Investigation on Flowback Behavior of Imbibition Fracturing Fluid in Gas–Shale Multiscale Pore Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of Shale Samples

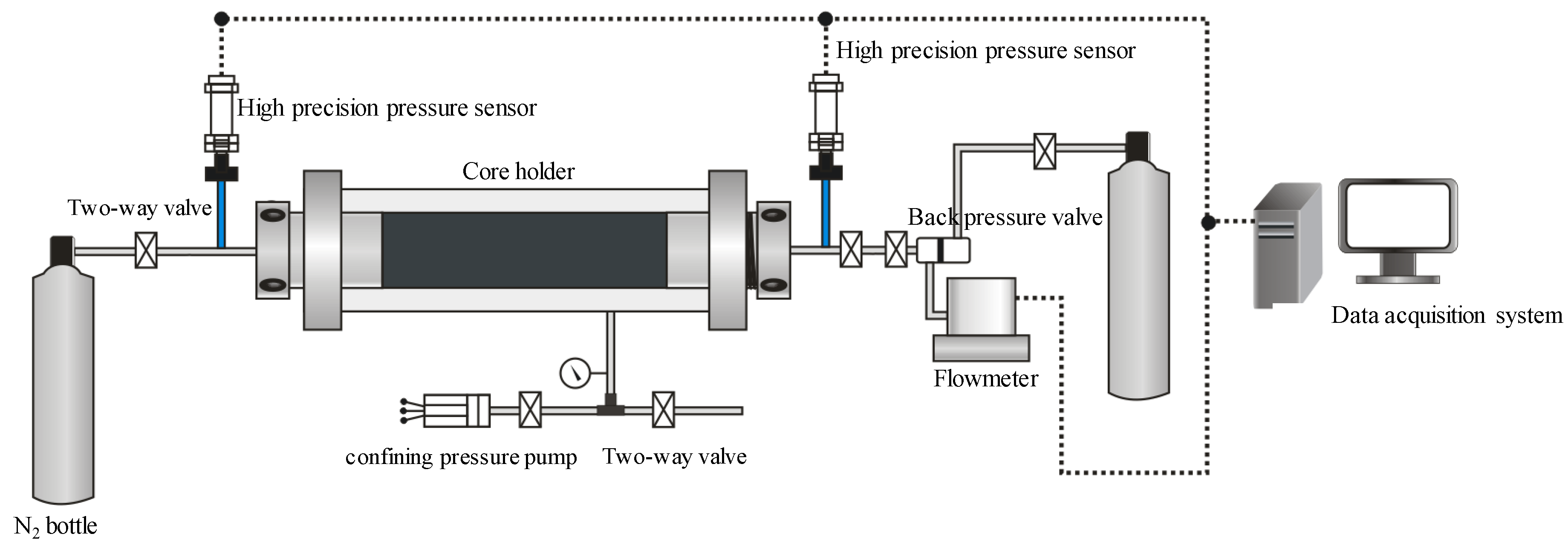

2.2. Experimental Procedures

2.2.1. Influence of Flowback Time on Flowback Behavior of Shale Fracturing Fluid

2.2.2. Influence of Flowback Pressure Difference on Flowback Behavior of Shale Fracturing Fluid

3. Results and Discussion

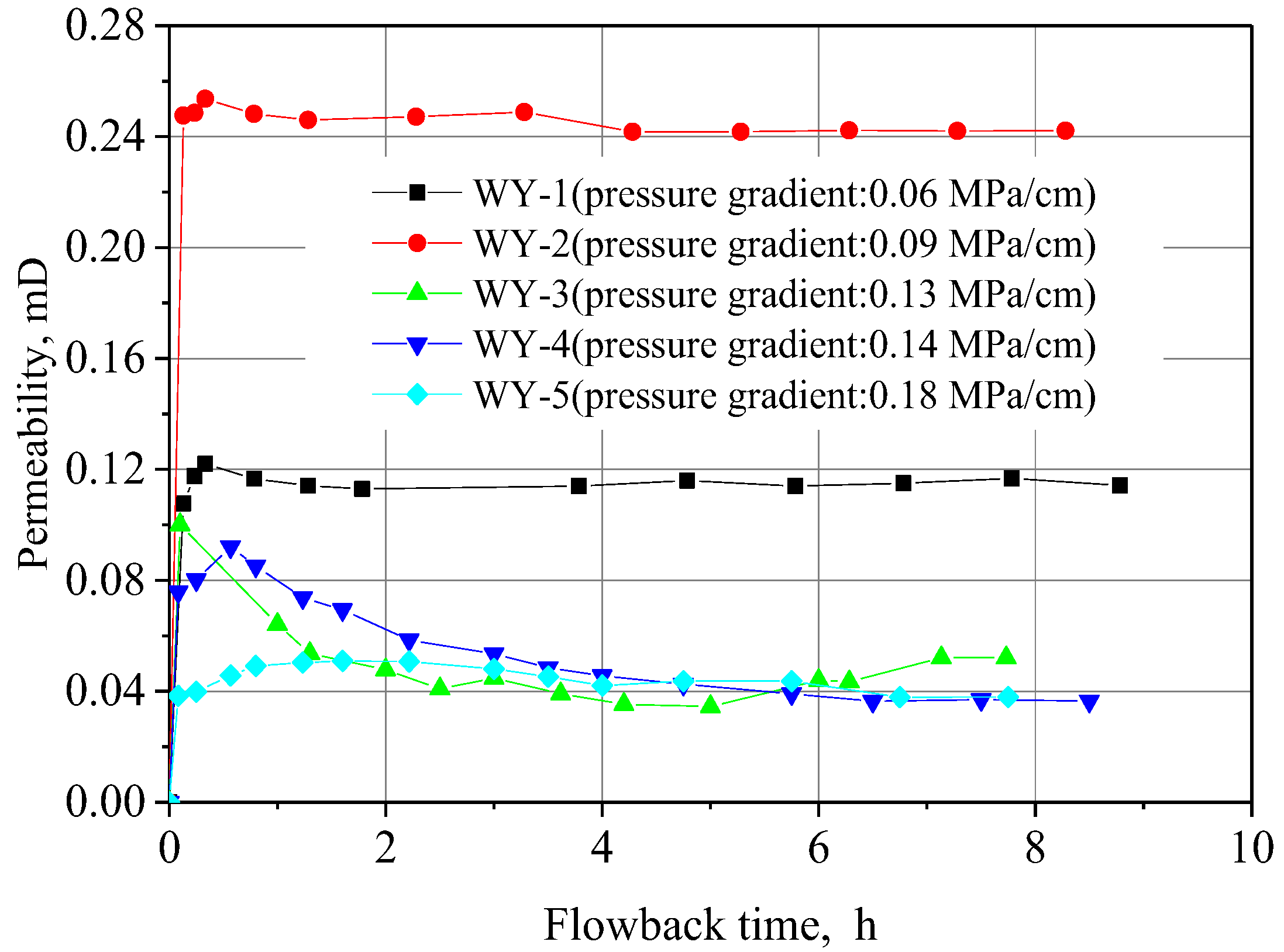

3.1. Response Characteristics of Shale Gas Permeability to Fracturing Fluid Flowback Time

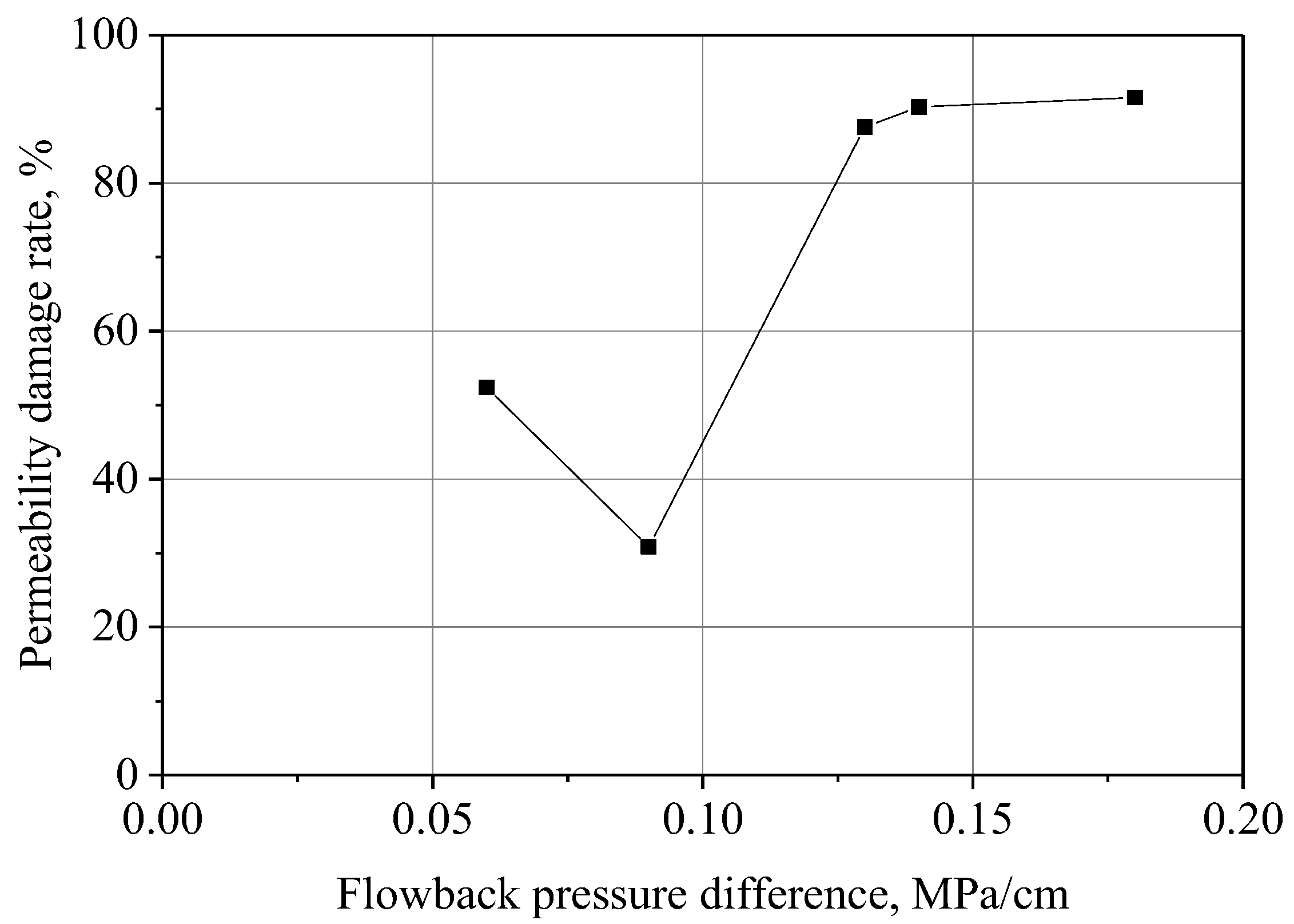

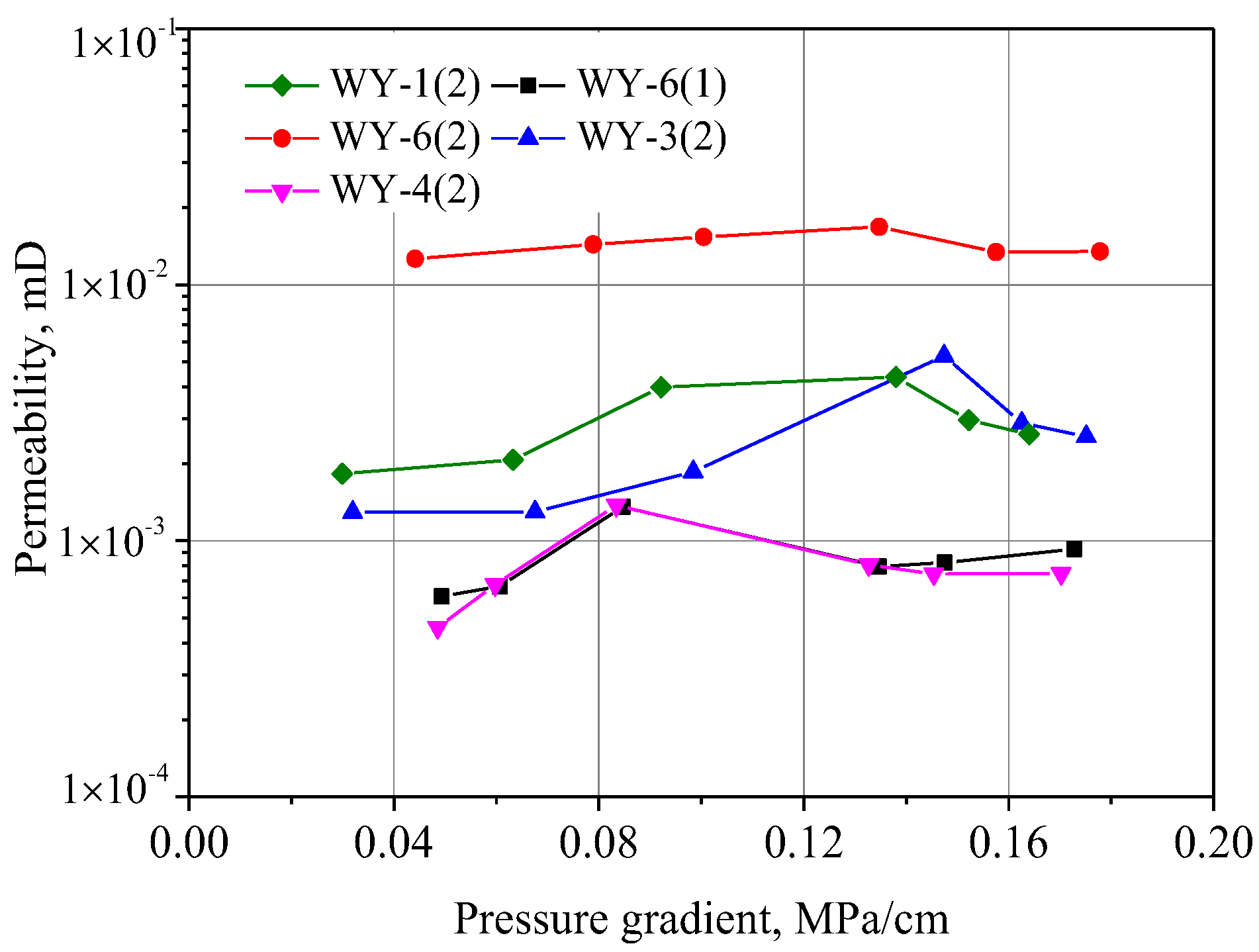

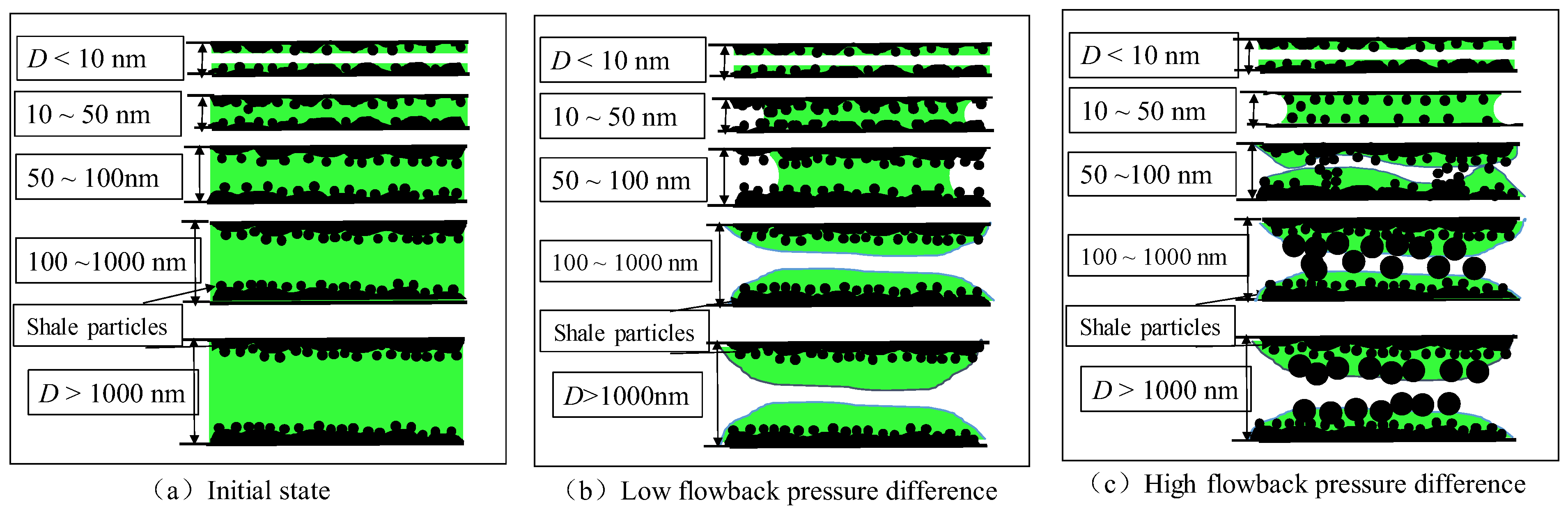

3.2. Response Characteristics of Shale Gas Phase Permeability to Pressure Difference of Fracturing Fluid Flowback

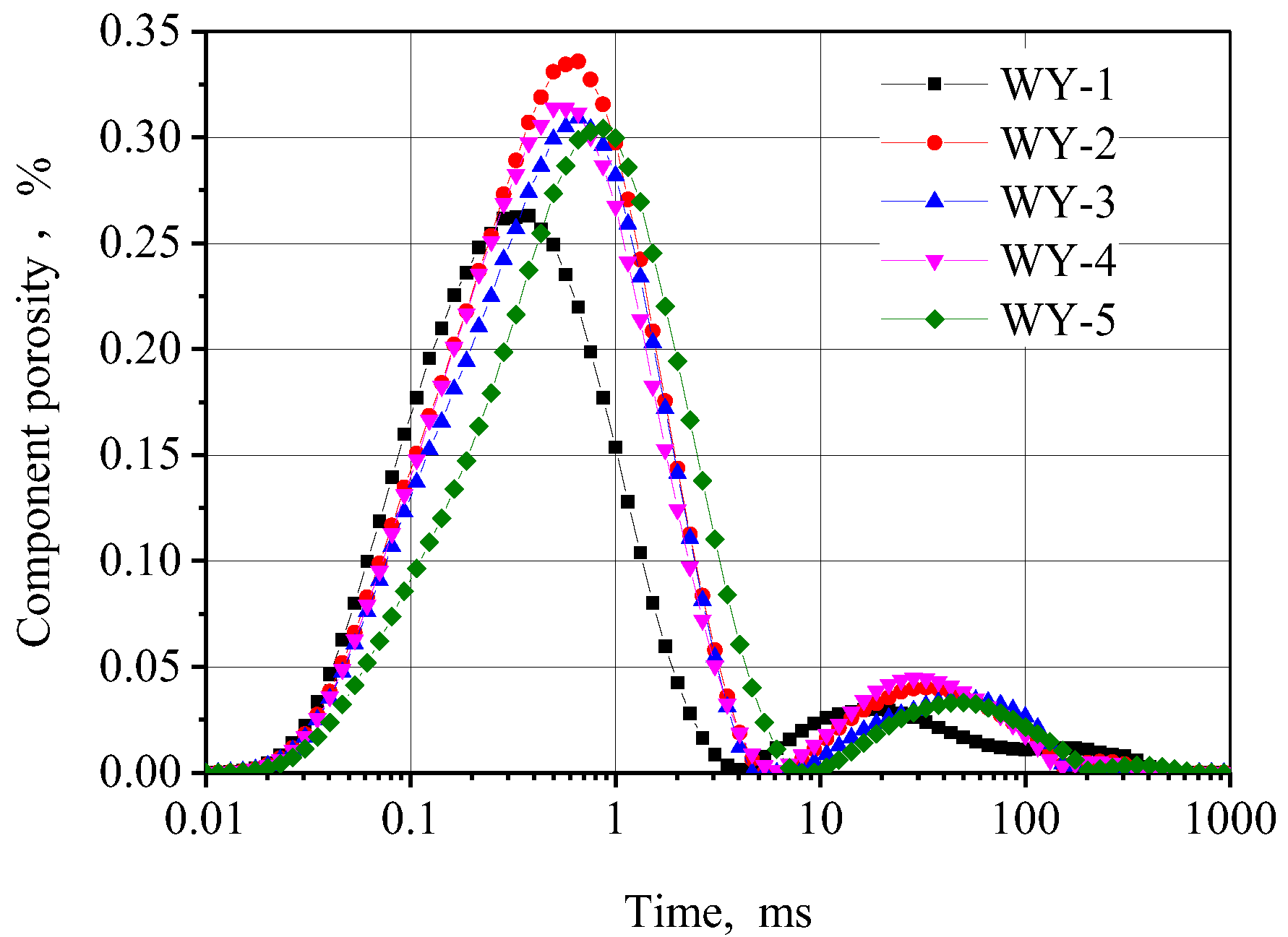

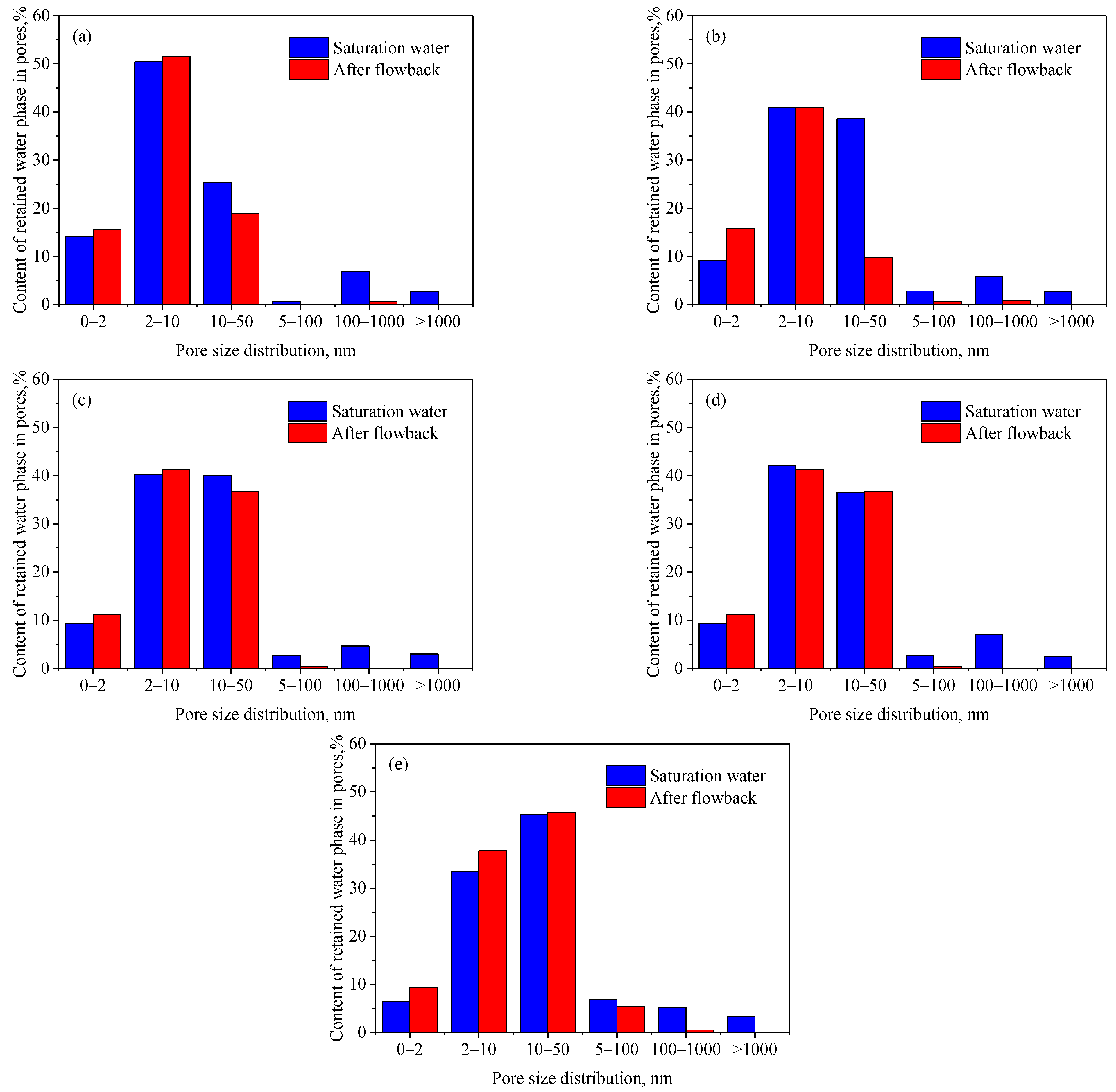

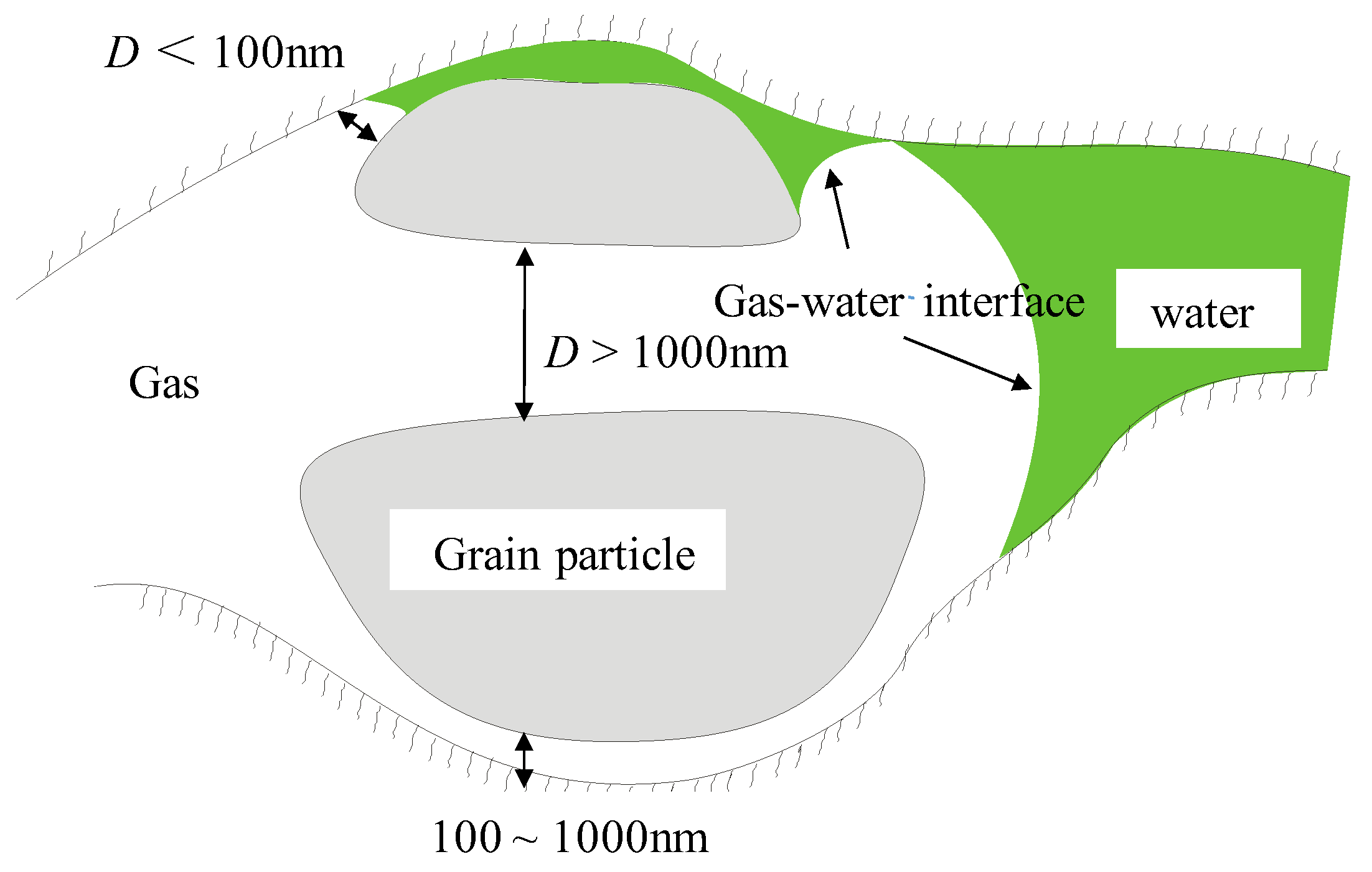

3.3. Distribution Characteristics of Water in Shale before and after Fracturing Fluid Flowback

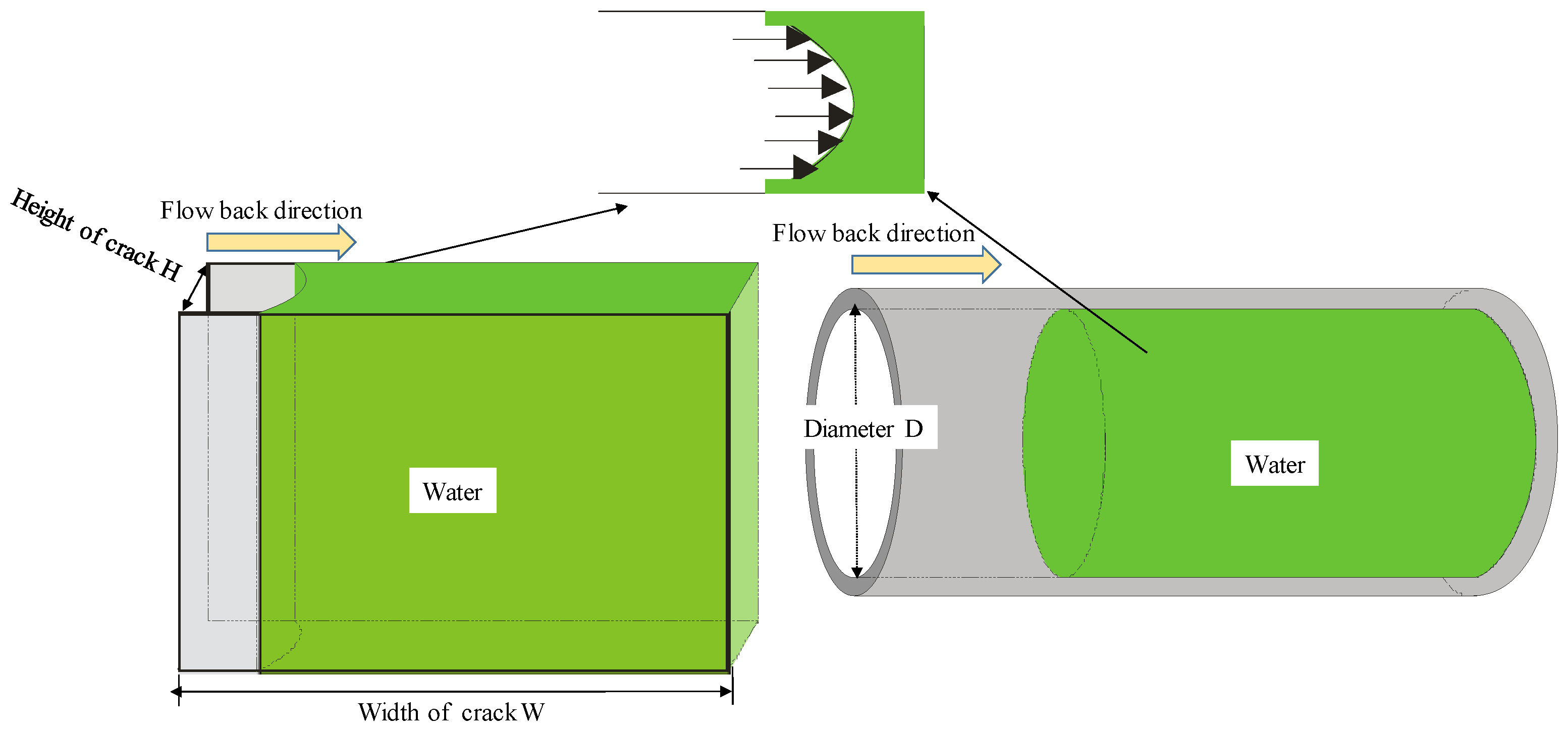

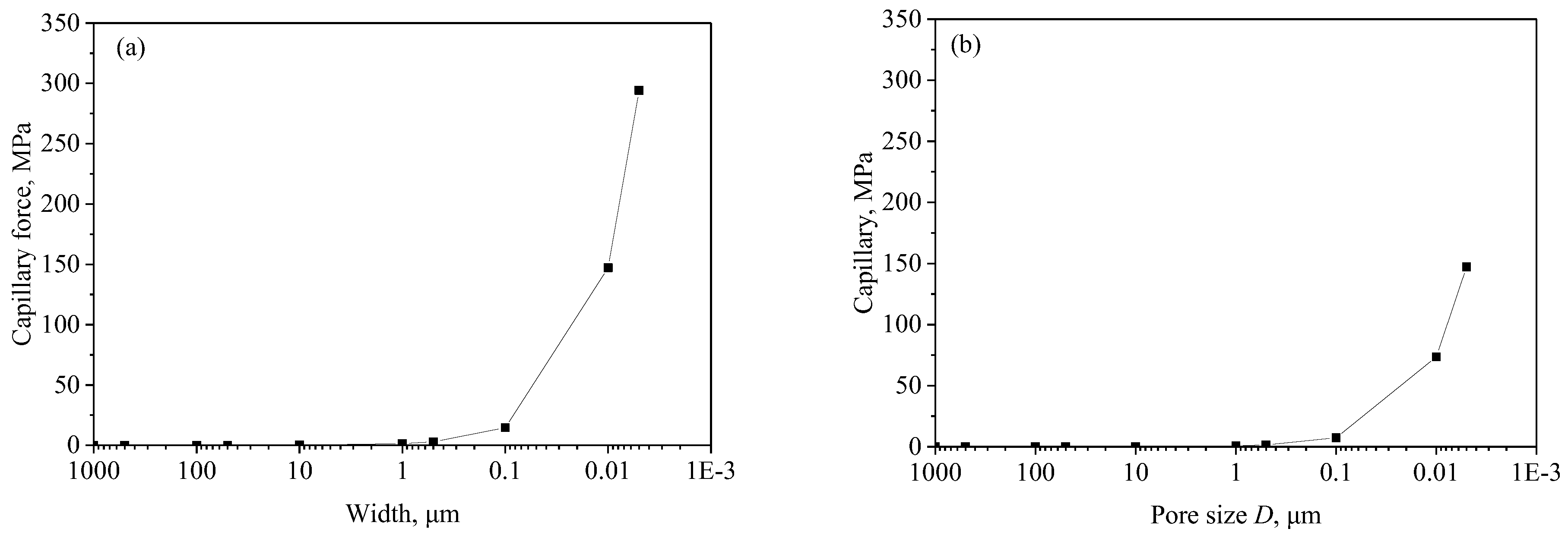

3.4. Influence of Particle Migration in Shale Fracture Surface on Shale Gas Phase Permeability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X.; Kang, J.; Lan, B. Focus on the Development of Shale Gas in China—Based on SWOT Analysis.21. Available online: https://www.sciencedirect.com/science/article/pii/S1364032112007496 (accessed on 12 February 2013).

- Yang, H.; Han, X.; Wang, L. Is there a bubble in the shale gas market? Energy 2021, 215, 119101. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0360544220322088 (accessed on 27 October 2020). [CrossRef]

- Gao, S.; Dong, D.; Tao, K.; Guo, W.; Li, X.; Zhang, S. Experiences and lessons learned from China’s shale gas development: 2005–2019. J. Nat. Gas Sci. Eng. 2021, 85, 103648. Available online: https://linkinghub.elsevier.com/retrieve/pii/S1875510020305023 (accessed on 4 November 2020). [CrossRef]

- Kilian, L. The Impact of the Shale Oil Revolution on U.S. Oil and Gasoline Prices. Rev. Environ. Econ. Policy 2016, 10, 185–205. [Google Scholar] [CrossRef]

- Trainor, A.M.; McDonald, R.I.; Fargione, J. Energy Sprawl Is the Largest Driver of Land Use Change in United States. PLoS ONE 2016, 11, e0162269. [Google Scholar] [CrossRef]

- Wei, J.; Duan, H.; Yan, Q. Shale gas: Will it become a new type of clean energy in China?—A perspective of development potential. J. Clean. Prod. 2021, 294, 126257. Available online: https://www.sciencedirect.com/science/article/pii/S0959652621004777 (accessed on 8 February 2021). [CrossRef]

- Wang, Q.; Lyu, C.; Cole, D.R. Effects of hydration on fractures and shale permeability under different confining pressures: An experimental study. J. Pet. Sci. Eng. 2019, 176, 745–753. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0920410519300750 (accessed on 25 January 2019). [CrossRef]

- Wang, Q.; Hu, Q.; Larsen, C.; Zhao, C.; Sun, M.; Zhang, Y.; Zhang, T. Microfracture-pore structure characterization and water-rock interaction in three lithofacies of the Lower Eagle Ford Formation. Eng. Geol. 2021, 292, 106276. Available online: https://www.sciencedirect.com/science/article/pii/S0013795221002878 (accessed on 15 July 2021). [CrossRef]

- Bai, J.; Kang, Y.; Chen, Z.; You, L.; Chen, M.; Li, X. Changes in retained fracturing fluid properties and their effect on shale mechanical properties. J. Nat. Gas Sci. Eng. 2020, 75, 103163. Available online: https://linkinghub.elsevier.com/retrieve/pii/S1875510020300172 (accessed on 13 January 2020). [CrossRef]

- Zhong, C.; Zolfaghari, A.; Hou, D.; Goss, G.G.; Lanoil, B.D.; Gehman, J.; Tsang, D.C.W.; He, Y.; Alessi, D.S. Comparison of the Hydraulic Fracturing Water Cycle in China and North America: A Critical Review. Environ. Sci. Technol. 2021, 55, 7167–7185. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Li, J.; Zou, C.; Cui, H.; Ni, Y.; Liu, J.; Wu, W.; Zhang, L.; Coyte, R.; Kondash, A.; et al. Recycling flowback water for hydraulic fracturing in Sichuan Basin, China: Implications for gas production, water footprint, and water quality of regenerated flowback water. Fuel 2020, 272, 117621. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0016236120306165 (accessed on 3 April 2020). [CrossRef]

- Lin, B.; Guo, J.; Liu, X.; Xiang, J.; Zhong, H. Prediction of flowback ratio and production in Sichuan shale gas reservoirs and their relationships with stimulated reservoir volume. J. Pet. Sci. Eng. 2020, 184, 106529. Available online: https://www.sciencedirect.com/science/article/pii/S0920410519309507 (accessed on 25 September 2019). [CrossRef]

- Yang, B.; Zhang, H.; Kang, Y.; You, L.; She, J.; Wang, K.; Chen, Z. In Situ Sequestration of a Hydraulic Fracturing Fluid in Longmaxi Shale Gas Formation in the Sichuan Basin. Energy Fuels 2019, 33, 6983–6994. Available online: https://pubs.acs.org/doi/10.1021/acs.energyfuels.9b00712 (accessed on 9 July 2019). [CrossRef]

- Luo, L.; Cheng, S.; Lee, J. Characterization of refracture orientation in poorly propped fractured wells by pressure transient analysis: Model, pitfall, and application. J. Nat. Gas Sci. Eng. 2020, 79, 103332. Available online: https://www.sciencedirect.com/science/article/abs/pii/S1875510020301864 (accessed on 6 May 2020). [CrossRef]

- Hun, L.; Bing, Y.; Xixiang, S.; Xinyi, S.; Lifei, D. Fracturing fluid retention in shale gas reservoir from the perspective of pore size based on nuclear magnetic resonance. J. Hydrol. 2021, 601, 126590. Available online: https://www.sciencedirect.com/science/article/pii/S0022169421006387 (accessed on 29 June 2021). [CrossRef]

- Mahadevan, J.; Le, D.; Hoang, H. Impact of Capillary Suction on Fracture Face Skin Evolution in Waterblocked Wells. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Woodlands, TX, USA, 19–21 January 2009. [Google Scholar]

- Liu, Y.; Leung, J.Y.; Chalaturnyk, R.; Virues, C.J. Fracturing Fluid Distribution in Shale Gas Reservoirs Due to Fracture Closure, Proppant Distribution and Gravity Segregation. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 15 February 2017. [Google Scholar]

- Chen, M.; Bai, J.; Kang, Y.; Chen, Z.; You, L.; Li, X.; Zhang, Y. Redistribution of fracturing fluid in shales and its impact on gas transport capacity. J. Nat. Gas Sci. Eng. 2021, 86, 103747. Available online: https://www.sciencedirect.com/science/article/pii/S1875510020306016 (accessed on 9 December 2020). [CrossRef]

- Liu, H.; Hu, X.; Guo, Y.; Ma, X.; Wang, F.; Chen, Q. Fracture Characterization Using Flowback Water Transients from Hydraulically Fractured Shale Gas Wells. ACS Omega 2019, 4, 14688–14698. Available online: https://pubs.acs.org/doi/10.1021/acsomega.9b01117 (accessed on 9 September 2019). [CrossRef]

- Ghanbari, E.; Dehghanpour, H. The fate of fracturing water: A field and simulation study. Fuel 2016, 163, 282–294. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0016236115009370 (accessed on 28 September 2015). [CrossRef]

- Liu, D.; Ge, H.; Shen, Y.; Liu, H.; Zhang, Y. Experimental investigation on imbibition characteristics of shale with highly developed bedding fractures. J. Nat. Gas Sci. Eng. 2021, 96, 104244. Available online: https://linkinghub.elsevier.com/retrieve/pii/S187551002100442X (accessed on 14 September 2021). [CrossRef]

- You, L.; Zhang, N.; Kang, Y.; Xu, J.; Cheng, Q.; Zhou, Y. Zero Flowback Rate of Hydraulic Fracturing Fluid in Shale Gas Reservoirs: Concept, Feasibility, and Significance. Energy Fuels 2021, 35, 5671–5682. [Google Scholar] [CrossRef]

- Chen, M.; Kang, Y.; Li, X.; Wang, W.; Yang, B.; Liu, H. Investigation of multi-scale gas transport behavior in organic-rich shale. J. Nat. Gas Sci. Eng. 2016, 36, 1188–1198. Available online: https://www.sciencedirect.com/science/article/pii/S1875510016301688 (accessed on 19 April 2016). [CrossRef]

- Zhu, W.; Qi, Q.; Ma, Q.; Deng, J.; Yue, M.; Liu, Y. Unstable seepage modeling and pressure propagation of shale gas reservoirs. Pet. Explor. Dev. 2016, 43, 285–292. Available online: https://www.sciencedirect.com/science/article/pii/S1876380416300325 (accessed on 18 April 2016). [CrossRef]

- Ren, Q.-Y.; Chen, G.-J.; Yan, W.; Guo, T.-M. Interfacial Tension of (CO2 + CH4) + Water from 298 K to 373 K and Pressures up to 30 MPa. J. Chem. Eng. Data 2000, 45, 610–612. [Google Scholar] [CrossRef]

| Sample ID | Length, mm | Diameter, mm | Mass, g | He Porosity,% | Initial Gas Permeability, mD |

|---|---|---|---|---|---|

| WY-1 | 39.24 | 25.30 | 51.9271 | 4.32 | 0.24 |

| WY-2 | 38.24 | 25.30 | 50.1207 | 4.50 | 0.35 |

| WY-3 | 31.89 | 25.30 | 41.6026 | 3.90 | 0.42 |

| WY-4 | 38.24 | 25.30 | 49.7409 | 5.00 | 0.37 |

| WY-5 | 39.80 | 25.30 | 50.9580 | 4.90 | 0.45 |

| Production System | Pore Pressure, MPa | Bottom Hole Flowing Pressure, MPa | Pressure Gradient, MPa/cm | |

|---|---|---|---|---|

| Ⅰ | 7 mm nozzle × 16.00 mm pore plate | 70.35 | 57.42 | 0.06 |

| Ⅱ | 8 mm nozzle × 16.00 mm pore plate | 51.40 | 0.09 | |

| Ⅲ | 10 mm nozzle × 26.00 mm pore plate | 42.58 | 0.13 | |

| Ⅳ | 9 mm nozzle × 22.00 mm pore plate | 40.39 | 0.14 | |

| Sample ID | Pressure Gradient, MPa/cm | Pressure Difference, MPa |

|---|---|---|

| WY-1 | 0.06 | 0.24 |

| WY-2 | 0.09 | 0.34 |

| WY-3 | 0.13 | 0.41 |

| WY-4 | 0.14 | 0.54 |

| WY-5 | 0.18 | 0.72 |

| Sample ID | Flowback Pressure Gradient, MPa/cm | Water Content after Pressure Saturation, % | Water Content after Flowback, % |

|---|---|---|---|

| WY-1 | 0.06 | 100 | 9.68 |

| WY-2 | 0.09 | 100 | 11.25 |

| WY-3 | 0.13 | 100 | 12.76 |

| WY-4 | 0.14 | 100 | 14.91 |

| WY-5 | 0.18 | 100 | 16.97 |

| Sample ID | Treatment | Pore Volume, cm3 | 0~2 nm | 2~10 nm | 10~50 nm | 50~100 nm | 100~1000 nm | D > 1000 nm |

|---|---|---|---|---|---|---|---|---|

| Water Content,% | Water Content,% | Water Content,% | Water Content,% | Water Content,% | Water Content,% | |||

| WY-1 | Saturation water | 1.11 | 14.08 | 50.44 | 25.34 | 0.60 | 6.89 | 2.72 |

| After flowback | 15.54 | 51.50 | 18.89 | 0.08 | 0.73 | 0.11 | ||

| WY-2 | Saturation water | 1.38 | 9.22 | 40.97 | 38.61 | 2.83 | 5.83 | 2.63 |

| After flowback | 15.70 | 40.83 | 9.83 | 0.62 | 0.84 | 0.02 | ||

| WY-3 | Saturation water | 1.05 | 9.26 | 40.20 | 40.07 | 2.74 | 4.67 | 3.05 |

| After flowback | 11.10 | 41.34 | 36.75 | 0.41 | 0.07 | 0.09 | ||

| WY-4 | Saturation water | 1.31 | 9.26 | 42.08 | 36.54 | 2.68 | 7.00 | 2.58 |

| After flowback | 11.10 | 41.34 | 36.75 | 0.41 | 0.07 | 0.09 | ||

| WY-5 | Saturation water | 1.27 | 6.52 | 33.54 | 45.26 | 6.82 | 5.24 | 3.26 |

| After flowback | 9.33 | 37.79 | 45.73 | 5.42 | 0.56 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, J.; Wang, G.; Zhu, Q.; Tao, L.; Shi, W. Investigation on Flowback Behavior of Imbibition Fracturing Fluid in Gas–Shale Multiscale Pore Structure. Energies 2022, 15, 7802. https://doi.org/10.3390/en15207802

Bai J, Wang G, Zhu Q, Tao L, Shi W. Investigation on Flowback Behavior of Imbibition Fracturing Fluid in Gas–Shale Multiscale Pore Structure. Energies. 2022; 15(20):7802. https://doi.org/10.3390/en15207802

Chicago/Turabian StyleBai, Jiajia, Guoqing Wang, Qingjie Zhu, Lei Tao, and Wenyang Shi. 2022. "Investigation on Flowback Behavior of Imbibition Fracturing Fluid in Gas–Shale Multiscale Pore Structure" Energies 15, no. 20: 7802. https://doi.org/10.3390/en15207802

APA StyleBai, J., Wang, G., Zhu, Q., Tao, L., & Shi, W. (2022). Investigation on Flowback Behavior of Imbibition Fracturing Fluid in Gas–Shale Multiscale Pore Structure. Energies, 15(20), 7802. https://doi.org/10.3390/en15207802