Energy Productivity of Microinverter Photovoltaic Microinstallation: Comparison of Simulation and Measured Results—Poland Case Study

Abstract

:1. Introduction

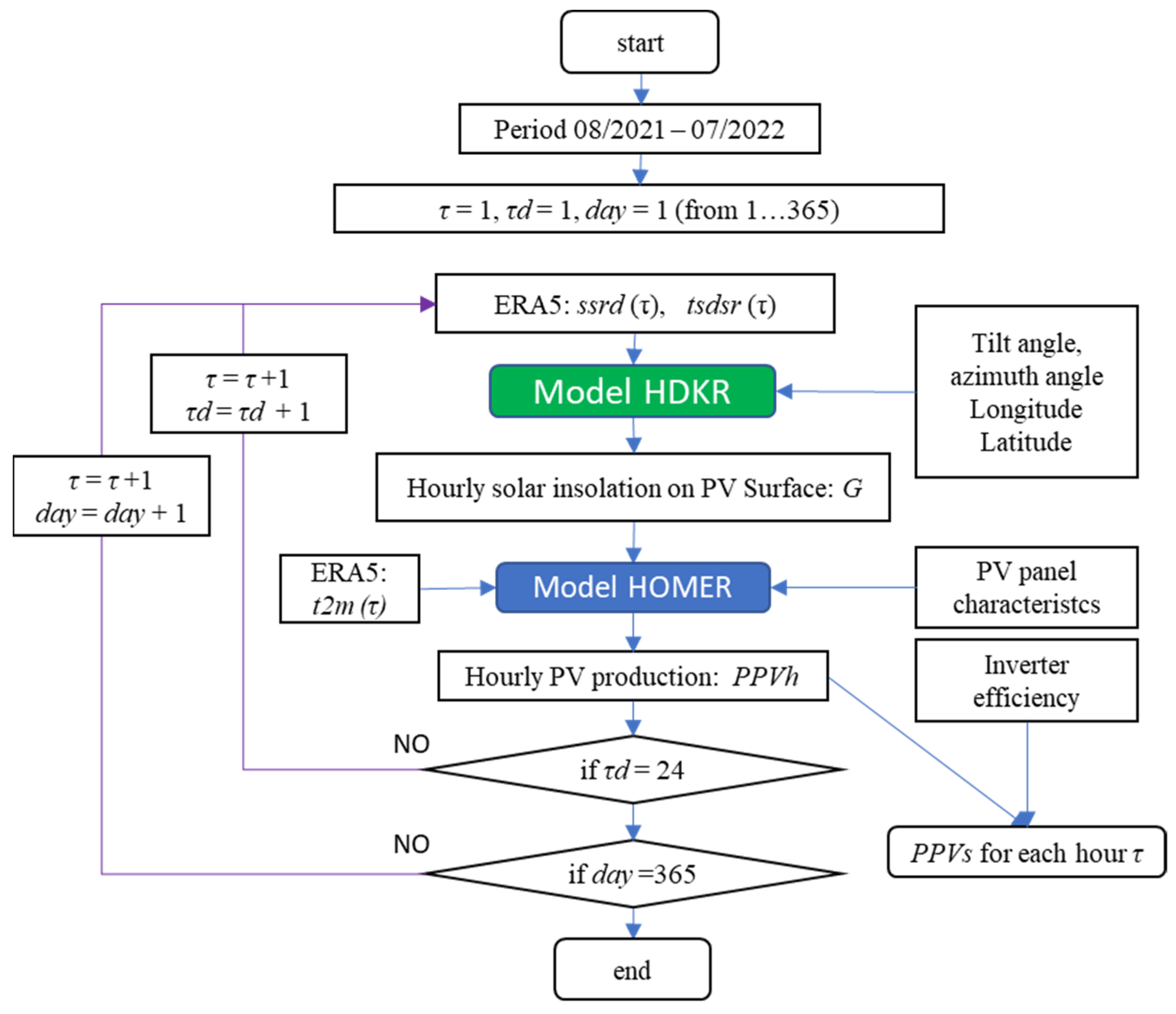

2. Materials and Methods

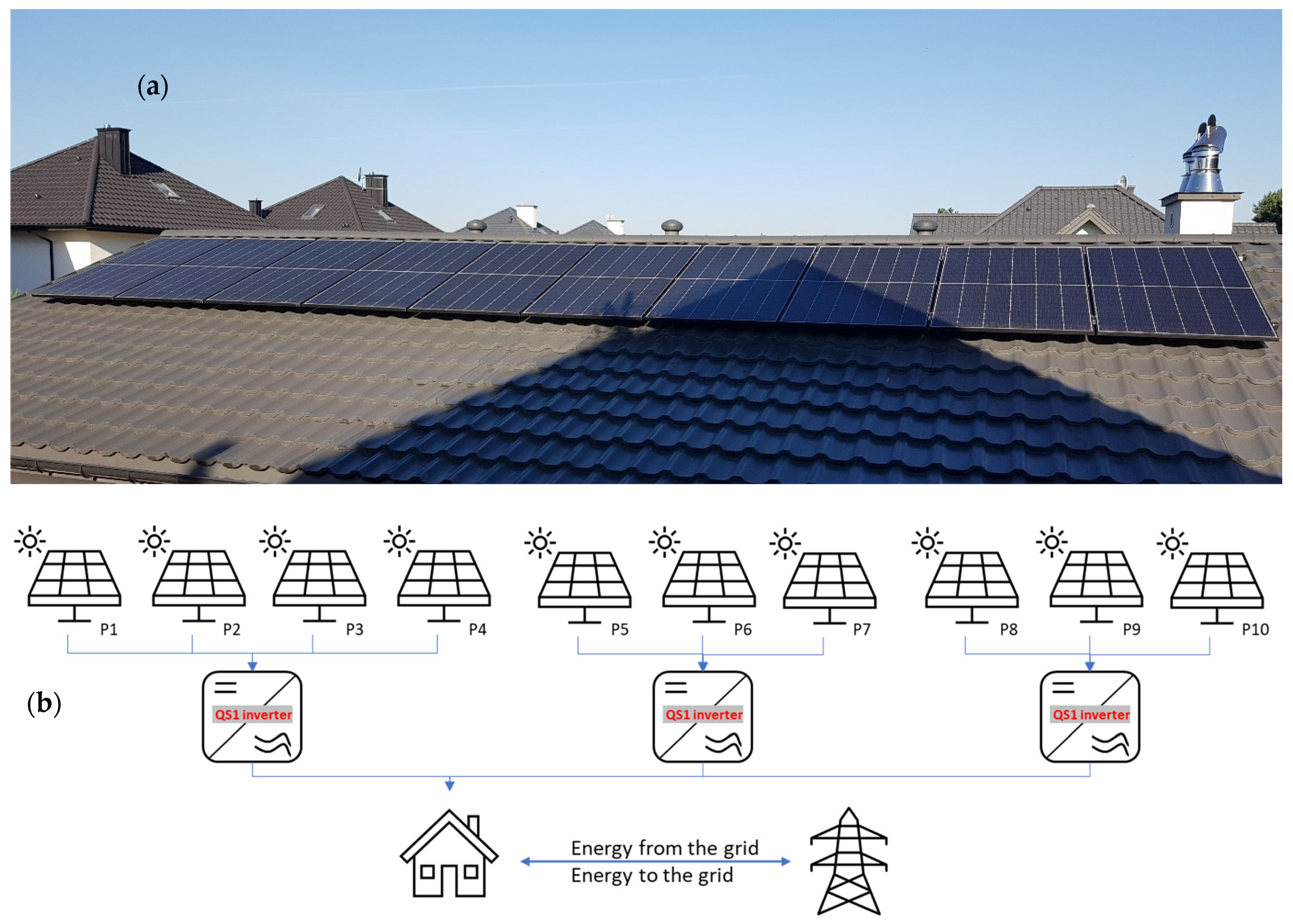

2.1. Research Object

2.2. Solar Radiation Calculation Method

- G—available intensity of solar radiation incident on surface dependent on time, tilt angle, and azimuth angle, W/m2

- τ—hour of year

- β—tilt angle, °

- γ—azimuth angle, °

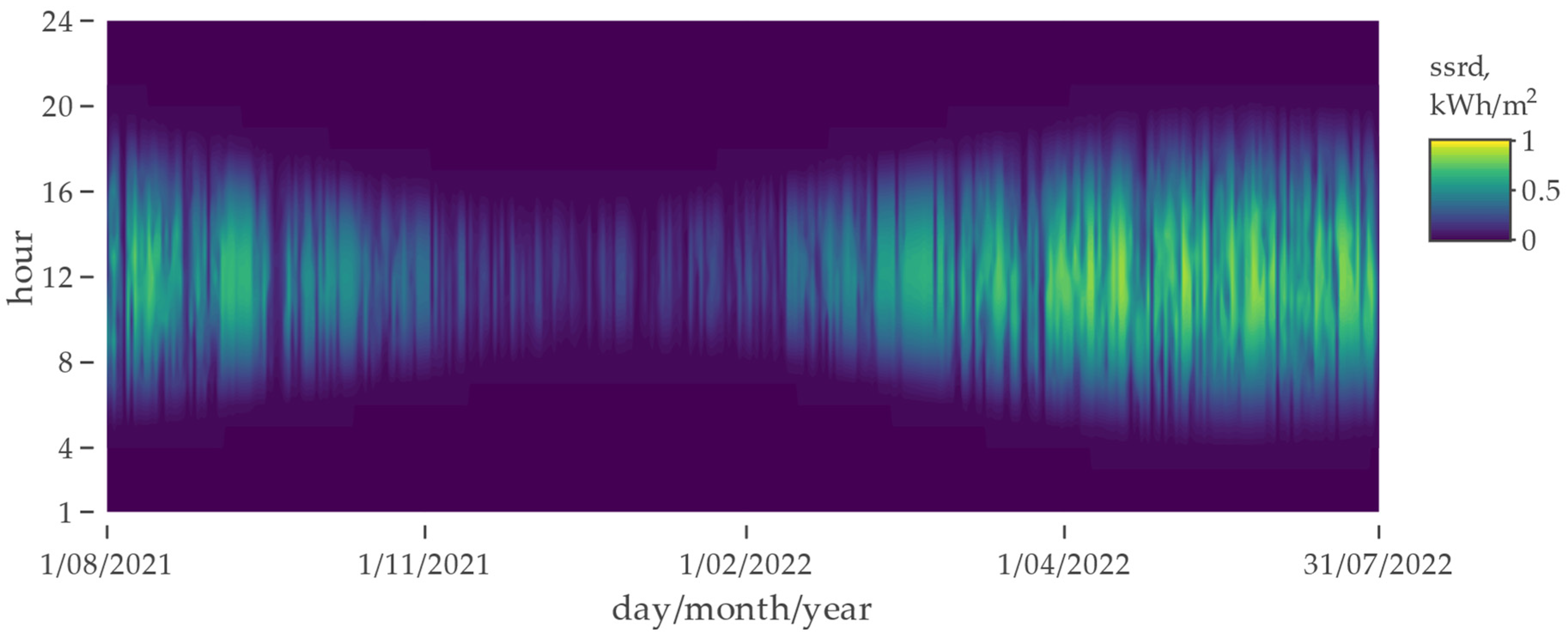

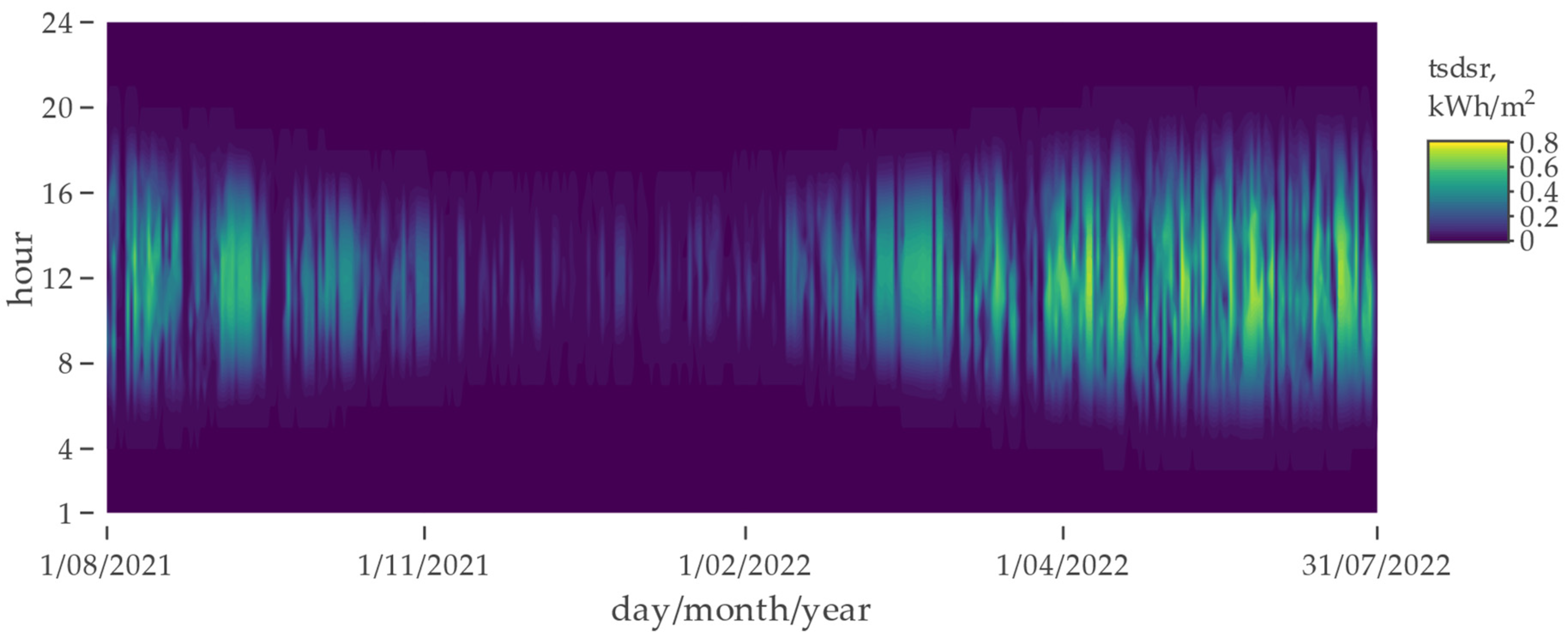

- tsdsr—beam radiation on a horizontal surface, from ERA5 database, please also see Figure A2, W/m2

- Gd—diffuse radiation on a horizontal surface, Equation (2), W/m2

- Ai—anisotropy index,

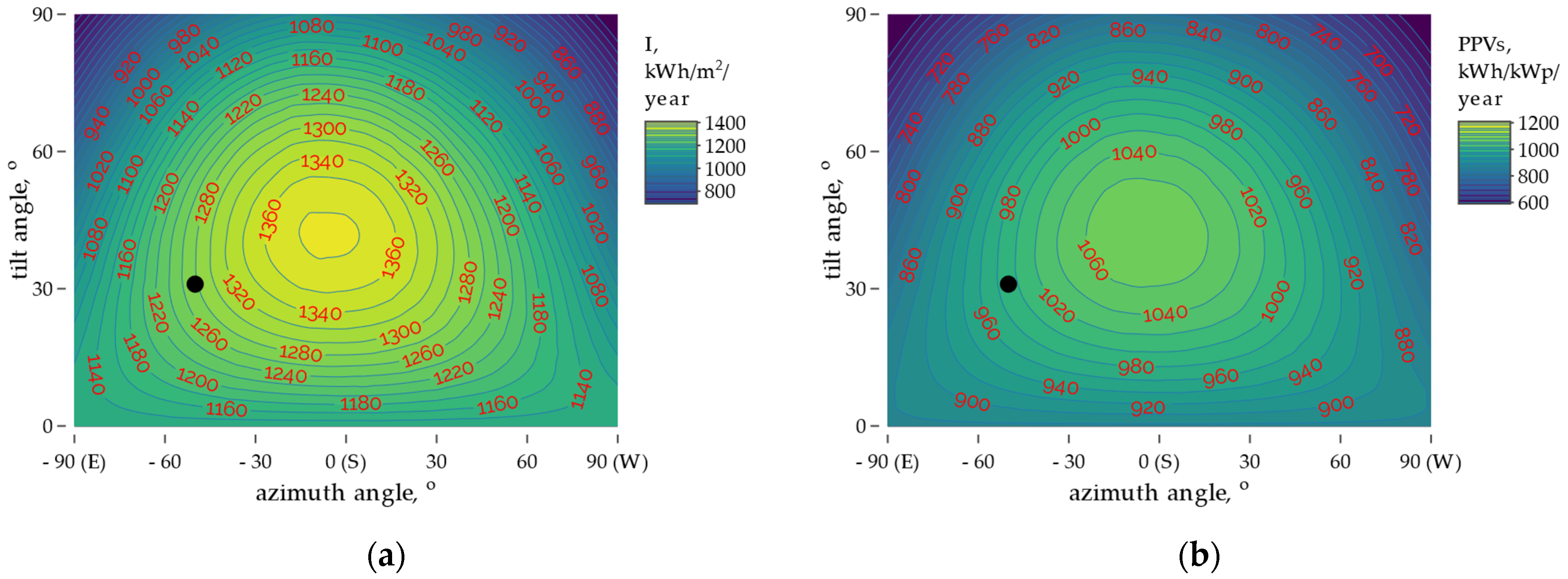

- I—insolation, kWh/m2/year

- G—available intensity of solar radiation incident on surface dependent on time, tilt angle β, and azimuth angle γ, W/m2

2.3. PV Energy Production Calculation Method

- PPVh—mean (for 10 PV panels) hourly energy output of photovoltaic panels, kWh/kWp

- YPV—rated capacity of the PV array, which implies that its output power under standard test conditions (1 kWp was used), kW/kWp

- G—available intensity of solar radiation incident on surface (for analysed installation: β = 30°, γ = −50° south-east direction) dependent on time, based on ERA5 data and HDKR model, W/m2

- GSTC—incident radiation at Standard Test Conditions, 1 kW/m2

- αp—temperature coefficient of power, based on Jinko PV Data (Table 1: 0.35) %/°C

- TC—PV cell temperature, based on equation included in [31] and ERA5 data (please see Equation (5)), °C

- TSTC—PV cell temperature under standard test conditions (25 °C)

- SF—Shadow factor of PV panels—Equation (6)

- TC—PV cell temperature, °C

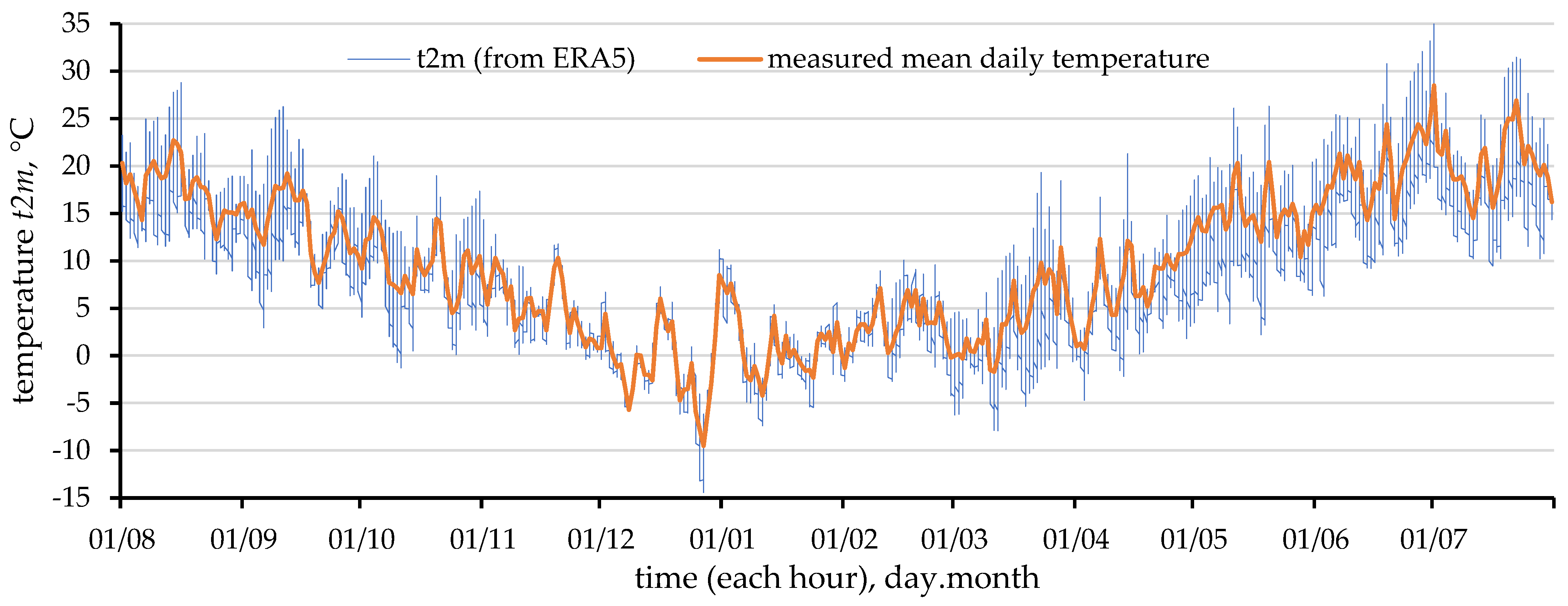

- t2m—temperature of air at 2 m above the surface of land, from ERA5 database, please also see Figure A3, °C

- TC.NOCT—nominal operating cell temperature (45 °C [15]), °C

- Ta.NOCT—ambient temperature at which the NOCT is defined (20 °C [15]), °C

- ηp—panel efficiency (from Table 1),

- ta—coefficient of transmittance and absorptance, 0.9 [25]

- SF—shadow factor of PV panels

- min2P—mean measured value of two PV panels with minimum yearly energy production, kWh/kWp/year

- PPV6m—mean measured value of PV energy production from 6 PV panels (with mean energy production from 10 PV panels), kWh/kWp/year

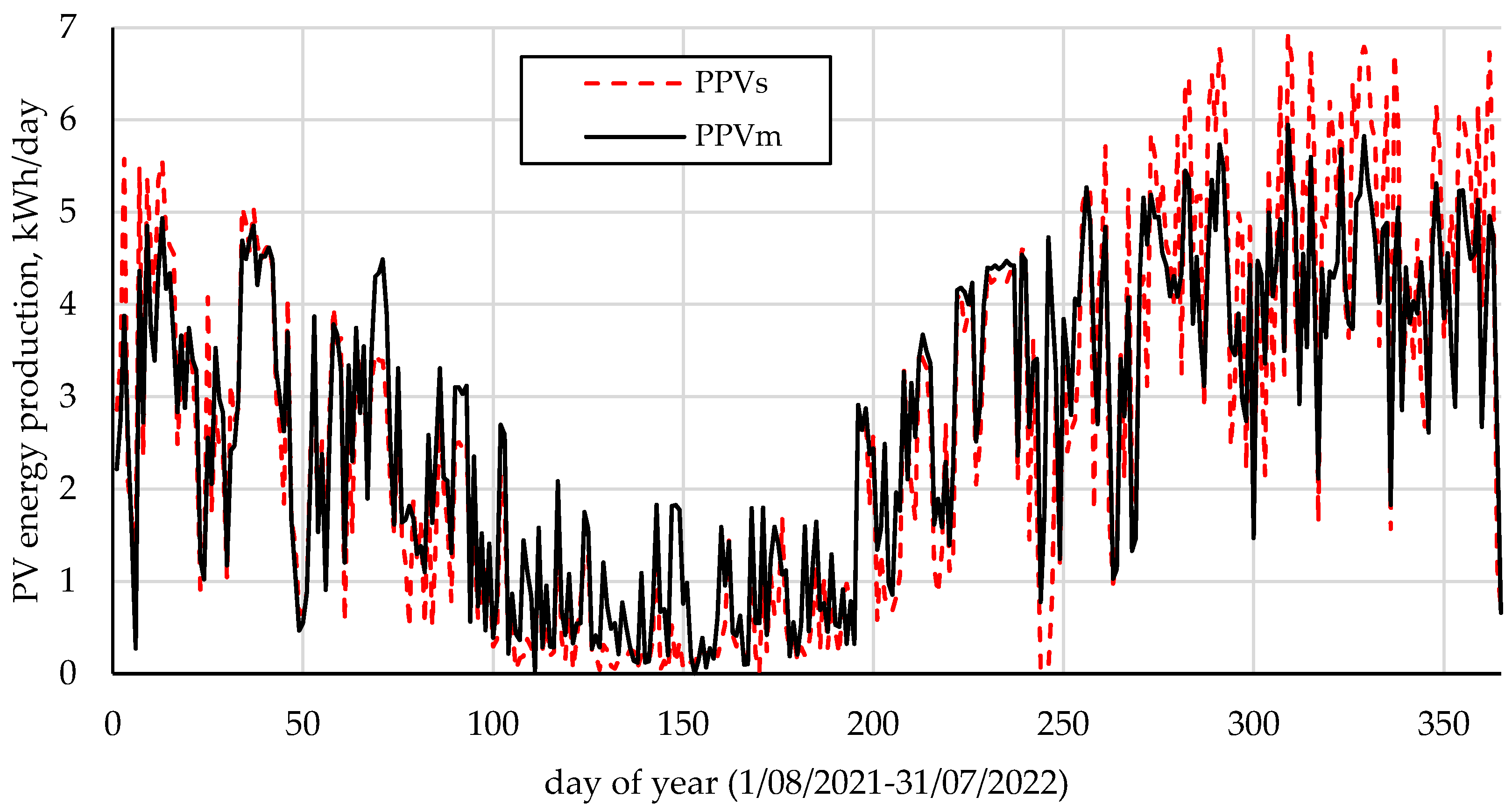

- PPVs—theoretical daily unit electricity production in PV installation in, kWh/kWp/day

- PPVh—hourly energy output of photovoltaic panels, kWh/kWp/hour

- ηinverter—inverter efficiency, %

- τd—day hour, extracted from hour of year (τ)

- day—the following day of first PV installation operational year

- n—total number of daily observations, whole year, n = 365

- day—day of calculation

- PPVm—measured value of daily PV energy production, kWh/kWp/day

- PPVs—simulated value of daily PV energy production, kWh/kWp/day

- d.—percentage difference between simulated (from model) and measured results (PV energy production), %

- month—month of calculation

3. Results and Discussion

3.1. Insolation and Theoretical Productivity Simulation Results

3.2. Comparison of Measured and Simulated Data of PV Energy Productivity

4. Conclusions

- a detailed analysis of the influence of the shading of the installation on the productivity of individual panels and the determination of their representativeness,

- economic analyses—comparison between PV installation with standard inverter and with micro-inverters for households PV.

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Milosavljević, D.D.; Kevkić, T.S.; Jovanović, S.J. Review and validation of photovoltaic solar simulation tools/software based on case study. Open Phys. 2022, 20, 431–451. [Google Scholar] [CrossRef]

- Barco Jiménez, J.; Pantoja, A.; Caicedo Bravo, E. Optimal sizing of a grid-connected microgrid and operation validation using HOMER Pro and DIgSILENT. Sci. Tech. 2022, 27, 28–34. [Google Scholar]

- Bentouba, S.; Bourouis, M.; Zioui, N.; Pirashanthan, A.; Velauthapillai, D. Performance assessment of a 20 MW photovoltaic power plant in a hot climate using real data and simulation tools. Energy Rep. 2021, 7, 7297–7314. [Google Scholar] [CrossRef]

- Roberts, J.; Cassula, A.; Freire, J.; Prado, P. Simulation and Validation Of Photovoltaic System Performance Models. In Proceedings of the XI Latin-American Congress on Electricity Generation and Transmission–CLAGTEE 2015, Sao Paulo, Brazil, 8–11 November 2015. [Google Scholar]

- Barros, L.A.M.; Tanta, M.; Sousa, T.J.C.; Afonso, J.L.; Pinto, J.G. New Multifunctional Isolated Microinverter with Integrated Energy Storage System for PV Applications. Energies 2020, 13, 4016. [Google Scholar] [CrossRef]

- Tariq, M.S.; Butt, S.A.; Khan, H.A. Impact of module and inverter failures on the performance of central-, string-, and micro-inverter PV systems. Microelectron. Reliab. 2018, 88–90, 1042–1046. [Google Scholar] [CrossRef]

- Gagrica, O.; Marzec, M.; Uhl, T. Comparison of reliability impacts of two active power curtailment methods for PV micro-inverters. Microelectron. Reliab. 2016, 58, 133–140. [Google Scholar] [CrossRef]

- Chub, A.; Vinnikov, D.; Stepenko, S.; Liivik, E.; Blaabjerg, F. Photovoltaic Energy Yield Improvement in Two-Stage Solar Microinverters. Energies 2019, 12, 3774. [Google Scholar] [CrossRef] [Green Version]

- Elanchezhian, P.; Chinnaiyan, V.K. Modeling and Simulation of High-Efficiency Interleaved Flyback Micro-inverter For Photovoltaic Applications. Mater. Today Proc. 2017, 4, 10417–10421. [Google Scholar] [CrossRef]

- Sinapis, K.; Litjens, G.B.M.A.; van den Donker, M.N.; Folkerts, W.; van Sark, W. Outdoor characterization and comparison of string and MLPE under clear and partially shaded conditions. Energy Sci. Eng. 2015, 3, 510–519. [Google Scholar] [CrossRef]

- Sinapis, K.; Tzikas, C.; Litjens, G.; van den Donker, M.; Folkerts, W.; van Sark, W.G.J.H.M.; Smets, A. A comprehensive study on partial shading response of c-Si modules and yield modeling of string inverter and module level power electronics. Sol. Energy 2016, 135, 731–741. [Google Scholar] [CrossRef] [Green Version]

- Sher, H.A.; Addoweesh, K.E. Micro-inverters—Promising solutions in solar photovoltaics. Energy Sustain. Dev. 2012, 16, 389–400. [Google Scholar] [CrossRef]

- Kouro, S.; Leon, J.I.; Vinnikov, D.; Franquelo, L.G. Grid-Connected Photovoltaic Systems: An Overview of Recent Research and Emerging PV Converter Technology. IEEE Ind. Electron. Mag. 2015, 9, 47–61. [Google Scholar] [CrossRef]

- European Centre for Medium-Range Weather Forecasts (ECMWF) ERA5. Available online: https://confluence.ecmwf.int/display/CUSF/ERA5+hourly+data+on+single+level+and+ERA5+hourly+on+pressure+levels+available+again+from+the+CDS?src=contextnavpagetreemode (accessed on 28 August 2022).

- Jinko. PV Jinko 440 Wp Monofacial. Available online: https://sklep.enexon.pl/amfile/file/download/file/268991/product/99172/ (accessed on 26 August 2022).

- Canales, F.A.; Jadwiszczak, P.; Jurasz, J.; Wdowikowski, M.; Ciapała, B.; Kaźmierczak, B. The impact of long-term changes in air temperature on renewable energy in Poland. Sci. Total Environ. 2020, 729, 138965. [Google Scholar] [CrossRef] [PubMed]

- APSystems. Micro–Inwerter QS1. Available online: https://b2b.eltech.net.pl/pl/product/83977,micro-inwerter-qs1 (accessed on 31 August 2022).

- Copernicus. ERA5 Hourly Data on Single Levels from 1979 to Present. Available online: https://cds.climate.copernicus.eu/cdsapp#!/dataset/reanalysis-era5-single-levels?tab=overview (accessed on 16 March 2022).

- ECMWF. Surface Solar Radiation Downwards. Available online: https://apps.ecmwf.int/codes/grib/param-db?id=169 (accessed on 3 September 2022).

- ECMWF. Total Sky Direct Solar Radiation at Surface (fdir). Available online: https://apps.ecmwf.int/codes/grib/param-db?id=228021 (accessed on 3 September 2022).

- ECMWF. 2 Metre Temperature. Available online: https://apps.ecmwf.int/codes/grib/param-db?id=167 (accessed on 3 September 2022).

- Karlsson, J. Windows—Optical Performance and Energy Efficiency; Acta Universitatis Upsaliensis: Uppsala, Sweden, 2001. [Google Scholar]

- Chwieduk, D.; Chwieduk, M. Determination of the Energy Performance of a Solar Low Energy House with Regard to Aspects of Energy Efficiency and Smartness of the House. Energies 2020, 13, 3232. [Google Scholar] [CrossRef]

- Chwieduk, D.A. Recommendation on modelling of solar energy incident on a building envelope. Renew. Energy 2009, 34, 736–741. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Olek, M.; Olczak, P.; Kryzia, D. The sizes of Flat Plate and Evacuated Tube Collectors with Heat Pipe area as a function of the share of solar system in the heat demand. In Proceedings of the 1st International Conference on the Sustainable Energy and Environment Development (SEED 2016), Kraków, Poland, 17–19 May 2016; Volume 10, p. 00139. [Google Scholar]

- Olczak, P.; Komorowska, A. An adjustable mounting rack or an additional PV panel? Cost and environmental analysis of a photovoltaic installation on a household: A case study in Poland. Sustain. Energy Technol. Assess. 2021, 47, 101496. [Google Scholar] [CrossRef]

- HOMER. Homer Energy. Available online: https://www.homerenergy.com/index.html (accessed on 20 October 2020).

- Jordan, D.C.; Deceglie, M.G.; Kurtz, S.R. PV Degradation Methodology Comparison—A Basis for a Standard. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016. [Google Scholar]

- Al Garni, H.Z.; Awasthi, A.; Ramli, M.A.M. Optimal design and analysis of grid-connected photovoltaic under different tracking systems using HOMER. Energy Convers. Manag. 2018, 155, 42–57. [Google Scholar] [CrossRef]

- Olczak, P.; Żelazna, A.; Matuszewska, D.; Olek, M. The “My Electricity” Program as One of the Ways to Reduce CO2 Emissions in Poland. Energies 2021, 14, 7679. [Google Scholar] [CrossRef]

- Shukla, K.N.; Rangnekar, S.; Sudhakar, K. Comparative study of isotropic and anisotropic sky models to estimate solar radiation incident on tilted surface: A case study for Bhopal, India. Energy Rep. 2015, 1, 96–103. [Google Scholar] [CrossRef] [Green Version]

- O’Sullivan, B.; Chalhoub-Deville, M. Language Testing for Migrants: Co-Constructing Validation. Lang. Assess. Q. 2021, 18, 547–557. [Google Scholar] [CrossRef]

- IMGW. Temperature for Warszawa Filtrowo Weather Station. Available online: https://danepubliczne.imgw.pl/data/dane_pomiarowo_obserwacyjne/dane_meteorologiczne/dobowe/klimat/ (accessed on 27 September 2022).

| Parameter | Unit | Value |

|---|---|---|

| Nominal power | Wp | 440 |

| Total length | m | 1.868 |

| Total width | m | 1.134 |

| Panel efficiency ηP | % | 20.77 |

| Temperature coefficient of the short-circuit current | %/°C | 0.048 |

| Temperature coefficient of the open-circuit voltage | %/°C | −0.28 |

| Temperature coefficient of the power αp | %/°C | −0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olczak, P. Energy Productivity of Microinverter Photovoltaic Microinstallation: Comparison of Simulation and Measured Results—Poland Case Study. Energies 2022, 15, 7582. https://doi.org/10.3390/en15207582

Olczak P. Energy Productivity of Microinverter Photovoltaic Microinstallation: Comparison of Simulation and Measured Results—Poland Case Study. Energies. 2022; 15(20):7582. https://doi.org/10.3390/en15207582

Chicago/Turabian StyleOlczak, Piotr. 2022. "Energy Productivity of Microinverter Photovoltaic Microinstallation: Comparison of Simulation and Measured Results—Poland Case Study" Energies 15, no. 20: 7582. https://doi.org/10.3390/en15207582