Effect of Aged Nonlinear Resistive Field Grading Material on Electric Field Distribution of DC Cone Spacer

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Material Preparation

2.2. Thermal Ageing Experiment

2.3. Fourier Transform Infrared Spectroscopy (FTIR) Measurement

2.4. Relative Permittivity and Loss Tangent Measurement

2.5. Breakdown Strength Measurement

2.6. DC Conductivity Measurement

3. Experimental Results

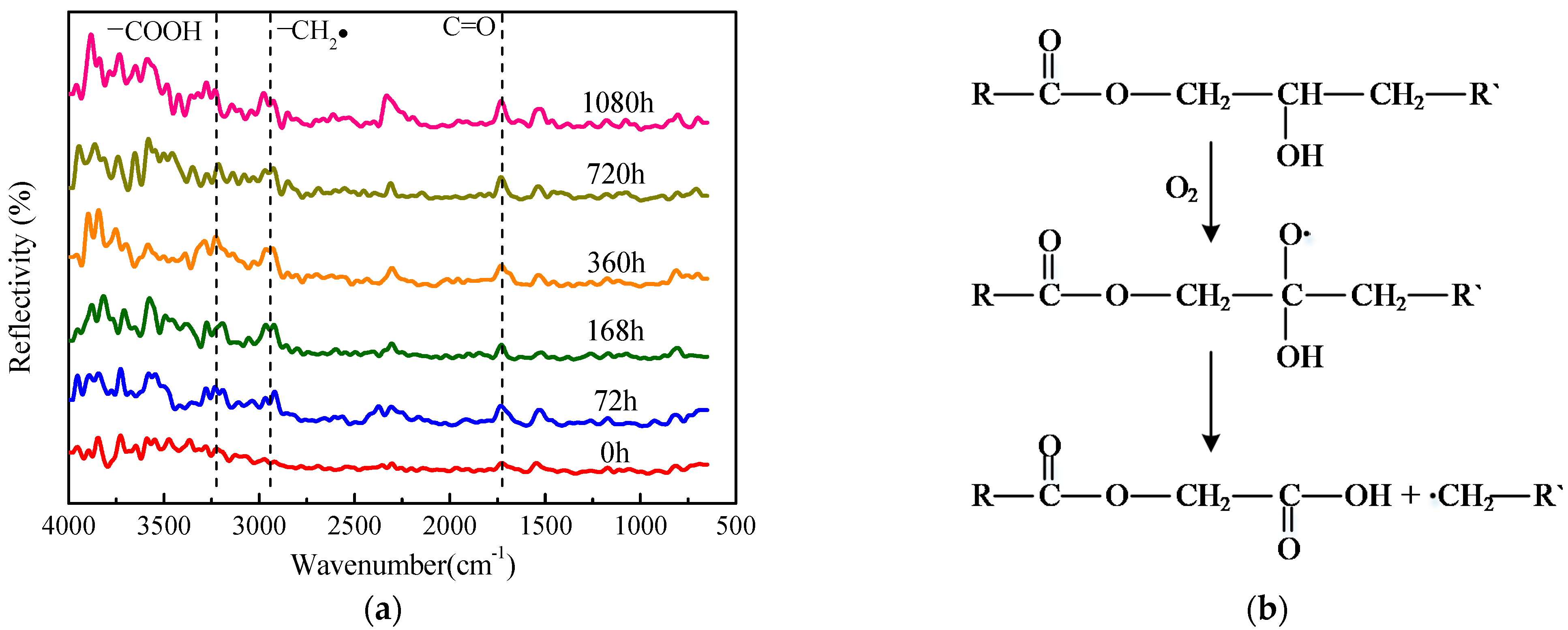

3.1. FTIR Spectroscopy

3.2. Dielectric Properties

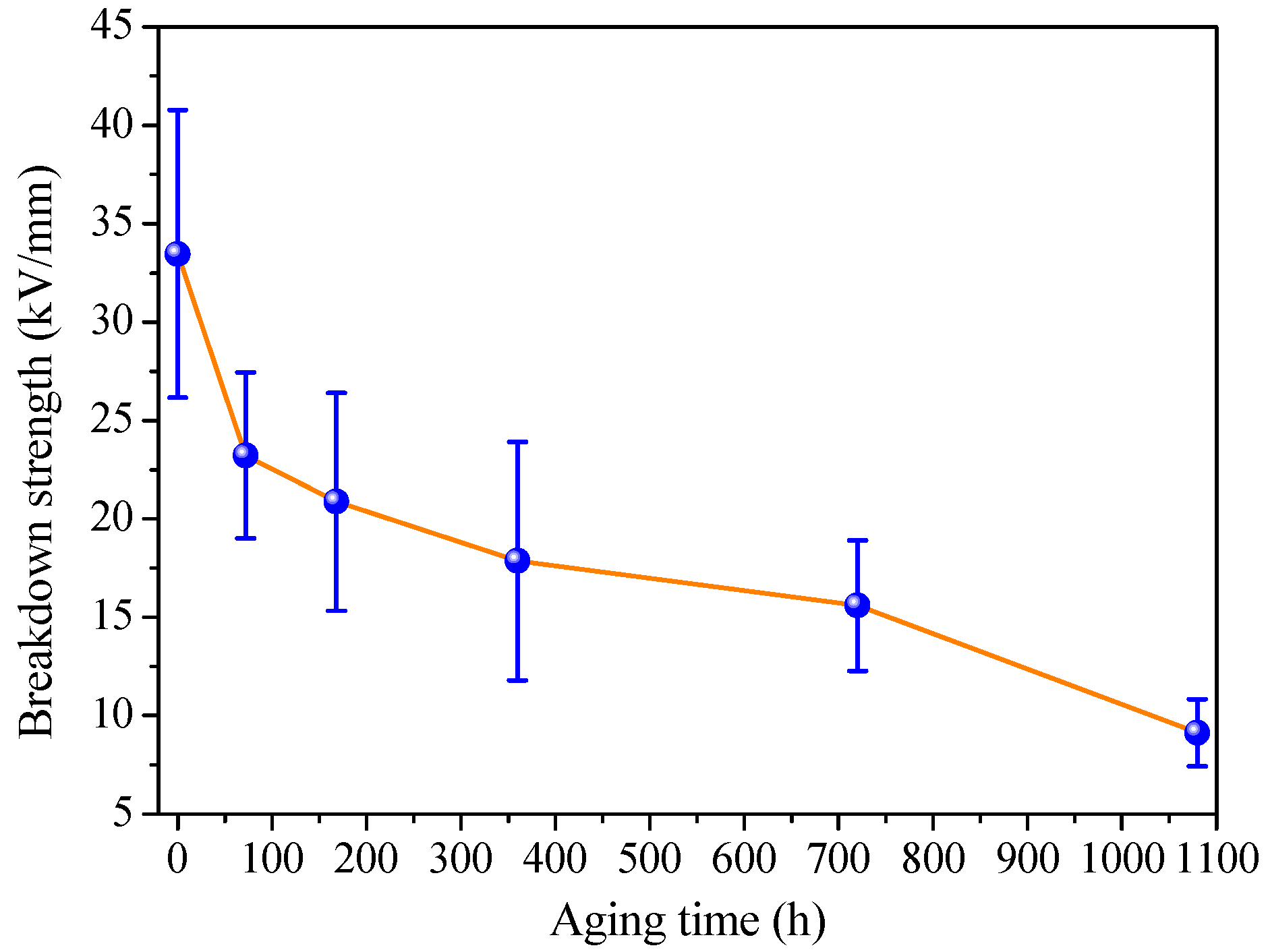

3.3. DC Breakdown Strength

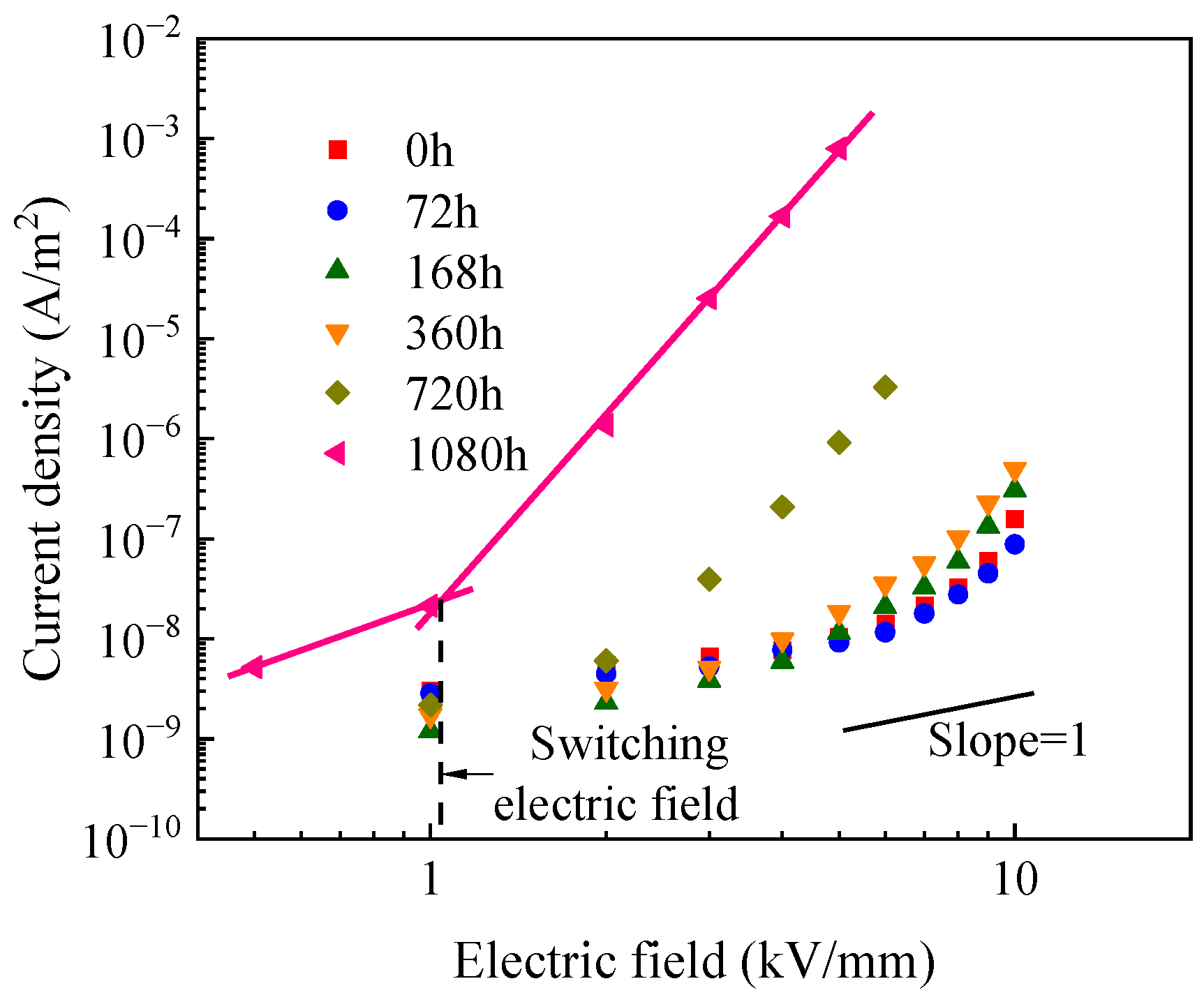

3.4. Nonlinear Conductivity

4. Simulation and Discussion

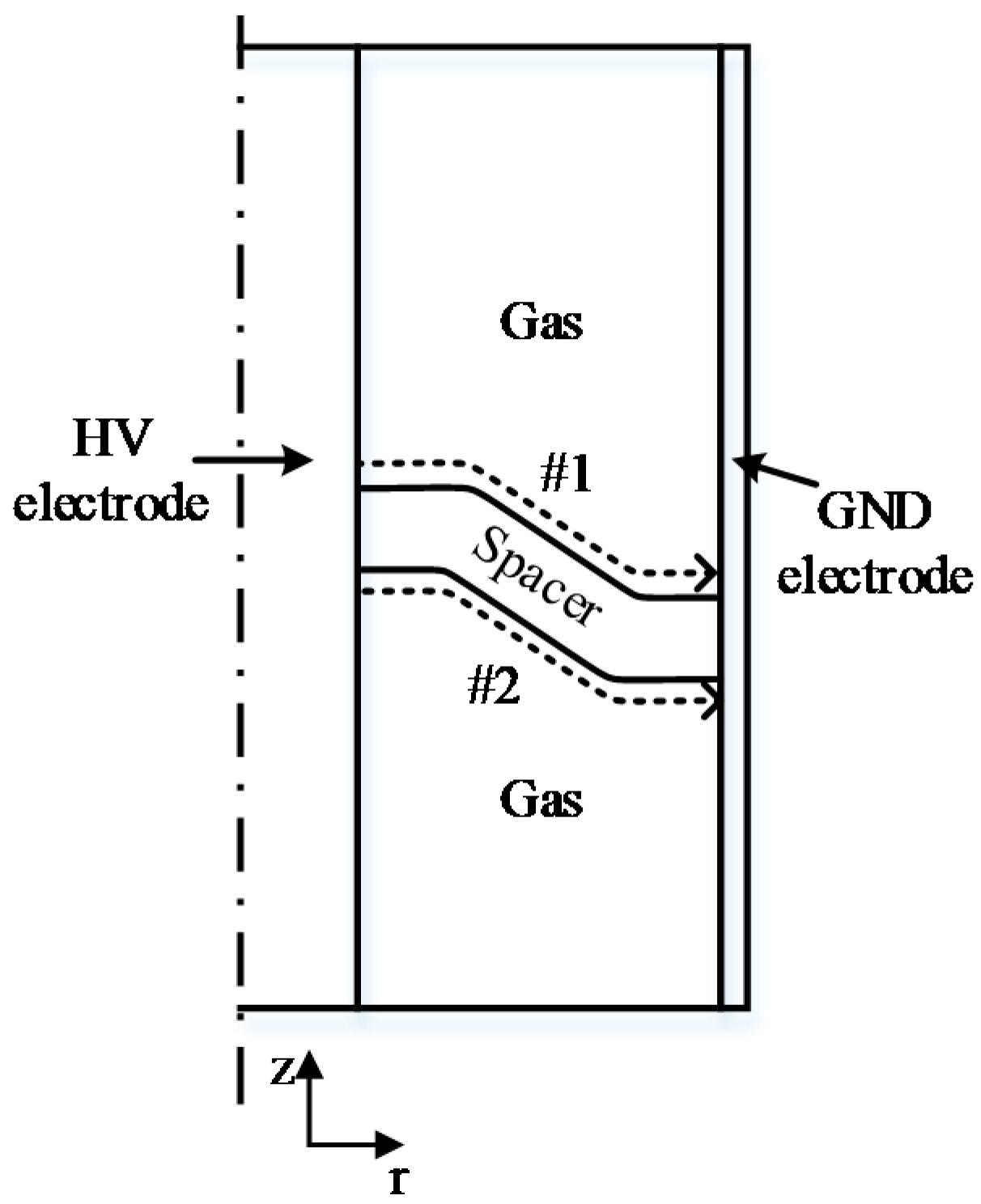

4.1. Cone Spacer Model

4.2. Electric Field Distribution

4.3. Power Dissipation Density Distribution

5. Conclusions

- The high temperature ageing causes the breaks in the epoxy macromolecular chain and the formation of a number of small molecules and free radicals;

- With the increase in ageing time, the relative permittivity and loss tangent increases, whereas the breakdown strength decreases;

- The aged SiC/epoxy micro-composites shows distinct nonlinear conductivity. The nonlinear coefficient nearly increases from 3.7 to 6.56, and the switching electric field decreases from 5.4 to 1.03 kV/mm when the ageing time ranges from 0 to 1080 h;

- The short-term (≤720 h) aged SiC/epoxy micro-composite not only homogenizes the electric field in the cone spacer, but also generates less power dissipation density compared with pure epoxy. By contrast, the long-term (1080 h) aged SiC/epoxy micro-composite is also able to homogenize the electric field in the cone spacer, but it causes a much higher power dissipation density. We should pay attention to the long-term stability of nonlinear resistive field grading material, and its improvement method will be carried out in future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zebouchi, N.; Li, H.; Haddad, M.A. Development of future compact and eco-friendly HVDC gas-insulated systems: Shape optimization of a DC spacer model and novel materials investigation. Energies 2020, 13, 3288. [Google Scholar] [CrossRef]

- Straumann, U.; Schüller, M.; Franck, C.M. Theoretical investigation of HVDC disc spacer charging in SF6 gas insulated systems. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 2196–2205. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, G.; Wang, X. Characteristics and mechanisms of surface charge accumulation on a cone-type insulator under dc voltage. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 150–155. [Google Scholar] [CrossRef]

- Christen, T.; Donzel, L.; Greuter, F. Nonlinear resistive electric field grading part 1: Theory and simulation. IEEE Electr. Insul. Mag. 2011, 26, 47–59. [Google Scholar] [CrossRef]

- Han, Y.; Li, S.; Min, D. Nonlinear conduction and surface potential decay of epoxy/SiC nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3154–3164. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, J.; Yuan, Z.; He, J. Design of adaptive bushing based on field grading materials. High Volt. 2021, 6, 625–636. [Google Scholar] [CrossRef]

- Pan, Z.; Tang, J.; Pan, C. Contribution of nano-SiC/epoxy coating with nonlinear conduction characteristic to surface charge accumulation under DC Voltage. J. Phys. D Appl. Phys. 2020, 53, 365303. [Google Scholar] [CrossRef]

- Espino-Cortes, F.P.; Jayaram, S.; Cherney, E.A. Stress grading materials for cable terminations under fast-rise time pulses. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 430–435. [Google Scholar] [CrossRef]

- Sharifi, E.; Jayaram, S.; Cherney, E.A. Temperature and electric field dependence of stress grading on form-wound motor coils. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 264–270. [Google Scholar] [CrossRef]

- Donzel, L.; Greuter, F.; Christen, T. Nonlinear resistive electric field grading, Part 2: Materials and applications. IEEE Electri. Insul. Mag. 2011, 27, 18–29. [Google Scholar] [CrossRef]

- Rogti, F.; David, E. Effect of SiC particles on the electrical conductivity of epoxy composites. J. Electron. Mater. 2017, 46, 742–746. [Google Scholar] [CrossRef]

- Tian, J.; Xu, R.; He, H.; Feng, Y. Influence of ZnO filler size on the nonlinear electrical properties of ZnO ceramic-epoxy composite material. J. Mater. Sci. Mater. Electron. 2016, 28, 5102–5105. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, X.; Hu, J. Grading electric field in high voltage insulation using composite materials. IEEE Electri. Insul. Mag. 2018, 34, 15–25. [Google Scholar] [CrossRef]

- Du, B.; Li, Z.; Yang, Z. Field-dependent conductivity and space charge behavior of silicone rubber/SiC composites. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3108–3116. [Google Scholar] [CrossRef]

- Yang, X.; Hu, J.; Chen, S.; He, J. Understanding the percolation characteristics of nonlinear composite dielectrics. Sci. Rep. 2016, 6, 30597. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Wang, Z.; Sun, J.; Li, Z. Enhanced switching electric field and breakdown strength of epoxy composites with core-shell silicon carbide nanoparticles. High Volt. 2022, 1–7. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Du, B. Electrical field simulation of epoxy spacer with nonlinear conductivity for DC GIL. High Volt. Eng. 2019, 45, 1056–1063. (In Chinese) [Google Scholar]

| Ageing Time (h) | Nonlinear Coefficient | Switching Electric Field (kV/mm) |

|---|---|---|

| 0 | 3.70 | 5.40 |

| 72 | 2.58 | 4.60 |

| 168 | 4.10 | 4.27 |

| 360 | 4.15 | 3.83 |

| 720 | 5.73 | 2.11 |

| 1080 | 6.56 | 1.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Yang, F.; Zhao, C. Effect of Aged Nonlinear Resistive Field Grading Material on Electric Field Distribution of DC Cone Spacer. Energies 2022, 15, 8361. https://doi.org/10.3390/en15228361

Han Y, Yang F, Zhao C. Effect of Aged Nonlinear Resistive Field Grading Material on Electric Field Distribution of DC Cone Spacer. Energies. 2022; 15(22):8361. https://doi.org/10.3390/en15228361

Chicago/Turabian StyleHan, Yongsen, Feng Yang, and Chenguang Zhao. 2022. "Effect of Aged Nonlinear Resistive Field Grading Material on Electric Field Distribution of DC Cone Spacer" Energies 15, no. 22: 8361. https://doi.org/10.3390/en15228361

APA StyleHan, Y., Yang, F., & Zhao, C. (2022). Effect of Aged Nonlinear Resistive Field Grading Material on Electric Field Distribution of DC Cone Spacer. Energies, 15(22), 8361. https://doi.org/10.3390/en15228361