,138]. For example, a MEMS-sensor-based velocity-damped resonant generator was demonstrated to generate 10 W of power [139]. Similarly, 3.9 W of power was obtained from the ankle motion using a magnetic induction generator for miniaturized IWM devices [140]. Flexible electromagnetic devices are gaining huge popularity due to device compatibility with energy-scavenging applications. A low-cost, flexible electromagnetic energy harvester was designed in [141] utilizing a polymeric magnetostrictive ribbon and poly-vinylidene fluoride (PVDF), which gives an output power and power density of 6.4 W and 1.5 mW/cm, respectively. Nonlinear dynamic characteristics are studied in [142], where the vibration energy harvester generating an output power of 620 W was designed using the Terfenol-D/PZT composite proposed. A similar type of vibration harvester was designed with micro-machined flexible polyimide films producing a 5 W peak output power [143]. However, MEMS fabrication is a complicated process, and the energy efficiency is low, which limits its widespread adoption.

Furthermore, the kinetic energy associated with blood flow can be a source of energy harvesting. An electromagnetic (EM) generator made of metal coils and permanent magnets has been demonstrated to harvest energy from blood flow [144]. A stack of magnets oscillating under the influence of external body acceleration would generate electrical energy based on EM induction. An EM generator device implanted in the right ventricular cavity of a pig and fixed on the endocardium could achieve a power of 0.78 W. Another EM generator placed in the pig heart through a catheter utilized intra-cardiac turbine motion to harvest energy from blood flow [133]. The device weighed about 1.3 g and output power in the 10.2 ± 4.8 W range.

Over the years, EM generators have been proven to be a sustainable method for kinetic energy harvesting. Traditionally, these energy harvesters are designed and fabricated using a resonant structure [145]. However, the resonant frequency ( 100 Hz) is much higher than the frequency of human motions (<5 Hz). This difference leads to a non-resonant condition and may cause poor efficiency in energy conversion. Thus, they need a coupling interface and an energy extraction circuit for extracting magnetic flux in synchronization. This circuit enables the rectification and the amplification of the voltages produced by an EM energy harvester at optimum levels. Apart from the popular choice of a nonlinear coupling interface [146], researchers have also demonstrated energy harvesting with a linear energy extraction circuit comprising a full-wave bridge rectifier. Frequency up-conversion structures [147] and rotational structures [148] have also been reported for energy harvesting at an ultra-low frequency.

In general, more energy can be harvested in an electromagnetic generator compared to an electrostatic generator. However, the reported output energy is comparatively low than the piezoelectric energy harvesters. The limitations of electromagnetic energy harvesters include low output power and low impedance, resulting in high output current [89]. Therefore, extra circuitry is required to obtain power conditioning. In addition, the EM generators can cause electromagnetic interference (EMI) with other medical devices, which can limit the application of this type of energy harvester.

Thermoelectric Methods

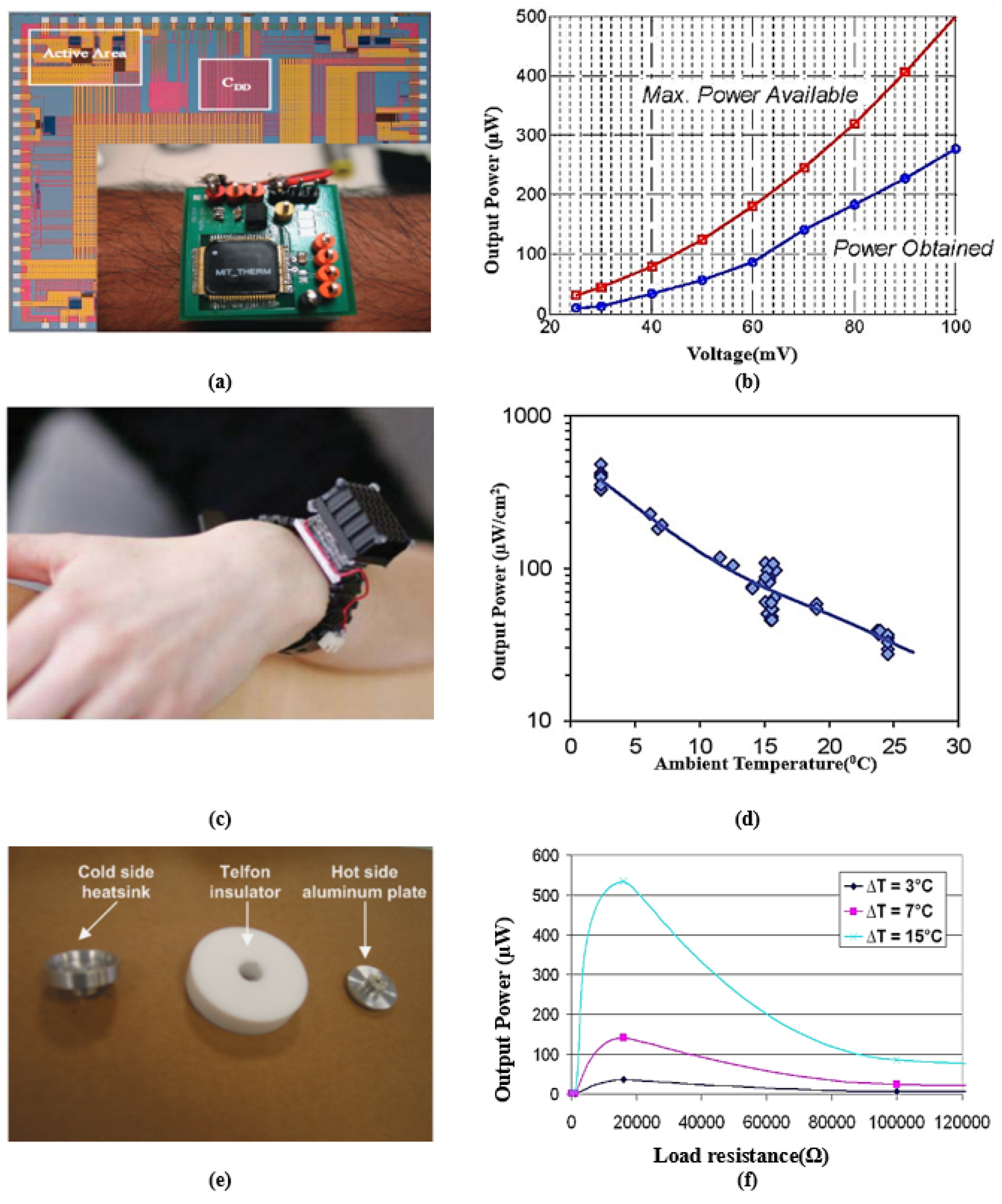

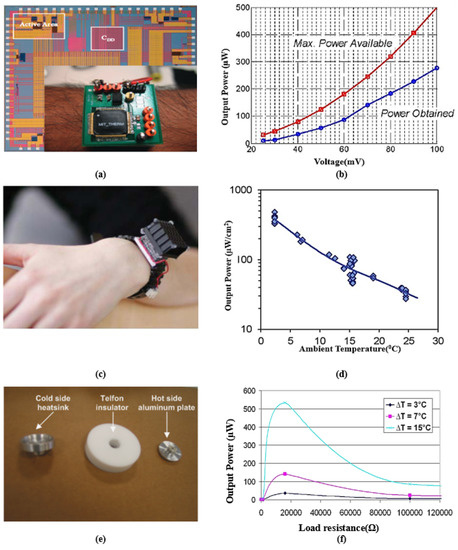

The concept of a thermoelectric energy harvester is the Seebeck effect, which uses temperature differences to generate electric energy. The temperature gradient between the body and the ambient environment is converted to a voltage output. A system overview of this category of energy harvesting is shown in Figure 3b. Both metals and semiconductors can be utilized to harness energy using the Seebeck effect. However, the Seebeck effect is much more prominent in semiconductors. A basic thermoelectric generator (TEG) for IWM devices consists of a series of connected n-type and p-type semiconductor materials, resulting in electron movement from the hot terminal to the cold one. Such electron movement produces a potential difference, resulting in a current flow in the closed circuit. Bismuth telluride, calcium manganese oxide, and lead telluride are a few examples of thermoelectric materials. The advantages of these materials are low thermal and high electric conductivity, compact size, light weight, long operational lifetime, and high Seebeck coefficient [27]. The output voltage of TEGs can be boosted using multiple p-n semiconductor connections in series, forming thermopiles [149]. The Seebeck effect can potentially generate sufficient power to operate implants such as nerve and muscle stimulators, hearing aids, etc. [150,151]. However, when the temperature gradient is below 5 K, only a few hundred microwatts of power can be extracted from the human body. For instance, exploiting the 5 K thermal difference, W [152] and W [153] of power is generated using a TEG of a size of 0.19 cm and 1 cm, respectively. A recently reported TEG demonstrated an output power of around W, exploiting the 5 K temperature gradient. Thermopiles can be integrated into wearable textiles to generate electrical energy from body heat [154]. For example, a cold plate of 4 cm in diameter was glued to carbon fabric, generating up to mW of power, where the ambient environment temperature varied from 15 °C to 27 °C. In [155], an IMD with an integrated accelerometer powered by a TEG to detect falls was presented, scavenging W of power at 15 °C. Illustrations of different TEGs are presented in Figure 5. Figure 5a shows an interfacing circuit for a batteryless thermometric energy harvester fabricated in a m CMOS process. An efficient control circuit was designed for transferring the obtained energy to a capacitor, which controls the output voltage at 1.8 V. Figure 5b presents the measured output power achieved from the buck converter compared to the maximum power extracted from the TEG. Figure 5c demonstrates a wearable TEG. The non-uniformity of skin temperature is dependent on the ambient temperature. Hence, the output power extracted from the TEG depends on the location and clothes. Figure 5e presents the design of a TEG structure using Aluminum and Teflon. Aluminum is used to design the hot plate for fast heat collection, while the cold plate works as a heat diffuser. Teflon works as an insulator sandwiched between the hot and cold plates, reducing the convection and radiation of heat to prevent warming of the device. Figure 5f presents the output power curve, which varies between 40 W to 520 W.

Figure 5.

(a) Interface circuit of thermal energy harvester where the inset presents the thermoelectric generator (TEG) chip worn on the arm. (b) Measured electrical power from the buck converter vs. maximum power available from the TEG. Reprinted with permission from [149]. Copyright 2010 IEEE. (c) Wearable TEGs with a cm radiator. (d) Output power variation with ambient temperature for a TEG. Reprinted with permission from [154]. Copyright 2013 IEEE. (e) A prototype of a TEG, harvesting energy from the human body. (f) Output power obtained from a TEG at different loading conditions. Reprinted with permission from [155]. Copyright 2009 IEEE.

Flexible and wearable electronic devices have gained significant attention owing to their light weight, easy accessibility, and ability to endure mechanical deformation. Polymer-based TEGs have gained widespread popularity due to their low cost, light weight, fast processing, mechanical flexibility, and low thermal conductivity. Organic thermoelectric nanomaterials were presented in [156], where single-wall carbon nanotubes (SWCNTs) were stabilized by poly. A high-performance thermoelectric poly (3-hexyl-thiophene)/CNT (P3HT/CNT) nanoparticle and flexible P3HT/CNT organic TEG were prepared in [157], using a spray-printing method, which exhibits excellent thermoelectric performance. A printable TEG composed of organic materials, graphene, PANi, and a double-wall nanotube (DWNT) was developed in [158] using a layer-by-layer assembly technique. Formulating an n-type SWCNT by doping diethylenetriamine (DETA) on the pristine SWCNT (p-type) was presented [159]. The pristine CNT presented a Seebeck coefficient of 43 V/K, and the DETA-doped CNT exhibited a negative Seebeck coefficient of V/K.

The fabrication of p- and n-type thin films for thermoelectric applications was demonstrated in [160] by doping tetrathiotetracene (TTT). A novel wet-spinning process was explained in [161] to develop an organic TEG using nanocomposite materials. The design of flexible thermoelectric threads using 3D-printable composite inks was introduced in [162]. A TEG prototype based on nanofibers was assembled in [163], which generated an output power density of Wcm from human body heat. This work forms the pathway to developing high-performance polymeric and flexible materials for TEGs.

Because of the low conversion efficiency, it is crucial to have a well-designed power conditioning module and coupling interface. Researchers have demonstrated a CMOS interface circuit in the 130 nm process, gaining up to 90% efficiency employing a single inductor-based buck–boost converter [164]. The proposed system also employed an automated zero-crossing detection feedback scheme to improve power efficiency. In addition, there has been a demonstration of an all-integrated MEMS thermoelectric power chip [165].

The limitations of TEGs are their low conversion efficiency and the high cost of realizing these devices. For instance, with a K temperature gradient in the human abdomen, one thousand thermocouples are needed to achieve W of power, requiring an area of cm [166]. These large area requirements in implantable and wearable devices are not practically feasible. In addition, due to low output voltage, TEGs require extra circuitry for boosting the converter, control, and initial start-up.

In achieving a high power density, researchers have been looking for newer materials. In simulation, different emerging materials are explored for better efficiency. It has been reported that phase-change materials can be used to enhance the thermal performance of a TEG by around 30% when the heat input is at around W [167]. Therefore, improved power conditioning methods, low-power start-up, efficient MPPT design, and novel thermoelectric material design are a few research prospects to commercialize TEGs.

Triboelectric Energy Harvesting

Triboelectric energy harvesting is an emerging technique to meet the energy needs of implantable and wearable medical devices [168]. The triboelectric nanogenerator (TENG) uses the electrification effect to generate energy. The charge is produced by the friction at an interface of two different materials, also called the triboelectric pair [169]. Electrodes are placed on each material, and the electrification effect is combined with the electrostatic induction to obtain a usable amount of power [170]. A representative working principle is shown in Figure 3c. Significant improvement has been observed in TENGs over the last few years, enabling the conversion of energy from gentle touches [171], palm tapping or walk [172], eye blinks [173], and vibration [174] into electrical energy. For example, human motion due to mild running at a speed of 5 m/s can generate 5.28 W of power [175]. A biodegradable TENG made of organic materials based on gelatin film was shown in [176]. This prototype can generate an output voltage, current, and power density of up to 500 V, mA/m, and 5 W/m, respectively.

Triboelectric materials are flexible and cost-effective. In addition, the high power density, pressure sensitivity, and conversion efficiency of TENGs have made them a promising energy harvesting technique for IWM devices [170]. For instance, a heart rate monitor was presented in [177] using a TENG to meet the energy need. The system can generate 2.28 mW of power, having an excellent 57.9% conversion efficiency using human walking motion of 10 Hz. However, the surface charge density retained in the dielectric layer of the TENG depends on the dielectric breakdown of the air, limiting the amount of harvested energy [178]. There has been ongoing research for various composite materials for TENGs. Nanowire arrays made of cobalt selenide on a Kevlar fiber and reduced graphene oxide dispersed in PDMS have been reported to output 1.1 mW cm, even at a low frequency of 5 Hz [179].

In addition, the pulsed output power, low current, and frictional damage in the contact surface are a few other limitations of TENGs. The triboelectric energy harvesting technique is still in the development phase and improvements are necessary to adopt it in powering IWM devices.

A summary of representative research in biomechanical energy harvesting is presented in Table 1. There is a lack of a universal figure of merit (FOM) for a fair comparison of energy harvesters. The performance of energy harvesters often depends on techniques, device architectures, materials, circuits, and various operational modes. The output power per unit volume, termed output power density, is a widely used metric for energy harvesters. Energy conversion efficiency is another FOM, which is the ratio of the output of the electrical form to the input, which can be biochemical, mechanical, light, heat, etc. The output voltage, current, power, power conversion efficiency, device dimension, weight, open circuit voltage, operating frequency, etc., are often used to quantify the performance of different energy harvesters. Due to wide acceptability and availability in the literature, the output power density is summarized in this review paper to provide an idea of the performance of representative energy harvesting research.

Table 1.

Summary of representative research on human-centric biomechanical energy harvesting.

Overall, biomechanical systems utilizing the kinetic energy from human body motion require a relatively larger size, producing low power. The output power of thermoelectric generators is low, which is insufficient for most IWM devices. There are challenges, as well as research opportunities to improve these energy harvesting techniques, as discussed in Section 8.

3.2. Environment-Centric Energy Harvesting

Energy harvesting from the environment scavenges electrical energy from various sources, including solar, infrared, RF, and wireless power transfer (WPT). This section presents different energy sources and state-of-the-art research to harvest energy from the environment.

3.2.1. Infrared Radiation

Earth continuously emits infrared heat into outer space in the range of Gigawatts [180]. Capturing even a fraction of that would end energy woes. Like the Seebeck effect in TEGs, whenever heat flows from a hotter to a colder body, energy can be harvested. One way to attain this is to treat waste or infrared heat as high-frequency EM waves. Appropriate antennas can collect these EM waves for further processing and use in IWM devices.

Some implantable devices have experimented with harvested energy from infrared radiation such as cardiac and brain-implanted pacemakers. A photodiode is usually implemented as part of implantable medical devices to capture infrared radiation [181]. For example, an implantable cardiac pacemaker presented in [182] achieved mW of power from infrared radiation. Biological tissue works as a source of wireless power transfer (WPT) in the near-infrared region (NIR) within the optical range of 650–1350 nm [183,184,185].

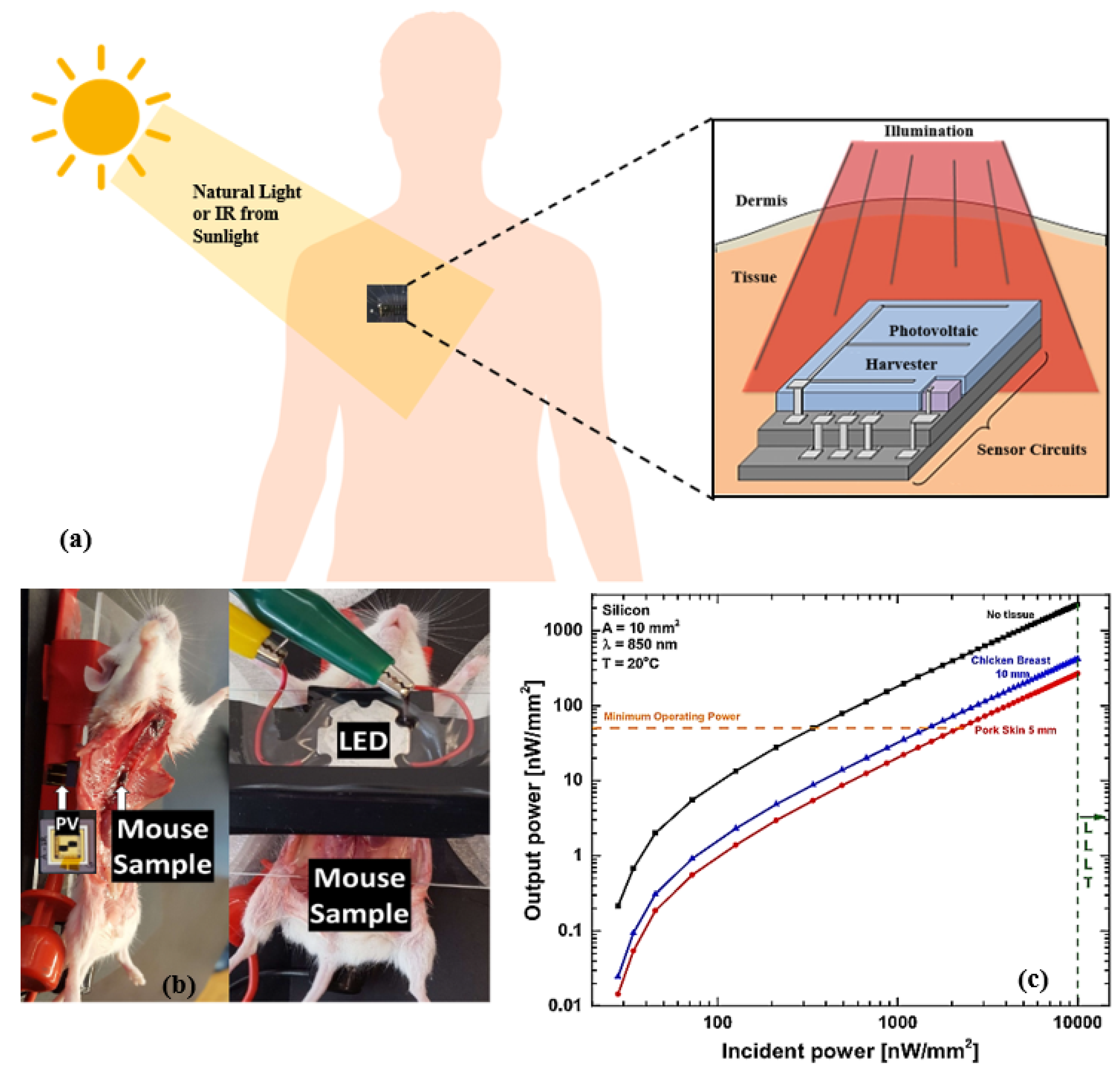

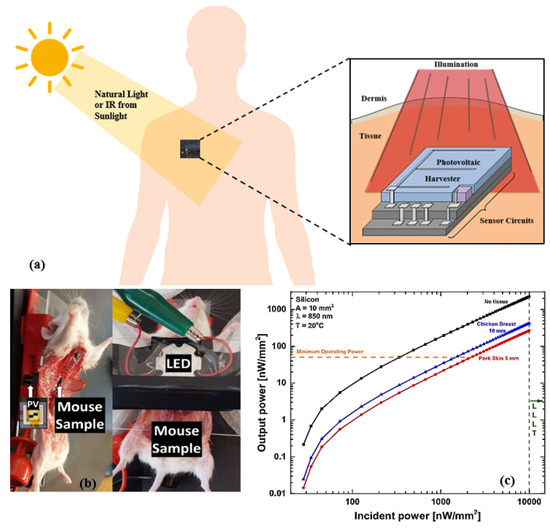

Figure 6 illustrates the concept of NIR subcutaneous energy harvesting in human, mouse, and output power variation in a photovoltaic (PV) cell implanted in a chicken breast. Silicon or GaAs PV cells convert energy in the NIR with an approximate external quantum efficiency of 100% [186,187]. As NIR can penetrate through the skin, researchers demonstrated its application in powering biomedical devices [188,189,190,191,192,193]. An artificial NIR light is attached outside the skin, which can be used as a reliable energy source. A recent work in this area presented a design of a rear reflector based on the bandgap of implanted PV cell materials, which utilize the transmission efficiency of NIR light underneath the skin [194]. The design in [192] includes a PV cell for biomedical implants, which uses infrared irradiation (850 nm), giving an output power density below 1.06 W/mm. Figure 6b illustrates the dissected sample of mouse placed between the LED and PV cell. Extracted energy is measured using LED irradiance and PV cells placed underneath the mouse. Relevant work on subcutaneous infrared energy harvesting for IMDs is reported in [190,191] with an output power of 60 W and 8.2 W, respectively. However, the limitations of using infrared radiation for IWM devices include increased skin heating, stimulating tissue damage, a low amount of harvested energy, and large device size occupying a large area, resulting in high power consumption.

Figure 6.

(a) Schematic of photovoltaic energy harvesting through subcutaneous tissue. (b) NIR energy measurement from photovoltaic cells implanted in mouse. (c) Incident versus output power of a silicon photovoltaic cell implanted at a 5 mm depth in porcine skin and a 10 mm depth in chicken breast using low-level laser therapy. Adapted with permission from [192]. Copyright 2017 IEEE.

IR transmission possesses several advantages in terms of the design of the coupling interface. These advantages include simple and relatively low-cost circuit fabrication, low power consumption, high noise immunity, etc. Infrared or near-infrared is usually employed for harvesting energy for under-skin IMDs. For those applications, regular IR transmitter–receiver systems have shown satisfactory performance [181]. It has been reported that transmitted power is dissipated in tissue by radiation and in coupling [212], causing permanent tissue damage. The transmitted IR radiation heavily depends on the distance between the source and target. The coupling interface and power transfer in IR are active research areas.

3.2.2. Radio Frequency Signal

Due to the widespread deployment and recent advancement in wireless communications technologies, energy harvesting from RF is gaining attention [213]. The EM waves used in wireless communications are available in ample amounts, which can be used in energy harvesting. For selecting a suitable operating frequency, different compact rectifying antennas (rectennas) have been designed using techniques such as dual polarization [214] or using emerging materials such as graphene [215]. The conversion performance of the designed rectenna is 80.23% with a signal input power of dBm. The size constraint of these invasive foreign substances in the human body led researchers to look into more compact solutions. A nanocomposite single-sided printed antenna can obtain an efficiency of 62.5% at 1.8 GHz [215]. However, the implantation of the rectenna is always a concern, leading to the proposal of a textile-based rectenna array [216]. The rectenna array could achieve a conversion efficiency of 70%. It has been demonstrated as a proof-of-concept that the system could power three LEDs at a distance of cm. A complete textile-based approach with an RF energy harvester and supercapacitor was shown in [217]. The system achieved a power conversion efficiency (PCE) of up to 80%. It can charge the supercapacitor to V in four minutes at a distance of m from the source. Moreover, wireless radio power and control systems employing thin, mechanically soft, implantable, stretchable RF energy harvesting schemes were used in neural implants using light-sensitive proteins [65]. An in-vivo demonstration in rat implants showed that the system successfully modulated peripheral and spinal pain circuitry.

One of the main limitations in an RF system is that it requires much peripheral circuitry, and sometimes, the size of those additional things might be even bigger than the sensor itself [65]. For that, researchers have looked into solid-state electronics solutions. For instance, Schottky barrier diodes are popular choices in rectification due to their low built-in voltage [218]. In [219], a wearable sensor tag was designed, which can monitor physiological signals such as PPG, body temperature, blood pressure, and respiratory sounds. The wearable sensors are powered by harvesting the RF energy from an mW source using a two-stage CMOS rectifier, generating 15 μW power at a m distance. Similar technologies were studied in [220,221], harvesting RF energy at different frequencies using CMOS circuits to power up IWM devices.

RF can provide a relatively predictable amount of energy, unlike other energy sources, which are dependent on natural forces. The near-field and far-field RF signals utilize different coupling interfaces. Inductive and magnetic resonance coupling is used in the near-field RF to extract the energy. In the near-field, a power conversion efficiency (PCE) of up to 50% can be achieved while having a limited transmission distance [222]. On the other hand, far-field RF harvesting technology uses radiative coupling. Power transfer in the electric field of the propagated waves can be specifically suitable for IMDs. However, this technology needs extra assisting circuitry such as a buck–boost converter, rectenna, and supercapacitor as coupling interfaces [223].

Wide abundance of RF sources is main advantage of harvesting energy from RF signals. However, the devices have low efficiency; the output efficiency sometimes can be unpredictable and depends on the distance between the source and the harvester and many other factors. The types of diodes used in the rectifier block and the impedance matching network, the shape, and the antenna’s size are a few of the challenging design blocks in the system.

3.2.3. Solar Energy Harvesting

Solar energy harvesters are a mature technology on the macro scale inspired by the photosynthesis process in plants. In a regular solar cell, an anode and a cathode are placed in a molecular dye. This arrangement can readily convert solar energy into electrons, thereby electrical energy, upon the availability of proper sunlight. Three types of materials widely used in solar energy harvesting in photovoltaic cells are amorphous, monocrystalline, and polycrystalline silicon. Amorphous silicon is suitable for wearable devices due to its flexibility, low cost, and high sensitivity to natural light, but it lacks widespread adoption because of its low energy efficiency of around 10%. On the other hand, crystalline silicon has a high conversion efficiency of approximately 15–20% in outdoor solar lights. The amount of harvested electrical energy is linearly related to the size of the solar cell and the amount of light illumination. For example, up to 100 mW/cm of energy with an efficiency of 15–20% can be achieved during the daytime [224]. For an indoor environment, the conversion efficiency of 8% and an energy density ranging from 10–100 W/mm is achievable.

Consumer electronics such as calculators and wristwatches have efficiently been using solar energy for several decades [225]. Although solar energy is considered one of the prominent renewable energy sources, sufficient electrical energy can be harvested in miniaturized photovoltaic cells to operate low-power electronics. The typical solar cell consists of nonlinear semiconductor devices that generate electricity while exposed to light.

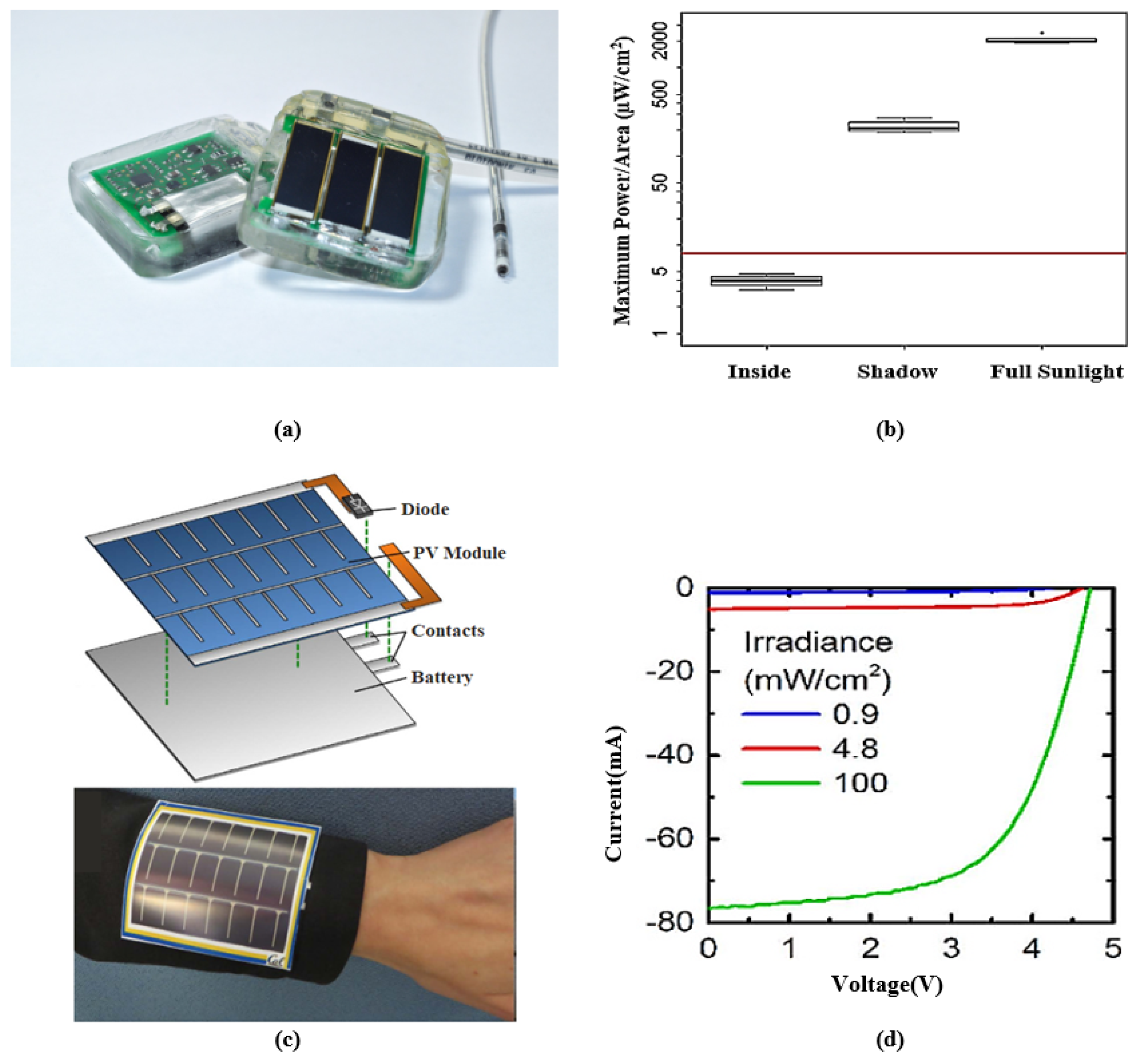

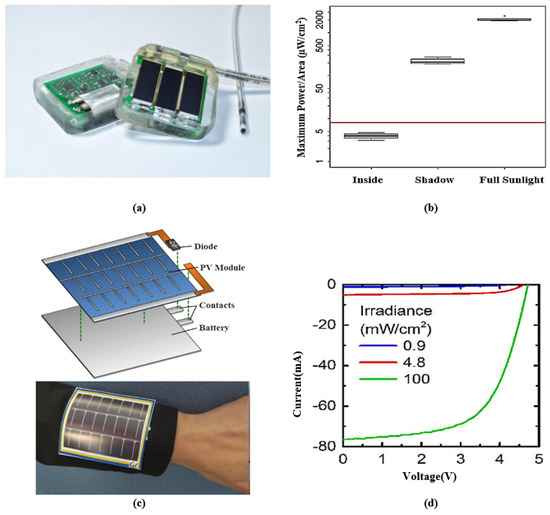

Although solar energy harvesting for IMDs remains challenging, the high conversion efficiency and availability make solar energy an attractive source for wearable devices. For instance, a wearable medical device was presented in [226], which uses monocrystalline PV cells for energy harvesting. The device can continuously monitor heart rate and blood oxygen saturation. An onboard mAh LiPo battery and a supercapacitor (which can deliver mW of power for up to 4 h) are charged when solar energy is available. A solar powered cardiac pacemaker and a flexible PV cell in a wristband are presented in Figure 7 with their output characteristics. Figure 7a presents a battery-less single-chamber pacemaker driven by solar energy harvesting. The PV cells are placed under pig skin flaps and exposed to different irradiation. The measured median output power presented in Figure 7b was found to be W/mm, W/mm, and W/mm for full sunlight outdoors, shade outdoors, and indoors, respectively. Figure 7c presents a wearable pulse oximeter with a flexible thin film amorphous silicon PV module. A flexible thin film lithium-ion battery was designed to operate this pulse oximeter. Since the PV module and battery were designed with flexible material, the system can be bent and attached to curved surfaces. Figure 7d illustrates the current–voltage (I-V) characteristics of the PV module under three lighting conditions.

Figure 7.

(a) A batteryless solar-powered cardiac pacemaker prototype; the rear part is lithium-polymer storage (silver color). (b) Boxplot demonstrates the output power at various irradiances. Reprinted from [232]. (c) Photovoltaic energy harvesting system with the flexible battery mounted on the curved surface (sleeves). (d) I-V characteristics of photovoltaic cell charging the flexible battery. Adapted from [227].

Amorphous silicon has allowed the development of flexible photovoltaic cells suitable for wearable devices [227,228]. For instance, a flexible printed circuit board (PCB) was presented in [228] to monitor body temperature, powered by solar energy. The excess energy is stored by incorporating a power management circuit. The device can operate uninterrupted for up to 15 h in indoor environments, requiring only about of light intensity. In addition, it can wirelessly transmit recorded information to a remote node at a GHz frequency. Moreover, incorporating flexible PV cells facilitates the reduced size and weight of the wearable device. Another flexible wearable device was presented in [229], which monitors heart rate, while an integrated accelerometer is employed for fall detection. Researchers have also explored organic materials as energy sources for IMDs. They offer cost-effectiveness, superior biocompatibility, and high sensitivity to NIR light. For example, printed organic solar cells have shown 7.6% PCE and 2.9% storage efficiency of supercapacitors for retinal implant, generating mJ of energy and mW of power [230].

In the NIR, the skin and subcutaneous tissues of the human body behave transparently to light illumination [192]. Hence, solar energy can be effectively converted to electrical energy in IMDs, using the photoelectric effects. Due to recent advances in CMOS technology, on-chip photovoltaic cells are feasible [231]. A PCE of 17% and 31% is achievable in silicon and GaAs PV cells, respectively, using 1.06 W/mm NIR light at a wavelength of nm. However, the GaAs material is toxic to the human body and requires proper encapsulation. Polymers such as silicone [232,233], polydimethylsiloxane [193], and diamond are often used in encapsulation due to their high flexibility.

The characteristic features of photovoltaic energy harvesting are high output power density, low fabrication cost, and telemedicine capacity through the optical link. However, the low irradiance in indoor conditions and internal non-uniform body temperature result in low output power and poor energy conversion efficiency. In addition, the irradiance might be interrupted by the clothing and placement of the IWM devices, which becomes prominent in small-scale devices. Moreover, the PV-powered implantable devices cannot be placed deep inside the body due to area constraints and the decrease in incident solar energy with tissue thickness. Due to the nonlinear characteristics of PV cells, maximum power point tracking (MPPT) is often incorporated into solar energy harvesting to maximize conversion efficiency. However, the requirement of additional circuitry and the power consumption of MPPT limit their applications in IWM devices.

3.2.4. Wireless Power Transfer

Wireless power transfer (WPT) is a sustainable powering solution for IWM devices. WPT minimizes the finite capacity of batteries problem and avoids transdermal wiring, which can cause infection. WPT works on Faraday’s concept of transferring power from one coil to another without requiring any conducting medium. Initial works on powering transcutaneous implants were based on building a near-field inductive coupling between transmitting and receiving coils at resonance. Three categories of WPT for IWM devices are discussed in this section.

Ultrasonic Techniques

Energy harvesting using sound waves is comparatively safe for the human body with minimal chances of electrical interference with other medical devices. Pulsed ultrasonic waves were studied in [234] to provide currents in the milliampere range in piezoelectric devices. Generating high-frequency current using ultrasound waves was demonstrated in [235]. The ultrasound wave generator is placed on the skin to couple energy to a MEMS sensor implanted inside the body, providing electrical charge output. Another significant improvement in this area was presented in [236], generating 21.4 nW of power in an implanted sensor using ultrasound waves. A MEMS-based piezoelectric ultrasonic energy harvester (PUEH) was reported in [237], which increased the battery lifetime of a pacemaker.

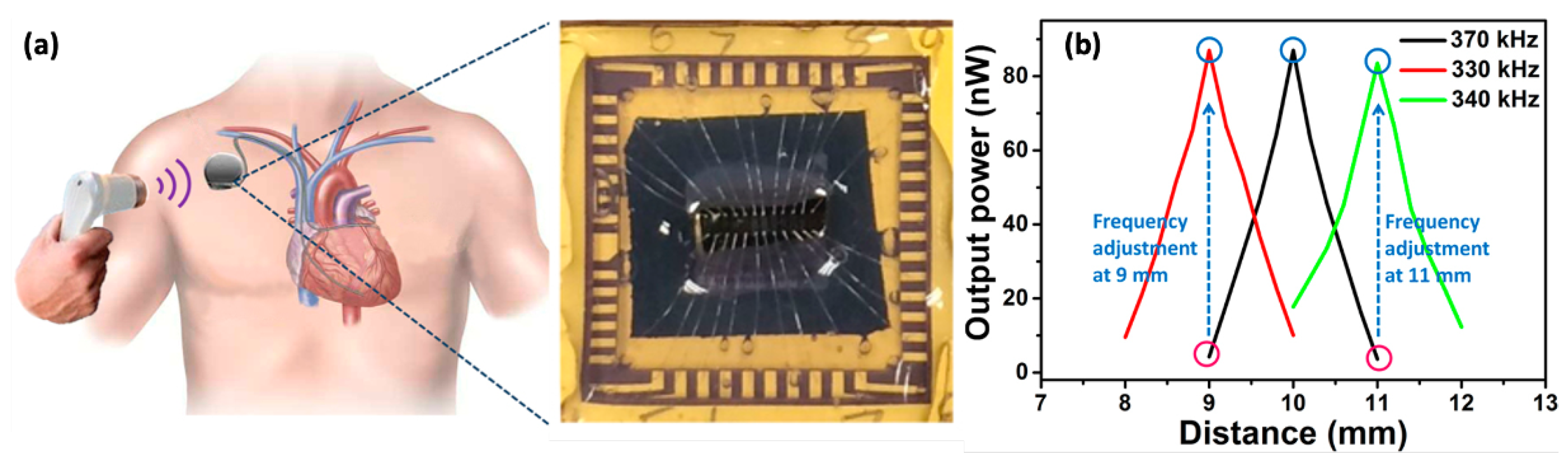

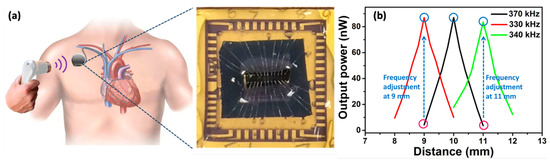

Figure 8 shows the concept of a PUEH driving a pacemaker inside the human body. The reported PUEH collects energy from an external ultrasound transducer used in hospitals for diagnostic purposes. The designed harvester provides a large bandwidth due to the two overlapping resonant modes, which increase the power density from 0.59 W/mm to W/mm at an ultrasound intensity of 1 mW/cm. A novel Samarium (Sm)-doped (Sm-PMN-PT) implantable PUEH was introduced in [238], giving an output power density of 1.1 W/cm. Electrophysiological experiments on rats confirmed its sustainability for deep brain stimulation and analgesia applications. A flexible-membrane-based PUEH was studied in [239], where the wireless charging is performed via ultrasound, producing a continuous voltage and current outputs of 2 and , respectively, on both planar and curved surfaces. A multilayered PUEH presented in [240] gives a peak output power of around 13.13 mW. However, the ultrasound energy harvesting to operate IWM devices is still in its infancy and limited by the insignificant amount of harvested energy and the requirement of large MEMS devices.

Figure 8.

(a) Ultrasonic energy harvester integrated with a pacemaker; the fabricated chip is shown at the right side. (b) Frequency adjustment for achieving high transfer power and efficiency due to breathing and muscle movement for a 1 mm fluctuation in distance. Reprinted from [237].

Capacitive Coupling

The basic principle of capacitive coupling to power IMDs is parallel plate capacitors. One of the plates is placed on the external skin, and the other is internal to the human body and attached to the implants. For instance, capacitive coupling was used in [241] to transfer power to implantable devices. The skin in between the parallel plates behaves like the dielectric, and the electric field works as the carrier to transfer power. A new approach to capacitive power transfer for implants was presented in [242]. The system transfers the power through a tissue layer, which acts as a return path for the current. This method reduces the size of the IMD while increasing power transmission efficiency. The data transmission through a capacitive coupling link between brain implants was studied in [243]. The designed capacitive link uses metal plates to attach to the bottom and side wall of the implant. The reported minimum input power required to establish the data link is 31 nW at an operating frequency of MHz. The limitations of capacitive coupling for WPT are tissue heating and user discomfort [244].

Inductive Coupling

The concept of inductive coupling is the use of magnetic fields to provide sufficient power to the IMDs [245]. Most inductive coupling techniques operate below a 20 MHz frequency to avoid tissue heating [246,247]. The overall system comprises two inductive coils: one placed outside the human body, while the other is attached to the implants. Both coils should be tuned at the same resonant frequency to achieve an efficient power transfer. The amount of power transfer is controllable by varying the number of coil turns and shapes. Most studies on inductive links reported a frequency range lower than 20 MHz [247,248] for avoiding tissue heating, which results from power absorption in tissue. The efficiency of the power transmission of a system depends on the coil shapes and sizes, the quality factor of the coil, the coupling coefficient, and alignment location. A hybrid inductive–ultrasonic wireless power transmission link was proposed in [249] for biomedical implants, which can achieve high power transfer efficiency. For instance, at 1.1 MHz, it can wirelessly power a mm ultrasonic transducer. The wireless inductive power transmission system finds potential application in the brain and spinal cord stimulants. A stimulator was designed in [250], operating at a 198 MHz resonant frequency at a distance of 14 cm from the body. The designed stimulator collects the energy from a switched capacitor and supplies it for boosting the output when the voltage reaches its threshold. Another inductive coupling work was presented in [251] to operate electromyography (EMG) implants in the gastrocnemius muscle of a rat. The system achieves a power transfer efficiency of % at 60 MHz and provides 1.3 mW of output power to the implanted device.

Table 2 summarizes the state-of-the-art environment-centric energy harvesting methods, generated output power, power density, and sizes. For subcutaneous IMDs, inductive coupling is a suitable technique at the ISM frequency band. On the other hand, several methods including capacitive coupling are still in the development phase and potentially can cause hazards to the human body.

Table 2.

Summary of representative works on environment-centric energy harvesting techniques.

3.3. Hybrid Energy Harvesting

Hybrid energy harvesting incorporates multiple energy sources to generate a larger electrical output. For example, the solar cell uses only a portion of the incident light, and photons outside the PV cell material band gap are wasted as heat dissipation. Therefore, combining photovoltaic systems with thermoelectric methods can utilize most of the incident energy, which increases the output power [262]. The PV-TEG combination requires a sufficient temperature gradient across TEGs [263]. The mathematical modeling and numerical analysis of heat transfer and temperature distribution to calculate the PV-TEG hybrid energy generation were presented in [264]. An energy efficiency of 23% is theoretically possible in PV-TEGs, higher than a single energy harvesters. A flexible PV-TEG was presented in [265], which utilizes solar energy and the human body dissipated heat to provide power support to WMDs. A lossless coupling is feasible in the PV-TEG combination. The system can achieve a power conversion efficiency of 16.3% utilizing a 15 °C temperature gradient in a TEG with a PV system [266]. As the PV-TEG combination is power-efficient and inexpensive, it can serve the energy demands of WMDs.

A hybrid energy harvester combining solar energy with human body motion was presented in [266] for self-charging textiles using a supercapacitor for energy storage. It contains a fiber-shaped TENG to use motion energy and fiber-shaped dye-sensitized solar cells to capture the solar energy. Due to the all-fiber structure, the system is flexible and can be integrated into clothes to serve the energy needs of WMDs.

A hybrid architecture combining a TENG with piezoelectric nanogenerators (PENGs) can utilize human body motion and ambient mechanical energy. For example, a TENG-PENG combination demonstrates sufficient energy generation from wind to operate digital watches [267]. Besides, TENG-PENG hybrid energy harvesters use hand vibrations to provide power support for cell phones [268]. Despite the increased output power, the challenges of hybrid energy harvesters include inflexibility, high cost, and complex mechanisms. Therefore, designing human-body-compatible hybrid energy harvesting for precision healthcare is still in the development phase.

Hybrid energy harvesting offers an excellent solution of taking the good features of multiple energy harvesting techniques. However, that makes the design of the coupling interface and power conditioning circuit much more complex. The challenges of the TENG-TEG and TENG-PV coupling effect were discussed for a metal–semiconductor interface in [269]. It has been also demonstrated that a circuit based on parallel-synchronous switch harvesting on an inductor (SSHI) can simultaneously harvest power from a PZT and a TEG, this too with a single shared inductor [270]. There have been demonstrations of highly integrated multi-source energy harvesters with the coupling technique and multiplexing schemes, which can simultaneously contribute to triboelectric, photovoltaic, and thermoelectric power generation [271].

4. Extraction of Maximum Power from Energy Harvesters

In IWM devices, capturing the maximum power from the harvester is immensely important as energy harvesters intermittently generate energy based on the availability of the source, and often, the generated power is low. To obtain the maximum power point, an impedance matching between the energy harvester and the load is crucial [272].

The two main techniques for MPPT are perturb and observe (P&O) and fractional open-circuit voltage (FOCV) [272,273]. The P&O method is also called the hill-climbing technique, mainly used in large-scale energy harvesting. The harvested voltage and current are repeatedly sensed to capture the maximum power. In addition, the duty cycle and switching frequency of the DC-DC converter are dynamically varied [273]. The P&O technique is highly accurate in finding the maximum power point. However, the P&O technique is complex and power-hungry due to digital controllers. Different techniques have been developed to minimize the power consumption of the controllers [274,275,276]. For example, maintaining a low controller duty cycle to maintain a longer sleep mode and short active period can minimize the power consumption [274,277].

The power consumption of the FOCV-based MPPT controller is relatively lower than that of the P&O technique. The FOCV controller can be implemented using analog or mixed signal circuitry having minimum complexity [278,279]. In the FOCV technique, the maximum power point is a fixed ratio of the open-circuit voltage (VOC) of the energy harvester [273]. For instance, in thermoelectric, radio frequency, and piezoelectric microgenerators, the MPP point is approximately 50% of the VOC. On the other hand, for photovoltaic cells, the MPP point is obtained as around 75–80% of the VOC [278]. To obtain the VOC, a voltage divider configuration or switched capacitor is frequently used [274]. The limitations of the FOCV-based MPPT method are the low conversion efficiency due to the frequent disconnection of the energy harvester and load to measure the VOC, which, in turn, reduces the power [279]. Table 3 presents the power consumption of different P&O- and FOCV-based MPPT systems for energy harvesting applications.

Table 3.

Summary of maximum power point tracking approaches and their power consumption.

The P&O and FOCV techniques use resistive impedance matching, which is inappropriate for electromagnetic and piezoelectric energy harvesters. The energy storage in parasitic elements limits the maximum real power transfer to load using resistive impedance matching. Different nonlinear MPPTs have been implemented in recent years. Among them, the synchronized switch harvesting on the inductor (SSHI) and synchronous electric charge extraction (SECE) methods are most commonly used to overcome the limitations of linear impedance matching [279].

5. Machine Learning for Emerging Energy Harvesters