Ensuring the Safety of Buildings by Reducing the Noise Impact through the Use of Green Wall Systems

Abstract

1. Introduction

- -

- Consider different landscaping systems;

- -

- Identify the pros and cons of each of them according to certain criteria;

- -

- Evaluate the noise-absorbing characteristics;

- -

- Determine the most soundproofing system.

2. Materials and Methods

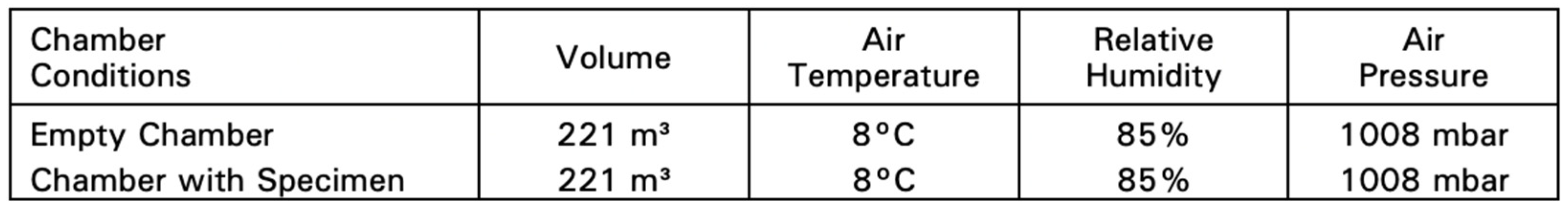

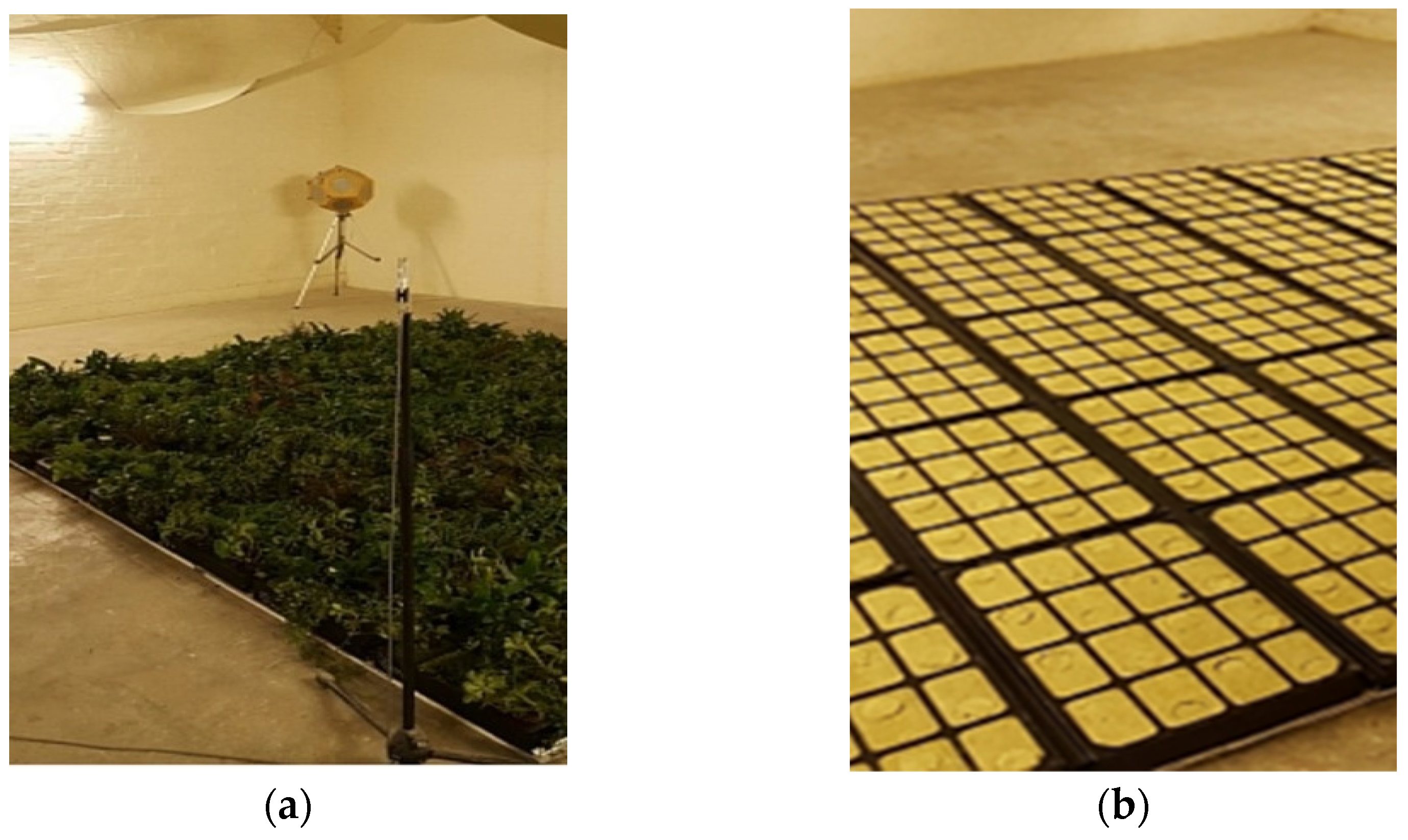

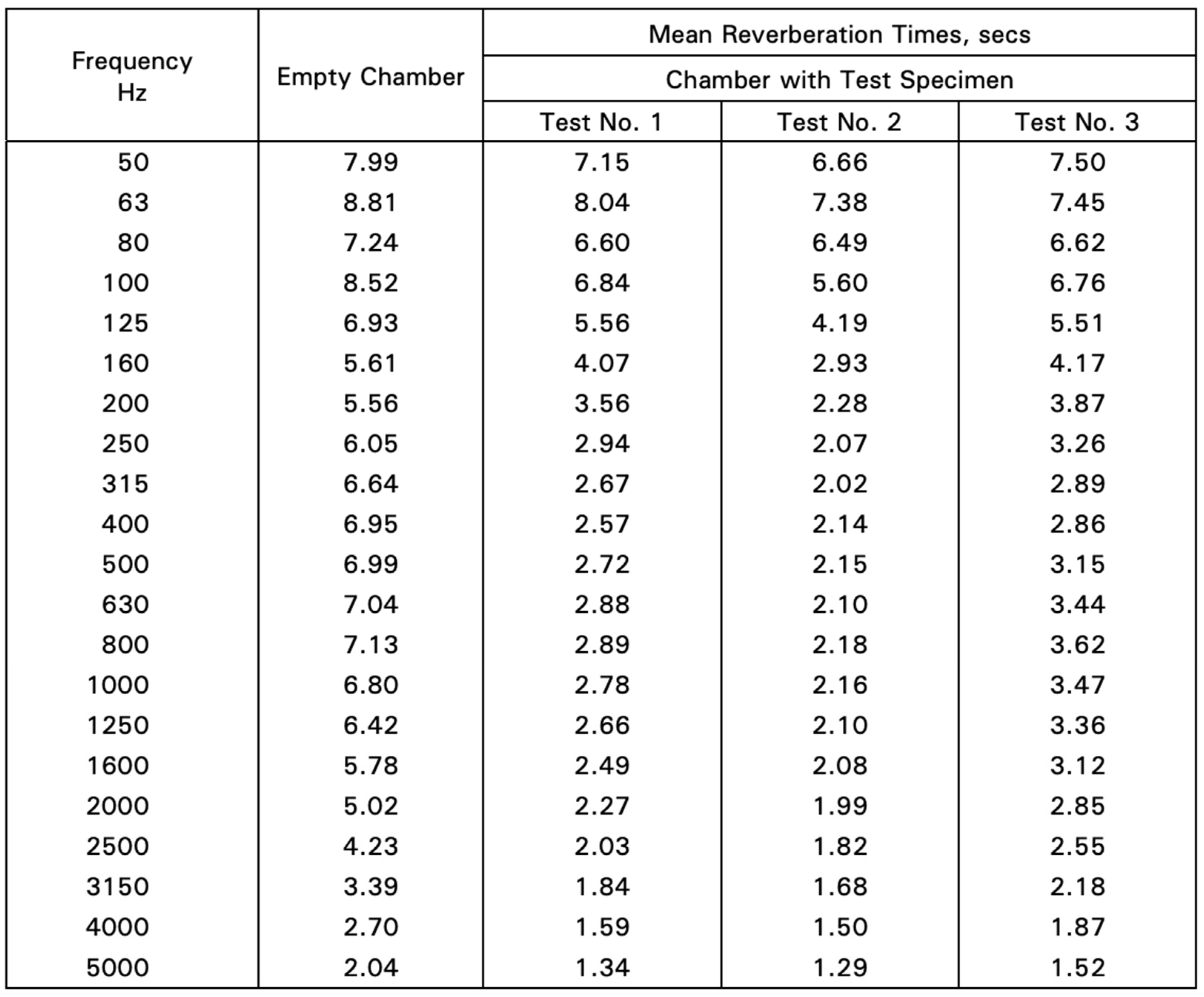

- Biotecture green wall system with fully planted panels (test no. L/3360/1)

- 2.

- Biotecture green wall system with dry panels (test no. l/3360/2)

- 3.

- Biotecture green wall system with wet un-planted panels (test no. l/3360/3)

3. Results and Discussion

4. Conclusions

- -

- Various solutions of green wall systems are considered and analyzed;

- -

- Compiled a comparative characteristic of these systems;

- -

- The most environmentally friendly and efficient landscaping options have been identified;

- -

- The most noise-absorbing systems have been identified.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OECD Environmental Outlook; OECD Publishing: Paris, France, 2001.

- McMichael, A.J. Planetary Overload. Global Environmental Change and the Health of the Human Species; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Patz, J.A.; Campbell-Lendrum, D.; Holloway, T.; Foley, J.A. Impact of regional climate change on human health. Nature 2005, 438, 310–317. [Google Scholar] [CrossRef] [PubMed]

- Burden of Disease from Environmental Noise; World Health Organization: Geneva, Switzerland, 2011; ISBN 978 92 890 02295.

- Climate Change. Available online: https://www.who.int/health-topics/climate-change#tab=tab_1 (accessed on 3 August 2021).

- The Top 7 Living Walls in Our World. Available online: https://blog.growup.green/blogs/the-tope-7-living-walls-in-our-world (accessed on 3 August 2021).

- Wei, Y.; Wu, J.; Huang, J.; Liu, X.; Han, D.; An, L.; Yu, H. Declining oxygen level as an emerging concern to global cities. Environ. Sci. Technol. 2021, 55, 7808–7817. [Google Scholar] [CrossRef] [PubMed]

- Pereira Barboza, E.; Cirach, M.; Khomenko, S.; Iungman, S.; Mueller, N.; Barrera-Gómez, J.; Rojas-Rueda, D.; Kondo, M.; Nieuwenhuijsen, M. Green space and mortality in European cities: A health impact assessment study. Lancet Planet. Health 2021, 5, e718–e730. [Google Scholar] [CrossRef]

- Urban Green Spaces and Health: A Review of Evidence. Available online: https://www.euro.who.int/en/health-topics/environment-and-health/urban-health/publications/2016/urban-green-spaces-and-health-a-review-of-evidence-2016 (accessed on 3 August 2021).

- Başdoğan, D.; Arzu, C. Ecological-social-economical impacts of vertical gardens in the sustainable city model. Yüzüncü Yıl Üniversitesi Tarım Bilim. Derg. 2016, 26, 430–438. [Google Scholar]

- Alexandri, E.; Jones, P. Temperature decreases in an urban canyon due to green walls and green roofs in diverse climates. Build. Environ. 2006, 43, 480–493. [Google Scholar] [CrossRef]

- Bass, B. Green Roofs and Green Walls: Potential Energy Savings in the Winter. 2007. Available online: https://www.researchgate.net/publication/242663071_Green_Roofs_and_Green_Walls_Potential_Energy_Savings_in_the_Winter (accessed on 3 August 2021).

- Binabid, J. The Study of Vertical Gardens and Their Benefits for Low-Rise Buildings in Moderate and Hot Climates; ProQuest LLC: Ann Arbor, MI, USA, 2010; p. 125. [Google Scholar]

- Huang, Y. Impact of Green Building Design on Healthcare Occupants with a Focus on Health Care Staff. Master’s Theses, Michigan State University Board of Trustees, East Lansing, MI, USA, 2011. [Google Scholar]

- Bruno, R.; Arcuri, N.; Carpino, C. The Passive House in Mediterranean Area: Parametric Analysis and Dynamic Simulation of the Thermal Behaviour of an Innovative Prototype. Energy Procedia 2015, 82, 533–539. [Google Scholar] [CrossRef]

- The Ultimate Guide to Living Wall Costs by Alex Lafreniere. Available online: https://planthardware.com/the-ultimate-guide-to-living-wall-costs/ (accessed on 3 August 2021).

- Onmura, S.; Matsumoto, M.; Hokoi, S. Study on evaporative cooling effect of roof lawn gardens. Energy Build. 2001, 33, 653–666. [Google Scholar] [CrossRef]

- Liu, K. Engineering performance on rooftop gardens through field evaluation. J. Roof Consult. Inst. 2004, 22, 4–12. [Google Scholar]

- Saiz, S.; Kennedy, C.; Bass, B.; Pressnail, K. Comparative life cycle assessment of standard and green roofs. Environ. Sci. Technol. 2006, 40, 4312–4316. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P.; Tsavdaridis, K.D.; Poologanathan, K. Digitally enabled modular construction for promoting modular components reuse: A UK view. J. Build. Eng. 2021, 42, 102820. [Google Scholar] [CrossRef]

- Azkorra, Z.; Pérez, G.; Coma, J.; Cabeza, F.L.; Burés, S.; Juan, E.A.; Erkoreka, A.; Urrestarazu, M. Evaluation of green walls as a passive acoustic insulation system for buildings. Appl. Acoust. 2015, 89, 46–56. [Google Scholar] [CrossRef]

- Tudiwer, D.; Korjenic, A. The effect of an Indoor Living Wall System on humidity, mould spores and CO 2-concentration. Energy Build. 2017, 146, 73–86. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Q.; Gan, V.J.L.; Peh, L. Envelope Thermal Performance Analysis Based on Building Information Model (BIM) Cloud Platform—Proposed Green Mark Collaboration Environment. Energies 2020, 13, 586. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Arcuri, N. Eco-Efficient Materials for Reducing Cooling Needs in Buildings and Construction; Woodhead Publishing: Cambridge, UK, 2021; pp. 205–245. [Google Scholar]

- Piro, P.; Carbone, M.; De Simone, M.; Maiolo, M.; Bevilacqua, P.; Arcuri, N. Energy and Hydraulic Performance of a Vegetated Roof in Sub-Mediterranean Climate. Sustainability 2018, 10, 3473. [Google Scholar] [CrossRef]

- Carbone, M.; Garofalo, G.; Nigro, G. Green Roofs in the Mediterranean Area: Interaction between Native Plant Species and Sub-Surface Runoff. Appl. Mech. Mater. 2015, 737, 749–753. [Google Scholar] [CrossRef]

- Fleck, R.; Gill, R.L.; Saadeh, S.; Pettit, T.; Wooster, E.; Torpy, F.; Irga, P. Urban green roofs to manage rooftop microclimates: A case study from Sydney, Australia. Build. Environ. 2022, 209, 108673. [Google Scholar] [CrossRef]

- Korol, E.; Shushunova, N.; Feoktistova, O.; Shushunova, T.; Rubtsov, O. Technical and economical factors in green roof using to reduce the aircraft noise. MATEC Web Conf. 2018, 170, 01081. [Google Scholar] [CrossRef][Green Version]

- Bevilacqua, P.; Mazzeo, D.; Bruno, R.; Arcuri, N. Experimental investigation of the thermal performances of an extensive green roof in the Mediterranean area. Energy Build. 2016, 122, 63–79. [Google Scholar] [CrossRef]

- Banirazi Motlagh, S.H.; Pons, O.; Hosseini, S.M.A. Sustainability model to assess the suitability of green roof alternatives for urban air pollution reduction applied in Tehran. Build. Environ. 2021, 194, 107683. [Google Scholar] [CrossRef]

- Shafique, M.; Xue, X.; Luo, X. An overview of carbon sequestration of green roofs in urban areas. Urban For. Urban Green. 2020, 47, 126515. [Google Scholar] [CrossRef]

- Karteris, M.; Theodoridou, I.; Mallinis, G.; Tsiros, E.; Karteris, A. Towards a green sustainable strategy for Mediterranean cities: Assessing the benefits of large-scale green roofs implementation in Thessaloniki, Northern Greece, using environmental modelling, GIS and very high spatial resolution remote sensing data. Renew. Sustain. Energy Rev. 2016, 58, 510–525. [Google Scholar] [CrossRef]

- Majumdar, M. Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 144–157. [Google Scholar]

- Zhang, G.; He, B.J. Towards green roof implementation: Drivers, motivations, barriers and recommendations. Urban For. Urban Green. 2021, 58, 126992. [Google Scholar] [CrossRef]

- Susca, T. Green roofs to reduce building energy use? A review on key structural factors of green roofs and their effects on urban climate. Build. Environ. 2019, 162, 106273. [Google Scholar] [CrossRef]

- Su, Y.; Wang, L.; Feng, W.; Zhou, N.; Wang, L. Analysis of green building performance in cold coastal climates: An in-depth evaluation of green buildings in Dalian, China. Renew. Sustain. Energy Rev. 2021, 146, 111149. [Google Scholar] [CrossRef]

- Wang, R.; Lam, C.M.; Alvarado, V.; Hsu, S.-C. A modeling framework to examine photovoltaic rooftop peak shaving with varying roof availability: A case of office building in Hong Kong. J. Build. Eng. 2021, 44, 103349. [Google Scholar] [CrossRef]

- Bevilacqua, P. The effectiveness of green roofs in reducing building energy consumptions across different climates. A summary of literature results. Renew. Sustain. Energy Rev. 2021, 151, 111523. [Google Scholar] [CrossRef]

- Zhang, X.; Mohandes, S.R. Occupational Health and Safety in green building construction projects: A holistic Z-numbers-based risk management framework. J. Clean. Prod. 2020, 275, 122788. [Google Scholar] [CrossRef]

- Viola, S. Green roofs for built environment recovery: Technological transitions. J. Clean. Prod. 2017, 153, 592–599. [Google Scholar] [CrossRef]

- Besir, A.B.; Cuce, E. Green roofs and facades: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 915–939. [Google Scholar] [CrossRef]

- Green Walls. Available online: https://www.growinggreenguide.org/technical-guide/construction-and-installation/green-walls/ (accessed on 3 August 2021).

- BS EN ISO 11654; Acoustics. Sound Absorbers for Use in Buildings. Rating of Sound Absorption. ISO: Geneva, Switzerland, 1997.

- Korol, E.; Shushunova, N. Benefits of a Modular Green Roof Technology. Procedia Eng. 2016, 161, 1820–1826. [Google Scholar] [CrossRef]

- Shushunova, N.S.; Shushunova, T.N. Role of green roofs in increasing the economic efficiency of the agricultural sector of the Russian economy. A review. AlfaBuild 2022, 21, 2102. [Google Scholar]

- ISO 9613-1; Acoustics. Attenuation of Sound during Propagation Outdoors. Part 1: Calculation of the Absorption of Sound by the Atmosphere. ISO: Geneva, Switzerland,, 1993.

- Romanova, A.; Horoshenkov, K.; Hurrell, A. An application of a parametric transducer to measure acoustic absorption of a living green wall. Appl. Acoust. 2019, 145, 89–97. [Google Scholar] [CrossRef]

- Yang, H.S.; Kang, J.; Choi, M.S. Acoustic effects of green roof systems on a low-profiled structure at street level. Build. Environ. 2012, 50, 44–55. [Google Scholar] [CrossRef]

- Yang, H.S.; Kang, J.; Cheal, C. Random-incidence absorption and scattering coefficients of vegetation. Acta Acust. United Acust. 2013, 99, 379–388. [Google Scholar] [CrossRef]

- Horoshenkov, K.; Khan, A.; Benkreira, H. Acoustic properties of low growing plants. J. Acoust. Soc. Am. 2013, 133, 2554–2565. [Google Scholar] [CrossRef] [PubMed]

- Horoshenkov, K.; Khan, A.; Benkreira, H.; Mandon, A.; Rohr, R. The effect of moisture and soil type on the acoustical properties of green noise control elements. In Proceedings of the Forum Acusticum, Aalborg, Denmark, 27 June–1 July 2011; pp. 845–849. [Google Scholar]

- Cook, D.; Van Haverbeke, D.F. Suburban noise control with plant materials and solid barriers. In Proceedings of the Conference on Metropolitan Physical Environment; Heisler Gordon, M., Herrington Lee, P., Eds.; Gen. Tech. Rep. NE-25; U.S. Department of Agriculture, Forest Service, Northeastern Forest Experiment Station: Upper Darby, PA, USA, 1977; pp. 234–241. [Google Scholar]

- Wong, N.H.; Tan, A.; Puay Yok, T.; Chiang, K.; Wong, N. Acoustics evaluation of vertical greenery systems for building walls. Build. Environ. 2010, 45, 411–420. [Google Scholar] [CrossRef]

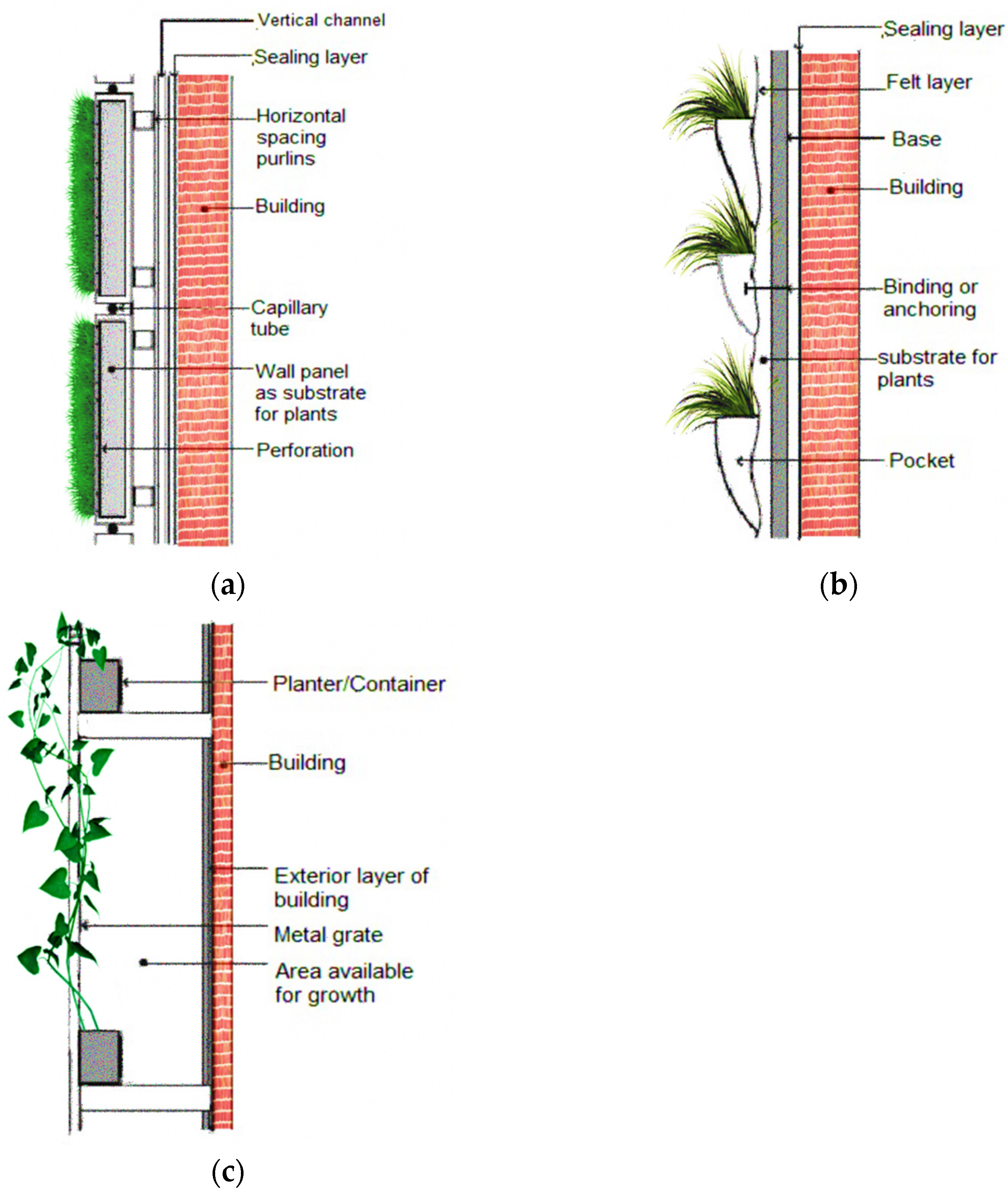

| Parameter | Hydroponic System | Modular System | Container System |

|---|---|---|---|

| Rooting Space | Brackets protruding from the load-bearing wall | Substrate-holding containers | Supporting waterproof metal frame: frame grid, built-in frame rack, portable frame rack with guides |

| Substrate | Horticultural foam, mineral fibre, felt mat | Soil substrate in water permeable, synthetic fibre bag | Soil substrate |

| Maintenance | Pruning/replacement | Pruning/replacement | Pruning/replacement |

| Advantages | No structural decay of the growing medium | The growing medium support the plant and facilitates water, providing nutrient access | Irrigation system is connected to the water supply and sewerage system |

| Disadvantages | Constant management and maintenance | Accumulation of salts in the growning medium, high system weight | |

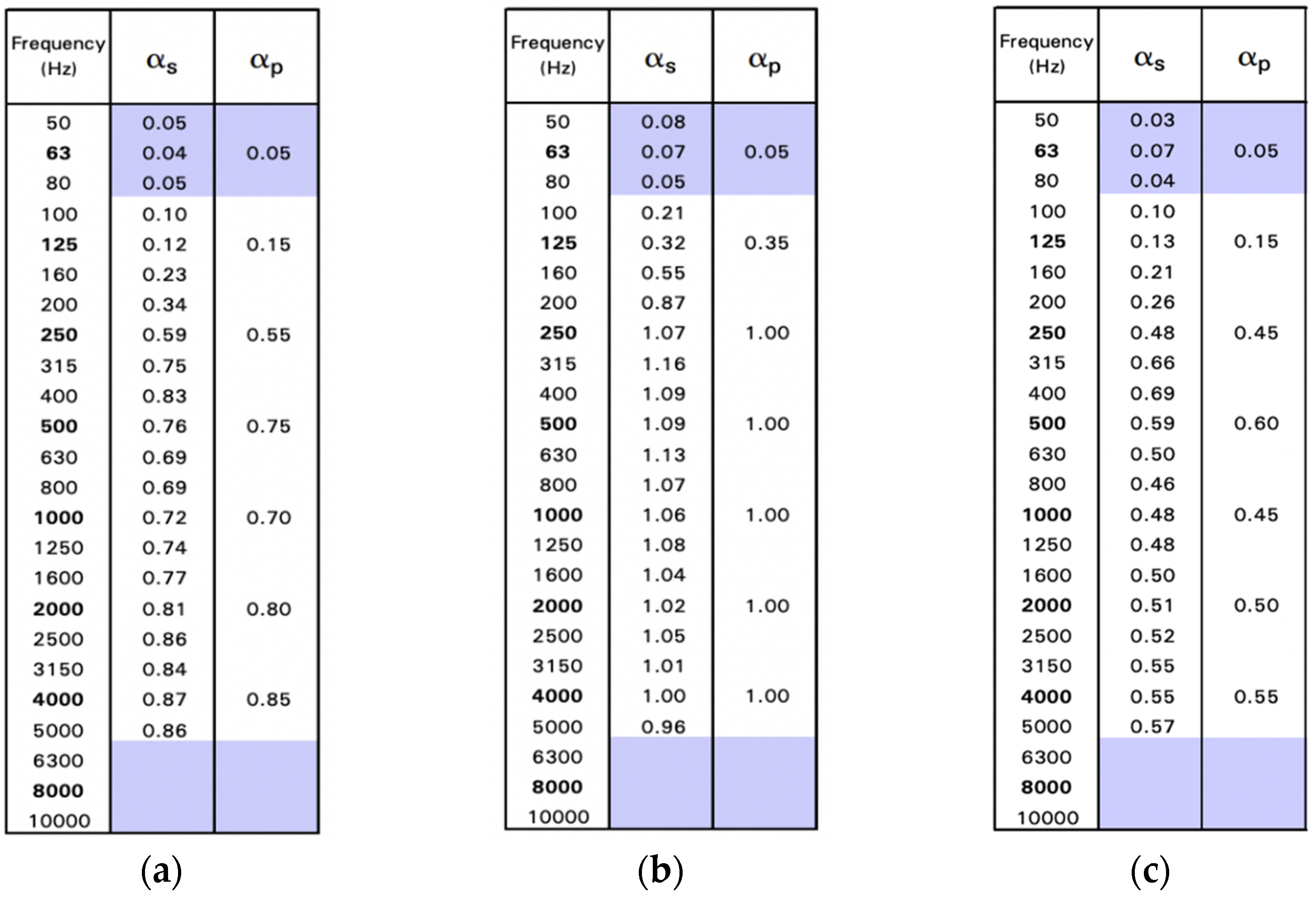

| Parameter | Biotecture Living Wall System with Fully Planted Panels (Type 1) | Biotecture Living Wall System with Dry Panels (Type 2) | Biotecture Living Wall System with Wet Un-planted Panels (Type 3) |

|---|---|---|---|

| Description | The panels were wet with average moisture content of 60 to 70%, and were fully planted with 640 plants of a mixed perennial plant selection. | The panels were dry, excluded plants but did include the removable Grodan growing medium plugs. | The panels were wet with average moisture content of 60 to 70%, excluded plants but did include the removable Grodan growing medium plugs. |

| Mass per unit area of the planted panels | 42 kg/m2 | 10 kg/m2 | 42 kg/m2 |

| Weighted Sound absorption coefficient (αw) | 0.75 | 1.00 | 0.5 |

| Sound absorption class according to BS EN ISO 11654:1997 (45) | C | A | D |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shushunova, N.; Korol, E.; Luzay, E.; Shafieva, D.; Bevilacqua, P. Ensuring the Safety of Buildings by Reducing the Noise Impact through the Use of Green Wall Systems. Energies 2022, 15, 8097. https://doi.org/10.3390/en15218097

Shushunova N, Korol E, Luzay E, Shafieva D, Bevilacqua P. Ensuring the Safety of Buildings by Reducing the Noise Impact through the Use of Green Wall Systems. Energies. 2022; 15(21):8097. https://doi.org/10.3390/en15218097

Chicago/Turabian StyleShushunova, Natalia, Elena Korol, Elisaveta Luzay, Diana Shafieva, and Piero Bevilacqua. 2022. "Ensuring the Safety of Buildings by Reducing the Noise Impact through the Use of Green Wall Systems" Energies 15, no. 21: 8097. https://doi.org/10.3390/en15218097

APA StyleShushunova, N., Korol, E., Luzay, E., Shafieva, D., & Bevilacqua, P. (2022). Ensuring the Safety of Buildings by Reducing the Noise Impact through the Use of Green Wall Systems. Energies, 15(21), 8097. https://doi.org/10.3390/en15218097