Spray Cooling as a High-Efficient Thermal Management Solution: A Review

Abstract

1. Introduction

2. Heat-Transfer Mechanism and Influence Factors of Spray Cooling

2.1. Influence of Spray Parameters on Heat-Transfer Performance

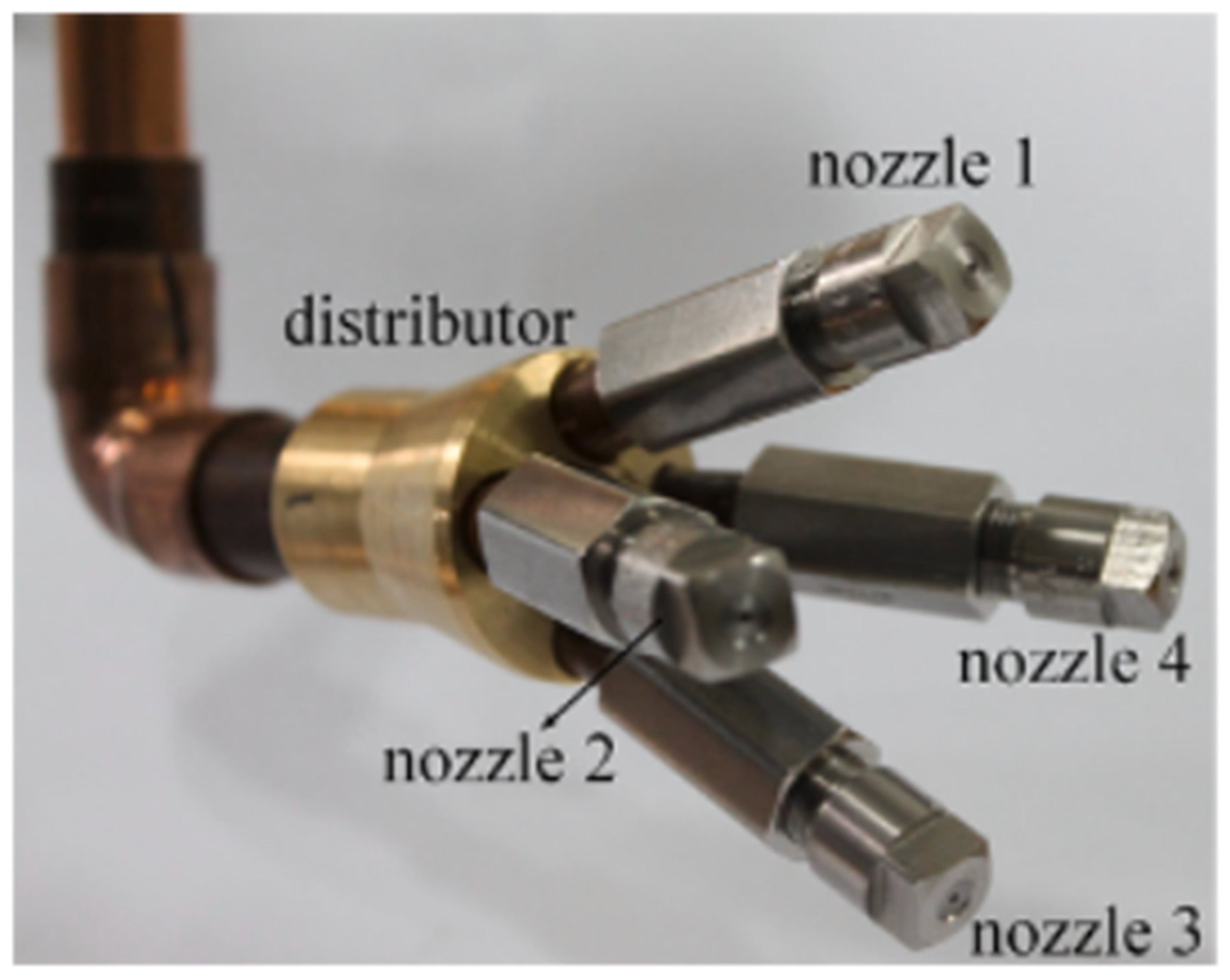

2.1.1. Nozzle Type

2.1.2. Flow Rate

2.1.3. Spray Distance and Spurt Duration

2.1.4. Spray Angle

2.2. Properties of the Working Fluid on Heat-Transfer Performance

2.2.1. Coolant Used in Spray Cooling

2.2.2. Soluble Additives

2.2.3. Nanofluids Adopted in Spray Cooling

2.3. Surface Modification

2.4. System and Environmental Parameters

3. Practical Applications and Challenges

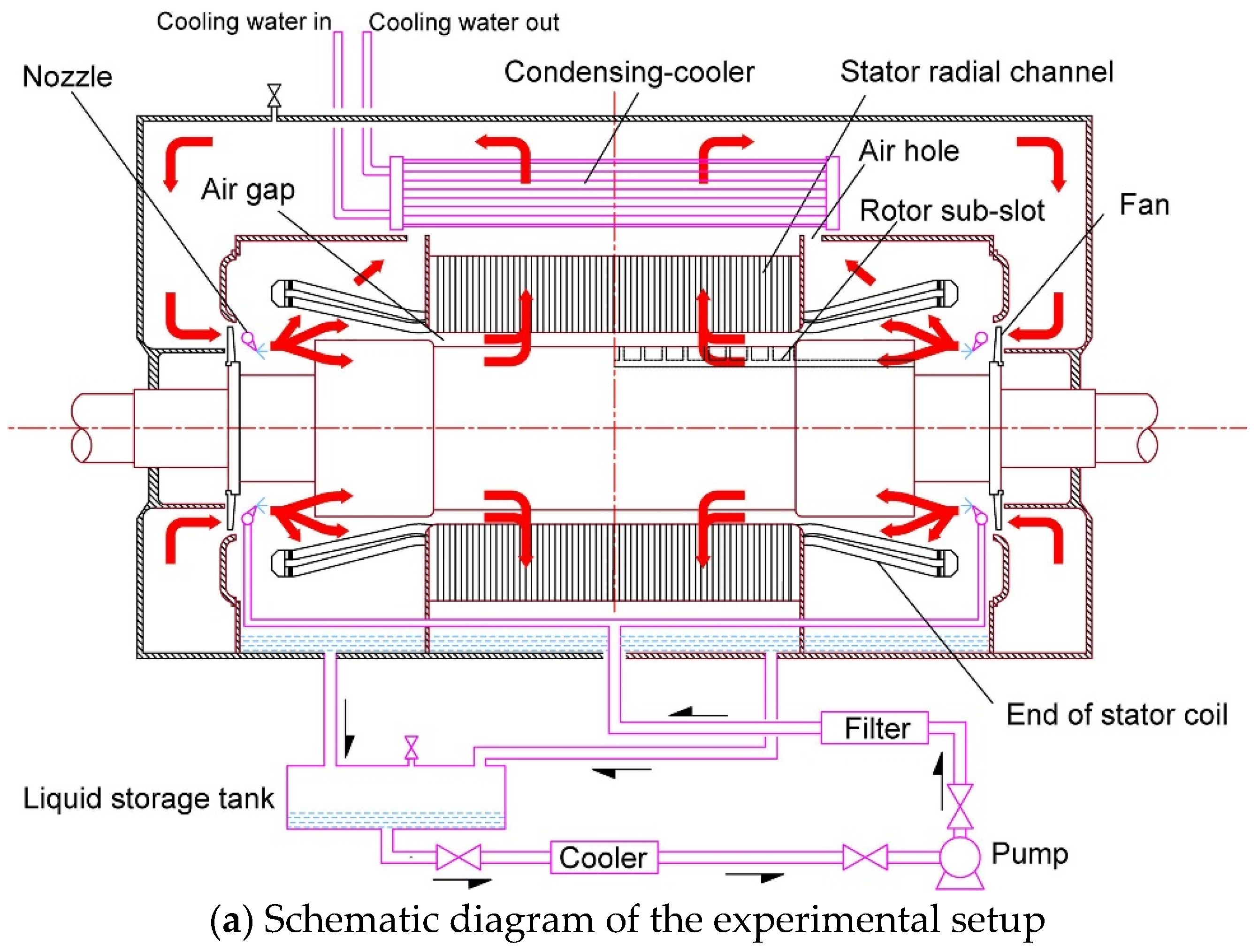

3.1. Configurations of Spray System

3.2. Applications of Spray System

3.2.1. High-Performance Computer and Data Center

3.2.2. Aerospace and Spacecraft

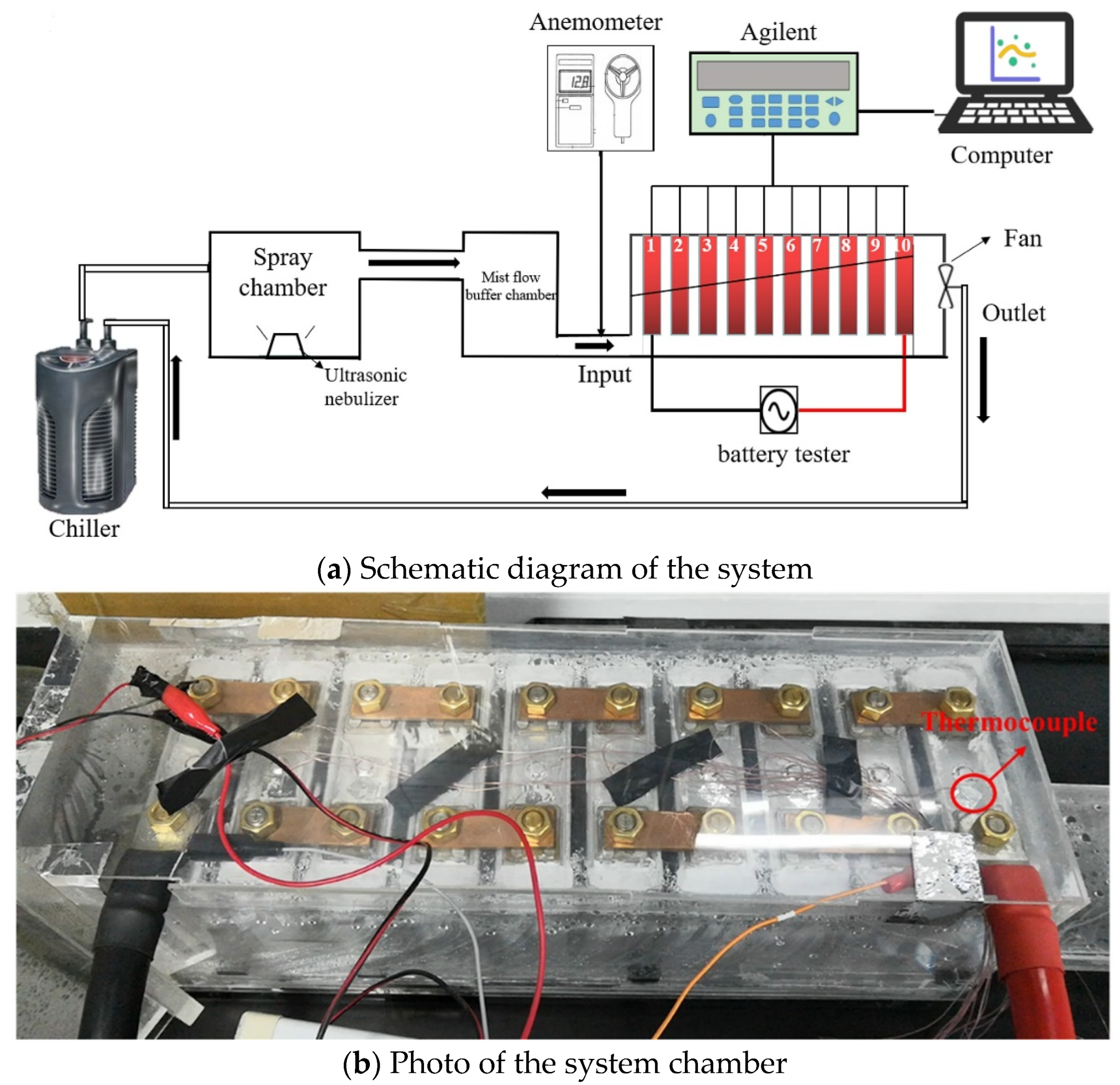

3.2.3. Hybrid Electric Vehicle

3.2.4. Reactor Pressure Vessel

3.3. Challenges and Future Work

- (1)

- Owing to the multiple parameters and their complicated interrelation in the spray cooling system with different equipment and experimental conditions, the heat-transfer laws derived are less universal, and in absence of the refinement of crucial factors to establishing a more unified heat-transfer theory. For example, for the same kind of coolant, the optimal parameters (flow rate, subcooled degree, etc.) to achieve the best cooling performance are usually different in different experimental systems.

- (2)

- There are still great challenges in the quantitative measurement of atomization characteristics of the neat nozzle outlet, especially lacking reliable technical means for the accurate measurement of droplet temperature and velocity in the low-temperature fog field without interference.

- (3)

- Some present strategies to enhance the cooling performance of spray systems are of low practicality in industry. For instance, microstructure/nanostructure surface modification are expensive, and macroscopic ribbed fin structures cannot achieve the desired improvement in cooling performance of spray systems due to the design requirements of electronic device package sizes. In future work, 3D printing or all-in-one packaging technology can be innovatively and reasonably introduced.

- (4)

- To adapt the dynamic heat load of electronic equipment, the cooling ability can only be regulated by adjusting the system pressure, yielding the delayed control of spray system, especially in the case of rapidly changed dynamic thermal load. In future, it is urgent to increase the response speed of the spray system to reach the steady state, i.e., the ability to quickly match the cooling capacity with dynamic heat load.

- (5)

- As a key part of spray-cooling systems, the structural design of nozzles is generally more complex. When system works for a long time, the nozzle is prone to blockage or corrosion. For some compact spray systems, the pipeline will also suffer blockage and throttling faults. In future practical system designs, nozzle structure, pipeline laying, maintenance difficulty, and other factors should be considered.

- (6)

- Current electronic devices tend to be more miniaturized and integrated. How to adapt complex spray-cooling systems to the limited space in small electronic devices is critical to further develop the application of spray-cooling technology.

4. Conclusions

- (1)

- Compared with the traditional cooling technology, spray cooling has advantages of small heat-transfer temperature difference, large cooling capacity, and uniform temperature distribution on the cooling surface, which has great potential in the future heat dissipation of high-power equipment.

- (2)

- There are many parameters affecting the cooling performance of spray systems, including spray parameters, types of working fluid, surface modification, and environmental parameters. Complicated interrelation exists between these multiple parameters, and the parameter sets to achieve optimal cooling effect are generally different.

- (3)

- Spray cooling systems have been designed for high-performance computers and data centers, spacecraft, hybrid electric vehicles, and reactor pressure vessels, but have not been widely industrialized. Compared with traditional thermal management solutions, spray cooling shows better cooling performance and temperature-control characteristics.

- (4)

- The scientific challenges and technical bottlenecks encountered in theoretical research and industrial application of spray-cooling technology were discussed and analyzed, and the directions of important research significance in the future were reasonably speculated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| CHF | critical heat flux (W/cm2) |

| hfg | latent heat of vaporization at 1 atm (kJ/kg) |

| HTC | heat-transfer coefficient (W/cm2K) |

| SMD | Sauter mean diameter (mm) |

| Tb | boiling point at 1 atm (°C) |

| Tsat | saturation temperature of coolant corresponding to spray chamber pressure (°C) |

| Tw | average temperature on the hot surface (°C) |

| Δt | spurt duration (s) |

| Greek symbols | |

| η | cooling efficiency (%) |

References

- Janicki, M.; Napieralski, A. Modelling electronic circuit radiation cooling using analytical thermal model. Microelectron. J. 2000, 31, 781–785. [Google Scholar] [CrossRef]

- Pokorni, S. Reliability prediction of electronic equipment: Problems and experience. In Proceedings of the 7th International Scientific Conference on Defensive Technologies OTEH, Belgrade, Serbia, 6–7 October 2016. [Google Scholar]

- Hsieh, S.-S.; Luo, S.-Y. Droplet impact dynamics and transient heat transfer of a micro spray system for power electronics devices. Int. J. Heat Mass Transf. 2016, 92, 190–205. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Maurer, J.J.; Felbinger, J.G. Darpa’s intra/interchip enhanced cooling (icecool) program. In Proceedings of the 2013 International Conference on Compound Semiconductor Manufacturing Technology, CS MANTECH 2013, New Orleans, LA, USA, 13–16 May 2013; pp. 171–174. [Google Scholar]

- Mudawar, I. Assessment of high-heat-flux thermal management schemes. IEEE Trans. Compon. Packag. Technol. 2001, 24, 122–141. [Google Scholar] [CrossRef]

- Xu, R.; Wang, G.; Jiang, P. Spray cooling on enhanced surfaces: A review of the progress and mechanisms. J. Electron. Packag. 2021, 144, 010802. [Google Scholar] [CrossRef]

- Sefiane, K.; Kosar, A. Prospects of heat transfer approaches to dissipate high heat fluxes: Opportunities and challenges. Appl. Therm. Eng. 2022, 215, 118990. [Google Scholar] [CrossRef]

- Tilton, D.E.; Pais, M.R.; Chow, L. High Power Density Spray Cooling; Wright Laboratory: New Haven, OH, USA, 1989. [Google Scholar]

- Rini, D.; Chen, R.-H.; Chow, L. Bubble behavior and nucleate boiling heat transfer in saturated FC72 spray cooling. J. Heat Transf.-Trans. ASME 2002, 124, 63–72. [Google Scholar] [CrossRef]

- Mascarenhas, N.; Mudawar, I. Analytical and computational methodology for modeling spray quenching of solid alloy cylinders. Int. J. Heat Mass Transf. 2010, 53, 5871–5883. [Google Scholar] [CrossRef]

- Freund, S.; Pautsch, A.; Shedd, T.; Kabelac, S. Local heat transfer coefficients in spray cooling systems measured with temperature oscillation IR thermography. Int. J. Heat Mass Transf. 2007, 50, 1953–1962. [Google Scholar] [CrossRef]

- Aguilar, G.; Diaz, S.; Lavernia, E.; Nelson, J. Cryogen spray cooling efficiency: Improvement of port wine stain laser therapy through muttiple-intermittent cryogen spurts and laser pulses. Lasers Surg. Med. 2002, 31, 27–35. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, J.; Su, X.; Qian, Y.; Liu, L.; Liu, X. Experimental study on the characteristics of a closed loop R134-a spray cooling. Exp. Therm. Fluid Sci. 2014, 61, 194–200. [Google Scholar] [CrossRef]

- Hsieh, S.-S.; Tsai, H.-H. Thermal and flow measurements of continous cryogenic spray cooling. Arch. Dermatol. Res. 2006, 298, 82–95. [Google Scholar] [CrossRef] [PubMed]

- Kim, J. Spray cooling heat transfer: The state of the art. Int. J. Heat Fluid Flow. 2007, 28, 753–767. [Google Scholar] [CrossRef]

- Martínez-Galván, E.; Antón, R.; Ramos, J.; Khodabandeh, R. Effect of the spray cone angle in the spray cooling with R134a. Exp. Therm. Fluid Sci. 2013, 50, 127–138. [Google Scholar] [CrossRef]

- Rashad, M.; Huang, Y.; Zekun, Z. Effect of geometric parameters on spray characteristics of pressure swirl atomizers. Int. J. Hydrogen Energy 2016, 41, 15790–15799. [Google Scholar] [CrossRef]

- Wang, R.; Rui; Zhou, Z.; Chen, B.; Bai, F.; Wang, G.-X. Surface heat transfer characteristics of R404A pulsed spray cooling with an expansion-chambered nozzle for laser dermatology. Int. J. Refrig. 2015. [Google Scholar] [CrossRef]

- Wang, X.; Chen, B.; Zhou, Z. Atomization and surface heat transfer characteristics of cryogen spray cooling with expansion-chambered nozzles. Int. J. Heat Mass Transf. 2018, 121, 15–27. [Google Scholar] [CrossRef]

- Karapetian, E.; Aguilar, G.; Lavernia, E.; Nelson, J. Effects of mass flow rate and droplet velocity on surface heat flux during cryogen spray cooling. Phys. Med. Biol. 2003, 48, N1–N6. [Google Scholar] [CrossRef]

- Zhou, N.; Chen, F.; Cao, Y.; Mengmeng, C.; Yu, W. Experimental investigation on the performance of a water spray cooling system. Appl. Therm. Eng. 2016, 112, 1117–1128. [Google Scholar] [CrossRef]

- Estes, K.; Mudawar, I. Correlation of Sauter mean diameter and critical heat flux for spray cooling of small surfaces. Int. J. Heat Mass Transf. 1995, 38, 2985–2996. [Google Scholar] [CrossRef]

- Rybicki, J.R.; Mudawar, I. Single-phase and two-phase cooling characteristics of upward-facing and downward-facing sprays. Int. J. Heat Mass Transf. 2006, 49, 5–16. [Google Scholar] [CrossRef]

- Karwa, N.; Kale, S.; Subbarao, P. Experimental study of non-boiling heat transfer from a horizontal surface by water sprays. Exp. Therm. Fluid Sci. 2007, 32, 571–579. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, W.-L.; Peng, Y.-H.; Zhang, W.-W.; Jiang, L.-J. Experimental study on optimal spray parameters of piezoelectric atomizer based spray cooling. Int. J. Heat Mass Transf. 2016, 103, 57–65. [Google Scholar] [CrossRef]

- Cheng, W.-L.; Zhang, W.-W.; Jiang, L.-J.; Yang, S.-L.; Hu, L.; Chen, H. Experimental investigation of large area spray cooling with compact chamber in the non-boiling regime. Appl. Therm. Eng. 2015, 80, 160–167. [Google Scholar] [CrossRef]

- Fu, H.; Zhao, R.; Long, W.; Cheng, W.-L. Study on Cooling performance of rapid cooling system based on Vacuum spray flash evaporation. Appl. Therm. Eng. 2022, 201, 117751. [Google Scholar] [CrossRef]

- Cheng, W.-L.; Han, F.-Y.; Liu, Q.-N.; Zhao, R.; Fan, H.-l. Experimental and theoretical investigation of surface temperature non-uniformity of spray cooling. Energy 2011, 36, 249–257. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Q.; Hu, D. Experimental investigation on heat transfer characteristics of R1336mzz flash spray cooling. Appl. Therm. Eng. 2020, 174, 115277. [Google Scholar] [CrossRef]

- Chen, R.-H.; Chow, L.C.; Navedo, J.E. Optimal spray characteristics in water spray cooling. Int. J. Heat Mass Transf. 2004, 47, 5095–5099. [Google Scholar] [CrossRef]

- Pautsch, A.G.; Shedd, T.A.; Nellis, G.F. Thickness measurements of the thin film in spray evaporative cooling. In Proceedings of the Ninth Intersociety Conference on Thermal and Thermomechanical Phenomena, Ninth Intersociety Conference on Thermal and Thermomechanical Phenomena In Electronic Systems (IEEE Cat. No.04CH37543), Las Vegas, NV, USA, 1–4 June 2004. [Google Scholar]

- Yan, Z.; Toh, K.; Duan, F.; Wong, T.; Choo, K.; Chan, P.; Chua, Y. Experimental study of impingement spray cooling for high power devices. Appl. Therm. Eng. 2010, 30, 1225–1230. [Google Scholar] [CrossRef]

- Pais, M.R.; Tilton, D.E.; Chow, L.; Mahefkey, E.T. High-heat-flux, low-superheat evaporative spray cooling. In Proceedings of the 27th Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1989. [Google Scholar]

- Aguilar, G.; Wang, G.-X.; Nelson, J. Effect of spurt duration on the heat transfer dynamics during cryogen spray cooling. Phys. Med. Biol. 2003, 48, 2169–2181. [Google Scholar] [CrossRef]

- Aguilar, G.; Wang, G.-X.; Nelson, J. Dynamic behavior of cryogen spray cooling: Effects of spurt duration and spray distance. Lasers Surg. Med. 2003, 32, 152–159. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, B.; Wang, Y.; Guo, L.; Wang, G.-X. An experimental study on pulsed spray cooling with refrigerant R-404a in laser surgery. Appl. Therm. Eng. 2012, 39, 29–36. [Google Scholar] [CrossRef]

- Tian, J.; Bufa, L.; Wang, J.; Chen, B.; Zhou, Z.; Wang, H. Transient analysis of cryogenic cooling performance for high-power semiconductor lasers using flash-evaporation spray. Int. J. Heat Mass Transf. 2022, 195, 123216. [Google Scholar] [CrossRef]

- Tian, J.; Chen, B.; Zhou, Z.; Li, D. Theoretical study on cryogen spray cooling in laser treatment of Ota’s Nevus: Comparison and optimization of R134a, R404A and R32. Energies 2020, 13, 5647. [Google Scholar] [CrossRef]

- Mudawar, I.; Estes, K.A. Optimizing and predicting CHF in spray cooling of a square surface. J. Heat Transf.-Trans. ASME 1996, 118, 672–679. [Google Scholar] [CrossRef]

- Cheng, W.-L.; Liu, Q.-N.; Zhao, R.; Fan, H.-l. Experimental investigation of parameters effect on heat transfer of spray cooling. Heat Mass Transf. 2010, 46, 911–921. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, R.; Chen, B.; Yang, T.; Wang, G.-X. Heat transfer characteristics during pulsed spray cooling with R404A at different spray distances and back pressures. Appl. Therm. Eng. 2016, 102, 813–821. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhi, f.; Chen, B.; Wang, R.; Bai, F.-l.; Wang, G.-x. Coupling effect of hypobaric pressure and spray distance on heat transfer dynamics of R134a pulsed flashing spray cooling. Exp. Therm. Fluid Sci. 2016, 70, 96–104. [Google Scholar] [CrossRef]

- Tian, J.-M.; Chen, B.; Zhou, Z. Parametric effect investigation on surface heat transfer performances during cryogen spray cooling. Appl. Therm. Eng. 2018, 143, 767–776. [Google Scholar] [CrossRef]

- Sarmadian, A.; Dunne, J.F.; Jose, J.; Long, C.A.; Pirault, J.P. Correlation models of critical heat flux and associated temperature for spray evaporative cooling of vibrating surfaces. Int. J. Heat Mass Transf. 2021, 179, 121735. [Google Scholar] [CrossRef]

- Sarmadian, A.; Jose, J.; Dunne, J.F.; Long, C.A.; Pirault, J.P.; Rouaud, C. The effect of key parameter changes on the critical heat flux of spray evaporatively-cooled vibrating surfaces using a single misting nozzle. Appl. Therm. Eng. 2022, 213, 118815. [Google Scholar] [CrossRef]

- Schwarzkopf, J.; Cader, T.; Okamoto, K.; Li, B.Q.; Ramaprian, B. Effect of spray angle in spray cooling thermal management of electronics. In Proceedings of the ASME 2004 Heat Transfer/Fluids Engineering Summer Conference, Charlotte, NC, USA, 11–15 July 2004. [Google Scholar]

- Silk, E.; Kim, J.; Kiger, K. Investigation of enhanced surface spray cooling. In Proceedings of the ASME 2004 International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004. [Google Scholar]

- Li, B.Q.; Cader, T.; Schwarzkopf, J.; Okamoto, K.; Ramaprian, B. Spray angle effect during spray cooling of microelectronics: Experimental measurements and comparison with inverse calculations. Appl. Therm. Eng. 2006, 26, 1788–1795. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, M.; Liu, D.; Xu, K.; Chen, Y. Experimental study on the effects of spray inclination on water spray cooling performance in non-boiling regime. Exp. Therm. Fluid Sci. 2010, 34, 933–942. [Google Scholar] [CrossRef]

- Jiang, L.-J.; Jiang, S.-L.; Cheng, W.-L.; Nian, Y.L.; Zhao, R. Experimental study on heat transfer performance of a novel compact spray cooling module. Appl. Therm. Eng. 2019, 154, 150–156. [Google Scholar] [CrossRef]

- Guo, Y.-X.; Zhou, Z.; Jia, J.-Y.; Zhou, S.-R. Optimal heat transfer criterion and inclination angle effects on non-boiling regime spray cooling. In Proceedings of the 2009 25th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 15–19 March2009. [Google Scholar]

- Qiao, Y.M.; Chandra, S. Experiments on adding a surfactant to water drops boiling on a hot surface. Proc. R. Soc. Lond. A 1997, 453, 673–689. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, B.; Wang, R.; Wang, G.-X. Comparative investigation on the spray characteristics and heat transfer dynamics of pulsed spray cooling with volatile cryogens. Exp. Therm. Fluid Sci. 2016, 82, 189–197. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Nieto de Castro, C. A critical review of traditional and emerging techniques and fluids for electronics cooling. Renew. Sust. Energy Rev. 2017, 78, 821–833. [Google Scholar] [CrossRef]

- Lin, L.; Ponnappan, R. Heat transfer characteristics of spray cooling in a closed loop. Int. J. Heat Mass Transf. 2003, 46, 3737–3746. [Google Scholar] [CrossRef]

- Zhou, N.; Feng, H.; Guo, Y.; Chen, H.; Liu, W.; Peng, H.; Lei, Y.; Deng, S.; Xu, Y. Experimental study on the spray cooling heat transfer performance and dimensionless correlations for ethylene glycol water solution. Appl. Therm. Eng. 2022, 214, 118824. [Google Scholar] [CrossRef]

- Liu, H.; Cai, C.; Jia, M.; Gao, J.; Yin, H.; Chen, H. Experimental investigation on spray cooling with low-alcohol additives. Appl. Therm. Eng. 2018, 146, 921–930. [Google Scholar] [CrossRef]

- Sadafi, H.; Gonzalez Ruiz, S.; Vetrano, M.R.; Jahn, I.; Beeck, J.; Buchlin, J.-M.; Hooman, K. An investigation on spray cooling using saline water with experimental verification. Energy Convers. Manag. 2016, 108, 336–347. [Google Scholar] [CrossRef]

- He, F.; Wu, N.; Zhou, Z.; Wang, J. Experimental investigation on transpiration cooling using propylene glycol aqueous solution. Int. J. Therm. Sci. 2021, 164, 106890. [Google Scholar] [CrossRef]

- Bhatt, N.; Karna, L.; Raj, R.; Varshney, P.; Pati, A.; Chouhan, D.; Kumar, A.; Munshi, B.; Mohapatra, S. Enhancement of heat transfer rate of high mass flux spray cooling by ethanol-water and ethanol-tween20-water solution at very high initial surface temperature. Int. J. Heat Mass Transf. 2017, 110, 330–347. [Google Scholar] [CrossRef]

- Mudawar, I.; Valentine, W. Determination of the local quench curve for spray-cooled metallic surfaces. J. Heat Treat. 1989, 7, 107–121. [Google Scholar] [CrossRef]

- Chen, R.-H.; Chow, L.; Navedo, J. Effects of spray characteristics on critical heat flux in subcooled water spray cooling. Int. J. Heat Mass Transf. 2002, 45, 4033–4043. [Google Scholar] [CrossRef]

- Pais, M.R.; Chow, L.C.; Mahefkey, E.T. Surface roughness and its effects on the heat transfer mechanism in spray cooling. J. Heat Transf. 1992, 114, 211–219. [Google Scholar] [CrossRef]

- Hsieh, S.-S.; Fan, T.-C.; Tsai, H.-H. Spray cooling characteristics of water and R-134a. Part II: Transient cooling. Int. J. Heat Mass Transf. 2004, 47, 5713–5724. [Google Scholar] [CrossRef]

- Lin, Y.; Zhou, Z.; Fang, Y.; Tang, H.-L.; Chen, B. Heat transfer performance and optimization of a close-loop R410A flash evaporation spray cooling. Appl. Therm. Eng. 2019, 159, 113966. [Google Scholar] [CrossRef]

- Zimmermann, S.; Meijer, I.; Tiwari, M.K.; Paredes, S.; Michel, B.; Poulikakos, D. Aquasar: A hot water cooled data center with direct energy reuse. Energy 2012, 43, 237–245. [Google Scholar] [CrossRef]

- Kadam, S.; Kumar, R. Twenty first century cooling solution: Microchannel heat sinks. Int. J. Therm. Sci. 2014, 85, 73–92. [Google Scholar] [CrossRef]

- Mohapatra, S. An overview of liquid coolants for electronics cooling. Electron. Cool. 2006, 12, 1–6. [Google Scholar]

- Visaria, M.; Mudawar, I. Effects of high subcooling on two-phase spray cooling and critical heat flux. Int. J. Heat Mass Transf. 2008, 51, 5269–5278. [Google Scholar] [CrossRef]

- Hou, Y.; Liu, X.; Liu, J.; Li, M.; Pu, L. Experimental study on phase change spray cooling. Exp. Therm. Fluid Sci. 2013, 46, 84–88. [Google Scholar] [CrossRef]

- Chen, S.; Liu, J.; Liu, X.; Hou, Y. An experimental comparison of heat transfer characteristic between R134-a and R22 in spray cooling. Exp. Therm. Fluid Sci. 2015, 66, 206–212. [Google Scholar] [CrossRef]

- Tian, J.-M.; Chen, B.; Li, D.; Zhou, Z. Transient spray cooling: Similarity of dynamic heat flux for different cryogens, nozzles and substrates. Int. J. Heat Mass Transf. 2017, 108, 561–571. [Google Scholar] [CrossRef]

- Bellerova, H.; Tseng, A.; Pohanka, M.; Raudensky, M. Spray cooling by solid jet nozzles using alumina/water nanofluids. Int. J. Therm. Sci. 2011, 62, 127–137. [Google Scholar] [CrossRef]

- Bellerova, H.; Tseng, A.; Pohanka, M.; Raudensky, M. Heat transfer of spray cooling using alumina/water nanofluids with full cone nozzles. Heat Mass Transf. 2012, 48, 1971–1983. [Google Scholar] [CrossRef]

- Tseng, A.; Bellerova, H.; Pohanka, M.; Raudensky, M. Effects of titania nanoparticles on heat transfer performance of spray cooling with full cone nozzle. Appl. Therm. Eng. 2014, 62, 20–27. [Google Scholar] [CrossRef]

- Qiao, Y.M.; Chandra, S. Spray cooling enhancement by addition of a surfactant. J. Heat Transf. 1998, 120, 92–98. [Google Scholar] [CrossRef]

- Liu, N.; Yu, Z.; Liang, Y.; Zhang, H. Effects of mixed surfactants on heat transfer performance of pulsed spray cooling. Int. J. Heat Mass Transf. 2019, 144, 118593. [Google Scholar] [CrossRef]

- Cheng, W.-L.; Xie, B.; Han, F.; Chen, H. An experimental investigation of heat transfer enhancement by addition of high-alcohol surfactant (HAS) and dissolving salt additive (DSA) in spray cooling. Exp. Therm. Fluid Sci. 2013, 45, 198–202. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sarkar, I.; Roshan, A.; Pal, S.; Chakraborty, S. Spray cooling of hot steel plate using aqueous solution of surfactant and polymer. Therm. Sci. Eng. Prog. 2019, 10, 217–231. [Google Scholar] [CrossRef]

- Panda, A.; Kumar, A.; Mohapatra, S. Water soluble polymer added high mass flux spray: A novel approach for the attainment of enhanced heat transfer rate in transition boiling regime. Int. J. Heat Mass Transf. 2020, 157, 119838. [Google Scholar] [CrossRef]

- Tilton, D.E.; Chow, L.; Mahefkey, E.T.; Switzer, G.L. Critical heat flux phenomena in spray cooling. In Proceedings of the 5th AIAA and ASME, Joint Thermophysics and Heat Transfer Conference, Seattle, WA, USA, 18–20 June 1990. [Google Scholar]

- Jia, W.; Qiu, H. Experimental investigation of droplet dynamics and heat transfer in spray cooling. Exp. Therm. Fluid Sci. 2003, 27, 829–838. [Google Scholar] [CrossRef]

- Cui, Q.; Chandra, S.; McCahan, S. The effect of dissolving gases or solids in water droplets boiling on a hot surface. J. Heat Transf.-Trans. ASME 2001, 123, 719–728. [Google Scholar] [CrossRef]

- Cui, Q.; Chandra, S.; McCahan, S. The effect of dissolving salts in water sprays used for quenching a hot surface: Part 1—Boiling of single droplets. J. Heat Transf.-Trans. ASME 2003, 125, 326–332. [Google Scholar] [CrossRef]

- Mohapatra, S.; Bandaru, R.; Andhare, S.; Chakraborty, S.; Pal, S. Experimental study and optimization of air atomized spray with surfactant added water to produce high cooling rate. J. Enhanc. Heat Transf. 2012, 19, 397–408. [Google Scholar] [CrossRef]

- Bandaru, R.; Jha, J.; Sarkar, I.; Mohapatra, S.; Pal, S.; Chakraborty, S. Achievement of ultrafast cooling rate in a hot steel plate by air-atomized spray with different surfactant additives. Exp. Therm. Fluid Sci. 2013, 50, 79–89. [Google Scholar] [CrossRef]

- Bandaru, R.; Jha, J.; Sarkar, I.; Pal, S.; Chakraborty, S. Mixed-surfactant additives for enhancement of air-atomized spray cooling of a hot steel plate. Exp. Therm. Fluid Sci. 2014, 55, 210–220. [Google Scholar] [CrossRef]

- Liu, N.; Zhan, T.-J.; Zhang, Y.-W.; Yin, X.-M.; Zhang, L.-X. Experimental investigation of comprehensive effects of surfactant and inclined mode on spray cooling heat transfer. Int. J. Therm. Sci. 2019, 136, 457–466. [Google Scholar] [CrossRef]

- Zhang, W.-W.; Li, Y.-Y.; Long, W.-J.; Cheng, W.-L. Enhancement mechanism of high alcohol surfactant on spray cooling: Experimental study. Int. J. Heat Mass Transf. 2018, 126, 363–376. [Google Scholar] [CrossRef]

- Aksoy, Y.; Zhu, Y.; Eneren, P.; Koos, E.; Vetrano, M.R. The impact of nanofluids on droplet/spray cooling of a heated surface: A critical review. Energies 2020, 14, 80. [Google Scholar] [CrossRef]

- Hsieh, S.-S.; Leu, H.-Y.; Liu, H.-H. Spray cooling characteristics of nanofluids for electronic power devices. Nanoscale Res. Lett. 2015, 10, 139. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, S.-S.; Liu, H.-H.; Yeh, Y.-F. Nanofluids spray heat transfer enhancement. Int. J. Heat Mass Transf. 2016, 94, 104–118. [Google Scholar] [CrossRef]

- Malý, M.; Moita, A.S.; Jedelsky, J.; Ribeiro, A.; Moreira, A.L.N. Effect of nanoparticles concentration on the characteristics of nanofluid sprays for cooling applications. J. Therm. Anal. Calorim. 2018, 135, 3375–3386. [Google Scholar] [CrossRef]

- Chang, T.-B.; Lin, T.-H.; Huang, J.-W. Effects of spray operating time on spray cooling heat transfer performance and surface hydrophilicity using Al2O3-water nanofluid. J. Mech. Sci. Technol. 2018, 32, 2897–2904. [Google Scholar] [CrossRef]

- Tiara, A.; Chakraborty, S.; Sarkar, I.; Pal, S.; Chakraborty, S. Heat Transfer in Jet Impingement on a hot steel surface using Surfactant based Cu-Al layered double hydroxide Nanofluid. Int. J. Heat Mass Transf. 2016, 101, 825–833. [Google Scholar] [CrossRef]

- Assael, M.; Chen, C.F.; Metaxa, I.; Wakeham, W. Thermal Conductivity of Suspensions of Carbon Nanotubes in Water. Int. J. Thermophys. 2004, 25, 971–985. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q.; Tie, P. The effect of surfactants on heat transfer feature of nanofluids. Exp. Therm. Fluid Sci. 2013, 46, 259–262. [Google Scholar] [CrossRef]

- Bandaru, R.; Haldar, K.; Jha, J.; Chakraborty, S.; Sarkar, I.; Pal, S.; Chakraborty, S. Heat transfer enhancement using air-atomized spray cooling with water–Al2O3 nanofluid. Int. J. Therm. Sci. 2015, 96, 85–93. [Google Scholar] [CrossRef]

- Bandaru, R.; Jha, J.; Haldar, K.; Pal, S.; Chakraborty, S. Surfactant-Based Cu–Water Nanofluid Spray for Heat Transfer Enhancement of High Temperature Steel Surface. J. Heat Transf. 2015, 137, 051504. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sarkar, I.; Ashok, A.; Sengupta, I.; Pal, S.; Chakraborty, S. Synthesis of Cu-Al LDH nanofluid and its application in spray cooling heat transfer of a hot steel plate. Powder Technol. 2018, 335, 285–300. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sarkar, I.; Ashok, A.; Sengupta, I.; Pal, S.; Chakraborty, S. Thermo-physical properties of Cu-Zn-Al LDH nanofluid and its application in spray cooling. Appl. Therm. Eng. 2018, 141, 339–351. [Google Scholar] [CrossRef]

- Chakraborty, S.; Sengupta, I.; Sarkar, I.; Pal, S.; Chakraborty, S. Effect of surfactant on thermo-physical properties and spray cooling heat transfer performance of Cu-Zn-Al LDH nanofluid. Appl. Clay Sci. 2018, 168, 43–55. [Google Scholar] [CrossRef]

- Bingxing, W.; Liu, Z.; Zhang, B.; Xia, Y.; Wang, Z.; Wang, G. Effect of nanoparticle type and surfactant on heat transfer enhancement in spray cooling. J. Therm. Sci. 2020, 29, 708–717. [Google Scholar] [CrossRef]

- Bao, J.; Wang, Y.; Kosonen, R.; Xu, X.; Liu, J. Investigation on spray cooling heat transfer performance with different nanoparticles and surfactants. Heat Mass Transf. 2022, 58, 887–901. [Google Scholar] [CrossRef]

- Akram, S.; Athar, M.; Saeed, K. Numerical simulation of effects of Soret and Dufour parameters on the peristaltic transport of a magneto six-constant Jeffreys nanofluid in a non-uniform channel: A bio-nanoengineering model. Eur. Phys. J.-Spec. Top. 2021, 231, 535–543. [Google Scholar] [CrossRef]

- Akram, S.; Athar, M.; Saeed, K. Hybrid impact of thermal and concentration convection on peristaltic pumping of Prandtl nanofluids in non-uniform inclined channel and magnetic field. Case Stud. Therm. Eng. 2021, 25, 100965. [Google Scholar] [CrossRef]

- Akram, S.; Athar, M.; Saeed, K.; Razia, A.; Muhammad, T. Hybridized consequence of thermal and concentration convection on peristaltic transport of magneto Powell–Eyring nanofluids in inclined asymmetric channel. Math. Methods Appl. Sci. 2021, 1–17. [Google Scholar] [CrossRef]

- Akram, S.; Athar, M.; Saeed, K.; Razia, A.; Alghamdi, M.; Muhammad, T. Impact of partial slip on double diffusion convection of sisko nanofluids in asymmetric channel with peristaltic propulsion and inclined magnetic field. Nanomaterials 2022, 12, 2736. [Google Scholar] [CrossRef]

- Athar, M.; Khan, Y.; Akram, S.; Saeed, K.; Alameer, A.; Hussain, A. Consequence of double-diffusion convection and partial slip on magneto-oldroyd-4 constants nanofluids with peristaltic propulsion in an asymmetric channel. Complexity 2022, 2022, 1–20. [Google Scholar] [CrossRef]

- Khan, Y.; Akram, S.; Razia, A.; Hussain, A.; Sulaimani, H. Effects of double diffusive convection and inclined magnetic field on the peristaltic flow of fourth grade nanofluids in a non-uniform channel. Nanomaterials 2022, 12, 3037. [Google Scholar] [CrossRef] [PubMed]

- Saeed, K.; Akram, S.; Ahmad, A.; Athar, M. Impact of slip boundaries on double diffusivity convection in an asymmetric channel with magneto-tangent hyperbolic nanofluid with peristaltic flow. Z. Angew. Math. Mech. 2022, e202100338. [Google Scholar] [CrossRef]

- Saeed, K.; Athar, M.; Akram, S.; Razia, A.; Muhammad, T. Theoretical investigation of double diffusion convection of six constant Jeffreys nanofluid on waves of peristaltic with induced magnetic field: A bio-nano-engineering model. Waves Random Complex Media 2022, 1–21. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of pool boiling enhancement with additives and nanofluids. Int. J. Heat Mass Transf. 2018, 124, 423–453. [Google Scholar] [CrossRef]

- Yu, Y.; Qiu, Y.; Liu, J.; Chen, J.; Ding, Y.; Xie, J. Impact of geometrical surface modification on spray cooling heat transfer performance with liquid nitrogen: An experimental investigation. Cryogenics 2022, 122, 103438. [Google Scholar] [CrossRef]

- Salman, A.; Abdulrazzaq, N.; Oudah, S.; Tikadar, A.; Anumbe, N.; Paul, T.; Khan, J. Experimental investigation of the impact of geometrical surface modification on spray cooling heat transfer performance in the non-boiling regime. Int. J. Heat Mass Transf. 2019, 133, 330–340. [Google Scholar] [CrossRef]

- Zhou, Z.; Lin, Y.; Tang, H.-L.; Fang, Y.; Wang, Y.-C. Heat transfer enhancement due to surface modification in the close-loop R410A flash evaporation spray cooling. Int. J. Heat Mass Transf. 2019, 139, 1047–1055. [Google Scholar] [CrossRef]

- Wang, J.-X.; Li, Y.-Z.; Zhong, M.-L.; Zhang, H.-S. Investigation on a gas-atomized spray cooling upon flat and micro-structured surfaces. Int. J. Therm. Sci. 2020, 161, 106751. [Google Scholar] [CrossRef]

- Liu, P.; Kandasamy, R.; Ho, J.Y.; Xie, J.; Wong, T. Experimental study on heat transfer enhancement using combined surface roughening and macro-structures in a confined double-nozzle spray cooling system. Appl. Therm. Eng. 2021, 202, 117850. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Srinivasan, V. Enhanced Spray Cooling Using Micropillar Arrays: A Systematic Study. J. Heat Transf. 2020, 142, 092501. [Google Scholar] [CrossRef]

- Chen, J.; Xu, R.; Zhang, Z.; Chen, X.; Ouyang, X.-L.; Wang, G.; Jiang, P. Phenomenon and mechanism of spray cooling on nanowire arrayed and hybrid micro/nano structured surfaces. J. Heat Transf. 2018, 140, 112401. [Google Scholar] [CrossRef]

- Wang, H.; Wu, J.; Yang, Q.; Zhu, X.; Liao, Q. Heat transfer enhancement of ammonia spray cooling by surface modification. Int. J. Heat Mass Transf. 2016, 101, 60–68. [Google Scholar] [CrossRef]

- Xu, R.; Cao, L.; Wang, G.; Chen, J.-N.; Jiang, P. Experimental investigation of closed loop spray cooling with micro- and hybrid micro-/nano-engineered surfaces. Appl. Therm. Eng. 2020, 180, 115697. [Google Scholar] [CrossRef]

- Liu, N.; Yu, Z.; Zhu, T.; Yin, X.; Zhang, H. Effects of microstructured surface and mixed surfactants on the heat transfer performance of pulsed spray cooling. Int. J. Therm. Sci. 2020, 158, 106530. [Google Scholar] [CrossRef]

- Silk, E.A.; Kim, J.; Kiger, K. Spray cooling of enhanced surfaces: Impact of structured surface geometry and spray axis inclination. Int. J. Heat Mass Transf. 2006, 49, 4910–4920. [Google Scholar] [CrossRef]

- Bostanci, H.; Altalidi, S.S.; Nasrazadani, S. Two-phase spray cooling with HFC-134a and HFO-1234yf on practical enhanced surfaces. Appl. Therm. Eng. 2018, 131, 150–158. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Choi, C.; Lee, K.-j.; Han, D. Experimental study of spray cooling performance on micro-porous coated surfaces. Heat Mass Transf. 2009, 45, 1285–1292. [Google Scholar] [CrossRef]

- Silk, E.; Bracken, P. Spray cooling heat flux performance using POCO HTC foam. J. Thermophys. Heat Transf. 2010, 24, 157–164. [Google Scholar] [CrossRef]

- Ulson de Souza, A.G.; Barbosa, J.R. Spray cooling of plain and copper-foam enhanced surfaces. Exp. Therm. Fluid Sci. 2012, 39, 198–206. [Google Scholar] [CrossRef]

- Bostanci, H.; Rini, D.; Kizito, J.; Singh, V.; Seal, S.; Chow, L. High heat flux spray cooling with ammonia: Investigation of enhanced surfaces for CHF. Int. J. Heat Mass Transf. 2012, 55, 3849–3856. [Google Scholar] [CrossRef]

- Thiagarajan, S.J.; Narumanchi, S.; Yang, R. Effect of flow rate and subcooling on spray heat transfer on microporous copper surfaces. Int. J. Heat Mass Transf. 2014, 69, 493–505. [Google Scholar] [CrossRef]

- Puterbaugh, R.; Yerkes, K.; Thomas, S. Partially confined FC-72 spray-cooling performance: Effect of dissolved air. J. Thermophys. Heat Transf. 2008, 23, 107. [Google Scholar] [CrossRef]

- Elston, L.; Yerkes, K.; Thomas, S.; McQuillen, J. Effect of variable gravity on the cooling performance of a 16-nozzle spray array. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Horacek, B.; Kiger, K.; Kim, J. Single nozzle spray cooling heat transfer mechanisms. Int. J. Heat Mass Transf. 2005, 48, 1425–1438. [Google Scholar] [CrossRef]

- Liu, P.; Kandasamy, R.; Feng, H.; Wong, T.; Toh, K. Influence of air on heat transfer of a closed-loop spray cooling system. Exp. Therm. Fluid Sci. 2019, 111, 109903. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of spray cooling—Part 1: Single-phase and nucleate boiling regimes, and critical heat flux. Int. J. Heat Mass Transf. 2017, 115, 1174–1205. [Google Scholar] [CrossRef]

- Cheng, W.-L.; Zhang, W.-W.; Chen, H.; Hu, L. Spray cooling and flash evaporation cooling: The current development and application. Renew. Sustain. Energy Rev. 2016, 55, 614–628. [Google Scholar] [CrossRef]

- Wang, J.-X.; Guo, W.; Xiong, K.; Wang, S.-N. Review of aerospace-oriented spray cooling technology. Prog. Aerosp. Sci. 2020, 116, 100635. [Google Scholar] [CrossRef]

- Golliher, E.; Zivich, C.; Yao, S. Exploration of unsteady spray cooling for high power electronics at microgravity using NASA Glenn’s drop tower. In Proceedings of the ASME 2005 Summer Heat Transfer Conference collocated with the ASME 2005 Pacific Rim Technical Conference and Exhibition on Integration and Packaging of MEMS, NEMS, and Electronic Systems, San Francisco, CA, USA, 17–22 July 2005. [Google Scholar]

- Ohta, H.; Kawasaki, K.; Okada, S.; Azuma, H.; Yoda, S.; Nakamura, T. On the heat transfer mechanisms in microgravity nucleate boiling. Adv. Space Res. 1999, 24, 1325–1330. [Google Scholar] [CrossRef]

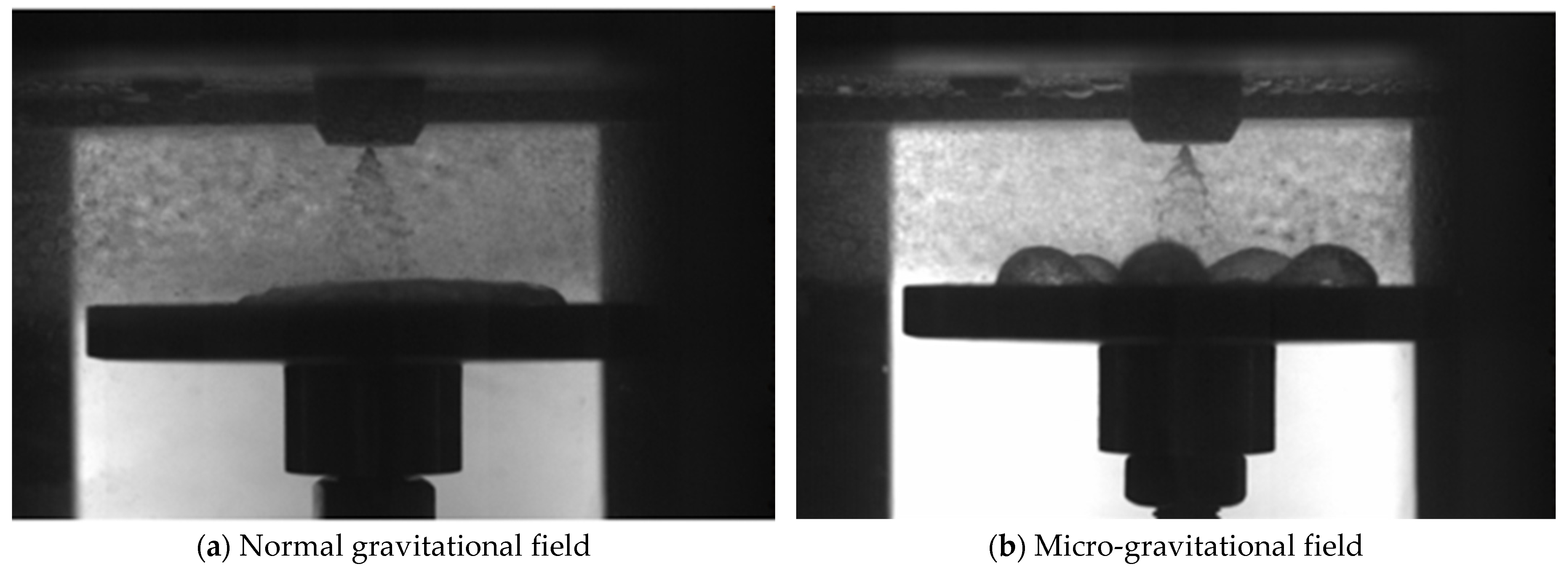

- Yoshida, K.-i.; Abe, Y.; Oka, T.; Mori, Y.; Nagashima, A. Spray cooling under reduced gravity condition. J. Heat Transf.-Trans. ASME 2001, 123, 309–318. [Google Scholar] [CrossRef]

- Gambaryan-Roisman, T.; Kyriopoulos, O.; Roisman, I.; Stephan, P.; Tropea, C. Gravity effect on spray impact and spray cooling. Microgravity Sci. Technol. 2007, 19, 151–154. [Google Scholar] [CrossRef]

- Elston, L.; Yerkes, K.; Thomas, S.; McQuillen, J. Cooling performance of a 16nozzle array in variable gravity. J. Thermophys. Heat Transf. 2009, 23, 571–581. [Google Scholar] [CrossRef]

- Xie, J.; Kandasamy, R.; Wong, T.N.; Lee, H.M. Comparative study on the heat transfer characteristics of spray cooling in confined spray chambers. Appl. Therm. Eng. 2019, 164, 114463. [Google Scholar] [CrossRef]

- Shedd, T. Next generation spray cooling: High heat flux management in compact spaces. Heat Transfer Eng. 2007, 28, 87–92. [Google Scholar] [CrossRef]

- Xu, X.; Wang, Y.; Jiang, y.; Liu, J.; Yuan, X. Recent advances on closed-loop spray cooling and the potential application on airborne system. J. Therm. Sci. 2020, 30, 32–50. [Google Scholar] [CrossRef]

- Xue, R.; Lin, X.; Ruan, Y.; Chen, L.; Hou, Y. Cooling performance of multi-nozzle spray with liquid nitrogen. Cryogenics 2021, 121, 103389. [Google Scholar] [CrossRef]

- Bandaru, S.V.R.; Villanueva, W.; Konovalenko, A.; Komlev, A.; Thakre, S.; Sköld, P.; Bechta, S. Upward-facing multi-nozzle spray cooling experiments for external cooling of reactor pressure vessels. Int. J. Heat Mass Transf. 2020, 163, 120516. [Google Scholar] [CrossRef]

- Smakulski, P.; Pietrowicz, S. A review of the capabilities of high heat flux removal by porous materials, microchannels and spray cooling techniques. Appl. Therm. Eng. 2016, 104, 636–646. [Google Scholar] [CrossRef]

- Kandasamy, R.; Ho, J.Y.; Liu, P.; Wong, T.; Toh, K. Two-phase spray cooling for high ambient temperature data centers: Evaluation of system performance. Appl. Energy 2022, 305, 117816. [Google Scholar] [CrossRef]

- Wang, J.-X.; Li, Y.-Z.; Zhang, Y.; Li, J.-X.; Mao, Y.-F.; Ning, X.-W. A hybrid cooling system combining self-adaptive single-phase mechanically pumped fluid loop and gravity-immune two-phase spray module. Energy Convers. Manag. 2018, 176, 194. [Google Scholar] [CrossRef]

- Wu, T.; Wang, C.; Hu, Y.; Fan, X.; Fan, C. Research on spray cooling performance based on battery thermal management. Int. J. Energy Res. 2022, 46, 8977–8988. [Google Scholar] [CrossRef]

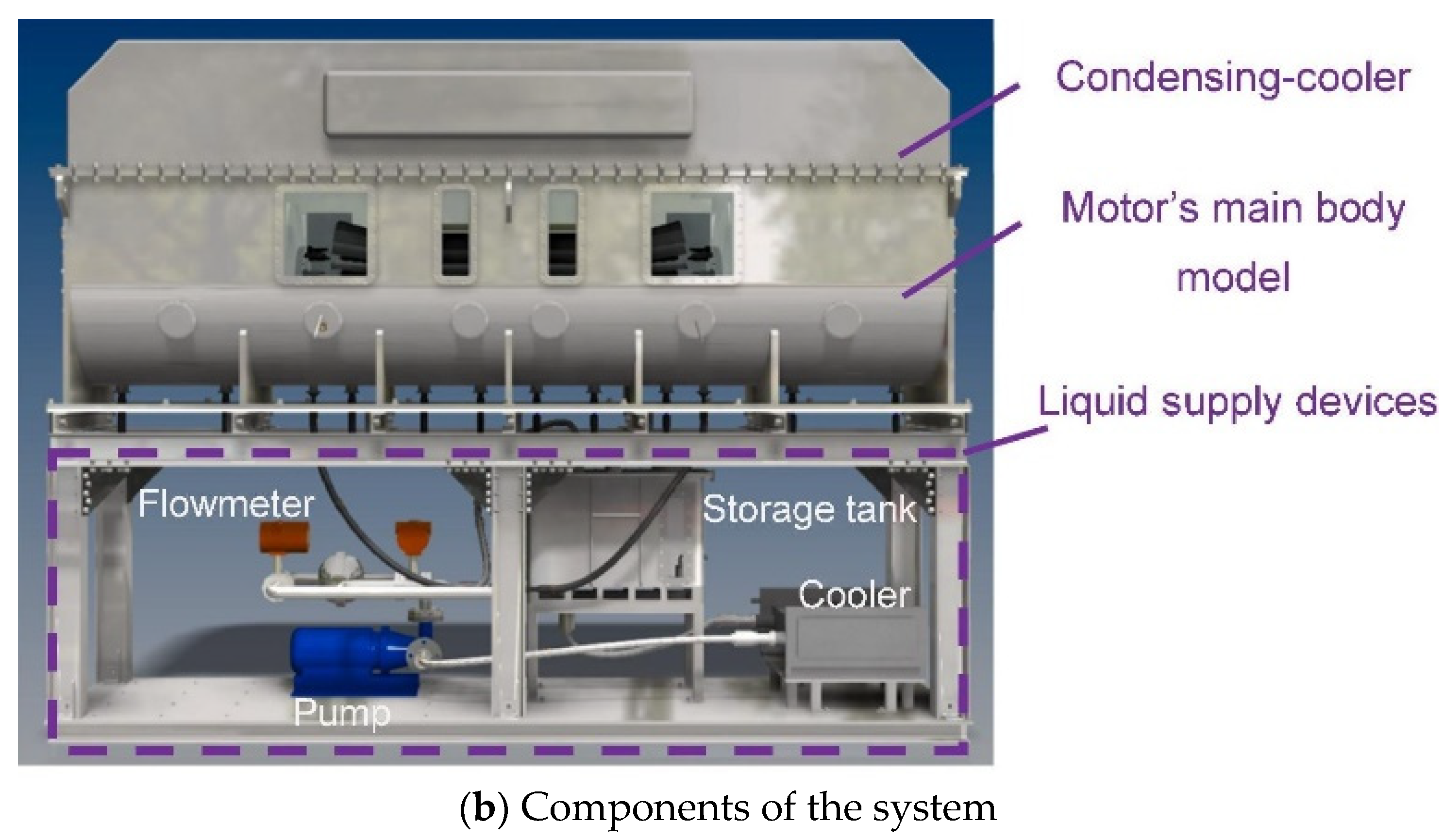

- Dong, H.; Ruan, L.; Wang, Y.; Yang, J.; Liu, F.; Guo, S. Performance of air/spray cooling system for large-capacity and high-power-density motors. Appl. Therm. Eng. 2021, 192, 116925. [Google Scholar] [CrossRef]

- Bandaru, R.; Villanueva, W.; Thakre, S.; Bechta, S. Multi-nozzle spray cooling of a reactor pressure vessel steel plate for the application of ex-vessel cooling. Nucl. Eng. Des. 2021, 375, 111101. [Google Scholar] [CrossRef]

| Authors | Working Fluid | Tb (°C) | hfg (kJ/kg) | Tsat (°C) | Tw (°C) | CHF (W/cm2) | HTC (W/cm2K) |

|---|---|---|---|---|---|---|---|

| Lin and Ponnappan [55] | Water | 100 | 2256 | 70 | 121.1 | >500 | 9.78 |

| Mudawar and Valentine [61] | Water | 100 | 2256 | 23 | 145 | 638 | 2.0615 |

| Chen et al. [62] | Water | 100 | 2256 | 25 | 137.8 | 945.7 | 8.38 |

| Pais et al. [63] | Water | 100 | 2256 | 24–29 | >100 | >1200 | - |

| Lin and Ponnappan [55] | Methanol | 64.7 | 1109 | 53 | 129 | 490 | 6.45 |

| Zhou et al. [56] | Ethylene glycol (EG) | - | - | 30 | >110 | 143.79 | 1.75 |

| Zhou et al. [56] | 65 wt% EG-water solution | - | - | 30 | >100 | 144.50 | 2.6 |

| Bhatt et al. [60] | 500 ppm ethanol solution | - | - | 25 | - | 200 | 0.9 |

| Liu et al. [57] | 4% n-propanol + 96% water | - | - | 25 | 120 | 420 | 4.75 |

| Lin and Ponnappan [55] | FC-87 | - | - | 54 | 97.7 | 90.0 | 2.06 |

| Lin and Ponnappan [55] | FC-72 | 56 | 88 | 42.5 | 79.9 | 83.5 | 2.23 |

| Visaria and Mudawar [69] | FC-77 | 97 | 89 | 25 | 129.4 | 349 | - |

| Hou et al. [70] | R22 | −40.8 | 233 | −3 | 26.8 | 276.1 | 7.1 |

| Hou et al. [13] | R134a | −26 | 217 | −10 | 46 | 117.2 | 2.55 |

| Tian et al. [72] | R134a | −26 | 217 | - | −46.1 | 29.49 | - |

| Tian et al. [72] | R407C | −43.6 | 250 | - | −55.9 | 36.41 | - |

| Tian et al. [72] | R404A | −46.8 | 207 | - | −57.9 | 37.74 | - |

| Lin et al. [65] | R410A | −51 | 279 | −11.7 | 30 | 264 | 21 |

| Scale | Author | Enhancement Strategy | Working Fluid | Highest Heat Flux (W/cm2) | Related Surface Temperature (°C) | Enhancement Rate |

|---|---|---|---|---|---|---|

| Marco | Yu et al. [114] | Straight-grooved surfaces with different groove depths | Liquid Nitrogen | 106.8 | ~127 | 64.2% in HTC |

| Macro | Wang et al. [117] | Cubic pin fins with different lengths on enhanced surfaces | Water | 643.4 | 50.1 | 54.4% in Heat flux, 57.4% in HTC |

| Macro & micro | Liu et al. [118] | Straight and pin fins. Flat surfaces with different roughness by EDM (electrical discharge machining) | Water | ~600 | ~120 | 136% in HTC for straight fin, 288% in HTC for pin fin |

| Marco | Salman et al. [115] | Circular grooves with radial grooves | Water | ~286 | ~90 | 80% in HTC |

| Micro | Muthukrishnan and Srinivasan [119] | Micropillar arrays | Water | ~830 (CHF) | ~120 | 25% in HTC |

| Macro & micro | Zhou et al. [116] | Pyramid and square fined Surfaces with silica nano-porous | R410A | 330 (CHF) | ~10 | 60% in CHF (marco), 85% in CHF (marco&micr) |

| Micro | Chen et al. [120] | Nanowire arrayed surfaces | Water | 243 (CHF) | ~120 | 110% in CHF |

| Marco & micro | Wang et al. [121] | Electrochemical corrosion surfaces, porous surfaces, and hybrid surfaces with straight-fin surfaces coated by a porous layer | Ammonia | 350 | ~−15 | 200% in heat flux |

| Marco & micro | Xu et al. [122] | Cubic pin fins with irregular ZnO nanowires | R134a | 180 (CHF) | ~73 | 59% in CHF, 42% in HTC |

| Marco | Liu et al. [123] | Straight fins | Water with different surfactants | ~43 | ~55 | 16.36 °C lower on surface 33.04% in HTC |

| Marco | Silk et al. [124] | Cubic pin fins, pyramids, and straight fins | PF-5060 | 140 (CHF) | ~70 | 46% in HTC |

| Micro | Bostanci et al. [125] | Electroplated-microporous surface sanded surface blasted surface | R134a and R1234yf | 370 (CHF) | 36.1 | 38.8% in CHF for R134a, 34.2% in CHF for R1234yf |

| Micro | Kim et al. [126] | Micro-porous particle coated surfaces with different particle size | Water | ~550 (CHF) | ~110 | 130% in HTC |

| Micro | Silk and Bracken [127] | Surfaces bonded and S-Bond soldered with 5.9 mm-high porous POCO HTC foam | PF-5060 | 133 | 120 | 66% in CHF |

| Micro | Augusto et al. [128] | Surface brazed with 5 mm-high copper foam | R134a | 30 (CHF) | / | 139% in HTC |

| Marco and micro | Bostanci et al. [129] | Pyramidal fins, triangular straight fins, rectangular fins, and square pin fins; indentations and protrusions fabricated by particle blasting and thermal spray coating | Ammonia | 910 (CHF) | ~53 | 18% in CHF 161% in HTC |

| Micro | Thiagarajan et al. [130] | Surface coated with 100 μm-thick 57% porosity 3M L-20,227 powder | HFE-7100 | ~188 | ~80 | 80% in CHF |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Wang, S.; Sang, X.; Zhou, Z.; Chen, B.; Thrassos, P.; Romeos, A.; Giannadakis, A. Spray Cooling as a High-Efficient Thermal Management Solution: A Review. Energies 2022, 15, 8547. https://doi.org/10.3390/en15228547

Yin J, Wang S, Sang X, Zhou Z, Chen B, Thrassos P, Romeos A, Giannadakis A. Spray Cooling as a High-Efficient Thermal Management Solution: A Review. Energies. 2022; 15(22):8547. https://doi.org/10.3390/en15228547

Chicago/Turabian StyleYin, Jing, Shangming Wang, Xuehao Sang, Zhifu Zhou, Bin Chen, Panidis Thrassos, Alexandros Romeos, and Athanasios Giannadakis. 2022. "Spray Cooling as a High-Efficient Thermal Management Solution: A Review" Energies 15, no. 22: 8547. https://doi.org/10.3390/en15228547

APA StyleYin, J., Wang, S., Sang, X., Zhou, Z., Chen, B., Thrassos, P., Romeos, A., & Giannadakis, A. (2022). Spray Cooling as a High-Efficient Thermal Management Solution: A Review. Energies, 15(22), 8547. https://doi.org/10.3390/en15228547