Research on the Mixing Mechanism and Parameter Optimization of Liquid Nitrogen Foam Generator

Abstract

1. Introduction

2. Models

2.1. Geometry Models

2.2. Mathematical Models

2.2.1. Turbulence Models

2.2.2. Mixture Multiphase Models

2.2.3. Evaporation-Condensation Models

2.3. Boundary Conditions

2.4. Solution Methods

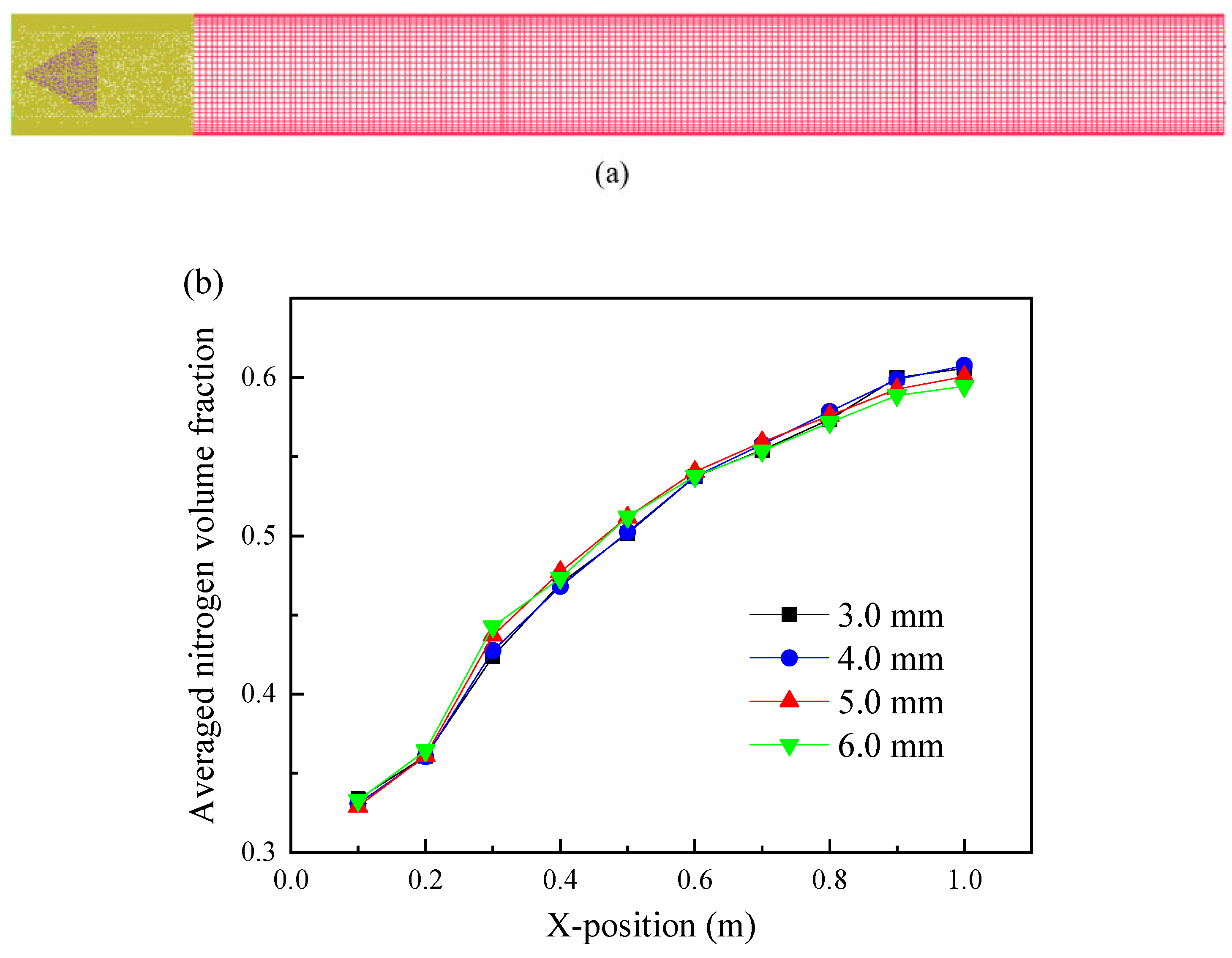

2.5. Mesh Independence

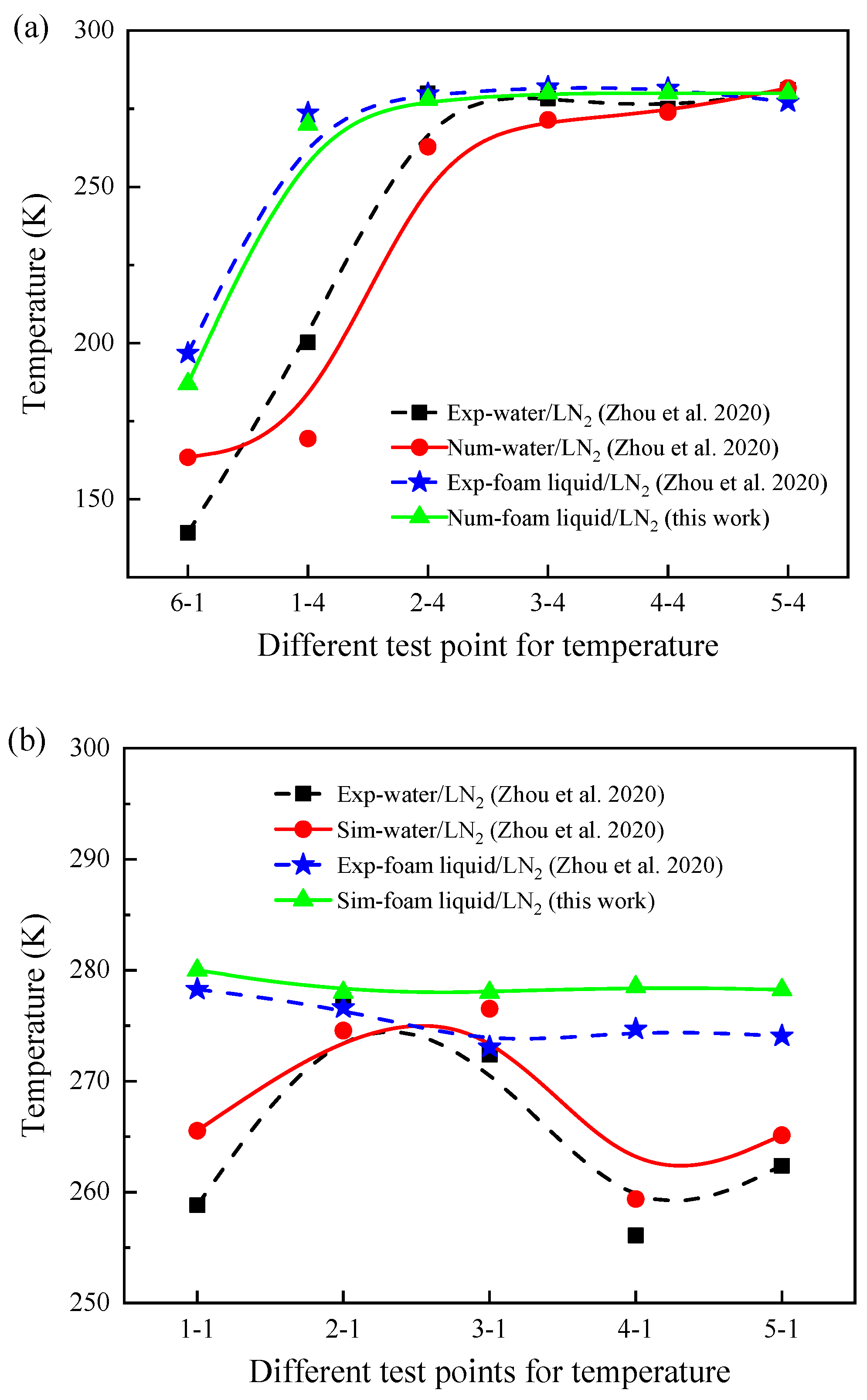

2.6. Model Validation

3. Results and Discussion

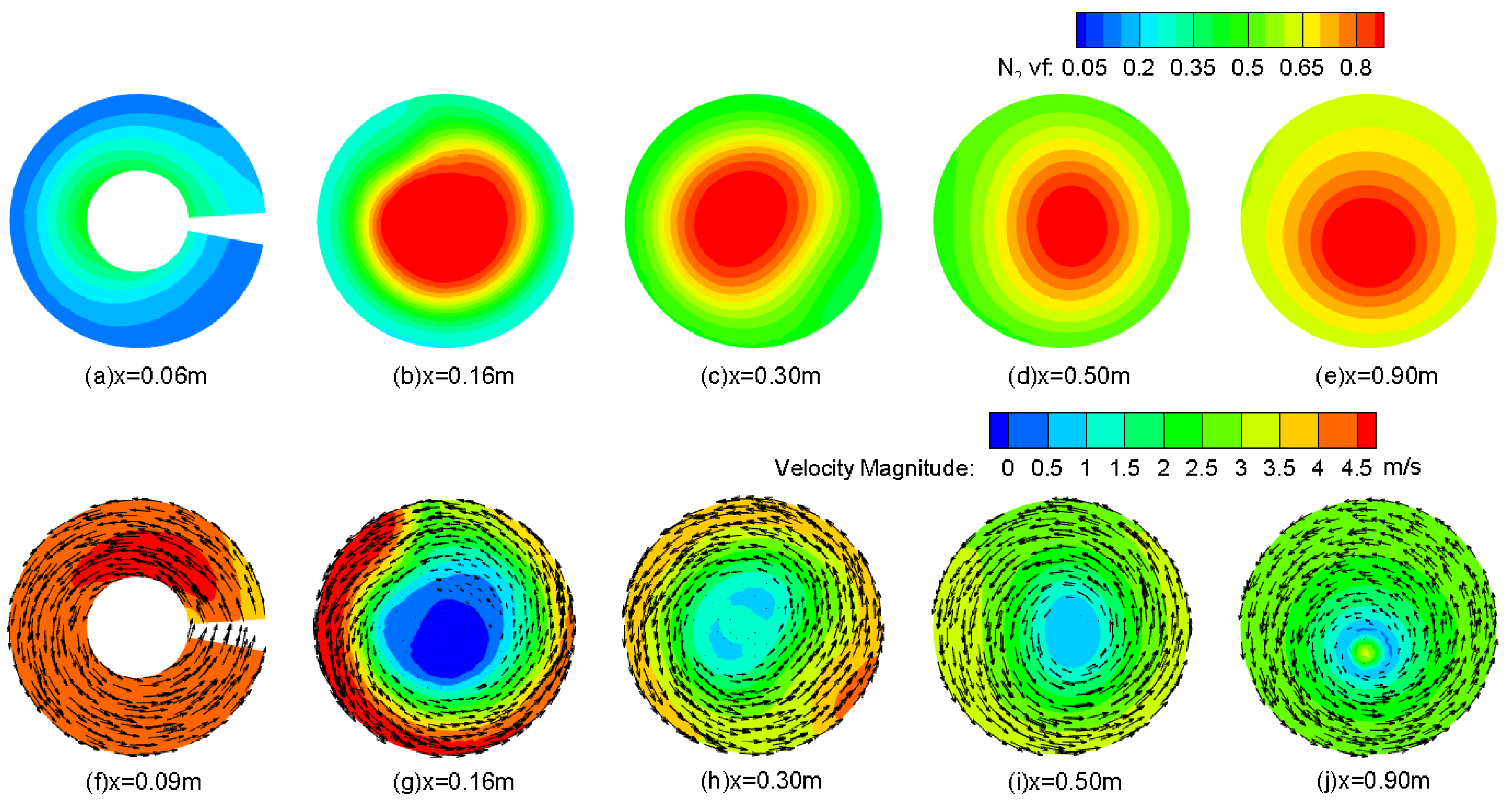

3.1. The Flow and Heat Transfer Characteristics of the Foaming Process

3.2. Factors Affecting the Foaming Performance

3.2.1. Distance between the Inlets and Spoiler

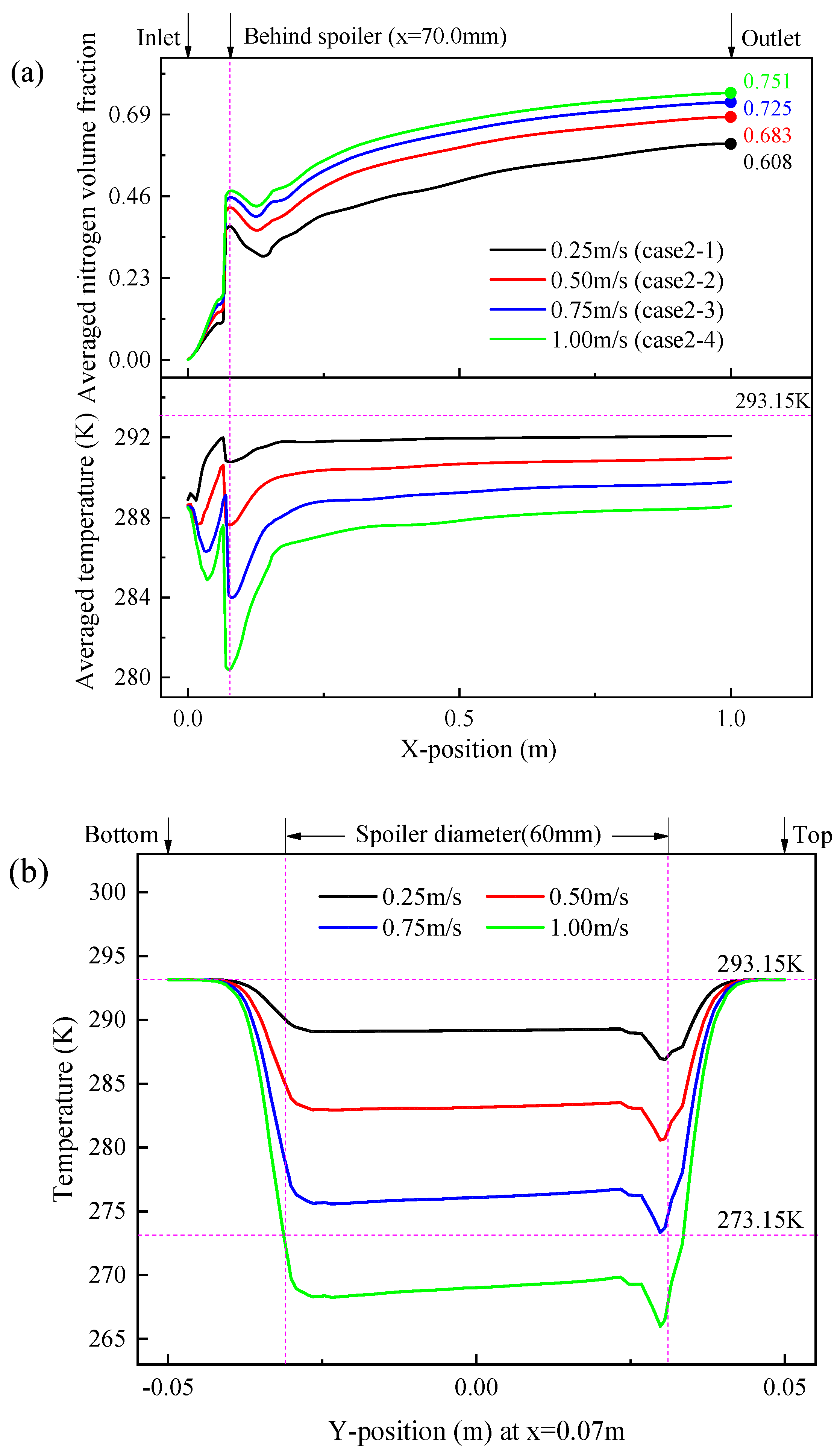

3.2.2. Flow Rate of the Liquid Nitrogen

3.2.3. Different Shapes of the Spoiler

4. Conclusions

- (1)

- The function of the spoiler is to smash liquid nitrogen into droplets, enhance turbulence, and improve the uniformity of foam. The foaming process of the foam generator with a cone spoiler can be divided into a spoiler zone (x < 0.07 m), a floating zone (0.07 m < x < 0.14 m), and a development zone (x > 0.14 m), according to the correlation between flow characteristics and nitrogen distribution.

- (2)

- The distance between inlets and spoiler mainly affects whether the spoiler can break liquid nitrogen into droplets. The shorter the distance, the more nitrogen is generated. Compared with the distances of 20 mm, 30 mm, and 40 mm, the optimal distance is determined as 10 mm.

- (3)

- With a bigger flow rate of liquid nitrogen, the volume fraction of nitrogen increases, but it may absorb more heat from the foam solution, leading to ice formation at the place with the lowest temperature (spoiler tail), which is not conducive to the fluid flow in the foaming process. Thus, a rational flow rate ratio of liquid nitrogen to foam solution is selected as 1:50.

- (4)

- The flow pattern of the foam generator with a semisphere spoiler is similar to that with a cone spoiler due to their similar shapes. The best shape of spoilers is the spiral, and its N2 volume fraction at the outlet is improved from 0.616 to 0.717 compared to no spoiler, due to its circumferential motion of fluids instead of translation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | |

| diameter of foam generator (mm) | |

| length of foam generator (mm) | |

| diameter of LN2 inlet (mm) | |

| distance between inlets and spoiler (mm) | |

| generatrix length of cone spoiler (mm) | |

| radius of semisphere spoiler (mm) | |

| distance from blade to the front of spiral spoiler (mm) | |

| blade thickness of spiral spoiler (mm) | |

| length of the cylinder in spiral spoiler (mm) | |

| blade height of spiral spoiler (mm) | |

| turbulent kinetic energy (m2·s−2) | |

| mean-velocity component in the axis (m·s−1) | |

| time (s) | |

| mass-averaged velocity (m·s−1) | |

| number of phases | |

| pressure (Pa) | |

| surface tension (N) | |

| surface tension of phase k (N) | |

| drift velocity of phase k (m·s−1) | |

| velocity of secondary phase k (m·s−1) | |

| volumetric energy of phase k (J·kg−1) | |

| enthalpy of species j in phase k (J·kg−1) | |

| diffusive flux of species j in phase k (kg·m−2·s−1) | |

| effective conductivity (W·m−1·K−1) | |

| equilibrium temperature of fluid (K) | |

| conductivity of phase k (W·m−1·K−1) | |

| turbulent thermal conductivity (W·m−1·K−1) | |

| volumetric heat sources (W·m−3) | |

| sensible enthalpy of phase k (J·kg−1) | |

| relative velocity of phase p relative to phase q (m·s−1) | |

| velocity of phase p (m·s−1) | |

| velocity of phase q (m·s−1) | |

| mass transfer from phase q to phase p (kg·s−1·m−3) | |

| mass transfer from phase p to phase q (kg·s−1·m−3) | |

| mass transfer by evaporation (kg·s−1·m−3) | |

| mass transfer by condensation (kg·s−1·m−3) | |

| mass transfer intensity factor (s−1) | |

| temperature of liquid nitrogen (K) | |

| temperature of gas nitrogen (K) | |

| saturation temperature of liquid nitrogen (K) | |

| vapor phase velocity (m·s−1) | |

| volume flow rate of liquid nitrogen (m3·h−1) | |

| volume flow rate of foam solution (m3·h−1) | |

| Greek symbols | |

| thickness of the cylinder of cone and semisphere spoilers (mm) | |

| diameter of the cylinder in spiral spoiler (mm) | |

| dissipation rate | |

| density of fluid (kg·m−3) | |

| effective turbulent viscosity (Pa·s) | |

| dynamic viscosity (Pa·s) | |

| turbulent viscosity (Pa·s) | |

| density of the mixture (kg·m−3) | |

| del operator | |

| volume fraction of phase k | |

| density of phase k (kg·m−3) | |

| viscosity of mixture (Pa·s) | |

| vapor volume fraction | |

| vapor density (kg·m−3) | |

| liquid volume fraction | |

| liquid density (kg·m−3) | |

| Abbreviations | |

| N2 | nitrogen |

| LN2 | liquid nitrogen |

| CFD | computer fluid dynamics |

| RPT | rapid phase transition |

| CAFS | compressed air foam systems |

| AFFF | aqueous film-forming foam |

| CO2 | carbon dioxide |

| O2 | oxygen |

| CO | carbon monoxide |

| LNG | liquified natural gas |

| BOG | boil-off-gas |

| VOF | volume of fluid |

| RNG | renormalization-group |

References

- Reniers, G.; Cozzani, V. Domino Effects in the Process Industries: Modelling, Prevention and Managing; Elsevier: Amsterdam, The Netherlands, 2013; Volume 127. [Google Scholar]

- Wang, Z.-N.; Chen, J.; Cheng, W.-C.; Arulrajah, A.; Horpibulsuk, S. Investigation into the tempo-spatial distribution of recent fire hazards in China. Nat. Hazards 2018, 92, 1889–1907. [Google Scholar] [CrossRef]

- Kim, A.K.; Crampton, G.P. Evaluation of the Fire Suppression Effectiveness of Manually Applied Compressed-Air-Foam (CAF) System. Fire Technol. 2009, 48, 549–564. [Google Scholar] [CrossRef]

- Ankit, D.; Goutham, R.; Tauseef, S.M. CFD-based study and analysis on the effectiveness of water mist in interacting pool fire suppression. Process Saf. Environ. Prot. 2021, 152, 614–629. [Google Scholar]

- Wang, K.; Fang, J.; Shah, H.R.; Mu, S.; Lang, X.; Wang, J.; Zhang, Y. A theoretical and experimental study of extinguishing compressed air foam on an n-heptane storage tank fire with variable fuel thickness. Process Saf. Environ. Prot. 2020, 138, 117–129. [Google Scholar] [CrossRef]

- Wang, K.; Fang, J.; Shah, H.R.; Lang, X.; Mu, S.; Zhang, Y.; Wang, J. Research on the influence of foaming gas in compressed air/nitrogen foam on extinguishing the n-heptane tank fire. J. Loss Prev. Process Ind. 2021, 72, 104533. [Google Scholar] [CrossRef]

- Ray, S.K.; Singh, R.P. Recent Developments and Practices to Control Fire in Underground Coal Mines. Fire Technol. 2007, 43, 285–300. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, G.; Zhu, G.; Jia, B.; Zhang, P. Applicability of liquid nitrogen fire extinguishing in urban underground utility tunnel. Case Stud. Therm. Eng. 2020, 21, 100657. [Google Scholar] [CrossRef]

- Shao, Z.; Wang, D.; Wang, Y.; Zhong, X.; Tang, X.; Hu, X. Controlling coal fires using the three-phase foam and water mist techniques in the Anjialing Open Pit Mine, China. Nat. Hazards 2014, 75, 1833–1852. [Google Scholar] [CrossRef]

- Adamus, A. Review of the use of nitrogen in mine fires. Min. Technol. 2002, 111, 89–98. [Google Scholar] [CrossRef]

- Zifeng, L.; Hongfang, X.; Chaoyue, Z. Liquid nitrogen gasification fracturing technology for shale gas development. J. Petrol. Sci. Eng. 2016, 138, 253–256. [Google Scholar]

- Fu-Bao, Z.; Bo-Bo, S.; Jian-Wei, C.; Ling-Jun, M. A New Approach to Control a Serious Mine Fire with Using Liquid Nitrogen as Extinguishing Media. Fire Technol. 2013, 51, 325–334. [Google Scholar] [CrossRef]

- Zhou, F.; Ren, W.; Wang, D.; Song, T.; Li, X.; Zhang, Y. Application of three-phase foam to fight an extraordinarily serious coal mine fire. Int. J. Coal Geol. 2006, 67, 95–100. [Google Scholar] [CrossRef]

- Lu, X.; Wang, D.; Qin, B.; Tian, F.; Shi, G.; Dong, S. Novel approach for extinguishing large-scale coal fires using gas–liquid foams in open pit mines. Environ. Sci. Pollut. Res. 2015, 22, 18363–18371. [Google Scholar] [CrossRef]

- Zhang, Y.; Lei, B.; Wu, B.; Meng, Y.; He, B. An Experimental Study on the Heat and Mass Transfer of Liquid Nitrogen in a Loose Medium. Energies 2019, 12, 3464. [Google Scholar] [CrossRef]

- Aobo, L.; Michael, A.D.; Yiannis, A.L. On the trajectory and reach of fire-suppressant liquid nitrogen droplets released from a spray nozzle. Process Saf. Environ. Prot. 2022, 161, 273–284. [Google Scholar]

- Clarke, H.; Martinez-Herasme, A.; Crookes, R.; Wen, D. Experimental study of jet structure and pressurisation upon liquid nitrogen injection into water. Int. J. Multiph. Flow 2010, 36, 940–949. [Google Scholar] [CrossRef]

- Rupak, K.; Lokesh, R.; Arup Kumar, D. Understanding interfacial behaviour during boiling of nitrogen from liquid-liquid contact plane. Int. J. Heat Mass Tran. 2021, 165, 120661. [Google Scholar]

- Federico, U.; Nicola, P.; Filippo, B. Loss of integrity of hydrogen technologies: A critical review. Int. J. Hydrog. Energ. 2020, 45, 23809–23840. [Google Scholar]

- Saleem, A.; Farooq, S.; Karimi, I.A.; Banerjee, R. A CFD simulation study of boiling mechanism and BOG generation in a full-scale LNG storage tank. Comput. Chem. Eng. 2018, 115, 112–120. [Google Scholar] [CrossRef]

- Zhou, R.; Zhang, X.; Yang, Z.; Mu, X.; Lang, X.; Wang, X.; He, L. Study on the flow characteristics of nitrogen gas foam in horizontal foam generator. Int. J. Multiph. Flow 2020, 129, 103326. [Google Scholar] [CrossRef]

- Lu, X.; Wang, D.; Shen, W.; Wang, H.; Zhu, C.; Liu, J. Experimental investigation of the pressure gradient of a new spiral mesh foam generator. Process Saf. Environ. Prot. 2014, 94, 44–54. [Google Scholar] [CrossRef]

- Jabarkhyl, S.; Barigou, M.; Zhu, S.; Rayment, P.; Lloyd, D.M.; Rossetti, D. Foams generated from viscous non-Newtonian shear-thinning liquids in a continuous multi rotor-stator device. Innov. Food Sci. Emerg. Technol. 2019, 59, 102231. [Google Scholar] [CrossRef]

- Odsæter, L.; Skarsvåg, H.; Aursand, E.; Ustolin, F.; Reigstad, G.; Paltrinieri, N. Liquid Hydrogen Spills on Water—Risk and Consequences of Rapid Phase Transition. Energies 2021, 14, 4789. [Google Scholar] [CrossRef]

- Zhongqi, Z.; Wenbing, J.; Xujin, Q.; Yonghua, H. A numerical model for liquid–vapor transition in self-pressurized cryogenic containers. Appl. Therm. Eng. 2021, 193, 117005. [Google Scholar]

- Chen, D.; Cui, B.; Zhu, Z. Numerical simulation of the effect of upstream swirling flow on swirl meter performance. J. Therm. Sci. 2018, 27, 117–124. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent Theory Guide; ANSYS Inc.: Canonsburg, PA, USA, 2021; pp. 611–616. [Google Scholar]

- On the Mixture Model for Multiphase Flow. Available online: https://www.osti.gov/etdeweb/biblio/434874 (accessed on 4 March 1997).

- Lee, W.H. Pressure Iteration Scheme for Two-Phase Flow Modeling; Hemisphere Publishing Corp: Scottsdale, AZ, USA, 1980. [Google Scholar]

- Pankhurst, G.A. Foam formation and foam stability: The effect of the adsorbed layer. Trans. Faraday Soc. 1941, 37, 496–505. [Google Scholar] [CrossRef]

- Yong, G.L. An Unstructured Grid Method for a Pressure-Based Flow and Heat Transfer Solver. Numer. Heat Transf. Part B Fundam. 1997, 32, 267–281. [Google Scholar]

- Adam, W.; Uwe, S. Some remarks on the PISO and SIMPLE algorithms for steady turbulent flow problems. Comput. Fluids 1989, 17, 555–570. [Google Scholar]

- Wang, L.; Zhang, Y.; Li, X.; Zhang, Y. Experimental investigation and CFD simulation of liquid-solid-solid dispersion in a stirred reactor. Chem. Eng. Sci. 2010, 65, 5559–5572. [Google Scholar] [CrossRef]

- Xiao, J.; Chen, Z.; Shen, X.; Jiang, C.; Lu, P. Orthogonal Experiments on the Key Structural Parameters Optimization of Mine Dust Removal Foam Generator by Fluent Numerical Simulation. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Anhui, China, 19 October 2018; IOP: Bristol, UK, 2019. [Google Scholar]

- Jushi, C. Property experiments on the foam generator and its influencing factors during down-the-hole drilling. Process Saf. Environ. Prot. 2018, 114, 169–178. [Google Scholar]

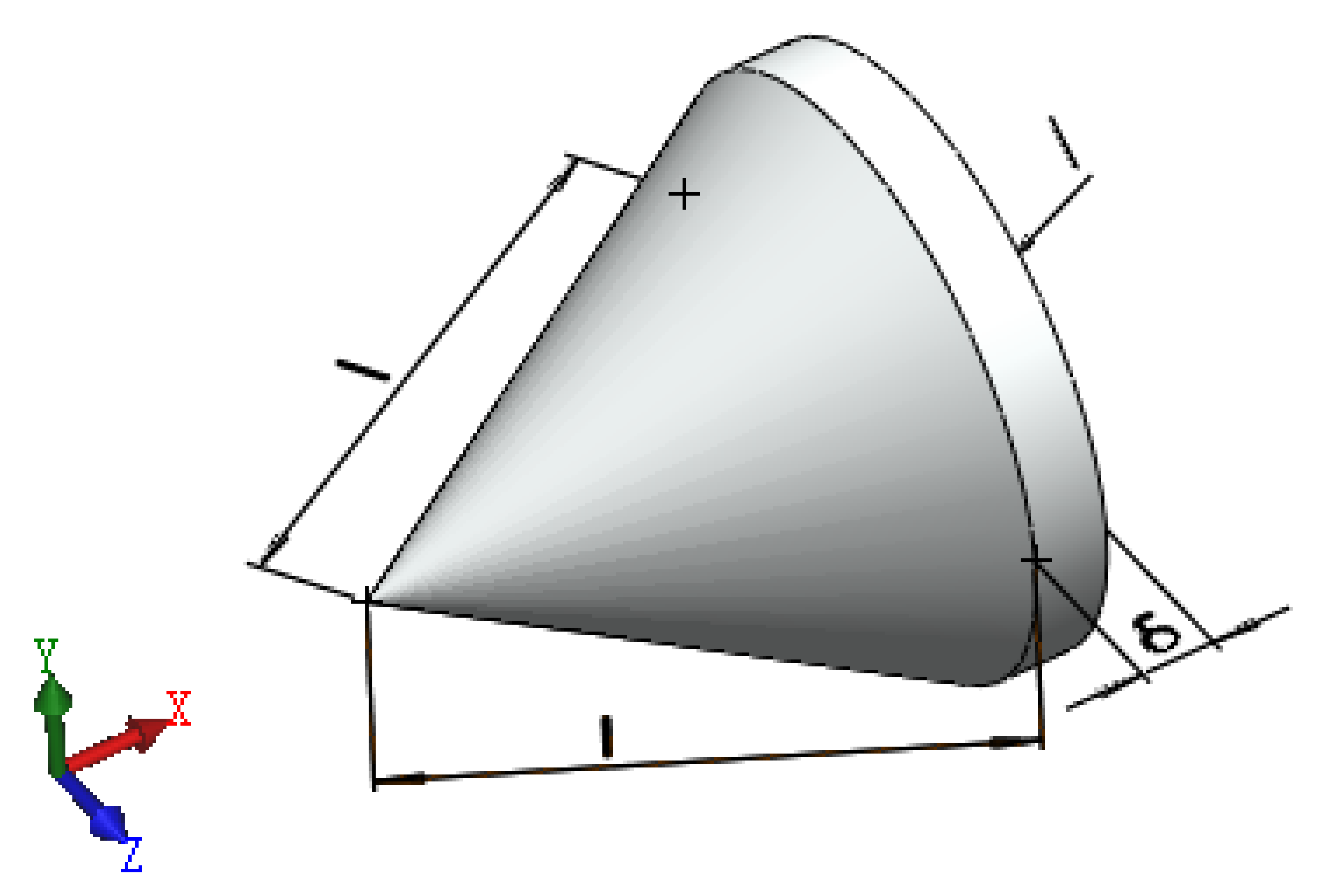

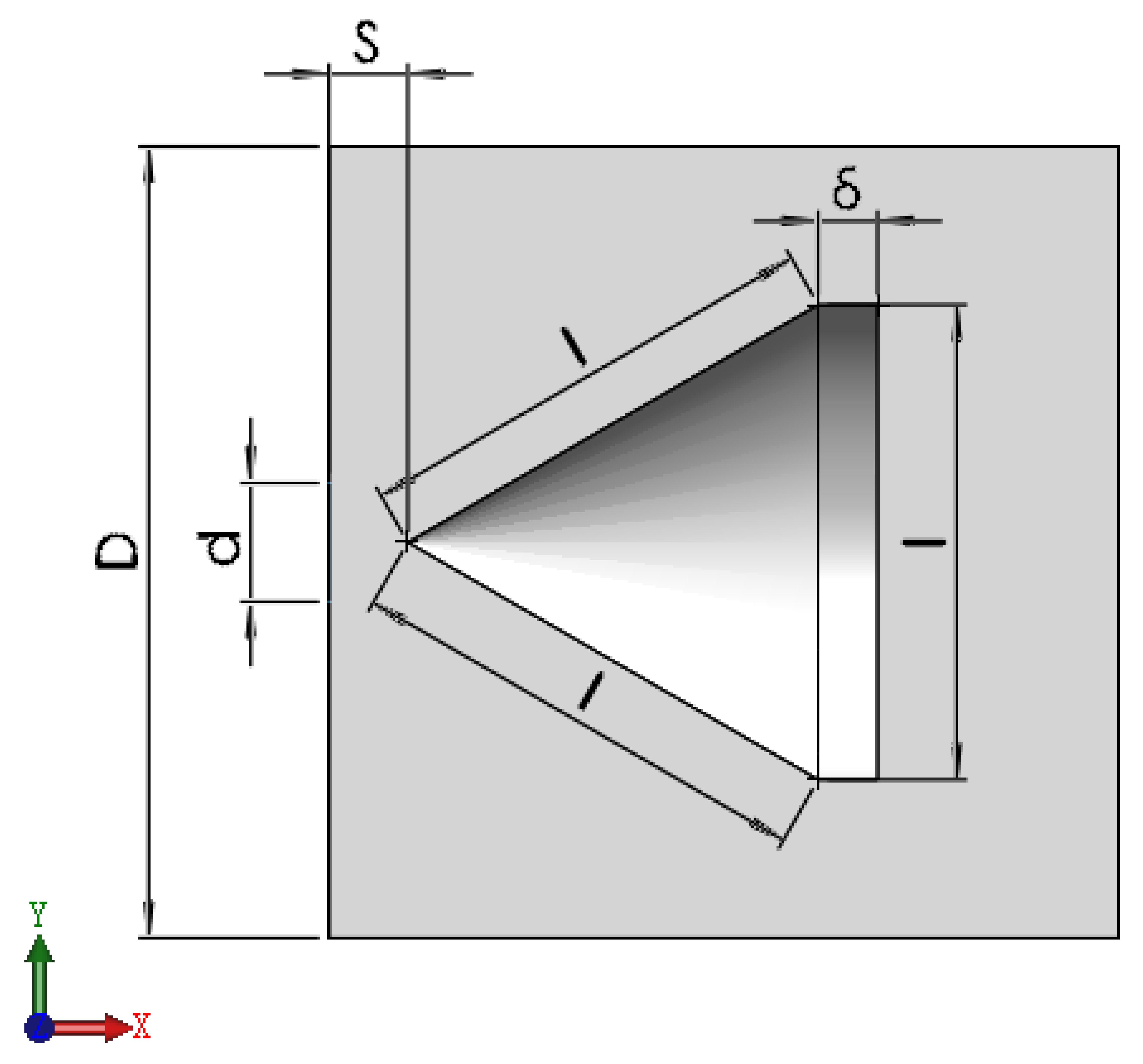

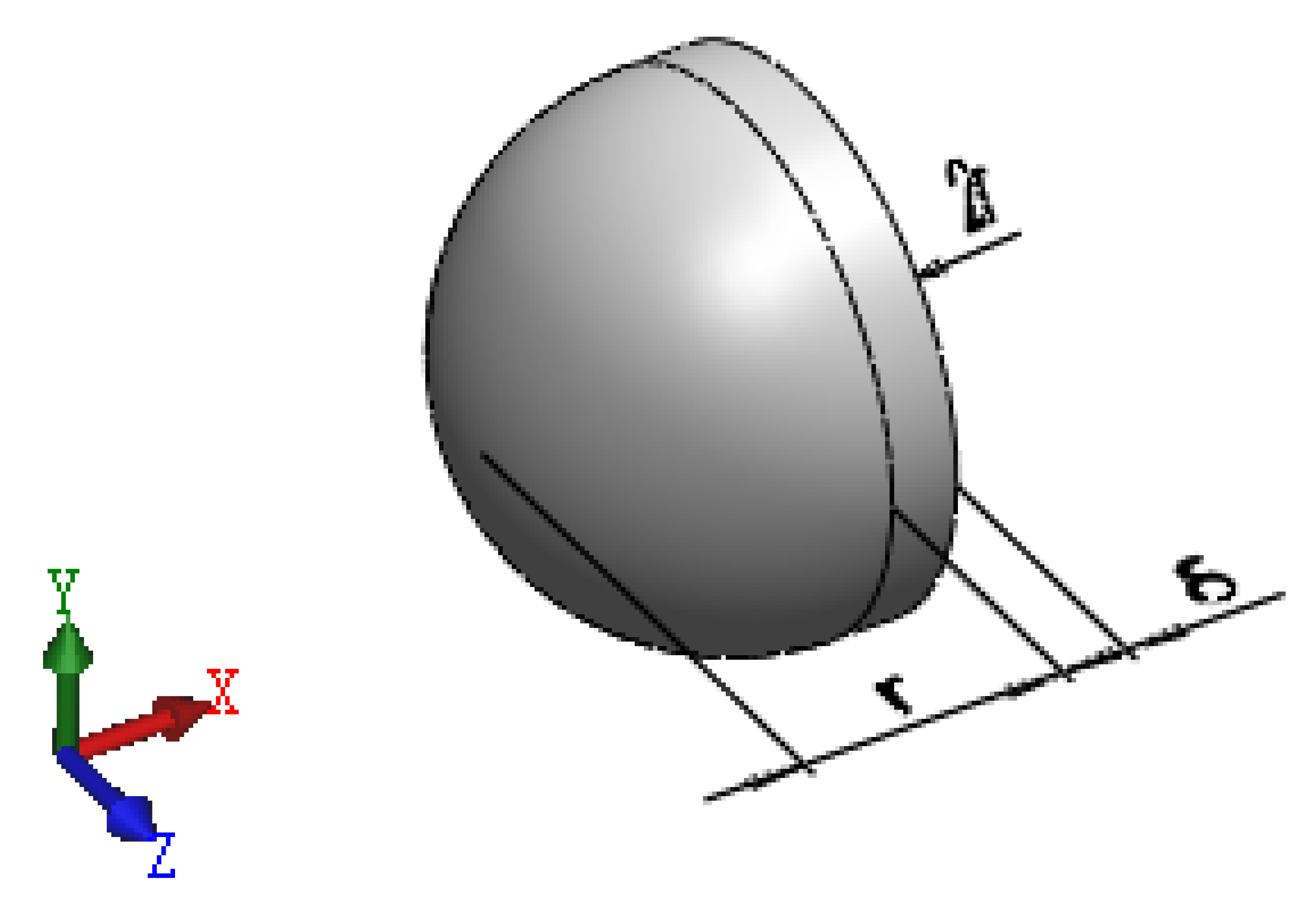

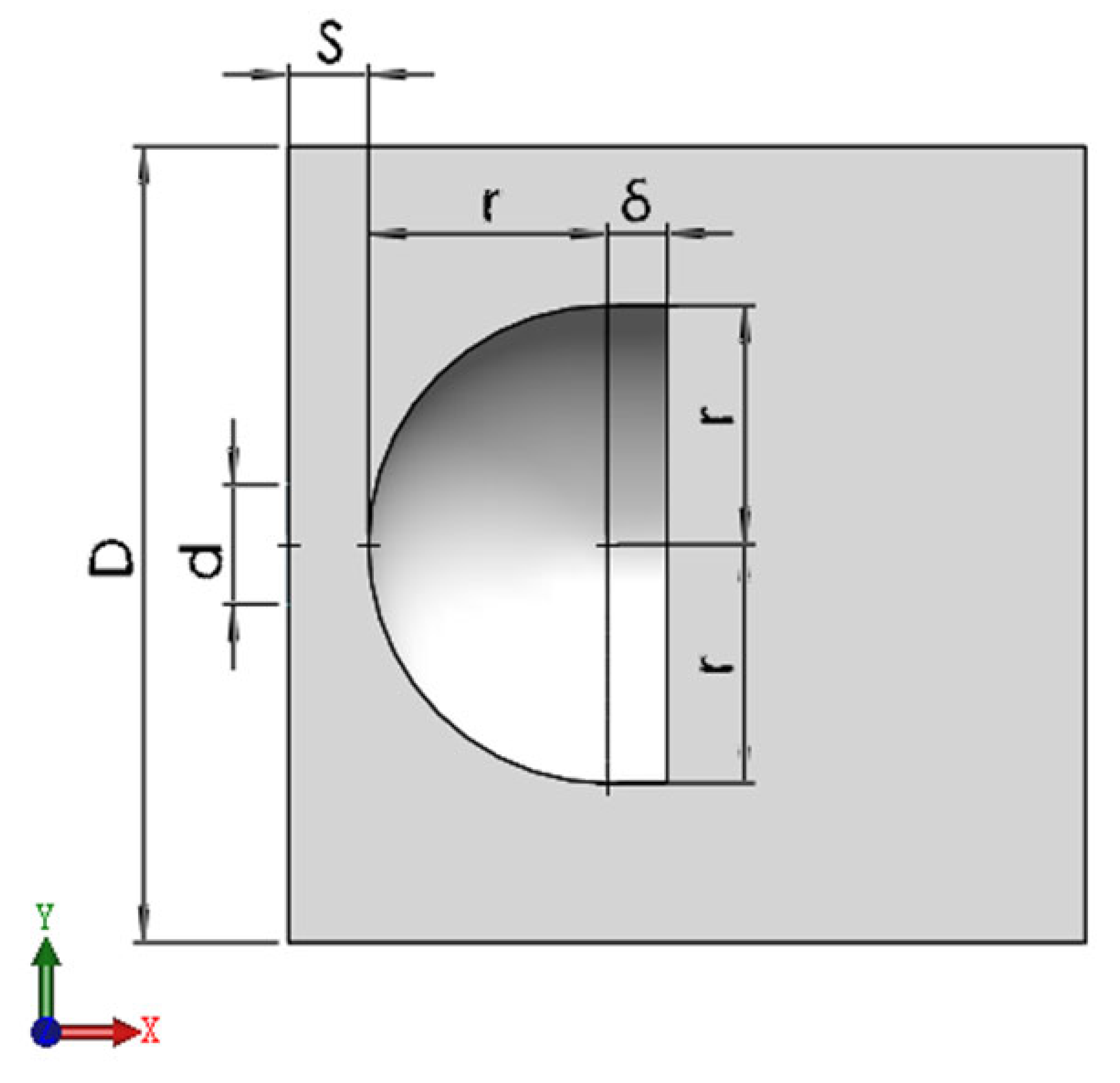

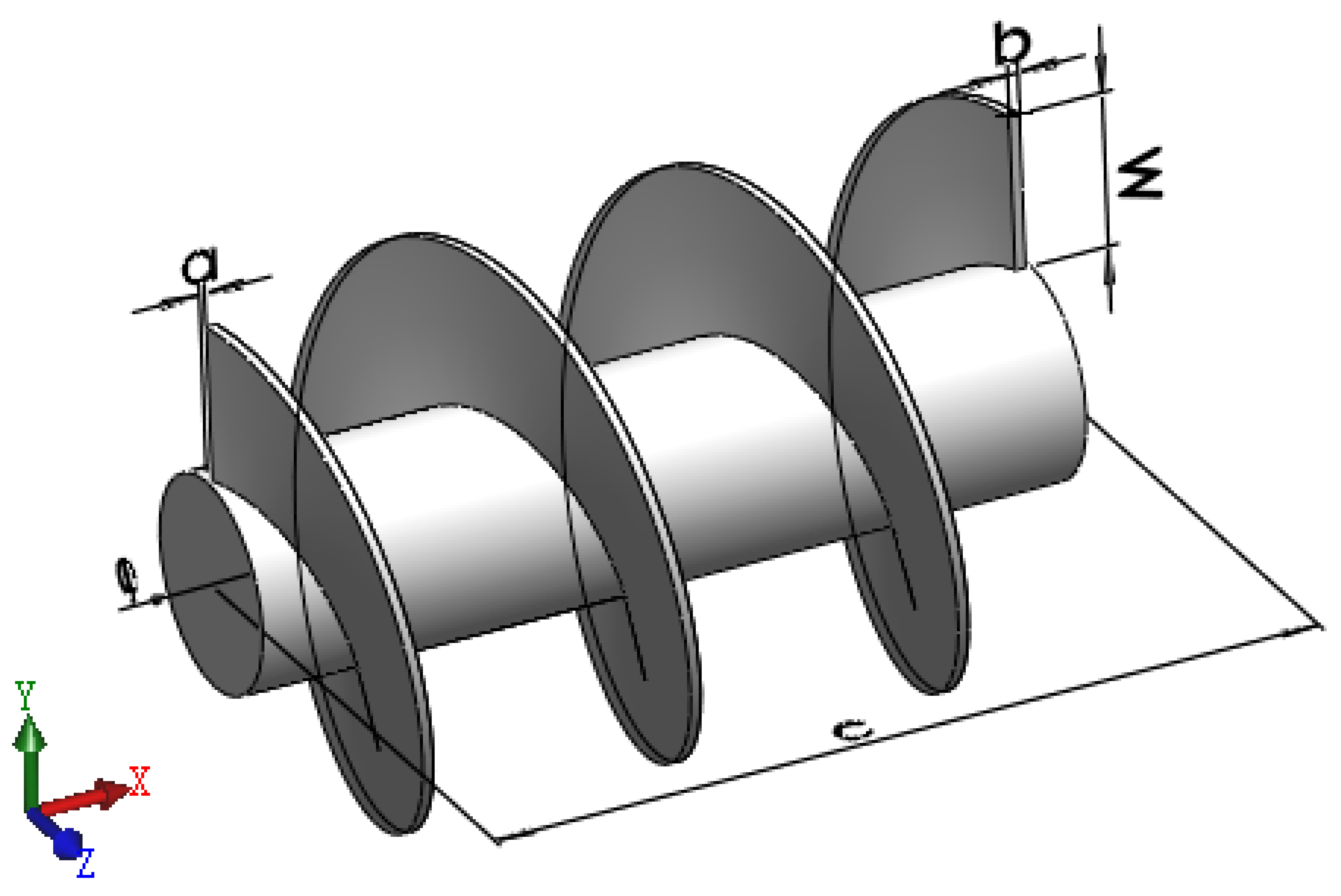

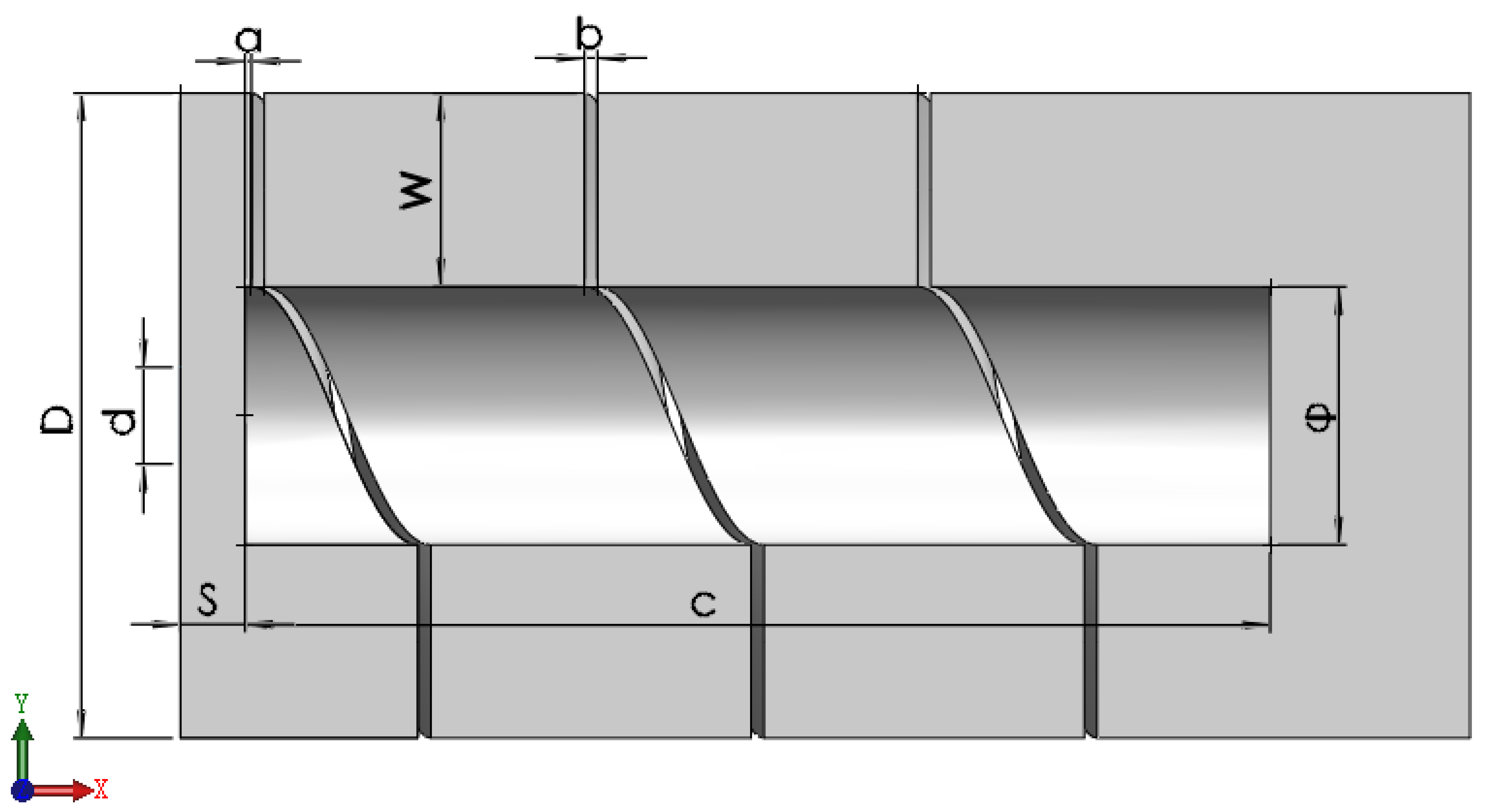

| Item | Geometry | Profile of the Computational Fluid Domain * | Parameters |

|---|---|---|---|

| Foam generator |  | = 100 mm = 15 mm = 1000 mm is the distance between inlets and spoiler | |

| (a) Cone spoiler |  |  | = 60 mm = 7.5 mm |

| (b) Semisphere spoiler |  |  | = 30 mm = 7.5 mm |

| (c) Spiral spoiler |  |  | = 40 mm = 1 mm = 2 mm = 159 mm = 30 mm |

| Item | Density | Specific Heat | Thermal Conductivity | Standard State Enthalpy |

|---|---|---|---|---|

| kg·m−3 | J·kg−1·K−1 | W·m−1·K−1 | J·kg−1·mol−1 | |

| N2 | 1.14 | Piecewise-polynomial | 0.0242 | 2792.8 |

| Foam solution | 998.20 | 4182.0 | 0.6000 | -- |

| LN2 | 806.08 | 2014.5 | 0.1458 | -- |

| Name | LN2 Velocity/m·s−1 | Foam Solution Velocity/m·s−1 | Distance/mm | Spoiler Shape |

|---|---|---|---|---|

| Case 0 | 0.25 | 0.57 | -- | -- |

| Case 1-1 | 0.25 | 0.57 | 10 | Cone |

| Case 1-2 | 0.25 | 0.57 | 20 | Cone |

| Case 1-3 | 0.25 | 0.57 | 30 | Cone |

| Case 1-4 | 0.25 | 0.57 | 40 | Cone |

| Case 2-1 | 0.25 | 0.57 | 10 | Cone |

| Case 2-2 | 0.50 | 0.57 | 10 | Cone |

| Case 2-3 | 0.75 | 0.57 | 10 | Cone |

| Case 2-4 | 1.00 | 0.57 | 10 | Cone |

| Case 3-0 | 0.50 | 0.57 | -- | -- |

| Case 3-1 | 0.50 | 0.57 | 10 | Cone |

| Case 3-2 | 0.50 | 0.57 | 10 | Semisphere |

| Case 3-3 | 0.50 | 0.57 | 10 | Spiral |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, D.; Xie, M.; Xu, H.; Ren, X. Research on the Mixing Mechanism and Parameter Optimization of Liquid Nitrogen Foam Generator. Energies 2022, 15, 8714. https://doi.org/10.3390/en15228714

Liu Y, Wang D, Xie M, Xu H, Ren X. Research on the Mixing Mechanism and Parameter Optimization of Liquid Nitrogen Foam Generator. Energies. 2022; 15(22):8714. https://doi.org/10.3390/en15228714

Chicago/Turabian StyleLiu, Yulin, Dongming Wang, Min Xie, Huanhuan Xu, and Xiaohan Ren. 2022. "Research on the Mixing Mechanism and Parameter Optimization of Liquid Nitrogen Foam Generator" Energies 15, no. 22: 8714. https://doi.org/10.3390/en15228714

APA StyleLiu, Y., Wang, D., Xie, M., Xu, H., & Ren, X. (2022). Research on the Mixing Mechanism and Parameter Optimization of Liquid Nitrogen Foam Generator. Energies, 15(22), 8714. https://doi.org/10.3390/en15228714