Abstract

The implementation of Industry 4.0 currently concerns mainly large enterprises. However, the economy of most European countries is based on the activities of small and medium-sized enterprises (SMEs). For this reason, the further development of the I4.0 concept and the technology of Logistics 4.0 depends on adjusting its assumptions to the needs of SMEs. The article aims to identify research areas regarding the adaptation of Industry 4.0 and Logistics 4.0 solutions to the needs of the SME sector, based on a review of the literature. The PRISMA method, one of the popular analytical methods used in a literature review, was used for the research. The selection of publications for the analysis was based on the Web of Science database, an important interdisciplinary research platform. Ninety-five publications were accepted for the final analysis, which concerned only the application of Industry 4.0 in SMEs and 10 publications on Logistics 4.0. The conducted studies of the literature allowed to identify the scope of research on the implementation of the concept of Industry 4.0 and Logistics 4.0 in the SME sector. The research allowed us to distinguish five thematic groups in total, which have been characterized. One of the identified groups concerns the adaptation of Logistics 4.0 systems to the needs of SMEs. The number of publications on this group of studies is minimal, therefore this area has been recognized as the currently existing research gap.

1. Introduction

Since the publication of the term “Industry 4.0” in 2011, the digital transformation required by this concept has attracted more and more attention from companies from various sectors [1]. It is worth noting, however, that since its publication, this concept has constantly been evolving [2]. Currently, Industry 4.0 includes not only factories but the digital transformation of the entire industrial and consumer market, from the emergence of intelligent production to the digitization of whole channels of value delivery [3]. For this reason, the digitization strategy has also led to the development of other production-related systems, such as Logistics 4.0.

It is worth focusing on the example of the entire European Union and Germany. It would seem that since Germany was the reformer and initiator of the Industry 4.0 concept in Europe, it will also be the most advanced country in digitalization. So let us look at the digital economy of the European Union with an emphasis on Germany.

In the EU, household next-generation (NGA) coverage increased from 83% to 86%. Additionally, in recent years, households’ access to fixed broadband networks offering a capacity of at least 100 mb/s has increased from 15% to 26%. Denmark, Sweden, and Luxembourg achieved the highest score in this category. Bulgaria, Cyprus, and Greece achieved the lowest score. Germany is above the EU average but not in the lead (8) [4].

The proportion of people with at least basic digital skills increased from 55% to 58%. Unfortunately, many EU citizens still lack basic digital skills, even though most jobs require digital skills. Last year, as many as 64% of large enterprises and 56% of SMEs had difficulties recruiting ICT (Information and Communication Technology) specialists. Finland, Sweden, and Estonia achieved the highest score in this category. Bulgaria, Romania, and Italy achieved the lowest score. However, Germany is above the EU average, but far from first place (10) [5].

Data on the integration of digital technologies in enterprises show a wide variation by company size, sector, and member state. In 2019, 38.5% of large companies relied on advanced cloud computing services, and 32.7% used Big Data solutions. At the same time, the vast majority of SMEs declared that they did not use these solutions—17% of SMEs use cloud services, and 12% use Big Data. According to the DESI 2020 report, only 17.5% of SMEs sold their products online. Ireland, Finland, and Belgium achieved the highest score in this category. The lowest score was achieved by: Hungary, Romania, and Bulgaria. Germany is below the EU average, occupying a distant position (19) [6].

Effective e-government can significantly facilitate and speed up procedures for citizens and entrepreneurs. According to the DESI 2020 report, the number of people who used e-government services increased to 67%. Estonia, Spain, and Denmark achieved the highest score in this category. The lowest score was obtained by Slovakia, Greece, and Romania. Germany is below the EU average, occupying a distant position (29) [7].

Some large European companies have already implemented Industry 4.0 solutions in their digital transformations [8]. Thanks to this, they can quickly and effectively adapt to internal and external events, using advanced technologies in new products and innovative business models. The solutions allow large companies to improve their efficiency, reduce waste, and increase customer satisfaction. However, despite the benefits of the Industry 4.0 concept, the small and medium-sized enterprise sector is still not ready to develop its production and logistics system by investing in new technologies [8]. This is primarily due to the lack of knowledge about solutions supporting Industry 4.0 [9] and the high costs related to investments in new technologies [8]. It is also worth emphasizing that SMEs often do not adopt new solutions, mainly because they fear investing in the wrong technologies or adopting inapt practices [10].

As stated by the European Commission, micro, small, and medium-sized enterprises (SMEs) are enterprises with fewer than 250 employees and an annual turnover not exceeding EUR 50 million, and with an annual balance sheet total not exceeding EUR 43 million. According to statistics: the EU has 25 million SMEs that play a crucial role in the EU economy: they represent 99% of all enterprises, employ around 100 million people (providing two-thirds of jobs in the private sector) and provide approximately 56% of the gross domestic product EU [11,12]. Micro enterprises constitute the largest segment of SMEs in all European Union member states. According to Eurostat data, their share ranges from 82% in Germany to 97.4% in Greece. The most significant number of small companies is in Germany—here, they constitute 15.1% of all enterprises. Only two other countries have a share of over 10%—Austria (10.9%) and Luxembourg (10.1%). The leader, in terms of the share of medium-sized companies, is also Germany—2.4%. In no other country do they exceed the share of 2%, although in some cases they are approaching it, as in Denmark (1.9%), Luxembourg (1.9%), or Romania (1.8%) [12]. The statistical data presented above clearly show that small and medium-sized enterprises have a decisive influence on the economic development of the European Union member states.

Meanwhile, the current business conditions mean a growing need to improve the level of digitization in small and medium-sized enterprises. This situation becomes even more critical when SMEs act as a subcontractor of large enterprises that demand the utilization of certain digital operations [13]. For this reason, it is necessary to adapt solutions from Industry 4.0 to the needs of the SME sector. These enterprises have their business specificity, which should be considered both at the stage of implementation and operation of new digital solutions [14]. This awareness is growing in both the industrial and scientific communities. For this reason, more and more publications in the Industry 4.0 focus on the needs of small and medium-sized enterprises. These studies, however, mainly concern global issues related to implementing this concept in enterprises from the SME sector. However, since these companies are part of the digitized supply chains, in addition to the intelligent factory, the adaptation must also apply to logistics systems, i.e., the implementation of solutions in the area of Logistics 4.0.

The outbreak of the COVID pandemic accelerated the digitization processes in enterprises from the SME sector. It is estimated that 80% of all SMEs increased their use of digital tools during the pandemic. According to a report prepared, based on 5000 companies from the SME sector in the EU, it was indicated that 42% of companies from the SME sector are digitally advanced in Europe. They use more digital tools and prioritize their importance. They achieve better business results and thus, higher revenues. They focus on accelerating transformation, innovation, and resilience [15]. The remaining 58% of SME companies are aware of the necessity of digitization, but this is not reflected in their activities. The dominant approach is the status quo, keeping expenses and employment. A digitization strategy is still the exception, not the rule. One can get the impression that SMEs are trying to wait through the difficult and uncertain period and quietly counting on returning to normalcy. However, digitization will not slow down or stop; it will only accelerate.

The article aims to identify the research areas concerning the adaptation of Industry 4.0 solutions to the needs of the SME sector, based on a review of the literature from the last five years. Based on the literature analysis, the scope of adapting Logistics 4.0 solutions to the needs of small and medium-sized enterprises will also be assessed. Following this, the main contributions of this paper include:

- Summary of the research on adjusting Industry 4.0 solutions to the needs of the SME sector;

- Conducting the qualification procedure following the adopted distribution criteria, based on the results of the literature research;

- Assessment of the scope and level of adjustment of Logistics 4.0 solutions, described in the literature to the needs of the SME sector;

- Identification of the research gaps in adapting Logistics 4.0 to the SME specificity.

In conclusion, the outline of this review paper is as follows: Section 2 will present the research background that was the basis for our literature research. Section 3 presents the test method used and describes the main results of the conducted bibliometric analysis. Section 4 presents the research results, and a structure for grouping issues will be proposed. Section 5 will deliver the results of the discussion and identify the identified research gaps in the analyzed area. Finally, Section 6 describes the main conclusions of the conducted bibliometric analysis.

2. Research Background

The term Industry 4.0 was first defined in 2011 by a team representing representatives of various fields (such as business, politics, and academia) [16]. The basis of the announced initiative was to increase the competitiveness of the German manufacturing industry. The concept’s success was undoubtedly determined by the German federal government announcing that Industry 4.0 would be an integral part of the “High Technology Strategy for Germany 2020” initiative, the aim of which was to introduce technological innovations to German enterprises [16].

Although Industry 4.0 is based on the foundations of previous industrial revolutions [17], its advantage is to be built on providing the highest degree of digitalization, automation, virtualization, and decentralization across all industries when coming to its maturity [18]. The impact of Industry 4.0 is to be very broad. Numerous publications emphasize its effect on the applicable rules of competition, value delivery functions, labor market, socio-environmental norms, and even educational priorities (among other things [19,20]). Expectations for the further development of Industry 4.0 mean that international associations, governments, industrial communities, and academia have valued and prioritized the understanding of its role, possibilities, and driving force for the economy, but also the socio-economic effects and future trends [21].

As noted in the Introduction Section, the concept of Industry 4.0 has significantly evolved since 2011. In the first phase of the development of this concept, the primary attention of the researchers was focused on aspects related to the digitization of the production processes. Therefore, one of the key concepts within Industry 4.0 is the so-called smart factory, also termed digital or intelligent factory [22]. Intelligent factories include a completely integrated manufacturing system without human involvement that can work for the production of goods in which information and data to perform tasks can be shared, interpreted, and processed between each function of production [23]. However, the Industry 4.0 concept has undergone revolutionary changes since the genesis of this research stream [21]. It is mainly because of the dynamic nature of Industry 4.0, the constant paradigm shifts in the dynamics of digital technologies, and radical changes in the business environment. The interest of researchers is also focused on the possibility of using Industry 4.0 technology in production-related processes and even transferring them to the management level of the entire supply chain. For this reason, it can observe the intensive development of such concepts as Logistics 4.0, digital supply chain, or Maintenance 4.0.

Logistics 4.0 uses new technologies, such as cyber-physical systems, to support the functioning of traditional logistics systems [24]. Unique solutions improve networking and the automation of storage system transportation and decentralized software control [25]. The important concept of Logistics 4.0 is gaining more and more importance. This is confirmed by the number of publications referring to these solutions, which has been systematically increasing since 2017 [26]. The most frequently discussed solutions in this area include the smart warehouse trend [27], especially: AGV systems—automated guided vehicle (e.g., [28,29]) and UAV—unmanned aerial vehicle (e.g., [30,31]). No less important an issue is the use of the Internet of Things to improve the supply chain and increase its productivity [32]. The application of Logistics 4.0 is also examined in the context of increasing the resilience of the supply chains to undesirable events occurring [33]. Concerning Maintenance 4.0, the main application of new technologies relates to the predictive machine maintenance strategy [34,35]. For this reason, maintenance departments were forced to reorganize, integrate new sensors, and process collected data for a better performance [34]. Machine learning is also gaining importance, which is used to forecast the future states of machines in predictive maintenance strategies [36].

Published literature reviews indicate that the most critical technologies related to the functioning of Industry 4.0 are currently [16,37,38,39,40]: (1) cyber-physical systems, (2) robotics, (3) Internet of Things (IoT), including industrial wireless networks (IWNs) with sensing, identification, processing, and communication sensor capabilities, (4) cloud computing, (5) big data analytics, (6) augmented reality, (7) artificial intelligence and machine learning, (8) digital twins, (9) additive manufacturing, and (10) smart products. These technologies will also play a key role in Industry 4.0 initiatives in the near future. Digital technology, with engineering data at its core, is helping engineers gain control over their assets [39]. Thanks to Industry 4.0, several innovative systems, such as collaborative robots, additive and hybrid manufacturing systems, have been successfully developed to achieve high production rates and to overcome inherent restrictions related to conventional manufacturing processes [40]. Cotrino et al. [41] distinguished four main technological revolutions related to Industry 4.0, to which they assigned detailed solutions/concepts. The classification they propose is presented in Table 1.

Table 1.

Industry 4.0 Technologies (own work, based on [41].)

A critical element of Industry 4.0 is the robotization of production and production-related operations. For this reason, autonomous transport systems should also be distinguished from the abovementioned concepts. They are currently being developed as a key innovation within the Logistics 4.0 concept. However, it should be noted that despite the observed development of the Industry 4.0 concept. There is still a lack of knowledge on the effective implementation of the above technologies and the understanding of how companies can effectively use the potential associated with the fourth industrial revolution [16]. This is confirmed, among others, by the results presented in [42], which show that among 92 surveyed manufacturing companies, the implementation of the fundamental technologies for Industry 4.0 is still a big challenge.

Research confirms that Industry 4.0 can be implemented in any industrial sector [41]. However, the cost-consumption and complexity of the implemented solutions [16], as well as the high demand for highly competent employees [43] mean that most scientific studies and business implementations related to Industry 4.0, refer to large enterprises and take into account the specificity of operation and the need for this audience. Large-sized companies (LSCs) eagerly digitize business processes. Cotrino et al. [41] note in their research that, regardless of the business sector, most large enterprises have a roadmap for the digital transformation and the implementation of Industry 4.0 technologies, and they are in the process of digitizing the supply chain, customer services, and finances. At the same time, the research results indicate that SMEs do not have the economic resources to implement Industry 4.0 technologies [41]. For this reason, solutions developed for the LSC sector will not be suitable for the capabilities and needs of SMEs. Since the further development of Industry 4.0 depends on implementing this concept, first of all, in small and medium-sized enterprises [44], the technological and business solutions of Industry 4.0 must be adapted to the operating conditions of this group of enterprises. The discrepancies in the functioning of these two groups of enterprises are so significant that applying the same implementation standards cannot be successful. Table 2 presents the most critical differences between LSC and SME, most often described in the literature.

Table 2.

Comparison of the SME and LSC (own work, based on [45]).

Considering the differences between both groups of enterprises and the specificity of the solutions supporting the development of Industry 4.0 (also with regard to the evolution of this concept), it is justified to study the opportunities and challenges related to its implementation in small and medium-sized enterprises. Considering the current development of I4.0 solutions, we focused on their application in production-related processes, particularly in the area of Logistics 4.0. According to our research, small and medium-sized enterprises constitute a large group of suppliers for large factories operating, based on Industry 4.0. This means that adjusting their logistics processes to the needs of the supported cyber-physical systems will determine the efficiency of the entire supply chain.

3. Materials and Methods

One of the manifestations of digital transformation is a synthetic and systematic review of the literature and a meta-analysis of the data. Observation of research in selected fields is practiced by scientists worldwide and is a crucial tool for managing the diversity of knowledge. Examples include publications on bibliometric analyses concerning the concept of a sustainable supply chain [46]; elasticity research [47]; the smart factory concept [48]; considerations on reverse logistics [49]; blockchain technology [50]; ocean renewable energy [51].

The method of bibliometric dynamic analysis of the literature network (SLNA) and the PRISMA framework was adopted as the bibliometric analysis method. The PRISMA framework is an evidence-based approach to accurately and reliably report the findings from articles for a systematic review [52]. A systematic review using the PRISMA framework will collect all empirical evidence to fit the eligibility criteria to answer the identified research question. This method minimizes bias and provides guidance and structure for reporting [53].

A systematic literature review was carried out to identify the research problems indicated above. The article search strategy was based on a procedure that searched for scientific publications in the Web of Science (WoS) Core Collection. This is the database provided by Clarivate Analytics. It is an interdisciplinary (multidisciplinary) research platform that records the content of over 12,000 high-profile journals and over 160,000 conferences worldwide. It allows researchers to search multiple databases simultaneously from a single interface—via the Web of Science ™ Core Collection. The WoS database provides many bibliometric indicators and contains literature from most disciplines.

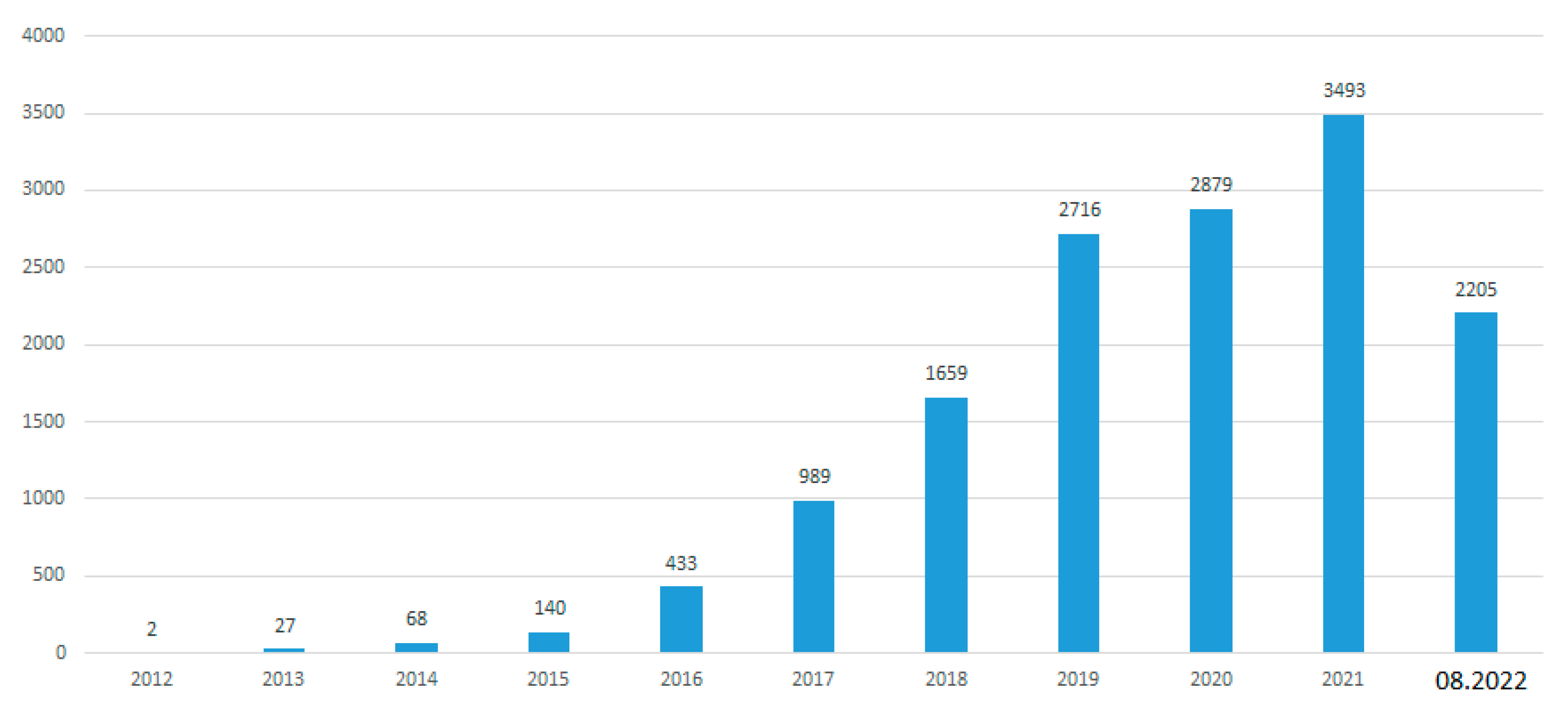

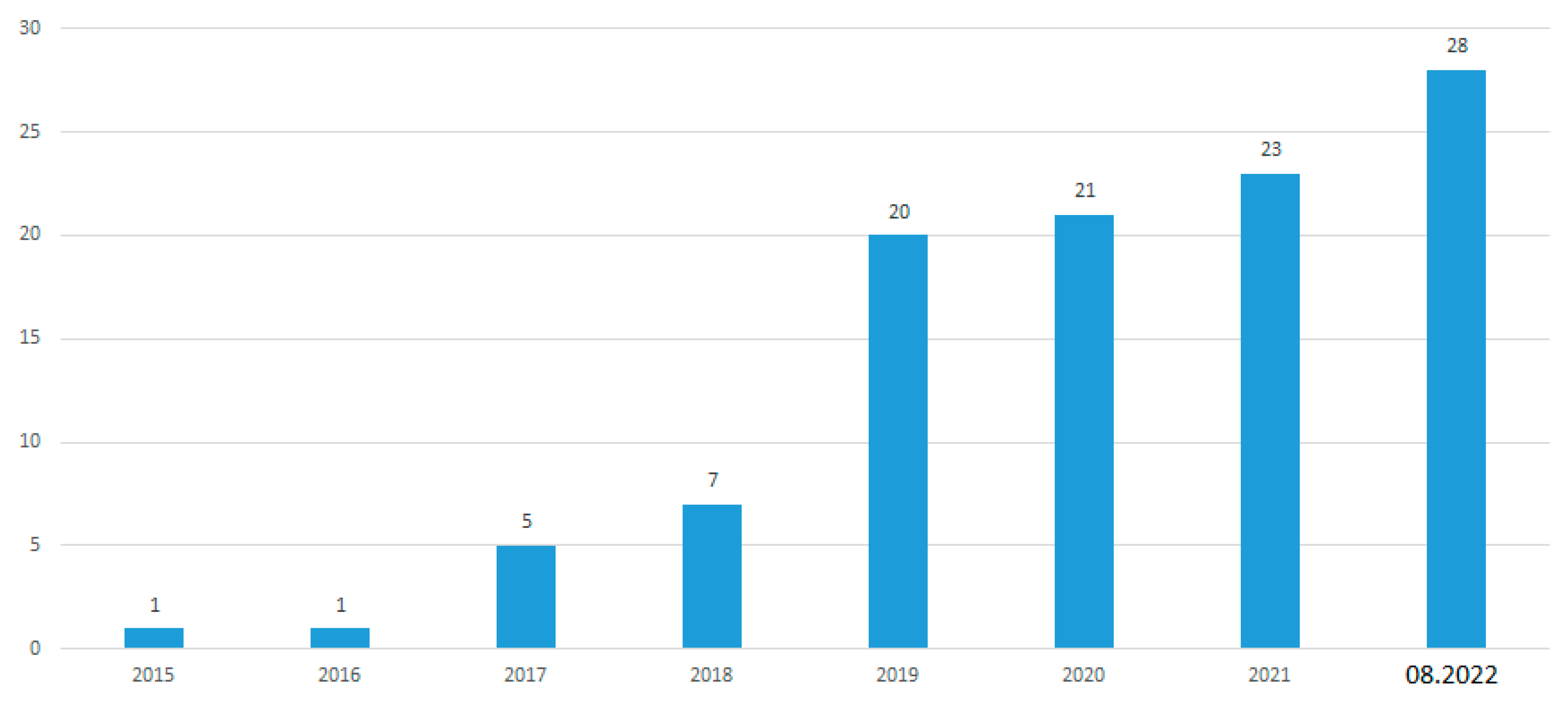

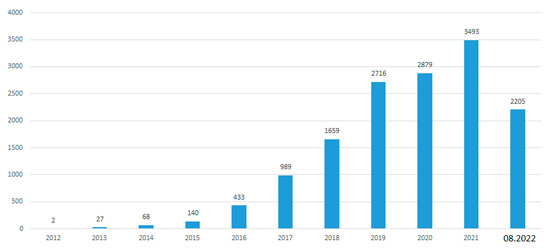

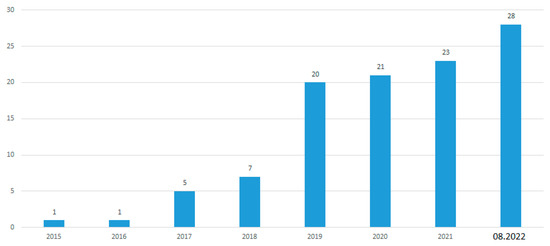

It can be observed that the amount of knowledge related to research on industry 4.0 and Logistics 4.0 is widely spread (Figure 1 and Figure 2). The growing trend of publishing scientific papers in both of these areas can be observed all the time, although there is a clear difference in the number of published articles. The concept of Industry 4.0 has entered the dictionaries and language of scientists and practitioners around the world for good. Moreover, the idea of Logistics 4.0 is used primarily by scientists from European countries, hence a small but growing trend. The increasing number of published works yearly indicates that both issues are essential for science and business practices. Therefore, the current state of knowledge on the topics noted requires research to systematize and rationalize the knowledge generated on this subject.

Figure 1.

The number of scientific publications over the years—the Industry 4.0 keyword. Source: own study.

Figure 2.

The number of scientific publications over the years—the Logistics 4.0 keyword. Source: own study.

The preparation of a systematic review and the development of research results is a multi-stage process that requires the use of specific methods and the careful documentation of the process with a detailed application of knowledge and available scientific publications. For the research described in this paper, an in-depth keyword search was carried out, organized according to the PRISMA assumptions, and carried out in several steps. This research method offers many advantages over analyzing aggregated data from scientific publications. These steps include developing the search strategy, defining the selection criteria, and performing the quality assessment and data extraction process [54].

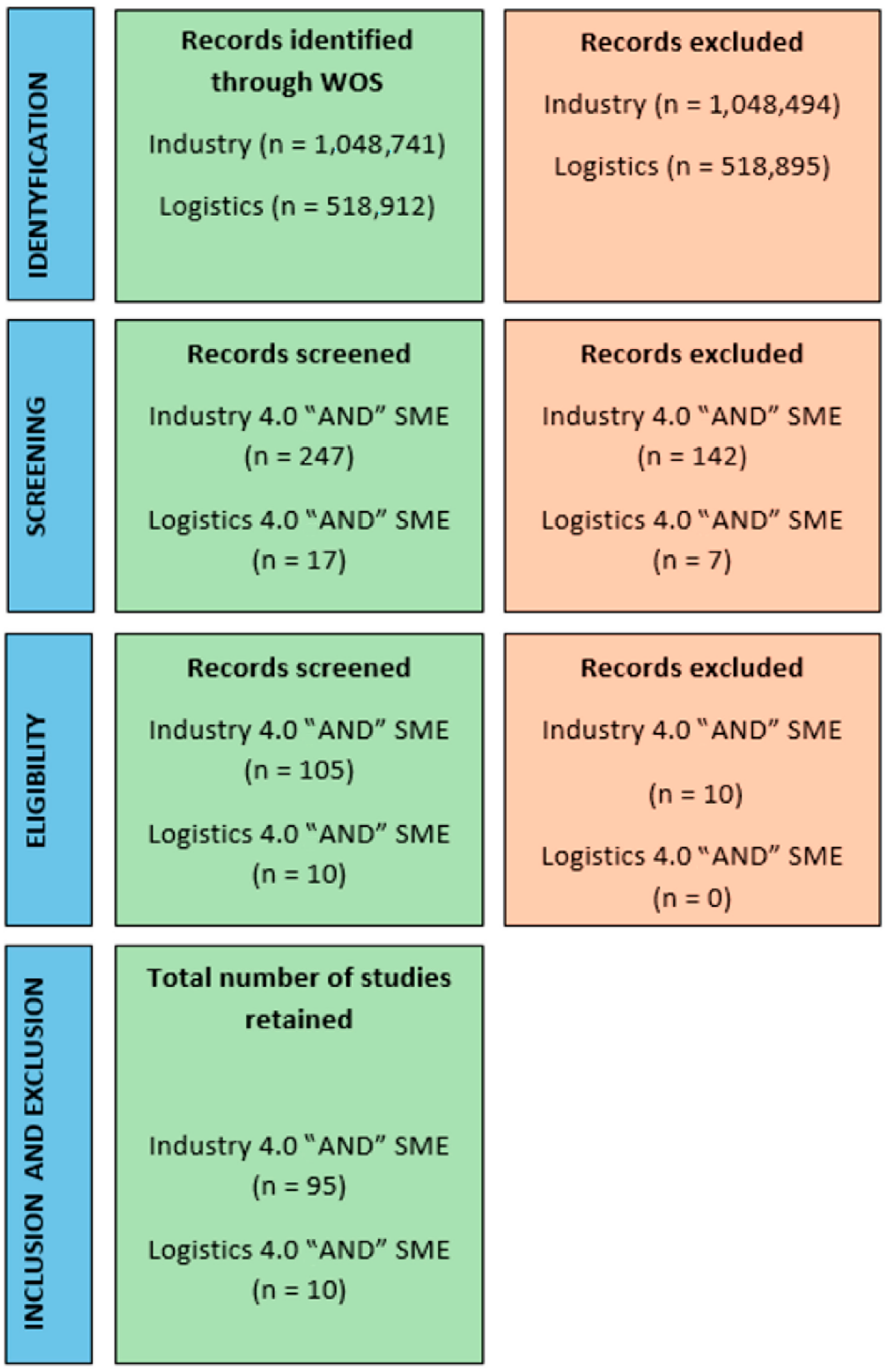

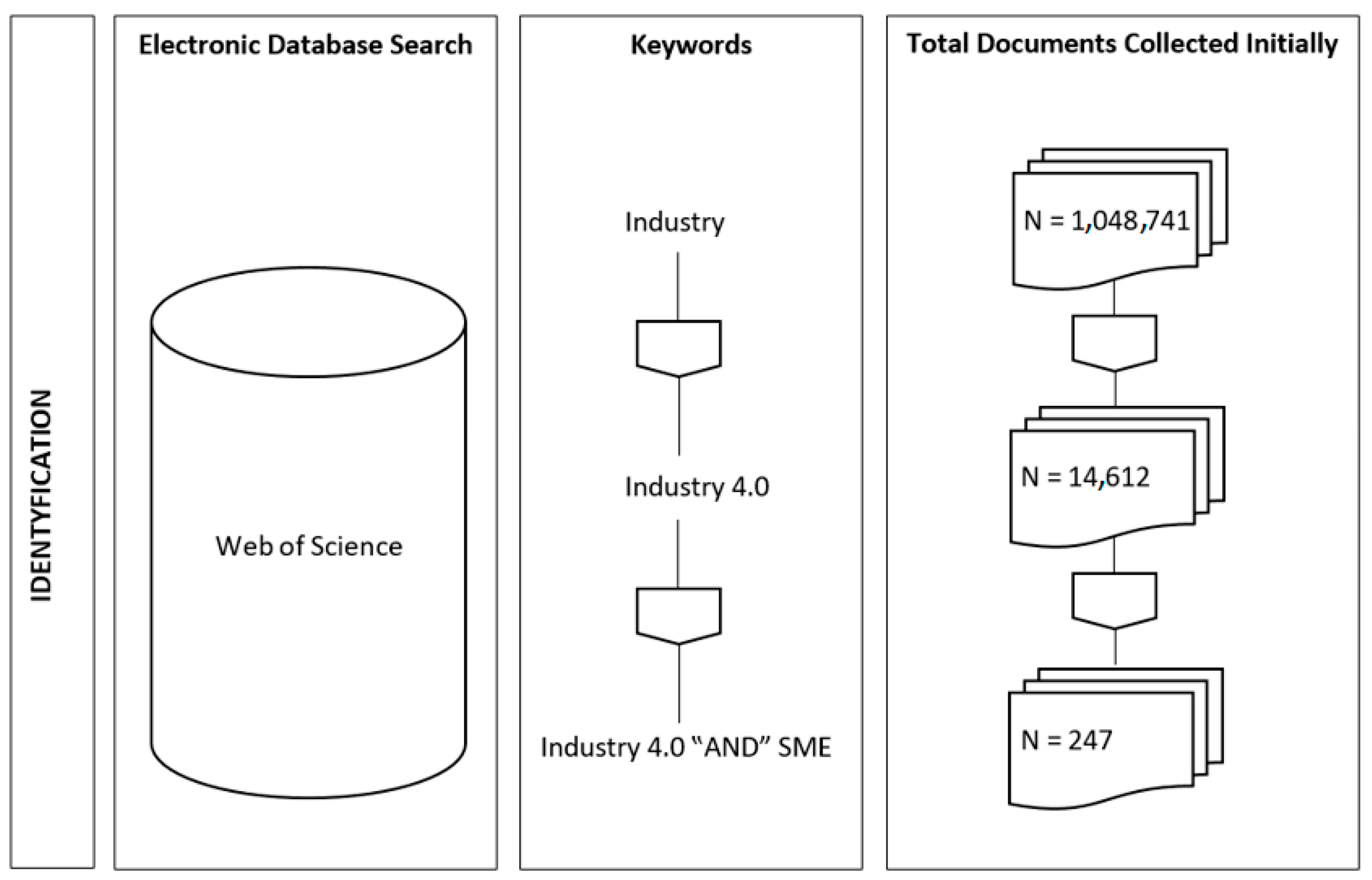

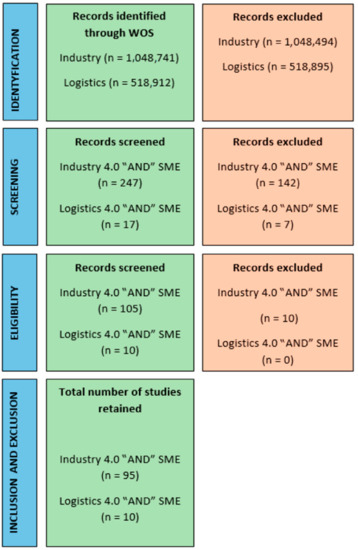

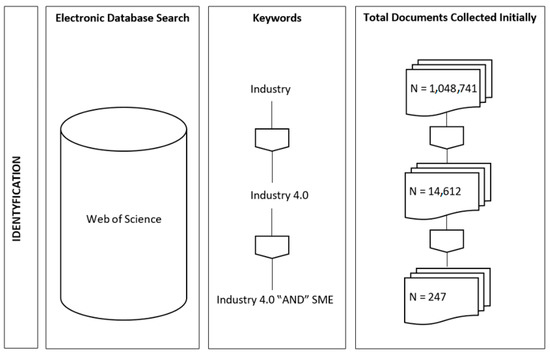

The flowcharts used in the bibliographic synthesis will enable the reader to understand the research steps quickly. The primary research stages are shown in Figure 3, while the detailed results of the procedure are shown in Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8.

Figure 3.

The flow chart in the PRISMA consort diagram of the screening and selection of studies.

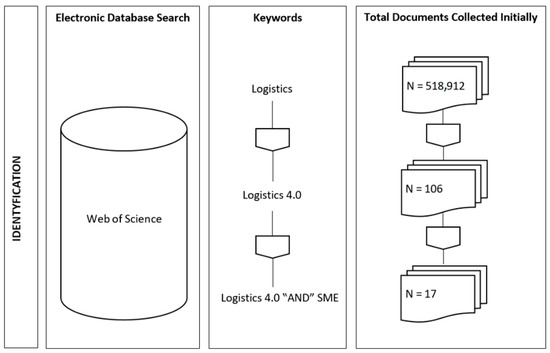

Figure 4.

Identification stage of the PRISMA framework related to Industry 4.0 in the SME sector. Source: own study, based on the PRISMA methodology.

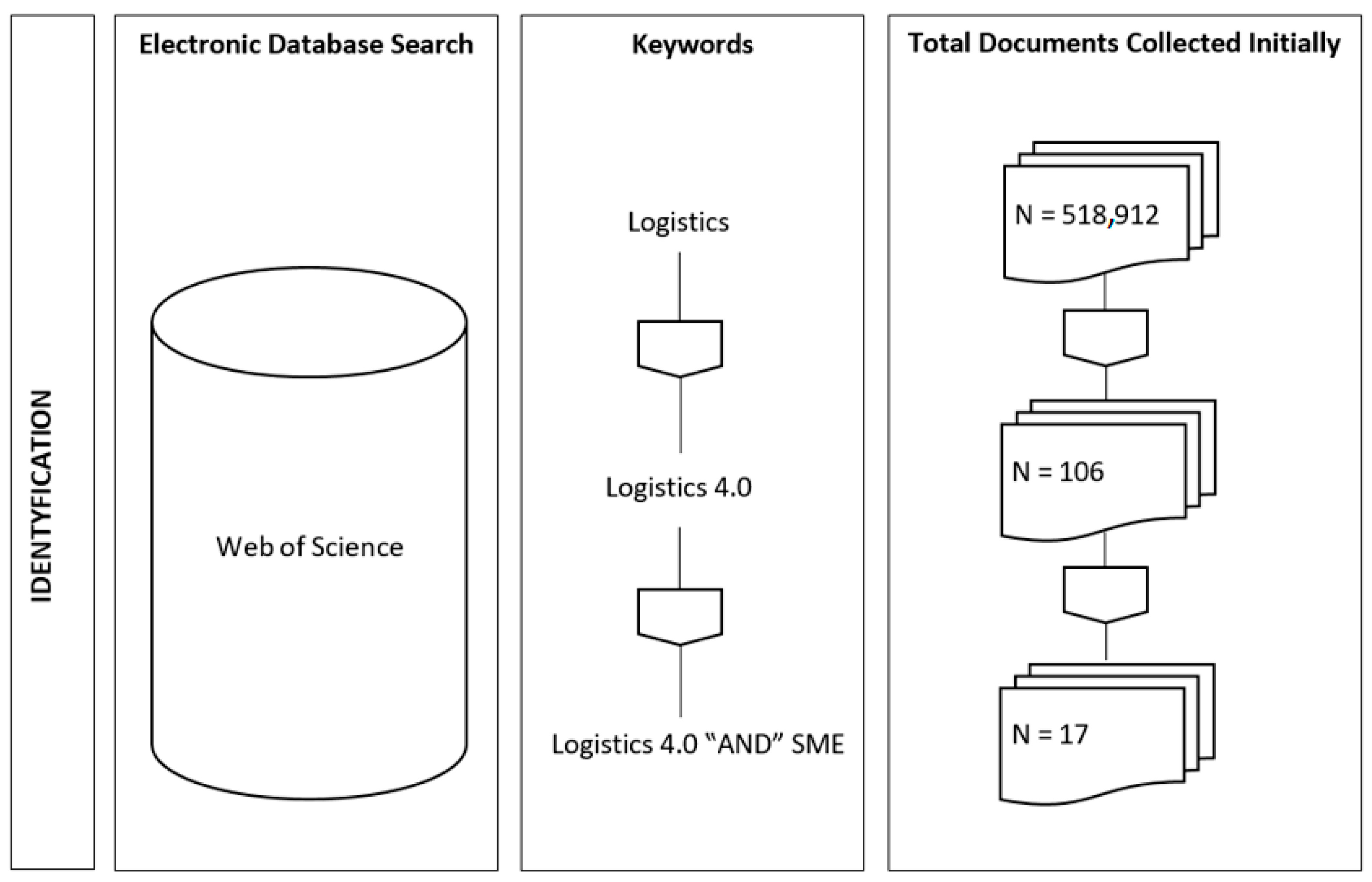

Figure 5.

Identification stage of the PRISMA framework related to Logistics 4.0 in the SME sector. Source: own study, based on the PRISMA methodology.

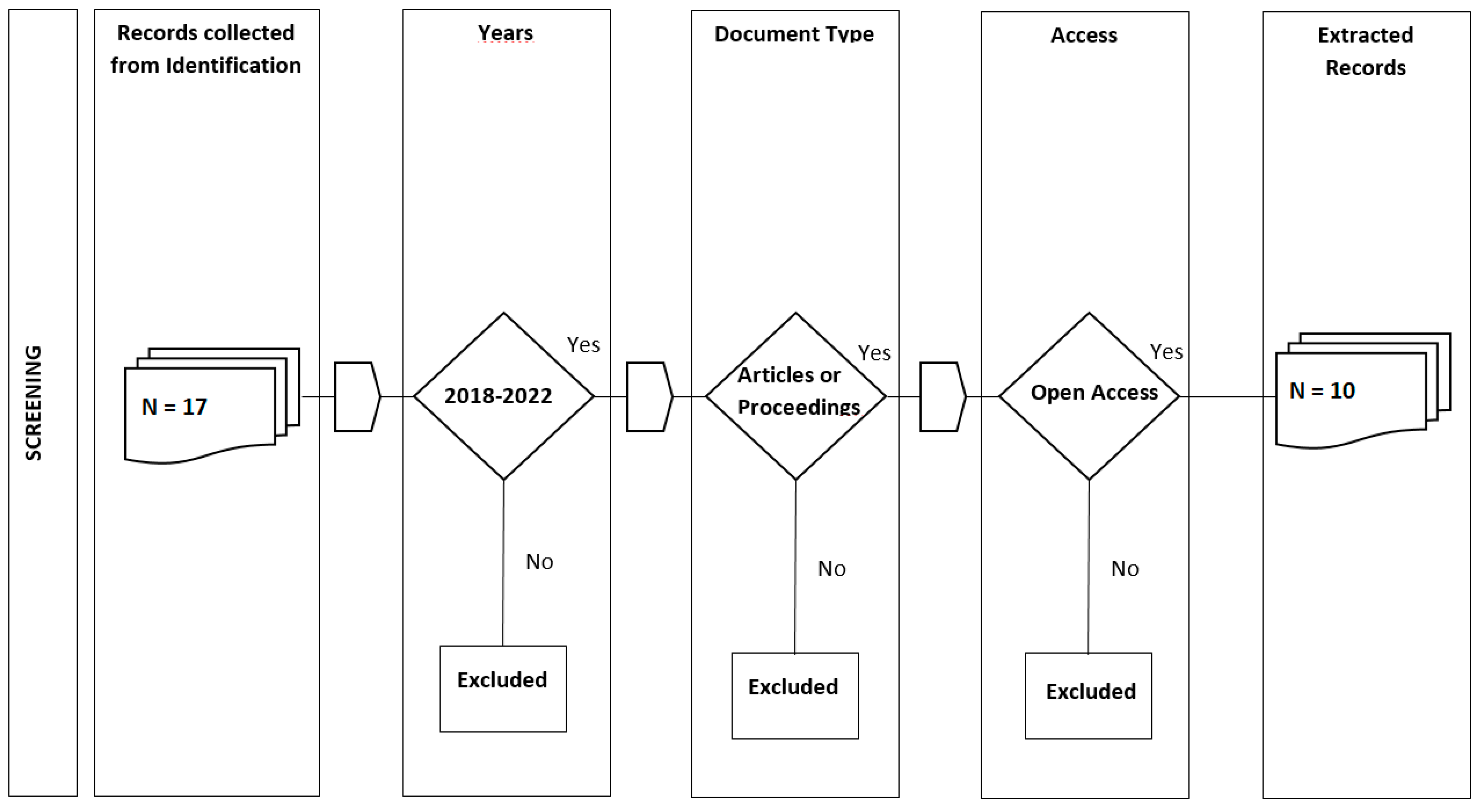

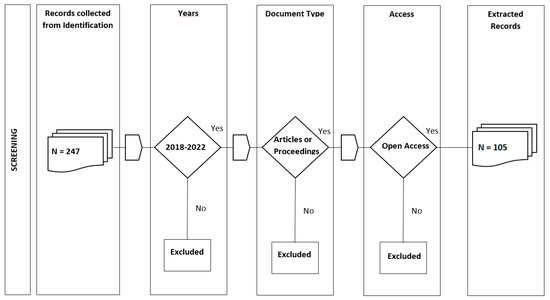

Figure 6.

Screening step of the PRISMA framework related to Industry 4.0 in the SME sector. Source: own study, based on the PRISMA methodology.

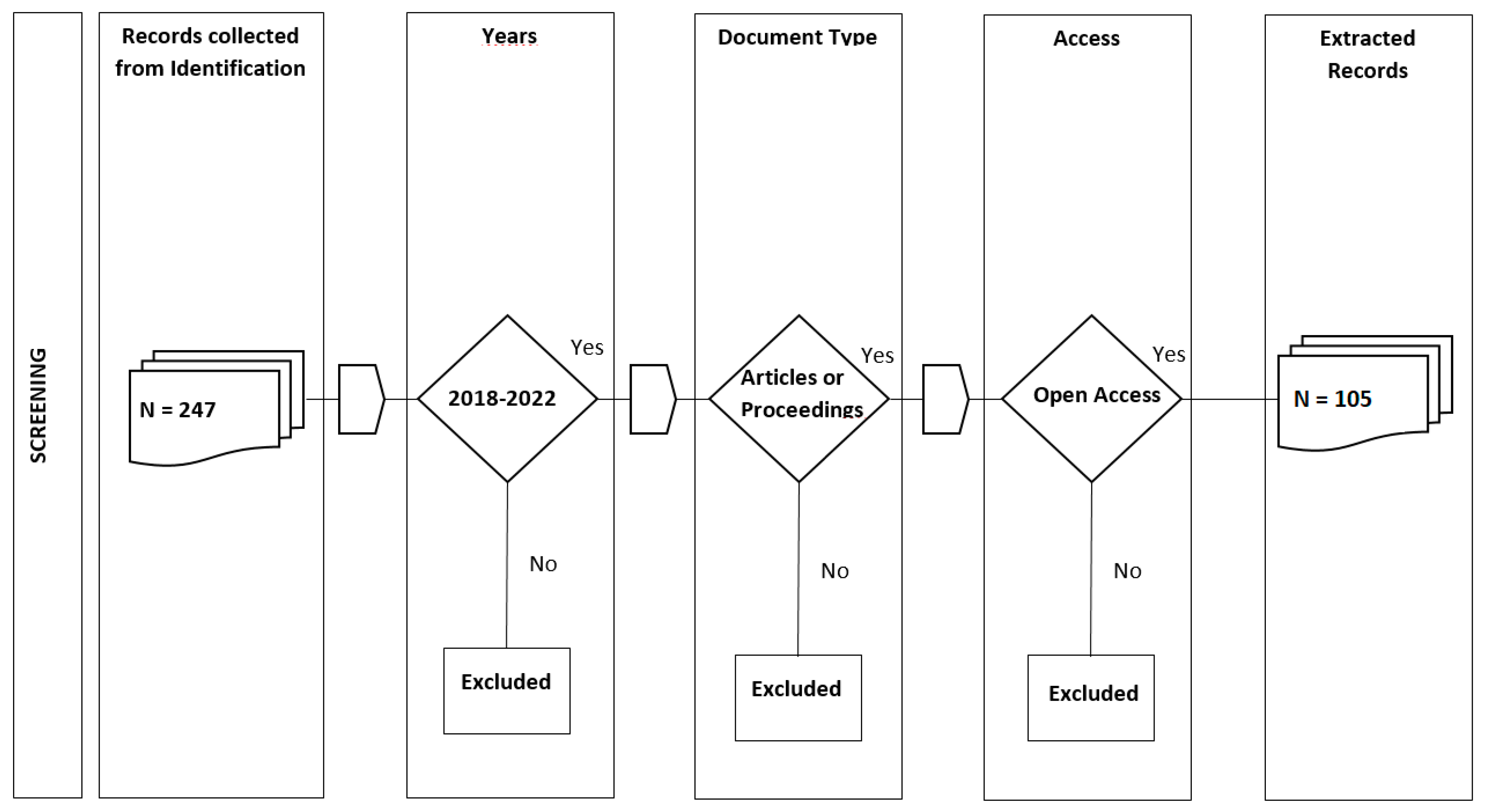

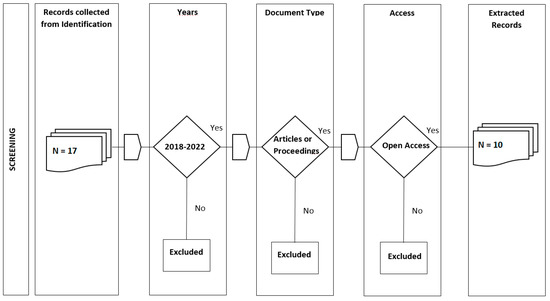

Figure 7.

Screening step of the PRISMA framework related to Logistics 4.0 in the SME sector. Source: own study based on the PRISMA methodology.

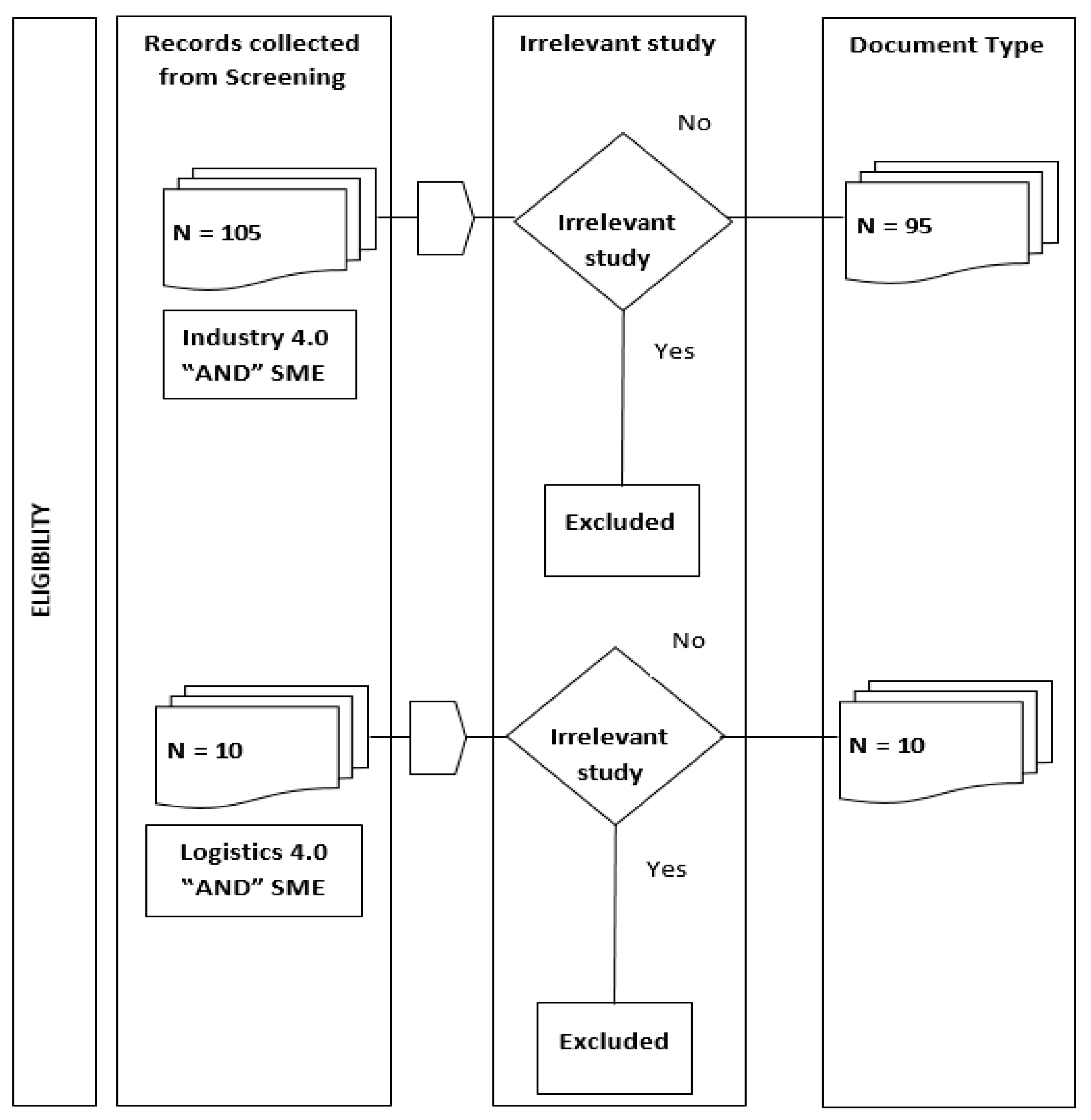

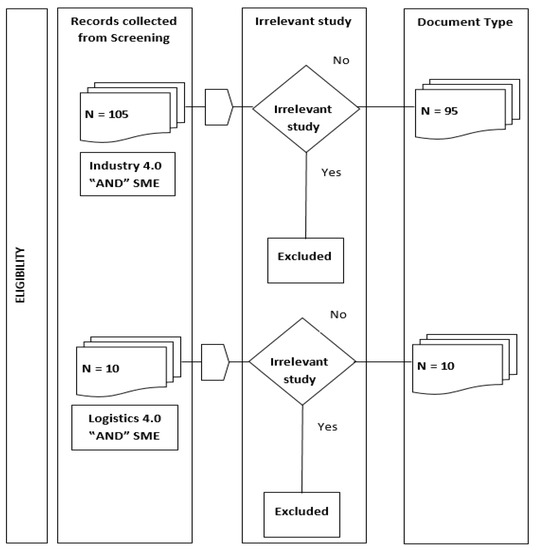

Figure 8.

Eligibility step of the PRISMA framework. Source: own study, based on the PRISMA methodology.

First, a search paradigm was defined, and a reliable database was selected and used to find the preliminary results. As mentioned earlier, the study includes search results from the Web of Science database, due to its global reach, intuitiveness, and order.

Then, we defined the research selection paradigm in which the screening process occurred. The selection criteria included such criteria as time limits, research field limitations, language selection, scientific articles, and the filtering of review articles. Research works that did not pass the screening process were removed from the study and were not subject to further analysis.

The following research step was to analyze each scientific publication and make an evaluation. The most relevant research articles that met the objectives of this study were selected and integrated into the literature review.

Step 1. Identification

At this stage, the search criteria are defined and executed. The search is mainly focused on collecting the existing literature on Industry 4.0 (Figure 4) and Logistics 4.0 (Figure 5). Considering that we are looking for research in small and medium-sized enterprises, the search has been expanded to include this aspect. Thus, in the in-depth keyword search, the terms were searched for in titles, abstracts, and keywords of publications indexed in the Web of Science ™ Core Collection database. The conducted preliminary search focused on two keywords:

- Industry—the acquired knowledge base included 1,048,741 scientific publications and was narrowed down to the concept of Industry 4.0 (14,612 scientific publications);

- Logistics—the acquired knowledge comprised 518,912 scientific publications and was narrowed down to the concept of Logistics 4.0 (106 scientific publications).

Then the keywords were combined using the “AND” operator to connect them with the implementation area of interest of the SME. As a result, the following was obtained:

Including the Identification stage:

- 1,048,494 scientific publications were excluded for the concept of Industry 4.0 “AND” SME;

- 518,895 scientific publications were excluded for the concept of Logistics 4.0 “AND” SME.

Step 2. Screening

According to the PRISMA assumptions, screening is an important study stage. This is the next stage of the study. It concerned narrowing the search scope to the years in the period 2018–08.2022. Those scientific publications published before 2018 were removed and not subject to further research. This move is justified because the research intention is to review the literature on the latest available publications. Thus, the study was narrowed down to the scientific publications available from the last five years:

- Industry 4.0 “AND” SME; 2018–2022—217 scientific publications;

- Logistics 4.0 “AND” SME; 2018–2022—15 scientific publications.

Another deepening of the search for scientific publications relevant to our research concerned their type. Those published in peer-reviewed scientific journals and as peer-reviewed conference papers were selected for further study. Of course, those papers that were full articles and reviews were selected. So, the further study included:

- Industry 4.0 “AND” SME; 2018–2022; document type—207 scientific publications;

- Logistics 4.0 “AND” SME; 2018–2022; document type—11 scientific publications.

The last step in narrowing down the selection of scientific publications for analysis was limiting the selection to open access publications. This deepening of the search was based on the selection of only open-access scientific publications. Open access to scientific publications assumes that it will be free of charge to the full content of the peer-reviewed scientific publications on the public Internet without legal and technical barriers and without the need to register and log in. Therefore, publications with limited or paid access were not subject to further research. Finally, the following was obtained and transferred to the next stage:

- Industry 4.0 “AND” SME; 2018–2022; document type; open access—105 scientific publications;

- Logistics 4.0 “AND” SME; 2018–2022; document type; open access—10 scientific publications.

As can be seen, Stage 2 also examines the exhaustion of irrelevant entries throughout the review process. In total, at the screening stage:

- for the concept of Industry 4.0 “AND” SME; 2018–2022; document type; open access excluded 142 scientific publications;

- for the concept of Logistics 4.0 “AND” SME; 2018–2022; document type; open access excluded seven scientific publications.

Screening processes in the second step of Prisma of the scientific publications related to Industry 4.0 in the SME sector are presented in Figure 6. Scientific publications related to Logistics 4.0 in the SME sector are presented in Figure 7.

Step 3. Eligibility

As shown previously, the study was based on full scientific and conference papers. A summary of each article has been read. The purpose of the work and the obtained results of the study were checked, and the accuracy and adjustment of scientific papers to the purpose and scope of own research were thoroughly checked. Subsequently, all articles underwent a deep evaluation. At the eligibility stage, ten scientific publications related to Industry 4.0 in the SME sector were excluded, making it possible to establish the number of publications used for further research at 95 scientific papers. The basis for the exclusion was the substantially unjustified qualification of the scientific work by the system, e.g., the article appeared in the Society of Manufacturing Engineers, which also has the abbreviation SME. No scientific publication related to Logistics 4.0 in the SME sector was excluded at this study stage. The results of step 3 for both analyzed areas are presented in the joint Figure 8.

Step 4. Inclusion and Exclusion

Ultimately, 95 scientific publications were selected for the literature review for the concept of Industry 4.0 “AND” SME, and 10 scientific publications for the concept of Logistics 4.0 “AND” SME.

3.1. Statistics of the Scientific Publications Related to Industry 4.0 in the SME Sector

Following the arrangement of the collection of 95 selected scientific publications related to Industry 4.0 in the SME sector, 69 scientific articles and 26 scientific papers published as conference materials were identified.

The conducted analyses indicate that 69 articles were published in 10 scientific journals. Five of them can be considered leading journals, as they published 45.72% of all analyzed works in this area. Table 3 shows the list of found source titles in which the analyzed scientific works appeared.

Table 3.

Main source titles which contributed to the publication of scientific articles in scientific journals related to Industry 4.0 in the SME sector; Source: own study.

Statistics show that 10 source titles contributed to the publication of post-conference papers related to Industry 4.0 in the SME sector. It was found that in four of them, 14 scientific papers were published, constituting about 13.34% of all published documents of this type (Table 4).

Table 4.

Main source titles which contributed to the publication of post-conference scientific publications related to Industry 4.0 in the SME sector; Source: own study.

The research subject is characterized by a multidisciplinary specificity related to the mutual complementation of issues and concepts from various areas of science. It should be noted that the total number of scientific papers corresponding to individual areas of science does not add up to the identified group of 95 scientific publications. The most popular group of sciences is Engineering, for which 56 scientific papers have been identified. The second leading group of sciences is Computer Science. Twenty-one scientific publications were established for this group. There was also a field of science related to science and technology; 19 scientific papers are indicated here. The fourth large area of knowledge is business economics and environmental sciences ecology, for which 16 scientific papers have been identified (Table 5).

Table 5.

The main areas of science to which the analyzed articles were classified; Source: own study.

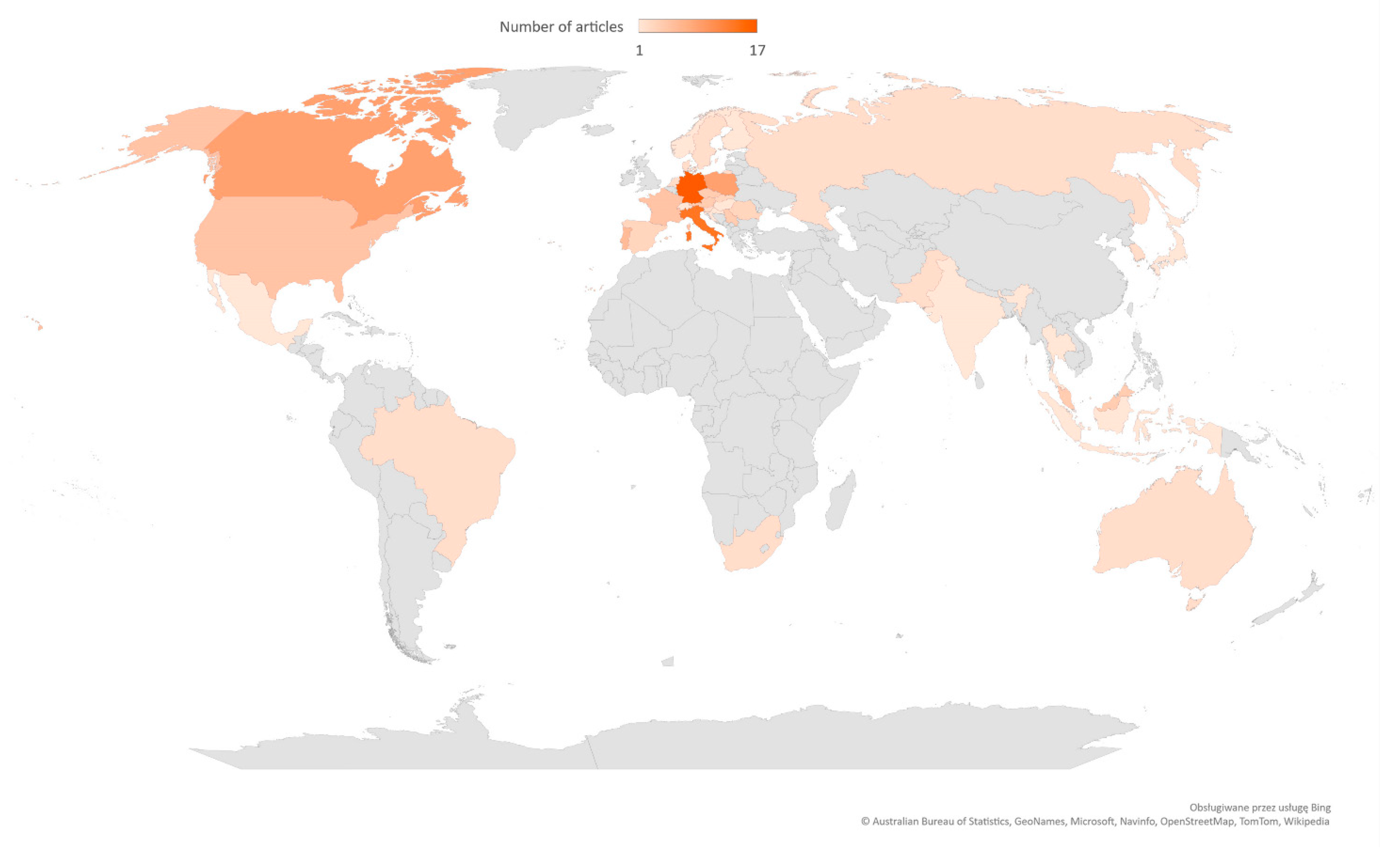

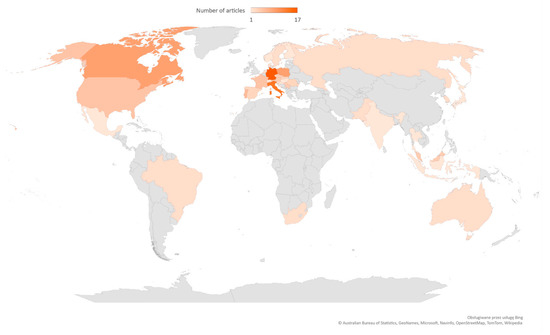

For the analyzed group of scientific publications, the statistics show that authors from Germany dominate (Figure 9). Researchers affiliated with research institutions in Germany have published 17 scientific papers listed in the WoS database. This gives a ratio of 16.19%. The Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Technische Hochschule Ingolstadt, and Technische Universität Bergakademie Freiberg are important research centers.

Figure 9.

Scientific contribution by country and geographic region related to Industry 4.0 in the SME sector; Source: own study.

Authors from Italy are in second place and have published a total of 14 items (an index of 13.33%). In Italy, important centers are the Polytechnic University of Bari, the Parthenope University of Naples, and the University of Turin. The leading region in terms of published materials is England—10 publications issued by researchers from English research centers. Canada and Poland come fourth—after nine scientific publications.

3.2. Statistics of Scientific Publications Related to Logistics 4.0 in the SME Sector

Similarly, the list was prepared for the selected publications, considering the terms Logistics 4.0 “AND” SME.

Following the arrangement of the collection of 10 publications related to Logistics 4.0 in the SME sector, six scientific articles and four post-conference materials were identified.

Statistics show that seven scientific journals influenced the publication of 10 scientific articles. The statistical summary shows that two scientific journals have more than one published work, constituting 36.36% of all published papers of this type (Table 6).

Table 6.

Main source titles which contributed to the publication of the scientific articles in scientific journals related to Logistics 4.0 in the SME sector; Source: own study.

The statistical summary shows that one conference contributed to publishing more than one post-conference paper related to Logistics 4.0 in the SME sector. Two scientific studies were published there, constituting about 18.18% of all published works of this type (Table 7).

Table 7.

Main source title which contributed to the publication of post-conference scientific publications related to Logistics 4.0 in the SME sector; Source: own study.

The studied subject matter is primarily characterized by engineering specificity. Nine areas of science have been specified, including the analyzed publications. However, the most popular is engineering, for which seven scientific papers were identified (Table 8), accounting for 63.64% of the researched publications (one article can be assigned to several research areas).

Table 8.

The main area of science to which the analyzed articles were classified; Source: own study.

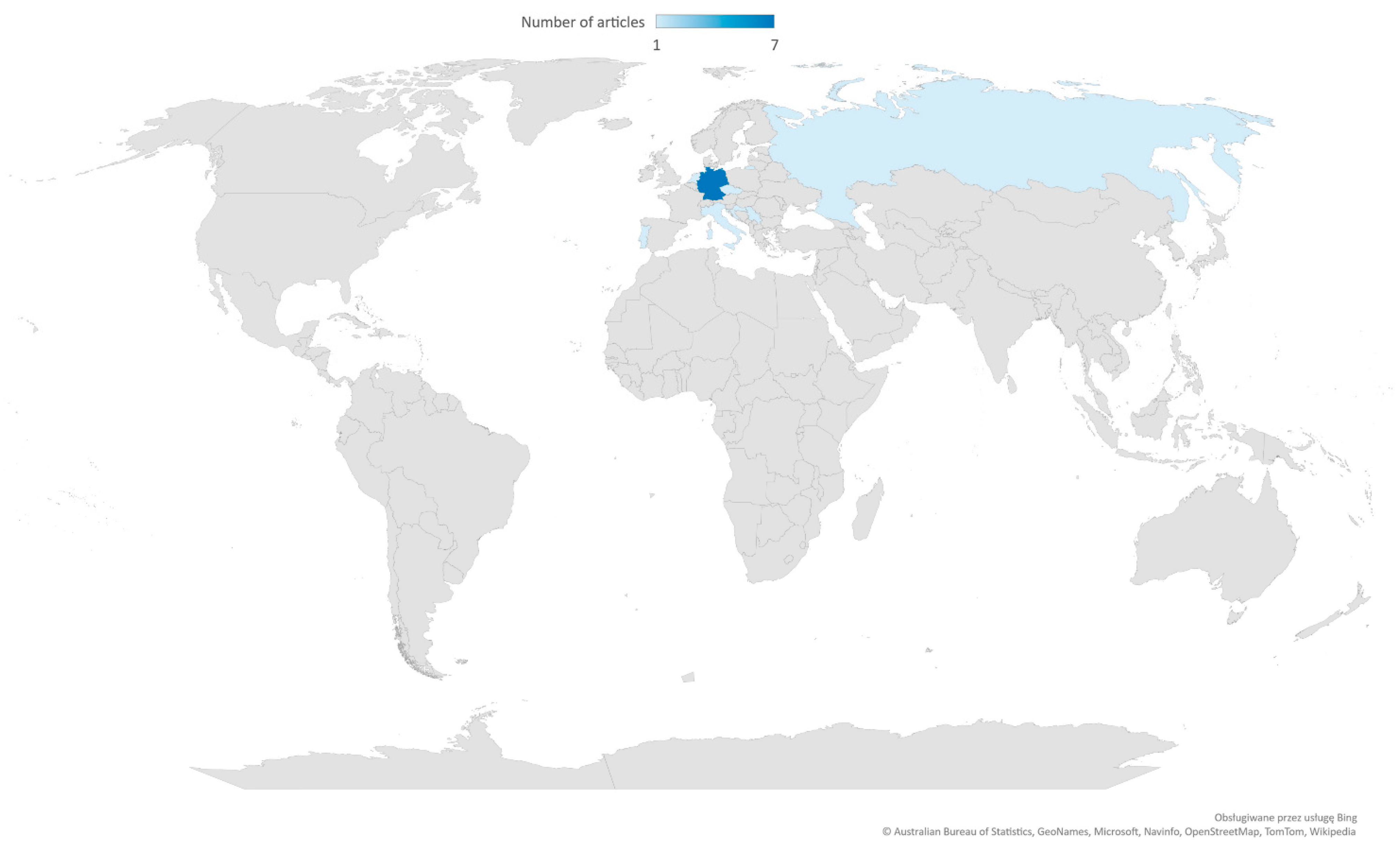

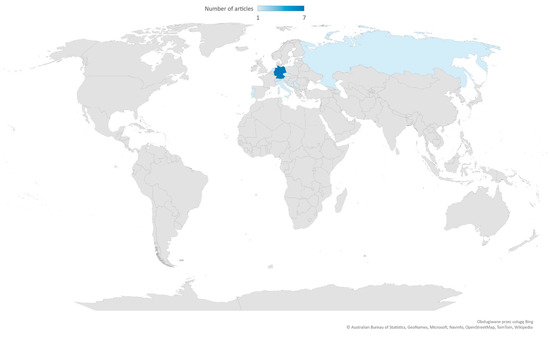

For the studied group of scientific publications, the statistics show that also in this area, researchers from Germany dominate (Figure 10). Researchers affiliated with research institutions in Germany have published seven scientific papers listed in the WoS database. This gives the ratio equal to 63.64%. It is a leadership that contributes significantly to the development of the area under study. Important centers are the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Technische Hochschule Ingolstadt, and the Chemnitz University of Technology. The other countries the research came from were: Croatia, the Czech Republic, England, Italy, the Netherlands, and Portugal. They published one scientific work each on the topic under study.

Figure 10.

Scientific contribution by country and geographic region related to Logistics 4.0 in the SME sector; Source: own study.

4. Results

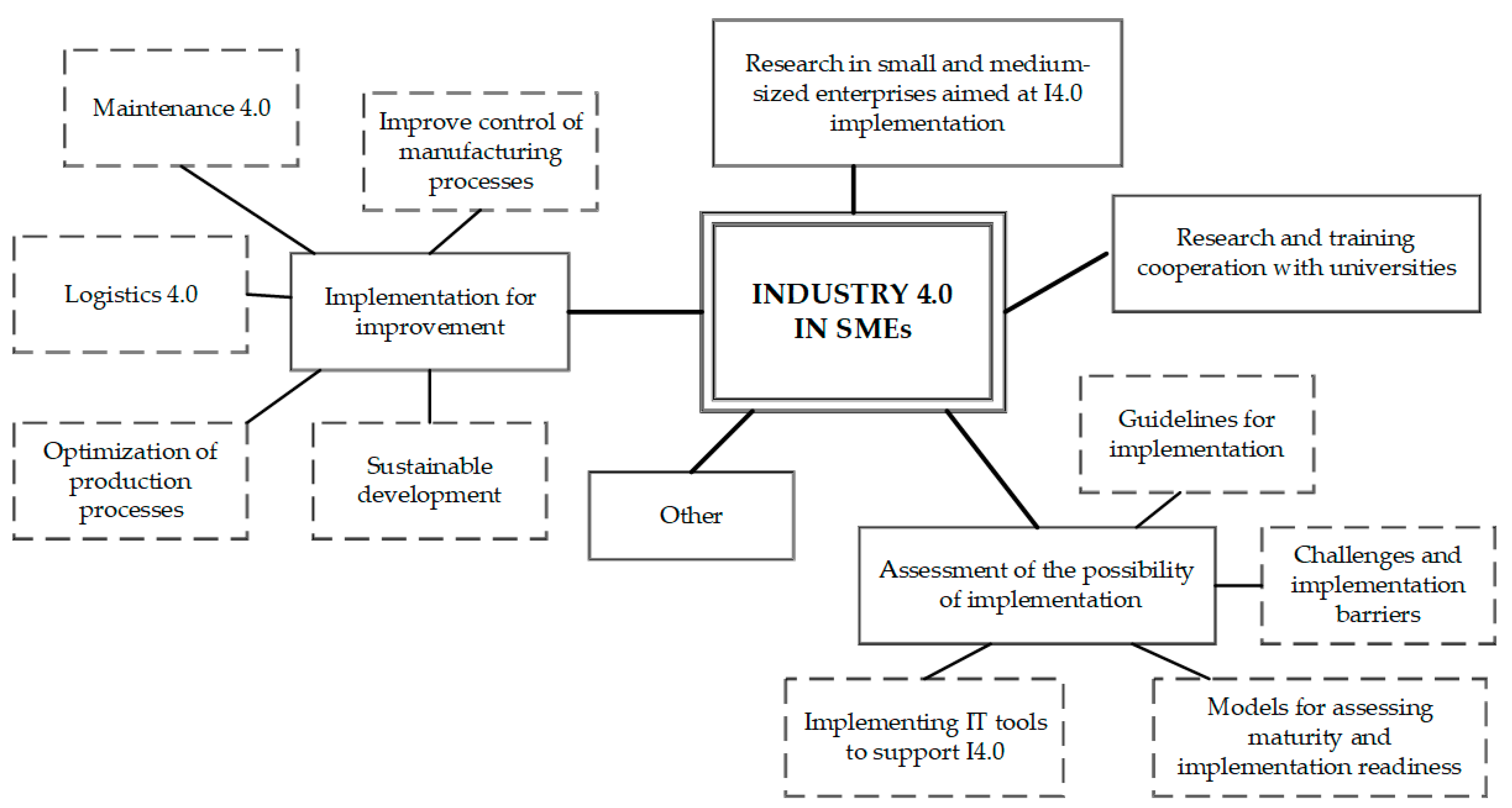

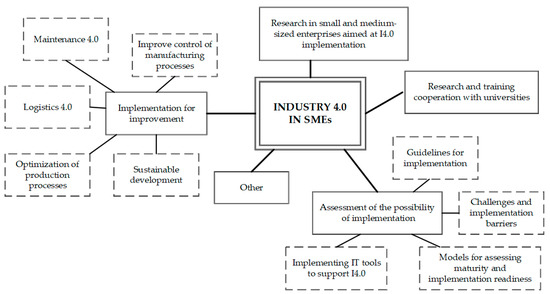

The literature studies allowed to identify the scope of research concerning the implementation of the Industry 4.0 concept in the SME sector. The conducted classification procedure allowed to distinguish five primary groups (1st classification level) and nine detailed groups (2nd classification level). The highlighted groups with their assignment are presented in Figure 11.

Figure 11.

Classification of the scientific publications related to Industry 4.0 in the SME sector. Source: own study.

The two most important research areas concerning the application of the Industry 4.0 concept in the SME sector include:

- methods of assessing the possibility of implementing selected solutions (tools) in enterprises from the analyzed sector;

- assumptions for implementing this concept to improve specific areas of activity conducted by these enterprises.

However, it is worth noting that the other two groups—surveys in enterprises and research and training cooperation—are primarily focused on the aspects related to the possibility of implementing the Industry 4.0 concept and adapting it to the needs of the SME sector. Table 9 presents the classification of the analyzed publications into distinguished research areas.

A large group of studies that concern the assessment of the possibility of implementing the Industry 4.0 concept is focused on the development of tools to assess the level of preparation of enterprises from the SME sector to the requirements of I4.0. The most frequently described evaluation tools include various models of process and the infrastructure maturity assessment [9,45,55,56,57]. Noteworthy are publications that refer to the characteristics of the so-called tool for assessing the readiness of small and medium enterprises (SMEs) in Industry 4.0 [58,59,60,61,62,63,64]. This tool usually assesses the readiness of an organization in such categories as data sharing, data storage, data quality, data processing, product design and development, smart material planning, smart production, smart maintenance, smart logistic, digitalization, IT security, machine readiness, and communication between machines. Some authors propose SME performance models that will monitor the readiness level to implement the I4.0 concept [8].

Table 9.

The results of classifying the analyzed articles on Industry 4.0 in the SME sector. Source: own study.

Table 9.

The results of classifying the analyzed articles on Industry 4.0 in the SME sector. Source: own study.

| Level 1 | Level 2 | Articles |

|---|---|---|

| Assessment of the possibility of implementation | Models for assessing maturity and implementation readiness | [8,9,45,55,56,57] |

| Challenges and implementation barriers | [65,66,67,68,69,70,71,72] | |

| Guidelines for implementation | [13,73,74,75,76,77,78,79,80] | |

| Implementing IT tools to support I4.0 | [81,82,83,84,85,86,87,88,89,90] | |

| Implementation for improvement | Optimization of the production processes | [91,92,93,94,95] |

| Sustainable development | [96,97,98,99,100,101,102] | |

| Improve control of manufacturing processes | [103,104,105,106,107,108,109] | |

| Maintenance 4.0 | [110,111] | |

| Logistics 4.0 | [112,113,114,115,116] | |

| Research in small and medium-sized enterprises aimed at I4.0 implementation | [62,63,64,65,66,117,118,119,120,121,122,123,124,125,126,127] | |

| Research and training cooperation with universities | [128,129,130,131,132,133,134] | |

| Other | [135,136,137,138] |

Research on the assessment of the feasibility of implementing the Industry 4.0 concept also focuses on the challenges and barriers related to its adaptation to the needs of the SME sector. Particular implementation barriers mainly concern the level of the digitization of processes carried out by SMEs [65], and the limited resources [66,67]. The researchers describe the organizational, social, and technological challenges related to implementing the selected solutions I4.0 [68]. Research from this group also indicates the benefits of implementing I4.0, such as the possibility of collaboration in the supply chain [69]. Some of the presented implementation challenges are formulated, based on the research by a specific group of companies that have decided to implement the selected tool I4.0 [70,71,72].

The challenges and implementation barriers identified in the literature and industry are an impulse for many researchers to formulate guidelines for implementing Industry 4.0 tools and adapt known solutions to the needs of the SME sector [73]. The proposed solutions are a response to the limitations and shortcomings of small and medium-sized enterprises, such as a lack of information and limits on their knowledge of new information technologies [74]. Therefore, reference models are being developed [75,76] and implementation strategies [77,78,79], which are to facilitate the SME implementation of individual solutions supporting Industry 4.0. Some studies focus on identifying the key success factors [80] and other attributes [13], that determine the success of the Industry 4.0 implementation in small and medium-sized enterprises.

The assessment of the feasibility of implementing Industry 4.0 relates primarily to ensuring adequate IT support in the industrial processes. For this reason, in many publications, the attention of researchers is focused on the characteristics of IT tools that can support the development of Industry 4.0 in enterprises from the SME sector [81,82,83,84,85,86,87,88,89,90]. The most critical aspects of the implemented applications (base solutions) are simplicity, intuitiveness, and maximum use of the current potential of the enterprise. The proposed solutions respond to the information and decision-making needs of small and medium-sized enterprises, which differ from the needs of LSC.

The second group of studies we distinguished concerns the implementation of Industry 4.0 solutions in order to improve the selected areas of activity conducted by SMEs. For obvious reasons, some publications consider optimizing production processes by implementing I4.0 solutions [91,92,93]. This optimization usually concerns the maximization of added value and the minimization of losses [94]. The aim of the introduced improvements may be to improve efficiency [92,93,95]. However, the vast majority of contemporary publications focus on improving the processes in terms of meeting the principles of sustainable development [96,97,98,99]. The researchers’ attention is focused on rationalizing the resources used [100], limiting the impact of production on the natural environment [101], and implementing solutions supporting the circular economy [102].

The second goal of the implemented implementations is to increase the level of control exercised over the manufacturing process [103]. This applies to both real-time inspection and monitoring [104,105,106,107] and controlling as a management support tool in the context of Industry 4.0 [108,109].

It is worth noting that in the case of solutions dedicated to the needs of the SME sector, few publications refer to the improvement of production-related processes. Our research on Industry 4.0 in the SME sector distinguished only five publications on the implementation of logistics 4.0 solutions and only two publications on the improvement of machine maintenance processes [110,111]. The identified publications on Logistics 4.0 referred primarily to intralogistics [112,113,114] and perfect warehouse services [115,116].

A large group of publications is research conducted by scientists among enterprises from the SME sector in the form of surveys and structured and unstructured direct interviews. Their goal is to identify the implementation barriers (including [117,118,119]), the factors affecting the effective implementation of digitization processes [66,120,121], determining the technological and organizational readiness to implement the Industry 4.0 concept (including [62,122,123,124,125]), as well as the impact of the COVID-19 pandemic on the process of implementing the I4.0 concept in SMEs [126]. The subject of the survey was also to determine the relationship between innovation and employee capability and the readiness to implement the I4.0 concept [127].

Noteworthy are publications describing the research and training cooperation projects between universities and industry in the field of Industry 4.0 solutions, tailored to the needs of SMEs. The purpose of such joint research is:

- Building a learning factory and teaching laboratories considering the needs of small-to-medium enterprise (SME) challenges in Industry 4.0. [128,129,130,131].

- Development of training courses on implementing Industry 4.0 in enterprises from the SME sector [132] and tools supporting science [133].

- Temporary secondment of scientists from a research and technology organization (RTO) into an SME to jointly work on a practical project objective-which is directly tailored to the demands of the SME [134].

Four articles could not be classified into any of the distinguished groups presented in Figure 11. For this reason, a separate group, “Other,” was created, which included publications on:

- Assessment of tools from Industry 4.0 [135].

- The idea of establishing a team of consultants supporting the implementation of Industry 4.0 in SMEs [136].

- Standardization of suppliers concerning Industry 4.0 [137].

- Evacuation of autonomous robots from the factory in emergencies [138].

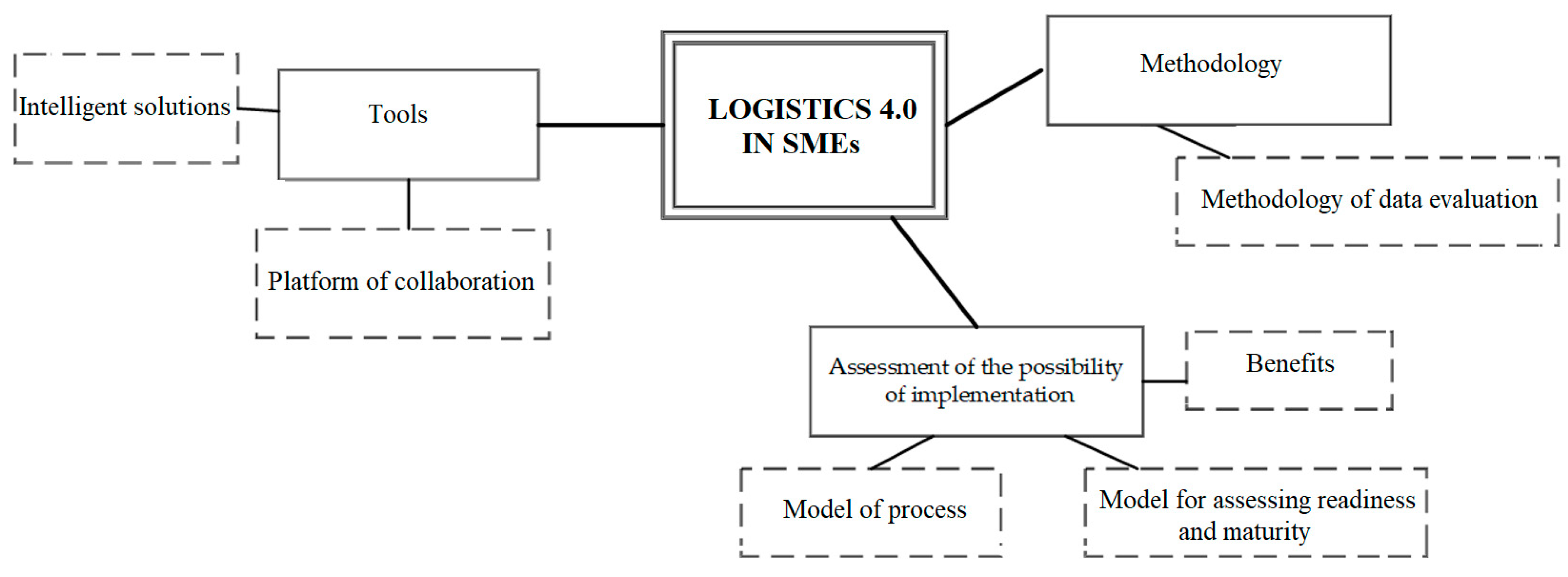

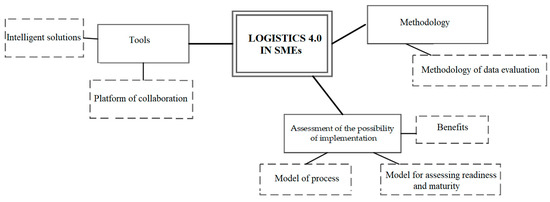

A similar study was prepared for the needs to analyze the Logistics 4.0 concept in the SME sector. The conducted analysis and in-depth studies of the literature allowed to identify the scope of the research. The classification procedure for this area allowed to distinguish three primary groups (1st level of classification) and six detailed groups (2nd level of classification). The distinguished groups and their assignment are presented in Figure 12 and Table 10.

Figure 12.

Classification of the scientific publications related to Logistics 4.0 in the SME sector. Source: own study.

A significant research area can be specified, which concerns assessing the possibility of implementing solutions related to the selected Logistics 4.0 solutions in small and medium-sized enterprises. The authors indicate that assessing the current readiness of small and medium-sized enterprises is crucial for companies. This allows enterprises to decide on a digital company’s right strategy and actions [58]. However, companies from the SME sector hesitate to introduce modern and often innovative technologies. They are primarily concerned with the high implementation costs, low benefits, and a lack of know-how.

In contrast, the implementation process is slow [120]. As it was indicated in part 1 of this article, most companies from the SME sector are not sufficiently prepared, and their level of maturity is low. Therefore, researchers are working on developing readiness models. One of the rules for creating them is: first improve the processes, then automate them. However, taking a logistics system’s complex structures and processes to a higher level of maturity is not easy. Hence, the need to focus on elements of the maturity model, e.g., Intralogistics 4.0 [113], which will then facilitate their integration with the industrial revolution [65]. Process models are also being developed that focus on identifying potential problems that hinder the increase in product quality and logistics efficiency [55]. The analyzed publications indicate that not only models are conceptually developed. Procedures that allow companies from the SME sector to assess the benefits independently are also effective [112]. However, if they appear, these benefits are identified primarily with economic opportunities and not, for example, with a positive impact on environmental sustainability [101].

Table 10.

The results of classifying the analyzed articles on Logistics 4.0 in the SME sector. Source: own study.

Table 10.

The results of classifying the analyzed articles on Logistics 4.0 in the SME sector. Source: own study.

| Level 1 | Level 2 | Articles |

|---|---|---|

| Assessment of the possibility of implementation | Model for assessing the readiness and maturity | [55,58,65,101,112,113,120] |

| Benefit | ||

| Models of process | ||

| Tools | Intelligent Solutions | [90,116] |

| Platform of collaboration | ||

| Methodology | Methodology of data evaluation | [139] |

The second group of scientific publications detailed by us concerns tools. For example, the described collaboration platform architecture is based on the event oriented architecture (EDSOA) model to support the collaboration between SMEs, dynamic modeling of their systems and services, and their integration into supply chains [90] or an intelligent solution using open source software tools [116].

Both Industry 4.0 and Logistics 4.0 use more and more data sets to analyze and support strategic and operational decisions. One of the most critical problems is assessing the data quality to be useful for small and medium-sized enterprises. Hence the need to implement also a methodology that simplifies the performance of data quality evaluation and improves the comprehensibility of its results [139].

5. Discussion

The literature review presented in Section 2 confirms that most studios and developments focus on larger companies [73]. The presented solutions and implementation guidelines consider the potential and requirements (needs) of large enterprises that were the first recipients of new tools and concepts proposed by Industry 4.0. However, as noted in Section 1, the economy of modern European countries relies primarily on small and medium-sized enterprises. They constitute the majority of participants in supply chains, both from local and global perspectives. This means that the further development of the Industry 4.0 concept depends primarily on whether SMEs will implement the proposed technological and organizational solutions.

Meanwhile, as the literature review we prepared shows, the described and recommended tool I4.0 and Logistics 4.0 technologies often disregard the SME-specific digitalization challenges, such as knowledge, resource, and technology-awareness limitations. This is also confirmed by the research of other authors (e.g., [73]). Recognition of the specificity of enterprises from the SME sector has been proven in many publications cited in Section 4. Articles from the group “Challenges and implementation barriers” clearly indicate that the main implementation barrier is limited resources, which concern not only material resources but also knowledge and competencies. This is also confirmed by the characteristics presented in Table 2. So, if large enterprises want their small and medium-sized partners to meet the development challenges they face, they must be aware that their support in the form of access to proven IT solutions is also necessary and substantive. At the same time, it should be noted that the information needs (communication, monitoring, reporting) differ from the needs of the LSCs. For this reason, the implemented cyber-physical systems must take into account the specificity of the functioning of SMEs, but also that the expected effects from the implemented I4.0 implementations may be different.

An additional goal of our research was to determine the degree of adaptation of the I4.0 and L4.0 solutions to the production-related processes in SMEs, particularly in logistics services. These aspects were of particular interest to us because small and medium-sized enterprises constitute the largest group of members of logistics networks that handle the flow of goods in all sectors of the economy. Although the increasing interest in Industry 4.0 is undisputable, the literature on how this new technology revolution affects supply chain activities and intralogistics and material handling has been restricted up to now [140]. Our research clearly shows that there is a research gap in this area. The limited number of publications in the basic search, and above all, only 10 scientific publications found in the dedicated search, indicate an evident lack of adaptation of this area of Industry 4.0 to the needs of SMEs.

Another research gap that should be distinguished at the discussion stage is issues related to the implementation of Industry 4.0 solutions, in order to improve the sustainable development in small and medium-sized enterprises. It should be noted that the published research focused mainly on aspects related to environmental protection, including, in particular, issues related to waste management. Even in the case of those publications, concerning the rationalization of enterprise resource management, there were no studies on the consumption of energy resources and energy.

Meanwhile, considering the current energy crisis in the European Union countries related to the geopolitical situation in Europe, the limited availability of these resources will primarily affect enterprises in the SME sector. In our opinion, the countries of Europe are on the verge of a severe economic and social crisis, which has not been seen in these countries since World War II, precisely because of the energy crisis. It should be expected that in the countries of the entire European Union, there will be large-scale energy rationing and a significant increase in costs. Hence, the further evident growth of Industry 4.0 technologies and solutions, as well as their direction, are highly questionable. In our opinion, it will be necessary to develop new methods of operation, the aim of which will be to develop energy-saving technology of Industry 4.0 and Logistics 4.0, and ways to become independent from one supplier, not only of raw materials and resources, but also technology.

The lack of interest in these issues in the pre-crisis period means that many small and medium-sized enterprises will not take up the challenge of implementing I4.0 and L4.0 solutions, fearing rising energy prices. This may cause a significant drop in interest in further developing this concept, particularly among enterprises in the SME sector. In our opinion, these phenomena will be the subject of significant analysis in the coming months, the results of which will be published in 2023–2024.

6. Conclusions

The transformation towards Industry 4.0 and the use of Logistics 4.0 technology in the economy is a long-term process that is still evolving. Tools supporting the implementation of Industry 4.0 are tailored primarily to the requirements of large enterprises. However, it is necessary to develop them also to meet the needs of small and medium-sized enterprises, without which the economy of the European Union countries does not exist. The current political and economic crisis will undoubtedly slow the implementation of I4.0 solutions in SMEs. Limited access to the required resources, and rising energy prices, with their simultaneous limitation, will not encourage entrepreneurs to invest in such solutions. Only a clear definition of a goal adequate to the current needs of enterprises in the SME sector can convince owners and managers to take up the challenge of implementing selected tools. The lack of such activities will mean that large enterprises that have invested in adjusting their processes to the requirements of I4.0 will not achieve the assumed effects. Each of them is a link in supply chains dominated by small and medium-sized enterprises.

As a result of the research, the formulated conclusions, and the discussion undertaken in the work, it should be stated that there is a growing need to implement new methods of operation dedicated to enterprises from the SME sector and to revise the existing business models of these enterprises. In the context of the geopolitical situation, when we observe rationing and significant increases in energy costs and, as a result, also the limitation of raw material resources, we should consider transformational thinking. The next stage of the research will try to answer the following questions:

- Q1: In which direction should include the further transformation of Industry 4.0 and Logistics 4.0 go, as a result of the pandemic and the current energy crisis?

- Q2: To what extent can technological transformation be used to deal with the energy crisis and the search for sustainable and resistant strategies to the disruptions of organizational solutions, also dedicated to SMEs?

Author Contributions

Conceptualization, A.A.T. and K.G.; methodology, A.A.T. and K.G.; validation, A.A.T. and K.G.; formal analysis, A.A.T. and K.G.; investigation, A.A.T. and K.G.; resources, A.A.T. and K.G.; data curation, A.A.T. and K.G.; writing—original draft preparation, A.A.T. and K.G.; writing—review and editing, A.A.T. and K.G; visualization, A.A.T. and K.G.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Schroeder, A.; Ziaee Bigdeli, A.; Galera Zarco, C.; Baines, T. Capturing the Benefits of Industry 4.0: A Business Network Perspective. Prod. Plan. Control. 2019, 30, 1305–1321. [Google Scholar] [CrossRef]

- Digital Economy and Society Index (DESI) 2020 Connectivity. Available online: https://digital-strategy.ec.europa.eu/en/policies/desi-connectivity (accessed on 7 September 2022).

- Digital Economy and Society Index Report 2020—Human Capital. Available online: https://digital-strategy.ec.europa.eu/en/policies/desi-human-capital (accessed on 7 September 2022).

- Digital Economy and Society Index Report 2020—Integration of Digital Technology. Available online: https://digital-strategy.ec.europa.eu/en/policies/desi-integration-technology-enterprises (accessed on 7 September 2022).

- Digital Economy and Society Index Report 2020—Use of Internet Services. Available online: https://digital-strategy.ec.europa.eu/en/policies/desi-digital-public-services (accessed on 7 September 2022).

- Dossou, P.-E.; Laouénan, G.; Didier, J.-Y. Development of a Sustainable Industry 4.0 Approach for Increasing the Performance of SMEs. Processes 2022, 10, 1092. [Google Scholar] [CrossRef]

- Rauch, E.; Unterhofer, M.; Rojas, R.A.; Gualtieri, L.; Woschank, M.; Matt, D.T. A Maturity Level-Based Assessment Tool to Enhance the Implementation of Industry 4.0 in Small and Medium-Sized Enterprises. Sustainability 2020, 12, 3559. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Available online: Https://Www.Parp.Gov.Pl/Component/Publications/Publication/Sektor-Msp-w-Polsce-i-w-Ue (accessed on 7 September 2022).

- Eurostat. Available online: https://ec.europa.eu/eurostat (accessed on 7 September 2022).

- Barton, M.; Budjac, R.; Tanuska, P.; Gaspar, G.; Schreiber, P. Identification Overview of Industry 4.0 Essential Attributes and Resource-Limited Embedded Artificial-Intelligence-of-Things Devices for Small and Medium-Sized Enterprises. Appl. Sci. 2022, 12, 5672. [Google Scholar] [CrossRef]

- Szopa, Ł.; Cyplik, P. The Concept of Building a Digital Transformation Model for Enterprises from the SME Sector–Case Study. LogForum 2020, 16, 593–601. [Google Scholar]

- Available online: Https://Digitallydriven.Connectedcouncil.Org/Europe/Wp-Content/Uploads/Sites/2/2021/03/Digitally-Driven-Europe-FINAL-1.Pdf (accessed on 7 September 2022).

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the Definition of Industry 4.0: Analysis and Open Questions. Int. J. Prod. Econ 2020, 226, 107617. [Google Scholar] [CrossRef]

- Bordeleau, F.-E.; Mosconi, E.; de Santa-Eulalia, L.A. Business Intelligence and Analytics Value Creation in Industry 4.0: A Multiple Case Study in Manufacturing Medium Enterprises. Production. Plan. Control 2020, 31, 173–185. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 Integration with Socio-Technical Systems Theory: A Systematic Review and Proposed Theoretical Model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Matthyssens, P. Reconceptualizing Value Innovation for Industry 4.0 and the Industrial Internet of Things. J. Bus. Ind. Mark. 2019, 34, 1203–1209. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 Ten Years on: A Bibliometric and Systematic Review of Concepts, Sustainability Value Drivers, and Success Determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as Enabler for a Sustainable Development: A Qualitative Assessment of Its Ecological and Social Potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The Smart Factory as a Key Construct of Industry 4.0: A Systematic Literature Review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2019, 12, 86. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A Systematic Review towards a New Logistics System. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Bigliardi, B.; Casella, G.; Bottani, E. Industry 4.0 in the Logistics Field: A Bibliometric Analysis. IET Collab. Intell. Manuf. 2021, 3, 4–12. [Google Scholar] [CrossRef]

- Żuchowski, W. The Smart Warehouse Trend: Actual Level of Technology Availability. Logforum 2022, 18, 227–235. [Google Scholar] [CrossRef]

- Naseem, M.H.; Yang, J. Role of Industry 4.0 in Supply Chains Sustainability: A Systematic Literature Review. Sustainability 2021, 13, 9544. [Google Scholar] [CrossRef]

- Tubis, A.A.; Poturaj, H. Challenges in the Implementation of Autonomous Robots in the Process of Feeding Materials on the Production Line as Part of Logistics 4.0. LogForum 2021, 17, 411–423. [Google Scholar] [CrossRef]

- Simoni, M.D.; Kutanoglu, E.; Claudel, C.G. Optimization and Analysis of a Robot-Assisted Last Mile Delivery System. Transp. Res. E. Logist. Transp. Rev. 2020, 142, 102049. [Google Scholar] [CrossRef]

- Tubis, A.A.; Ryczyński, J.; Żurek, A. Risk Assessment for the Use of Drones in Warehouse Operations in the First Phase of Introducing the Service to the Market. Sensors 2021, 21, 6713. [Google Scholar] [CrossRef] [PubMed]

- Legenvre, H.; Henke, M.; Ruile, H. Making Sense of the Impact of the Internet of Things on Purchasing and Supply Management:A Tension Perspective. J. Purch. Supply Manag. 2020, 26, 100596. [Google Scholar] [CrossRef]

- Spieske, A.; Birkel, H. Improving Supply Chain Resilience through Industry 4.0: A Systematic Literature Review under the Impressions of the COVID-19 Pandemic. Comput. Ind. Eng. 2021, 158, 107452. [Google Scholar] [CrossRef]

- Rodrigues, J.A.; Farinha, J.T.; Mendes, M.; Mateus, R.; Cardoso, A. Short and Long Forecast to Implement Predictive Maintenance in a Pulp Industry. Eksploat. I Niezawodn. Maint. Reliab. 2021, 24, 33–41. [Google Scholar] [CrossRef]

- Matuszczak, M.; Żbikowski, M.; Teodorczyk, A. Predictive Modelling of Turbofan Engine Components Condition Using Machine and Deep Learning Methods. Eksploat. I Niezawodn. Maint. Reliab. 2021, 23, 359–370. [Google Scholar] [CrossRef]

- Chen, C.; Wang, C.; Lu, N.; Jiang, B.; Xing, Y. A Data-Driven Predictive Maintenance Strategy Based on Accurate Failure Prognostics. Eksploat. I Niezawodn. Maint. Reliab. 2021, 23, 387–394. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Balta, M.E. Climate Change and Big Data Analytics: Challenges and Opportunities. Int. J. Inf. Manag. 2022, 63, 102448. [Google Scholar] [CrossRef]

- Kopetz, H.; Steiner, W. Internet of Things. In Real-Time Systems; Springer International Publishing: Cham, Switzerland, 2022; pp. 325–341. [Google Scholar]

- Piromalis, D.; Kantaros, A. Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence. Appl. Syst. Innov. 2022, 5, 65. [Google Scholar] [CrossRef]

- Parmar, H.; Khan, T.; Tucci, F.; Umer, R.; Carlone, P. Advanced Robotics and Additive Manufacturing of Composites: Towards a New Era in Industry 4.0. Mater. Manuf. Process. 2022, 37, 483–517. [Google Scholar] [CrossRef]

- Cotrino, A.; Sebastián, M.A.; González-Gaya, C. Industry 4.0 Roadmap: Implementation for Small and Medium-Sized Enterprises. Appl. Sci. 2020, 10, 8566. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Grzybowska, K.; Łupicka, A. Key Competencies for Industry 4.0. Econ. Manag. Innovations. 2017, 1, 250–253. [Google Scholar]

- Chavez, Z.; Hauge, J.B.; Bellgran, M. Industry 4.0, Transition or Addition in SMEs? A Systematic Literature Review on Digitalization for Deviation Management. Int. J. Adv. Manuf. Technol. 2022, 119, 57–76. [Google Scholar] [CrossRef]

- Mittal, S.; Romero, D.; Wuest, T. Towards a Smart Manufacturing Maturity Model for SMEs (SM3E). In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0; Springer: Cham, Switzerland, 2018; pp. 155–163. [Google Scholar]

- Taticchi, P.; Tonelli, F.; Pasqualino, R. Performance Measurement of Sustainable Supply Chains. Int. J. Product. Perform. Manag. 2013, 62, 782–804. [Google Scholar] [CrossRef]

- Seebacher, G.; Winkler, H. A Citation Analysis of the Research on Manufacturing and Supply Chain Flexibility. Int. J. Prod. Res. 2013, 51, 3415–3427. [Google Scholar] [CrossRef]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature Review on the ‘Smart Factory’ Concept Using Bibliometric Tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar] [CrossRef]

- Wang, J.-J.; Chen, H.; Rogers, D.S.; Ellram, L.M.; Grawe, S.J. A Bibliometric Analysis of Reverse Logistics Research (1992-2015) and Opportunities for Future Research. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 666–687. [Google Scholar] [CrossRef]

- Kuzior, A.; Sira, M. A Bibliometric Analysis of Blockchain Technology Research Using VOSviewer. Sustainability 2022, 14, 8206. [Google Scholar] [CrossRef]

- Hu, H.; Xue, W.; Jiang, P.; Li, Y. Bibliometric Analysis for Ocean Renewable Energy: An Comprehensive Review for Hotspots, Frontiers, and Emerging Trends. Renew. Sustain. Energy Rev. 2022, 167, 112739. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. BMJ 2009, 339, b2535. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.F.; Belcher, T.W.; Zimmerman, B.; Franklin, J. Interprofessional Partnerships Involving School Counsellors for Children with Special Needs: A Broad Based Systematic Review Using the PRISMA Framework. Support Learn. 2020, 35, 43–67. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Peukert, S.; Treber, S.; Balz, S.; Haefner, B.; Lanza, G. Process Model for the Successful Implementation and Demonstration of SME-Based Industry 4.0 Showcases in Global Production Networks. Prod. Eng. 2020, 14, 275–288. [Google Scholar] [CrossRef]

- Grooss, O.F.; Presser, M.; Tambo, T. Balancing Digital Maturity and Operational Performance-Progressing in a Low-Digital SME Manufacturing Setting. Procedia Comput. Sci. 2022, 200, 495–504. [Google Scholar] [CrossRef]

- Amaral, A.; Peças, P. A Framework for Assessing Manufacturing SMEs Industry 4.0 Maturity. Appl. Sci. 2021, 11, 6127. [Google Scholar] [CrossRef]

- Axmann, B.; Harmoko, H. Industry 4.0 Readiness Assessment. Teh. Glas. 2020, 14, 212–217. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Jafarnejad, H. The Smart SME Technology Readiness Assessment Methodology in the Context of Industry 4.0. J. Manuf. Technol. Manag. 2021, 32, 1037–1065. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Jafarnejad, H.; Putra, M.F. Smart Production Planning and Control: Technology Readiness Assessment. Procedia. Comput. Sci. 2021, 180, 618–627. [Google Scholar] [CrossRef]

- Rahamaddulla, S.R.B.; Leman, Z.; Baharudin, B.T.H.T.; Ahmad, S.A. Conceptualizing Smart Manufacturing Readiness-Maturity Model for Small and Medium Enterprise (SME) in Malaysia. Sustainability 2021, 13, 9793. [Google Scholar] [CrossRef]

- Ingaldi, M.; Ulewicz, R. Problems with the Implementation of Industry 4.0 in Enterprises from the SME Sector. Sustainability 2019, 12, 217. [Google Scholar] [CrossRef]

- Chonsawat, N.; Sopadang, A. Defining SMEs’ 4.0 Readiness Indicators. Appl. Sci. 2020, 10, 8998. [Google Scholar] [CrossRef]

- Kamišalić, A.; Šestak, M.; Beranič, T. Supporting the Sustainability of Natural Fiber-Based Value Chains of SMEs through Digitalization. Sustainability 2020, 12, 8121. [Google Scholar] [CrossRef]

- Amaral, A.; Peças, P. SMEs and Industry 4.0: Two Case Studies of Digitalization for a Smoother Integration. Comput. Ind. 2021, 125, 103333. [Google Scholar] [CrossRef]

- Michna, A.; Kmieciak, R. Open-Mindedness Culture, Knowledge-Sharing, Financial Performance, and Industry 4.0 in SMEs. Sustainability 2020, 12, 9041. [Google Scholar] [CrossRef]

- Grau, A.; Indri, M.; lo Bello, L.; Sauter, T. Robots in Industry: The Past, Present, and Future of a Growing Collaboration with Humans. IEEE Ind. Electron. Mag. 2021, 15, 50–61. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Pušavec, F.; Likar, B. The Role and Meaning of the Digital Transformation as a Disruptive Innovation on Small and Medium Manufacturing Enterprises. Front. Psychol. 2021, 12, 592528. [Google Scholar] [CrossRef]

- Kazantsev, N.; Pishchulov, G.; Mehandjiev, N.; Sampaio, P.; Zolkiewski, J. Investigating Barriers to Demand-Driven SME Collaboration in Low-Volume High-Variability Manufacturing. Supply Chain. Manag. Int. J. 2022, 27, 265–282. [Google Scholar] [CrossRef]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Li, D.; Fast-Berglund, Å.; Paulin, D. Current and Future Industry 4.0 Capabilities for Information and Knowledge Sharing. Int. J. Adv. Manuf. Technol. 2019, 105, 3951–3963. [Google Scholar] [CrossRef]

- Cimini, C.; Boffelli, A.; Lagorio, A.; Kalchschmidt, M.; Pinto, R. How Do Industry 4.0 Technologies Influence Organisational Change? An Empirical Analysis of Italian SMEs. J. Manuf. Technol. Manag. 2020, 32, 695–721. [Google Scholar] [CrossRef]

- Schönfuß, B.; McFarlane, D.; Hawkridge, G.; Salter, L.; Athanassopoulou, N.; de Silva, L. A Catalogue of Digital Solution Areas for Prioritising the Needs of Manufacturing SMEs. Comput. Ind. 2021, 133, 103532. [Google Scholar] [CrossRef]

- Taurino, T.; Villa, A. A Method for Applying Industry 4.0 in Small Enterprises. IFAC Pap. 2019, 52, 439–444. [Google Scholar] [CrossRef]

- Esposito, G.; Romagnoli, G. A Reference Model for SMEs Understanding of Industry 4.0. IFAC Pap. 2021, 54, 510–515. [Google Scholar] [CrossRef]

- Dossou, P.E. Impact of Sustainability on the Supply Chain 4.0 Performance. Procedia Manuf. 2018, 17, 452–459. [Google Scholar] [CrossRef]

- Bouchard, S.; Abdulnour, G.; Gamache, S. Agility and Industry 4.0 Implementation Strategy in a Quebec Manufacturing SME. Sustainability 2022, 14, 7884. [Google Scholar] [CrossRef]

- Abdulnour, S.; Baril, C.; Abdulnour, G.; Gamache, S. Implementation of Industry 4.0 Principles and Tools: Simulation and Case Study in a Manufacturing SME. Sustainability 2022, 14, 6336. [Google Scholar] [CrossRef]

- Rusly, F.H.; Talib, Y.Y.A.; Hussin, M.R.A.; Mutalib, H.A. MODELLING THE INTERNAL FORCES OF SMEs DIGITAL ADAPTATION STRATEGY TOWARDS INDUSTRY REVOLUTION 4.0. Pol. J. Manag. Stud. 2021, 24, 306–321. [Google Scholar] [CrossRef]

- Brodeur, J.; Pellerin, R.; Deschamps, I. Operationalization of Critical Success Factors to Manage the Industry 4.0 Transformation of Manufacturing SMEs. Sustainability 2022, 14, 8954. [Google Scholar] [CrossRef]

- Baptista, L.F.; Barata, J. Piloting Industry 4.0 in SMEs with RAMI 4.0: An Enterprise Architecture Approach. Procedia Comput. Sci. 2021, 192, 2826–2835. [Google Scholar] [CrossRef]

- Bakir, D.; Bakir, R.; Engels, F. Industry_Integrator as Retrofit Solution for Digital Manufacturing Methods in Existing Industrial Plants. Procedia Manuf. 2018, 17, 1009–1014. [Google Scholar] [CrossRef]

- Chiang, H.-K.; Nagai, Y.; Lin, Y.-Y. Link up Industry 4.0 with the Enterprise Collaboration System to Help Small and Medium Enterprises. Math. Probl. Eng. 2020, 2020, 1–13. [Google Scholar] [CrossRef]

- Messeni Petruzzelli, A.; Murgia, G.; Parmentola, A. How Can Open Innovation Support SMEs in the Adoption of I4.0 Technologies? An Empirical Analysis. RD Manag. 2022, 52, 615–632. [Google Scholar] [CrossRef]

- Sherlekar, R.; Starly, B.; Cohen, P.H. Provisioned Data Distribution for Intelligent Manufacturing via Fog Computing. Procedia Manuf. 2019, 34, 893–902. [Google Scholar] [CrossRef]

- Konur, S.; Lan, Y.; Thakker, D.; Morkyani, G.; Polovina, N.; Sharp, J. Towards Design and Implementation of Industry 4.0 for Food Manufacturing. Neural Comput. Applications. 2021. [Google Scholar] [CrossRef]

- Haghi, S.; Heinrichs, V.; Kukulies, J.; Schmitt, R. Existing Challenges and the Corresponding Approach Towards a Smart Complaint and Failure Management Process. Procedia CIRP 2018, 72, 989–994. [Google Scholar] [CrossRef]

- Valencia, E.T.; Lamouri, S.; Pellerin, R.; Dubois, P.; Moeuf, A. ProductionF Planning in the Fourth Industrial Revolution: A Literature Review. IFAC Pap. 2019, 52, 2158–2163. [Google Scholar] [CrossRef]

- Dassisti, M.; Giovannini, A.; Merla, P.; Chimienti, M.; Panetto, H. An Approach to Support I4.0 Adoption in SMEs: A Core-Metamodel and Applications. IFAC Pap. 2018, 51, 42–47. [Google Scholar] [CrossRef]

- Liu, Z.; Sampaio, P.; Pishchulov, G.; Mehandjiev, N.; Cisneros-Cabrera, S.; Schirrmann, A.; Jiru, F.; Bnouhanna, N. The Architectural Design and Implementation of a Digital Platform for Industry 4.0 SME Collaboration. Comput. Ind. 2022, 138, 103623. [Google Scholar] [CrossRef]

- Gasparetto, W.; Egger, G.; Giusti, A.; Rauch, E.; Riedl, M.; Matt, D.T. Intelligent Workpiece Carrier for Distributed Data Collection and Control in Manufacturing Environments. Procedia Manuf. 2018, 24, 190–195. [Google Scholar] [CrossRef]

- Urban, W.; Łukaszewicz, K.; Krawczyk-Dembicka, E. Application of Industry 4.0 to the Product Development Process in Project-Type Production. Energies 2020, 13, 5553. [Google Scholar] [CrossRef]

- Selicati, V.; Cardinale, N. The Benefits in Coupling Exergy Analysis and Life Cycle Assessment in the Context of Sustainable Manufacturing for Industry 4.0: A Real Industrial Case. Int. J. Heat Technol. 2021, 39, 12–22. [Google Scholar] [CrossRef]

- Klimecka-Tatar, D.; Ingaldi, M. Digitization of Processes in Manufacturing SMEs-Value Stream Mapping and OEE Analysis. Procedia Comput. Sci. 2022, 200, 660–668. [Google Scholar] [CrossRef]

- Gualtieri, L.; Palomba, I.; Merati, F.A.; Rauch, E.; Vidoni, R. Design of Human-Centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study. Sustainability 2020, 12, 3606. [Google Scholar] [CrossRef]

- Voza, D.; Szewieczek, A.; Grabara, D. Environmental Sustainability in Digitalized SMEs: Comparative Study from Poland and Serbia. Serb. J. Manag. 2022, 17, 15–31. [Google Scholar] [CrossRef]

- Ali Shah, S.; Url, P.; Vorraber, W.; Janics, T.; Katschnig, M. Transformation towards Sustainable Business Models in Production. Teh. Glas. 2020, 14, 224–231. [Google Scholar] [CrossRef]

- Tick, A.; Saáry, R.; Kárpáti-Daróczi, J. Conscious or Indifferent: Concerns on Digitalisation and Sustainability among Smes in Industry 4.0. Serb. J. Manag. 2022, 17, 145–160. [Google Scholar] [CrossRef]

- Ondov, M.; Rosova, A.; Sofranko, M.; Feher, J.; Cambal, J.; Feckova Skrabulakova, E. Redesigning the Production Process Using Simulation for Sustainable Development of the Enterprise. Sustainability 2022, 14, 1514. [Google Scholar] [CrossRef]

- Dassisti, M.; Semeraro, C.; Chimenti, M. Hybrid Exergetic Analysis-LCA Approach and the Industry 4.0 Paradigm: Assessing Manufacturing Sustainability in an Italian SME. Procedia Manuf. 2019, 33, 655–662. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

- Dura, C.C.; Iordache, A.M.M.; Ionescu, A.; Isac, C.; Breaz, T.O. Analyzing Performance in Wholesale Trade Romanian SMEs: Framing Circular Economy Business Scenarios. Sustainability 2022, 14, 5567. [Google Scholar] [CrossRef]

- Didden, J.B.H.C.; Dang, Q.V.; Adan, I.J.B.F. A Semi-Decentralized Control Architecture for High-Mix-Low-Volume Factories in Industry 4.0. Manuf. Lett. 2021, 30, 11–14. [Google Scholar] [CrossRef]

- Vukicevic, A.M.; Djapan, M.; Todorovic, P.; Eric, M.; Stefanovic, M.; Macuzic, I. Decision Support System for Dimensional Inspection of Extruded Rubber Profiles. IEEE Access 2019, 7, 112605–112616. [Google Scholar] [CrossRef]

- Adesta, E.Y.T.; Hilmy, I.; Avicenna; Agusman, D. Toward Real Time IoT Based Paste Monitoring System for Small to Medium Enterprise (SME). J. Phys. Conf. Ser. 2019, 1167, 012006. [Google Scholar] [CrossRef]

- Costa, J.P.; Avila, P.; Bastos, J.; Pinto Ferreira, L. A New Simple, Flexible and Low-Cost Machine Monitoring System. Dyna (Medellin) 2021, 96, 640–646. [Google Scholar] [CrossRef]