Abstract

In normal operation, there is no significant thermal stratification phenomenon in the tube bundle area of the steam generator of the nuclear power plant. However, this phenomenon is detected in marine nuclear power plant isolation loops in the presence of feedwater leakage. Therefore, an experiment was designed to verify the presence of thermal stratification, and the influence factors were analyzed by the RELAP5/MOD3.2 program. The results show that thermal stratification is mainly influenced by the initial water level at isolation, the initial pressure at isolation, the total leakage mass, and the internal circulation of the steam generator. Leakage flow has little effect on it. This phenomenon causes the coolant temperature at the primary side of the steam generator in the isolated loop to be lower than the temperature measured in the reactor inlet pipe or outlet pipe. This study aids the operator in determining the real coolant temperature at the primary side of the steam generator in the isolated loop and prevents reactivity insertion accidents when the isolated loop is put into operation.

1. Introduction

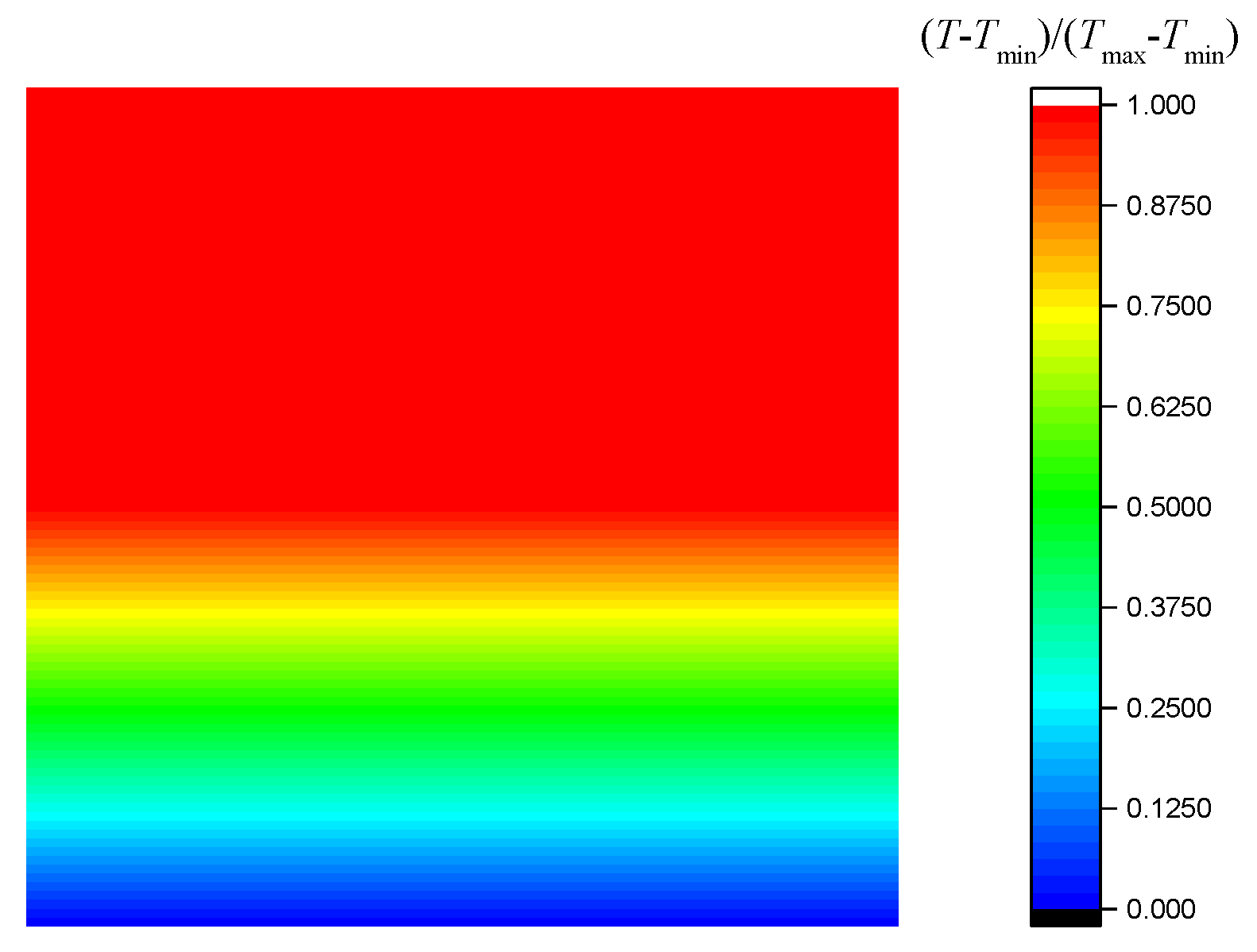

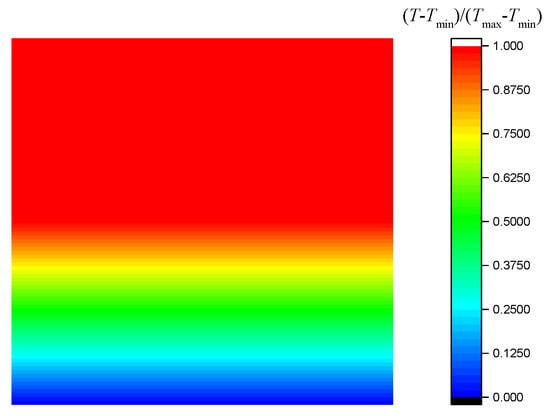

Thermal stratification refers to the phenomenon in which the fluid with high temperature and low density is in the upper region, while the fluid with low temperature and high density is in the lower region. An example of the thermal stratification phenomenon in a tank is shown in Figure 1. It is caused by the uneven mixing of hot and cold fluids [1,2].

Figure 1.

Thermal stratification phenomenon in a tank.

In nuclear reactor systems, the thermal stratification phenomenon may occur in places such as large water tanks, pressurizer surge lines, and steam generator feed pipes. This phenomenon can bring safety risks to the operation of nuclear power plants, such as thermal fatigue of pipelines [3,4]. In recent decades, many scholars carried out experimental verification and numerical analysis of the thermal stratification phenomenon at different positions of the nuclear reactor system. They put forward a series of suggestions to reduce the thermal stratification phenomenon through reasonable design [5,6,7].

Byeongnam Jo et al. studied the thermal stratification phenomenon in the suppression pool of Fukushima Daiichi Nuclear Power Plants using a 1/20 scaled-down facility, and proposed a dimensionless Richardson parameter as the criterion of thermal stratification [8]:

Among them, g, β, L, u, Tsat, and Tw represent the gravity acceleration, the thermal expansion coefficient, the characteristic length, the fluid velocity, the saturation temperature, and the water temperature in the suppression tank, respectively.

The results show that, when the value of Richardson is greater than 1, the thermal stratification phenomenon occurs and, on the contrary, the thermal stratification phenomenon disappears. The greater the temperature difference between the cold and hot fluid is, and the smaller the velocity of the fluid is, the more likely the thermal stratification phenomenon occurs.

For steam generators, the thermal stratification phenomenon mainly occurs in feed pipes. Sun Yan et al. studied the main factors of the thermal stratification phenomenon in feed pipes and proposed mitigation measures [9].

At the tube bundle area of the steam generator, it is generally considered that there is no obvious thermal stratification phenomenon in normal operation. This is because the feedwater is quickly heated to saturation temperature in the feed pipes and the descending channel, even if it has a subcooling degree of more than 60 K when entering the steam generator. The water temperature at the tube bundle area of the steam generator is usually considered to be at saturation temperature in the normal operation of nuclear power plants or marine nuclear power plants. As a result, the thermal stratification phenomenon in the tube bundle area has rarely been considered and researched.

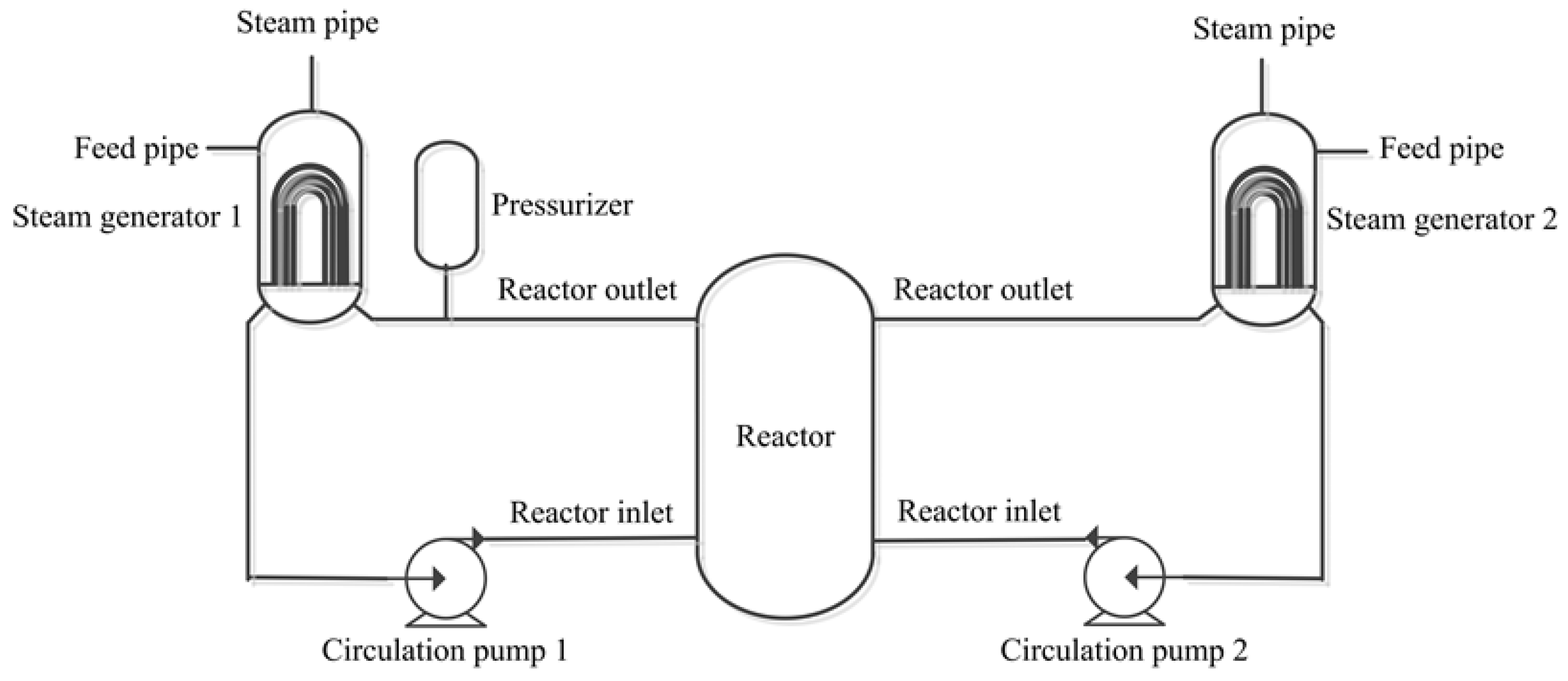

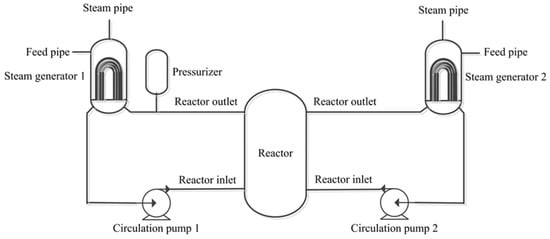

However, the thermal stratification phenomenon has been detected in marine nuclear power plant isolation loops in the presence of feedwater leakage. A marine nuclear power plant composed of a pressurized water reactor (PWR) has two loops, as shown in Figure 2. The primary coolant absorbs heat from the reactor through the two loops and transfers heat to the steam generators. The steam generators power the ship by generating steam. When one of the loops has failed, this loop can stop operation by isolation methods, while the other loop can remain in power operation. The loop that stops running is called an isolated loop. When the isolated loop is repaired, it can be put into operation again.

Figure 2.

Simplified diagram of a PWR marine nuclear power plant.

However, if a large amount of cold feedwater leaks into the steam generator of the isolated loop during isolation, the thermal stratification phenomenon will occur at the tube bundle area of the steam generator. It causes the coolant temperature at the primary side of the steam generator to be much lower than the temperature measured in the reactor inlet pipe or outlet pipe. When the isolated loop is put into operation, the cold water enters the core, causing the reactivity insertion accident.

Therefore, next, the relevant experiment and numerical calculation are carried out to analyze the thermal stratification phenomenon in the steam generator tube bundle area of the isolated loop of the marine nuclear power plants in this special case. This study helps to estimate the coolant temperature in the steam generator of the isolated loop. It can guide operators to avoid reactivity insertion accidents when the isolated loop is put into operation.

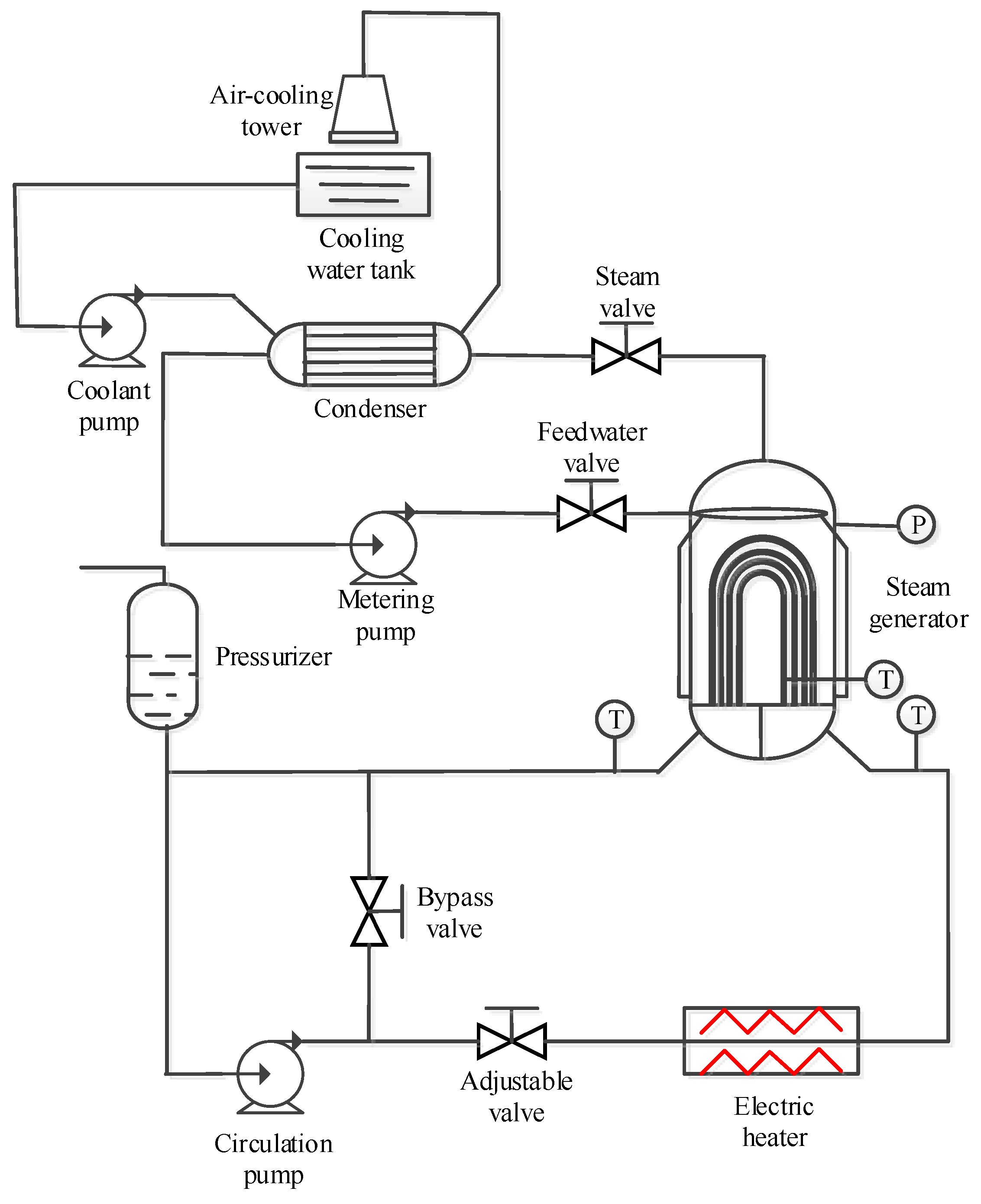

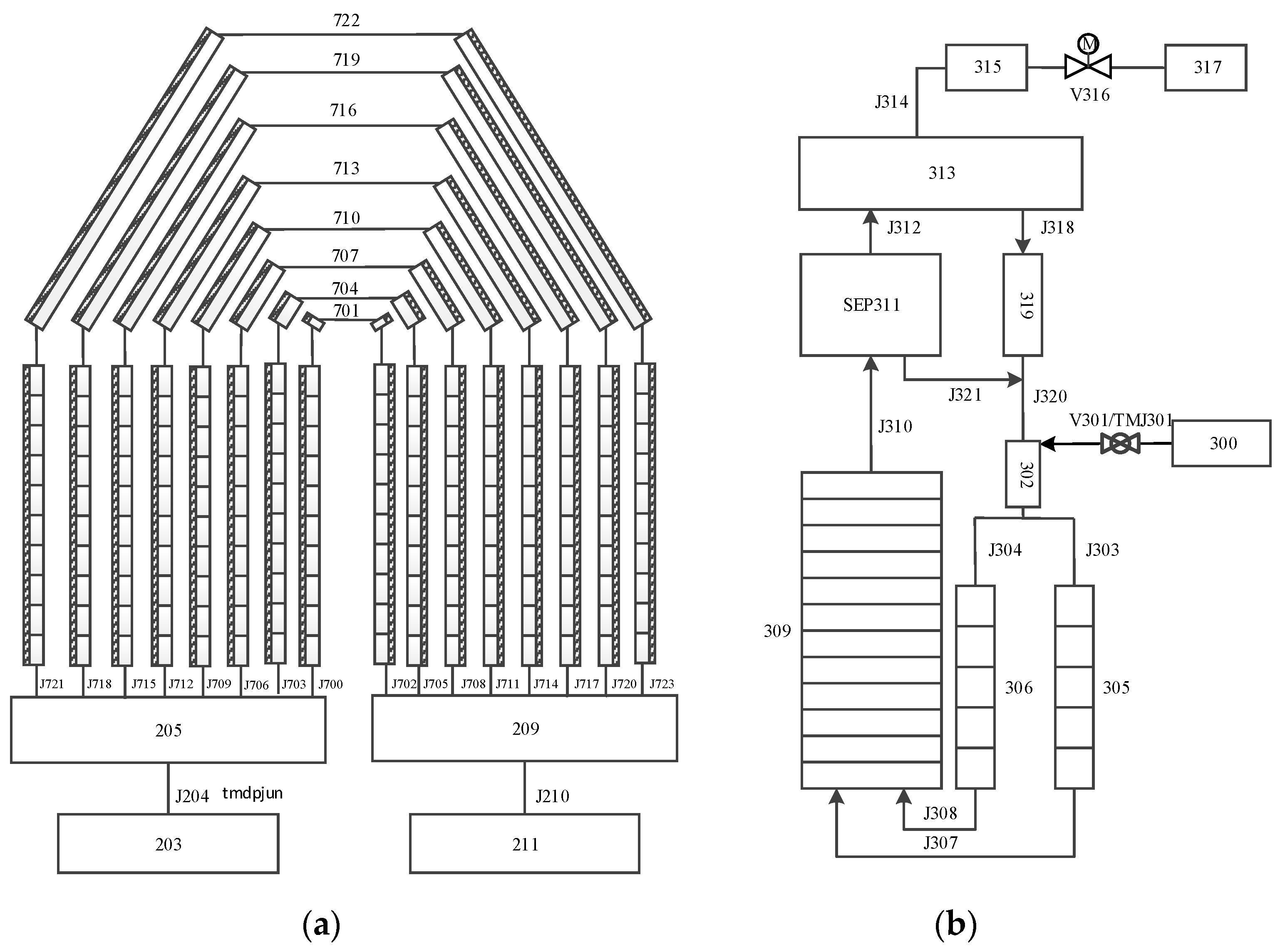

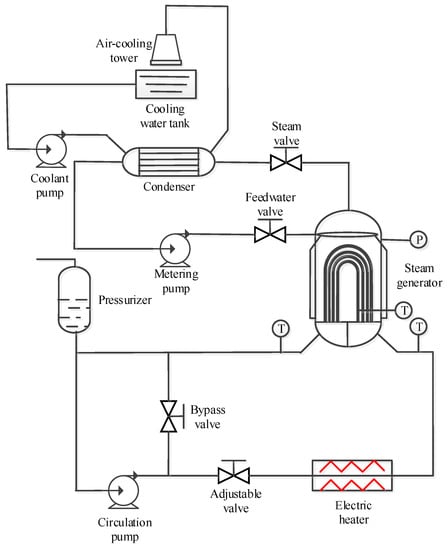

2. Experiment Design and Research

The experimental loop was designed with reference to the isolated loop of a PWR marine nuclear power system. It consisted of pumps, an electric heater, a steam generator, a condenser, a pressurizer, a cooling water tank, pipes, and measurement instruments, as shown in Figure 3. It included a primary loop sub-system, a secondary loop sub-system, and a cooling water sub-system. The steam generator was designed with a proportion of 1/3 to the marine nuclear power system, and the heat transfer coefficient of the U-tubes in the steam generator was consistent with the actual device of marine nuclear power plants. In addition, there were temperature measurement points at the inlet and outlet pipes of the steam generator. In the steam generator, the temperature measurement points were set along the vertical direction of the innermost U-tubes, and the pressure measurement point was on the upper part of the steam generator. For more details, please refer to the bibliography [10,11].

Figure 3.

Experiment loops.

The experimental process was as follows: after the experimental loop ran to a thermal steady state, the feedwater valve was manually closed to reduce the water level at the secondary side of the steam generator. Then, the steam valve, electric heater, centrifugal pump, etc., were closed to stop the loop. Finally, the cold feedwater was injected into the secondary side of the steam generator to simulate the leakage process of the feedwater valve, and then the loop was naturally cooled for 5 h.

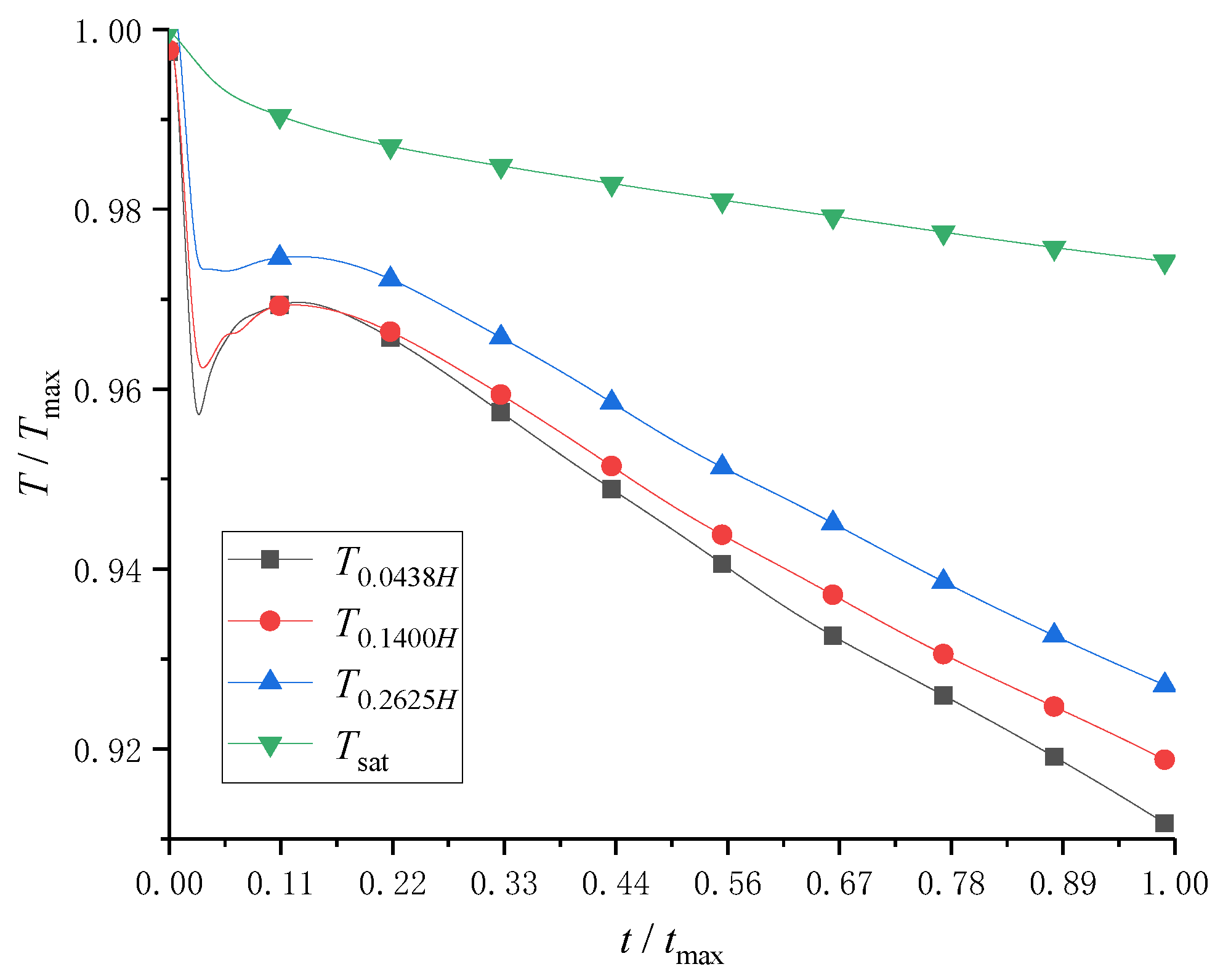

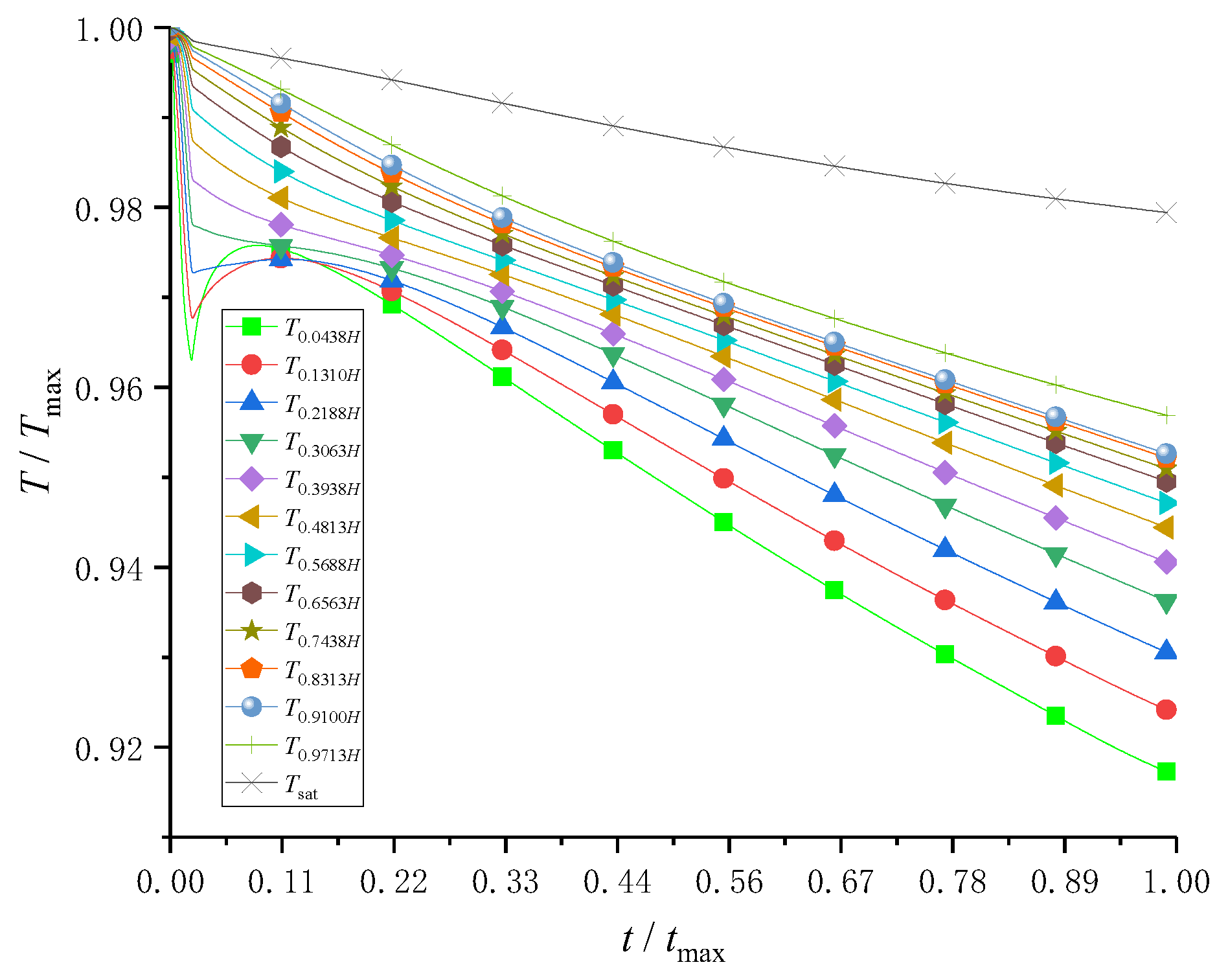

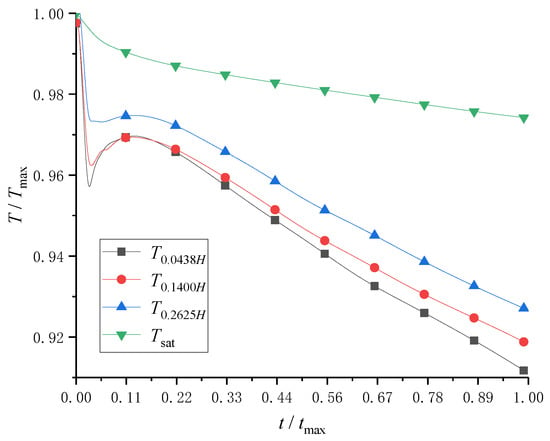

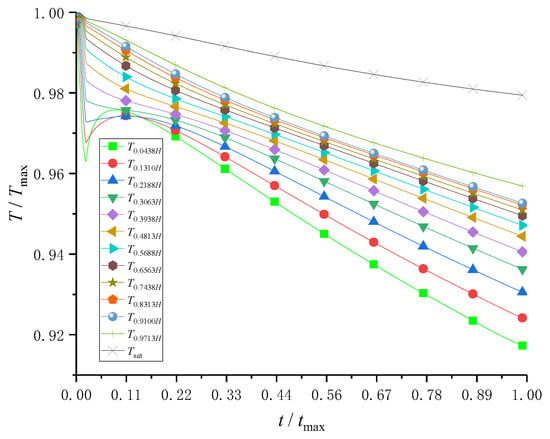

The variation of temperature at different heights of the steam generator is shown in Figure 4, in which Tsat is the saturation temperature and H is the height of the tube bundle area in the steam generator.

Figure 4.

The variation of temperature at different heights of the steam generator in experiment.

Referencing the value at 0 s, the water temperature at the tube bundle area of the steam generator was almost equal to the saturation temperature in normal operation. There was no thermal stratification phenomenon. This was because the feedwater was quickly heated to saturation temperature in the feed pipes and the descending channel by convection heat transfer. After the loop stopped operation, the feedwater leaked into the secondary side of the steam generator. However, the convection heat transfer was not sufficient to heat the feedwater to saturation and the water temperature at the bottom of the secondary side of the steam generator dropped rapidly. Finally, there was a large difference between the saturation temperature and the water temperature at the bottom of the secondary side of the steam generator. At this time, the value of Ri was approximately 27,000 and the thermal stratification phenomenon occurred. After turning off the feedwater valve, the water temperature at the secondary side rose. This was because the primary coolant conducted heat to the water at the secondary side of the steam generator, which caused the temperature difference to narrow and the thermal stratification phenomenon to be weakened. Then, in the process of natural cooling, the pressure and temperature at the secondary side of the steam generator kept decreasing slowly, but the water temperature at the bottom of the secondary side of the steam generator decreased faster than the saturation temperature. Therefore, the temperature difference became larger and larger, and the thermal stratification phenomenon became more and more obvious. After 5 h of natural cooling, there was still an obvious thermal stratification phenomenon. At this moment, the coolant temperature at the bottom of the steam generator was much lower than the saturation temperature and the temperature measured at the reactor inlet or reactor outlet. The operator was unable to determine the coolant temperature at the bottom of the steam generator from the available measured parameters. Therefore, an analysis of the thermal stratification phenomenon and its influencing factors is useful for the operator to estimate the coolant temperature at the bottom of the steam generator.

3. Simulation Analysis

3.1. Model Establishment and Verification

Although the CFD software is accurate in calculation and can simulate the thermal stratification phenomenon, it is complicated and highly expensive in computation when it is used to simulate the entire nuclear reactor system.

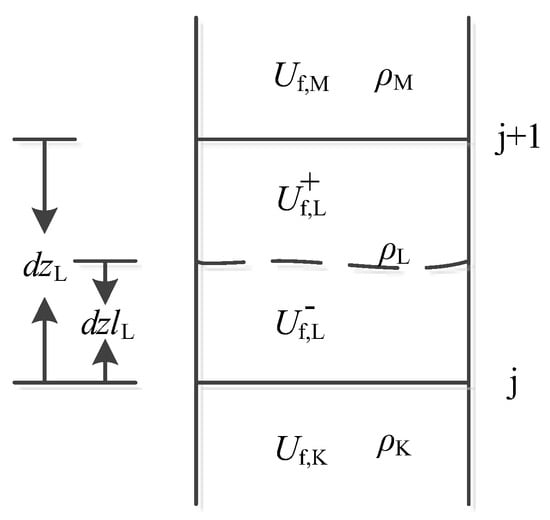

The RELAP5/MOD3.2 program is dedicated to the thermal–hydraulic analysis of nuclear systems. The program is equipped with the following thermal stratification model, which can track the thermal front in the volume and improve the accuracy of the solution [12]. The thermal-front detection logic for cell j is shown in Figure 5, in which dzL is the length of volume L and dzlL is the position of the thermal front. U and ρ are the internal energy and density of the liquid, respectively.

Figure 5.

Thermal front in a tank.

If the density of the liquid satisfies Equation (2) or Equation (3), the thermal front exists in volume L.

The internal energy of the liquid above and below the thermal front is set equal to that in volume M and volume K, respectively, as follows:

Then, the location of the thermal front in volume L can be provided by

Finally, the interfacial heat transfer coefficient hif can be recomputed as

The energy transfer term between vapor and liquid can be modified from to , where is the temperature of the hot fluid in volume L including the thermal front.

However, this model can only be used for the vertical component, in which the warm fluid is above the cold fluid. By dividing the component into multiple volumes, the temperature distribution of the component along the vertical direction can be obtained [13]. Rex Shumway et al. used the RELAP5 thermal stratification model to reproduce the thermal stratification phenomenon in the pressurizer [14]. P.K. Verma et al. used the RELAP5 program to simulate the thermal stratification phenomenon in a large pool [15]. The axial thermal stratification problem of the steam generator is similar to these situations, so the RELAP5/MOD3.2 program was selected to simulate the thermal stratification phenomenon of the steam generator.

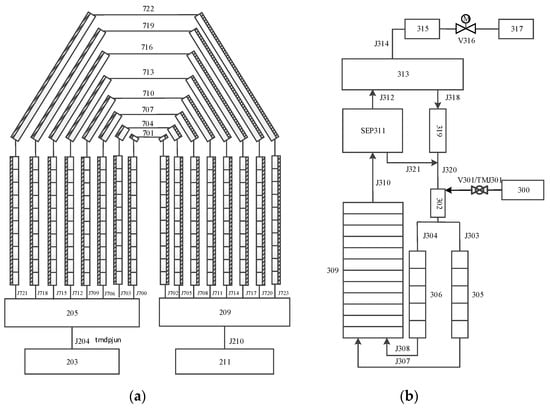

Referring to the experiment, a simulation model was established by the RELAP5/MOD3.2 program. The nodalization scheme is shown in Figure 6. The U-tubes were divided into eight groups of different sizes, including volume 701, 704, 707, 710, 713, 716, 719, and 722. Volume 203 and 211 are the inlet and outlet pipes at the primary side of the steam generator, respectively. The feedwater from volume 300 entered the bottom of the secondary side of the steam generator through two descending channels of volume 305 and volume 306. In addition, thermal components were built outside the pipes and the steam generator volume, which was connected to the air to simulate the natural cooling process. In numerical calculation, the boundary conditions, including temperature and flow of volume 203 and volume 300, were controlled by experimental values.

Figure 6.

Nodalization scheme: (a) the primary loop; (b) the secondary loop.

In order to make the results more reliable, different numbers of volumes, different calculation steps, and different numbers of channels were carried out to analyze the sensitivity. Finally, 0.01 s was selected as the calculation step. The secondary side of the steam generator was modeled with a single channel and component 309 was divided into 12 volumes.

The variation of temperature at different heights of the steam generator is shown in Figure 7, in which Tsat is the saturation temperature and H is the height of the tube bundle area in the steam generator. There was an obvious thermal stratification phenomenon at the secondary side of the steam generator and the variation of temperature in the simulation was consistent with the experiment.

Figure 7.

The variation of temperature at different heights of the steam generator in simulation.

The comparison of experiment results and simulation results after 5 h of natural cooling are shown in Table 1, in which Tmin is the temperature at the bottom of the secondary side of steam generator. It shows that the errors between the experimental values and the simulation values were very small. Therefore, the RELAP5/MOD3.2 program can be used for the thermal stratification phenomenon in this paper.

Table 1.

Comparison of experiment and simulation results.

3.2. Influencing Factors Analysis

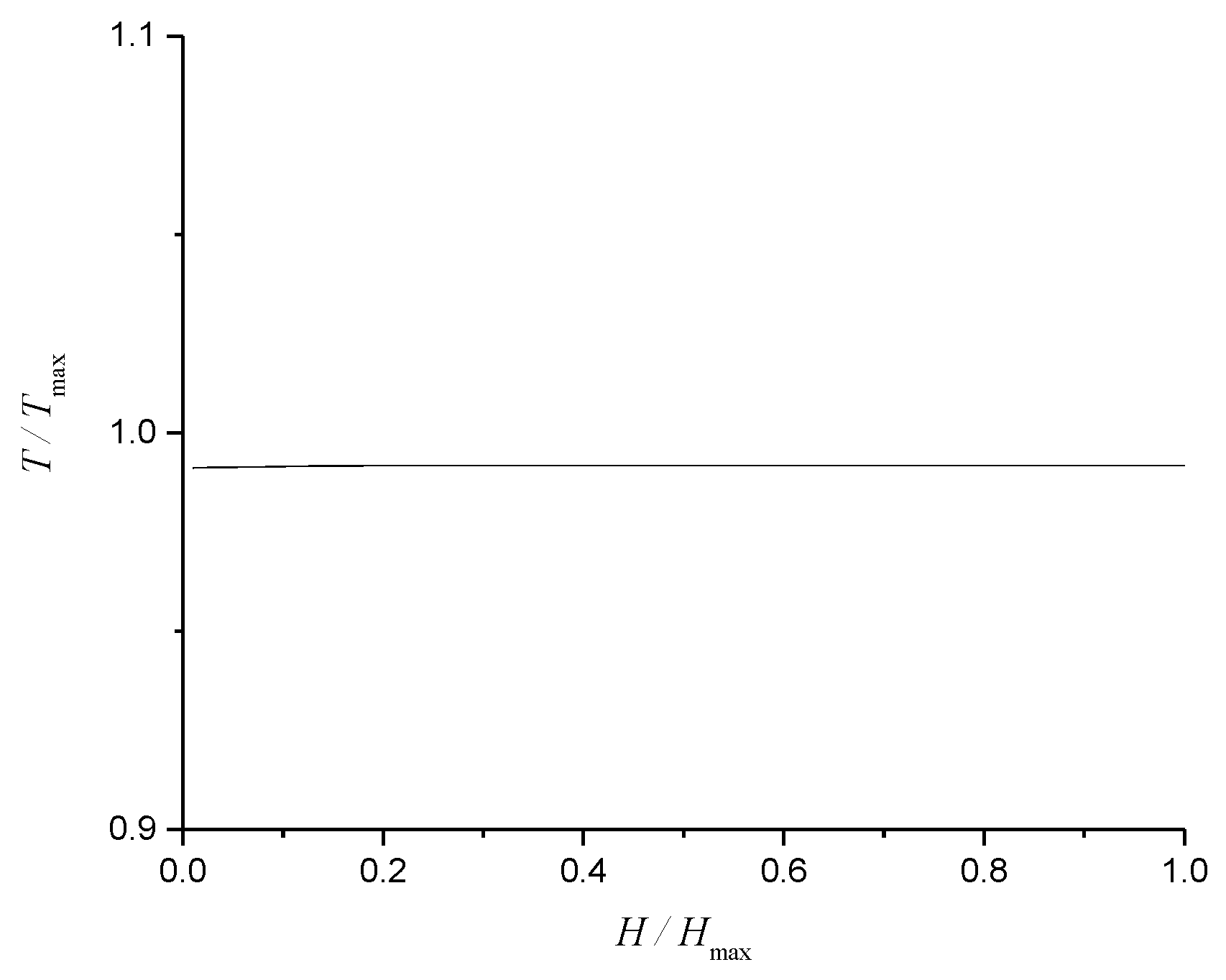

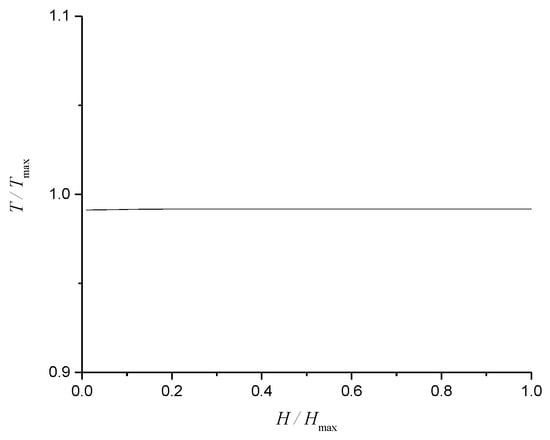

When there was no water leaking into the isolated steam generator, the simulation results show that there was no thermal stratification phenomenon at the secondary side of the steam generator, as shown in Figure 8.

Figure 8.

Temperature distribution in the height direction of the steam generator in the absence of feedwater leakage.

After the feedwater leaked into the isolated steam generator, the thermal stratification phenomenon occurred. In the isolated steam generator, the thermal stratification may be affected by the parameters of the initial water level, the initial pressure, the total leakage mass, and the water leakage flow. Therefore, the development laws of thermal stratification in these different parameters were analyzed by RELAP5/MOD3.2.

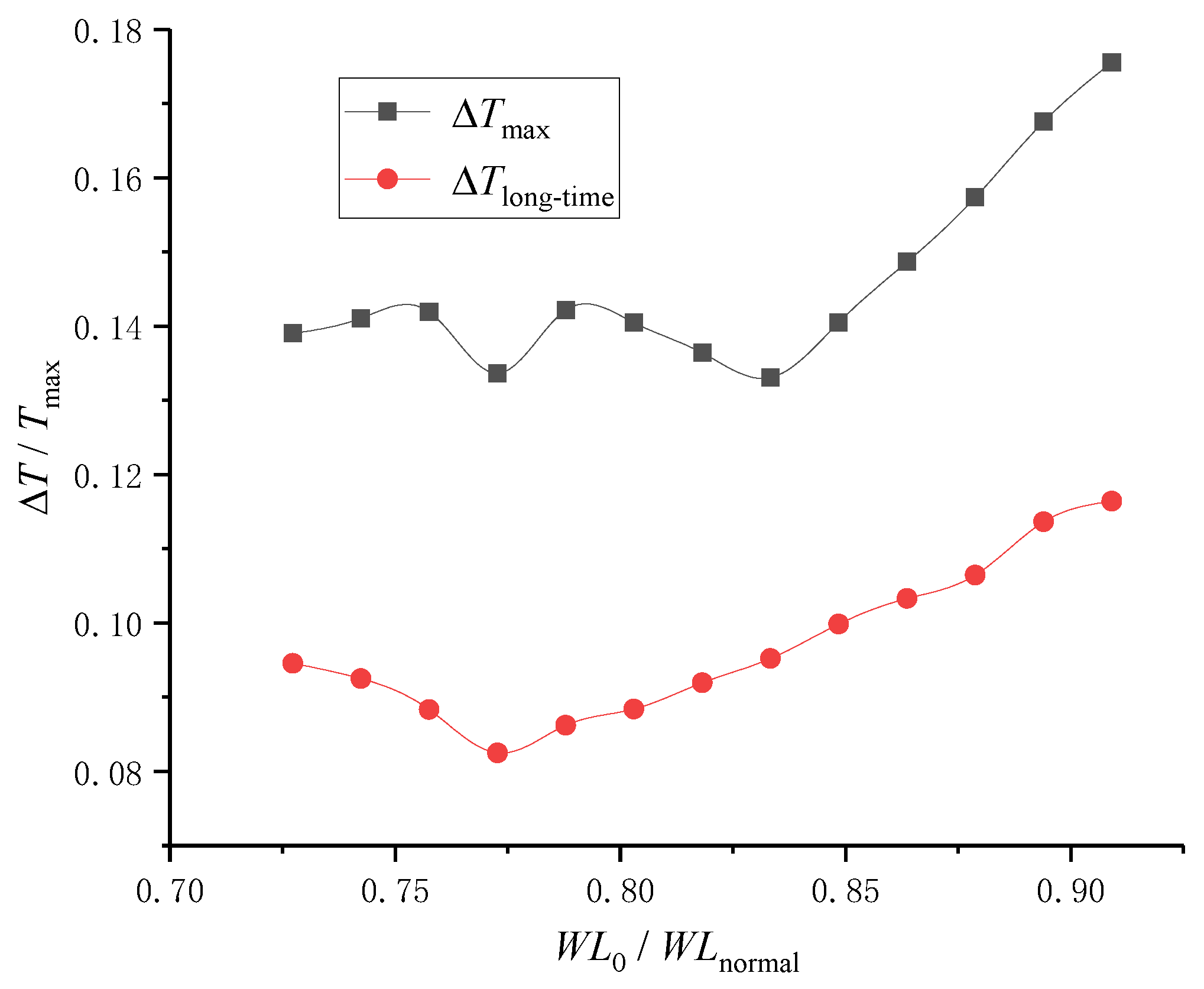

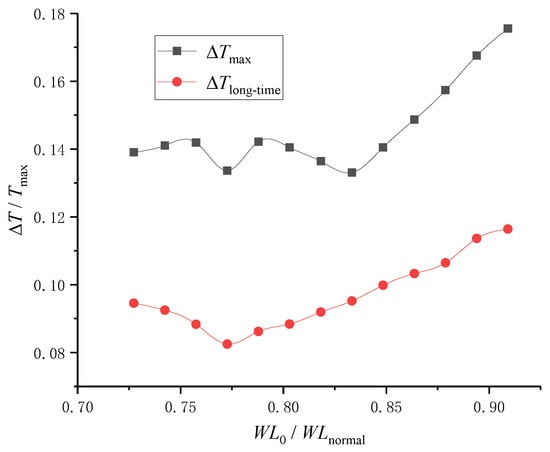

The temperature difference ∆T between the saturation temperature and the lowest temperature at the secondary side of the steam generator in different initial water levels are shown in Figure 9, in which ∆Tmax is the maximum temperature difference in the natural cooling process and ∆Tlong-time is the temperature difference after a long-time natural cooling. When the initial water level was higher than 0.84WLnormal, the higher the initial water level, and the greater the temperature difference. This is because the water level can affect the characteristic length in Equation (1). The higher the initial water level, the longer the characteristic length, and the greater the value of Ri. Therefore, the thermal stratification phenomenon was more obvious. However, when the initial water level was lower than 0.84WLnormal, the maximum temperature difference fluctuated. This is because the internal cycle was formed in the steam generator. It caused the thermal stratification phenomenon to change with the initial irregular water level. ∆Tlong-time decreased to a minimum at 0.772 and then increased. Two factors had an impact on it. (1) The higher the initial water level, the easier it was to form thermal stratification and, the lower the temperature at the bottom of the steam generator, then the more heat transfer from the primary side of the steam generator to the secondary side, resulting in a smaller final temperature difference. (2) The higher the initial water level, the less convective heat transfer during the descent of the feedwater and the smaller the pressure drop, resulting in a larger final temperature difference. Before 0.772, the first factor had a greater impact, while after 0.772, the second factor was more impressive.

Figure 9.

The temperature difference in different initial water levels (WL).

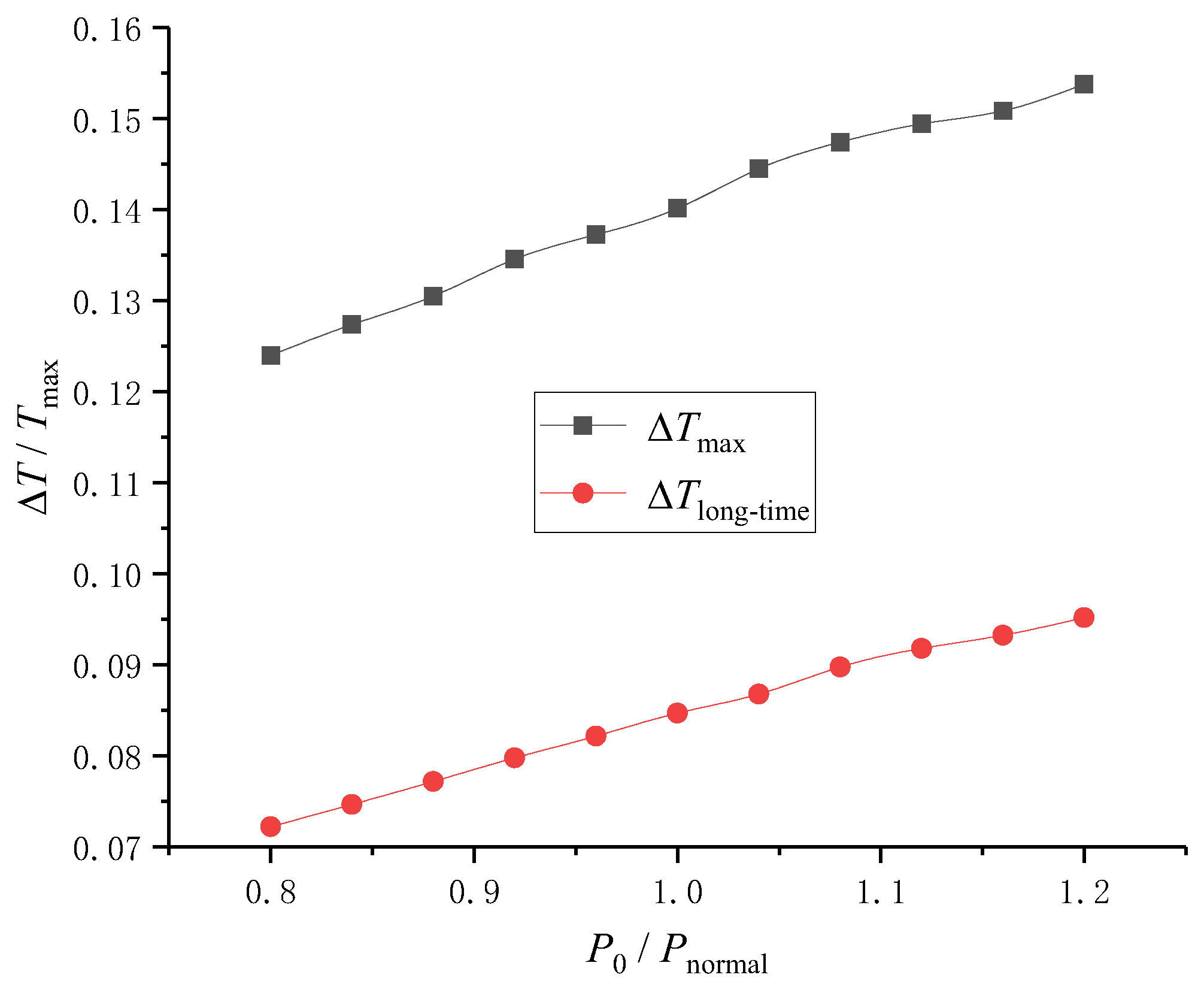

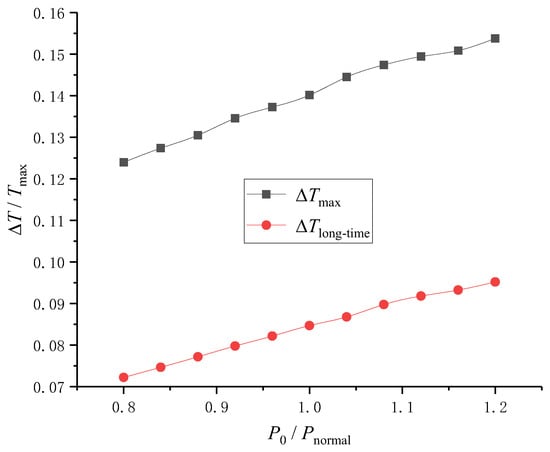

The temperature difference ∆T in different initial pressures is shown in Figure 10. The higher the initial pressure, the greater the temperature difference. This is because the pressure can affect the saturation temperature. The higher the pressure, the higher the saturation temperature, and the greater the value of Ri. Therefore, under the same total leakage mass, the higher the initial pressure, and the more obvious the thermal stratification phenomenon.

Figure 10.

The temperature difference in different initial pressures.

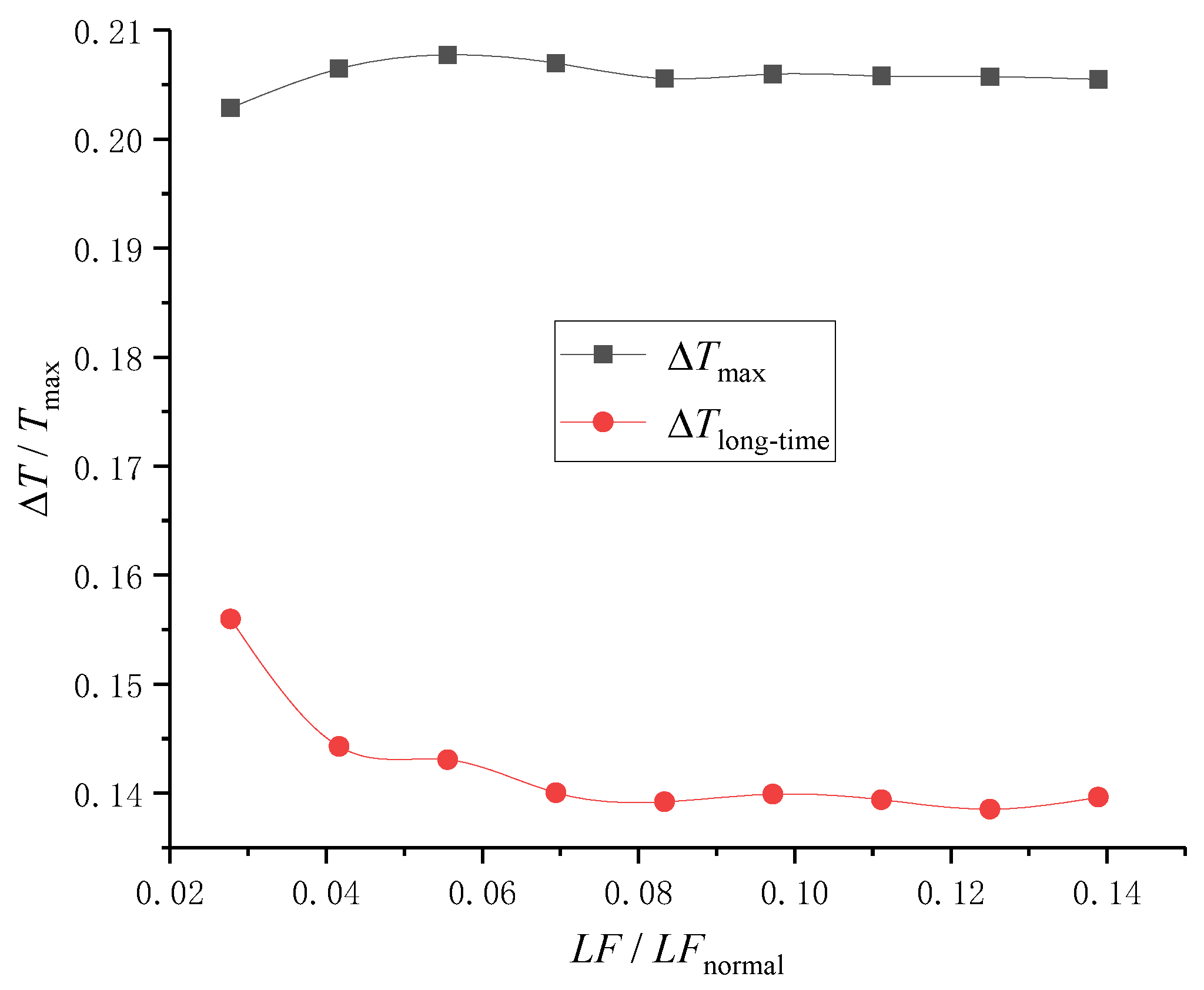

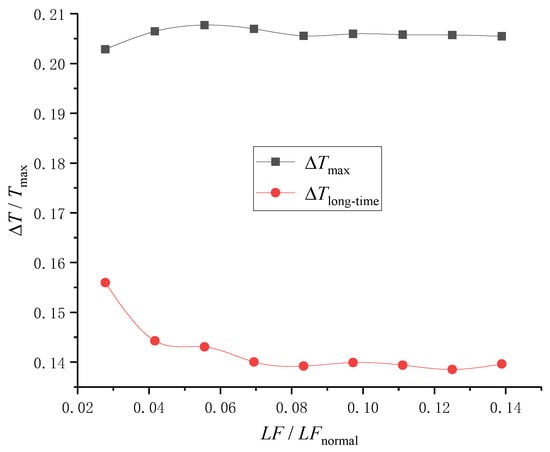

The temperature difference ∆T in different water leakage flows are shown in Figure 11. The water leakage flow had little effect on the temperature difference. This is because the water leakage flow was far less than the feedwater flow in normal operation and there were multiple J-type tubes distributed on the feedwater ring of the steam generator. Under different low water leakage flows, the feedwater entered the descending channel through different numbers of J-type tubes, so their velocities were almost equal, and the values of Ri were almost the same. Therefore, the water leakage flow had little effect on the thermal stratification phenomenon.

Figure 11.

The temperature difference in different water leakage flow (LF).

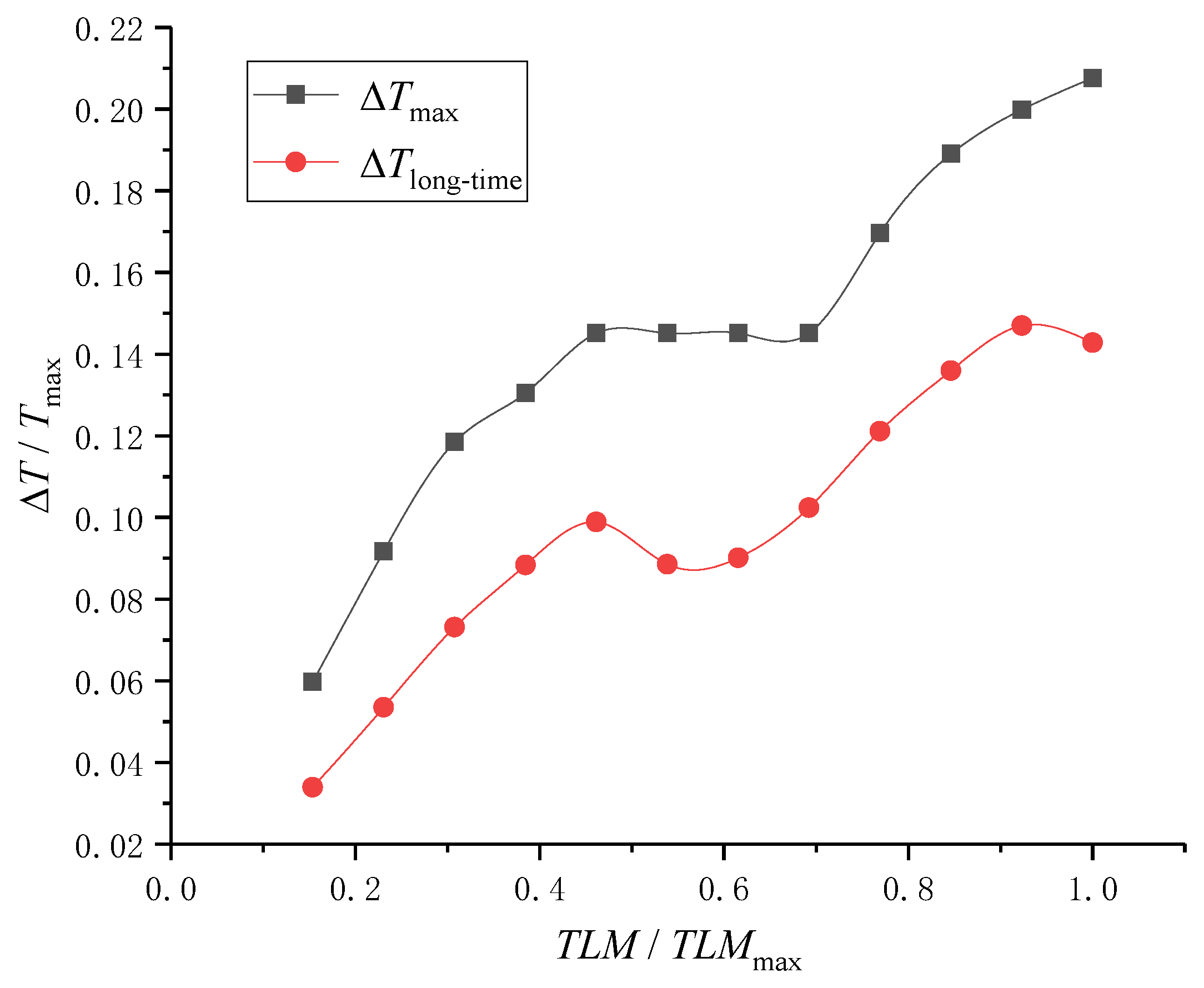

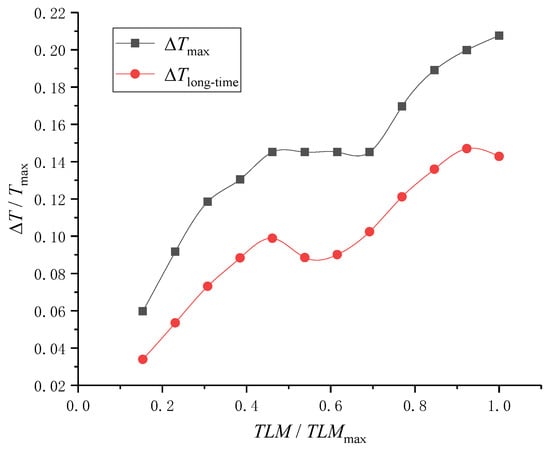

The temperature difference ∆T in different total leakage masses is shown in Figure 12. The larger the total leakage mass, the larger the temperature difference. This is because the temperature of the feedwater was lower than the water temperature in the steam generator. The more feedwater entering the isolated steam generator, the lower the temperature at the bottom of the secondary side of the steam generator. The change in saturation temperature was far slower than the change in the bottom temperature caused by the cold feedwater. Therefore, the thermal stratification phenomenon became more obvious. When the total leakage mass was between 0.4TLMmax and 0.7TLMmax, the temperature difference fluctuated. At this moment, a short internal cycle was formed in the steam generator. It caused the temperature difference to no longer continue to rise and the thermal stratification phenomenon to be weakened.

Figure 12.

The temperature difference in different total leakage masses (TLM).

In summary, the thermal stratification phenomenon occurs in the isolated loop of the marine nuclear power plant when there is cold feedwater leaking into the isolated steam generator. As the initial water level, the initial pressure, or the total leakage mass increases, it becomes more obvious, but the internal cycle in the steam generator will weaken the thermal stratification phenomenon. Furthermore, the water leakage flow had little effect on it.

4. Conclusions

In the normal operation of the marine nuclear power plant, the cold feedwater is quickly heated to saturation temperature in the feed pipes and the descending channel. There is no obvious thermal stratification phenomenon at the secondary side of the steam generator. However, this phenomenon has been found in the isolated loop when one of the loops stops operation and the cold feedwater leaks into the isolated steam generator.

In order to analyze this phenomenon, in this paper, the experiment and numerical simulation are carried out. The results obtained by the experiment and simulation are in good agreement. It shows that, in this special case, the obvious thermal stratification phenomenon does exist in the isolated steam generator. Finally, the development laws of thermal stratification are analyzed. The results show that the thermal stratification is mainly affected by the initial water level, the initial pressure, the total leakage mass, and the internal cycle in the steam generator. The water leakage flow has little effect on it.

When the thermal stratification phenomenon occurs, the water temperature at the bottom of the secondary side of the steam generator is obviously lower than the saturation temperature. It leads to a lower coolant temperature on the primary side of the steam generator. In this case, when the isolated loop is put into operation, the low-temperature coolant will enter the core and the reactivity insertion accident is very likely to occur.

In actual operation, this phenomenon is difficult to be detected because there is no temperature measurement point in the steam generator. Therefore, based on the research in this paper, a method for predicting coolant temperature in the isolated loop of steam generators will be proposed in the future, which can provide guidance to operators and reduce the possibility of reactivity insertion accidents.

Author Contributions

Data curation, J.H.; Methodology, L.Y. and W.C.; Writing—original draft, X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China grant number 11502298. And the APC was funded by the National Natural Science Foundation of China grant number 11402300.

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bieniussa, K.W.; Reck, H. Piping specific analysis of stresses due to thermal stratification. Nucl. Eng. Des. 1999, 190, 239–249. [Google Scholar]

- Lu, T.; Han, W.; Zhai, H. Numerical simulation of temperature fluctuation reduction by a vortex breaker in an elbow pipe with thermal stratification. Ann. Nucl. Energy 2015, 75, 462–467. [Google Scholar] [CrossRef]

- Cai, B.; Weng, Y.; Wang, Y.; Qin, X.; Cao, F.; Gu, H.; Wang, H. Experimental investigation on thermal stratification in a pressurizer surge line with different arrangements. Prog. Nucl. Energy 2017, 98, 239–247. [Google Scholar] [CrossRef]

- Minocha, N.; Joshi, J.B.; Nayak, A.K.; Vijayan, P.K. 3D CFD simulations to study the effect of inclination of condenser tube on natural convection and thermal stratification in a passive decay heat removal system. Nucl. Eng. Des. 2016, 305, 582–603. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Zhuo, W.; Niu, F.; Yu, Y.; Guo, Z.; Shen, Y.; Chen, W.; Jiang, X. Experimental analysis of steam mixing and thermal stratification phenomena related to small steel containment studies. Ann. Nucl. Energy 2017, 109, 103–112. [Google Scholar] [CrossRef]

- Ensel, C.; Colas, A.; Barthez, M. Stress analysis of a 900 MW pressurizer surge line including stratification effects. Nucl. Eng. Des. 1995, 153, 197–203. [Google Scholar] [CrossRef]

- Jo, B.; Erkan, N.; Takahashi, S.; Song, D.; Sagawa, W.; Okamoto, K. Thermal stratification in a scaled-down suppression pool of the Fukushima Daiichi nuclear power plants. Nucl. Eng. Des. 2016, 305, 39–50. [Google Scholar] [CrossRef]

- Jo, B.; Erkan, N.; Okamoto, K. Richardson number criteria for direct-contact-condensation-induced thermal stratification using visualization. Prog. Nucl. Energy 2020, 118, 103095. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, Q.; Huang, W.; Li, F. Analysis for influence factor and ease measure to thermal stratification intensity in feedwater ring and pipe of steam generator. At. Energy Sci. Technol. 2017, 51, 59–66. [Google Scholar]

- Hao, J.; Chen, W.; Zhang, D.; Wang, S. Scaling modeling analysis of flow instability in U-tubes of steam generator under natural circulation. Ann. Nucl. Energy 2014, 64, 169–175. [Google Scholar] [CrossRef]

- Li, M.; Chen, W.; Hao, J.; Li, W. Experimental and numerical investigations on effect of reverse flow on transient from forced circulation to natural circulation. Nucl. Eng. Technol. 2020, 52, 1955–1962. [Google Scholar] [CrossRef]

- The RELAP5 Code Development Team. RELAP5/MOD3 Code Manual Vol. I: Code Structure, System Models, and Solution Methods; INEL-95/0174 Volume I, Revision 3.4.9; Idaho National Engineering Laboratory: Idaho Falls, ID, USA, 1995. [Google Scholar]

- Vincenzo Narcisi; Fabio Giannetti; Gianfranco Caruso. Investigation on RELAP5-3D© capability to predict thermal stratification in liquid metal pool-type system and comparison with experimental data. Nucl. Eng. Des. 2019, 352, 110152. [Google Scholar] [CrossRef]

- Shumway, R.; Bolander, M.; Aktas, B. Prediction of MIT Pressurizer Data Using RELAP5 and TRAC-M. In Proceedings of the 10th International Conference on Nuclear Engineering, Arlington, VA, USA, 14–18 April 2002. [Google Scholar]

- Verma, P.; Nayak, A.; Jain, V.; Vijayan, P.; Vaze, K. Suppression of thermal stratification in gravity driven water pool of an advanced reactor using shrouds. Ann. Nucl. Energy 2013, 58, 221–227. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).