Applications of Computational Fluid Dynamics for Mine Ventilation in Mineral Development

Abstract

:1. Introduction

2. Numerical Simulations: Computational Fluid Dynamics

2.1. Governing Equations in CFD

2.2. Discretization: Finite Volume Method

2.3. CFD Codes

2.4. Turbulence Models

2.5. Procedures of CFD Modeling

2.6. Convergence, Grid-Independence Test, and Validation

2.6.1. Convergence

2.6.2. Grid-Independence Test

2.6.3. Validation

2.7. Governing Equations for the Dispersion of Hazardous Gases in CFD

2.8. Governing Equations for the Motion of Harmful Dust in CFD

2.9. Prediction of the Fluid Age

3. Applications of CFD in Mine Ventilation

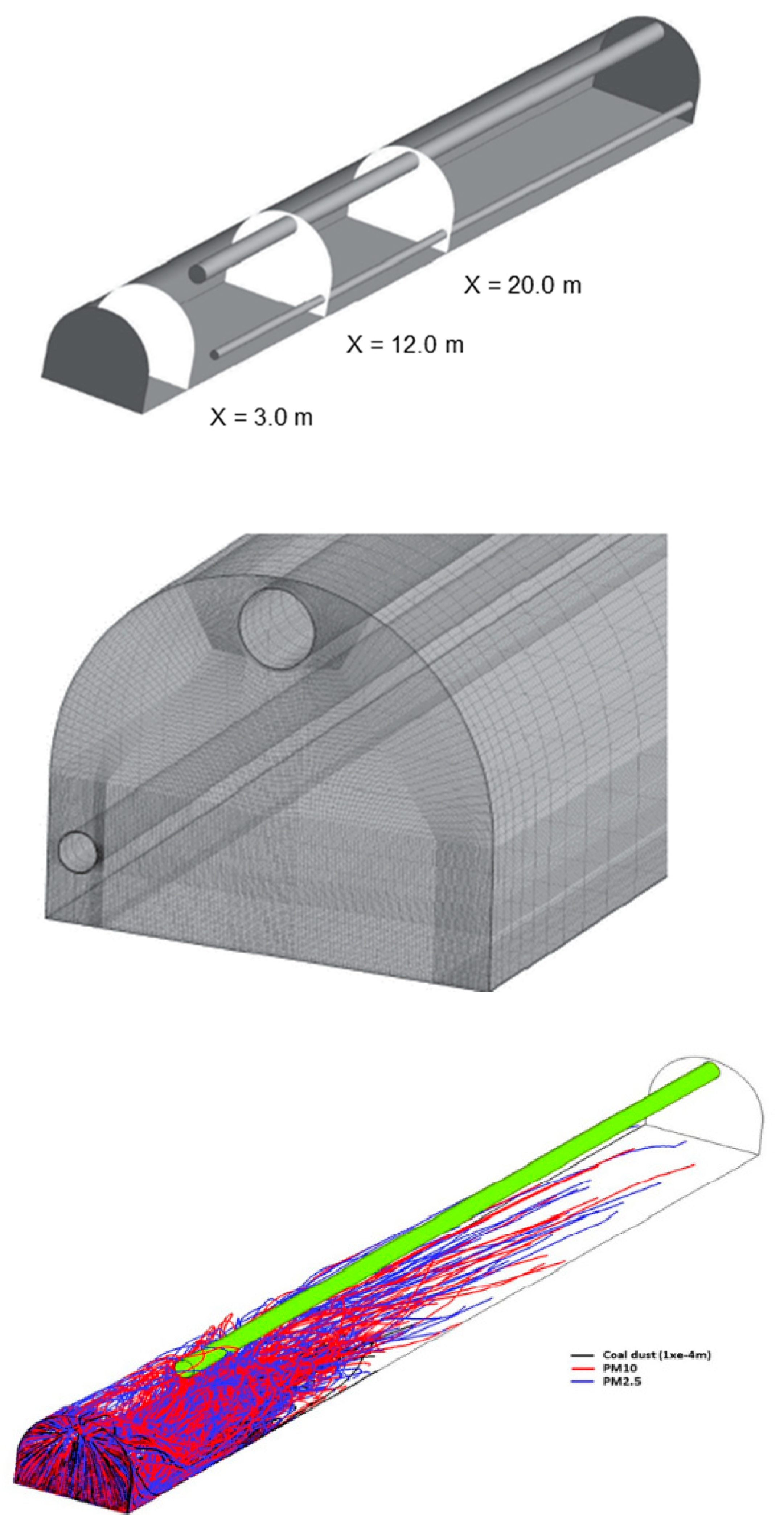

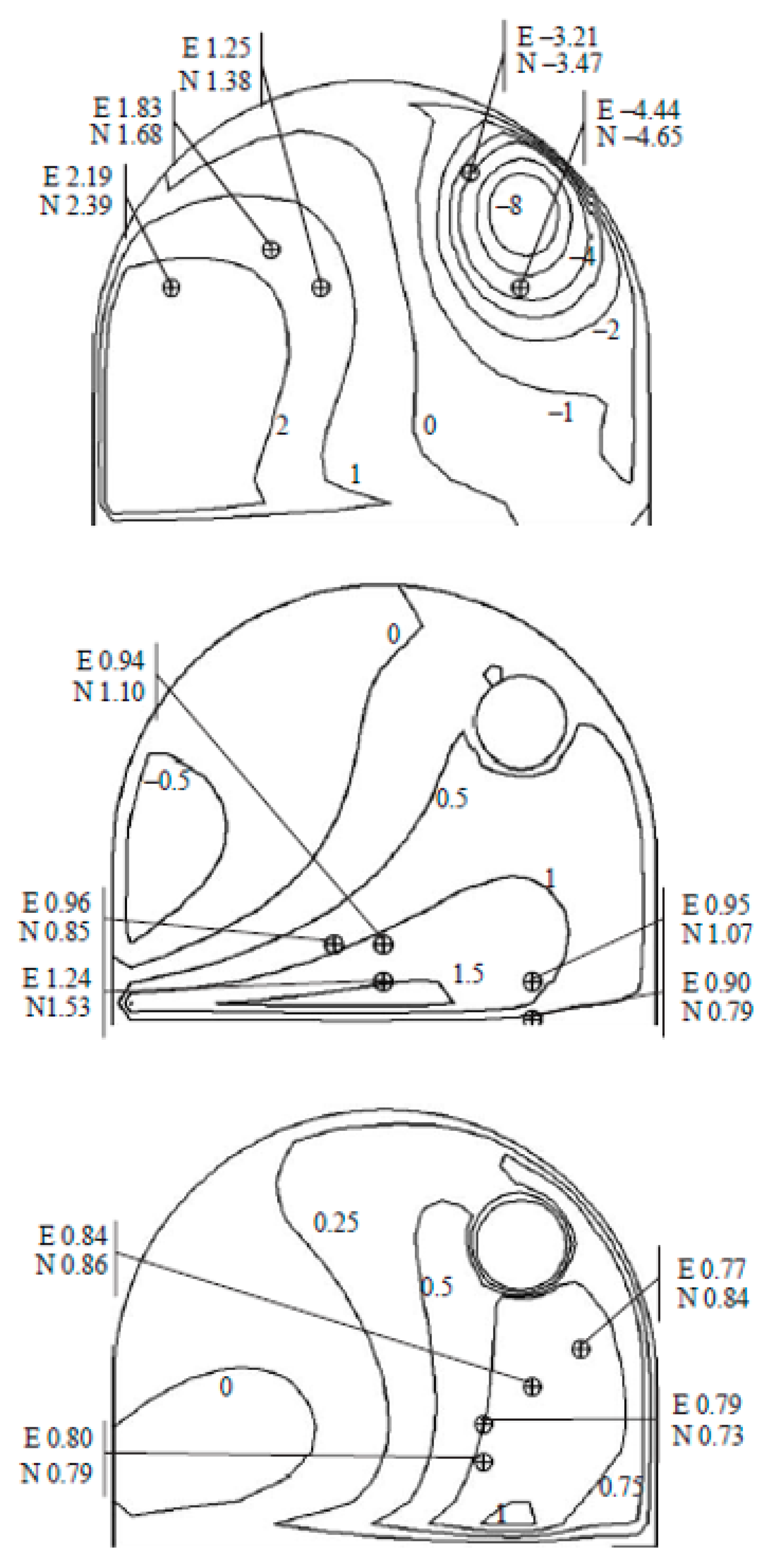

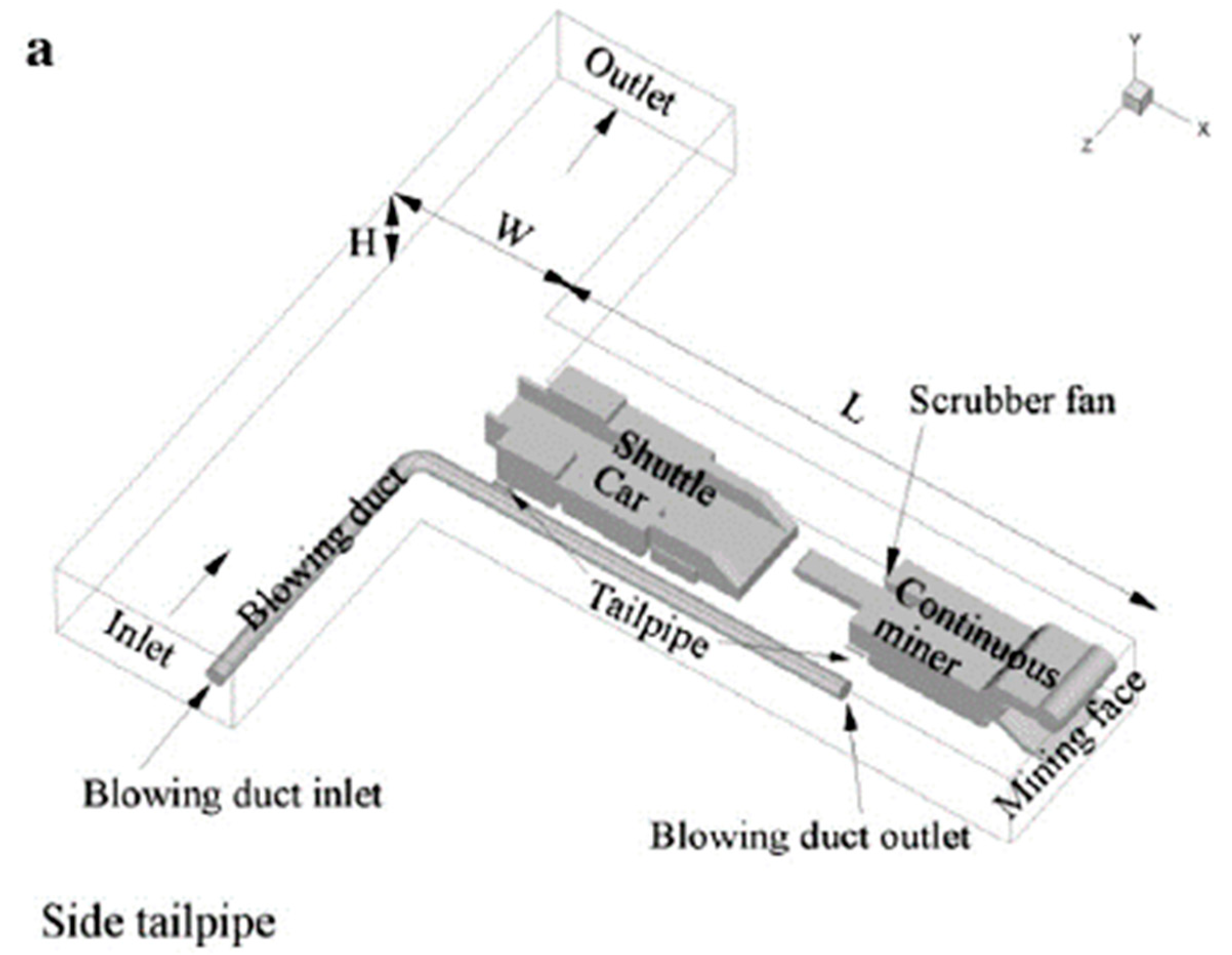

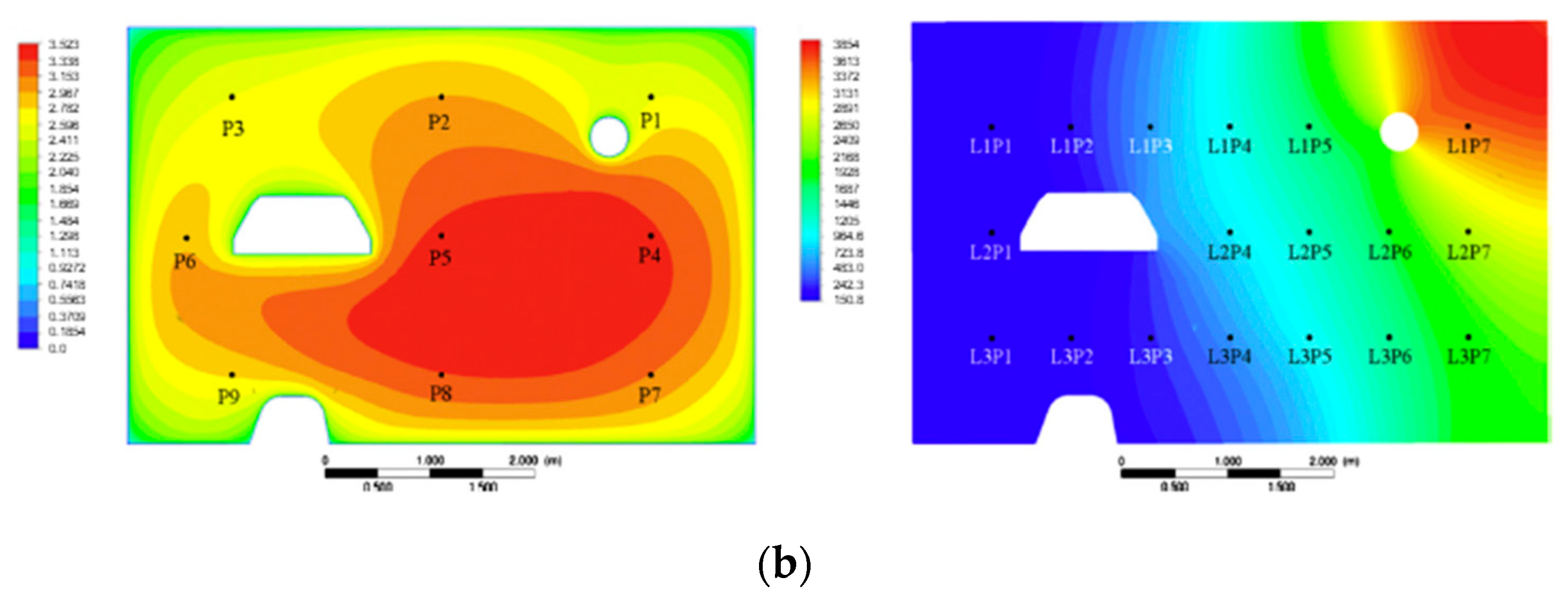

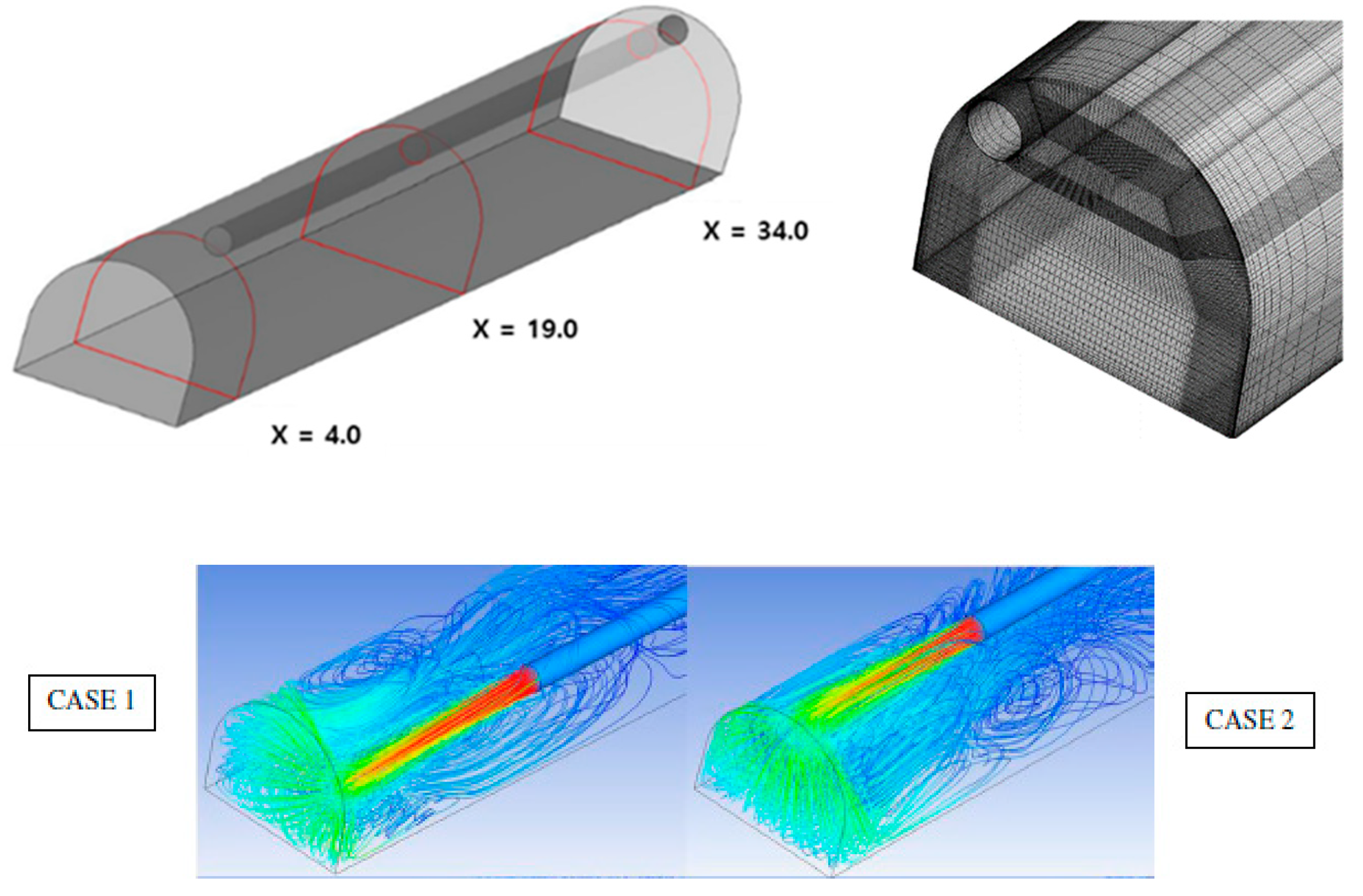

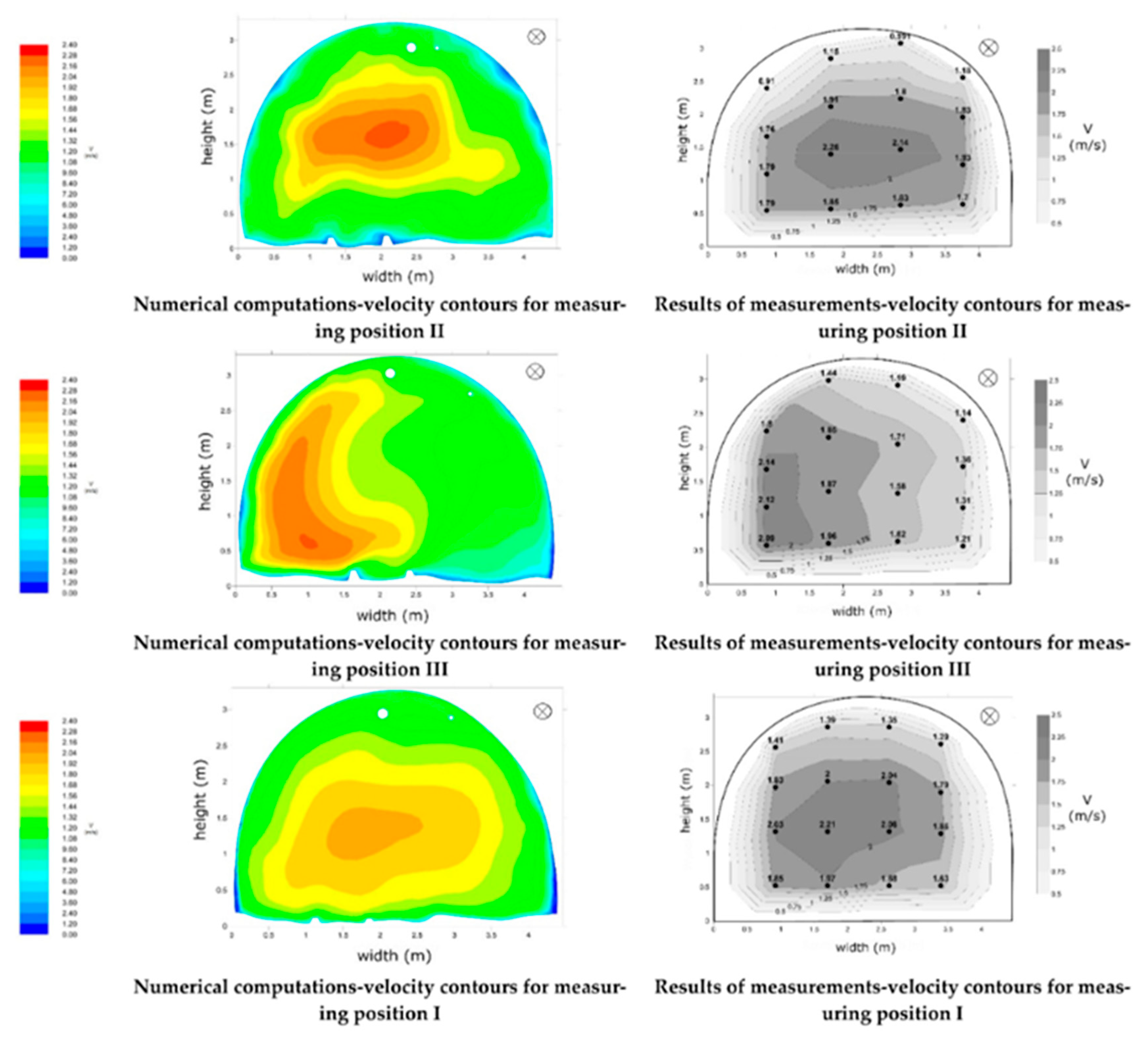

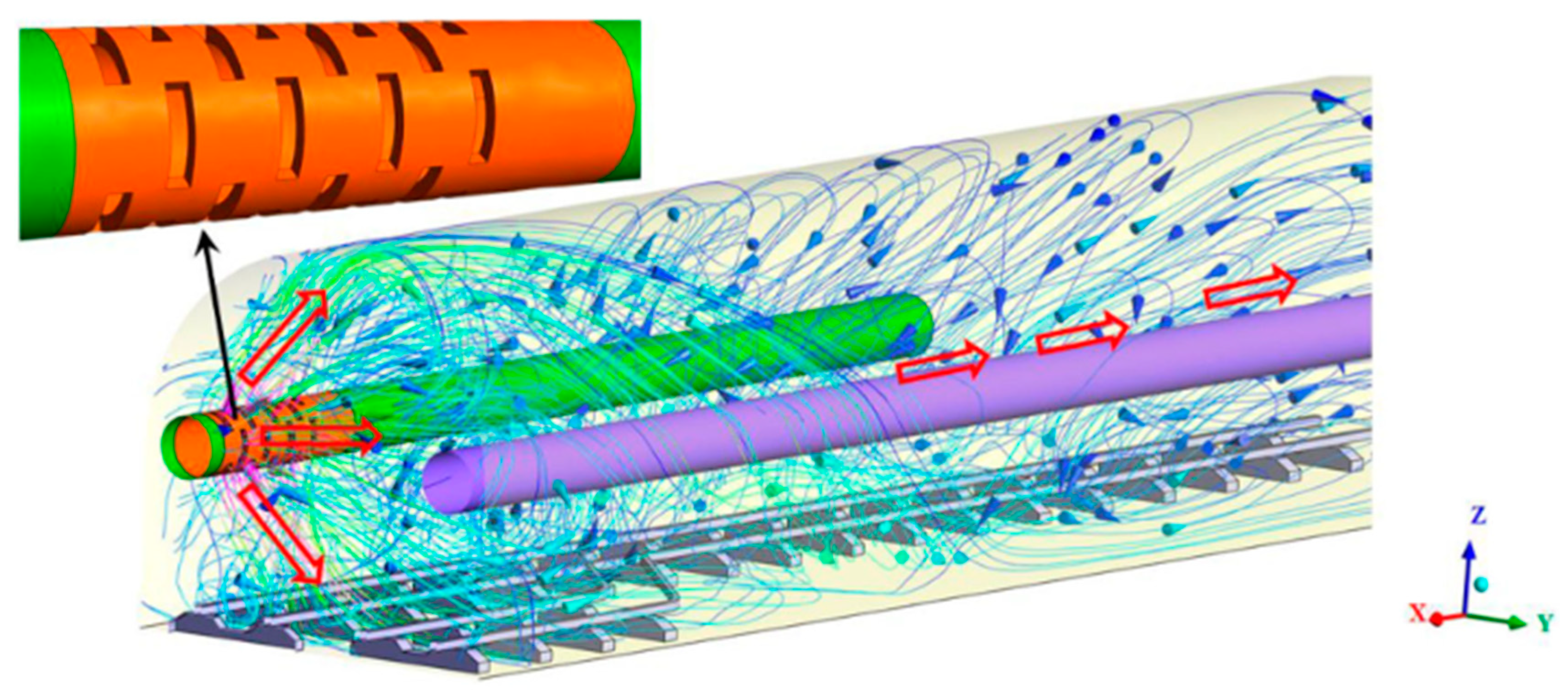

3.1. Ventilation at the Working Faces of Mines

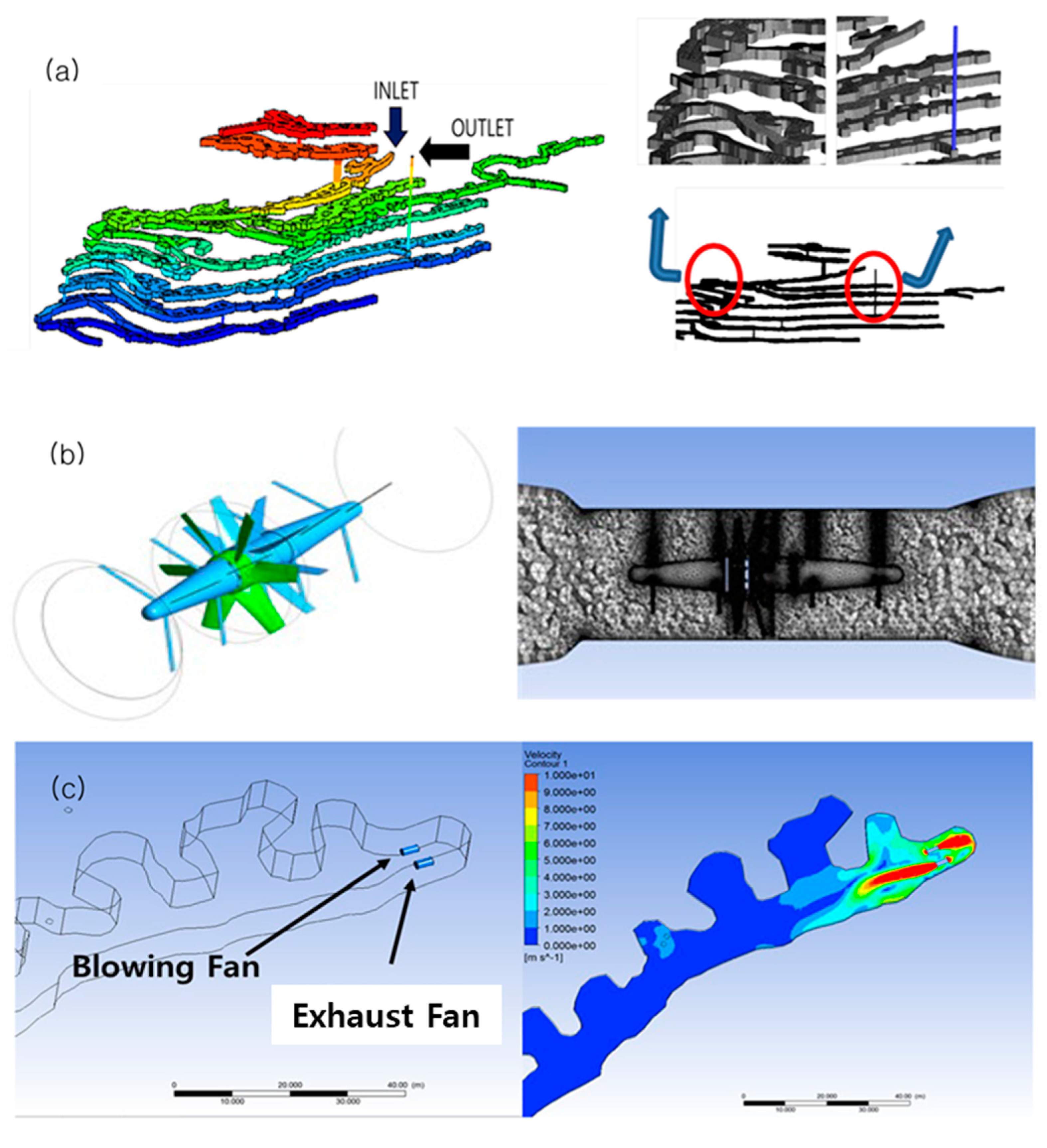

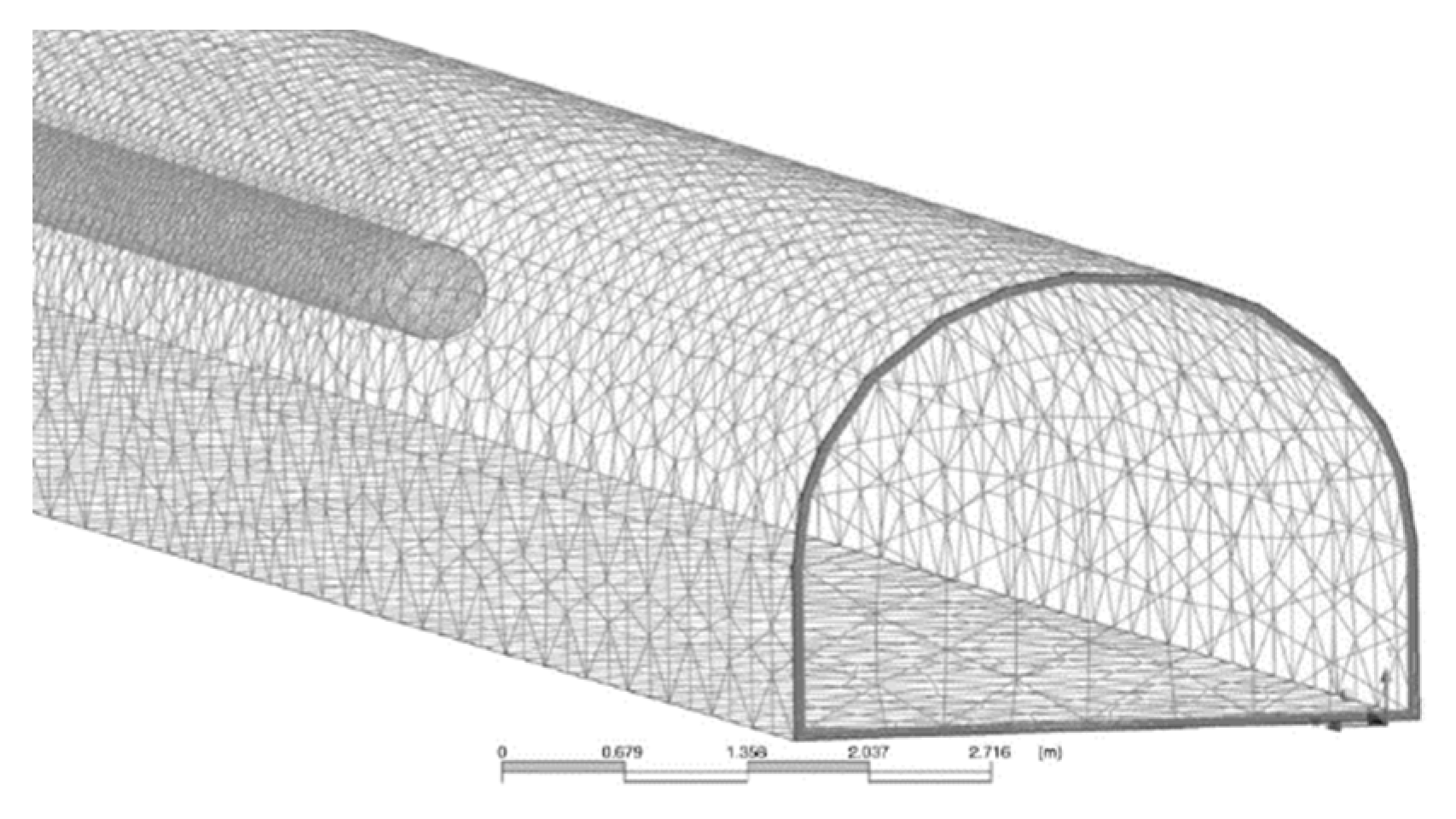

3.2. Mine Ventilation in Mine Tunnels and Galleries

3.3. CFD Applications in Open-Pit Mines

3.4. Mine Ventilation Systems

3.5. CFD Applications for Mine Fire and Thermal Energy

4. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anderson, J.D. Computational Fluid Dynamics; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics, 2nd ed.; Prentice Hall, Pearson Education Ltd.: London, UK, 2007. [Google Scholar]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Hemisphere Publishing Corporation: New York, NY, USA, 1980. [Google Scholar]

- Wala, A.M.; Vytla, S.; Taylor, C.D.; Huang, G. Mine face ventilation: A comparison of CFD results against benchmark experiments for the CFD code validation. NIOSH Min. Eng. 2007, 59, 49–55. [Google Scholar]

- Torano, J.; Rodriguez, R.; Diego, I. Computational Fluid Dynamics (CFD) use in the simulation of the death end ventilation in tunnels and galleries. WIT Trans. Eng. Sci. 2006, 52, 113–121. [Google Scholar]

- Coleman, B.; Wedding, W.C.; Petrov, T. Design considerations for construction of a face ventilation gallery using computational fluid dynamics modeling. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Chang, P.; Xu, G.; Zhou, F.; Mullins, B.; Abishek, S.; Chalmers, D. Minimizing DPM pollution in an underground mine by optimizing auxiliary ventilation systems using CFD. Tunn. Undergr. Space Technol. 2019, 87, 112–121. [Google Scholar] [CrossRef]

- Vives, J.; Bascompta, M.; Felipe, J.J.; Sanmiquel, L. Computational Fluid Dynamics (CFD) study to optimize the auxiliary ventilation system in an underground mine. DYNA 2022, 89, 84–91. [Google Scholar] [CrossRef]

- Menter, F. Two-equation Eddy-viscosity Turbulence Model for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Park, J.; Jo, Y.; Lee, D.; Yi, H. Numerical Investigation of Characteristics of Mine Ventilation Using One or Two Ducts in Underground Mining Faces. In Proceedings of the International Conference on Innovations for Sustainable and Responsible Mining, Hanoi, Vietnam, 15–17 October 2020. [Google Scholar]

- Parra, M.T.; Villafruela, J.M.; Castro, F.; Mendez, C. Numerical and experimental analysis of different ventilation systems in deep mines. Build. Environ. 2006, 41, 87–93. [Google Scholar] [CrossRef]

- ANSYS. ANSYS FLUENT Theory Guide; ANSYS: Canonsburg, PA, USA, 2016. [Google Scholar]

- Sun, D. Computational Fluid Dynamics in Food Processing; CRC-Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Park, J.; Jo, Y.; Park, G. Flow characteristics of fresh air discharged from a ventilation duct for mine ventilation. J. Mech. Sci. Technol. 2018, 32, 1187–1194. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, C.; Yang, W.; Xu, H.; Li, S.; Li, C.; Ma, H.; Qi, G. In Situ Measurements and CFD Numerical Simulations of Thermal Environment in Blind Headings of Underground Mines. Processes 2019, 7, 313. [Google Scholar] [CrossRef] [Green Version]

- Aminossadati, S.M.; Hooman, K. Numerical Simulation of Ventilation Air Flow in Underground Mine Workings. In Proceedings of the 12th U.S./North American Mine Ventilation Symposium, Reno, NV, USA, 9–11 June 2008. [Google Scholar]

- Torano, J.; Torno, S.; Menendez, M.; Gent, M.; Velasco, J. Models of methane behavior in auxiliary ventilation of underground coal mining. Int. J. Coal Geol. 2009, 80, 35–43. [Google Scholar] [CrossRef]

- Diego, I.; Torno, S.; Torano, J.; Menendez, M.; Gent, M. A practical use of CFD for ventilation of underground works. Tunn. Undergr. Space Technol. 2011, 26, 189–200. [Google Scholar] [CrossRef]

- Lee, D.K. A Computational Flow Analysis for Choosing the Diameter and Position of an Air Duct in a Working Face. J. Min. Sci. 2011, 47, 664–674. [Google Scholar] [CrossRef]

- Torno, S.; Torano, J.; Ulecia, M.; Allende, C. Conventional and numerical models of blasting gas behaviour in auxiliary ventilation of mining headings. Tunn. Undergr. Space Technol. 2013, 34, 73–81. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. Simulation of a novel intermittent ventilation system for underground mines. Tunn. Undergr. Space Technol. 2014, 42, 206–215. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Wong, W.Y.; Mujumdar, A.S. Prediction and innovative control strategies for oxygen and hazardous gases from diesel emission in underground mines. Sci. Total Environ. 2014, 481, 317–334. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Jong, E.C.; Luxbacher, K.D.; Ragab, S.A.; Karmis, M.E. Remote characterization of ventilation systems using tracer gas and CFD in an underground mine. Saf. Sci. 2015, 74, 140–149. [Google Scholar] [CrossRef]

- Zhoua, L.; Pritchardb, C.; Zhenga, Y. Computational fluid dynamics modeling of methane distribution at a continuous miner face under various methane release conditions. In Proceedings of the 15th U.S./North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015; pp. 419–426. [Google Scholar]

- Zhoua, L.; Pritchardb, C.; Zhenga, Y. CFD modeling of methane distribution at a continuous miner face with various curtain setback distances. Int. J. Min. Sci. Technol. 2015, 25, 297–306. [Google Scholar] [CrossRef]

- Zheng, Y.; Thiruvengadam, M.; Lan, H.; Tien, J.C. Simulation of DPM Dispersion for Different Mining Operations Inside a Dead-end Entry. In Proceedings of the 15th U.S./North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015; pp. 297–306. [Google Scholar]

- Li, M.; Aminossadati, S.M.; Wu, C. Numerical simulation of air ventilation in super-large underground developments. Tunn. Undergr. Space Technol. 2016, 52, 38–43. [Google Scholar] [CrossRef]

- Lu, Y.; Akhtar, S.; Sasmito, A.P.; Kurnia, J.C. Numerical Study of simultaneous methane and coal dust dispersion in a room and pillar mining face. In Proceedings of the 3rd International Symposium on Mine Safety Science and Engineering, Montreal, QC, Canada, 13–19 August 2016. [Google Scholar]

- Park, J.; Park, S.; Lee, D. CFD modeling of ventilation ducts for improvement of air quality in closed mines. Geosyst. Eng. 2016, 19, 177–187. [Google Scholar] [CrossRef]

- Geng, F.; Luo, G.; Wang, Y.; Peng, Z.; Hu, S.; Zhang, T.; Chai, H. Dust dispersion in a coal roadway driven by ahybrid ventilation system: A numerical study. Process Saf. Environ. Prot. 2018, 113, 388–400. [Google Scholar] [CrossRef]

- Mishra, D.P.; Panigrahi, D.C.; Kumar, P. Computational investigation on effects of geo-mining parameters on layering and dispersion of methane in underground coal mines- A case study of Moonidih Colliery. J. Nat. Gas Sci. Eng. 2018, 53, 110–124. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, G.; Qian, X.; Yuan, M.; Sun, Y.; Wang, D. Diffuse pollution characteristics of respirable dust in fully-mechanized mining face under various velocities based on CFD investigation. J. Clean. Prod. 2018, 184, 239–250. [Google Scholar] [CrossRef]

- Liu, Q.; Nie, W.; Hua, Y.; Peng, H.; Liu, C.; Wei, C. Research on tunnel ventilation systems: Dust Diffusion and Pollution Behaviour by air curtains based on CFD technology and field measurement. Build. Environ. 2019, 147, 444–460. [Google Scholar] [CrossRef]

- Torno, S.; Torano, J. On the prediction of toxic fumes from underground blasting operations and dilution ventilation. Conventional and numerical models. Tunn. Undergr. Space Technol. 2020, 96, 103194. [Google Scholar] [CrossRef]

- Yi, H.; Park, J.; Kim, M. Characteristics of mine ventilation air flow using both blowing and exhaust ducts at the mining face. J. Mech. Sci. Technol. 2020, 34, 1167–1174. [Google Scholar] [CrossRef]

- Jiang, W.; Xu, X.; Wen, Z.; Wei, L. Applying the similarity theory to model dust dispersion duringcoal-mine tunneling. Process Saf. Environ. Prot. 2021, 148, 415–442. [Google Scholar] [CrossRef]

- Duan, J.; Zhou, G.; Yang, Y.; Jing, B.; Hu, S. CFD numerical simulation on diffusion and distribution of diesel exhaust particulates in coal mine heading face. Adv. Powder Technol. 2021, 32, 3660–3671. [Google Scholar] [CrossRef]

- Zhou, G.; Jing, B.; Xu, Z.; Jiang, B.; Xu, R.; Ren, B.; Sun, B. Simulation study on gas-bearing dust and its application combined with air curtain in development heading, a case study. Process Saf. Environ. Prot. 2022, 163, 601–612. [Google Scholar] [CrossRef]

- Rahimi, S.; Ataee-pour, M.; Madani, H.; Aminossadati, S.M. Investigating the impact of gas emission uncertainty on airflow distribution in an auxiliary ventilation system using CFD and Monte-Carlo simulation. Build. Environ. 2021, 204, 108165. [Google Scholar] [CrossRef]

- Du, T.; Nie, W.; Chen, D.; Xiu, Z.; Yang, B.; Liu, Q. CFD modeling of coal dust migration in an 8.8-meter-high fully mechanized mining face. Energy 2020, 212, 118616. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Birgersson, E.; Ly, H.C.; Mujumdar, A.S. Some approaches to improve ventilation system in underground coal mines environment—A computational fluid dynamic study. Tunn. Undergr. Space Technol. 2013, 34, 82–95. [Google Scholar] [CrossRef]

- Erogul, D.; Baysal, A.; Ajayi, K.M.; Tukkaraja, P.; Shahbazi, K.; Katzenstein, K.; Loring, D. Effect of the Air Gap Associated with Cave Evolution on Cave Resistance. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Juganda, A.; Brune, J.F.; Bogin Jr, G.E.; Grubb, J.W.; Lolon, S.A. CFD Modeling of Longwall Tailgate Ventilation Conditions. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Baysal, A.; Ajayi, K.M.; Tukkaraja, P.; Shahbazi, K.; Katzenstein, K.; Loring, D. Prediction of Airflow Resistance of a Mature Panel Cave. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Rueda, N. Co-simulation: 1D to 3D coupling in an underground mine ventilation simulated model. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Wang, Z.; Ren, T.; Ma, L.; Zhang, J. Investigations of Ventilation Airflow Characteristics on a Longwall Face—A Computational Approach. Energies 2017, 11, 1564. [Google Scholar] [CrossRef] [Green Version]

- Biswal, P.K.; Parida, D.; Mishra, G.; Sahoo, A.K. Study of air flow pattern in mine model gallery and its validation using CFD modelling. WSN 2019, 130, 1–24. [Google Scholar]

- Janus, J.; Krawczyk, J. Measurement and Simulation of Flow in a Section of a Mine Gallery. Energies 2021, 14, 4894. [Google Scholar] [CrossRef]

- Ajayi, K.M.; Tukkaraja, P.; Shahbazi, K.; Katzenstein, K.; Loring, D. Computational Fluid Dynamics Study of Radon Gas Migration in a Block Caving Mine. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Lolon, S.A.; Gilmore, R.C.; Brune, J.F.; Bogin Jr, G.E.; Grubb, J.W.; Zipf Jr, R.K.; Juganda, A.; Saki, S.A. Effect of Decreasing Barometric Pressure on Explosive Gas Zones in Bleeder Ventilated Longwall Gobs. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Lolon, S.; Brune, J.F.; Bogin Jr, G.E.; Grubb, J.W.; Juganda, A. Understanding Gob Outgassing Associated with Pressure Disturbances in Longwall Mine. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Karacan, C.O.; Yuan, L. Effect of Discrete Fracture Network Representation of Gob on Airflow Distribution Near the Longwall Face. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Kollipara, V.K.; Chugh, Y.P. CFD Modeling of Dust Dispersion in a Room-and-Pillar Mining Area: A Case Study. Int. J. Environ. Poll. 2016, 59, 230–249. [Google Scholar]

- Erogul, D.; Ajayi, K.M.; Tukkaraja, P.; Shahbazi, K.; Katzenstein, K.; Loring, D. Evaluation of Cave Airflow Resistance Associated with Multiple Air Gap Geometries during Cave Evolution. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Tutak, M.; Brodny, J. Analysis of the Impact of Auxiliary Ventilation Equipment on the Distribution and Concentration of Methane in the Tailgate. Energies 2018, 11, 3076. [Google Scholar] [CrossRef] [Green Version]

- Saki, S.A.; Brune, J.F.; Khan, M.U. Optimization of gob ventilation boreholes design in longwall mining. Int. J. Min. Sci. Techol. 2020, 30, 811–817. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, S.; Ma, X.; Wu, Z.; Shao, H.; Zhang, W.; Cui, C. Numerical simulation and application study on a remote emergency rescue system during a belt fire in coal mines. Nat. Hazards 2016, 84, 1463–1485. [Google Scholar] [CrossRef]

- Balusu, R.; Belle, B.; Tanguturi, K. Development of gas and spontaneous combustion control strategies for 6.0 km long longwall panels. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Skob, Y.A.; Ugryumov, M.L.; Granovskiy, E.A. Numerical assessment of hydrogen explosion consequences in a mine tunnel. Int. J. Hydrog. Energy 2021, 46, 12361–12371. [Google Scholar] [CrossRef]

- Janoszek, T.; Lubosik, Z.; Swierczek, L.; Walentek, A.; Jaroszewicz, J. Experimental and CFD Simulations of the Aerosol Flow in the Air Ventilating the Underground Excavation in Terms of SARS-CoV-2 Transmission. Energies 2021, 14, 4743. [Google Scholar] [CrossRef]

- Raj, K.V.; Bandopadhyay, S. A Large Eddy Simulation Model of Air Flow and Pollutant Transport in a Deep Open Pit Mine under Arctic Inversion. In Proceedings of the SME Annual Meeting, Salt Lake City, UT, USA, 23–26 February 2014. [Google Scholar]

- Raj, K.V.; Bandopadhyay, S. Mitigation of Pollutants in Deep Open-Pit Mines under Arctic Air Inversion. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Bhowmick, T.; Bandopadhyay, S. Comparison of Turbulence Models for Estimation of Fugitive Dust Retention in Open-Pit Mines. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Kia, S.; Flesch, T.K.; Freeman, B.S.; Aliabadi, A.A. Atmospheric transport over open-pit mines: The effects of thermal stability and mine depth. J. Wind Eng. Ind. Aerodyn. 2021, 214, 104677. [Google Scholar] [CrossRef]

- Haghighat, A.; Gillies, S.; Luxbacher, K. Behavior of Flow through Mine Elbows and Louvers. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Hua, Y.; Nie, W.; Cai, P.; Liu, Y.; Peng, H.; Liu, Q. Pattern characterization concerning spatial and temporal evolution of dust pollution associated with two typical ventilation methods at fully mechanized excavation faces in rock tunnels. Powder Techol. 2018, 334, 117–131. [Google Scholar] [CrossRef]

- Morla, R.; Karekal, S. Selection of fan(s) to dilute DPM for multi-seam board and pillar coal mines using Hardy Cross and CPM methods. Inter. J. Eng. Technol. Res. Manag. 2018, 6, 36–47. [Google Scholar]

- Fernandez, J. Using ventilation to drive mine productivity. In Proceedings of the the Australian Mine Ventilation Conference, Perth, Australia, 26–28 August 2019. [Google Scholar]

- Kurnia, J.C.; Sasmito, A.P.; Mujundar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math Model. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Akhtar, S.; Kumral, F.M.; Sasmito, A.P. Evaluation of duct leakage estimation methods in an auxiliary mine ventilation system: Empirical vs computational fluid dynamics. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Guo, L.; Nie, W.; Yin, S.; Liu, Q.; Hua, Y.; Cheng, L.; Cai, X.; Xiu, Z.; Du, T. The dust diffusion modeling and determination of optimal airflow rate for removing the dust generated during mine tunneling. Build Env. 2020, 178, 106846. [Google Scholar] [CrossRef]

- Arya, S.; Sottile, J.; Novak, T. Numerical Modeling of a Flooded-Bed Dust Scrubber Integrated into a Longwall Shearer. Min. Metall. Explor. 2020, 37, 1105–1119. [Google Scholar] [CrossRef]

- Obracaj, D.; Karzec, M.; Deszcz, P. Study onMethane Distribution in the Face Zone of the Fully Mechanized Roadway with Overlap Auxiliary Ventilation System. Energies 2021, 14, 6379. [Google Scholar] [CrossRef]

- Liu, Q.; Nie, W.; Hua, Y.; Peng, H.; Liu, Z. The effects of the installation position of a multi-radial swirling air-curtain generator on dust diffusion and pollution rules in a fully-mechanized excavation face: A case study. Powder Technol. 2018, 329, 371–385. [Google Scholar] [CrossRef]

- Yin, S.; Nie, W.; Liu, Q.; Hua, Y. Transient CFD modelling of space-time evolution of dust pollutants and air-curtain generator position during tunneling. J. Clean. Prod. 2019, 239, 117924. [Google Scholar] [CrossRef]

- Hua, Y.; Nie, W.; Liu, Q.; Yin, S.; Peng, H. Effect of wind curtain on dust extraction in rock tunnel working face: CFD and field measurement analysis. Energy 2020, 197, 117214. [Google Scholar] [CrossRef]

- Hua, Y.; Nie, W.; Guo, L.; Cai, X.; Cheng, L. The control effect of 3D spiral wind-curtain generator on respirable dust pollution during tunnelling process. Environ. Sci. Pollut. Res. 2021, 28, 68212–68228. [Google Scholar] [CrossRef]

- Wedding, W.C.; Novak, T.; Arya, S.; Kumar, A. CFD Modeling of a Flooded-Bed Scrubber Concept for a Longwall Shearer Operating in a U.S. Coal Seam. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Geortz, B.J.; Brune, J.; McDaniel, S.; Rockley, T.; Barreto, F.S.; Demontigny, N. Development of a Mine Dust Sampling Instrument for use in Underground Coal Mines. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Kumar, A.; Arya, S.; Wedding, W.C.; Novak, T. Examination of Capture Efficacies of a Shearer Mounted Flooded Bed Dust Scrubber Using Experiments and Computational Fluid Dynamics (CFD) Modeling on a Reduced Scaled Model. In Proceedings of the 16th North American Mine Ventilation Symposium, Golden, CO, USA, 17–22 July 2017. [Google Scholar]

- Zhou, G.; Zhang, Q.; Hu, Y.; Gao, D.; Wang, S.; Sun, B. Dust removal effect of negatively-pressured spraying collector for advancing support in fully mechanized coal mining face: Numerical simulation and engineering application. Tunn. Undergr. Space Technol. 2020, 95, 103149. [Google Scholar] [CrossRef]

- Arya, S.; Novak, T.; Sottile, J. Experimental and Numerical Investigation of the Effect of Integration of a Flooded-Bed Scrubber into a Longwall Shearer on Airflow along a Coal Mine Longwall Face. Appl Sci. 2021, 11, 3617. [Google Scholar] [CrossRef]

- Chen, D.; Nie, W.; Cai, P.; Liu, Z. The diffusion of dust in a fully-mechanized mining face with a mining height of 7m and the application of wet dust-collecting nets. J. Clean. Prod. 2018, 205, 463–476. [Google Scholar] [CrossRef]

- Xiu, Z.; Nie, W.; Yan, J.; Chen, D.; Cai, P.; Liu, Q.; Du, T.; Yang, B. Numerical simulation study on dust pollution characteristics and optimal dust control air flow rates during coal mine production. J. Clean. Prod. 2020, 248, 119197. [Google Scholar] [CrossRef]

- Hurtado, J.P.; Reyes, G.; Vargas, J.P.; Acuna, E. A Computational Fluid Dynamic Study of Developed Parallel Stations for Primary Fans. Processes 2021, 9, 1607. [Google Scholar] [CrossRef]

- Zhelnin, M.; Kostina, A.; Plekhov, O.; Zaitsev, A.; Olkhovskiy, D. Numerical Simulation on Temperature and Moisture Fields Around Cooling Towers Used in Mine Ventilation System. Fluids 2022, 7, 317. [Google Scholar] [CrossRef]

- Adjiski, V. Possibilities for simulating the smoke rollback effect in underground mines using CFD software. GeoSci. Eng. 2014, 2, 8–18. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Kim, H. CFD Analysis of Truck Fire in Large-Opening Limestone Mine. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Yuan, Y.; Smith, A.C. Numerical Study on the Effects of Water Spray Characteristics on Suppression of Conveyor Belt Fires. In Proceedings of the 15th North American Mine Ventilation Symposium, Blacksburg, VA, USA, 21–25 June 2015. [Google Scholar]

- Zhou, Z.; Cui, Y.; Tian, L.; Chen, J.; Pan, W.; Yang, S.; Hu, P. Study of the Influence of Ventilation Pipeline Setting on Cooling Effects in High-Temperature Mines. Energies 2019, 12, 4074. [Google Scholar] [CrossRef] [Green Version]

- Huang, R.; Shen, X.; Wu, E.; Li, Z. Study on the influence law of ventilation conditions on heat loss in a roadway of high altitude mine. Numer. Heat Transfer. 2020, 77, 69–79. [Google Scholar] [CrossRef]

- Xin, S.; Wang, W.; Zhang, N.; Zhang, C.; Yuan, S.; Li, H. Comparative studies on control of thermal environment in development headings using force/exhaust overlap ventilation systems. J. Build. Eng. 2021, 38, 102227. [Google Scholar] [CrossRef]

- Fernánez-Alaiz, F.; Castañón, A.M.; Gómez-Fernández, F.; Bernardo-Sánchez, A.; Bascompta, M. Analysis of the Fire Propagation in a Sublevel Coal Mine. Energies 2020, 13, 3754. [Google Scholar] [CrossRef]

- Fernánez-Alaiz, F.; Castañón, A.M.; Gómez-Fernández, F.; Bernardo-Sánchez, A.; Bascompta, M. Mine Fire Behavior under Different Ventilation Conditions: Real-Scale Tests and CFD Modeling. Appl. Sci. 2020, 10, 3380. [Google Scholar] [CrossRef]

| References | Base Experiment for Validation | Problems | Turbulence Model | Solver | Parameters or Results |

|---|---|---|---|---|---|

| Parra et al. [11] | Experiment conducted by the authors | Blowing and exhaust duct at the mining face | Spalart–Allmaras | Not mentioned | Location and length of ducts |

| Torano et al. [5] | Experiment conducted by the authors | Blowing duct at the mining face | k–ε | CFX 10.0 | Calculated cross-section |

| Wala et al. [4] | Experiment conducted by the authors | Blowing curtain at mining face | SST k–ω | FLUENT | Airflow and methane distribution |

| Kurnia et al. [22] | Parra et al. [11] | New blowing duct at the mining face | k–ε | FLUENT 6.3 | Inlet velocity and various geometries of ducts |

| Xu et al. [23] | Experiment conducted by the authors | SF6 concentration in tunnels | k–ε | ANSYS FLUENT | SF6 concentration with time |

| Zhou et al. [25] | Experiment conducted by the authors | Gas concentration | k–ε | ANSYS FLUENT 13 | Gas concentration with blowing curtains |

| Park et al. [14] | Parra et al. [11] | Blowing duct at the mining face | k–ε | ANSYS CFX 17 | Locations of ducts and airflow velocity |

| Torno et al. [34] | Experiment conducted by the authors | CO and NO2 diffusion at the mining face | k–ε | ANSYS CFX | CO and NO2 distribution with time |

| Vives et al. [8] | Experiment conducted by the authors | Optimal location of a blowing duct | k–ε | FLOW-3D | Temperature distribution with various duct positions |

| Obracaj et al. [73] | Experiment conducted by the authors | Methane distribution with blowing and exhaust ducts | k–ε | ANSYS FLUENT 2020 | Methane distribution with a whirl-flow air duct |

| Xin et al. [92] | Experiment conducted by the authors | Four cases of both blowing and exhaust ducts | k–ε | ANSYS FLUENT | Temperature and airflow distribution with various positions of ducts |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, H.; Kim, M.; Lee, D.; Park, J. Applications of Computational Fluid Dynamics for Mine Ventilation in Mineral Development. Energies 2022, 15, 8405. https://doi.org/10.3390/en15228405

Yi H, Kim M, Lee D, Park J. Applications of Computational Fluid Dynamics for Mine Ventilation in Mineral Development. Energies. 2022; 15(22):8405. https://doi.org/10.3390/en15228405

Chicago/Turabian StyleYi, Huiuk, Minsik Kim, Dongkil Lee, and Jongmyung Park. 2022. "Applications of Computational Fluid Dynamics for Mine Ventilation in Mineral Development" Energies 15, no. 22: 8405. https://doi.org/10.3390/en15228405

APA StyleYi, H., Kim, M., Lee, D., & Park, J. (2022). Applications of Computational Fluid Dynamics for Mine Ventilation in Mineral Development. Energies, 15(22), 8405. https://doi.org/10.3390/en15228405