Abstract

Supercapacitors can store a million times more energy per unit mass or volume compared to electrolytic capacitors. Due to their low internal resistance, they are capable of driving or absorbing pulsative high currents. Over the last quarter, century supercapacitor (SC) manufacturers have developed several families of mass-scale devices with high-power density and a longer cycle life that helped the end-users to improve their energy storage systems and products. Today, there are three common device families, namely, (i) symmetrical double-layer capacitors (EDLCs), (ii) hybrid capacitors with a lithium electrode, and (iii) battery capacitors based on pseudo capacitance concepts. This review paper compares these families and provides an overview of several state-of-the-art applications in electric vehicles (EVs), microgrids, and consumer electronics.

1. Introduction

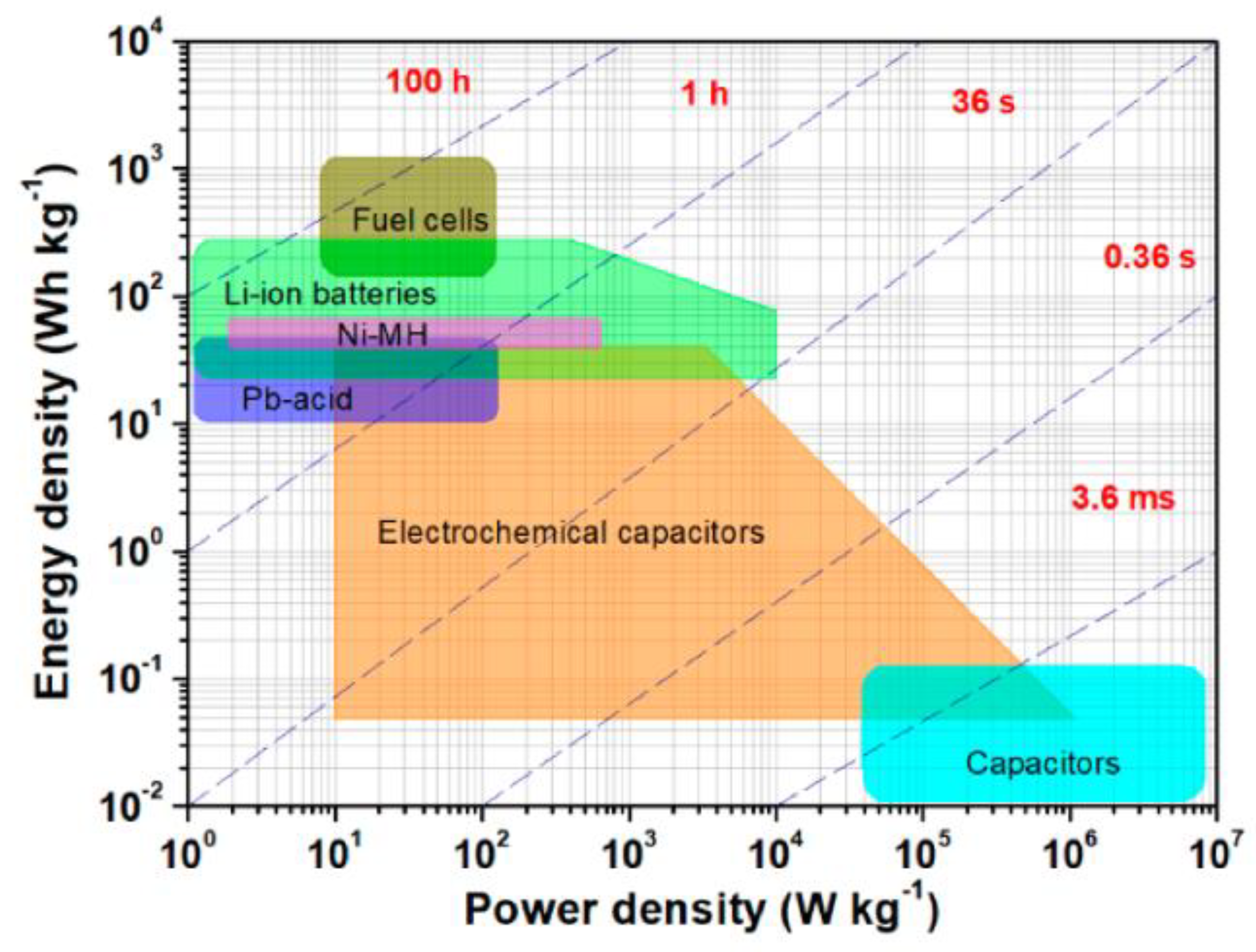

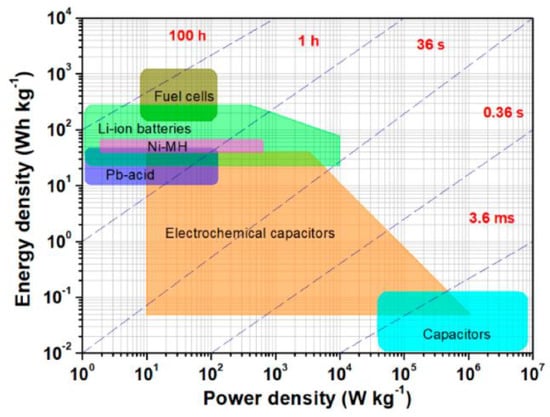

Capacitors are used for various functionalities in electrical circuits, such as smoothing, buffering, filtering, bypassing, and DC blocking. Normally, capacitors have a relatively small capacitance in the range of picofarads to microfarads, and their energy densities are small. Batteries, on the other hand, have been the normal solution for portable energy storage because they offer significantly higher energy density. By using electrodes with greater surface area and thinner dielectric materials, SCs can provide capacitances a million times greater than conventional capacitors. Thus, SCs are considered energy-storing devices that bridge the gap between conventional capacitors and batteries and suit the ever-increasing demand for reliable power in industrial, energy, and computing applications. SCs are also governed by the same fundamental equations applicable to conventional capacitors. Table 1 compares the major differences between capacitors, SCs, and batteries, and Figure 1 depicts the Ragone plot of various energy storage devices [1,2,3,4]. In the Ragone plot, x-axis represents the power density (W/kg), and the y-axis represents the energy density (Wh/kg) [4]. Parameters, such as internal losses and leakages, determine the boundaries of each energy storage device in the Ragone plot. Straight lines of the plot represent the time which is the ratio between energy and power.

Table 1.

Comparison of characteristics of supercapacitors versus batteries and conventional capacitors [1,2,3,5,6,7,8,9,10].

Figure 1.

Ragone plot of various energy-storing technologies [4].

Moreover, supercapacitors have further attractive features compared to batteries. The internal resistance of supercapacitors is almost constant during the charging and discharging processes and their cycle life is very high. Their charging and discharging limits are not critical, unlike for batteries, and they pose zero thermal runaway risk over a wide range of temperatures. They are also environmentally friendly as they do not contain heavy metals.

2. Supercapacitor Types

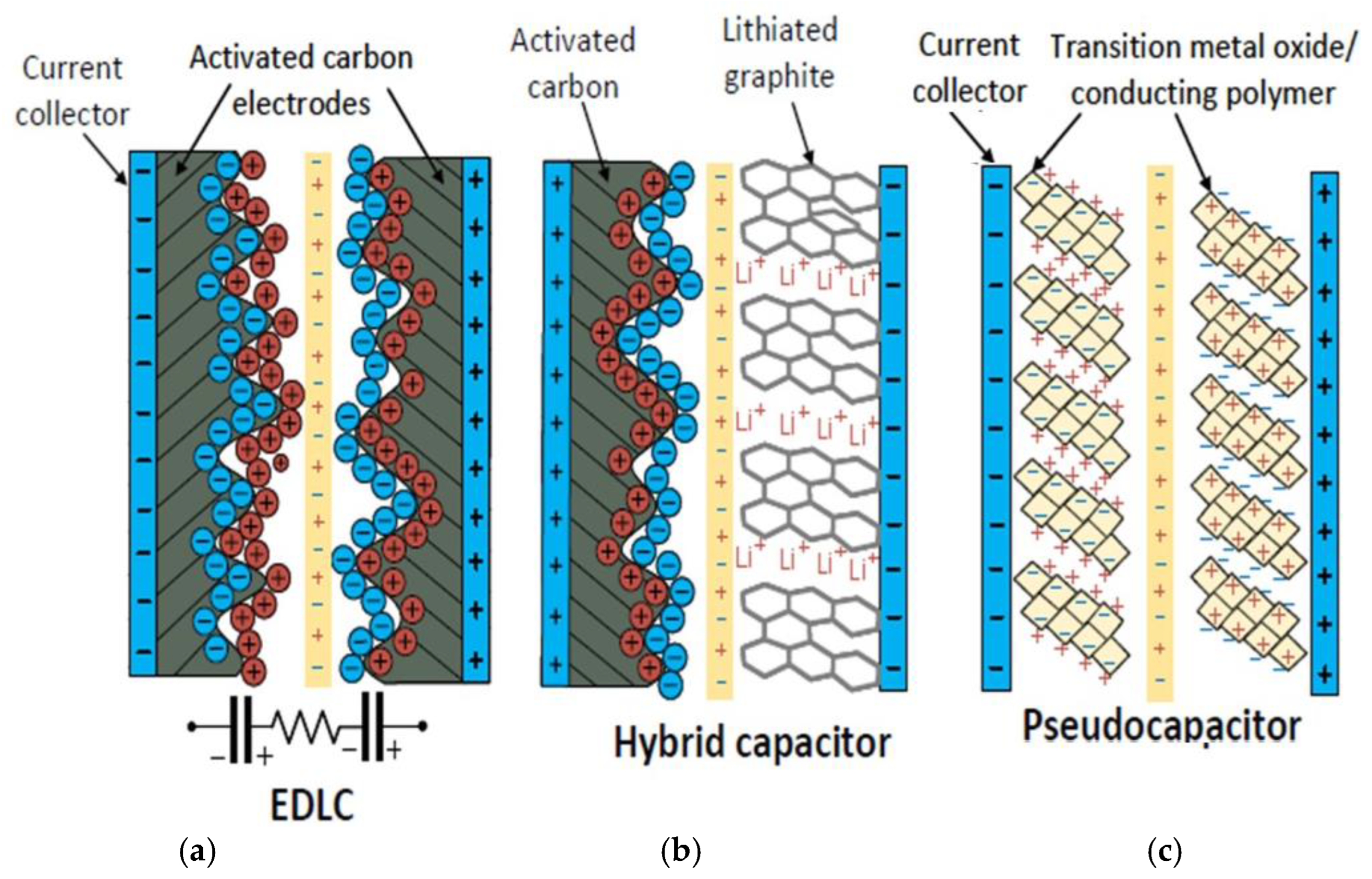

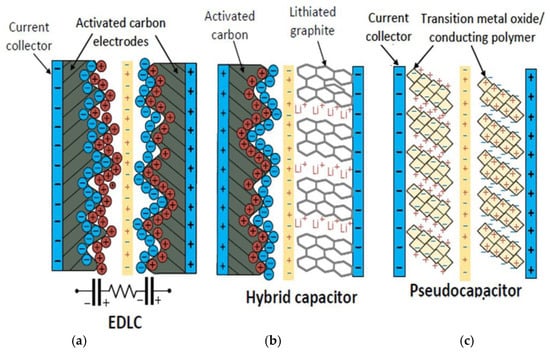

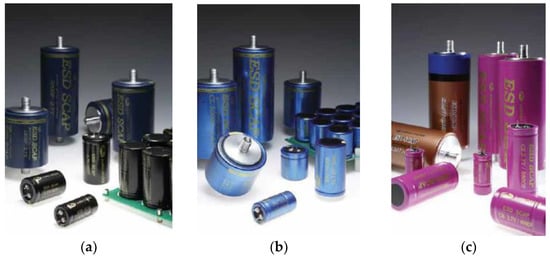

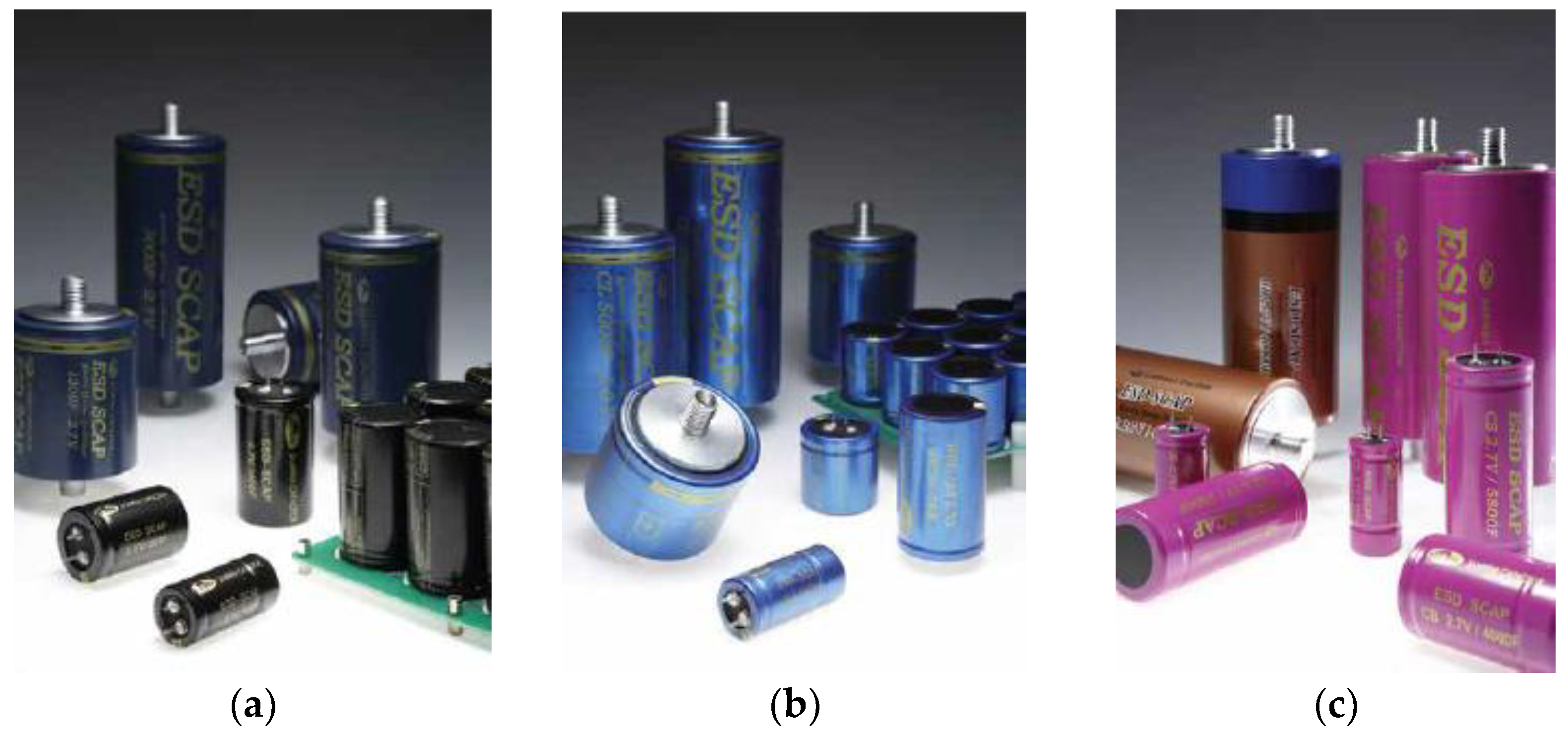

The three common basic types of SC families are symmetrical electric double-layer capacitors, hybrid capacitors, and pseudocapacitors. The structures of these three families are displayed in Figure 2, and three corresponding commercial examples are displayed in Figure 3. The basic characteristics of the three SC families are summarized in Table 2 [5,11,12].

Figure 2.

Electro-chemistry of three commercial SC families: (a) Electric double layer capacitor, (b) hybrid capacitor, (c) pseudocapacitor [11,12].

Table 2.

Comparison of electric double-layer capacitors and other supercapacitor types [1,2,3].

Hermann von Helmholtz, a German physicist, first introduced the EDLC concept in 1853, and then it was commercialized by Standard Oil of Ohio (SOHIO) Research Center, USA, in 1961 [13]. EDLCs are composed of two carbon-based electrodes and a dielectric separating them, as shown in Figure 2a. As the potential difference is applied across the electrodes, the charges in the material move to electrodes of opposite potentials [14]. The electrical double layer formed next to a large-area electrode and an electrolyte is effectively used, and hence the name EDLCs is used. Their larger area plates and shorter distance between plates can give a higher effective capacitance [5].

The next SC family is the hybrid supercapacitors that merge the chemistry of a battery with the physics of an SC in a single structure [15]. Due to their higher specific energy compared to EDLCs and good power density, there has been a strong demand for these devices in recent years [14,16]. As shown in Figure 2b, in hybrid supercapacitors, one electrode is activated carbon, and the other is similar to an electrode in Li-ion batteries [5]. These SCs can provide reliable ride-through or backup power in applications, such as data storage systems, servers, utility meters, and controllers for automated systems [14].

The third type is battery-capacitors, based on the concept of pseudocapacitance [13]. Although these have an energy density similar to lead-acid batteries they suffer from a relatively low power density and lack of cycling stability compared to EDLCs [17]. Figure 2c depicts the structure of the electro-chemistry of a pseudocapacitor [5].

Figure 3.

Commercial supercapacitor families from SAMWHA: (a) electric double-layer capacitors, (b) hybrid capacitors, (c) pseudocapacitors [18].

Figure 3.

Commercial supercapacitor families from SAMWHA: (a) electric double-layer capacitors, (b) hybrid capacitors, (c) pseudocapacitors [18].

3. Supercapacitor Equivalent Circuit Models

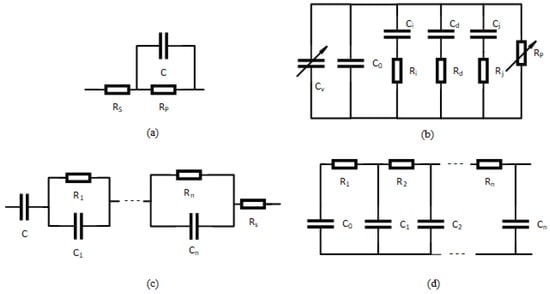

In the current literature, different types of circuit models are used to emulate the behavior of SCs when considering the steady state and the transient response. Figure 4 represents the SC equivalent circuit models of ELDCs [19,20].

Figure 4a shows a basic simplified model of the SC where C is the capacitance, Rs represents the equivalent resistance of the SC, and Rp is the parallel resistance that interprets the self-discharging phenomena [19,21,22]. This model is able only to adequately represent the dynamic behavior of an SC for several seconds, which limits its applicability.

Figure 4b shows an equivalent model developed by Zubieta and Boner for a wide variety of power electronic applications [23]. The three RC branches (immediate branch, delayed branch, and long-term branch) represent the SC characteristics on a distinct time scale. The parallel resistor (Rp) represents the self-discharging properties of the SC [23].

Each branch has different time constants to create a model that is more easily measurable during various periods. The immediate branch is composed of a voltage-dependent nonlinear capacitor (CV), a constant capacitor (CO), and a constant resistor (Ri). This branch is used to capture the transient behavior of the SC over periods of seconds. The delayed branch can emulate the behavior of the SC in the range of minutes, and it is composed of a constant capacitor (Cd) and a constant resistor (Rd). Finally, to capture the behavior of the SC in long time scales (typically higher than 10 min), the long-term branch is used, which consists of a constant capacitor (Cj) and a constant resistor (Rj).

In [24], the authors present a method to extract the parameters for the model in Figure 4b. As shown in Figure 4c, a model combined with a series resistor (Rs), a bulk capacitor (C), and n number of parallel RC networks represents a dynamic model of SC using electrochemical impedance spectroscopy in the frequency domain [25].

As shown in Figure 4d, transmission line modules are used to emulate the distributed capacitance and electrolyte resistance determined by the porous electrodes [26]. In general, a higher number of RC networks increases the fidelity of the model with the cost of high computational power.

Figure 4.

Supercapacitor equivalent circuit models [19,23,24,26]. (a): Simplified model, (b) Zubieta and Boner developed model, (c) modified version of Zubieta and Boner developed model, (d) Transmission line model.

Figure 4.

Supercapacitor equivalent circuit models [19,23,24,26]. (a): Simplified model, (b) Zubieta and Boner developed model, (c) modified version of Zubieta and Boner developed model, (d) Transmission line model.

4. Limitations and Future Trends of Supercapacitor

One of the major drawbacks of SCs is their low voltage rating, which is typically less than 4 V for a single cell. Due to this limitation, SC modules (SCMs) have been introduced by connecting a large number of SCs in series to increase the voltage ratings up to several hundred volts [27]. However, these SCMs have higher total equivalent resistance due to the series of connected SCs.

Normally, SCs have a 20% tolerance in their rated capacitance. As a result, in an SC bank, the total voltage will not be equally distributed among the individual SC cells [5]. This could create an overcharging issue in some SC cells and potentially cause damage. Active and passive voltage balancing techniques are used to mitigate this issue by monitoring and controlling the charging of each SC cell. Another solution is to use hybrid SC modules that maintain a high voltage rating (typically up to 100 V) while keeping the internal resistance and the size minimum [16]. The concept of hybrid SC modules is to combine an anode of a Titanium electrolyte capacitor with a cathode of electrochemical capacitors. In [28], the authors have demonstrated a hybrid SC module set up rate at 30 J, which has a working voltage of 100 V and the equivalent internal resistance is 0.05 Ω.

Although the energy density of SCs is relatively low compared to batteries, there is much ongoing research to enhance this. In [16], the authors fabricated SCs with nitrogen-incorporated, thiol-functionalized, reduced graphene oxide scrolls (NTGS) powder and determined an energy density of 206 Wh/kg and a power density of 32 kW/h. Moreover, the NTGS cell has cycling stability for 20,000 cycles. Another team from University College London and the Chinese Academy of Sciences developed an SC using graphene laminate films and concentrating on the space between layers [29]. They tested their design and it achieved an energy density of 88.1 Wh/L and retained 97.8% of its energy capacity even after 5000 cycles [29]. Likewise, many researchers and SC manufacturers are in the process of introducing high-energy density SCs to the market. These developments grow the market potential for SCs. It is predicted that the SC market size will grow from USD 472 million in 2022 to USD 912 million by 2027 at an average compound annual growth rate of 14.1% [30].

5. Supercapacitor Applications

5.1. Electrical Vehicle Applications

EV manufacturers use new techniques to enhance the performance and driving range of their products. The unique qualities of SCs, such as higher power density and long-life cycles, are used in EVs to capture regenerative energy more efficiently and deliver a quick power boost with minimal power fluctuations in the DC bus, which reduces stress on the battery pack.

5.1.1. SC and Battery Pack Integrated EV Systems

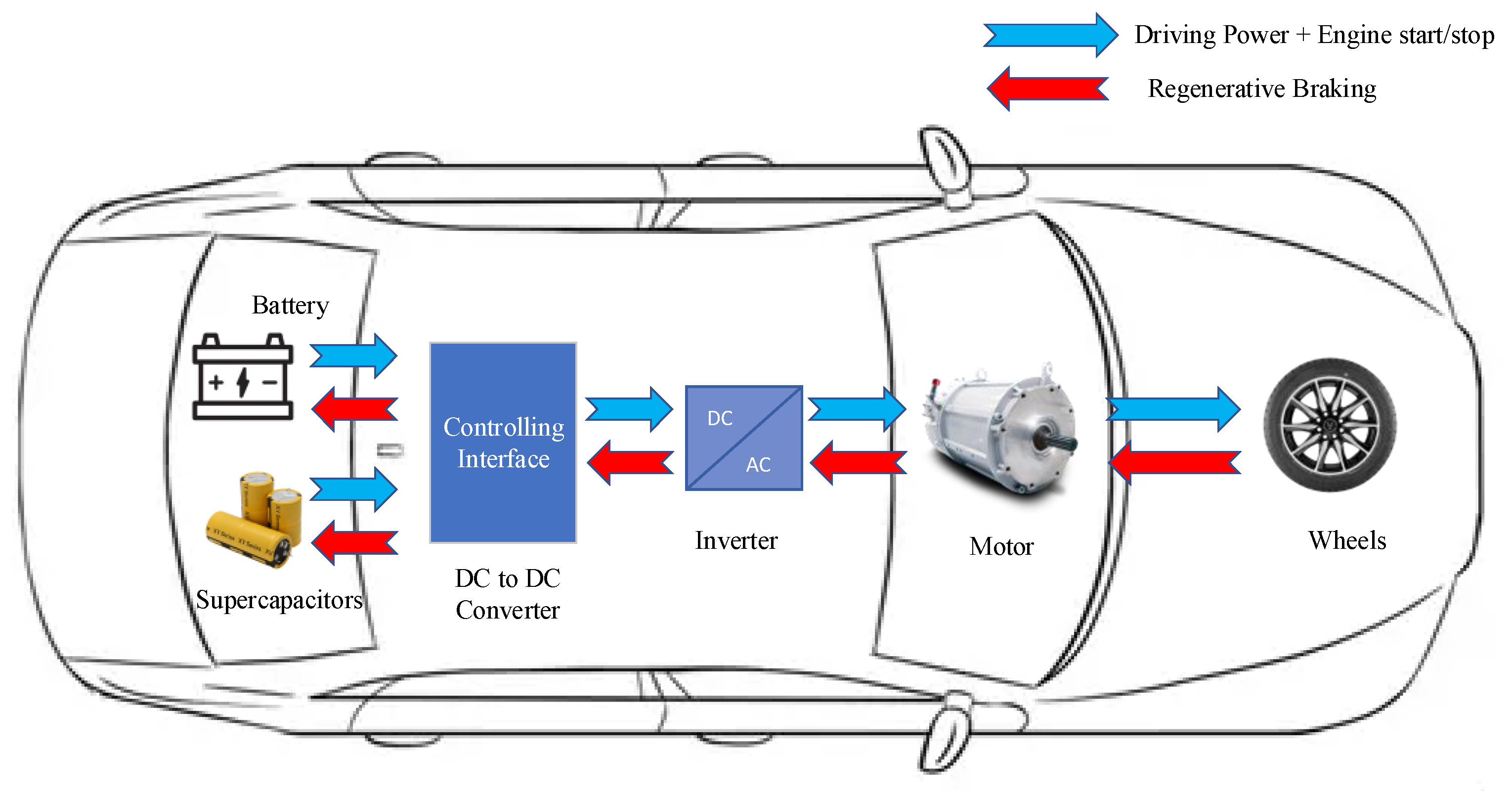

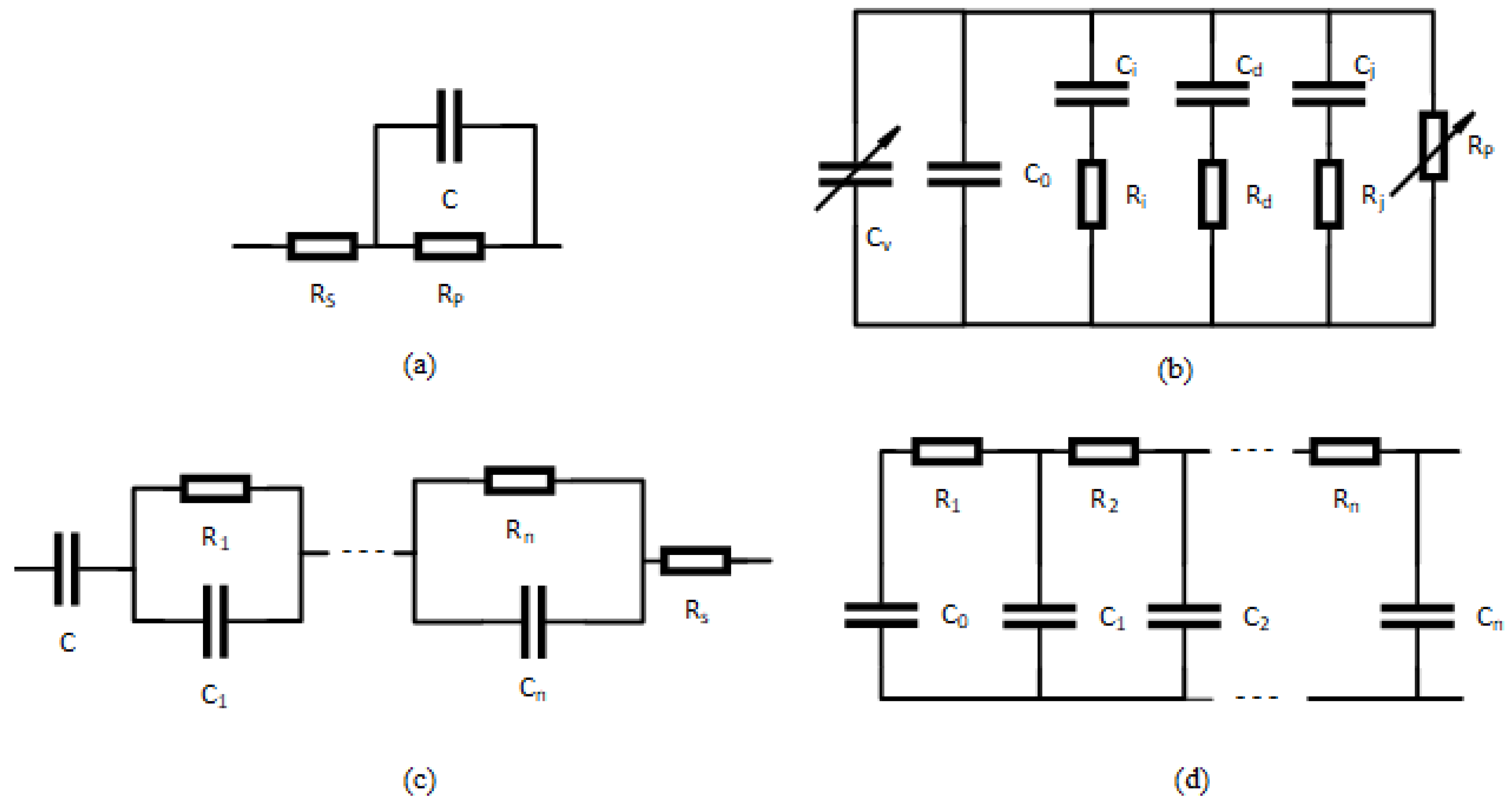

Figure 5 shows a generalized diagram of how SCs are integrated with batteries to power the drive train of an EV. When the accelerator pedal is pressed, the main control system commands the motor to generate the required torque and speed. When braking, the motor goes into generating mode, and the power flow is reversed to charge the battery and the SC, as shown.

Figure 5.

Power management in an electric vehicle.

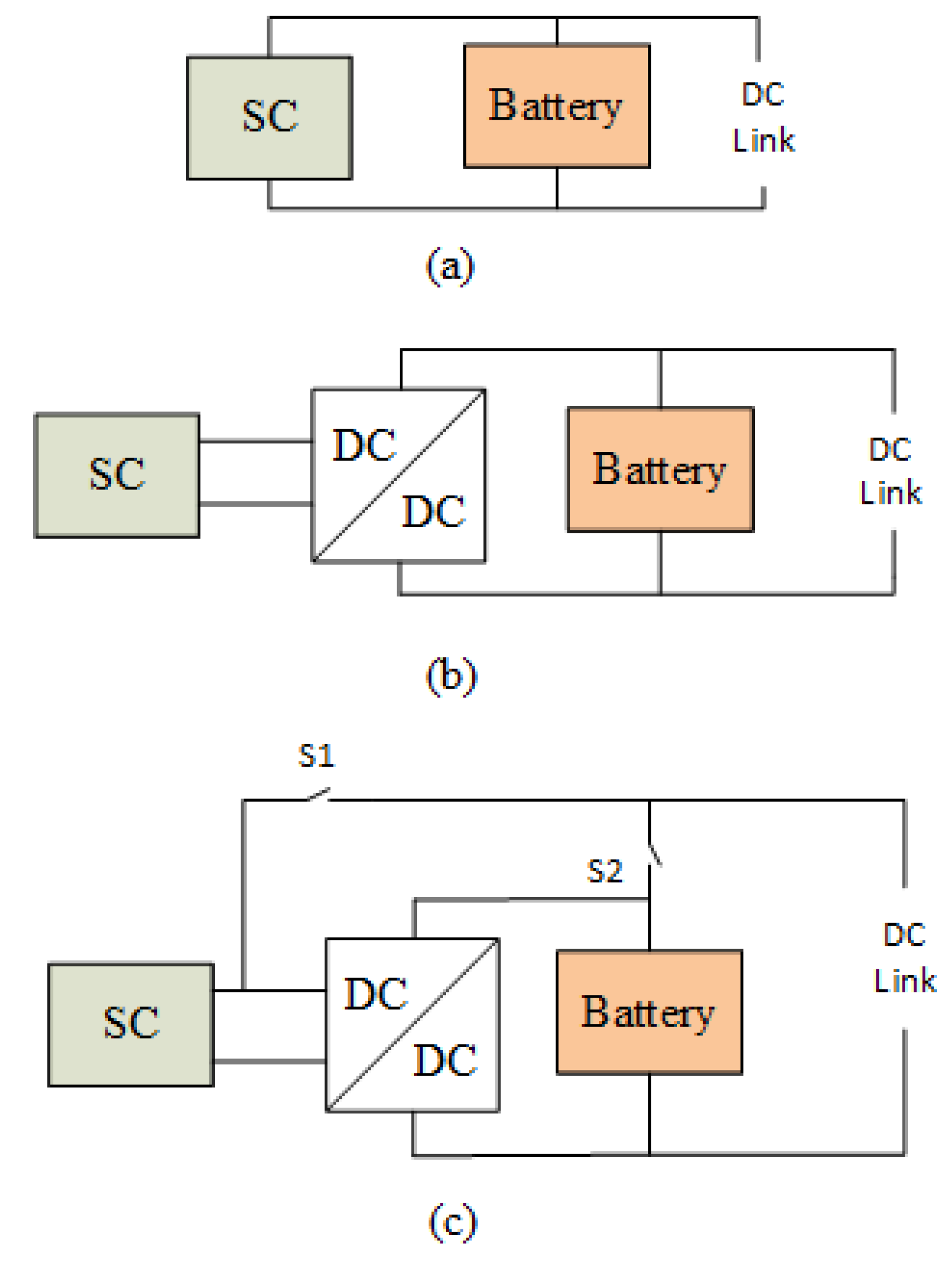

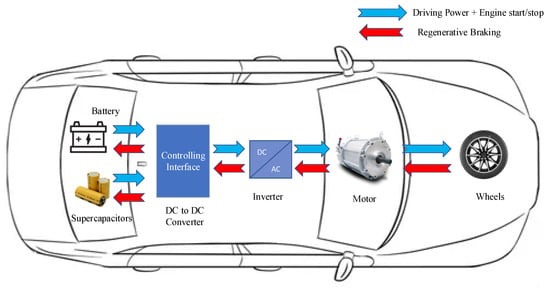

Depending on the power requirement and the type of batteries used, three configurations are available to interface the SC with the battery pack and the DC link of an EV. These configurations are passive, semi-active, and active, depicted in Figure 6 [31].

Figure 6.

Clarification of SC + battery configurations used in EVs: (a) Passive configuration, (b) semi-active configuration, and (c) active configuration [31].

In the passive configuration, as shown in Figure 6a, the battery and the SC are connected directly in parallel to the DC link [32]. Although this configuration is the simplest and most economical method due to the absence of any intermediate DC-to-DC converters, it has some disadvantages [33]. For example, the terminal voltage always follows the discharging characteristics of the battery, which limits the usage of SC voltage. Similarly, the battery requires to supply both load and the SC soon after the SC discharges, which creates additional stresses on the battery [33].

To overcome the issues in passive configuration, the semi-active configuration displayed in Figure 6b has been developed. In this configuration, the battery is directly connected to the DC link, while the SC is connected to the DC link through a DC-to-DC converter. Since the battery is directly connected to the DC link, it can maintain the DC link voltage, while SCs can be operated to deal with large current fluctuations [34]. This approach is typically preferred when a smaller SC pack is used due to its cost-effectiveness and compactness [34]. Moreover, with the direct connection of the battery to the DC link, it is possible to have situations where large currents may be drawn from the battery instead of the SC due to the converter delays [35].

Figure 6c shows the active configuration. This is the most recent development in the SC battery hybrid configurations used in EVs. Here, both the SC and the battery are connected parallel to the DC link through separate DC-to-DC converters. Using this method, a wider operating voltage range of the SC can be achieved while maintaining a constant current flow through the battery. The active configuration can be further modified to achieve a series connection. More details are available in [36]. Even regarding the advantages of this novel configuration, there are still some technical challenges that need to be addressed. For example, this topology requires multiple input variables and a high level of control architecture to give precise control [37].

These configurations are beneficial in regenerative braking (RB) and engine start-stop function in EVs and hybrid EVs where a higher amount of power is required over a short period.

5.1.2. Regenerative Breaking

In modern EVs or hybrid EVs, the kinetic energy is converted to electrical energy during the braking by driving the motor as a generator. As shown in Figure 5, reverse power flow is directed to the SC and the battery. This RB method extends the driving range of an EV or improves the fuel economy of a hybrid EV [38]. Nevertheless, directing the rapid energy recovery during RB into the battery itself can cause stress on the battery, and its long-term performance will degrade [39]. SCs are used as an alternative method to capture the regenerative energy, which is ideal for work during rapid high-power variation situations. With the use of the configurations discussed in Section 5.1.1, all or part of the regenerative energy can be diverted into SCs, depending on the requirement. Most of the major car manufacturers use SCs to capture the energy from the RB. Toyota Supra and FCHV, Mazda 6 and 3, Hyundai Tucson, and Chevrolet Equinox are a few examples [40]. A project demonstrated that the deployment of the RB into the trolley bus system in Ningbo, China, by using a 1500 V SC pack, improved the driving range from 4 to 10 km [41].

There have been many studies to further investigate the best approaches to harvest most of the RB energy while not compromising the safety-braking technologies, such as anti-locked brake systems (ABS). In [42], a team of researchers investigated an optimization method to identify the required braking power to capture the maximum amount of regenerative energy whilst not compromising safety. They formulated an optimal control framework using Pontryagin’s maximum theorem.

A constant current control technique [39] is proposed to capture the regenerative energy using a passive series configuration where the SCs alone absorb the regenerative energy and reduce the stress on the battery.

A simulation-based study was performed to identify the energy-recapturing efficiency of LiFePO4 batteries vs. SCs [43]. Results show that LiFePO4 batteries have an efficiency of approximately 67% when recovering the regenerative energy and the SCs achieved 97% efficiency in capturing it.

A novel approach to control the regenerative power flow between the battery and the SC is proposed in [44], where the controller is programmed either to direct the current to the battery or the SC during the RB based on the pre-defined current threshold values. Afterwards, there is current sharing between the battery and the SC within their respective current limits to keep the charge balance between the battery and the SC. One drawback of this concept is that the entire control is based on pre-defined current threshold values, and this could change from one system to another. Moreover, as the batteries age, the current rating changes, and the threshold values should be updated.

5.1.3. Start and Stop Systems

Typically, when restarting EVs or hybrid EVs, a high current is drawn over a short period. Drawing this current from a conventional battery will cause significant stress and will reduce its life span. Due to the low ESR of SCs compared to batteries, they can be used to supply this burst of power to start the vehicle [45]. This extends the life of the battery by lowering the stress on it and provides a faster and smoother starting capability [45,46]. Moreover, this method is attractive as the SCs are maintenance-free and typically last the entire life of the vehicle [46].

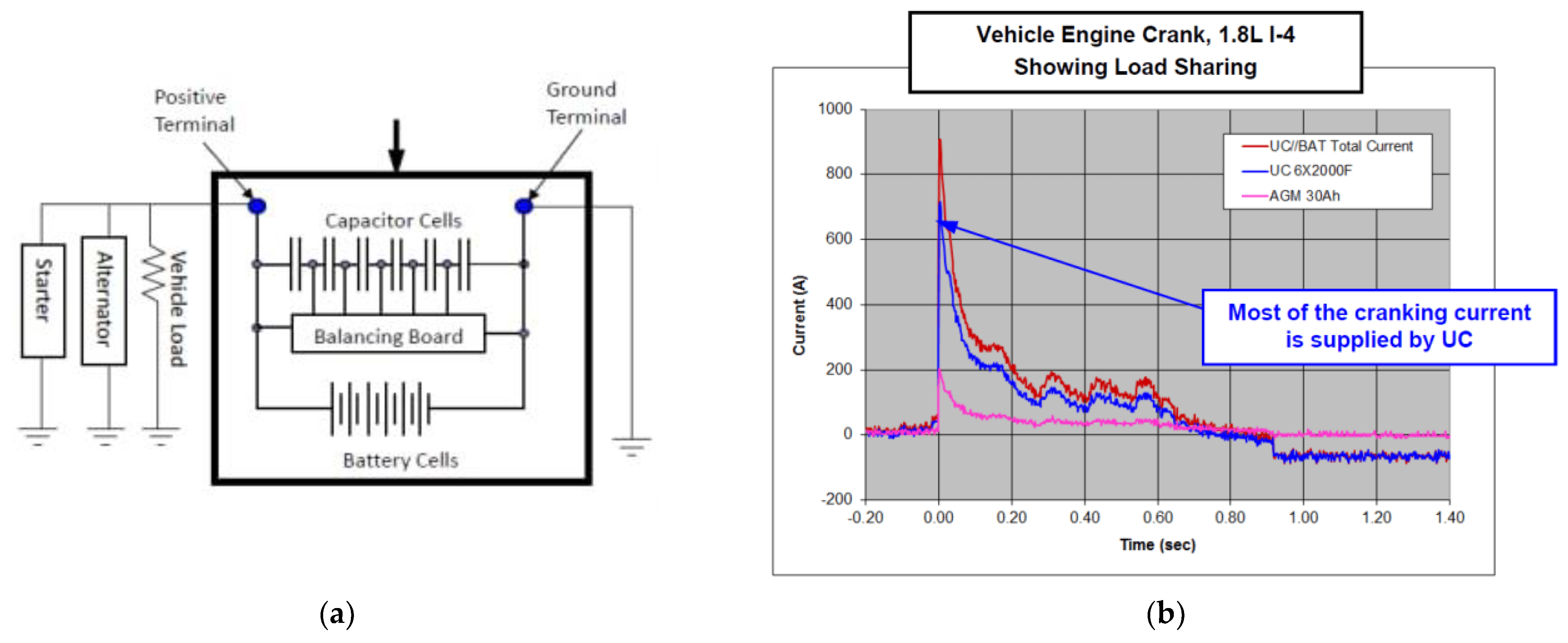

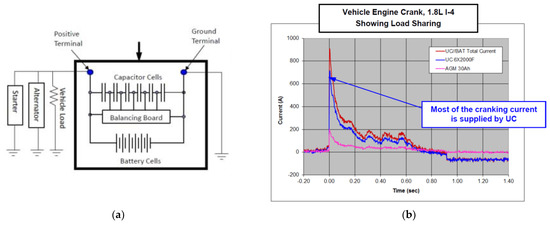

Maxwell Technologies’ Continental Automotive Systems’ Maxwell-powered voltage stabilization system (VSS) is one of the well-established automotive applications where SCs are used for the engine start-stop function. This technique used in Cadillac ATS, CTS sedans and ATS coupés [46]. As shown in Figure 7a, six 2000F ultracapacitors (UCs) are connected parallel with a 30 Ah battery to assist the battery during the start and stop [47]. As shown in the performance curves in Figure 7b, most of the starting current is supplied by the UCs, alleviating stress on the battery.

Figure 7.

Maxwell-powered voltage stabilization system (VSS) (a) capacitor and battery setup, (b) performances characteristics [47].

Skeleton Technologies’, SkelStart Engine Start Module (shown in Figure 8) is another SC automotive application primarily used in trucks to assist the start-stop function [48]. The 12 V SkelStart Engine Start Module with a rated capacitance of 1280F can deliver 7644 A in 0.4 s and achieve a peak power is 62.9 kW. Due to its wide operating temperature range (−40 °C to +65 °C), this module can be used in a wider range of environments. The module is installed between the battery and the starter motor of the vehicle. While the Skelstart module drives the starter motor, the battery powers up the other electrical loads, such as light fans. It was found that this module can reduce fuel consumption by 2% to 6% and increase the battery life up to 1.5 to 2 times [48].

Figure 8.

SkelStart module installation [48].

5.2. Microgrid Applications

Recently, microgrids have become popular due to the distributed power generation. Most of the distributed power generators, such as solar and wind in microgrids, depend highly on weather conditions and are treated as intermittent power sources. Therefore, microgrids require energy storage to compensate for power fluctuations. Although batteries are used for this purpose, their performance degrades, and their lifetime becomes shorter due to the rapid charging and discharge currents [31,49]. SCs are the perfect solution to stabilize power fluctuations and reduce the stress on batteries. Therefore, hybrid energy storage (HES) systems are typically used in microgrids to integrate both batteries and SCs [31,49,50].

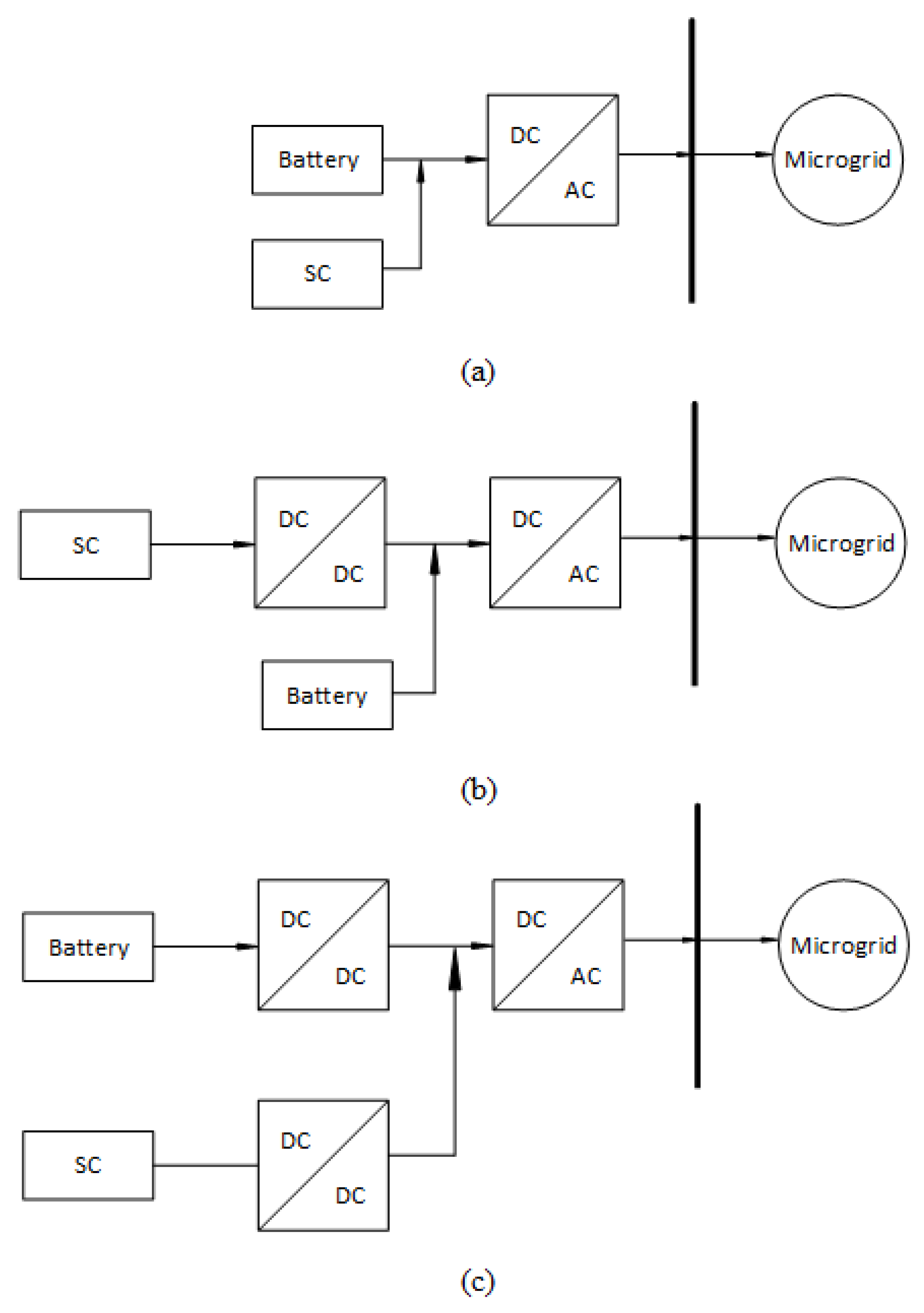

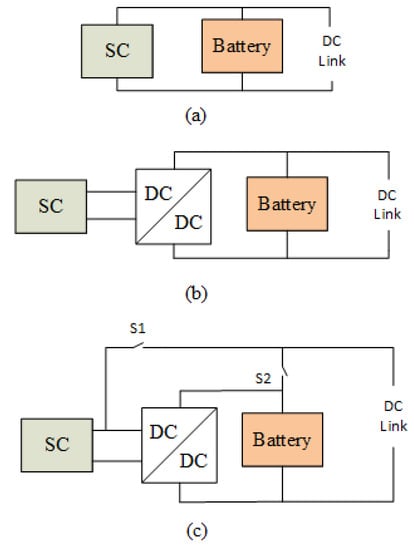

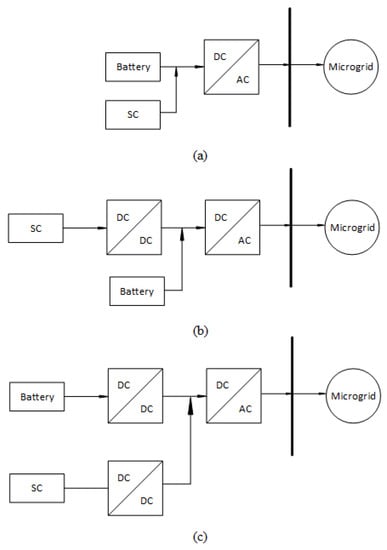

Researchers focus on implementing new strategies to integrate SCs in HES systems., Three main topologies have been proposed in the literature to control HES systems [51]: Passive topology, semi-active topology, and active topology. In passive topology, as shown in Figure 9a, batteries and SCs directly connect to the inverter [52]. Although this topology is a cost-effective and simple solution, it brings some limitations, such as less controllability in sharing power between the battery and the SC, vulnerability of the battery to sudden power variations, and the requirement for exact voltage matching to the DC bus voltage [53]. To overcome these issues, a semi-active topology was introduced, as depicted in Figure 9b, which has some flexibility in the power flow control [54]. In this configuration, while the battery is directly connected to the inverter, the SC is connected through a DC-to-DC converter. Hence the battery maintains the DC link voltage, and the SCs compensate for the sudden fluctuations. The main drawback of semi-active topology is that it requires expensive high current rated DC-to-DC converters to meet high power demands. Figure 9c shows the active topology where both the SC and the battery are connected to the inverter via separate DC-to-DC converters [55]. Although active control topology offers a high level of controllability in both power sharing and voltage control, it is the most expensive approach of the three methods.

Figure 9.

Supercapacitor + battery hybrid topologies used in microgrids (a) passive topology, (b) semi-active topology, and (c) active topology [51].

So far, there have been few real-world applications of SCs in microgrids as most of the HES technologies are at the research level. In 2016, Duke Energy installed a 1.2 MW HES system using Maxwell Technologies’ fast response ultra-capacitors in North Carolina in the United States. In 2018, the Fraunhofer Institute for Solar Energy Systems energized a HES system utilizing renewable energy in Borkum Island in Germany. This microgrid HES system consists of 1 MW/10 kWh of Maxwell ultracapacitors and 500 kW/500 kWh of Li-ion batteries [56]. Moreover, in 2019, a hydrogen-supercapacitor-based rural microgrid pilot project was successfully executed in the Malaysian mountainside village of “Orang Asli”. This consists of 4.7 kW (peak power) solar PV, a 1.1 kW fuel cell, and 10 kWh supercapacitors [57]. With continuous successes at the research level, there will be more real-world applications of SCs in microgrids in the near future.

5.3. Portable Applications

In general, camera flashes require high instantaneous power, and most traditional devices use batteries to fulfill this requirement, which makes the overall design bulkier, heavier, and more expensive. In modern camera flash systems, the batteries are supplemented by SCs to achieve a longer lifetime, less complexity, high flash intensity, and high stability. Some commercialized brands, such as Dual 1080P Dash Cam, Avaett D60 (No battery included), and SC WIFI GPS dash cam- Q6S4 already use this technology.

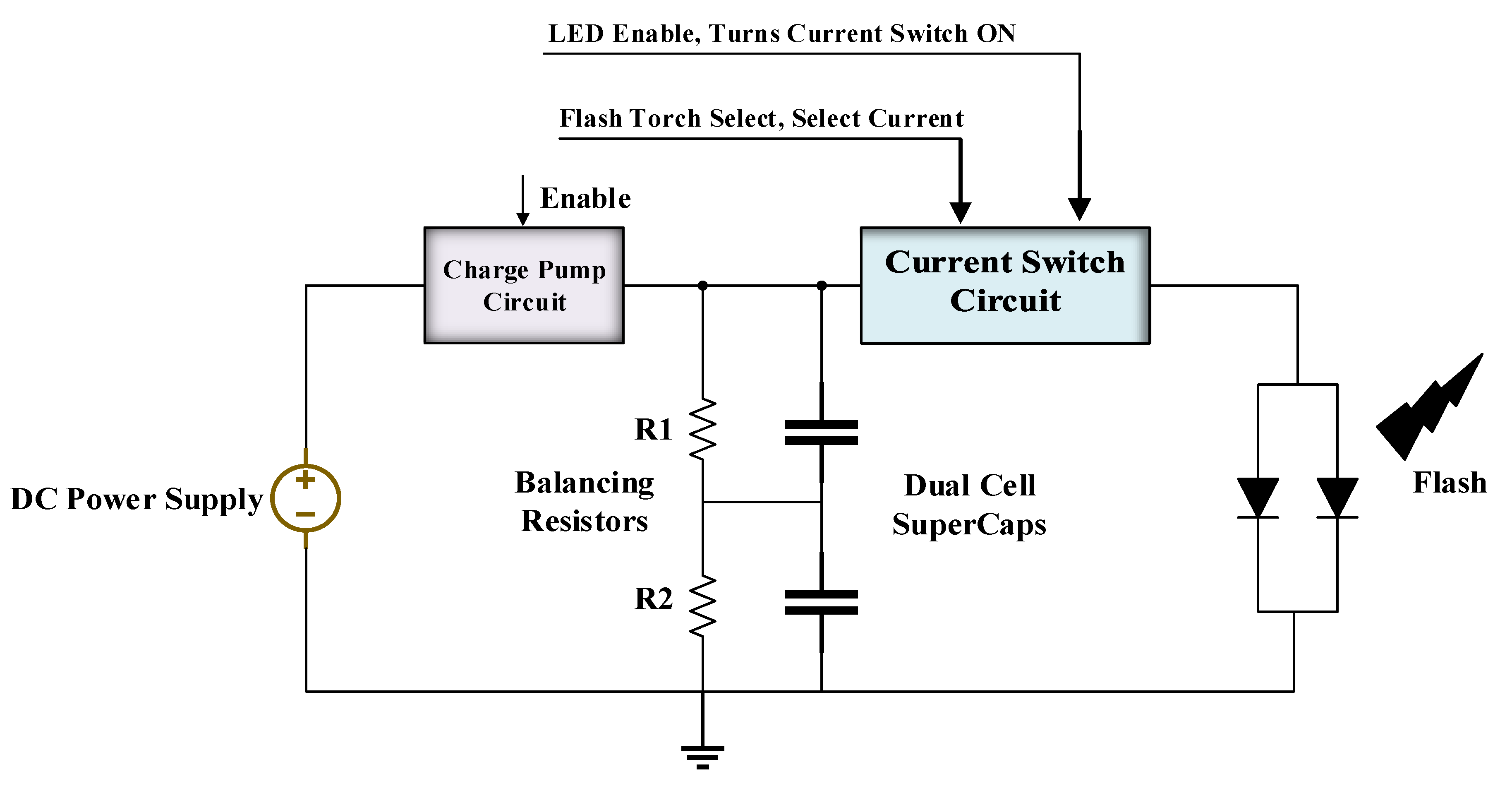

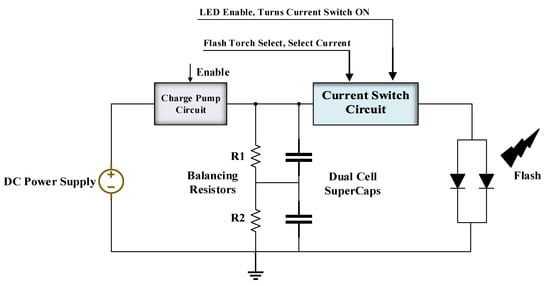

Figure 10 depicts a dual-cell SC-based camera flash system [58,59]. This circuit is activated through a series of external commands, such as activation of the charge pump circuit to charge the SCs, LED enabling, flash torch selection, and flash current limiting. Once the charge pump circuit is enabled, the SCs are charged, and when the flashlight drive is enabled, the SCs release high instantaneous power into the flashlight. The balancing resistors ensure that the voltage on each cell is equal to half of the output voltage to prevent an overvoltage condition on either cell. Some flashlight driver chip manufacturers often use active balancing circuits instead of resistors to minimize the losses and reduce the self-discharge [59]. The current switch solid-state circuit ensures that the right amount of light is provided for high-quality photography. Additionally, it provides a current limiting function, overload protection, and a steady and consistent range of the flash.

Figure 10.

Camera Flash SC-based block diagram [58,59].

Cordless screwdrivers are another application where SCs are used to give power boost function along with a fast-charging capability. For example, the 5.4 V cordless FlashCell screwdriver from Coleman shown in Figure 11a can charge quickly (typically in 90 s) and drive 22 screws per single charge compared to the 37 screws capability of the equivalent battery-powered screwdriver, shown in Figure 11b, which takes hours to recharge.

Figure 11.

Cordless screwdrivers: (a) Coleman 5.4 V Flash-Cell ultracapacitor driven screwdriver, (b) SKIL 2336-02 iXO 3.6 V Lithium-ion battery driven screwdriver.

In summary, supercapacitors are cutting-edge energy storage devices that offer a wide range of desirable features, including high capacitance, high power density, and extended cycle times, and they are now being used in a large variety of applications, such as EVs, microgrids, and portable products. Table 3 summarizes three practical examples of applications of supercapacitors with their voltage ratings and capacity.

Table 3.

Summary of supercapacitor applications [47,56,57,58].

6. Conclusions

It is evident that SC technology has matured over the past decade into a variety of SC families, which achieve energy densities above 10,000 F with a longer cycle life and many other attractive characteristics complementary to battery energy storage. With the exponentially growing electrical vehicle market, the attractive properties of SCs have a wide application scope as power boost mechanisms. In addition, SCs as hybrid energy stores in microgrids support the growing distributed energy applications. Furthermore, an SC is a reliable energy source for power boost requirements in some portable devices, such as camera flashes, screwdrivers, etc. The application scope will continue to grow in other domains due to the fast-evolving SC technological advancements.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Viswanathan, A.; Shetty, A.N. The high energy supercapacitor from rGO/Ni(OH)2/PANI nanocomposite with methane sulfonic acid as dopant. J. Colloid Interface Sci. 2019, 557, 367–380. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Zhao, B.; Zhang, W.; Shi, F.; Zheng, G.; Zhang, D.; Yang, J. High-Performance Supercapacitor Applications of NiO-Nanoparticle-Decorated Millimeter-Long Vertically Aligned Carbon Nanotube Arrays via an Effective Supercritical CO2-Assisted Method. Adv. Funct. Mater. 2015, 25, 7381–7391. [Google Scholar] [CrossRef]

- Jiang, C.; Zhao, B.; Cheng, J.; Li, J.; Zhang, H.; Tang, Z.; Yang, J. Hydrothermal synthesis of Ni(OH)2 nanoflakes on 3D graphene foam for high-performance supercapacitors. Electrochim. Acta 2015, 173, 399–407. [Google Scholar] [CrossRef]

- Lamedica, R.; Ruvio, A.; Tobia, M.; Buffarini, G.G.; Carones, N. A Preliminary Techno-Economic Comparison between DC Electrification and Trains with On-Board Energy Storage Systems. Energies 2020, 13, 6702. [Google Scholar] [CrossRef]

- Kularatna, N.; Subasinghage, K.; Gunawardane, K.; Jayananda, D.; Ariyarathna, T. Supercapacitor-Assisted Techniques and Supercapacitor-Assisted Loss Management Concept: New Design Approaches to Change the Roadmap of Power Conversion Systems. Electronics 2021, 10, 1697. [Google Scholar] [CrossRef]

- Automotive & Passenger Car Applications—Supercapacitors | Skeleton. Available online: http://www.skeletontech.com/automotive-applications (accessed on 1 October 2022).

- Large-Scale, Available Graphene Supercapacitors; How Close Are We? Available online: https://www.azonano.com/article.aspx?ArticleID=6053 (accessed on 1 October 2022).

- Lemian, D.; Bode, F. Battery-Supercapacitor Energy Storage Systems for Electrical Vehicles: A Review. Energies 2022, 15, 5683. [Google Scholar] [CrossRef]

- Houache, M.S.E.; Yim, C.-H.; Karkar, Z.; Abu-Lebdeh, Y. On the Current and Future Outlook of Battery Chemistries for Electric Vehicles—Mini Review. Batteries 2022, 8, 70. [Google Scholar] [CrossRef]

- Gunawardane, K.; Bandara, N.; Subasinghage, K.; Kularatna, N. Extending the Input Voltage Range of Solar PV Inverters with Supercapacitor Energy Circulation. Electronics 2021, 10, 88. [Google Scholar] [CrossRef]

- Zhou, Z. Modeling and Power Control of a Marine Current Turbine System with Energy Storage Devices; Universit’e de Bretagne, Occidentale: Brest, France, 2014. [Google Scholar]

- Roth, W.D. Super and Ultracapacitors Thousands of Farads Thanks to Double Layer Technology; EETech Media: Boise, ID, USA, 2019. [Google Scholar]

- Kularatna, N.; Gunawardane, K. Energy Storage Devices for Renewable Energy-Based Systems; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Eaton’s HS Hybrid Supercapacitors Combine Proprietary Materials to Achieve Greater Energy Density and Cycle Lifetimes; EATON Electronics Division: Cleveland, OH, USA, 2021.

- Schweber, B. Use Hybrids To Bring the Benefits of Both Batteries and Supercapacitors to Power IoT Designs. Available online: https://www.digikey.com/en/articles/use-hybrids-to-bring-the-benefits-of-both-batteries-and-supercapacitors-to-power-iot-designs (accessed on 17 August 2022).

- Muzaffar, A.; Ahamed, M.B.; Deshmukh, K.; Thirumalai, J. A review on recent advances in hybrid supercapacitors: Design, fabrication and applications. Renew. Sustain. Energy Rev. 2019, 101, 123–145. [Google Scholar] [CrossRef]

- Zhou, L.; Li, C.; Liu, X.; Zhu, Y.; Wu, Y.; van Ree, T. 7—Metal oxides in supercapacitors. In Metal Oxides in Energy Technologies; Wu, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 169–203. [Google Scholar] [CrossRef]

- Samwha Capacitor Group. Available online: http://www.samwha.com/ (accessed on 12 September 2022).

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Corti, F.; Gulino, M.-S.; Laschi, M.; Lozito, G.M.; Pugi, L.; Reatti, A.; Vangi, D. Time-Domain Circuit Modelling for Hybrid Supercapacitors. Energies 2021, 14, 6837. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, W.; Lee, K.B.; Choi, S. Advanced Dynamic Simulation of Supercapacitors Considering Parameter Variation and Self-Discharge. IEEE Trans. Power Electron. 2011, 26, 3377–3385. [Google Scholar]

- Spyker, R.L.; Nelms, R.M. Classical equivalent circuit parameters for a double-layer capacitor. IEEE Trans. Aerosp. Electron. Syst. 2000, 36, 829–836. [Google Scholar] [CrossRef]

- Zubieta, L.; Bonert, R. Characterization of double-layer capacitors for power electronics applications. IEEE Trans. Ind. Appl. 2000, 36, 199–205. [Google Scholar] [CrossRef]

- Rajani, S.V.; Pandya, V.J.; Shah, V.A. Experimental validation of the ultracapacitor parameters using the method of averaging for photovoltaic applications. J. Energy Storage 2016, 5, 120–126. [Google Scholar] [CrossRef]

- Musolino, V.; Piegari, L.; Tironi, E. New Full-Frequency-Range Supercapacitor Model With Easy Identification Procedure. IEEE Trans. Ind. Electron. 2013, 60, 112–120. [Google Scholar] [CrossRef]

- Torregrossa, D.; Bahramipanah, M.; Namor, E.; Cherkaoui, R.; Paolone, M. Improvement of Dynamic Modeling of Supercapacitor by Residual Charge Effect Estimation. IEEE Trans. Ind. Electron. 2014, 61, 1345–1354. [Google Scholar] [CrossRef]

- Kularatna, N. Supercapacitors Improve the Performance of Linear Power-Management Circuits: Unique new design options when capacitance jump from micro-farads to farads with a low equivalent series resistance. IEEE Power Electron. Mag. 2016, 3, 45–59. [Google Scholar] [CrossRef]

- Zhang, L.; Song, J.Y.; Zou, J.Y.; Wang, N. High Voltage Super-Capacitors for Energy Storage Devices Applications. In Proceedings of the 2008 14th Symposium on Electromagnetic Launch Technology, Victoria, BC, Canada, 10–13 June 2008; pp. 1–4. [Google Scholar]

- Blain, L. Researchers Achieve a 10x Supercapacitor Energy Density Breakthrough. Available online: https://newatlas.com/energy/supercapacitor-density-breakthrough/ (accessed on 1 October 2022).

- Li, Z.; Gong, L. Research Progress on Applications of Polyaniline (PANI) for Electrochemical Energy Storage and Conversion. Materials 2020, 13, 548. [Google Scholar] [CrossRef] [PubMed]

- Jing, W.L.; Lai, C.H.; Wong, W.S.H.; Wong, M.L.D. Cost analysis of battery-supercapacitor hybrid energy storage system for standalone PV systems. In Proceedings of the 4th IET Clean Energy and Technology Conference (CEAT 2016), Kuala Lumpur, Malaysia, 14–15 November 2016; pp. 1–6. [Google Scholar]

- Kuperman, A.; Aharon, I.; Malki, S.; Kara, A. Design of a Semiactive Battery-Ultracapacitor Hybrid Energy Source. IEEE Trans. Power Electron. 2013, 28, 806–815. [Google Scholar] [CrossRef]

- Lijun, G.; Dougal, R.A.; Shengyi, L. Power enhancement of an actively controlled battery/ultracapacitor hybrid. IEEE Trans. Power Electron. 2005, 20, 236–243. [Google Scholar]

- Girard, H.-L.; Wang, H.; d’Entremont, A.L.; Pilon, L. Enhancing Faradaic Charge Storage Contribution in Hybrid Pseudocapacitors. Electrochim. Acta 2015, 182, 639–651. [Google Scholar] [CrossRef]

- Lukic, S.M.; Cao, J.; Bansal, R.C.; Rodriguez, F.; Emadi, A. Energy Storage Systems for Automotive Applications. IEEE Trans. Ind. Electron. 2008, 55, 2258–2267. [Google Scholar] [CrossRef]

- Kuperman, A.; Aharon, I. Battery–ultracapacitor hybrids for pulsed current loads: A review. Renew. Sustain. Energy Rev. 2011, 15, 981–992. [Google Scholar] [CrossRef]

- Chia-Hao, T.; Emadi, A. A novel series-parallel reconfigurable hybrid energy storage system for electrified vehicles. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–4. [Google Scholar]

- Chau, K.T. 21—Pure electric vehicles. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance; Folkson, R., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 655–684. [Google Scholar] [CrossRef]

- Pan, C.; Wang, J.; Dai, W.; Chen, L.; Chen, L. Constant current control for regenerative braking of passive series hybrid power system. Int. Trans. Electr. Energy Syst. 2020, 30, e12577. [Google Scholar] [CrossRef]

- Horn, M.; MacLeod, J.; Liu, M.; Webb, J.; Motta, N. Supercapacitors: A new source of power for electric cars? Econ. Anal. Policy 2019, 61, 93–103. [Google Scholar] [CrossRef]

- Lin, J.; Niu, J.; Li, H.; Atiquzzaman, M. A Secure and Efficient Location-based Service Scheme for Smart Transportation. Future Gener. Comput. Syst. 2019, 92, 694–704. [Google Scholar] [CrossRef]

- Parvini, Y.; Vahidi, A. Optimal charging of ultracapacitors during regenerative braking. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012; pp. 1–6. [Google Scholar]

- Perrotta, D.; Ribeiro, B.; Rossetti, R.J.F.; Afonso, J.L. On the Potential of Regenerative Braking of Electric Buses as a Function of Their Itinerary. Procedia Soc. Behav. Sci. 2012, 54, 1156–1167. [Google Scholar] [CrossRef]

- Jin, L.-q.; Zheng, Y.; Li, J.-h.; Liu, Y.-l. A study of novel regenerative braking system based on supercapacitor for electric vehicle driven by in-wheel motors. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef]

- Xie, D.; Liu, M.; Xu, L.; Lu, W. Bi-level programming approach for coordinated configuration of distributed generations and automation devices in distribution networks. Int. J. Electr. Power Energy Syst. 2021, 133, 107210. [Google Scholar] [CrossRef]

- Taranovich, S. General Motors Chooses Ultracapacitors for Start-Stop. Available online: https://www.edn.com/general-motors-chooses-ultracapacitors-for-start-stop/ (accessed on 20 August 2022).

- Werkstetter, S. Ultracapacitors for Start-Stop Systems in Micro-Hybrids. Available online: https://www.engineering.com/story/ultracapacitors-for-start-stop-systems-in-micro-hybrids (accessed on 20 August 2022).

- Skelstart Engine Start Module: A Powerful Module for Reliable Engine Starting for Large Diesel Engines under All Weather Conditions. Available online: https://www.skeletontech.com/skelstart-ultracapacitor-engine-start-module (accessed on 25 August 2022).

- Şahin, M.E.; Blaabjerg, F. A Hybrid PV-Battery/Supercapacitor System and a Basic Active Power Control Proposal in MATLAB/Simulink. Electronics 2020, 9, 129. [Google Scholar] [CrossRef]

- Glavin, M.E.; Chan, P.K.W.; Armstrong, S.; Hurley, W.G. A stand-alone photovoltaic supercapacitor battery hybrid energy storage system. In Proceedings of the 2008 13th International Power Electronics and Motion Control Conference, Poznan, Poland, 1–3 September 2008; pp. 1688–1695. [Google Scholar]

- Babu, T.S.; Vasudevan, K.R.; Ramachandaramurthy, V.K.; Sani, S.B.; Chemud, S.; Lajim, R.M. A Comprehensive Review of Hybrid Energy Storage Systems: Converter Topologies, Control Strategies and Future Prospects. IEEE Access 2020, 8, 148702–148721. [Google Scholar]

- Zheng, J.P.; Jow, T.R.; Ding, M.S. Hybrid power sources for pulsed current applications. IEEE Trans. Aerosp. Electron. Syst. 2001, 37, 288–292. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L. Development of hybrid battery–supercapacitor energy storage for remote area renewable energy systems. Appl. Energy 2015, 153, 56–62. [Google Scholar]

- Song, Z.; Hofmann, H.; Li, J.; Han, X.; Zhang, X.; Ouyang, M. A comparison study of different semi-active hybrid energy storage system topologies for electric vehicles. J. Power Sources 2015, 274, 400–411. [Google Scholar]

- Cohen, I.J.; Wetz, D.A.; Heinzel, J.M.; Dong, Q. Design and Characterization of an Actively Controlled Hybrid Energy Storage Module for High-Rate Directed Energy Applications. IEEE Trans. Plasma Sci. 2015, 43, 1427–1433. [Google Scholar]

- Maxwell Ultracapacitors Providing Resilience to Island Microgrids. Available online: https://ease-storage.eu/news/netfficient-maxwell-ultracapacitors-providing-resiliency-to-island-microgrids/ (accessed on 1 October 2022).

- Hydrogen-Supercapacitor Rural Microgrid. Available online: https://www.enapter.com/application/hydrogen-supercapacitor-rural-microgrid (accessed on 1 October 2022).

- Using Supercapacitors to Solve LED Flash Power Issues for High Resolution Camera Phones. Available online: https://www.cap-xx.com/wp-content/uploads/2015/04/Using-Supercapacitors-to-Solve-LED-Flash-Power-Issues-for-High-Res-CamPhones.pdf (accessed on 2 October 2022).

- LM3550 5-A Super-Capacitor Flash LED Driver; Texas Instruments Incorporate: Dallas, TX, USA, 2009; Available online: https://www.ti.com/product/LM3550 (accessed on 12 September 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).