An Economical Boil-Off Gas Management System for LNG Refueling Stations: Evaluation Using Scenario Analysis

Abstract

:1. Introduction

2. Materials and Methods

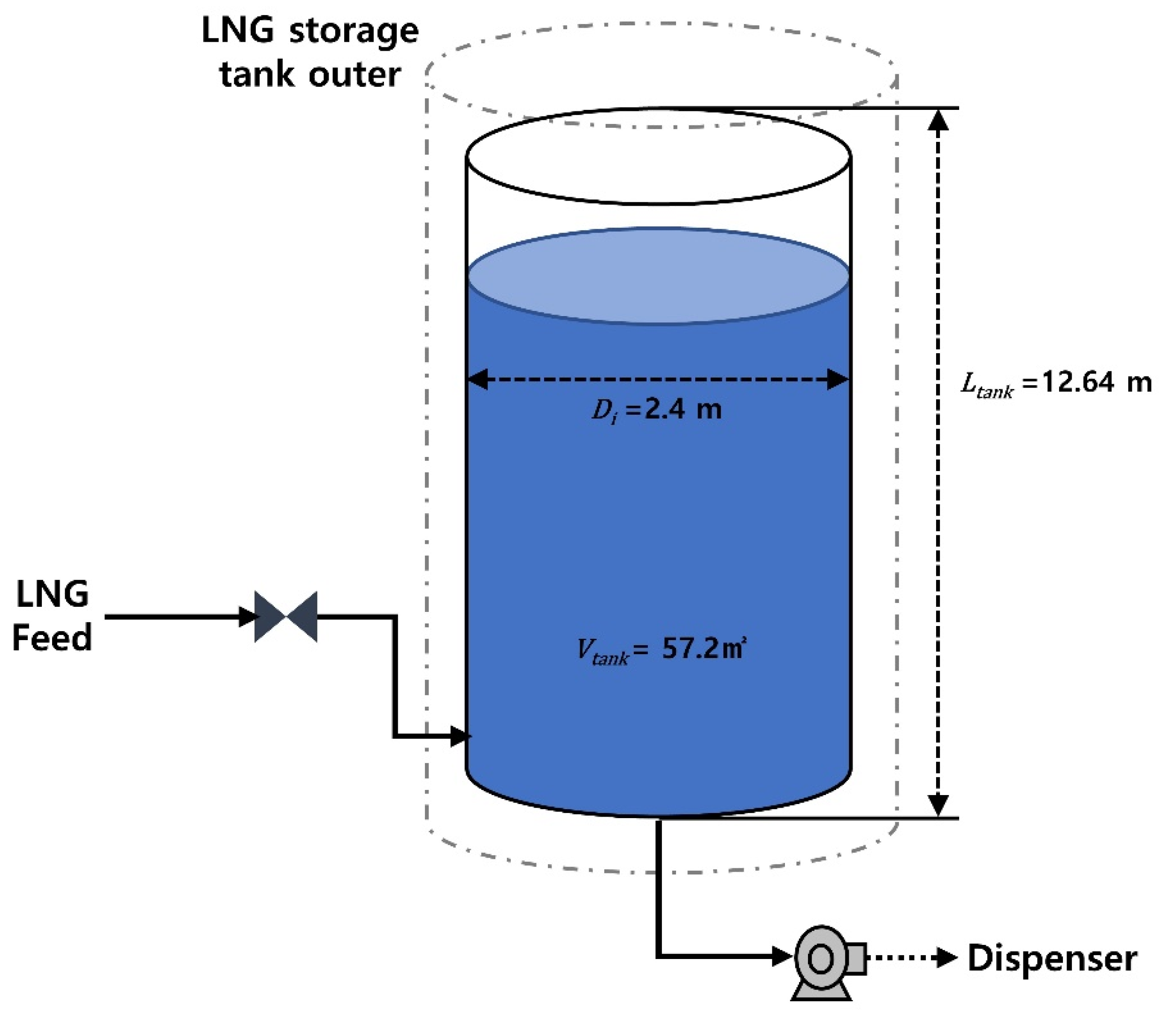

2.1. LNG Storage Tank Design

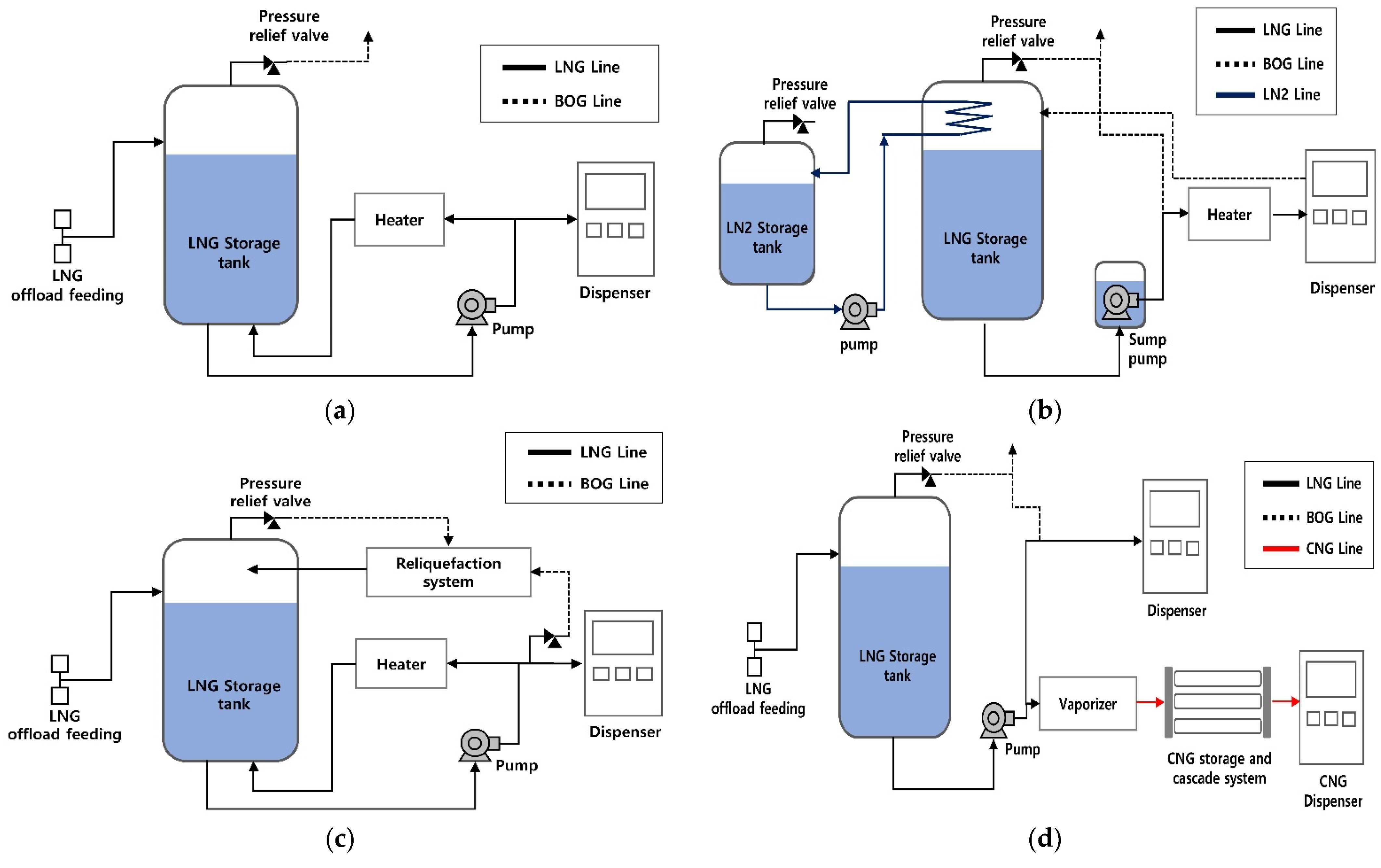

2.2. Scenario Development

2.3. Process Economic Evaluation

2.4. Sensitivity, Uncertainty, and Profitability Analyses

3. Results and Discussion

3.1. Capital and Operating Costs

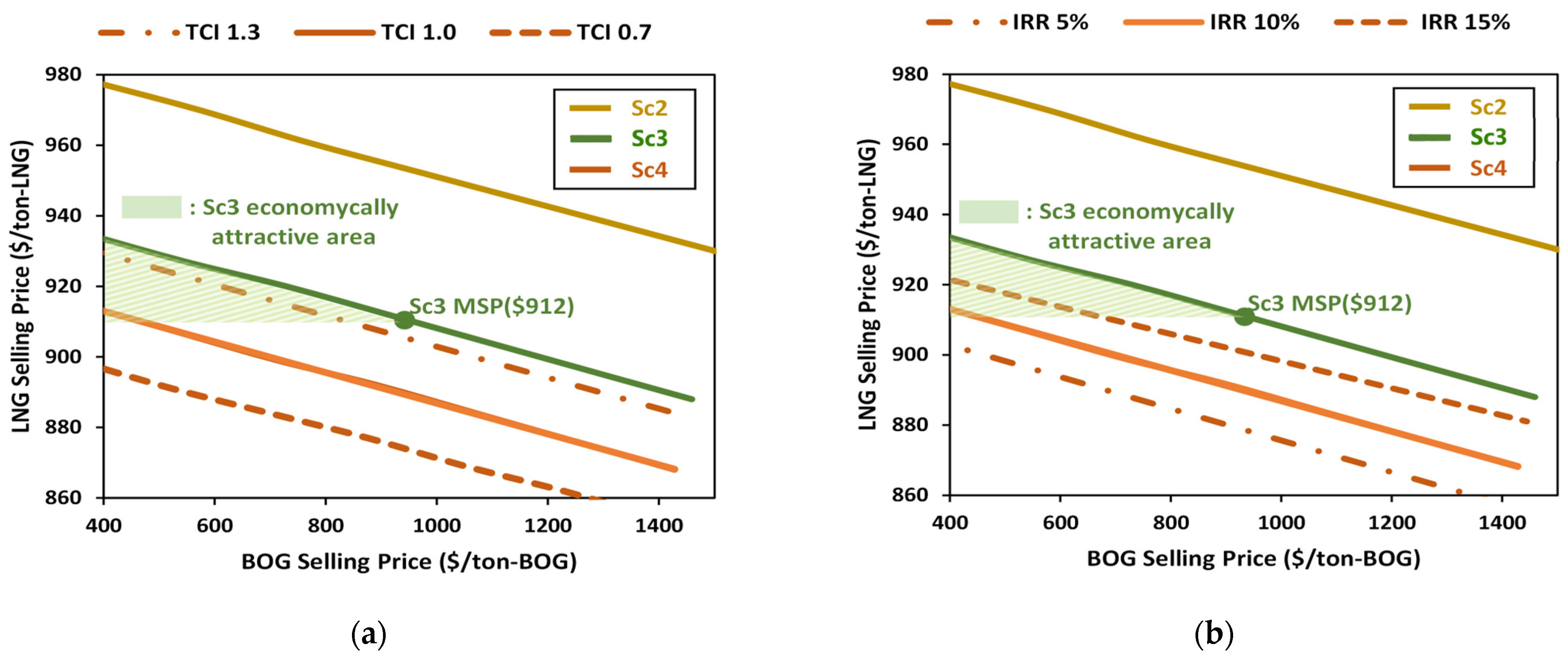

3.2. MSP of LNG Refueling Station

3.3. Sensitivity Analysis (SA)

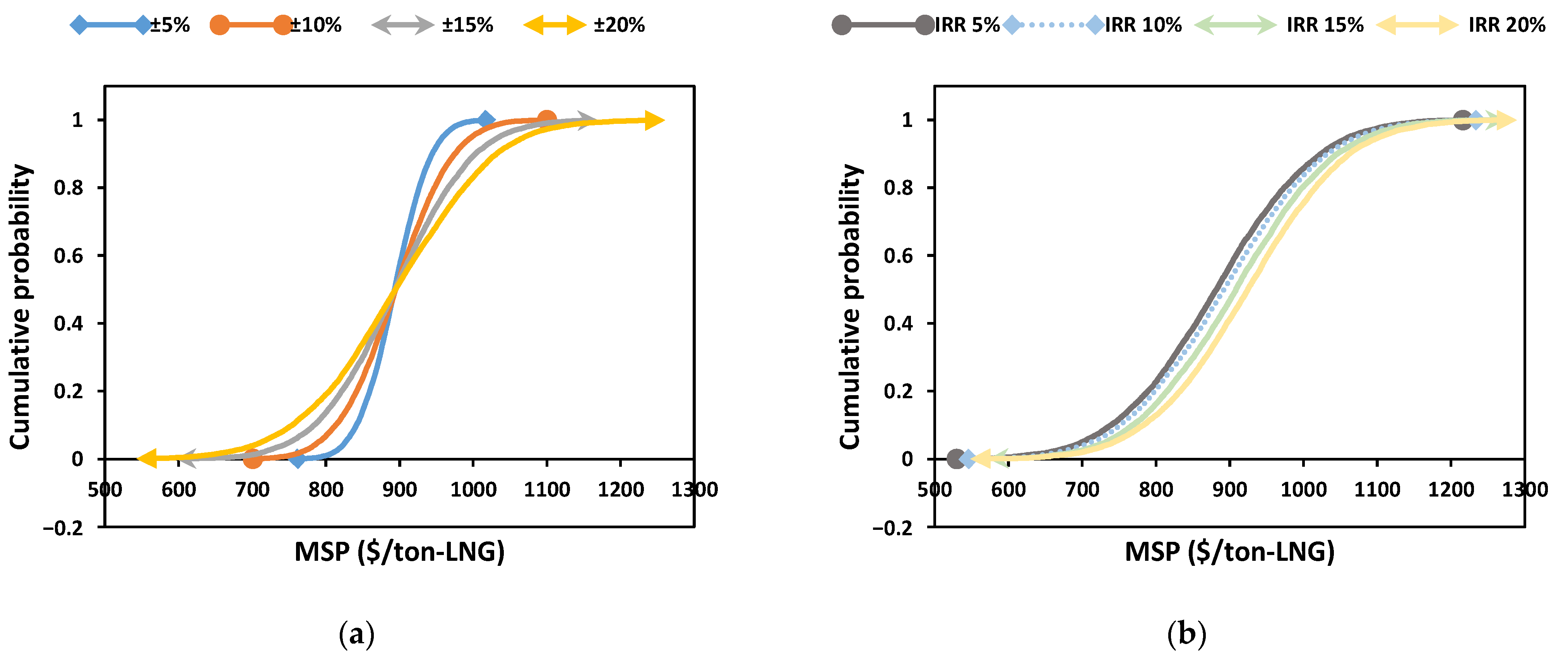

3.4. Uncertainty Analysis (UA)

3.5. Profitability Analysis (PA)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Richter, B. Beyond Smoke and Mirrors: Climate Change and Energy in the 21st Century; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Kim, M.; Won, W.; Kim, J. Integration of carbon capture and sequestration and renewable resource technologies for sustainable energy supply in the transportation sector. Energy Convers. Manag. 2017, 143, 227–240. [Google Scholar] [CrossRef]

- Liimatainen, H.; Kallionpää, E.; Pöllänen, M.; Stenholm, P.; Tapio, P.; McKinnon, A. Decarbonizing road freight in the future—Detailed scenarios of the carbon emissions of Finnish road freight transport in 2030 using a Delphi method approach. Technol. Forecast. Soc. Change 2014, 81, 177–191. [Google Scholar] [CrossRef]

- EPA 430-R-21-005; Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2019. EPA: Washington, DC, USA, 2021.

- Bouckaert, S.; Pales, A.F.; McGlade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Hoeven, M.V.D. CO2 emissions from fuel combustion IEA statistics. In International Energy Agency: Highlights; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Li, J.; Dong, X.; Shangguan, J.; Hook, M. Forecasting the growth of China’s natural gas consumption. Energy 2011, 36, 1380–1385. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.S.; Qyyum, M.A.; Ali, W.; Wazwaz, A.; Ansari, K.B.; Lee, M. Energy Saving through Efficient BOG Prediction and Impact of Static Boil-off-Rate in Full Containment-Type LNG Storage Tank. Energies 2020, 13, 5578. [Google Scholar] [CrossRef]

- Guo, Y.; Hawkes, A. The impact of demand uncertainties and China-US natural gas tariff on global gas trade. Energy 2019, 175, 205–217. [Google Scholar] [CrossRef]

- Alliance, C.N.G.V. Study On Natural Gas Research and Development Priority Setting For Transportation in Canada, Road Map, 1; Canadian Natural Fas Vechicle Alliance: Ottawa, ON, Canada, 2015. [Google Scholar]

- International Gas Union. LNG as Fuel. In Proceedings of the 26th World Gas Conference, Paris, France, 1–5 June 2015; pp. 1–120. [Google Scholar]

- Bassi, A. Liquefied Natural Gas (LNG) as fuel For Road Heavy Duty Vehicles Technologies and Standardization (No. 2011-24-0122), SAE Technical Paper; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Dunn, M.E.; LeBlanc, V.N. Two Engine System with a Gaseous Fuel Stored in Liquefied Form. U.S. Patent No. 8,763,565 B2, 1 July 2014. [Google Scholar]

- Seo, S.; Han, S.; Lee, S.; Chang, D. A pump-free boosting system and its application to liquefied natural gas supply for large ships. Energy 2016, 105, 70–79. [Google Scholar] [CrossRef]

- Bouabidi, Z.; Almomani, F.; Al-Musleh, E.; Katebah, M.; Hussein, M.; Shazed, A.; Karimi, I.; Alfadala, H. Study on Boil-off Gas (BOG) Minimization and Recovery Strategies from Actual Baseload LNG Export Terminal: Towards Sustainable LNG Chains. Energies 2021, 14, 3478. [Google Scholar] [CrossRef]

- China’s Gas-Fueled Vehicle Population Rose to the World Top. 2016. Available online: http://www.ngvexpo.com/msg.php?Id=1631 (accessed on 25 November 2016).

- Sharafian, A.; Talebian, H.; Blomerus, P.; Herrera, O.; Mérida, W. A review of liquefied natural gas refueling station designs. Renew. Sustain. Energy Rev. 2017, 69, 503–513. [Google Scholar] [CrossRef]

- KANGV (Korea Asscoiation for Natural Gas & Fuel Cell Electric Vehicles). 2021. Available online: http://www.kangv.org/ (accessed on 11 February 2022).

- AFDC (Alternative Fuels Data Center). 2020. Available online: https://afdc.energy.gov/fuels/natural_gas_stations.html (accessed on 14 February 2022).

- Hydrogen Refueling Station Network Growing Worldwide: 142 New Stations Opened in 2021. Available online: http://sustainable-bus.com (accessed on 3 February 2022).

- Burnham, A.; Han, J.; Elgowainy, A.; Wang, M. Updated Fugitive Greenhouse Gas Emissions for Natural Gas Pathways in the GREET1_2015 Model; Argonne National Laboratory: Lemont, IL, USA, 2015. [Google Scholar]

- Powars, C.A. Best Practices to Avoid LNG Fueling Station Venting Losses; Brookhaven National Laboratory: San Jose, CA, USA, 2010. [Google Scholar]

- LNG Boil off Gas (BOG) Emissions Cannot Be Ignored. 2015. Available online: http://paper.people.com.cn/zgnyb/html/2015-12/21/content_1642385.htm (accessed on 6 May 2016).

- Hailer, J.T. LNG Station Analysis for the Prediction of Pressure Rise and Vented Emissions. West Virginia University. 2015. Available online: http://ezproxy.library.ubc.ca/loginurl=http://search.proquest.com/docview/1752230020?accountid=14656 (accessed on 21 February 2022).

- Carboni, M.; Pio, G.; Mocellin, P.; Vianello, C.; Maschio, G.; Salzano, E. On the flash fire of stratified cloud of liquefied natural gas. J. Loss Prev. Process Ind. 2022, 75, 104680. [Google Scholar] [CrossRef]

- Ma, G.; Huang, Y. Safety assessment of explosions during gas stations refilling process. J. Loss Prev. Process Ind. 2019, 60, 133–144. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, X.; Zuo, T.; Wang, W.; Song, X. A systematic literature review on port LNG bunkering station. Transp. Res. Part D Transp. Environ. 2021, 91, 102704. [Google Scholar] [CrossRef]

- Liu, S.; Li, X.; Huo, Y.; Li, H. An analysis of the primary energy consumed by the re-liquefaction of boil-off gas of LNG storage tank. Energy Procedia 2015, 75, 3315–3321. [Google Scholar] [CrossRef] [Green Version]

- Jiqiang, J.; Bin, P.; Chunyan, Z. Study and economic analysis on BOG re-liquefaction process at LNG filling station. Chem. Eng. Oil Gas 2017, 46, 45–50. [Google Scholar]

- Chart Industries LNG Storage Vessels. 2016. Available online: http://files.chartindustries.com/20810915_VerticalStorage.pdf (accessed on 10 March 2022).

- Sharafian, A.; Herrera, O.E.; Mérida, W. Performance analysis of liquefied natural gas storage tanks in refueling stations. J. Nat. Gas Sci. Eng. 2016, 36, 496–509. [Google Scholar] [CrossRef]

- NamKoong, K.-W.; Chu, S.-J. Prediction of Thermal Behavior of Automotive LNG Fuel Tank. Trans. Korean Soc. Mech. Eng. B 2010, 34, 875–883. [Google Scholar] [CrossRef]

- Wiens, J.; Powars, C.; Pope, G. LNG vehicle fuel pressure strategy alternatives. SAE Trans. 2001, 110, 1098–1112. [Google Scholar]

- Linde’s LNG Fueling Solutions: Now Available for Fleets. 2014. Available online: http://lindelng.com/pdf/Linde_LNG_Fueling_Solutions-forFleets.pdf (accessed on 21 March 2022).

- Liqal Home Page. 2022. Available online: https://www.liqal.com/index.php/en/lng-fuelling-solutions/liquefaction-lng (accessed on 4 April 2022).

- Chart Industires. 2016. Available online: http://www.chartindustries.com/ (accessed on 23 March 2022).

- Minutillo, M.; Perna, A.; Forcina, A.; Di Micco, S.; Jannelli, E. Analyzing the levelized cost of hydrogen in refueling stations with on-site hydrogen production via water electrolysis in the Italian scenario. Int. J. Hydrog. Energy 2021, 46, 13667–13677. [Google Scholar] [CrossRef]

- Davis, R.; Tao, L.; Scarlata, C.; Tan, E.C.D.; Ross, J.; Lukas, J.; Sexton, D. Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbons: Dilute-Acid and Enzymatic Deconstruction of Biomass to Sugars and Catalytic Conversion of Sugars to Hydrocarbons; National Renewable Energy Laboratory: Golden, CO, USA, 2015. [Google Scholar]

- KOGAS. 2022. Available online: https://www.kogas.or.kr (accessed on 28 February 2022).

- KEPCO. 2022. Available online: https://www.home.kepco.co.kr (accessed on 28 February 2022).

- Davis, R.E.; Grundl, N.J.; Tao, L.; Biddy, M.J.; Tan, E.C.D.; Beckham, G.T.; Humbird, D.; Thompson, D.N.; Roni, M.S. Process Design and Economics for the Conversion of Lignocellulosic Biomass to Hydrocarbon Fuels and Coproducts: 2018 Biochemical Design Case Update; National Renewable Energy Laboratory: Golden, CO, USA, 2018. [Google Scholar]

- Mariani, F. Cost Analysis of LNG Refueling Stations. 2016. Available online: https://lngbc.eu/downloads (accessed on 28 October 2016).

- Mac Dowell, N.; Fennell, P.S.; Shah, N.; Maitland, G.C. The role of CO2 capture and utilization in mitigating climate change. Nat. Clim. Chang. 2017, 7, 243–249. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.; Chae, H.; Choi, N.H.; Moon, C.; Moon, S.; Lim, H. Economic evaluation with sensitivity and profitability analysis for hydrogen production from water electrolysis in Korea. Int. J. Hydrogen Energy 2017, 42, 6462–6471. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.S.; Park, J.; Kang, B.M.; Cho, C.H.; Lim, H.; Won, W. Scenario-Based Techno-Economic Analysis of Steam Methane Reforming Process for Hydrogen Production. Appl. Sci. 2021, 11, 6021. [Google Scholar] [CrossRef]

- Liang, F.; Lindberg, P.; Lindblad, P. Engineering photoautotrophic carbon fixation for enhanced growth and productivity. Sustain. Energy Fuels 2018, 2, 2583–2600. [Google Scholar] [CrossRef]

- The Chemical Engineering Plant Cost Index. 2021. Available online: https://www.chemengonline.com/pci-home (accessed on 3 May 2021).

- Paul, F.; Neil, B.; Phillip, P.; Reibstein, D. Marketing Metrics: The Definitive Guide to Measuring Marketing Performance; Wharton School Publishing: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- KPMG. Diagnosis of Gas Station Management Status and How to Strengthen Competitiveness. 2015. Available online: https://scienceon.kisti.re.kr/srch/selectPORSrchReport.do?cn=TRKO201700005198 (accessed on 19 January 2015).

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A. Analysis, Synthesis, and Design of Chemical Processes, 4th ed.; Pearson: Upper Saddle River, NJ, USA, 2013. [Google Scholar]

| Parameters | Values | References |

|---|---|---|

| Tank net capacity, Vtank | 57.2 m3 | [30] |

| Length of inner tank, Ltank | 12.64 m | [31] |

| Inner diameter, Di | 2.4 m | [31] |

| Surface area of inner tank, Atank | 104.35 m2 | [31] |

| Heat transfer rate to tank, Qtank | 430 W | [31] |

| Ambient temperature, Tambient | 25 °C | [31] |

| LNG temperature, TLNG | −162 °C | [22] |

| Category | Components | Characteristics |

|---|---|---|

| Scenario 1 (Sc1) | Storage tank, cryogenic pump, vaporizer (heater), vacuum pipe dispenser, controller, and valve | This unit releases BOG directly into the atmosphere. The initial investment is lower than that of other scenarios, the required land is small, and equipment composition is quite simple. However, BOG management is difficult. |

| Scenario 2 (Sc2) | LNG refueling station (Sc1) + liquefied nitrogen (LN2) tank, LN2 pump, LN2 vaporizer heat exchanger, and BOG capture tank | This unit re-liquefies BOG using the low liquefaction point (−192 °C) of LN2 and sends it to the storage tank with low pressure. Separate investment has to be made because a cryogenic pump, heat exchangers, and an LN2 storage tank for reliquefaction are required in addition to the refueling station of Sc1. Moreover, the operating cost increases because LN2 is used to re-liquefy BOG. |

| Scenario 3 (Sc3) | LNG refueling station (Sc1) + microreliquefaction system | This unit consists of a compressor, a heat exchanger, and a refrigerant circulator. It uses electric power to liquefy BOG into LNG and return it to the storage tank. The gas composition does not change but the unit consumes some power. The unit is standalone, easy to install and remove, and can be operated without a refueling station. |

| Scenario 4 (Sc4) | LNG refueling station (Sc1) + compressed natural gas (CNG) tank, CNG pump, dispenser | This is a complex refueling station that combines LNG and CNG. The unit stores BOG compressed with high pressure in a storage tank, and supplies it to CNG vehicles. It is most suitable for BOG management, but the operating cost increases because investment in initial facilities and installation area increase and additional operating personnel are required. |

| Parameters | Values | References |

|---|---|---|

| LNG purchase price ($/t) | 799.24 | [40] |

| Electricity price ($/kWh) | 0.09 | [41] |

| Carbon tax ($/t) | 29.00 | [43] |

| Financing equity ratio (%) | 40 | [39] |

| Term for debt financing (y) | 10 | [39] |

| Interest rate for debt financing (%) | 8 | [39] |

| Income tax (%) | 35 | [39] |

| Plant depreciation (y) | 7 | [39] |

| Land (% of fixed capital investment) | 2 | [39] |

| Working capital (% of fixed capital investment) | 5 | [39] |

| Labor cost (full time, $/y) | 34,167 | [44] |

| Labor cost (part time, $/y) | 16,667 | [44] |

| Project period (y) | 15 | |

| Construction period (y) | 1 |

| Capital Cost ($) | ||||

|---|---|---|---|---|

| Sc1 | Sc2 | Sc3 | Sc4 | |

| Storage tank | 156,600 | 175,227 | 156,600 | 182,932 |

| Compressor and pump | 73,660 | 87,989 | 73,660 | 284,142 |

| Dispenser | 56,426 | 56,426 | 56,426 | 88,906 |

| Vaporizer and other equipment | 53,650 | 76,577 | 357,922 | 53,650 |

| Total installed equipment cost | 340,336 | 396,219 | 644,608 | 609,630 |

| Total direct costs | 408,403 | 475,463 | 754,191 | 743,748 |

| Total indirect costs | 240,617 | 280,127 | 475,076 | 418,816 |

| Fixed capital investment | 649,021 | 755,589 | 1,229,267 | 1,162,564 |

| Total capital investment | 694,452 | 808,481 | 1,315,316 | 1,243,944 |

| Operating Cost ($/y) | ||||

| Sc1 | Sc2 | Sc3 | Sc4 | |

| LNG purchase | 2,836,943 | 2,836,943 | 2,836,943 | 2,836,943 |

| Electricity | 7500 | 7500 | 25,219 | 23,421 |

| LN2 | - | 328,572 | - | - |

| Carbon tax | 168,835 | - | - | - |

| BOG loss | 221,576 | - | - | - |

| Fixed operating costs | 64,723 | 84,504 | 111,307 | 109,880 |

| Total operating costs | 3,299,576 | 3,257,518 | 2,973,469 | 2,970,244 |

| Discount Rate (%) | |||||

|---|---|---|---|---|---|

| 5 | 8 | 10 | 12 | 15 | |

| NPV (USD 1000) | 404,658 | 220,194 | 123,468 | 42,753 | −55,058 |

| DPBP (year) | 9.87 | 12.01 | 13.02 | 14.61 | - |

| PVR | 1.0341 | 1.0337 | 1.0335 | 1.0333 | 1.0330 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-S.; Cho, C.-H. An Economical Boil-Off Gas Management System for LNG Refueling Stations: Evaluation Using Scenario Analysis. Energies 2022, 15, 8526. https://doi.org/10.3390/en15228526

Kim H-S, Cho C-H. An Economical Boil-Off Gas Management System for LNG Refueling Stations: Evaluation Using Scenario Analysis. Energies. 2022; 15(22):8526. https://doi.org/10.3390/en15228526

Chicago/Turabian StyleKim, Hyun-Seung, and Churl-Hee Cho. 2022. "An Economical Boil-Off Gas Management System for LNG Refueling Stations: Evaluation Using Scenario Analysis" Energies 15, no. 22: 8526. https://doi.org/10.3390/en15228526

APA StyleKim, H.-S., & Cho, C.-H. (2022). An Economical Boil-Off Gas Management System for LNG Refueling Stations: Evaluation Using Scenario Analysis. Energies, 15(22), 8526. https://doi.org/10.3390/en15228526