PV-CrackNet Architecture for Filter Induced Augmentation and Micro-Cracks Detection within a Photovoltaic Manufacturing Facility

Abstract

1. Introduction

1.1. Literature Review

1.2. Paper Contribution

2. Methodology

2.1. Dataset

2.2. Generic Domain Augmentations

Orientation-Based Scaling (Generic)

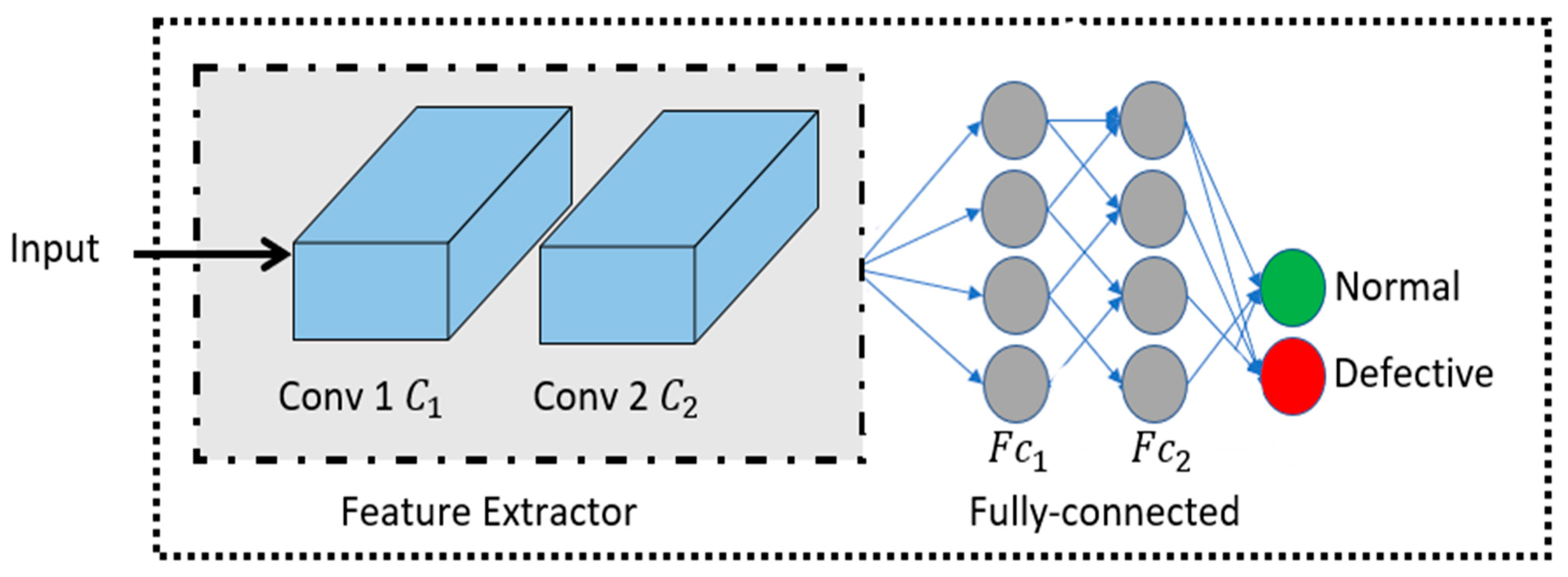

2.3. Proposed PV-CrackNet Architecture

2.4. Filter-Induced Augmentations (FIA)

2.5. Reactivating Optimizer

3. Results

3.1. Hyper-Parameters

3.2. Original Dataset Performance

3.3. Generic-Augmented Dataset Performance

3.4. Filter-Induced Augmentations Dataset Performance

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K.H. Solar Energy: Potential And Future Prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900. [Google Scholar] [CrossRef]

- Mahmoud, D.; Peter, M. Development of Novel Solar Cell Micro Crack Detection Technique. IEEE Trans. Semicond. Manuf. 2019, 32, 277–285. [Google Scholar]

- Mahmoud, D.; Violeta, H.; Mark, D.; Bruce, M. Effect of micro cracks on photovoltaic output power: Case study based on real time long term data measurements. Micro Nano Lett. 2017, 12, 803–807. [Google Scholar]

- Frazão, M.; Silva, J.A.; Lobato, K.; Serra, J.M. Electroluminescence of silicon solar cells using a consumer grade digital camera. Measurement 2017, 99, 7–12. [Google Scholar] [CrossRef]

- Fu, Y.; Ma, X.; Zhou, H. Automatic detection of multi-crossing crack defects in multi-crystalline solar cells based on machine vision. Mach. Vis. Appl. 2021, 32, 60. [Google Scholar] [CrossRef]

- Hussain, M.; Al-Aqrabi, H.; Hill, R. Statistical Analysis and Development of an Ensemble-Based Machine Learning Model for Photovoltaic Fault Detection. Energies 2022, 15, 5492. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X.; Zhu, C.; Ahmad, A. Automatic detection of photovoltaic module defects in infrared images with isolated and develop-model transfer deep learning. Sol. Energy 2020, 198, 175–186. [Google Scholar] [CrossRef]

- Ahmad, A.; Jin, Y.; Zhu, C.; Javed, I.; Maqsood, A.; Akram, M.W. Photovoltaic cell defect classification using convolutional neural network and support vector machine. IET Renew. Power Gener. 2020, 14, 2693–2702. [Google Scholar] [CrossRef]

- Dunderdale, C.; Brettenny, W.; Clohessy, C.; van Dyk, E.E. Photovoltaic defect classification through thermal infrared imaging using a machine learning approach. Prog. Photovolt. Res. Appl. 2020, 28, 177–188. [Google Scholar] [CrossRef]

- Tun, N.L.; Gavrilov, A.; Tun, N.M.; Aung, H. Remote Sensing Data Classification Using A Hybrid Pre-Trained VGG16 CNN-SVM Classifier. In Proceedings of the IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), Moscow, Russia, 26–29 January 2021. [Google Scholar]

- Zhang, J.; Feng, Y. Advanced Chinese Character Detection for Natural Scene Based on EAST. J. Phys. Conf. Ser. 2020, 1550, 032050. [Google Scholar] [CrossRef]

- Hussain, M.; Chen, T.; Hill, R. Moving toward Smart Manufacturing with an Autonomous Pallet Racking Inspection System Based on MobileNetV2. J. Manuf. Mater. Process. 2022, 6, 75. [Google Scholar] [CrossRef]

- Khan, Z.Y.; Niu, Z. CNN with depthwise separable convolutions and combined kernels for rating prediction. Expert Syst. Appl. 2021, 170, 114528. [Google Scholar] [CrossRef]

- Pierdicca, R.; Malinverni, E.S.; Piccinini, F.; Paolanti, M.; Felicetti, A.; Zingaretti, P. Deep Convolutional Neural Network for Automatic Detection of Damaged Photovoltaic Cells. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII-2, 893–900. [Google Scholar] [CrossRef]

- Napoletano, P.; Piccoli, F.; Schettini, R. Anomaly Detection in Nanofibrous Materials by CNN-Based Self-Similarity. Sensors 2018, 18, 209. [Google Scholar] [CrossRef]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic classification of defective photovoltaic module cells in electroluminescence images. arXiv 2019, arXiv:1807.02894v3. [Google Scholar] [CrossRef]

- Hussain, M.; Chen, T.; Titrenko, S.; Su, P.; Mahmud, M. A Gradient Guided Architecture Coupled with Filter Fused Representations for Micro-Crack Detection in Photovoltaic Cell Surfaces. IEEE Access 2022, 10, 58950–58964. [Google Scholar] [CrossRef]

- Tang, W.; Yang, Q.; Xiong, K.; Yan, W. Deep learning based automatic defect identification of photovoltaic module using electroluminescence images. Sol. Energy 2020, 201, 453–460. [Google Scholar] [CrossRef]

- Yap, X.Y.; Chia, K.S.; Tee, K.S. A Portable Gas Pressure Control and Data Acquisition System using Regression Models. Int. J. Electr. Eng. Inform. 2021, 13, 242–251. [Google Scholar] [CrossRef]

- Gao, M.; Song, P.; Wang, F.; Liu, J.; Mandelis, A.; Qi, D. A Novel Deep Convolutional Neural Network Based on ResNet-18 and Transfer Learning for Detection of Wood Knot Defects. J. Sens. 2021, 2021, 4428964. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the 2015 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Boston, MA, USA, 7–12 June 2015. [Google Scholar] [CrossRef]

- Hussain, M.; Al-Aqrabi, H.; Munawar, M.; Hill, R.; Parkinson, S. Exudate Regeneration for Automated Exudate Detection in Retinal Fundus Images. IEEE Access 2022. [Google Scholar] [CrossRef]

- Hussain, M.; Al-Aqrabi, H.; Munawar, M.; Hill, R.; Alsboui, T. Domain Feature Mapping with YOLOv7 for Automated Edge-Based Pallet Racking Inspections. Sensors 2022, 22, 6927. [Google Scholar] [CrossRef] [PubMed]

| Class | Samples |

|---|---|

| Normal | 140 |

| Defective | 200 |

| Class | Samples |

|---|---|

| Normal | 282 |

| Defective | 787 |

| Batch Size | 32 |

| Epochs | 40 |

| Optimizer | SGD-M |

| Learning Rate | 0.02 |

| Training Acc | 99.11% |

| Validation Acc | 97.42% |

| Precision | 98% |

| Recall | 96% |

| F1-score | 97% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, M.; Al-Aqrabi, H.; Hill, R. PV-CrackNet Architecture for Filter Induced Augmentation and Micro-Cracks Detection within a Photovoltaic Manufacturing Facility. Energies 2022, 15, 8667. https://doi.org/10.3390/en15228667

Hussain M, Al-Aqrabi H, Hill R. PV-CrackNet Architecture for Filter Induced Augmentation and Micro-Cracks Detection within a Photovoltaic Manufacturing Facility. Energies. 2022; 15(22):8667. https://doi.org/10.3390/en15228667

Chicago/Turabian StyleHussain, Muhammad, Hussain Al-Aqrabi, and Richard Hill. 2022. "PV-CrackNet Architecture for Filter Induced Augmentation and Micro-Cracks Detection within a Photovoltaic Manufacturing Facility" Energies 15, no. 22: 8667. https://doi.org/10.3390/en15228667

APA StyleHussain, M., Al-Aqrabi, H., & Hill, R. (2022). PV-CrackNet Architecture for Filter Induced Augmentation and Micro-Cracks Detection within a Photovoltaic Manufacturing Facility. Energies, 15(22), 8667. https://doi.org/10.3390/en15228667