Study on the Slurry Diffusion Law of Fluidized Filling Gangue in the Caving Goaf of Thick Coal Seam Fully Mechanized Caving Mining

Abstract

1. Introduction

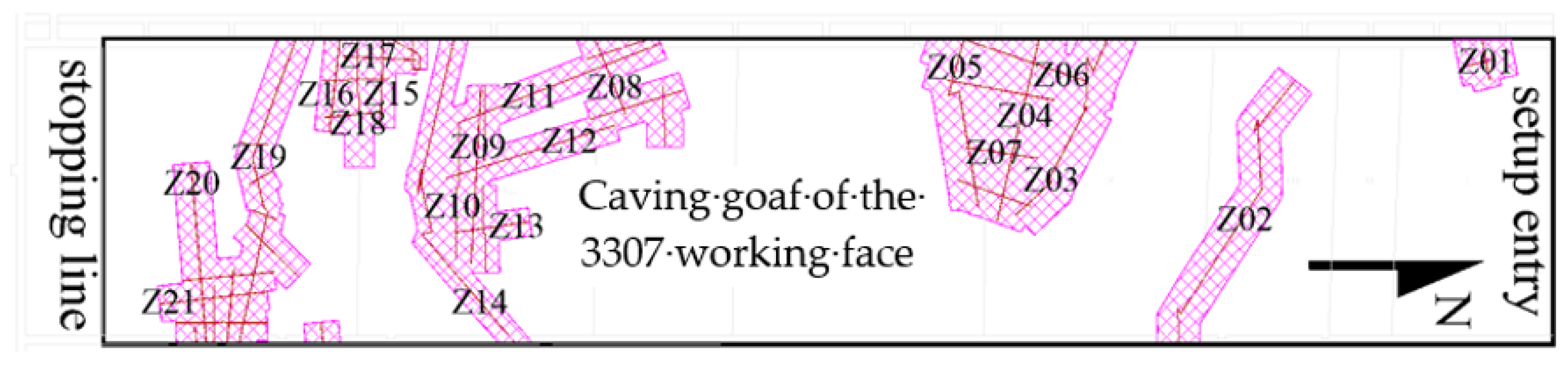

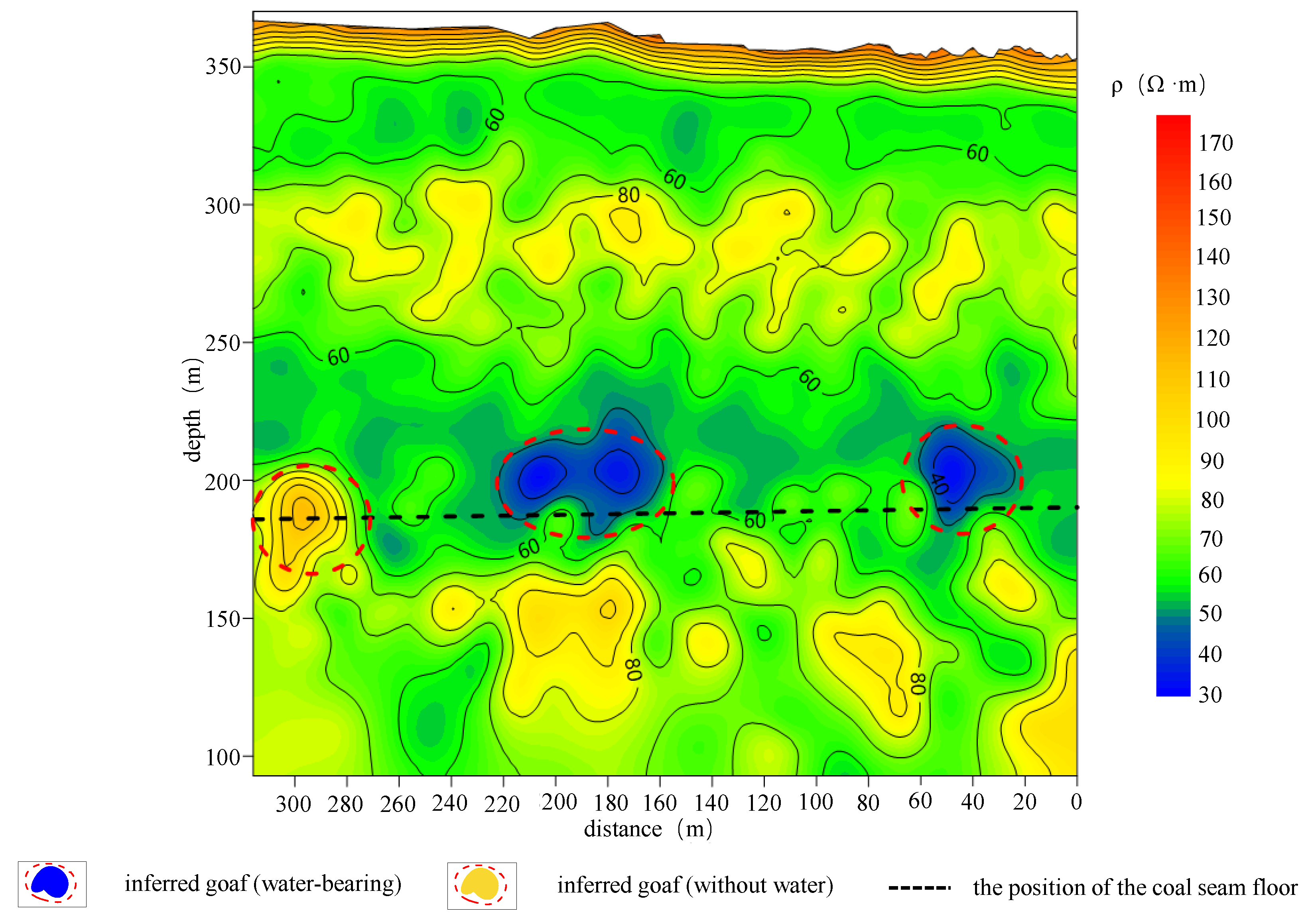

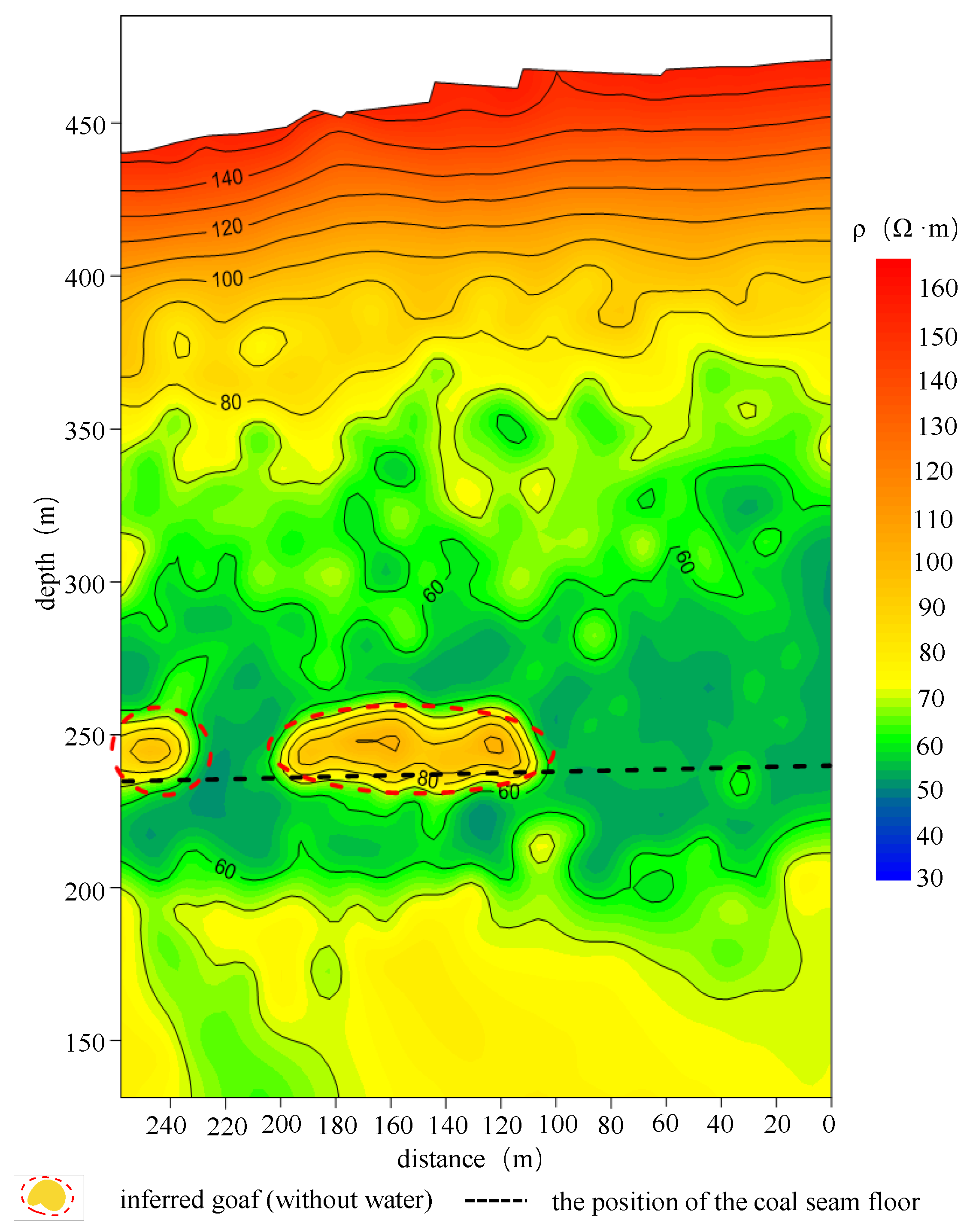

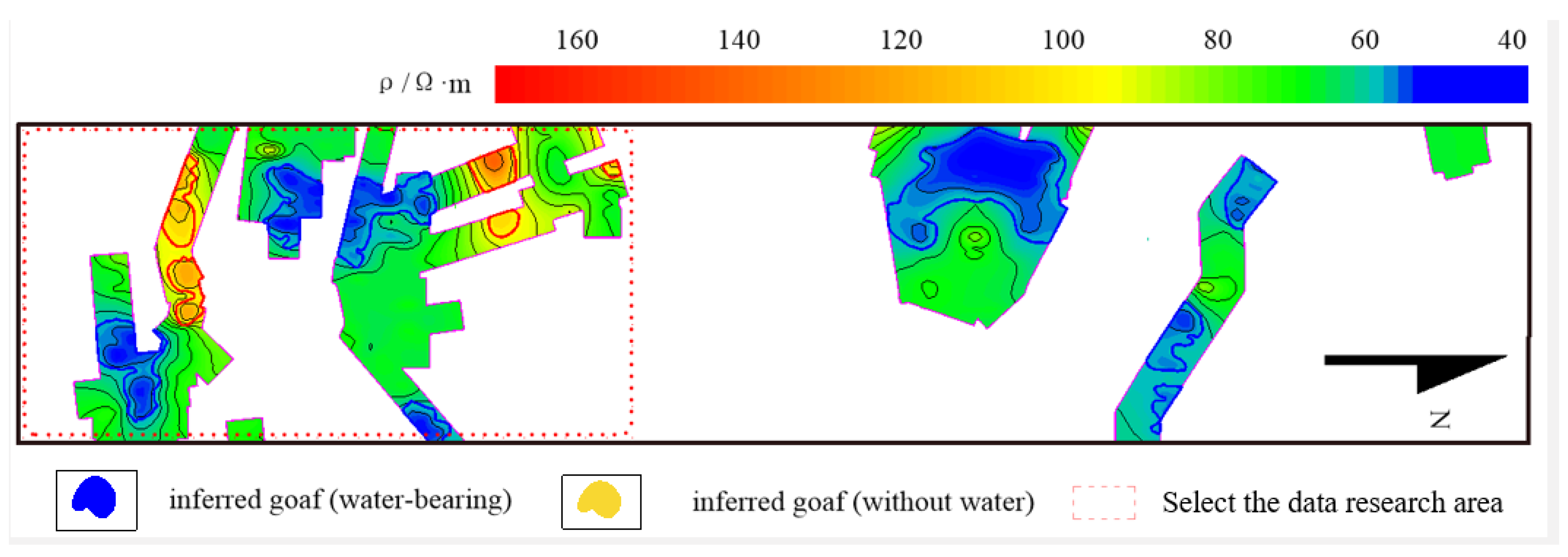

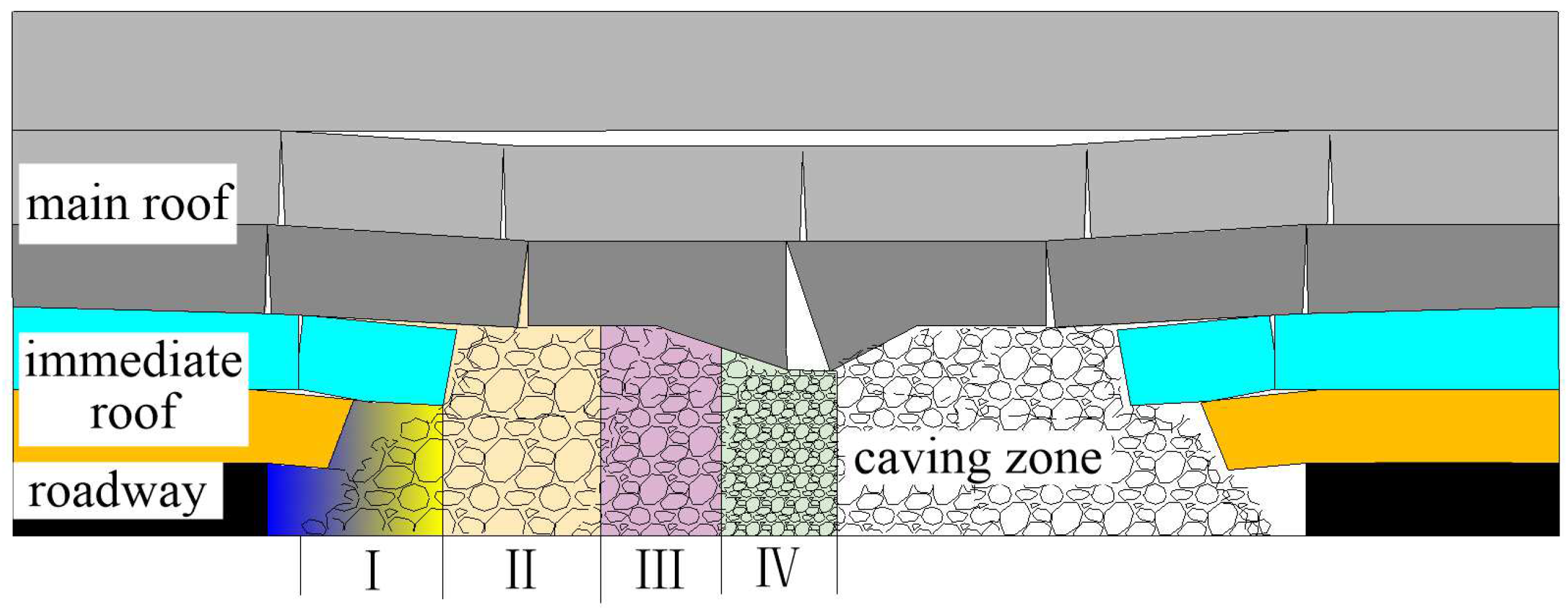

2. Measurement of Residual Spatial Distribution in the Caving Goaf

2.1. Layout of Measuring Points

2.2. Exploration Results and Analysis

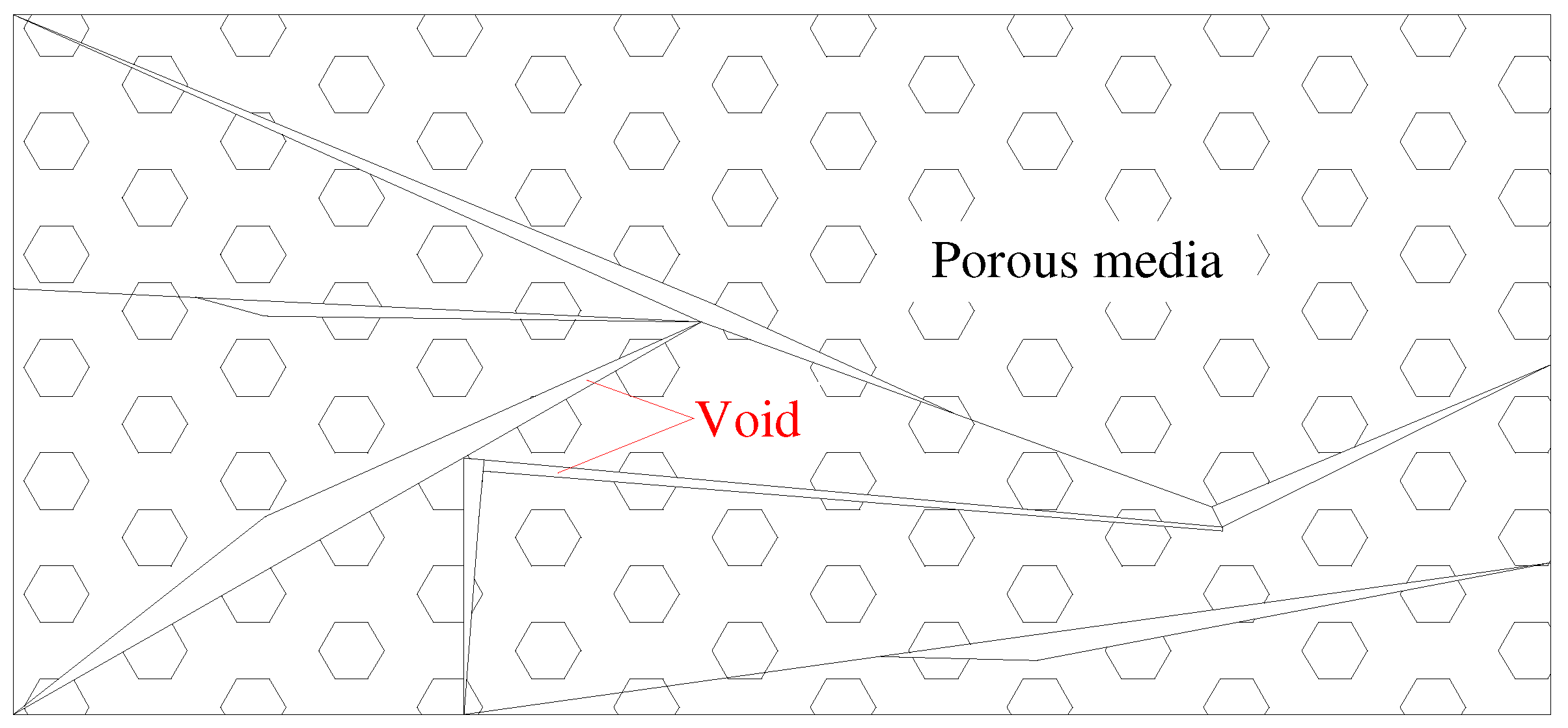

3. Numerical Simulation Test on the Diffusion Law of Gangue Slurry in Caving Goaf

- (1)

- The slurry is a homogeneous, isotropic, incompressible fluid, and the flow pattern remains unchanged during motion.

- (2)

- The fissures are distributed horizontally, the opening of the gap remains unchanged, and the rock mass on both sides of the crack is an isotropic porous medium.

- (3)

- The fissure network cuts the rock mass, and the fissures have strong water conductivity.

- (4)

- Neglecting the influence of the partial flow of the grout perpendicular to the crack on the grout crack flow, it is considered that the grout in the crack is centered on the grouting hole and diffuses in a radial circle, and the flow direction is parallel to the crack surface.

- (5)

- The influence of the slurry flow on the mechanical properties of the surrounding rock mass is ignored, and the surrounding rock structure and geometric characteristics remain unchanged.

- (1)

- The left and right boundaries of the model are defined as the maximum critical boundary of slurry diffusion.

- (2)

- The bottom boundary of the model is the wall boundary (the slurry cannot penetrate).

- (3)

- The upper boundary of the model is the coal pillar boundary, and the middle is the grouting hole, which is set as the inflow boundary.

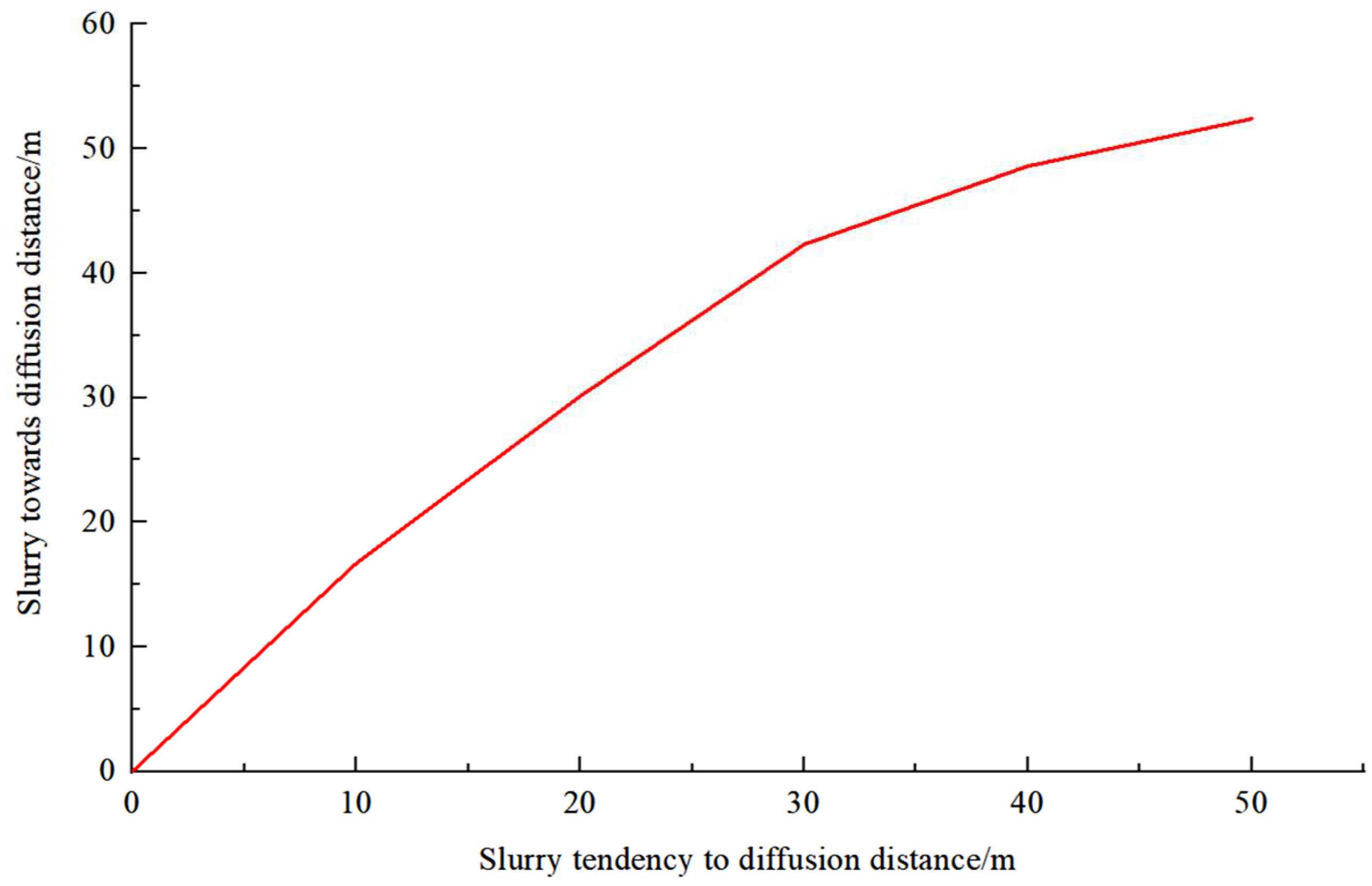

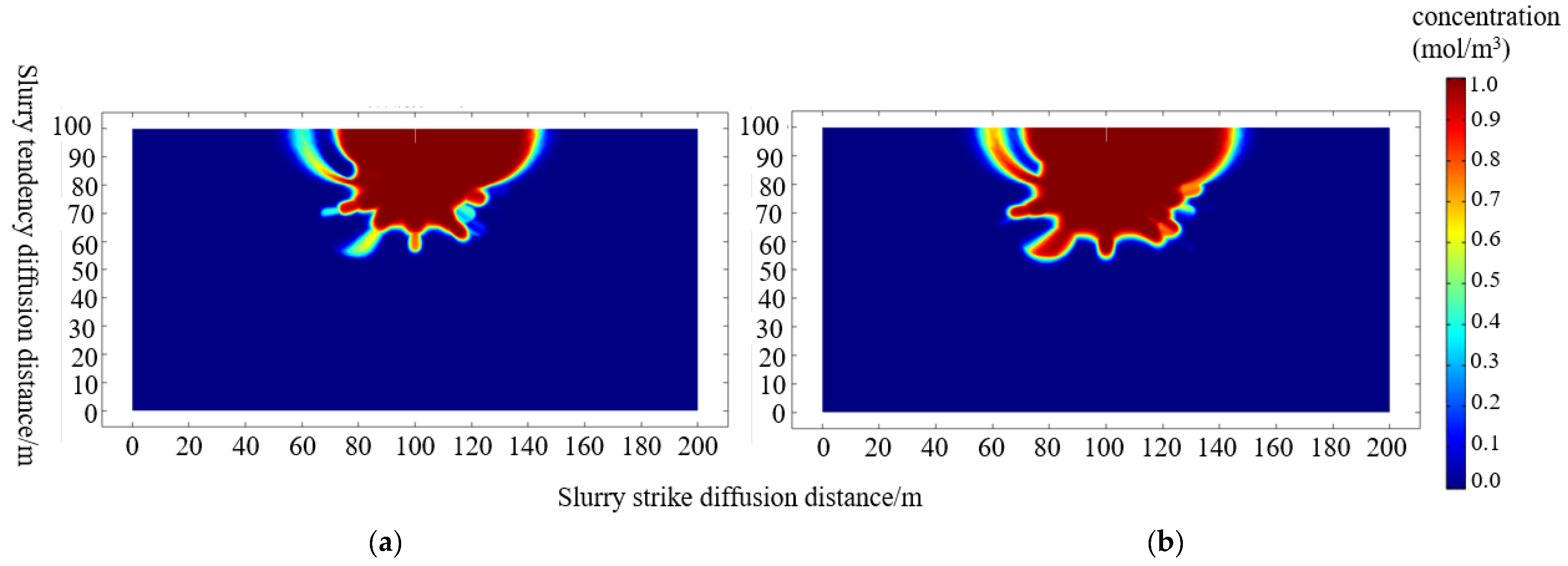

3.1. Slurry Tendency Diffusion Law

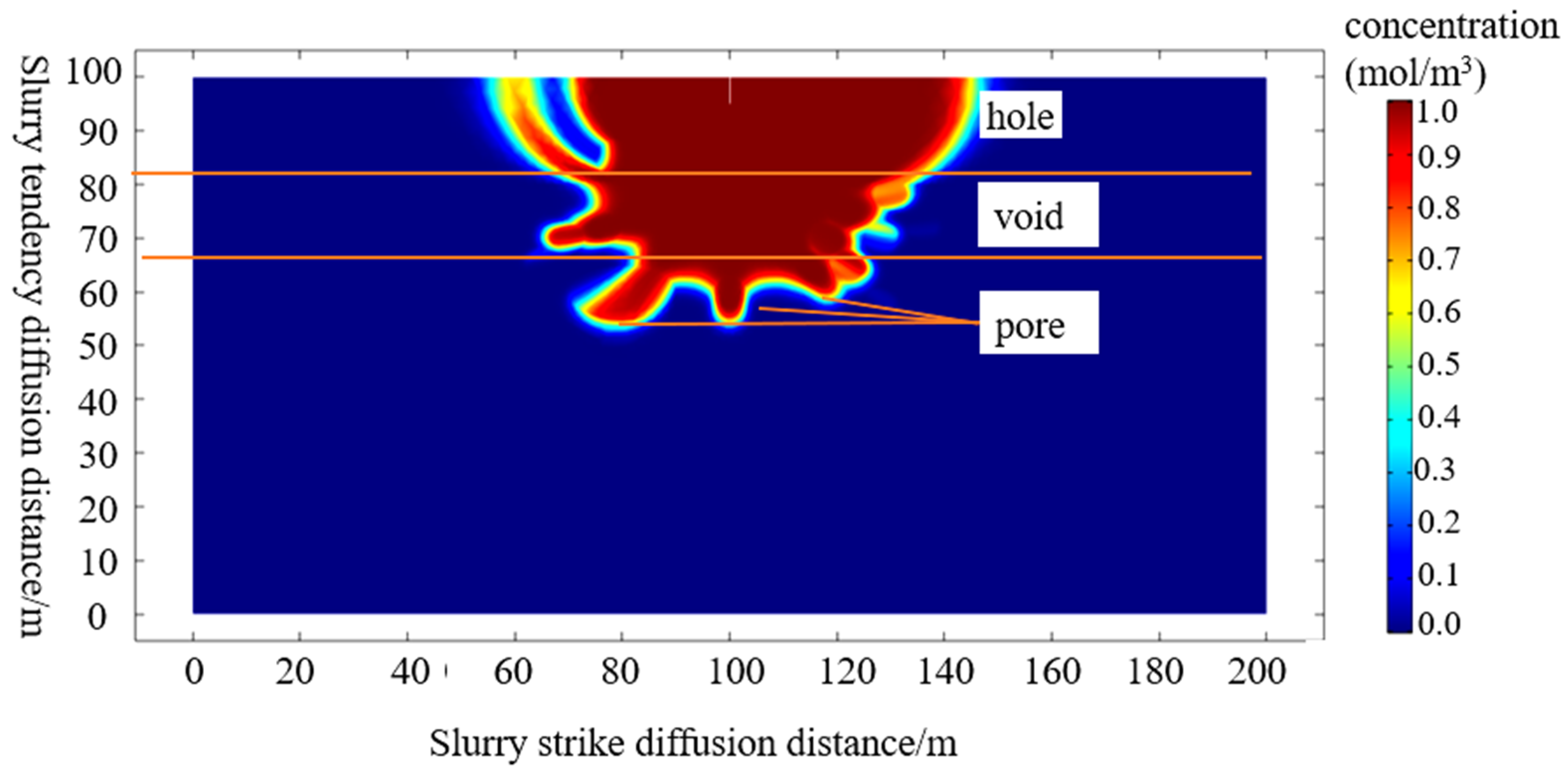

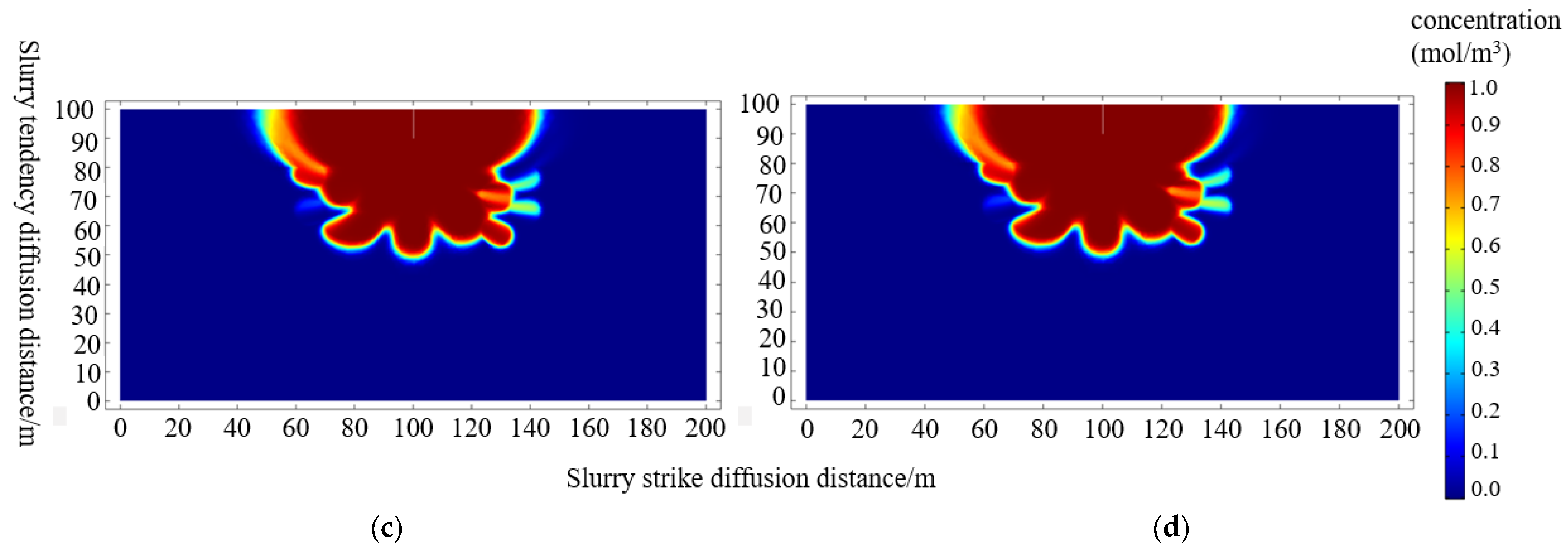

3.2. Slurry Strike Diffusion Law

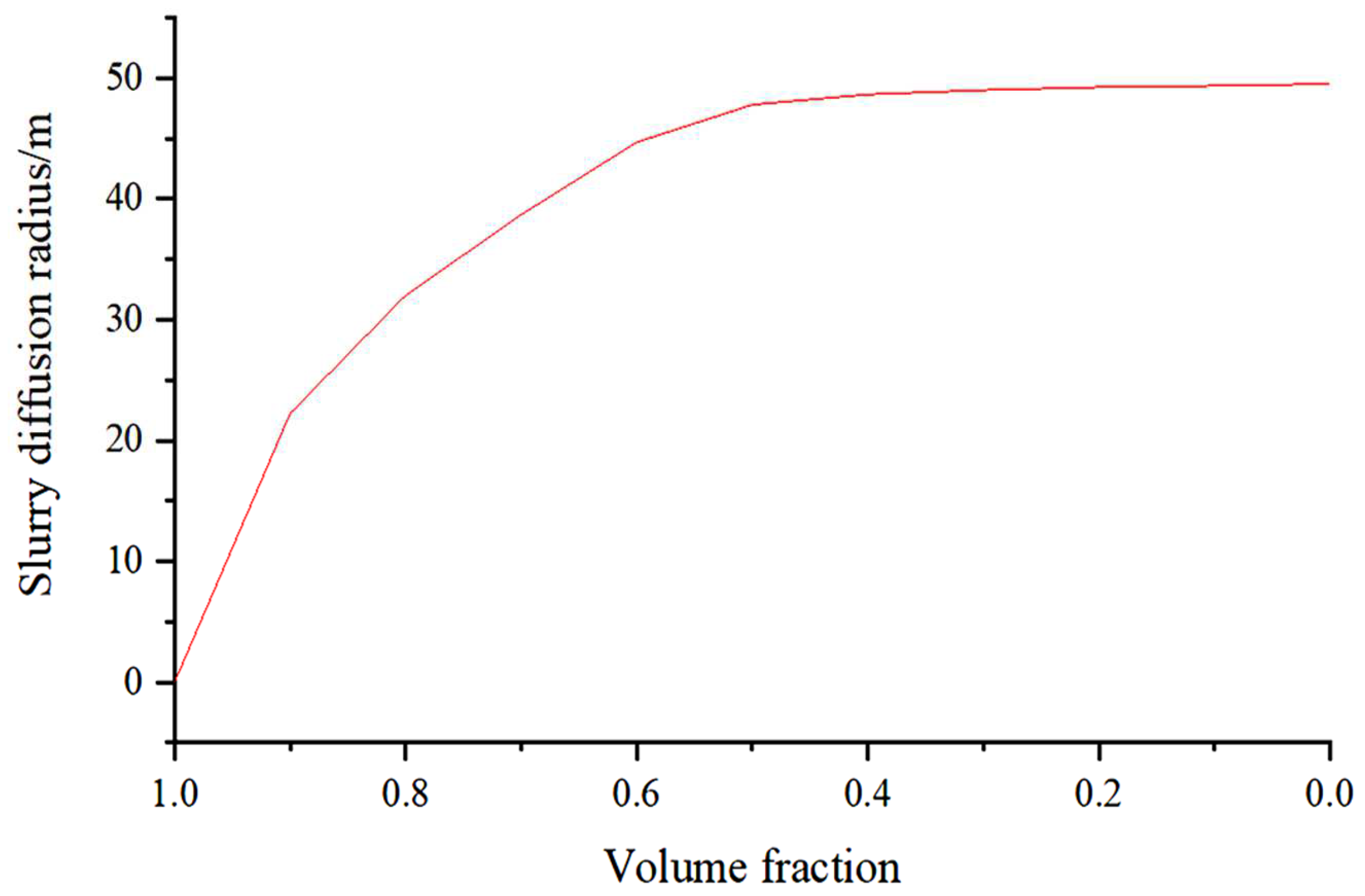

3.3. Influencing Factors of Slurry Diffusion Radius

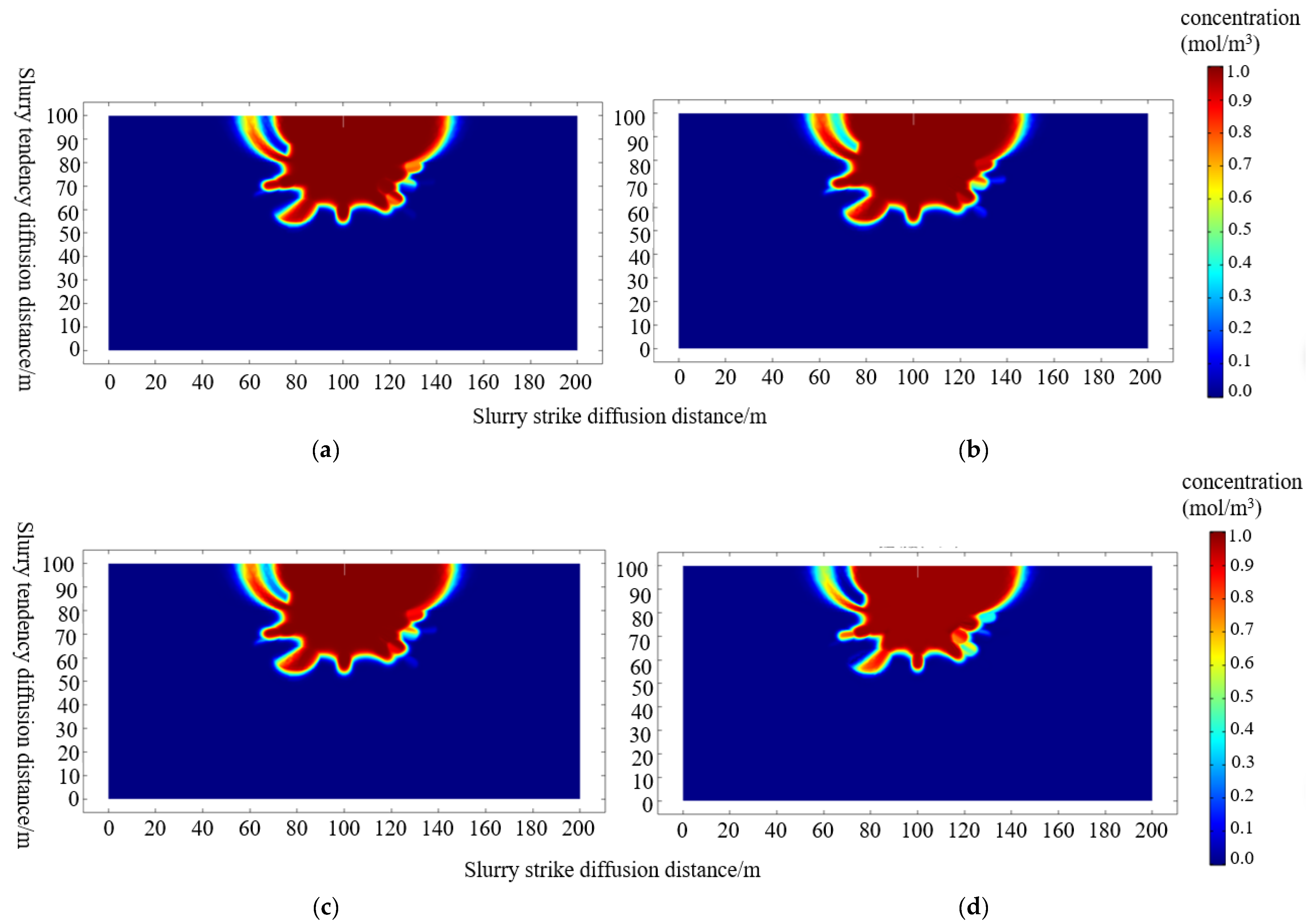

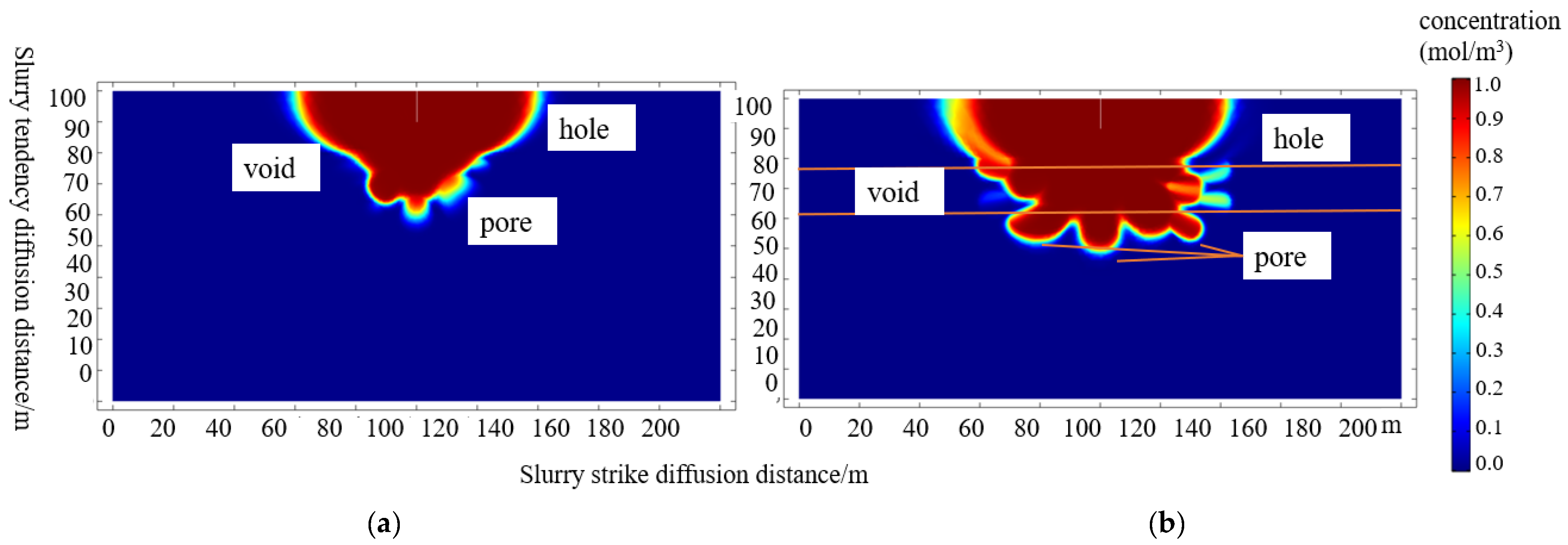

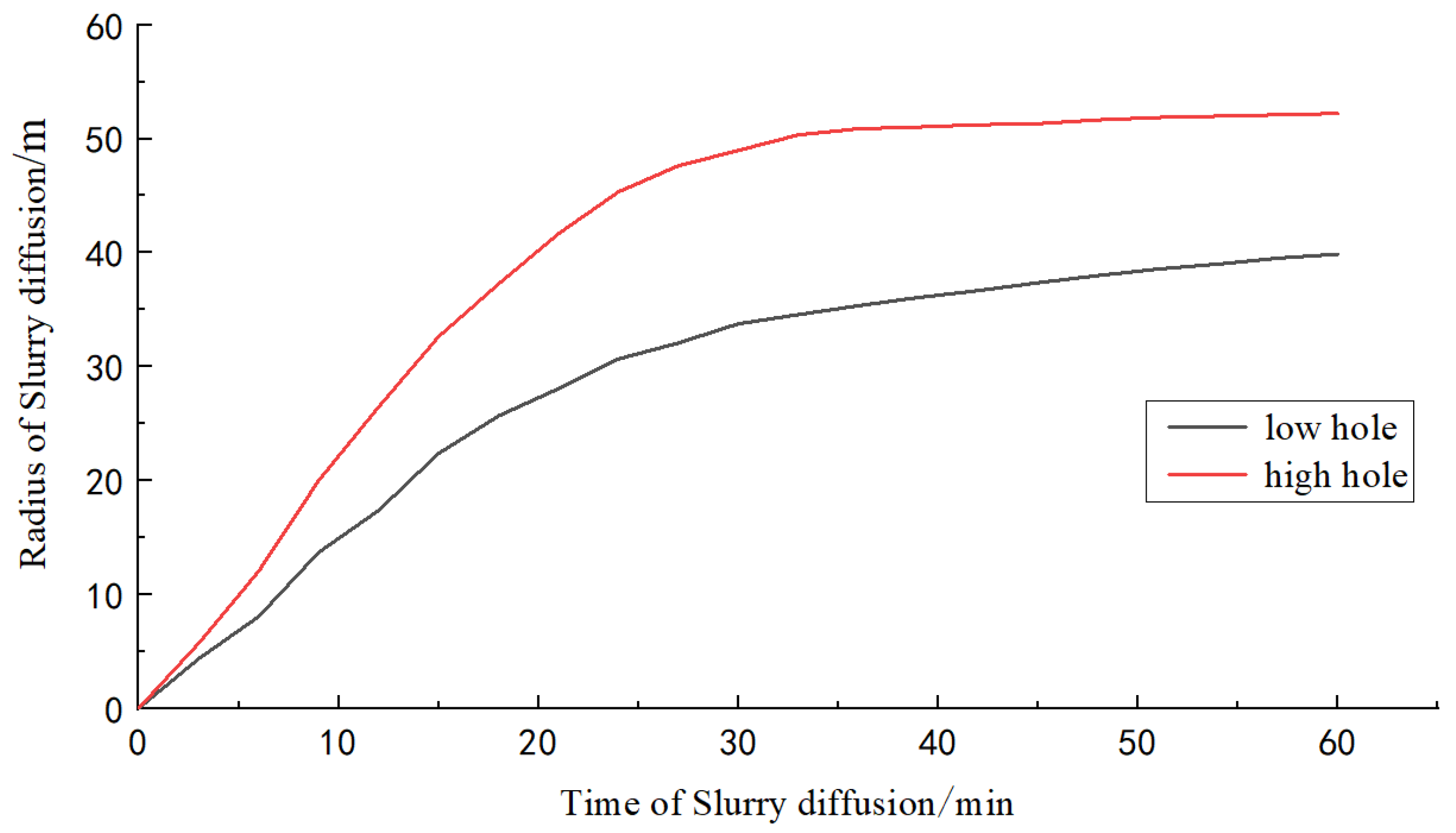

3.4. Diffusion Rule of High and Low Pore Filling Slurry

4. Fluidization Filling Space in the Caving Goaf

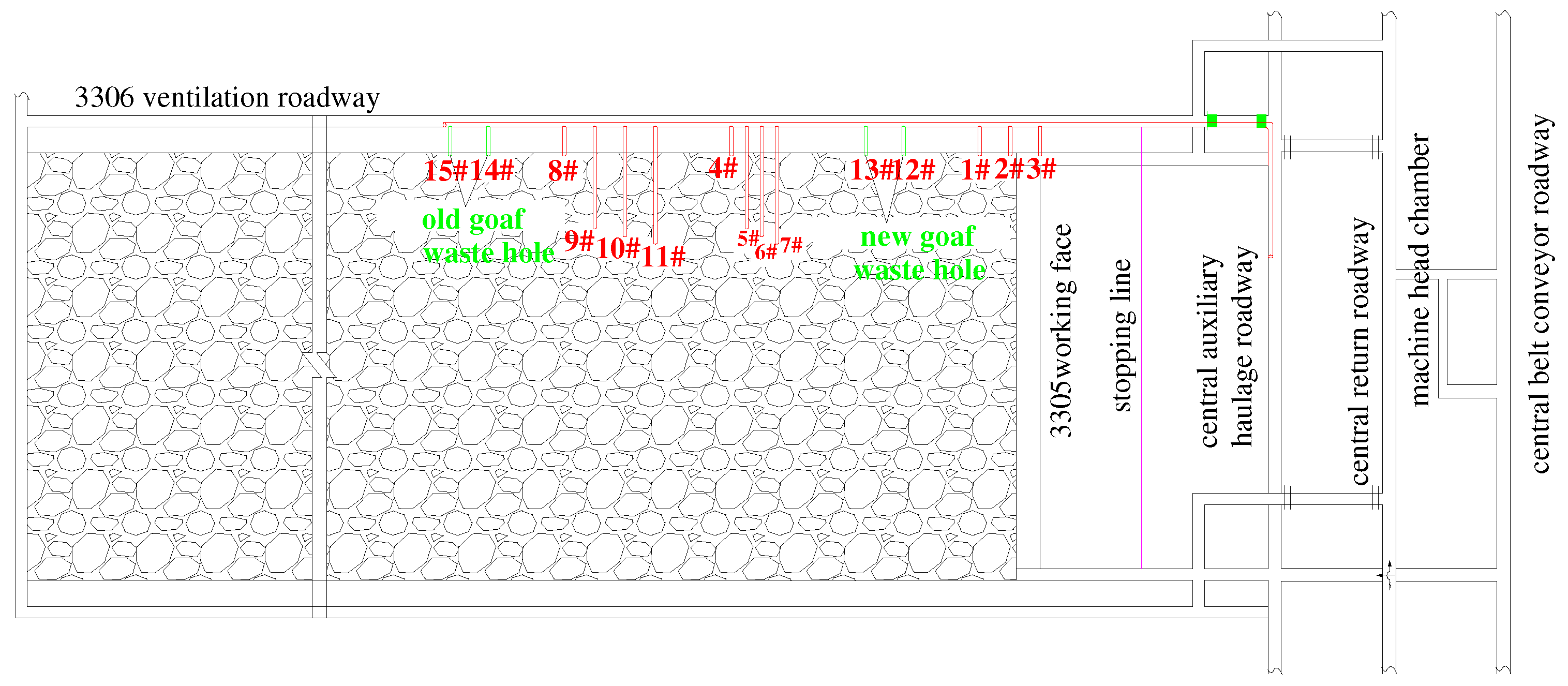

4.1. Overview of Working Face

4.2. Theoretical Prediction of Residual Space

4.3. Calculation of Residual Space in Caving Zone by Fractal Dimension Theory

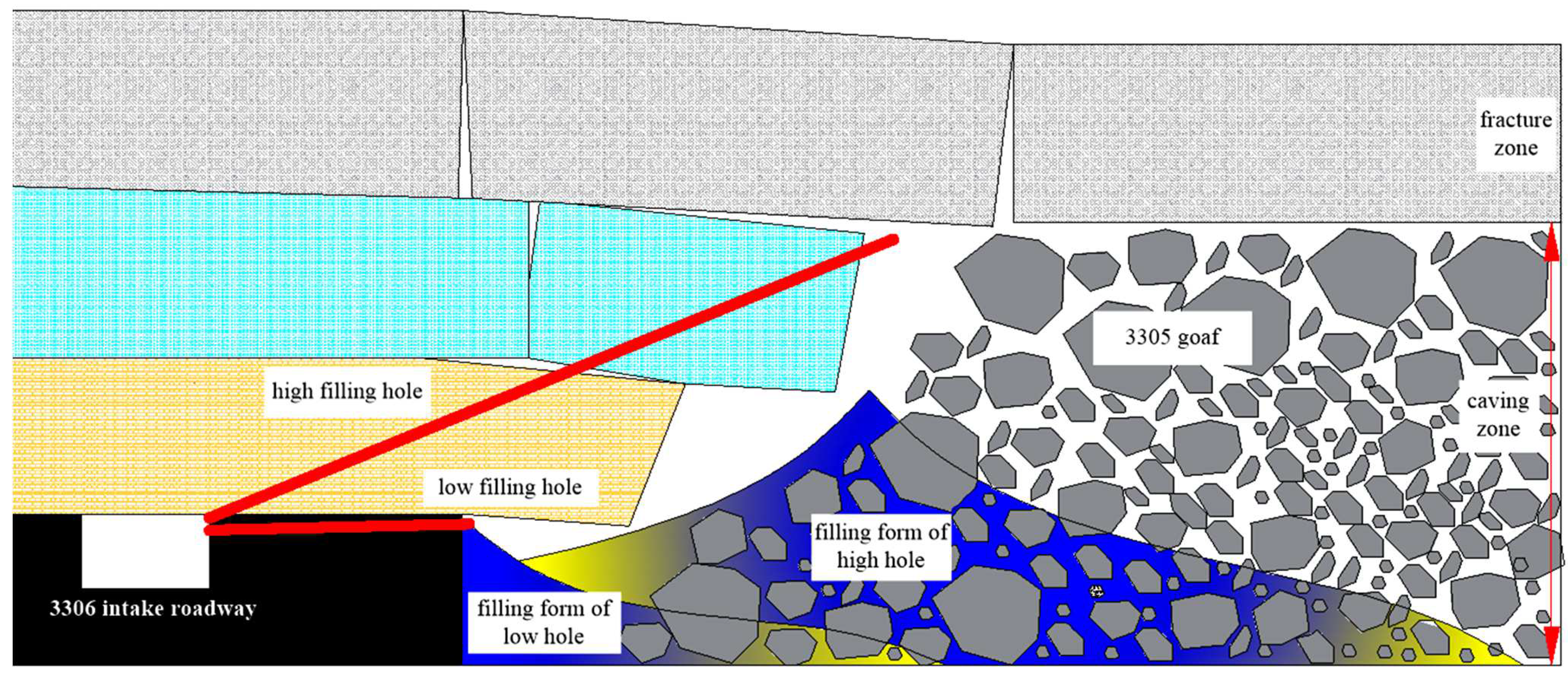

4.4. Filling Borehole Design

5. Test Verification

5.1. Test Plan

5.2. Test Result

- (1)

- Low-Level Horizontal Hole Filling Test

- (2)

- High-Position Hole Filling Test

- (3)

- Test Conclusion

6. Conclusions

- (1)

- Based on the results of transient electromagnetic exploration, there were four empty abnormal areas (containing water) and five empty abnormal areas (containing no water) in the study area. The actual residual space area of the detected caving goaf accounted for 23.5% of the whole study area. The detection results provided guidance for the accurate use of the residual space in the caving goaf.

- (2)

- The COMSOL simulation software was used to simulate and analyze the diffusion law of gangue slurry in the caving goaf. It is concluded that the gangue slurry spreads most obviously in the direction of the caving zone during the filling process, and diffusion in the inclination direction extends step by step in the multi-type residual space of “cavity–void–pore”. It is manifested that with the increase in diffusion distance, the diffusion resistance and slurry shape change significantly.

- (3)

- The industrial filling test was carried out. The test verified that the high and low filling holes in the caving goaf can safely and efficiently fill the gangue slurry. The technological characteristics of filling high- and low-level filling holes were summarized. Comprehensive numerical simulation and industrial tests were conducted. It is considered that there is a significant “channel effect” in the progressive extension of the multi-type residual space of “cavity–void–pore” in the gangue slurry, and reducing or removing the “channel effect” is an effective way to make efficient use of the residual space in the caving goaf.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, N.; Yao, Y.N.; Song, W.J.; He, Z.W.; Meng, G.H.; Liu, Y. Present situation and prospect of coal gangue treatment technology. J. Min. Saf. Eng. 2020, 37, 136–146. [Google Scholar]

- Rybak, J.; Gorbatyuk, S.M.; Kongar-Syuryun, C.B.; Khairutdinov, A.M.; Tyulyaeva, Y.S.; Makarov, P.S. Utilization of Mineral Waste: A Method for Expanding the Mineral Resource Base of a Mining and Smelting Company. Metallurgist 2021, 64, 851–861. [Google Scholar] [CrossRef]

- Zhang, Y.; Ling, T.C. Reactivity activation of waste coal gangue and its impact on the properties of cement-based materials e a review. Constr. Build. Mater. 2020, 234, 117424. [Google Scholar] [CrossRef]

- Tcvetkov, P.; Cherepovitsyn, A.; Fedoseev, S. Public perception of carbon capture and storage: A state-of-the-art overview. Heliyon 2019, 5, e02845. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.; Gao, X.; Su, A.; Li, Q. Effect of carbonation curing on sulfate resistance of cement-coal gangue paste. J. Clean. Prod. 2021, 278, 123897. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Y.; Wang, H.; Hnizdo, E.; Sun, Y.; Su, L.; Zhang, X.; Weng, S.; Bochmann, F.; Hearl, F.J.; et al. Long-term exposure to silica dust and risk of total and cause-specific mortality in Chinese workers: A cohort study. PLoS Med. 2012, 9, e1001206. [Google Scholar] [CrossRef]

- Field, R.W.; Withers, B.L. Occupational and environmental causes of lung cancer. Clin. Chest Med. 2012, 33, 681–703. [Google Scholar] [CrossRef]

- Miao, X.X. Progress of fully mechanized mining with solid backfilling technology. J. China Coal Soc. 2012, 37, 1247–1255. [Google Scholar]

- Cavusoglu, I.; Yilmaz, E.; Yilmaz, A.O. Sodium silicate effect on setting properties, strength behavior and microstructure of cemented coal fly ash backfill. Powder Technol. 2021, 384, 17–28. [Google Scholar] [CrossRef]

- Holmquist, D.V.; Thomas, D.B. Subsidence mitigation using void fill grouting. Geol. Soc. Lond. Spec. Publ. 2003, 120, 1103–1114. [Google Scholar]

- Ma, H.W.; Sui, W.G.; Ni, J.M. Environmentally sustainable mining: A case study on surface subsidence control of grouting into overburden. Environ. Earth. Sci. 2019, 78, 320. [Google Scholar] [CrossRef]

- Cao, W.H.; Wang, X.F.; Li, P.; Zhang, D.S.; Sun, C.D.; Qin, D.D. Wide Strip Backfill Mining for Surface Subsidence Control and Its Application in Critical Mining Conditions of a Coal Mine. Sustainability 2018, 10, 700. [Google Scholar] [CrossRef]

- Zorychta, A.; Chojnacki, J.; Krzyzowski, A.; Chlebowski, D. Potentials of mining in remnants in polish coal mines. Gospod. Surowcami Miner. (Miner. Resour. Manag.) 2008, 24, 169–184. [Google Scholar]

- Fall, M.; Celestin, J.; Sen, H.F. Potential use of densified polymerpastefill mixture as waste containment barrier materials. J. Waste Manag. 2010, 30, 2570–2578. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.M.; Zhao, B.; Zhang, C.S.; Zhang, Q.L. Paste-like self-flowing transportation backfilling technology based on coal gangue. Int. J. Min. Sci. Technol. 2009, 19, 137–143. [Google Scholar] [CrossRef]

- Rybak, J.; Khayrutdinov, M.M.; Kuziev, D.A.; Kongar-Syuryun, C.B.; Babyr, N.V. Prediction of the geomechanical state of the rock mass when mining salt deposits with stowing. J. Min. Inst. 2022, 253, 61–70. [Google Scholar] [CrossRef]

- Yu, G.G.; Mi, W.R.; Wang, D.N.; Gao, L.Y.; Lu, S.B.; Li, G. Research on the Relationship between the Surface Dynamic Subsidence and Overburden Separated Strata of Coal Mine and Its Model. Procedia Eng. 2017, 191, 196–205. [Google Scholar] [CrossRef]

- Andre, Z.; Anderson, W. Subsidence over room and pillar retreat mining in a low coal seamInternational. J. Min. Sci. Technol. 2019, 29, 51–57. [Google Scholar]

- Ren, W.S.; Qiu, W.Z. Analysis of Separation and Dislocation Characteristics of Layered Roof in the Mined-Out Areas. Appl. Mech. Mater. 2012, 256–259, 75–78. [Google Scholar]

- Zhu, L.; Gu, W.Z.; Pan, H.; Liu, Z.C.; Chai, J.; Ouyang, Y.B. Calculation model of overburden rock failure volume in mined-out area based on Brillouin optical time-domain analysis technology. Opt. Fiber Technol. 2021, 66, 102640. [Google Scholar] [CrossRef]

- Qian, M.G.; Xu, J.L. Study on “O” ring characteristics of mining induced fracture distribution in overburden. J. China Coal Soc. 1998, 5, 20–23. [Google Scholar]

- Guo, G.L.; Miao, X.X.; Zhang, Z.N. Research on Ruptured Rock Mass Deformation Characteristics of Longwall Goafs. J. Eng. Sci. Technol. 2002, 5, 44–47. [Google Scholar]

- Zhu, L.; Pan, H.; Gu, W.Z.; Zhao, M.Y.; Zhang, X.F.; Xu, K. Experimental study on flow and diffusion law of gangue filling slurry in caving zone. J. China Coal Soc. 2021, 46, 629–638. [Google Scholar]

- Chang, G.F.; Hua, X.Z.; Liu, X.; Li, C.; Wang, E.Q.; Sun, B.G. Fluidity Influencing Factor Analysis and Ratio Optimization of New Filling Slurry Based on the Response Surface Method. J. Renew. Mater. 2022, 10, 1439–1458. [Google Scholar] [CrossRef]

- Liu, Q. Regularity Research of Goaf Grouting Diffusion of Yang-Yi Freeway; Xi’an University Of Science And Technology: Xi’an, China, 2013. [Google Scholar]

- Wu, D.; Zhang, Y.L.; Wang, C. Modeling the thermal response of hydrating cemented gangue backfill with admixture of fly ash. Thermochim. Acta 2016, 623, 86–94. [Google Scholar] [CrossRef]

- Sun, W.B.; Wang, Y.; Qiu, H.F.; Ding, Z.W. Numerical simulation study of strip filling for water-preserved coal mining. Environ. Sci. Pollut. Res. 2020, 27, 12899–12907. [Google Scholar] [CrossRef]

- Michalczyk, Z.; Chmiel, S.; Glowacki, S.; Borowska-Pakula, J. Water resources threats in the leczna-wlodawa lake district as the result of mining activity. Monogr. Kom. Gospod. Wodnej Pol. Akad. Nauk 2018, 41, 161–171. [Google Scholar]

- Wang, L.H. Application Research of High Density Electric Method and Transient Electromagnetic Method on Colliery Gob; Chengdu University Of Technology: Chengdu, China, 2020. [Google Scholar]

- Liu, H. Research on Transient Electromagnetic Method Detection in Goaf of Hangshaotai Railway; China University Of Geosciences: Wuhan, China, 2019. [Google Scholar]

- Yang, Y. Study of Mechanism of Controlling. The Overlying Rock by Injecting Ash Thick Liquid into the Mining Collapse Zone; Liaoning Technical University: Fuxin, China, 2007. [Google Scholar]

- Chen, Z.M.; Luo, X.; Yin, Z.X.; Li, W. Electrical method exploration technology for goaf in Pingshuo mining area. J. Liaoning Tech. Univ. 2021, 40, 112–119. [Google Scholar]

- Wang, Y.; Su, B.; Xu, Z.Y. Review on seepage model of fractured rock mass. J. Adv. Water Sci. 1996, 3, 93–99. [Google Scholar]

- Biot, M.A. General of Propagation of elastic waves in a fluid-sat-urated porous solid Low-frequency range. Acoust. Soc. Am. 1956, 28, 168–178. [Google Scholar] [CrossRef]

- Long, J.; Remer, J.; Wilson, C. Porous media equivalents for networks of discontinuous fractures. Water Resour. Res. 1982, 18, 645–658. [Google Scholar] [CrossRef]

- Wang, Q.S. Study on the Numerical Simulation of the Goaf Grouting of the South-to-North Water Transfer Project; Tianjin University: Tianjin, China, 2014. [Google Scholar]

- Zheng, D.Z. Study on Grout Diffusion in Fracture-Pore Medium; Shandong University: Jinan, China, 2016. [Google Scholar]

- Wang, Q.; Feng, Z.Q.; Wang, L.X.; Tang, D.H.; Feng, C.; Li, S.H. Numerical analysis of grouting radius and grout quantity in fractured rock mass. J. China Coal Soc. 2016, 41, 2588–2595. [Google Scholar]

- Zhang, H.Z.; Deng, K.Z.; Gu, W. Study on the distribution law of residual voids in old goaf. J. Min. Saf. Eng. 2016, 33, 893–897. [Google Scholar]

- Li, X.S. Study on Mechanism of the Grouting Backfill in Caving Area with Strip Mining under Buildings; China University of Mining and Technology: Xuzhou, China, 2008. [Google Scholar]

- Wang, Y.T. Three-dimensional spatial dynamic distribution model on porosity and permeability characteristics of porous media in goaf. J. Saf. Sci. Tech. 2020, 16, 40–46. [Google Scholar]

- Gu, W.Z.; Zhu, L.; Liu, Z.C.; Song, T.Q.; Pan, H.; Zhang, X.F.; Qiu, F.Q.; Zhao, M.Y.; Huang, J.B. Fluidization slurry backfilling technology of coal mine solid waste. J. Coal Sci. Technol. 2021, 49, 83–91. [Google Scholar]

- Zhu, L.; Song, T.Q.; Gu, W.Z.; Xu, K.; Liu, Z.C.; Qiu, F.Q.; Yuan, C.F. Experimental research on transport resistance characteristics of gangue slurry and its flow trend in the goaf. J. China Coal Soc. 2022, 47, 39–48. [Google Scholar]

- Pei, L. Research on Slurry Diffusion Law of Horizontal Grouting Hole in Ordovician Karst Fissure Aquifer; General Coal Research Institute: Beijing, China, 2018. [Google Scholar]

| Category | Component | Thickness (m) | Nature |

|---|---|---|---|

| False Roof | Mudstone–sandy mudstone | 0.05–0.5 | Soft, broken, joint development, easy to collapse |

| Direct Roof | Sandy mudstone–fine sandstone | 2.5–5.5 | Thick layered, horizontal bedding, plant stem and leaf fossils can be seen on the bedding surface, joints and fissures are developed |

| Old Roof | Medium and fine-grained sandstone | 2.5–5.5 | Medium sorting, poor roundness, calcium and mud cementation, parallel bedding, oblique bedding |

| First Roof | Siltstone or argillaceous siltstone | 1.3–2.5 | Medium–thick layered, clayey cemented, with plant fossils |

| Group | Mass Fraction (%) | Mass Concentration (%) | Slurry Density (kg·m−3) | Characteristic | ||

|---|---|---|---|---|---|---|

| Gangue | Other Materials | Water | ||||

| H-2 | 55.5 | 20.5 | 24 | 76 | 1850 | The slurry has high viscosity, good fluidity, and low amount of gangue |

| S-1 | 75 | 2 | 23 | 76 | 1820 | Poor fluidity and viscosity, moderate diffusivity, high amount of gangue |

| Y-1 | 76 | 0 | 0 | 76 | 1800 | Poor fluidity, weak diffusivity, and the highest amount of gangue |

| mortar | 0 | 60 | 40 | 60 | Homogeneous slurry, used for lubricating and flushing before and after filling | |

| Filling Sequence | Filling Hole Number | Frequency | Proportion Number | Filling Slurry Volume (m3) | Fill Mortar Volume (m3) | Average Flow (m3/h) | Orifice Pressure (MPa) | Remark |

|---|---|---|---|---|---|---|---|---|

| Ⅰ | #1 | 1 | H-2 | 285 | 24 | 60 | 0.2 | debugging |

| Ⅱ | #2 | 1 | S-1 | 1103 | 60 | 120 | 0.2 | |

| Ⅲ | #5 | 1 | S-1 | 1063 | 49 | 101 | 0.3 | |

| Ⅳ | #7 | 1 | Y-1 | 221 | 48 | 100 | 7 | plugging holes |

| Ⅴ | #5 | 2 | H-2 | 1120 | 24 | 100 | 0.3 | |

| Ⅵ | #13 | 1 | S-1 | 540 | 12 | 110 | 3.5 | |

| Ⅶ | #12 | 1 | S-1 | 617 | 36 | 120 | 4 | plugging holes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Huang, Q.; Zuo, X.; Wu, J.; Wei, B.; He, Y.; Zhang, W.; Zhang, J. Study on the Slurry Diffusion Law of Fluidized Filling Gangue in the Caving Goaf of Thick Coal Seam Fully Mechanized Caving Mining. Energies 2022, 15, 8164. https://doi.org/10.3390/en15218164

Li L, Huang Q, Zuo X, Wu J, Wei B, He Y, Zhang W, Zhang J. Study on the Slurry Diffusion Law of Fluidized Filling Gangue in the Caving Goaf of Thick Coal Seam Fully Mechanized Caving Mining. Energies. 2022; 15(21):8164. https://doi.org/10.3390/en15218164

Chicago/Turabian StyleLi, Liang, Qingxiang Huang, Xiao Zuo, Jie Wu, Baoning Wei, Yanpeng He, Weilong Zhang, and Jie Zhang. 2022. "Study on the Slurry Diffusion Law of Fluidized Filling Gangue in the Caving Goaf of Thick Coal Seam Fully Mechanized Caving Mining" Energies 15, no. 21: 8164. https://doi.org/10.3390/en15218164

APA StyleLi, L., Huang, Q., Zuo, X., Wu, J., Wei, B., He, Y., Zhang, W., & Zhang, J. (2022). Study on the Slurry Diffusion Law of Fluidized Filling Gangue in the Caving Goaf of Thick Coal Seam Fully Mechanized Caving Mining. Energies, 15(21), 8164. https://doi.org/10.3390/en15218164