Estimating the Useful Energy of a Launcher’s Pneumatic Launch System UAV

Abstract

:1. Introduction

1.1. Status of the Issue

1.2. Formulation of the Research Problem

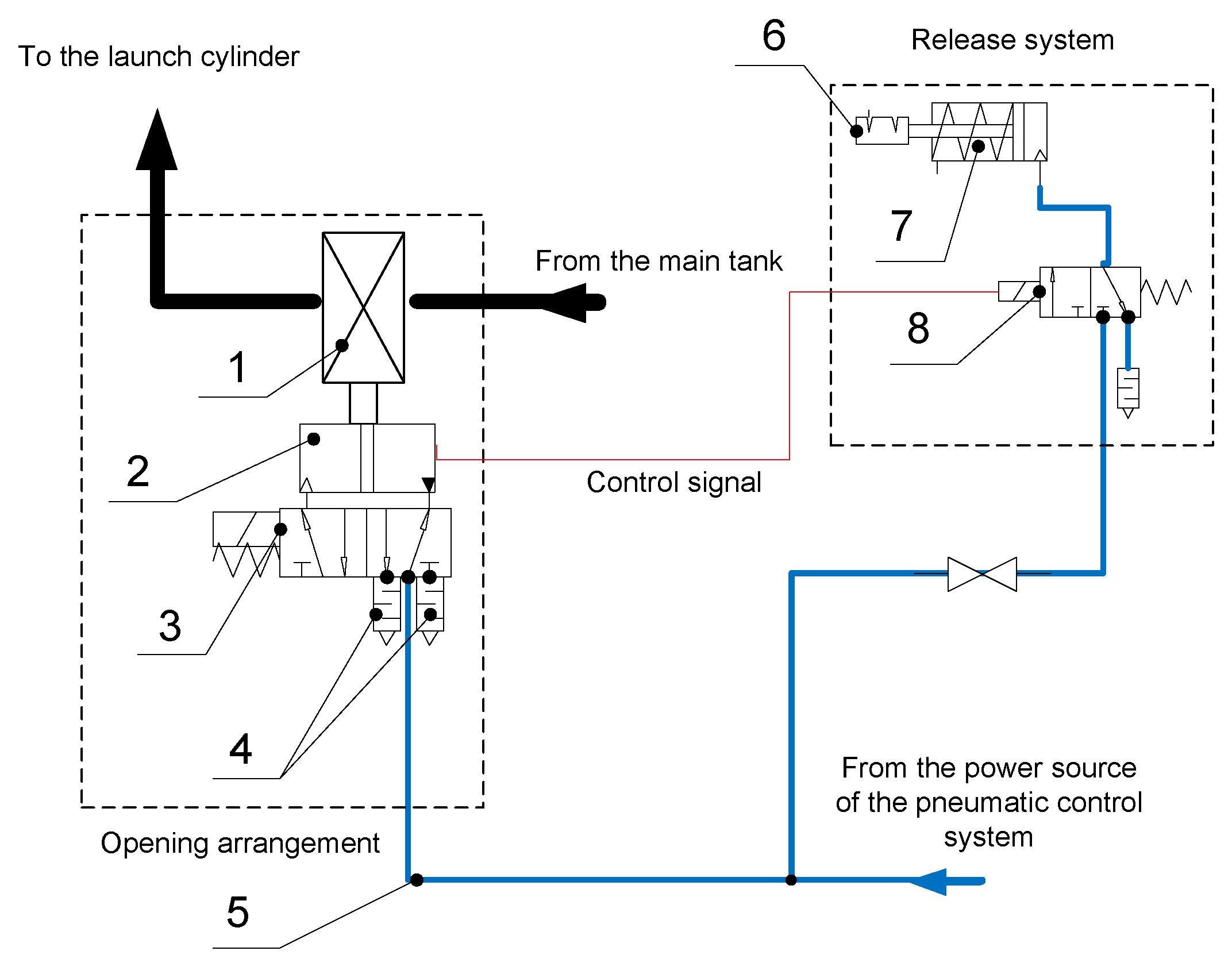

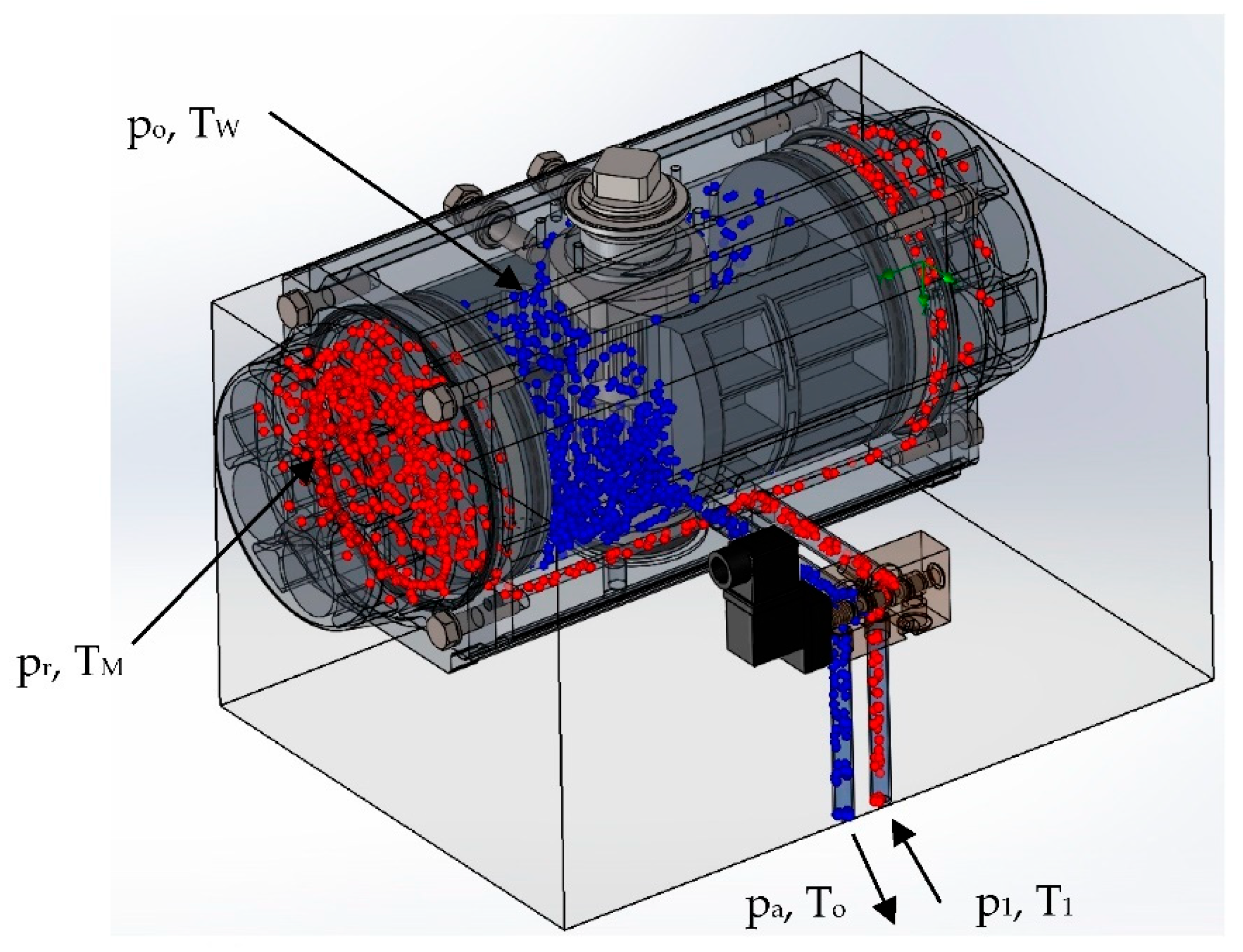

1.3. Description of the Research Subject

2. Materials and Methods

2.1. Research Object

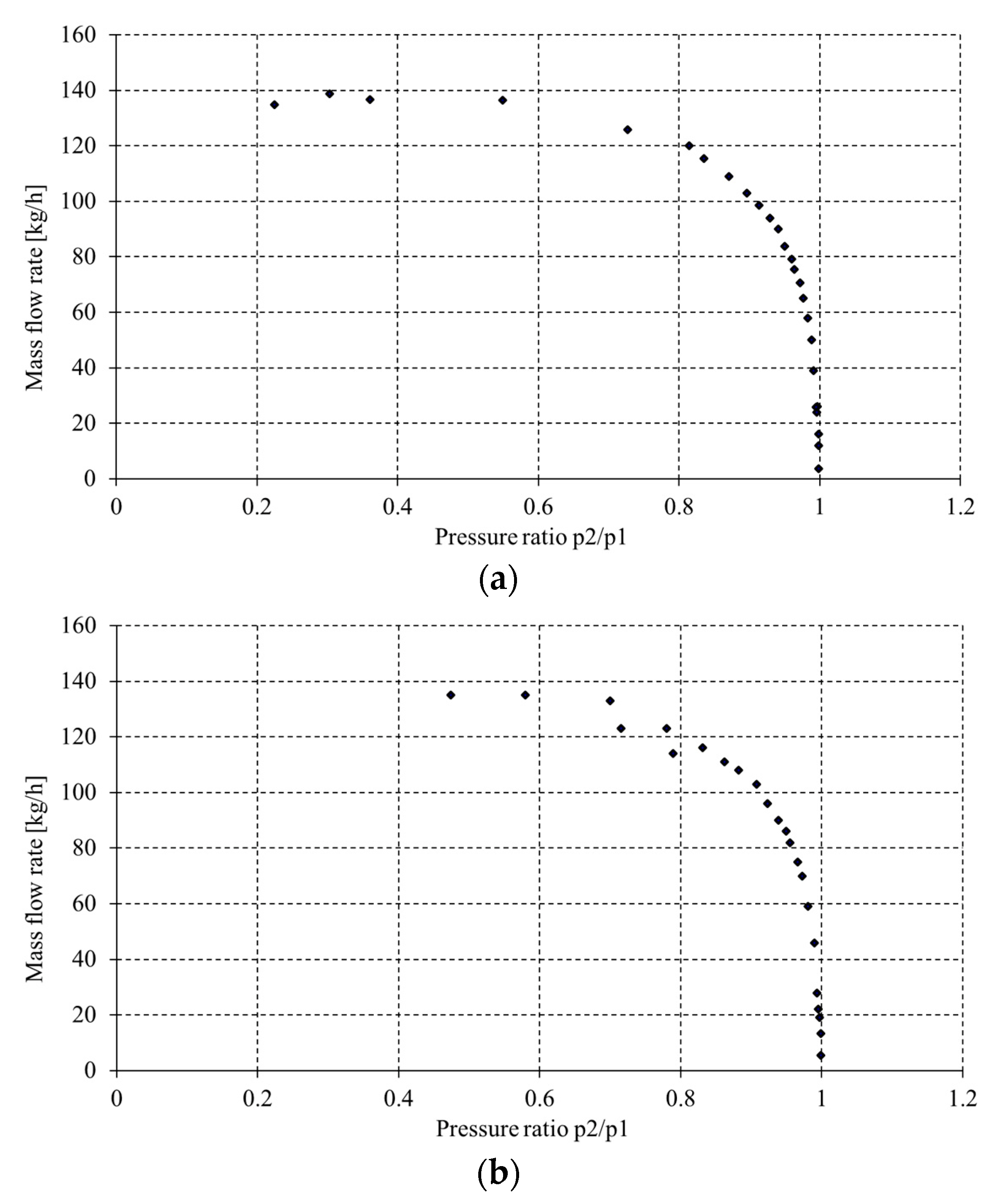

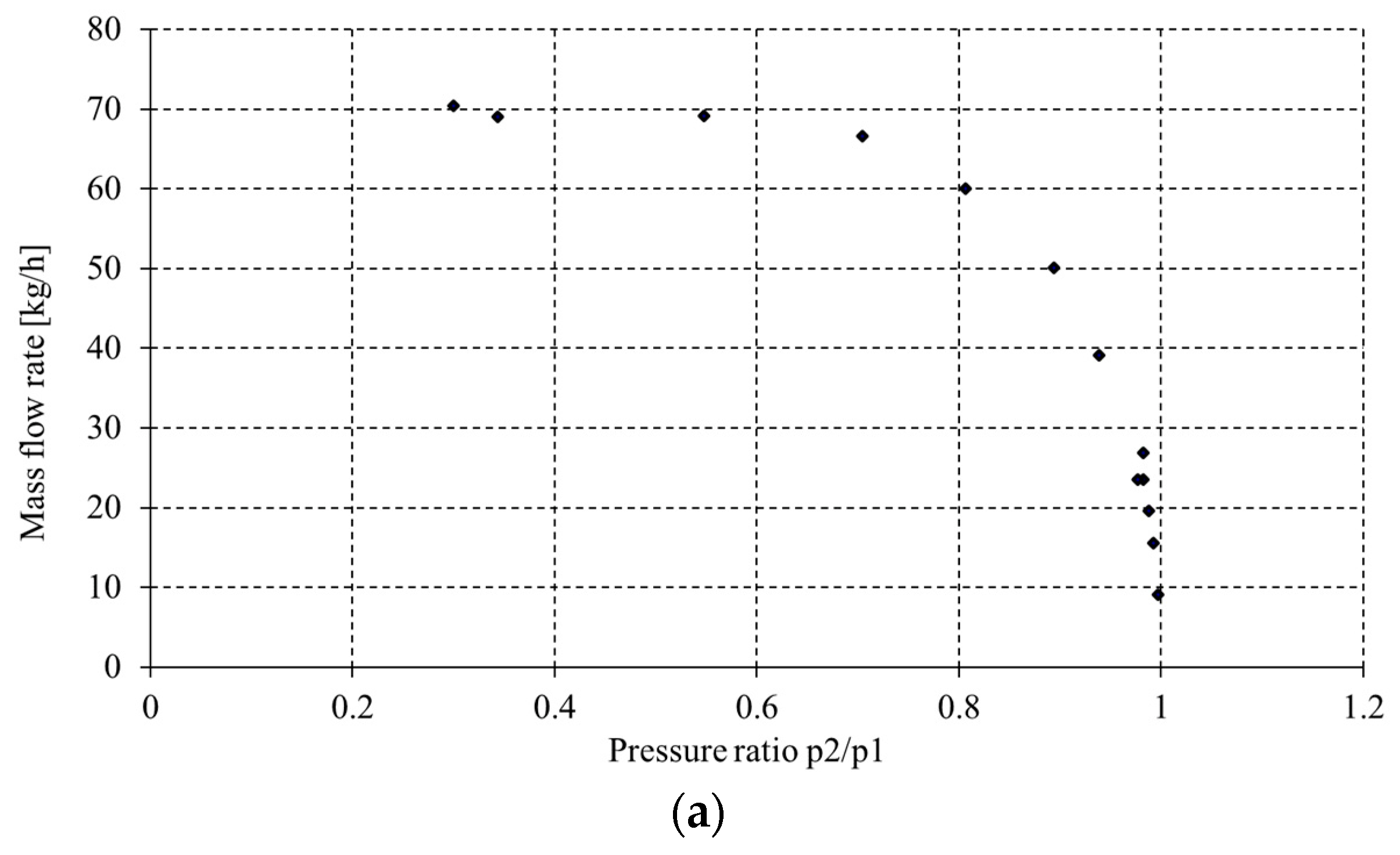

- C-sonic conductivity is the ratio of the mass flow rate of the gas through the element to the product of the inlet pressure and the density of this gas under conditions of a standardized reference atmosphere ANR at critical flow, described by Formula (9).

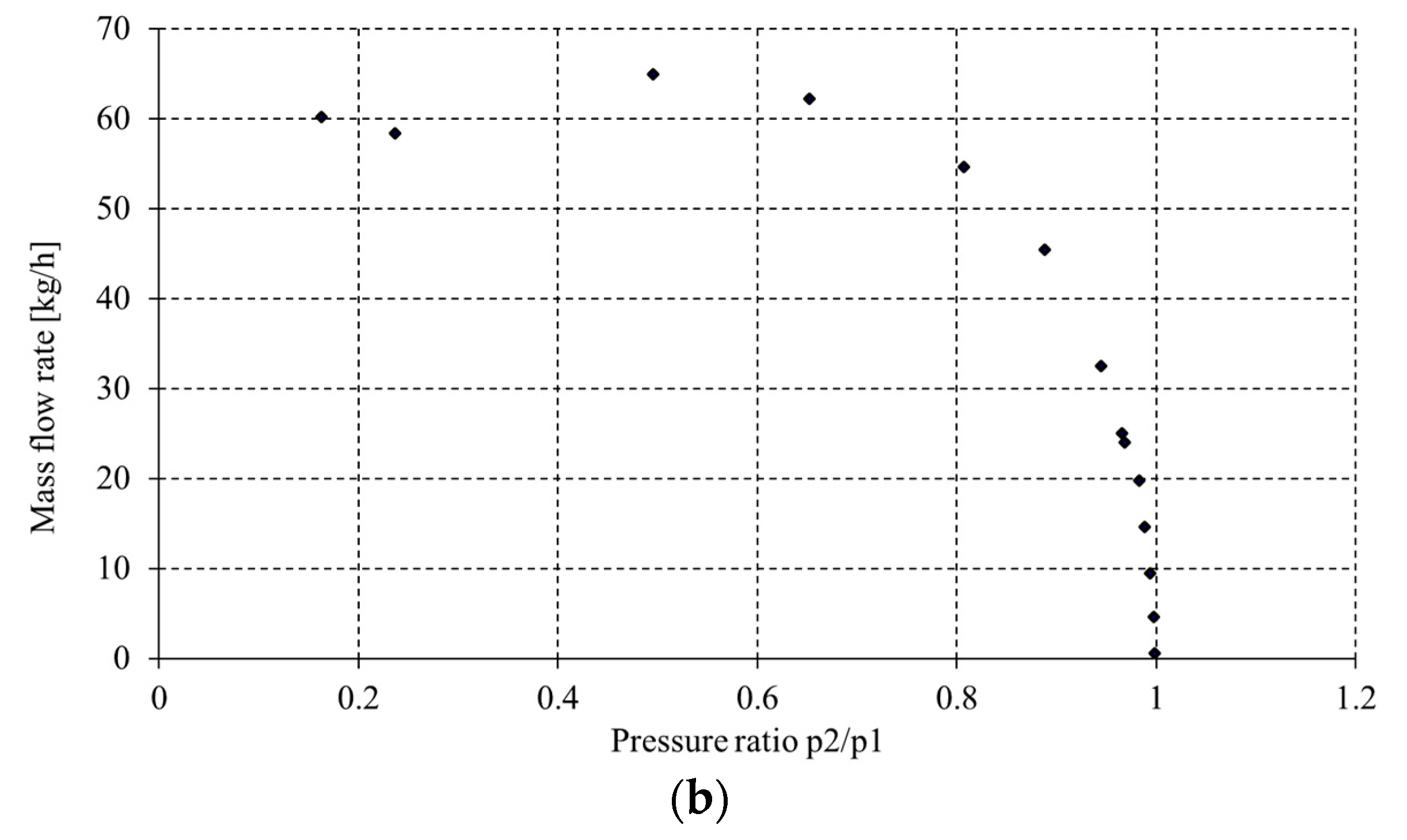

- b-critical pressure ratio is the highest ratio value outlet presser to inlet presser, at which critical flow occurs in the tested element.

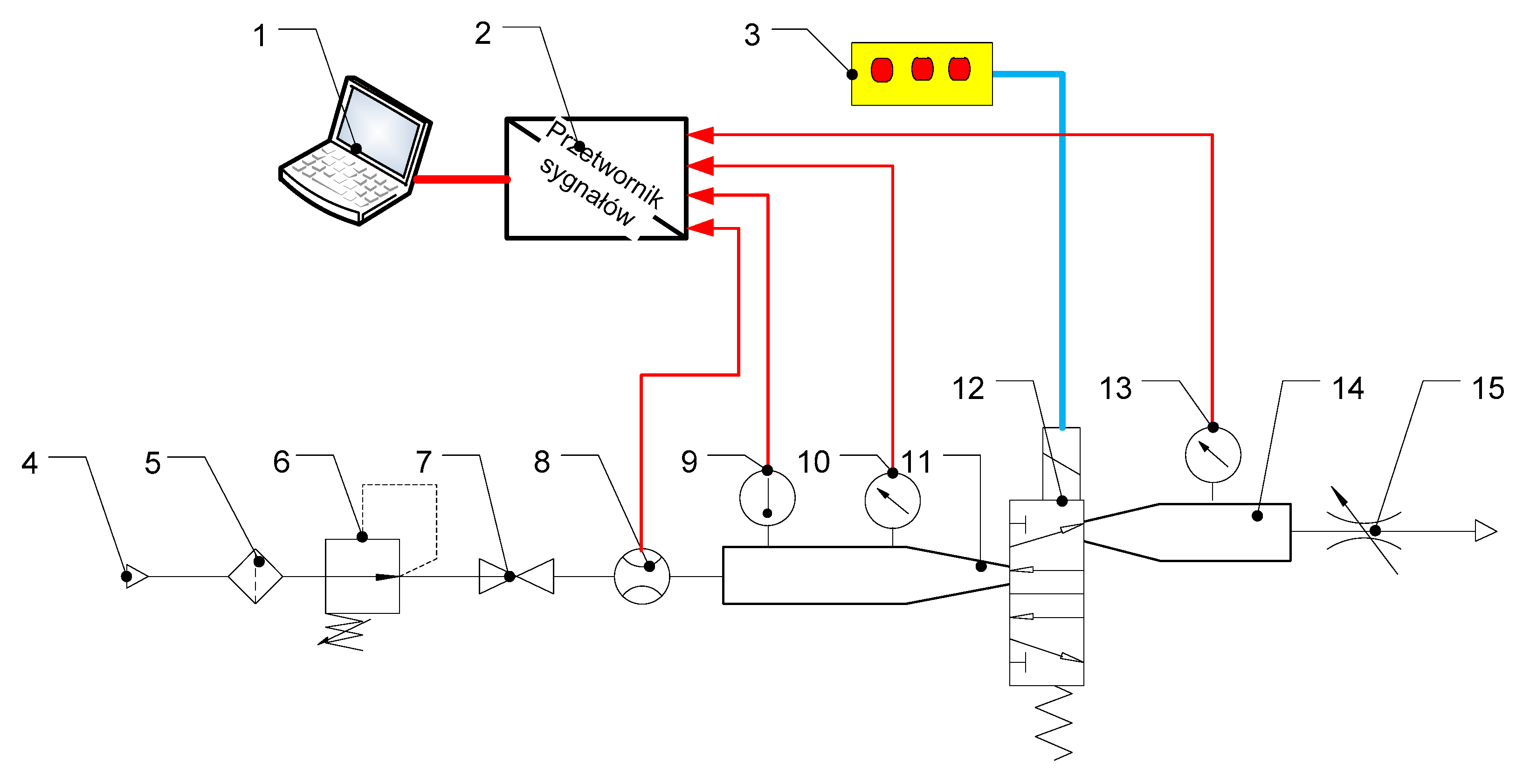

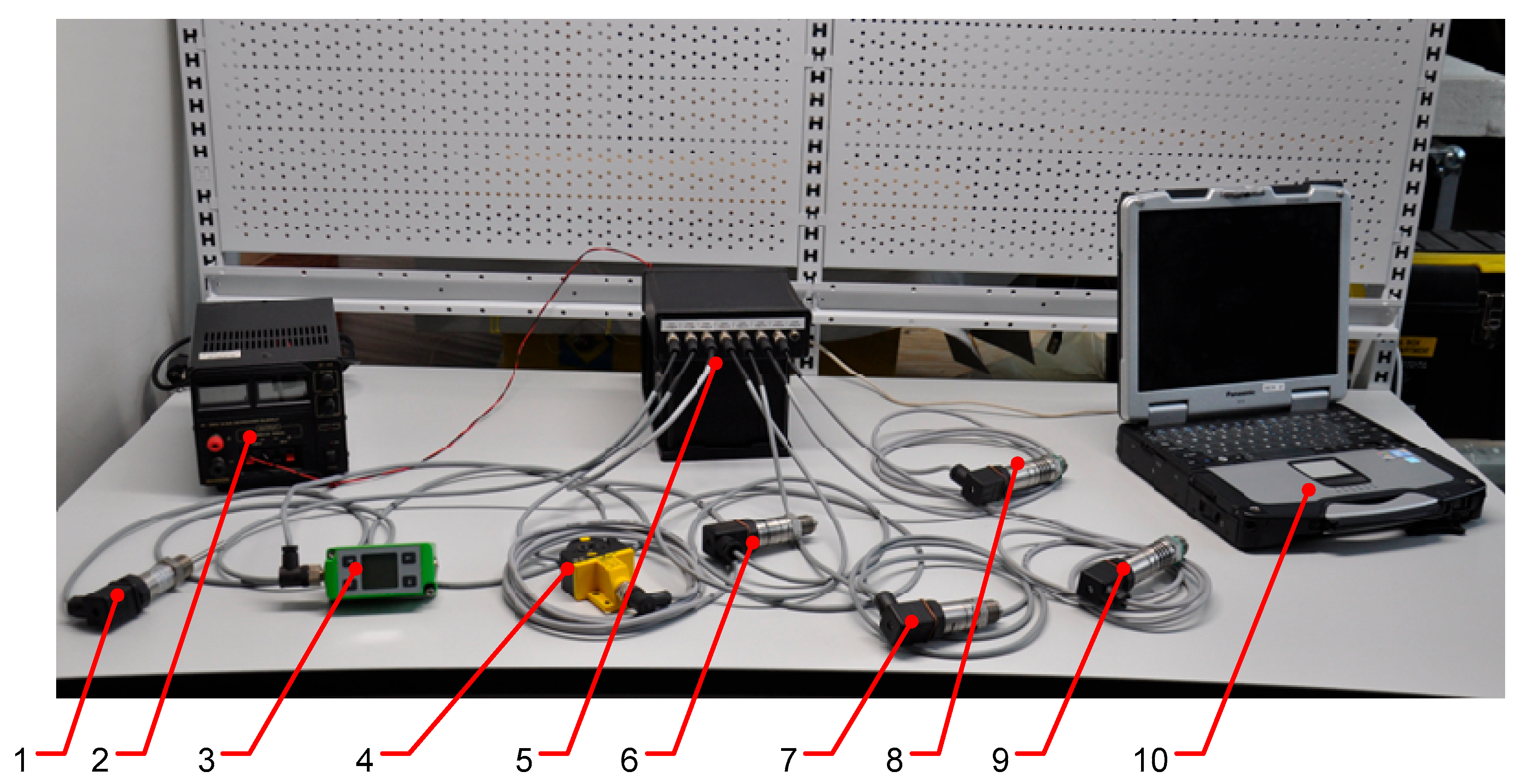

2.2. The Developed Method of Determining the Flow Coefficients

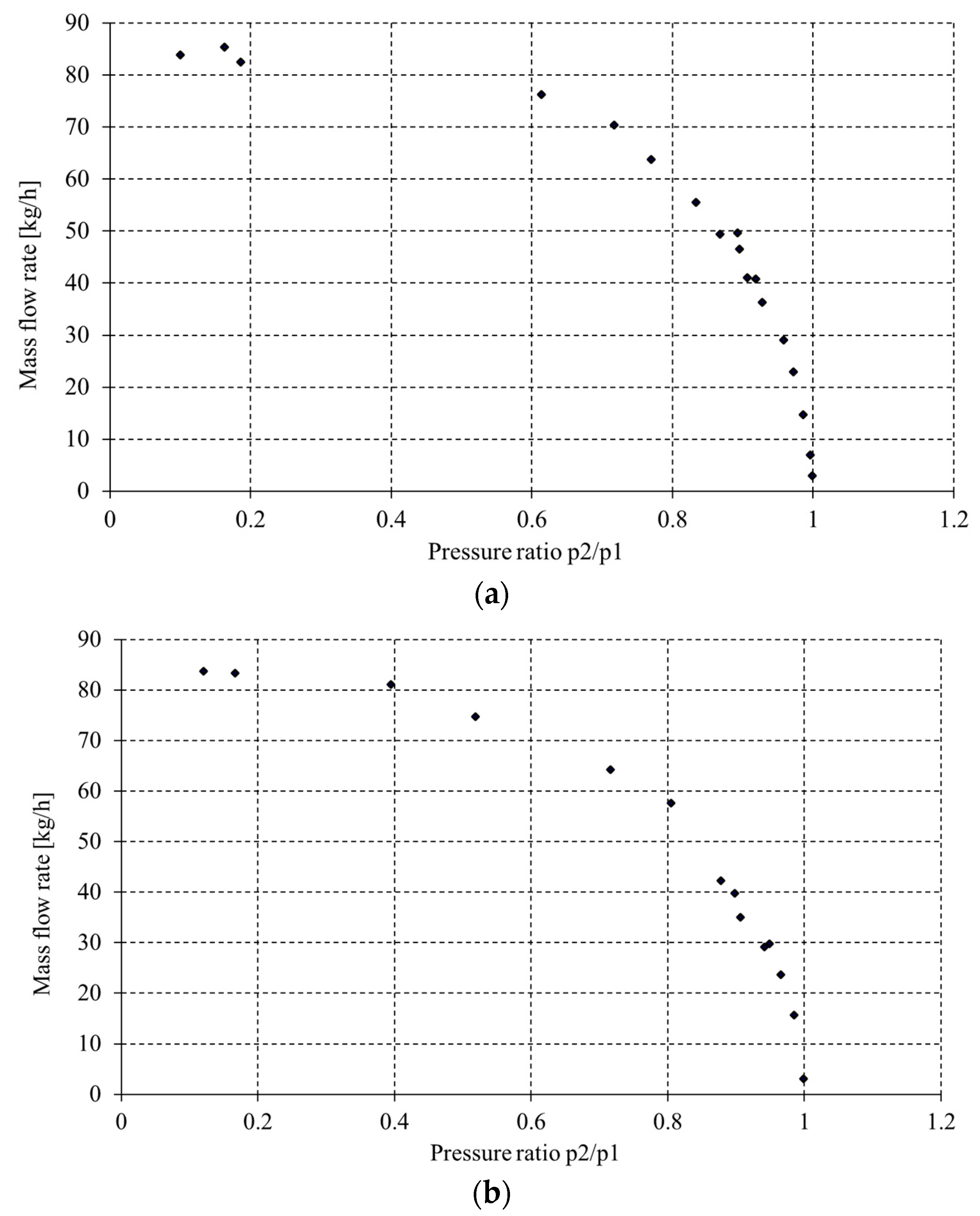

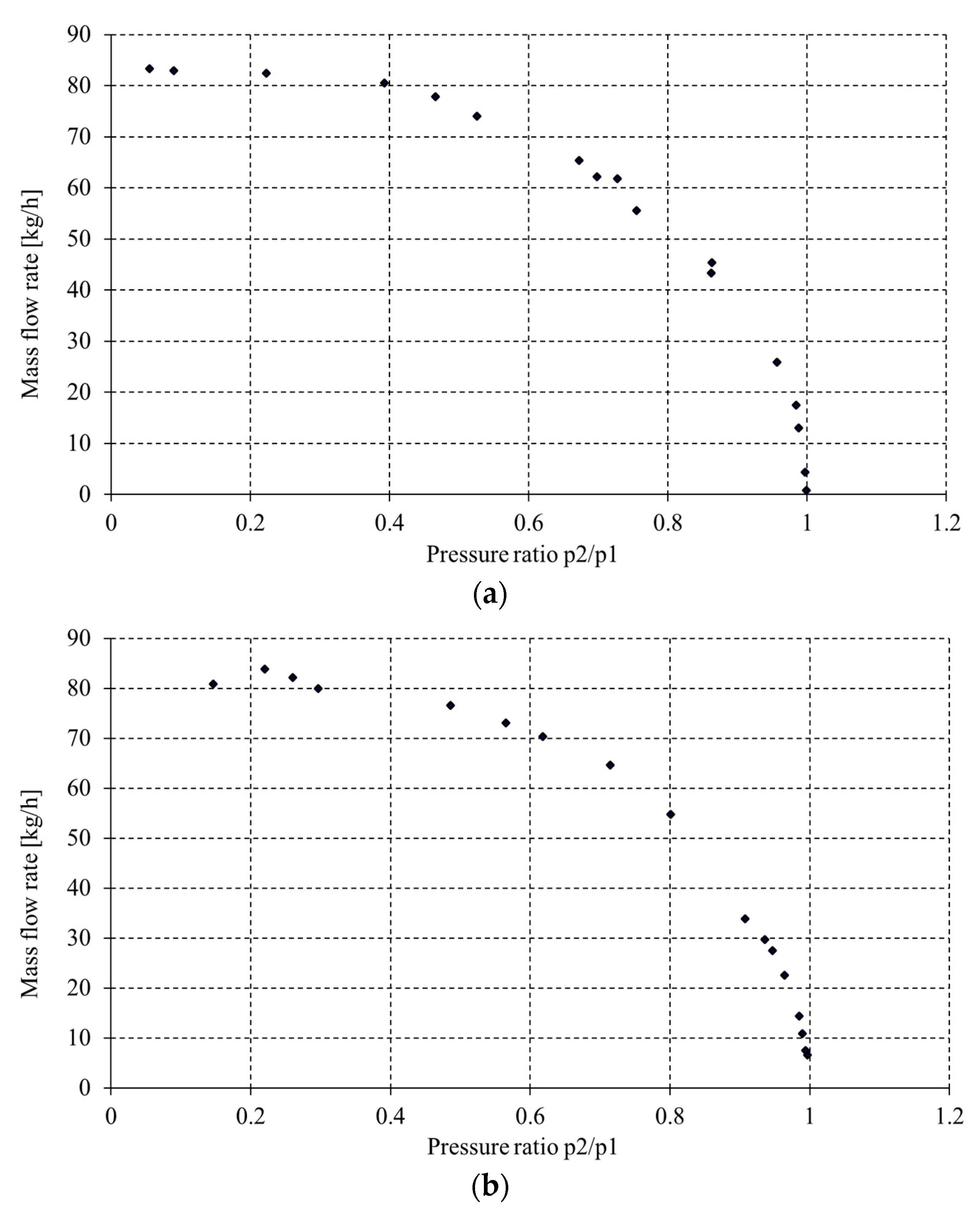

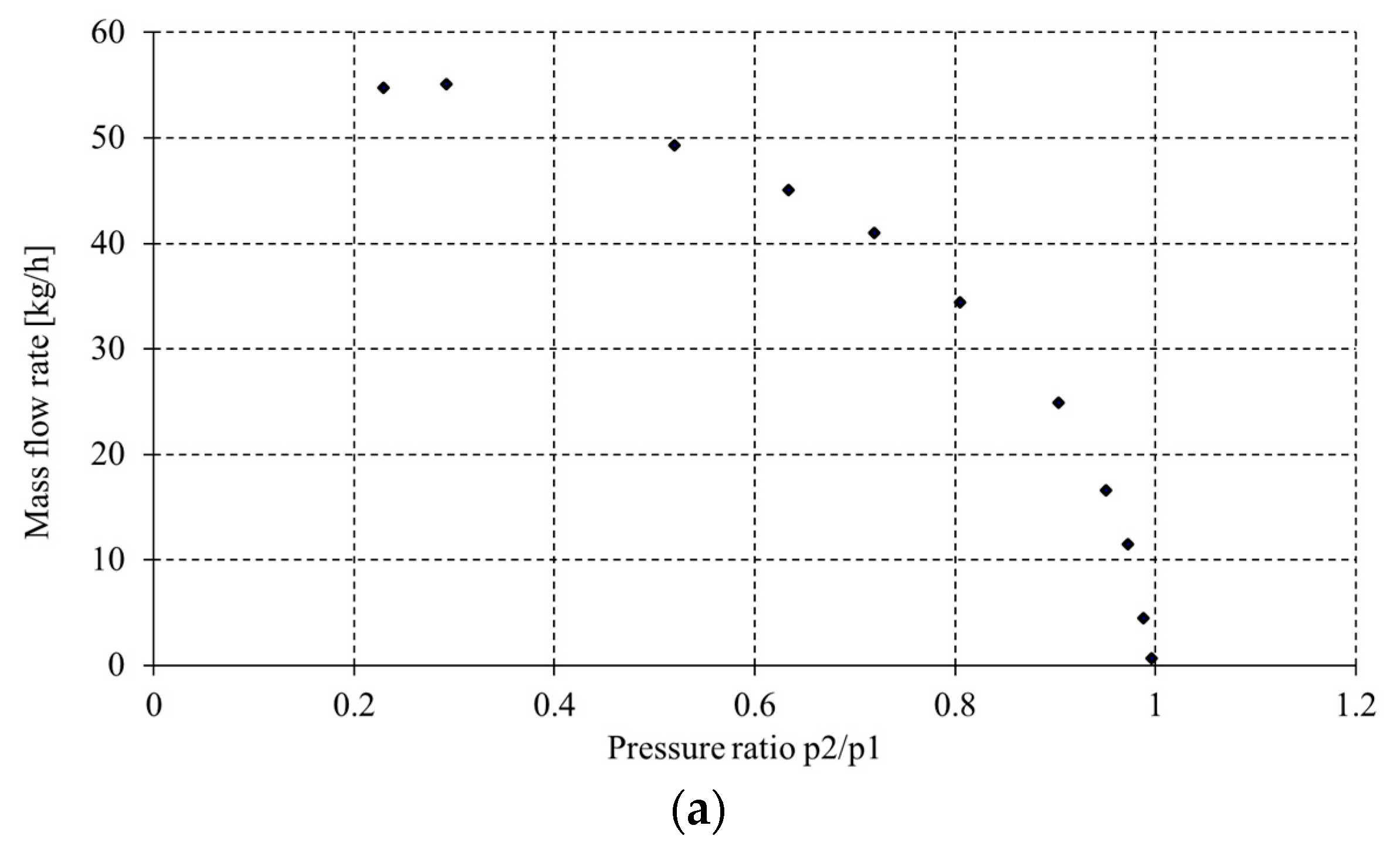

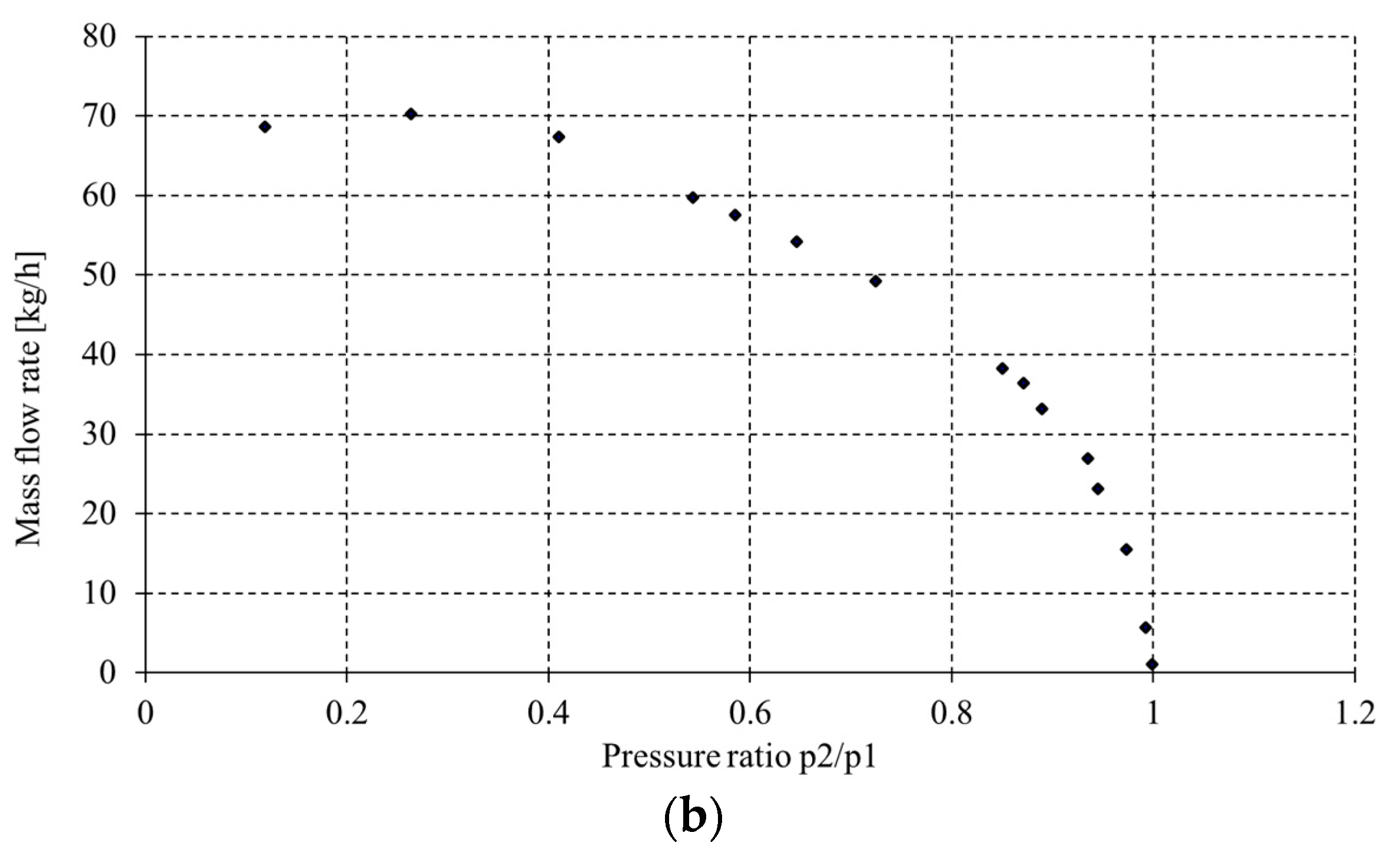

3. Results

4. Discussion

- ➢

- Determining the pneumatic resistance of pneumatic elements and systems;

- ➢

- Determining the working time of the pneumatic system;

- ➢

- Determination of pressure losses in pneumatic systems;

- ➢

- Selection of components of the designed pneumatic system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jurczyk, K. The prospect for the launche of a mini unmanned aerial vehicle. Sci. J. Pol. Nav. Acad. 2018, 1, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Novaković, Z.; Vasić, Z.; Ilić, I.; Medar, N.; Stevanović, D. Integration of Tactical—Medium Range UAV and Catapult Launch System. Sci. Tech. Rev. 2016, 66, 22–28. [Google Scholar] [CrossRef]

- Kondratiuk, M.; Ambroziak, L. Design and Dynamics of Kinetic Launcher for Unmanned Aerial Vehicles. Appl. Sci. 2020, 10, 2949. [Google Scholar] [CrossRef]

- Gan, L.; Fang, X.; Zhang, Z.; Chen, H.; Wei, X. Modular Clustering of UAV Launch System Architecture Based on HDDSM. Aerospace 2022, 9, 168. [Google Scholar] [CrossRef]

- Liu, D.; Liu, G.; Hong, G. Analysis of onboard takeoff and landing characteristics for unmanned aerial vehicles. In Proceedings of the AIAA Modeling and Simulation Technologies Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef]

- Zhang, M.; Nie, H.; He, Z. Parameter optimization of nose landing gear considering both take-off and landing performance of catapult take-off carrier-based aircraft. Trans. Nanjing Univ. Aeronaut. Astronaut. 2016, 33, 187–198. [Google Scholar]

- Munk, D.J.; Auld, D.J.; Steven, G.P.; Vio, G.A. On the benefits of applying topology optimization to structural design of aircraft components. Struct. Multidiscip. Optim. 2019, 60, 1245–1266. [Google Scholar] [CrossRef]

- Jastrzębski, G. Description of the pneumatic work cycle of the starting unit of the UAV launcher. J. KONES 2017, 4, 61–70. [Google Scholar]

- Zhang, Z.; Peng, Y.; Wei, X.; Nie, H.; Chen, H.; Li, L. Research on parameter matching characteristics of pneumatic launch systems based on co-simulation. Aeronaut. J. 2022, 126, 381–400; [Google Scholar] [CrossRef]

- Jastrzębski, G. Impact of opening time of the take-off pneumatic launcher main valve on take-off pressure losses. J. KONES 2016, 23, 175–182. [Google Scholar]

- Szczepaniak, P.; Jóźko, M. Research of Pneumatic Distributors for Launcher of Unmanned Aerial Vehicle (UAV). J. Konbin 2022, 43, 249–276. [Google Scholar] [CrossRef]

- Cesco, N.; Dupas, M.; Renaud, L.; Rossi, C.; Vales, M. The pyronumeric, a new technology to answer to the future launchers challenges. In Proceedings of the 9th European Conference for Aerospace Sciences (EUCASS-3AF), Lille, France, 27 June–1 July 2022. [Google Scholar]

- Grymek, S. Air Stream Models in Pneumatics; Publishing House of the Gdańsk University of Technology: Gdańsk, Poland, 2012. [Google Scholar]

- Thomas, L.D.; Burris, K. Generational Evolution in Complex Engineered Systems. In Disciplinary Convergence in Systems Engineering Research; Springer: Cham, Switzerland, 2018; pp. 751–764. [Google Scholar]

- Yang, F.; Li, G.; Hu, D.; Kagawa, T. A new method for calculating the sonic conductance of airflow throug a short-tube orifice. Adv. Mech. Eng. 2017, 2, 1–13. [Google Scholar]

- Dindorf, R.; Woś, P. Application of the indirect tank method to measure static characteristics of pneumatic valves. Hydraul. Pneumatyka 2015, 3, 9–13. [Google Scholar]

- Taraila Walter, M. Model Based Systems Engineering for a Venture Class Launch Facility. Master’s Thesis, Old Dominion University, Norfolk, VA, USA, 2020. [Google Scholar] [CrossRef]

- Huang, M.; He, C.; Pei, J. Dynamic Analysis and Optimization of Pneumatic Wedge-Shaped Launcher for UAV. Trans. Nanjing Univ. Aeronaut. Astronaut. 2018, 35, 866–873. [Google Scholar]

- ISO 8778:2003; Pneumatic Fluid Power—Standard Reference Atmosphere. ISO: Geneva, Switzerland, 1990.

- ISO 6358-2:2019; Pneumatic Fluid Power Components Using Compressible Fluids Determination of Flow-Rate Characteristics. ISO: Geneva, Switzerland, 1989.

- Saber, Y.; Alsharari, F.; Smarandache, F. An introduction to single-valued neutrosophic soft topological structure. Soft Comput. 2022, 26, 7107–7122. [Google Scholar] [CrossRef]

| Producer | Parameter |

|---|---|

| OBREiUP | Compressed air, max. working pressure |

| Hafner | Nominal flow [l/min], operating pressure |

| Parker | Operating pressure [bar], operating time [ms] |

| Hoerbiger | Nominal flow [l/min], working pressure [bar] |

| Marani | Working pressure [bar] |

| O.n. | Pneumatic Element | Type/Number/Dimensions |

|---|---|---|

| 1 | Valve 5/2 PARKER | 341NO3 |

| 2 | Valve 5/2 PARKER | 341NO3 with tube (Ø 8 mm) |

| 3 | Valve 5/2 OBREiUP G1/8 | 611.012.949 |

| 4 | Valve 5/2 OBREiUP G1/2 | 611.012.964 |

| 5 | Pneumatic conduit | 12 × 8 × 5 (Øext × Øint × len.) |

| 6 | Pneumatic conduit | 12 × 8 × 15 (Øext × Øint × len.) |

| 7 | Pneumatic conduit | 8 × 6 × 5 (Øext × Øint × len.) |

| 8 | Pneumatic conduit | 6 × 6 × 15 (Øext × Øint × len.) |

| O.n. | Pneumatic Element | b | |

|---|---|---|---|

| 1 | Valve 5/2 PARKER 341NO3-not powered | 2.99 × 10−8 | 0.6135 |

| 2 | Valve 5/2 PARKER 341NO3-powered up | 2.99 × 10−8 | 0.5185 |

| 3 | Valve 5/2 PARKER 341NO3 with tube (Ø 8 mm) not powered | 3.22 × 10−8 | 0.3922 |

| 4 | Valve 5/2 PARKER 341NO3 with tube (Ø 8 mm) powered up | 3.03 × 10−8 | 0.4860 |

| 5 | Valve 5/2 OBREiUP G1/8 611.012.949-not powered | 2.01 × 10−8 | 0.5198 |

| 6 | Valve 5/2 OBREiUP G1/8 611.012.949-powered up | 2.22 × 10−8 | 0.5433 |

| 7 | Valve 5/2 OBREiUP G1/2 611.012.964-not powered | 7.28 × 10−8 | 0.5057 |

| 8 | Valve 5/2 OBREiUP G1/2 611.012.964-powered up | 7.32 × 10−8 | 0.4277 |

| 9 | Pneumatic conduit 12 × 8 × 5 (Øext × Øint × len.) | 1.09 × 10−7 | 0.5492 |

| 10 | Pneumatic conduit 12 × 8 × 15 (Øext × Øint × len.) | 9.22 × 10−8 | 0.7 |

| 11 | Pneumatic conduit 8 × 6 × 5 (Øext × Øint × len.) | 3.11 × 10−8 | 0.5476 |

| 12 | Pneumatic conduit 6 × 6 × 15 (Øext × Øint × len.) | 2.83 × 10−8 | 0.4952 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jastrzębski, G.; Ułanowicz, L. Estimating the Useful Energy of a Launcher’s Pneumatic Launch System UAV. Energies 2022, 15, 8424. https://doi.org/10.3390/en15228424

Jastrzębski G, Ułanowicz L. Estimating the Useful Energy of a Launcher’s Pneumatic Launch System UAV. Energies. 2022; 15(22):8424. https://doi.org/10.3390/en15228424

Chicago/Turabian StyleJastrzębski, Grzegorz, and Leszek Ułanowicz. 2022. "Estimating the Useful Energy of a Launcher’s Pneumatic Launch System UAV" Energies 15, no. 22: 8424. https://doi.org/10.3390/en15228424