A Comprehensive Review on Current Performance, Challenges and Progress in Thin-Film Solar Cells

Abstract

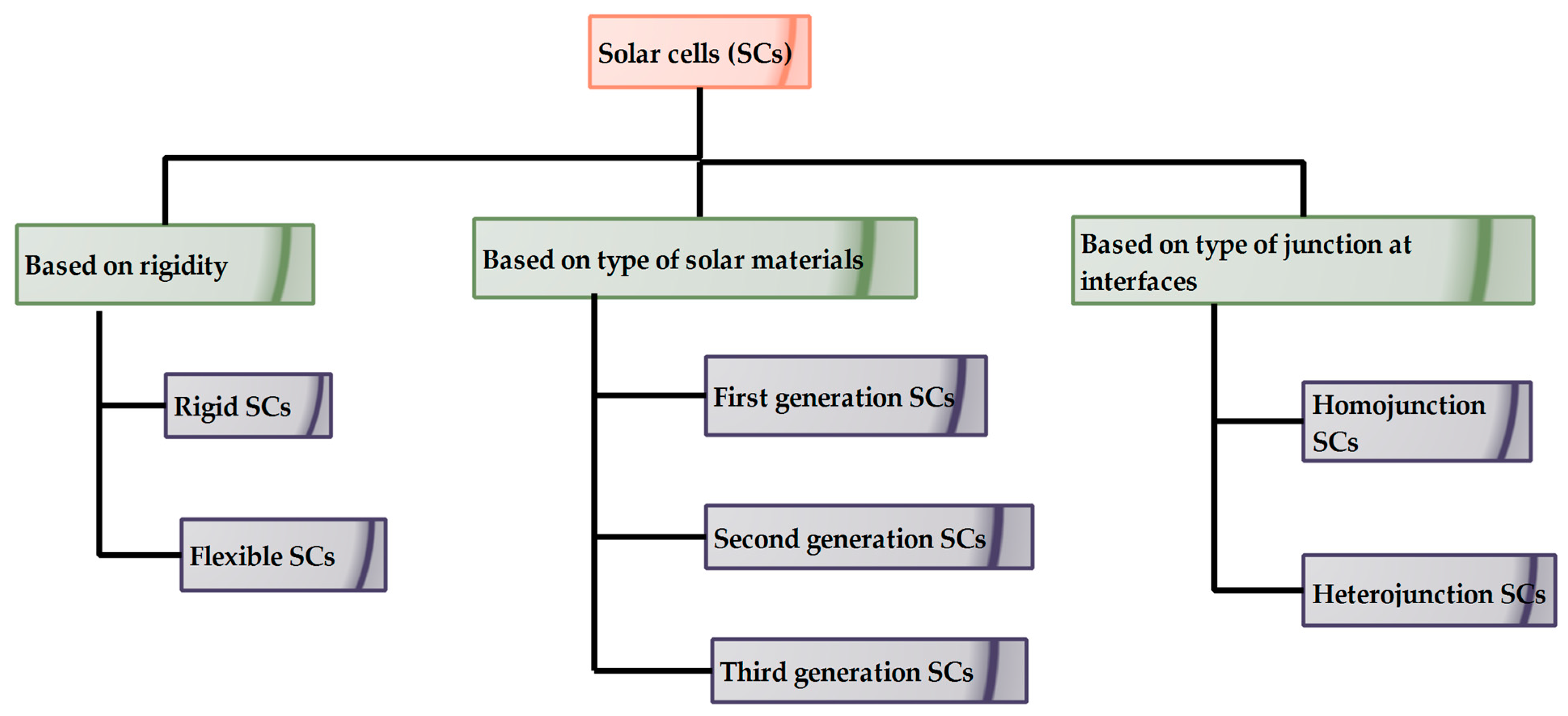

:1. Introduction

2. Second Generation Solar Cells

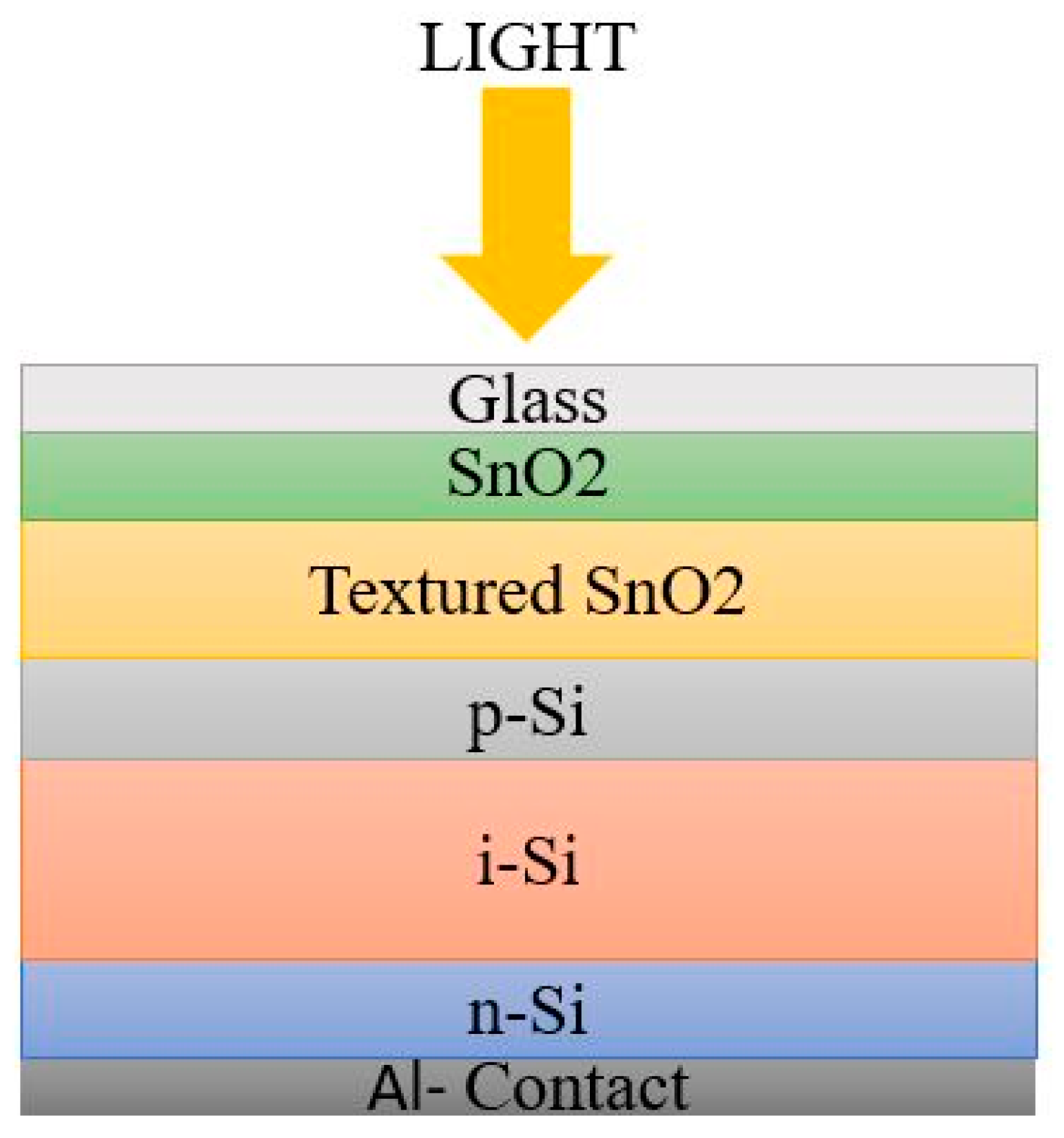

2.1. Amorphous Silicon Solar Cells

- Simple working mechanism and inexpensive

- With optimal thickness, light absorption is higher than in the C-Si

- Lesser raw material is required

- The capability to adhere over any sort of surfaces.

- Lesser working life due to low hole-mobility

- Harmful gases were needed during fabrication process [33]

- Mostly absorbs light at a wavelength not greater than 700 nm.

| S.No | Absorber Material | Voc (V) | Jsc (mA/cm2) | FF | eff | Ref |

|---|---|---|---|---|---|---|

| 1 | μc-Si:H | 0.542 | 27.44 | 73.8 | 10.97 | [31] |

| 2 | μc-Si:H | 1.411 | 12.6 | 67.8 | 12.1 | [34] |

| 3 | a-Si n type | 0.704 | 42.4 | 82.6 | 24.7 | [35] |

| 4 | a-Si:H | 0.877 | 17.28 | 66.6 | 10.09 | [36] |

| 5 | μc-Si:H | 0.548 | 29.39 | 73.1 | 11.77 | [37] |

| 6 | a-Si:H | 0.896 | 16.36 | 69.8 | 10.22 | [37] |

| 7 | μc-Si:H | 1.322 | 13.02 | 69 | 11.9 | [38] |

| 8 | a-Si:H μc-Si:H μc-Si:H | 1.936 | 8.96 | 71.5 | 12.41 | [39] |

| 9 | μc-Si:H | 0.521 | 28.17 | 71.6 | 10.5 | [40] |

| 10 | a-Si:H μc-Si:H μc-Si:H | 1.901 | 9.92 | 72.1 | 13.46 | [41] |

2.2. CIGS Solar Cell

- They are more resistant to heat than Si SCs.

- The active material (CIGS) does not contain harmful components.

- Holds easily tunable bandgap, facilitating tandem architecture.

- Its grain boundaries acts as buffer layer, which inhibits the surface recombination.

- Achieving improved performance takes longer than Si SCs.

- Less efficient than conventional SCs.

2.3. CdTe Solar Cell

- The preparation of CdTe SCs was performed in minimal time duration, compared to other SCs.

- It has a direct band gap with energy of 1.4 eV.

- It can absorb much shorter wavelengths than silicon solar panels.

- Raw material Cd was obtained as a sub-product of zinc extraction, hence has less price fluctuation than Si.

- Delivers less power output than Si SCs.

- Even though Cd was easily available, Te was rarely found in the crust.

- Cd was highly toxic and its disposal was a rather difficult process.

3. Third Generation Solar Cells

3.1. Dye sensitised Solar Cells

- Easier to fabricate under normal ambient condition.

- Lower fabrication cost.

- Better performance under higher working temperature and diffused light.

- Usage of liquid dye might leak which leads to defective SC.

- Platinum is used as a counter electrode in order to improve the dye regeneration, redox reaction and PCE, which was available only at higher cost when TiO2 was used.

- Ruthenium or osmium-based dye is versatile and not easily available at wider range; it is better to prefer dyes based on simple elements.

- The maximum PCE reported until now was 14.3%, which used a silyl linker with the triarylamine and cobalt redox couple.

- Degradation of electrolyte materials.

- Electrolytes possess a low freezing temperature, while at higher temperatures a sealing issues might arise. Solid state dyes were engineered to overcome the liquid state dyes’ drawbacks [102].

| S.No | Dye Used | Electrode Used | Counter Electrode Used | Electrolytes Used | Max. PCE (%) | Max. Fill Factor | Voc (V) | Jsc (mA cm−2) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 1. | Chlorophyll pigments | TiO2 | graphite | 0.49 | 0.44 | [103] | |||

| 2. | Acanthus sennii chiovenda flower and Euphorbia cotinifolia leaf | TiO2 | (PEDOT-coated FTO glass) | polymer gel electrolyte | 0.15 & 0.136 | 0.47 to 0.6 | 0.475 to 0.507 | 0.352 to 0.642 | [104] |

| 3. | N-719 dye | TiO2 | cobalt-nickel selenide nanoparticles dispersed on graphene nanosheets | I-/I3-redox electrolyte | 9.42 | 0.683 | 0.75 | 18.33 | [105] |

| 4. | N-719 dye | TiO2 | activated coconut shell charcoal | I-/I3-redox electrolyte | 7.85 | 0.62 | 0.65 | 19.49 | [106] |

| 5. | Betalains and anthocyanins | TiO2 | platinum metal clusters | 2.06 | 0.316 to 0.419 | 8.8 | [107] | ||

| 6. | Co/Se and Ni/Se nanocomposite | I-/I3-redox electrolyte | 6.43 & 5.23 | [108] | |||||

| 7. | Rhoeo spathacea dye | TiO2adsorbed Au nanoparticles | Pt | aqueous electrolyte of Ce4+/3+ system. | 1.49 | [109] | |||

| 8. | Anthocyanin dye | TiO2 | conductive plastic sheets containing graphite | [110] | |||||

| 9. | N3 dye | nano sized Cu with carbon dispersed in TiO2 | I-/I3- redox electrolyte | 2.8 & 23 | 0.55–0.70 | 0.76 to 0.81 | 6.1–7.4 | [111] | |

| 10. | 20% Basella alba(green dye) and 80% Amaranthus dubius (Red dye) | TiO2 | carbon coating | 0.847 | 0.515 | 0.385 | [112] | ||

| 11. | Dye from Pawpaw Leaf and Flame Tree Flower mixture | TiO2 | Pt | 0.27 | 0.69 | 0.518 | 0.744 | [113] | |

| 12. | C106 dye | double layered TiO2 | Pt | Z988 electrolyte | 9 | 0.762 | 0.694 | 8.702 | [114] |

| 13. | Male flowers Luffa cylindrica | TiO2 | Pt | 0.13 | 0.60, | 0.52 | 0.44 | [115] | |

| 14. | Spinach and ipomoea | TiO2 | Pt | 0.131& 0.278 | 0.51 & 0563 | 0.5 & 0.54 | [116] | ||

| 15. | Bixin, annato, Norbixin from Achiote seeds | TiO2 & ZnO2 | Pt | 0.37 (max) | 0.59 | 0.57 | 1.1 | [117] |

3.2. Perovskite Solar Cells

- Higher PCE.

- Higher absorption coefficient.

- Fabrication can be carried out through solution processing technique and wafer-based approach.

- Diffusion length is higher with higher charge carrier mobilities.

- Poor encapsulation leads to the degradation of perovskite material.

- Lead based Perovskite material is toxic in nature.

3.3. Organic Solar Cells

| S.No | Photo-Absorber Material | Voc (mV) | Jsc (mA cm−2) | FF | PCE (%) | Ref. |

|---|---|---|---|---|---|---|

| 1 | (5-AVA)x(MA)1-xPbI3/ZrO2/TiO2& (5-AVA)x(MA)1-xPbI3/TiO2 | 740, 592 | 21.68, 12.51 | 0.64, 0.56 | 10.3, 4.18 | [134] |

| 2 | CH3NH3PbI3/TiO2/Carbon | 0.76, 0.89, 0.97 & 0.92 | 14.3, 15.1, 16.7 & 16.3 | 0.404, 0.415, 0.558 &0.466 | 35, 51, 91 & 90 | [135] |

| 3 | ITO/(PEDOT:PSS)/CH3NH3PbI3/PCBM/(0.5 nmLiF/Al) | 0.846, 0.846 | 20.2, 19.2 | 0.767, 0.708 | 13.1, 11.5 | [136] |

| 4 | ITO/PTAA/MA0.6FA0.38Cs0.02PbI2.975Br0.025:5 mol% MACl film/C60/BCP/Cu | 1000 | 23.1 | 0.77 | 19.50 | [137] |

| 5 | ITO/PEDOT:PSS/CH3NH3PbI3/C60/BCP/Al | 780 | 19.7 | 0.736 | 11.30 | [138] |

| 6 | FTO/TiO2/CH3NH3PbI3-xClx/spiro-MeOTAD/Ag | 987, 946 | 18.72, 19.87 | 0.64, 0.6 | 12.14, 11.47 | [139] |

| 7 | ITO/PEDOT:PSS/CH3NH3PbI3/PCBM/LiF-Ag | 800, 950 | 15.89, 12.7 | 0.71, 0.64 | 9.05, 7.75 | [140] |

| 8 | Glass/TCO/NiO/Perovskite/PCBM/PEI/Ag & Glass/TCO/NiO/Perovskite with 5% Cl/PCBM/PEI/Ag | 1022, 1085 | 21.3, 21.2 | 0.71, 0.79 | 15.5, 18.2 | [141] |

| 9 | FTO/TiO2 Dense/TiO2/ZrO2/perovskite/Spheroidal graphite & FTO/TiO2 Dense/TiO2/ZrO2/perovskite/Flaky graphite | 878, 825 | 12.4, 10.6 | 0.61, 0.46 | 6.64, 4.08 | [142] |

| 10 | FTO/FAPbI3/Spiro-OMeTAD/Au | 970 | 21.6 | 0.62 | 13 | [143] |

| 11 | FTO/TiO2/CH3NH3PbI3/spiro-oMeTAD/Au | 1090 & 1090 | 23.50 & 17.62 | 0.61 & 0.69 | 11.70 & 17.71 | [144] |

| 12 | FTO/TiO2/(FAPbI3)0.85(MAPbBr3)0.15/PTAA/Ag & FTO/TiO2/(FAPbI3)0.85(MAPbBr3)0.15/PCBM/BCP/In | 1010, 1010 | 23.20, 22.34 | 0.7858 & 0.7826 | 20.05 & 19.23 | [145] |

- easy to synthesize

- available at low cost

- high degree of tunability

- high absorption coefficient

- flexible in nature.

- high exciton binding energy

- low carrier diffusion lengths

- low strength and stability.

3.3.1. Single Layer Device

3.3.2. Bilayer Devices

3.3.3. Bulk Heterojunction Device

| S.No | Cell Architecture | Voc | Jsc | FF | Eff | Ref. |

|---|---|---|---|---|---|---|

| 1 | Glass/ITO/PEDOT:PSS/(CD1:PBN-12)/LiF/Al | 1017 | 13.39 | 0.64 | 10.1 | [161] |

| 2 | ITO/ZnO/PTQ11−TPT10/MoO3/Ag | 880 | 24.79 | 0.74 | 16.32 | [162] |

| 3 | glass/ITO/PEDOT:PSS/active layers/PDIN | 854 | 23.01 | 72.27 | 14.2 | [163] |

| 4 | ITO/PEDOT:PSS/active layer/PDIN/Al | 0.853 | 25.68 | 78.61 | 17.22 | [164] |

| 5 | glass/ITO/PEDOT:PSS/active layer/PDINO/Al | 826 | 26.65 | 75.1 | 16.53 | [165] |

| 6 | (ITO)/ZnO/J71:ITIC:BTF/MoO3/Ag. | 952 | 18.48 | 70.03 | 12.35 | [166] |

| 7 | glass/ITO/PEDOT: PSS/PM6: PT-IDTTICr(8: 5.3 mg mL−1 in CHCl3)/PFN/Al | 970 | 18.19 | 68 | 12.06 | [167] |

| 8 | Active layer-ITCF3/PM6 | 840 | 20.9 | 76 | 13.3 | [168] |

| 9 | 20% wt of IT-4F acceptor | 844 | 25.4 | 75.9 | 16.27 | [169] |

| 10 | ITO/PEDOT:PSS/Pt10:Y6/OTF/Al | 810 | 26.45 | 76.3 | 16.35 | [153] |

| 11 | ITO/PEDOT:PSS/PM6:PFBDT-IDTIC/PNDITF3N-Br/Al | 960 | 15.38 | 69 | 10.3 | [170] |

| 12 | ITO/PEDOT:PSS/PM6:PZ1/ZnO/Al | 960 | 17.1 | 68.2 | 11.2 | [171] |

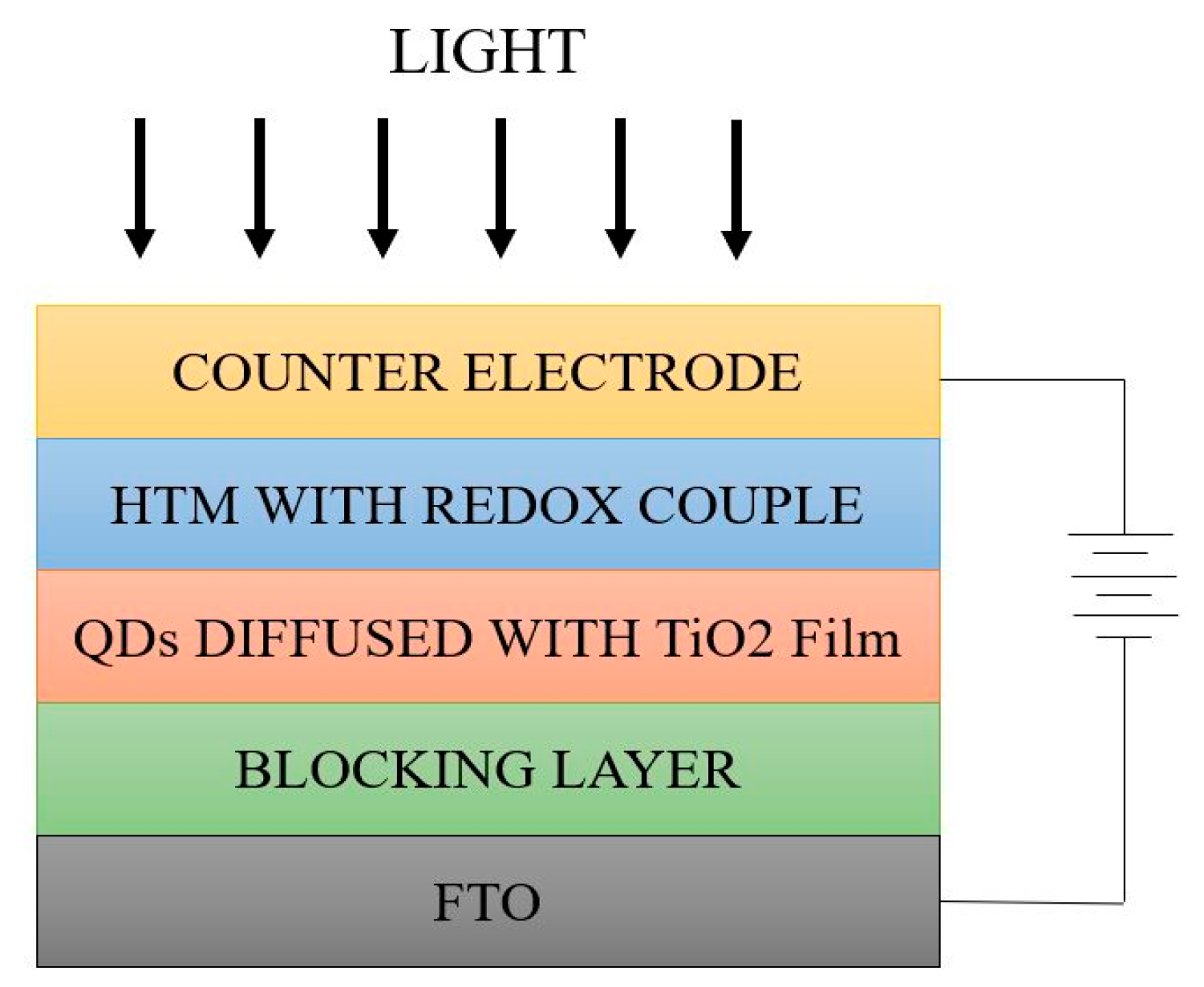

3.4. Quantum Dots Solar Cells

- Higher output performance with minimal fabrication cost.

- Minimal area required for more power output.

- Flexible nature leading to easier incorporation in any curvatures.

- Lesser weight.

- Under the inclusion of moisture and UV radiation, degradation of QDs was found to be higher.

- Shells in atomic configuration may modify the optical properties, and hence the size of particles is harder to control

- CdSe QDs are more toxic in nature.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pansal, K.; Ramani, B.; kumar Sadasivuni, K.; Panchal, H.; Manokar, M.; Sathyamurthy, R.; Israr, M. Use of solar photovoltaic with active solar still to improve distillate output: A review Groundwater sustain. Develop 2020, 10, 100341. [Google Scholar]

- Anand, A.; Shukla, A.; Panchal, H.; Sharma, A. Thermal regulation of photovoltaic system for enhanced power production: A review. J. Energy Storage 2021, 35, 102236. [Google Scholar] [CrossRef]

- Pandiaraj, S.; Jaffar, A.A.; Muthusamy, S.; Panchal, H.; Pandiyan, S. A study of solar heat gain variation in building applied photovoltaic buildings and its impact on environment and indoor air quality. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 6192–6212. [Google Scholar] [CrossRef]

- Shah, A.; Platz, R.; Keppner, H. Thin-film silicon solar cells: A review and selected trends. Sol. Energy Mater. Sol. Cells 1995, 38, 501–520. [Google Scholar] [CrossRef] [Green Version]

- Asghar, M.; Zhang, J.; Wang, H.; Lund, P. Device stability of perovskite solar cells–A review. Renew. Sustain. Energy Rev. 2017, 77, 131–146. [Google Scholar] [CrossRef] [Green Version]

- Santhosh, S.; Rajasekar, R.; Gobinath, V.; Moganapriya, C.; Arun Kumar, S.; Manju Sri, A. Influence of Electrosprayed MoSe2 Antireflective Surface Coatings on Performance of Multicrystalline Silicon Solar Cell. Silicon 2022, 14, 6039–6051. [Google Scholar] [CrossRef]

- Chinnasamy, M.; Rathanasamy, R.; Sivaraj, S.; Velu Kaliyannan, G.; Palanisamy, M.; Pal, S.K.; Uddin, M. Effective Utilization of Synthesized FeS2 for Improving Output Performance of Polycrystalline Silicon Solar Cell. Adv. Mater. Sci. Eng. 2022, 2022, 1252105. [Google Scholar] [CrossRef]

- Rathanasamy, R.; Velu Kaliyannan, G.; Sivaraj, S.; Saminathan, A.; Krishnan, B.; Palanichamy, D.; Uddin, M. Influence of Silicon Dioxide-Titanium Dioxide Antireflective Electrosprayed Coatings on Multicrystalline Silicon Cells. Adv. Mater. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Lee, Y.; Park, C.; Balaji, N.; Lee, Y.J.; Dao, V.A. High-efficiency silicon solar cells: A review. Isr. J. Chem. 2015, 55, 1050–1063. [Google Scholar] [CrossRef]

- Menna, P.; Di Francia, G.; La Ferrara, V. Porous silicon in solar cells: A review and a description of its application as an AR coating. Sol. Energy Mater. Sol. Cells 1995, 37, 13–24. [Google Scholar] [CrossRef]

- Lal, N.N.; Dkhissi, Y.; Li, W.; Hou, Q.; Cheng, Y.B.; Bach, U. Perovskite tandem solar cells. Adv. Energy Mater. 2017, 7, 1602761. [Google Scholar] [CrossRef]

- Bouich, A. Study and Characterization of Hybrid Perovskites and Copper-Indium-Gallium Selenide Thin Films for Tandem Solar Cells; Universitat Politècnica de València: Valencia, Spain, 2021. [Google Scholar]

- Mahmood, A. Triphenylamine based dyes for dye sensitized solar cells: A review. Sol. Energy 2016, 123, 127–144. [Google Scholar] [CrossRef]

- De Wolf, S.; Descoeudres, A.; Holman, Z.C.; Ballif, C. High-efficiency silicon heterojunction solar cells: A review. Green 2012, 2, 7–24. [Google Scholar] [CrossRef]

- Chopra, K.; Paulson, P.; Dutta, V. Thin-film solar cells: An overview. Prog. Photovolt. Res. Appl. 2004, 12, 69–92. [Google Scholar] [CrossRef]

- Shah, A.; Torres, P.; Tscharner, R.; Wyrsch, N.; Keppner, H. Photovoltaic technology: The case for thin-film solar cells. Science 1999, 285, 692–698. [Google Scholar] [CrossRef] [Green Version]

- Carlson, D.E.; Wronski, C.R. Amorphous silicon solar cell. Appl. Phys. Lett. 1976, 28, 671–673. [Google Scholar] [CrossRef]

- Elsayed, H.A.; Sayed, H.; Taha, T.; Alharbi, A.G.; Alenad, A.M.; Alshammari, B.A.; Ahmed, A.M.; Mehaney, A.; Aly, A.H. Simple and efficient design towards a significant improvement of the optical absorption of amorphous silicon solar cell. J. Quant. Spectrosc. Radiat. Transf. 2021, 275, 107890. [Google Scholar] [CrossRef]

- Eminian, C.; Haug, F.J.; Cubero, O.; Niquille, X.; Ballif, C. Photocurrent enhancement in thin film amorphous silicon solar cells with silver nanoparticles. Prog. Photovolt. Res. Appl. 2011, 19, 260–265. [Google Scholar] [CrossRef]

- Liu, W.; Shi, J.; Zhang, L.; Han, A.; Huang, S.; Li, X.; Peng, J.; Yang, Y.; Gao, Y.; Yu, J. Light-induced activation of boron doping in hydrogenated amorphous silicon for over 25% efficiency silicon solar cells. Nat. Energy 2022, 7, 427–437. [Google Scholar] [CrossRef]

- Krč, J.; Zeman, M.; Kluth, O.; Smole, F.; Topič, M. Effect of surface roughness of ZnO: Al films on light scattering in hydrogenated amorphous silicon solar cells. Thin Solid Film. 2003, 426, 296–304. [Google Scholar] [CrossRef]

- Baek, S.; Lee, J.C.; Lee, Y.-J.; Iftiquar, S.S.; Kim, Y.; Park, J.; Yi, J. Interface modification effect between p-type a-SiC: H and ZnO: Al in pin amorphous silicon solar cells. Nanoscale Res. Lett. 2012, 7, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Sichanugrist, P.; Sasaki, T.; Asano, A.; Ichikawa, Y.; Sakai, H. Amorphous silicon oxide and its application to metal/nip/ITO type a-Si solar cells. Sol. Energy Mater. Sol. Cells 1994, 34, 415–422. [Google Scholar] [CrossRef]

- Theuring, M.; Geissendörfer, S.; Vehse, M.; von Maydell, K.; Agert, C. Thin metal layer as transparent electrode in nip amorphous silicon solar cells. EPJ Photovolt. 2014, 5, 55205. [Google Scholar] [CrossRef]

- Yue, G.; Han, D.; Williamson, D.; Yang, J.; Lord, K.; Guha, S. Electronic states of intrinsic layers in nip solar cells near amorphous to microcrystalline silicon transition studied by photoluminescence spectroscopy. Appl. Phys. Lett. 2000, 77, 3185–3187. [Google Scholar] [CrossRef]

- Kwak, J.; Kwon, S.W.; Lim, K.S. Fabrication of an–p–p tunnel junction for a protocrystalline silicon multilayer/amorphous silicon tandem solar cell. J. Non-Cryst. Solids 2006, 352, 1847–1850. [Google Scholar] [CrossRef]

- Myong, S.Y.; Kwon, S.W.; Lim, K.S.; Konagai, M. Highly stabilized protocrystalline silicon multilayer solar cell using a silicon–carbide double p-layer structure. Sol. Energy Mater. Sol. Cells 2005, 85, 133–140. [Google Scholar] [CrossRef]

- Kim, K.-H.; Johnson, E.V.; i Cabarrocas, P.R. Irreversible light-induced degradation and stabilization of hydrogenated polymorphous silicon solar cells. Sol. Energy Mater. Sol. Cells 2012, 105, 208–212. [Google Scholar] [CrossRef]

- Street, R.A. Hydrogenated Amorphous Silicon; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Lee, T.D.; Ebong, A.U. A review of thin film solar cell technologies and challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297. [Google Scholar] [CrossRef]

- Sai, H.; Matsui, T.; Matsubara, K.; Kondo, M.; Yoshida, I. 11.0%-efficient thin-film microcrystalline silicon solar cells with honeycomb textured substrates. IEEE J. Photovolt. 2014, 4, 1349–1353. [Google Scholar] [CrossRef]

- Pakala, P.S.A.; Pattnaik, A.; Tomar, A. Comprehensive Study on Heterojunction Solar Cell. In Machine Learning, Advances in Computing, Renewable Energy and Communication; Springer: Berlib, Germany, 2022; pp. 543–552. [Google Scholar]

- Liu, H.; Du, Y.; Yin, X.; Bai, M.; Liu, W. Micro/Nanostructures for Light Trapping in Monocrystalline Silicon Solar Cells. J. Nanomater. 2022, 2022, 8139174. [Google Scholar] [CrossRef]

- Stannowski, B.; Gabriel, O.; Calnan, S.; Frijnts, T.; Heidelberg, A.; Neubert, S.; Kirner, S.; Ring, S.; Zelt, M.; Rau, B. Achievements and challenges in thin film silicon module production. Sol. Energy Mater. Sol. Cells 2013, 119, 196–203. [Google Scholar] [CrossRef]

- Yan, D.; Phang, S.P.; Wan, Y.; Samundsett, C.; Macdonald, D.; Cuevas, A. High efficiency n-type silicon solar cells with passivating contacts based on PECVD silicon films doped by phosphorus diffusion. Sol. Energy Mater. Sol. Cells 2019, 193, 80–84. [Google Scholar] [CrossRef]

- Benagli, S.; Borrello, D.; Vallat-Sauvain, E.; Meier, J.; Kroll, U.; Hötzel, J.; Bailat, J.; Steinhauser, J.; Marmelo, M.; Monteduro, G. High-efficiency amorphous silicon devices on LPCVD-ZnO TCO prepared in industrial KAI-M R&D reactor. In Proceedings of the 24th European Photovoltaic Solar Energy Conference, Hamburg, Germany, 21–25 September 2009; pp. 21–25. [Google Scholar]

- Matsui, T.; Maejima, K.; Bidiville, A.; Sai, H.; Koida, T.; Suezaki, T.; Matsumoto, M.; Saito, K.; Yoshida, I.; Kondo, M. High-efficiency thin-film silicon solar cells realized by integrating stable a-Si: H absorbers into improved device design. Jpn. J. Appl. Phys. 2015, 54, 08KB10. [Google Scholar] [CrossRef]

- Matsui, T.; Sai, H.; Saito, K.; Kondo, M. High-efficiency thin-film silicon solar cells with improved light-soaking stability. Prog. Photovolt. Res. Appl. 2013, 21, 1363–1369. [Google Scholar] [CrossRef]

- Banerjee, A.; Su, T.; Beglau, D.; Pietka, G.; Liu, F.S.; Almutawalli, S.; Yang, J.; Guha, S. High-efficiency, multijunction nc-Si: H-based solar cells at high deposition rate. IEEE J. Photovolt. 2012, 2, 99–103. [Google Scholar] [CrossRef]

- Sai, H.; Koida, T.; Matsui, T.; Yoshida, I.; Saito, K.; Kondo, M. Microcrystalline silicon solar cells with 10.5% efficiency realized by improved photon absorption via periodic textures and highly transparent conductive oxide. Appl. Phys. Express 2013, 6, 104101. [Google Scholar] [CrossRef]

- Sai, H.; Matsui, T.; Koida, T.; Matsubara, K.; Kondo, M.; Sugiyama, S.; Katayama, H.; Takeuchi, Y.; Yoshida, I. Triple-junction thin-film silicon solar cell fabricated on periodically textured substrate with a stabilized efficiency of 13.6%. Appl. Phys. Lett. 2015, 106, 213902. [Google Scholar]

- Ramanujam, J.; Bishop, D.M.; Todorov, T.K.; Gunawan, O.; Rath, J.; Nekovei, R.; Artegiani, E.; Romeo, A. Flexible CIGS, CdTe and a-Si: H based thin film solar cells: A review. Prog. Mater. Sci. 2020, 110, 100619. [Google Scholar] [CrossRef]

- Ramanujam, J.; Singh, U.P. Copper indium gallium selenide based solar cells–a review. Energy Environ. Sci. 2017, 10, 1306–1319. [Google Scholar] [CrossRef]

- Nicolaou, C.; Zacharia, A.; Delimitis, A.; Itskos, G.; Giapintzakis, J. Single-step growth of high quality CIGS/CdS heterojunctions using Pulsed Laser Deposition. Appl. Surf. Sci. 2020, 511, 145547. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Ogawa, H.; Nakashima, M.; Naoi, H.; Araki, H.; Jimbo, K.; Katagiri, H.; Sasano, J.; Izaki, M. Fabrication of Cu2ZnSn (S, Se) 4 thin-film solar cells by sulfurization using Cu2ZnSnSe4, NaF and KF compounds. Jpn. J. Appl. Phys. 2020, 59, SGGF11. [Google Scholar] [CrossRef]

- Kaliyannan, G.V.; Rathanasamy, R.; Sivaraj, S.; Chinnasamy, M.; Kandasamy, S. An Extensive Review Owing to the Influence of Surface Coating on the Technical Performance of Solar Cells. Adv. Funct. Smart Mater. 2022, 13–23. [Google Scholar] [CrossRef]

- Mufti, N.; Amrillah, T.; Taufiq, A.; Diantoro, M.; Nur, H. Review of CIGS-based solar cells manufacturing by structural engineering. Sol. Energy 2020, 207, 1146–1157. [Google Scholar] [CrossRef]

- Bensaad, A.; Garadi, A.; Beloufa, A.; Bensaad, Z. Efficiency enhancement of Cd-free buffer layers on CIGS solar cell performance using WxAMPS. Optik 2022, 267, 169736. [Google Scholar] [CrossRef]

- Zouache, R.; Bouchama, I.; Saidani, O.; Djedoui, L.; Zaidi, E. Numerical study of high-efficiency CIGS solar cells by inserting a BSF µc-Si: H layer. J. Comput. Electron. 2022, 21, 1386–1395. [Google Scholar] [CrossRef]

- Kamada, R.; Yagioka, T.; Adachi, S.; Handa, A.; Tai, K.F.; Kato, T.; Sugimoto, H. New world record Cu (In, Ga)(Se, S)2 thin film solar cell efficiency beyond 22%. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 1287–1291. [Google Scholar]

- Powalla, M.; Paetel, S.; Ahlswede, E.; Wuerz, R.; Wessendorf, C.D.; Magorian Friedlmeier, T. Thin-film solar cells exceeding 22% solar cell efficiency: An overview on CdTe-, Cu (In, Ga) Se2-, and perovskite-based materials. Appl. Phys. Rev. 2018, 5, 041602. [Google Scholar] [CrossRef]

- Youn, S.-M.; Park, M.-J.; Kim, J.H.; Jeong, C. Performance enhancement of CIGS thin-film solar cells with a functional-window NiO thin layer. J. Alloy. Compd. 2020, 836, 154803. [Google Scholar] [CrossRef]

- Zhao, Y.; Yuan, S.; Kou, D.; Zhou, Z.; Wang, X.; Xiao, H.; Deng, Y.; Cui, C.; Chang, Q.; Wu, S. High Efficiency CIGS Solar Cells by Bulk Defect Passivation through Ag Substituting Strategy. ACS Appl. Mater. Interfaces 2020, 12, 12717–12726. [Google Scholar] [CrossRef]

- Guchhait, A.; Dewi, H.A.; Leow, S.W.; Wang, H.; Han, G.; Suhaimi, F.B.; Mhaisalkar, S.; Wong, L.H.; Mathews, N. Over 20% efficient CIGS–perovskite tandem solar cells. ACS Energy Lett. 2017, 2, 807–812. [Google Scholar] [CrossRef]

- Poncelet, O.; Kotipalli, R.; Vermang, B.; Macleod, A.; Francis, L.A.; Flandre, D. Optimisation of rear reflectance in ultra-thin CIGS solar cells towards> 20% efficiency. Sol. Energy 2017, 146, 443–452. [Google Scholar] [CrossRef] [Green Version]

- Ma, P.; Li, W.; Yi, C.; Dai, C.; Luo, H.; Yang, C. Investigation of Mo films deposited on high temperature polyimide substrate by magnetron sputtering for flexible CIGS thin film solar cells application. AIP Adv. 2019, 9, 045024. [Google Scholar] [CrossRef] [Green Version]

- Uličná, S.; Arnou, P.; Abbas, A.; Togay, M.; Welch, L.M.; Bliss, M.; Malkov, A.V.; Walls, J.M.; Bowers, J.W. Deposition and application of a Mo–N back contact diffusion barrier yielding a 12.0% efficiency solution-processed CIGS solar cell using an amine–thiol solvent system. J. Mater. Chem. A 2019, 7, 7042–7052. [Google Scholar] [CrossRef]

- Jackson, P.; Wuerz, R.; Hariskos, D.; Lotter, E.; Witte, W.; Powalla, M. Effects of heavy alkali elements in Cu (In, Ga) Se2 solar cells with efficiencies up to 22.6%. Physica Status Solidi (RRL)–Rapid Res. Lett. 2016, 10, 583–586. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Chen, J.; Zhang, Y.; Wang, W.; Gu, H. Efficiency Enhancement of CIGS Solar Cells via Recombination Passivation. ACS Appl. Energy Mater. 2020. [Google Scholar] [CrossRef]

- Feurer, T.; Carron, R.; Torres Sevilla, G.; Fu, F.; Pisoni, S.; Romanyuk, Y.E.; Buecheler, S.; Tiwari, A.N. Efficiency Improvement of Near-Stoichiometric CuInSe2 Solar Cells for Application in Tandem Devices. Adv. Energy Mater. 2019, 9, 1901428. [Google Scholar] [CrossRef] [Green Version]

- Boubakeur, M.; Aissat, A.; Arbia, M.B.; Maaref, H.; Vilcot, J. Enhancement of the efficiency of ultra-thin CIGS/Si structure for solar cell applications. Superlattices Microstruct. 2020, 138, 106377. [Google Scholar] [CrossRef]

- Hsueh, T.J.; Shieh, J.M.; Yeh, Y.M. Hybrid Cd-free CIGS solar cell/TEG device with ZnO nanowires. Prog. Photovolt. Res. Appl. 2015, 23, 507–512. [Google Scholar] [CrossRef]

- Khatri, I.; Shudo, K.; Matsuura, J.; Sugiyama, M.; Nakada, T. Impact of heat-light soaking on potassium fluoride treated CIGS solar cells with CdS buffer layer. Prog. Photovolt. Res. Appl. 2018, 26, 171–178. [Google Scholar] [CrossRef]

- Tobbeche, S.; Kalache, S.; Elbar, M.; Kateb, M.N.; Serdouk, M.R. Improvement of the CIGS solar cell performance: Structure based on a ZnS buffer layer. Opt. Quantum Electron. 2019, 51, 284. [Google Scholar] [CrossRef]

- Rezaei, N.; Isabella, O.; Vroon, Z.; Zeman, M. Optical optimization of a multi-layer wideband anti-reflection coating using porous MgF2 for sub-micron-thick CIGS solar cells. Sol. Energy 2019, 177, 59–67. [Google Scholar] [CrossRef] [Green Version]

- Garud, S.; Gampa, N.; Allen, T.G.; Kotipalli, R.; Flandre, D.; Batuk, M.; Hadermann, J.; Meuris, M.; Poortmans, J.; Smets, A. Surface passivation of CIGS solar cells using gallium oxide. Phys. Status Solidi 2018, 215, 1700826. [Google Scholar] [CrossRef] [Green Version]

- Qiao, S.; Liu, J.; Fu, G.; Ren, K.; Li, Z.; Wang, S.; Pan, C. ZnO nanowire based CIGS solar cell and its efficiency enhancement by the piezo-phototronic effect. Nano Energy 2018, 49, 508–514. [Google Scholar] [CrossRef]

- Major, J.D.; Tena-Zaera, R.; Azaceta, E.; Bowen, L.; Durose, K. Development of ZnO nanowire based CdTe thin film solar cells. Sol. Energy Mater. Sol. Cells 2017, 160, 107–115. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Shen, K.; Yang, R.; Zhao, Y.; Lu, S.; Wang, R.; Dong, J.; Wang, D. Comparative study of GaAs and CdTe solar cell performance under low-intensity light irradiance. Sol. Energy 2017, 157, 216–226. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, X.; Li, W.; Zhang, J.; Wang, W. Incorporation of metal selenide thin films as the secondary absorber in the CdTe solar cells. J. Alloy. Compd. 2020, 828, 154415. [Google Scholar] [CrossRef]

- Li, D.-B.; Bista, S.S.; Song, Z.; Awni, R.A.; Subedi, K.K.; Shrestha, N.; Pradhan, P.; Chen, L.; Bastola, E.; Grice, C.R. Maximize CdTe solar cell performance through copper activation engineering. Nano Energy 2020, 73, 104835. [Google Scholar] [CrossRef]

- Zhao, J.; He, Y.; Tan, K.; Yang, J.; Chen, S.; Yuan, R. Novel ratiometric electrochemiluminescence biosensor based on BP-CdTe QDs with dual emission for detecting microRNA-126. Anal. Chem. 2021, 93, 12400–12408. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, X.C.; Wu, H.C.; Zhao, C.Z. Achievements and challenges of CdS/CdTe solar cells. Int. J. Photoenergy 2011. [Google Scholar] [CrossRef] [Green Version]

- Boudour, S.; Bouchama, I.; Bouarissa, N.; Hadjab, M. A study of CdTe solar cells using Ga-doped MgxZn1-xO buffer/TCO layers: Simulation and performance analysis. J. Sci. Adv. Mater. Devices 2019, 4, 111–115. [Google Scholar] [CrossRef]

- Colegrove, E.; Banai, R.; Blissett, C.; Buurma, C.; Ellsworth, J.; Morley, M.; Barnes, S.; Gilmore, C.; Bergeson, J.; Dhere, R. High-efficiency polycrystalline CdS/CdTe solar cells on buffered commercial TCO-coated glass. J. Electron. Mater. 2012, 41, 2833–2837. [Google Scholar] [CrossRef]

- Lv, B.; Yan, B.; Cai, P.; Gao, F.; Ye, Z.; Li, Y.; Chen, N.; Sui, C.; Lin, Q.; Cheng, G. The study on saturation current and ideality factor of CdTe solar cell based on CdS window layer deposited with hydrogen peroxide. Semicond. Sci. Technol. 2019, 34, 115025. [Google Scholar] [CrossRef]

- He, X.; Wu, L.; Hao, X.; Zhang, J.; Li, C.; Wang, W.; Feng, L.; Du, Z. The Band Structures of Zn1− xMgxO (In) and the Simulation of CdTe Solar Cells with a Zn1− xMgxO (In) Window Layer by SCAPS. Energies 2019, 12, 291. [Google Scholar] [CrossRef]

- Awni, R.A.; Li, D.B.; Song, Z.; Bista, S.S.; Razooqi, M.A.; Grice, C.R.; Chen, L.; Liyanage, G.K.; Li, C.; Phillips, A.B. Influences of buffer material and fabrication atmosphere on the electrical properties of CdTe solar cells. Prog. Photovolt. Res. Appl. 2019, 27, 1115–1123. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, S.; Howell, P.; Cheng, W.; Mubeen, S.; Stickney, J. Potential Pulse ALD for Room Temperature Fabrication of Stoichiometric CdTe Nanofilms. J. Electrochem. Soc. 2019, 166, H3249. [Google Scholar] [CrossRef]

- Li, X.; Xiao, D.; Wu, L.; Wang, D.; Wang, G.; Wang, D. CdTe thin film solar cells with copper iodide as a back contact buffer layer. Sol. Energy 2019, 185, 324–332. [Google Scholar] [CrossRef]

- Artegiani, E.; Menossi, D.; Shiel, H.; Dhanak, V.; Major, J.D.; Gasparotto, A.; Sun, K.; Romeo, A. Analysis of a novel CuCl2 back contact process for improved stability in CdTe solar cells. Prog. Photovolt. Res. Appl. 2019, 27, 706–715. [Google Scholar]

- Nagaoka, A.; Nishioka, K.; Yoshino, K.; Katsube, R.; Nose, Y.; Masuda, T.; Scarpulla, M.A. Comparison of Sb, As, and P doping in Cd-rich CdTe single crystals: Doping properties, persistent photoconductivity, and long-term stability. Appl. Phys. Lett. 2020, 116, 132102. [Google Scholar] [CrossRef]

- Ojo, A.; Dharmadasa, I. 15.3% efficient graded bandgap solar cells fabricated using electroplated CdS and CdTe thin films. Sol. Energy 2016, 136, 10–14. [Google Scholar] [CrossRef] [Green Version]

- Shen, K.; Yang, R.; Wang, D.; Jeng, M.; Chaudhary, S.; Ho, K.; Wang, D. Stable CdTe solar cell with V2O5 as a back contact buffer layer. Sol. Energy Mater. Sol. Cells 2016, 144, 500–508. [Google Scholar] [CrossRef]

- Yang, X.; Bao, Z.; Luo, R.; Liu, B.; Tang, P.; Li, B.; Zhang, J.; Li, W.; Wu, L.; Feng, L. Preparation and characterization of pulsed laser deposited CdS/CdSe bi-layer films for CdTe solar cell application. Mater. Sci. Semicond. Process. 2016, 48, 27–32. [Google Scholar] [CrossRef]

- Hu, A.; Zhou, J.; Zhou, P.; Wu, X.; Yang, D. The role of O2 in CdSeTe thin film deposition and CdSeTe/CdTe solar cell performance. Sol. Energy Mater. Sol. Cells 2020, 214, 110595. [Google Scholar] [CrossRef]

- Shukla, V.; Panda, G. Numerical modelling of ultrathin CdTe solar cell with back surface field layer. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tamil Nadu, India, 9–10 April 2020; p. 012106. [Google Scholar]

- Woods-Robinson, R.; Tursun Ablekim, A.N.; Johnston, S.; Persson, K.A.; Reese, M.O.; Metzger, W.K.; Zakutayev, A. Sputtered p-Type Cux Zn1−x S Back Contact to CdTe Solar Cells. ACS Appl. Energy Mater. 2020, 3, 5427–5438. [Google Scholar] [CrossRef]

- Parashar, D.; Krishna, V.G.; Moger, S.N.; Keshav, R.; Mahesha, M. Thickness Optimization of ZnO/CdS/CdTe Solar Cell by Numerical Simulation. Trans. Electr. Electron. Mater. 2020, 21, 587–593. [Google Scholar] [CrossRef]

- Rehman, Q.; Khan, A.D.; Khan, A.D.; Noman, M.; Ali, H.; Rauf, A.; Ahmad, M.S. Super absorption of solar energy using a plasmonic nanoparticle based CdTe solar cell. RSC Adv. 2019, 9, 34207–34213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Paul, S.; Swartz, C.; Sohal, S.; Grice, C.; Bista, S.S.; Li, D.-B.; Yan, Y.; Holtz, M.; Li, J.V. Buffer/absorber interface recombination reduction and improvement of back-contact barrier height in CdTe solar cells. Thin Solid Film. 2019, 685, 385–392. [Google Scholar] [CrossRef]

- Özen, Y. The enhancement in cell performance of CdTe-based solar cell with Si/SiO 2 distributed Bragg reflectors. Appl. Phys. A 2020, 126, 1–6. [Google Scholar] [CrossRef]

- Omar, A.; Ali, M.S.; Abd Rahim, N. Electron transport properties analysis of titanium dioxide dye-sensitized solar cells (TiO2-DSSCs) based natural dyes using electrochemical impedance spectroscopy concept: A review. Sol. Energy 2020, 207, 1088–1121. [Google Scholar] [CrossRef]

- Ikpesu, J.E.; Iyuke, S.E.; Daramola, M.; Okewale, A.O. Synthesis of improved dye-sensitized solar cell for renewable energy power generation. Sol. Energy 2020, 206, 918–934. [Google Scholar] [CrossRef]

- Mehmood, U.; Asghar, H.; Babar, F.; Younas, M. Effect of graphene contents in polyaniline/graphene composites counter electrode material on the photovoltaic performance of dye-sensitized solar cells (DSSCSs). Sol. Energy 2020, 196, 132–136. [Google Scholar] [CrossRef]

- Mohamad, A.A. Physical properties of quasi-solid-state polymer electrolytes for dye-sensitised solar cells: A characterisation review. Sol. Energy 2019, 190, 434–452. [Google Scholar] [CrossRef]

- Mahalingam, S.; Nugroho, A.; Floresyona, D.; Lau, K.S.; Manap, A.; Chia, C.H.; Afandi, N. Bio and non-bio materials-based quasi-solid state electrolytes in DSSC: A review. Int. J. Energy Res. 2022, 46, 5399–5422. [Google Scholar] [CrossRef]

- Chowdhury, F.I.; Buraidah, M.; Arof, A.; Mellander, B.-E.; Noor, I. Impact of tetrabutylammonium, iodide and triiodide ions conductivity in polyacrylonitrile based electrolyte on DSSC performance. Sol. Energy 2020, 196, 379–388. [Google Scholar] [CrossRef]

- Selvanathan, V.; Yahya, R.; Alharbi, H.F.; Alharthi, N.H.; Alharthi, Y.S.; Ruslan, M.H.; Amin, N.; Akhtaruzzaman, M. Organosoluble starch derivative as quasi-solid electrolytes in DSSC: Unravelling the synergy between electrolyte rheology and photovoltaic properties. Sol. Energy 2020, 197, 144–153. [Google Scholar] [CrossRef]

- Subalakshmi, K.; Kumar, K.A.; Paul, O.P.; Saraswathy, S.; Pandurangan, A.; Senthilselvan, J. Platinum-free metal sulfide counter electrodes for DSSC applications: Structural, electrochemical and power conversion efficiency analyses. Sol. Energy 2019, 193, 507–518. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, A.; Bhandari, S.; Selvaraj, P.; Sundaram, S.; Mallick, T.K. Color comfort evaluation of dye-sensitized solar cell (DSSC) based building-integrated photovoltaic (BIPV) glazing after 2 years of ambient exposure. J. Phys. Chem. C 2019, 123, 23834–23837. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, M.S.; Pandey, A.K.; Abd Rahim, N. Advancements in the development of TiO2 photoanodes and its fabrication methods for dye sensitized solar cell (DSSC) applications. A review. Renew. Sustain. Energy Rev. 2017, 77, 89–108. [Google Scholar] [CrossRef]

- Syafinar, R.; Gomesh, N.; Irwanto, M.; Fareq, M.; Irwan, Y. Chlorophyll pigments as nature based dye for dye-sensitized solar cell (DSSC). Energy Procedia 2015, 79, 896–902. [Google Scholar] [CrossRef] [Green Version]

- Ayalew, W.A.; Ayele, D.W. Dye-sensitized solar cells using natural dye as light-harvesting materials extracted from Acanthus sennii chiovenda flower and Euphorbia cotinifolia leaf. J. Sci. Adv. Mater. Devices 2016, 1, 488–494. [Google Scholar] [CrossRef] [Green Version]

- Murugadoss, V.; Panneerselvam, P.; Yan, C.; Guo, Z.; Angaiah, S. A simple one-step hydrothermal synthesis of cobaltnickel selenide/graphene nanohybrid as an advanced platinum free counter electrode for dye sensitized solar cell. Electrochim. Acta 2019, 312, 157–167. [Google Scholar] [CrossRef]

- Kumarasinghe, K.; Kumara, G.; Rajapakse, R.; Liyanage, D.; Tennakone, K. Activated coconut shell charcoal based counter electrode for dye-sensitized solar cells. Org. Electron. 2019, 71, 93–97. [Google Scholar] [CrossRef]

- Calogero, G.; Yum, J.-H.; Sinopoli, A.; Di Marco, G.; Grätzel, M.; Nazeeruddin, M.K. Anthocyanins and betalains as light-harvesting pigments for dye-sensitized solar cells. Sol. Energy 2012, 86, 1563–1575. [Google Scholar] [CrossRef]

- Wu, X.; Duan, J.; Zhao, Y.; Yang, X.; Chen, H.; He, B.; Tang, Q. Co/Se and Ni/Se nanocomposite films prepared by magnetron sputtering as counter electrodes for dye-sensitized solar cells. Sol. Energy 2019, 180, 85–91. [Google Scholar] [CrossRef]

- Lai, W.H.; Su, Y.H.; Teoh, L.G.; Hon, M.H. Commercial and natural dyes as photosensitizers for a water-based dye-sensitized solar cell loaded with gold nanoparticles. J. Photochem. Photobiol. A Chem. 2008, 195, 307–313. [Google Scholar] [CrossRef]

- Kohn, S.; Großerhode, C.; Storck, J.L.; Grötsch, G.; Cornelißen, C.; Streitenberger, A.; Grassmann, C.; Schwarz-Pfeiffer, A.; Ehrmann, A. Commercially available teas as possible dyes for dye-sensitized solar cells. Optik 2019, 185, 178–182. [Google Scholar] [CrossRef]

- Kang, H.-Y.; Wang, H.P. Cu@ C dispersed TiO2 for dye-sensitized solar cell photoanodes. Appl. Energy 2012, 100, 144–147. [Google Scholar] [CrossRef]

- Kabir, F.; Bhuiyan, M.; Manir, M.; Rahaman, M.; Khan, M.; Ikegami, T. Development of dye-sensitized solar cell based on combination of natural dyes extracted from Malabar spinach and red spinach. Results Phys. 2019, 14, 102474. [Google Scholar] [CrossRef]

- Mohammed, I.K.; Uthman, I.K.; Muhammad, M.N. Photoelectric characterization of dye sensitized solar cells using natural dye from pawpaw leaf and flame tree flower as sensitizers. Physics 2012, 3, 281–286. [Google Scholar]

- Babkair, S.S.; Alzubaydi, R.A.; Ansari, A.A.; Al-Hadeethi, Y. Dye sensitized solar cells based on double-layered titanium dioxide and their evaluation in tropical hot desert climate of Saudi Arabia. Superlattices Microstruct. 2019, 133, 106206. [Google Scholar] [CrossRef]

- Maurya, I.C.; Srivastava, P.; Bahadur, L. Dye-sensitized solar cell using extract from petals of male flowers Luffa cylindrica L. as a natural sensitizer. Opt. Mater. 2016, 52, 150–156. [Google Scholar] [CrossRef]

- Chang, H.; Wu, H.; Chen, T.; Huang, K.; Jwo, C.; Lo, Y. Dye-sensitized solar cell using natural dyes extracted from spinach and ipomoea. J. Alloy. Compd. 2010, 495, 606–610. [Google Scholar] [CrossRef]

- Gómez-Ortíz, N.; Vázquez-Maldonado, I.; Pérez-Espadas, A.; Mena-Rejón, G.; Azamar-Barrios, J.; Oskam, G. Dye-sensitized solar cells with natural dyes extracted from achiote seeds. Sol. Energy Mater. Sol. Cells 2010, 94, 40–44. [Google Scholar] [CrossRef]

- Park, N.-G. Perovskite solar cells: An emerging photovoltaic technology. Mater. Today 2015, 18, 65–72. [Google Scholar] [CrossRef]

- Petrus, M.L.; Schlipf, J.; Li, C.; Gujar, T.P.; Giesbrecht, N.; Müller-Buschbaum, P.; Thelakkat, M.; Bein, T.; Hüttner, S.; Docampo, P. Capturing the sun: A review of the challenges and perspectives of perovskite solar cells. Adv. Energy Mater. 2017, 7, 1700264. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Klein, T.R.; Kim, D.H.; Yang, M.; Berry, J.J.; van Hest, M.F.; Zhu, K. Scalable fabrication of perovskite solar cells. Nat. Rev. Mater. 2018, 3, 1–20. [Google Scholar] [CrossRef]

- Qiao, H.W.; Yang, S.; Wang, Y.; Chen, X.; Wen, T.Y.; Tang, L.J.; Cheng, Q.; Hou, Y.; Zhao, H.; Yang, H.G. A Gradient Heterostructure Based on Tolerance Factor in High-Performance Perovskite Solar Cells with 0.84 Fill Factor. Adv. Mater. 2019, 31, 1804217. [Google Scholar] [CrossRef]

- Chen, S.; Dai, X.; Xu, S.; Jiao, H.; Zhao, L.; Huang, J. Stabilizing perovskite-substrate interfaces for high-performance perovskite modules. Science 2021, 373, 902–907. [Google Scholar] [CrossRef]

- Yin, W.-J.; Yang, J.-H.; Kang, J.; Yan, Y.; Wei, S.-H. Halide perovskite materials for solar cells: A theoretical review. J. Mater. Chem. A 2015, 3, 8926–8942. [Google Scholar] [CrossRef]

- Song, Z.; Watthage, S.C.; Phillips, A.B.; Heben, M.J. Pathways toward high-performance perovskite solar cells: Review of recent advances in organo-metal halide perovskites for photovoltaic applications. J. Photonics Energy 2016, 6, 022001. [Google Scholar] [CrossRef]

- Dey, A.; Ye, J.; De, A.; Debroye, E.; Ha, S.K.; Bladt, E.; Kshirsagar, A.S.; Wang, Z.; Yin, J.; Wang, Y. State of the art and prospects for halide perovskite nanocrystals. ACS Nano 2021, 15, 10775–10981. [Google Scholar] [CrossRef]

- Madhavan, V.E.; Zimmermann, I.; Roldán-Carmona, C.; Grancini, G.; Buffiere, M.; Belaidi, A.; Nazeeruddin, M.K. Copper thiocyanate inorganic hole-transporting material for high-efficiency perovskite solar cells. ACS Energy Lett. 2016, 1, 1112–1117. [Google Scholar] [CrossRef]

- Bakr, Z.H.; Wali, Q.; Fakharuddin, A.; Schmidt-Mende, L.; Brown, T.M.; Jose, R. Advances in hole transport materials engineering for stable and efficient perovskite solar cells. Nano Energy 2017, 34, 271–305. [Google Scholar] [CrossRef] [Green Version]

- Salado, M.; Oliva-Ramirez, M.; Kazim, S.; González-Elipe, A.R.; Ahmad, S. 1-dimensional TiO2 nano-forests as photoanodes for efficient and stable perovskite solar cells fabrication. Nano Energy 2017, 35, 215–222. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, Z.; Li, T.; Chen, Y.; Huang, W. Stability of perovskite solar cells: A prospective on the substitution of the A cation and X anion. Angew. Chem. Int. Ed. 2017, 56, 1190–1212. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wright, M.; Elumalai, N.K.; Uddin, A. Stability of perovskite solar cells. Sol. Energy Mater. Sol. Cells 2016, 147, 255–275. [Google Scholar] [CrossRef]

- Bouich, A.; Marí-Guaita, J.; Soucase, B.M.; Palacios, P. Manufacture of high-efficiency and stable lead-free solar cells through antisolvent quenching engineering. Nanomaterials 2022, 12, 2901. [Google Scholar] [CrossRef]

- Freitas, J.N.; Gonçalves, A.S.; Nogueira, A.F. A comprehensive review of the application of chalcogenide nanoparticles in polymer solar cells. Nanoscale 2014, 6, 6371–6397. [Google Scholar] [CrossRef] [Green Version]

- Hau, S.K.; Yip, H.-L.; Jen, A.K.-Y. A review on the development of the inverted polymer solar cell architecture. Polym. Rev. 2010, 50, 474–510. [Google Scholar] [CrossRef]

- Mei, A.; Li, X.; Liu, L.; Ku, Z.; Liu, T.; Rong, Y.; Xu, M.; Hu, M.; Chen, J.; Yang, Y. A hole-conductor–free, fully printable mesoscopic perovskite solar cell with high stability. Science 2014, 345, 295–298. [Google Scholar] [CrossRef]

- Chen, H.; Wei, Z.; Zheng, X.; Yang, S. A scalable electrodeposition route to the low-cost, versatile and controllable fabrication of perovskite solar cells. Nano Energy 2015, 15, 216–226. [Google Scholar] [CrossRef]

- Seo, J.; Park, S.; Kim, Y.C.; Jeon, N.J.; Noh, J.H.; Yoon, S.C.; Seok, S.I. Benefits of very thin PCBM and LiF layers for solution-processed p–i–n perovskite solar cells. Energy Environ. Sci. 2014, 7, 2642–2646. [Google Scholar] [CrossRef]

- Tang, S.; Deng, Y.; Zheng, X.; Bai, Y.; Fang, Y.; Dong, Q.; Wei, H.; Huang, J. Composition engineering in doctor-blading of perovskite solar cells. Adv. Energy Mater. 2017, 7, 1700302. [Google Scholar] [CrossRef]

- Chang, W.C.; Lan, D.H.; Lee, K.M.; Wang, X.F.; Liu, C.L. Controlled deposition and performance optimization of perovskite solar cells using ultrasonic spray-coating of photoactive layers. ChemSusChem 2017, 10, 1405–1412. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Li, C.; Sun, X.; Xu, R.; Du, Y.; Ni, J.; Cai, H.; Li, J.; Hu, Z.; Zhang, J. Efficient and hysteresis-less pseudo-planar heterojunction perovskite solar cells fabricated by a facile and solution-saving one-step dip-coating method. Org. Electron. 2017, 40, 13–23. [Google Scholar] [CrossRef]

- Lee, J.-W.; Na, S.-I.; Kim, S.-S. Efficient spin-coating-free planar heterojunction perovskite solar cells fabricated with successive brush-painting. J. Power Sources 2017, 339, 33–40. [Google Scholar] [CrossRef]

- Liao, H.C.; Guo, P.; Hsu, C.P.; Lin, M.; Wang, B.; Zeng, L.; Huang, W.; Soe, C.M.M.; Su, W.F.; Bedzyk, M.J. Enhanced efficiency of hot-cast large-area planar perovskite solar cells/modules having controlled chloride incorporation. Adv. Energy Mater. 2017, 7, 1601660. [Google Scholar] [CrossRef]

- Ku, Z.; Rong, Y.; Xu, M.; Liu, T.; Han, H. Full printable processed mesoscopic CH3 NH3 PbI3/TiO2 heterojunction solar cells with carbon counter electrode. Sci. Rep. 2013, 3, 3132. [Google Scholar] [CrossRef] [Green Version]

- Leyden, M.R.; Lee, M.V.; Raga, S.R.; Qi, Y. Large formamidinium lead trihalide perovskite solar cells using chemical vapor deposition with high reproducibility and tunable chlorine concentrations. J. Mater. Chem. A 2015, 3, 16097–16103. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.-L.; Li, C.-X.; Li, C.-J.; Yang, G.-J. Large-area high-efficiency perovskite solar cells based on perovskite films dried by the multi-flow air knife method in air. J. Mater. Chem. A 2017, 5, 1548–1557. [Google Scholar] [CrossRef]

- He, M.; Li, B.; Cui, X.; Jiang, B.; He, Y.; Chen, Y.; O’Neil, D.; Szymanski, P.; Ei-Sayed, M.A.; Huang, J. Meniscus-assisted solution printing of large-grained perovskite films for high-efficiency solar cells. Nat. Commun. 2017, 8, 1–10. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Po, R.; Carbonera, C.; Bernardi, A.; Tinti, F.; Camaioni, N. Polymer-and carbon-based electrodes for polymer solar cells: Toward low-cost, continuous fabrication over large area. Sol. Energy Mater. Sol. Cells 2012, 100, 97–114. [Google Scholar] [CrossRef]

- Cai, W.; Gong, X.; Cao, Y. Polymer solar cells: Recent development and possible routes for improvement in the performance. Sol. Energy Mater. Sol. Cells 2010, 94, 114–127. [Google Scholar] [CrossRef]

- Wang, Q.; Xie, Y.; Soltani-Kordshuli, F.; Eslamian, M. Progress in emerging solution-processed thin film solar cells–Part I: Polymer solar cells. Renew. Sustain. Energy Rev. 2016, 56, 347–361. [Google Scholar] [CrossRef]

- Lu, L.; Zheng, T.; Wu, Q.; Schneider, A.M.; Zhao, D.; Yu, L. Recent advances in bulk heterojunction polymer solar cells. Chem. Rev. 2015, 115, 12666–12731. [Google Scholar] [CrossRef]

- You, J.; Dou, L.; Hong, Z.; Li, G.; Yang, Y. Recent trends in polymer tandem solar cells research. Prog. Polym. Sci. 2013, 38, 1909–1928. [Google Scholar] [CrossRef]

- Jhuo, H.J.; Yeh, P.N.; Liao, S.H.; Li, Y.L.; Cheng, Y.S.; Chen, S.A. Review on the recent progress in low band gap conjugated polymers for bulk hetero-junction polymer solar cells. J. Chin. Chem. Soc. 2014, 61, 115–126. [Google Scholar] [CrossRef]

- Xu, X.; Feng, K.; Bi, Z.; Ma, W.; Zhang, G.; Peng, Q. Single-junction polymer solar cells with 16.35% efficiency enabled by a platinum (II) complexation strategy. Adv. Mater. 2019, 31, 1901872. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, A.; Singh, A.; Abbas, S.A.; Lu, Y.-J.; Boopathi, K.M.; Hanmandlu, C.; Kaisar, N.; Lee, C.-H.; Chu, C.-W. Bilayer polymer solar cells prepared with transfer printing of active layers from controlled swelling/de-swelling of PDMS. Nano Energy 2019, 63, 103826. [Google Scholar] [CrossRef]

- Huang, L.; Jiang, P.; Zhang, Y.; Zhang, L.; Yu, Z.; He, Q.; Zhou, W.; Tan, L.; Chen, Y. Unraveling the Morphology in Solution-Processed Pseudo-Bilayer Planar Heterojunction Organic Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 26213–26221. [Google Scholar] [CrossRef]

- St. Onge, P.B.J.; Ocheje, M.U.; Selivanova, M.; Rondeau-Gagne, S. Recent advances in mechanically robust and stretchable bulk heterojunction polymer solar cells. Chem. Rec. 2019, 19, 1008–1027. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, S.; Lim, D.C.; Kim, D.H.; Nahm, S.; Han, S.H. Inverted bulk-heterojunction polymer solar cells using a sputter-deposited Al-doped ZnO electron transport layer. J. Alloy. Compd. 2019, 777, 717–722. [Google Scholar] [CrossRef]

- Li, Q.; Wang, L.-M.; Liu, S.; Zhan, X.; Zhu, T.; Cao, Z.; Lai, H.; Zhao, J.; Cai, Y.; Xie, W. Impact of Donor–Acceptor Interaction and Solvent Additive on the Vertical Composition Distribution of Bulk Heterojunction Polymer Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 45979–45990. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Yuan, J.; Liang, S.; Chen, J.-D.; Xia, Y.; Larson, B.W.; Wang, Y.; Su, G.M.; Zhang, Y.; Cui, C. Simultaneously improved efficiency and stability in all-polymer solar cells by a P–i–N architecture. ACS Energy Lett. 2019, 4, 2277–2286. [Google Scholar] [CrossRef]

- Kim, M.; Kim, H.I.; Ryu, S.U.; Son, S.Y.; Park, S.A.; Khan, N.; Shin, W.S.; Song, C.E.; Park, T. Improving the Photovoltaic Performance and Mechanical Stability of Flexible All-Polymer Solar Cells via Tailoring Intermolecular Interactions. Chem. Mater. 2019, 31, 5047–5055. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, N.; Yu, Y.; Liu, J. Organoboron polymer for 10% efficiency all-polymer solar cells. Chem. Mater. 2020, 32, 1308–1314. [Google Scholar] [CrossRef]

- Sun, C.; Qin, S.; Wang, R.; Chen, S.; Pan, F.; Qiu, B.; Shang, Z.; Meng, L.; Zhang, C.; Xiao, M. High efficiency polymer solar cells with efficient hole transfer at zero highest occupied molecular orbital offset between methylated polymer donor and brominated acceptor. J. Am. Chem. Soc. 2020, 142, 1465–1474. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, Z.; An, Q.; Zhang, F. Semitransparent polymer solar cells with 12.37% efficiency and 18.6% average visible transmittance. Sci. Bull. 2020, 65, 131–137. [Google Scholar] [CrossRef] [Green Version]

- An, Q.; Wang, J.; Gao, W.; Ma, X.; Hu, Z.; Gao, J.; Xu, C.; Hao, M.; Zhang, X.; Yang, C. Alloy-like ternary polymer solar cells with over 17.2% efficiency. Sci. Bull. 2020, 65, 538–545. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Zheng, Y.; Yang, H.; Sun, C.; Dong, Y.; Cui, C.; Yan, H.; Li, Y. Rationally pairing photoactive materials for high-performance polymer solar cells with efficiency of 16.53%. Sci. China Chem. 2020, 63, 265–271. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, X.; Cai, D.; Tu, Q.; Ma, W.; Zheng, Q. A minimal benzo [c][1, 2, 5] thiadiazole-based electron acceptor as a third component material for ternary polymer solar cells with efficiencies exceeding 16.0%. Mater. Horiz. 2020, 7, 117–124. [Google Scholar] [CrossRef]

- Yao, H.; Ma, L.K.; Yu, H.; Yu, J.; Chow, P.C.; Xue, W.; Zou, X.; Chen, Y.; Liang, J.; Arunagiri, L. All-Polymer Solar Cells with over 12% Efficiency and a Small Voltage Loss Enabled by a Polymer Acceptor Based on an Extended Fused Ring Core. Adv. Energy Mater. 2020, 10, 2001408. [Google Scholar] [CrossRef]

- Yao, C.; Zhao, J.; Zhu, Y.; Liu, B.; Yan, C.; Perepichka, D.F.; Meng, H. Trifluoromethyl Group-Modified Non-Fullerene Acceptor toward Improved Power Conversion Efficiency over 13% in Polymer Solar Cells. ACS Appl. Mater. Interfaces 2020, 12, 11543–11550. [Google Scholar] [CrossRef] [PubMed]

- An, Q.; Ma, X.; Gao, J.; Zhang, F. Solvent additive-free ternary polymer solar cells with 16.27% efficiency. Sci. Bull 2019, 64, 504–506. [Google Scholar] [CrossRef] [Green Version]

- Yao, H.; Bai, F.; Hu, H.; Arunagiri, L.; Zhang, J.; Chen, Y.; Yu, H.; Chen, S.; Liu, T.; Lai, J.Y.L. Efficient all-polymer solar cells based on a new polymer acceptor achieving 10.3% power conversion efficiency. ACS Energy Lett. 2019, 4, 417–422. [Google Scholar] [CrossRef]

- Meng, Y.; Wu, J.; Guo, X.; Su, W.; Zhu, L.; Fang, J.; Zhang, Z.-G.; Liu, F.; Zhang, M.; Russell, T.P. 11.2% Efficiency all-polymer solar cells with high open-circuit voltage. Sci. China Chem. 2019, 62, 845–850. [Google Scholar] [CrossRef]

- Nozik, A.J. Quantum dot solar cells. Phys. E: Low-Dimens. Syst. Nanostructures 2002, 14, 115–120. [Google Scholar] [CrossRef]

- Kamat, P.V. Quantum dot solar cells. Semiconductor nanocrystals as light harvesters. J. Phys. Chem. C 2008, 112, 18737–18753. [Google Scholar] [CrossRef]

- Liu, J.; Xian, K.; Ye, L.; Zhou, Z. Open-Circuit Voltage Loss in Lead Chalcogenide Quantum Dot Solar Cells. Adv. Mater. 2021, 33, 2008115. [Google Scholar] [CrossRef]

- Chen, J.; Jia, D.; Johansson, E.M.; Hagfeldt, A.; Zhang, X. Emerging perovskite quantum dot solar cells: Feasible approaches to boost performance. Energy Environ. Sci. 2021, 14, 224–261. [Google Scholar] [CrossRef]

- Albaladejo-Siguan, M.; Baird, E.C.; Becker-Koch, D.; Li, Y.; Rogach, A.L.; Vaynzof, Y. Stability of quantum dot solar cells: A matter of (Life) Time. Adv. Energy Mater. 2021, 11, 2003457. [Google Scholar] [CrossRef]

- Nozik, A.J.; Beard, M.C.; Luther, J.M.; Law, M.; Ellingson, R.J.; Johnson, J.C. Semiconductor quantum dots and quantum dot arrays and applications of multiple exciton generation to third-generation photovoltaic solar cells. Chem. Rev. 2010, 110, 6873–6890. [Google Scholar] [CrossRef] [PubMed]

- Kramer, I.J.; Sargent, E.H. Colloidal quantum dot photovoltaics: A path forward. ACS Nano 2011, 5, 8506–8514. [Google Scholar] [CrossRef] [PubMed]

- Ip, A.H.; Thon, S.M.; Hoogland, S.; Voznyy, O.; Zhitomirsky, D.; Debnath, R.; Levina, L.; Rollny, L.R.; Carey, G.H.; Fischer, A. Hybrid passivated colloidal quantum dot solids. Nat. Nanotechnol. 2012, 7, 577–582. [Google Scholar] [CrossRef] [PubMed]

- Yella, A.; Lee, H.-W.; Tsao, H.N.; Yi, C.; Chandiran, A.K.; Nazeeruddin, M.K.; Diau, E.W.-G.; Yeh, C.-Y.; Zakeeruddin, S.M.; Grätzel, M. Porphyrin-sensitized solar cells with cobalt (II/III)–based redox electrolyte exceed 12 percent efficiency. Science 2011, 334, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brown, P.; Kamat, P.V. Quantum dot solar cells. electrophoretic deposition of CdSe− C60 composite films and capture of photogenerated electrons with n C60 cluster shell. J. Am. Chem. Soc. 2008, 130, 8890–8891. [Google Scholar] [CrossRef]

- Park, J.; Kirch, J.; Mawst, L.; Liu, C.-C.; Nealey, P.; Kuech, T. Controlled growth of InGaAs/InGaAsP quantum dots on InP substrates employing diblock copolymer lithography. Appl. Phys. Lett. 2009, 95, 113111. [Google Scholar] [CrossRef]

- Palankar, R.; Medvedev, N.; Rong, A.; Delcea, M. Fabrication of quantum dot microarrays using electron beam lithography for applications in analyte sensing and cellular dynamics. ACS Nano 2013, 7, 4617–4628. [Google Scholar] [CrossRef]

- Di, D.; Perez-Wurfl, I.; Gentle, A.; Kim, D.-H.; Hao, X.; Shi, L.; Conibeer, G.; Green, M.A. Impacts of post-metallisation processes on the electrical and photovoltaic properties of Si quantum dot solar cells. Nanoscale Res. Lett. 2010, 5, 1762. [Google Scholar] [CrossRef] [Green Version]

- Verma, V.B.; Stevens, M.J.; Silverman, K.L.; Dias, N.; Garg, A.; Coleman, J.J.; Mirin, R.P. Time-resolved photoluminescence of lithographically defined quantum dots fabricated by electron beam lithography and wet chemical etching. J. Appl. Phys. 2011, 109, 123112. [Google Scholar] [CrossRef] [Green Version]

- Koguchi, N.; Ishige, K.; Takahashi, S. New selective molecular-beam epitaxial growth method for direct formation of GaAs quantum dots. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1993, 11, 787–790. [Google Scholar] [CrossRef]

- Watanabe, K.; Koguchi, N.; Gotoh, Y. Fabrication of GaAs quantum dots by modified droplet epitaxy. Jpn. J. Appl. Phys. 2000, 39, L79. [Google Scholar] [CrossRef]

- Leonard, D.; Krishnamurthy, M.; Fafard, S.; Merz, J.; Petroff, P. Molecular-beam epitaxy growth of quantum dots from strained coherent uniform islands of InGaAs on GaAs. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1994, 12, 1063–1066. [Google Scholar] [CrossRef]

- Nose, K.; Omata, T.; Otsuka-Yao-Matsuo, S. Colloidal synthesis of ternary copper indium diselenide quantum dots and their optical properties. J. Phys. Chem. C 2009, 113, 3455–3460. [Google Scholar] [CrossRef]

- Pu, Y.; Cai, F.; Wang, D.; Wang, J.-X.; Chen, J.-F. Colloidal synthesis of semiconductor quantum dots toward large-scale production: A review. Ind. Eng. Chem. Res. 2018, 57, 1790–1802. [Google Scholar] [CrossRef]

- Rajh, T.; Micic, O.I.; Nozik, A.J. Synthesis and characterization of surface-modified colloidal cadmium telluride quantum dots. J. Phys. Chem. 1993, 97, 11999–12003. [Google Scholar] [CrossRef]

- Lv, M.; Zhu, J.; Huang, Y.; Li, Y.; Shao, Z.; Xu, Y.; Dai, S. Colloidal CuInS2 quantum dots as inorganic hole-transporting material in perovskite solar cells. ACS Appl. Mater. Interfaces 2015, 7, 17482–17488. [Google Scholar] [CrossRef]

- Diguna, L.J.; Shen, Q.; Kobayashi, J.; Toyoda, T. High efficiency of CdSe quantum-dot-sensitized TiO2 inverse opal solar cells. Appl. Phys. Lett. 2007, 91, 023116. [Google Scholar] [CrossRef]

- Luo, J.; Wei, H.; Huang, Q.; Hu, X.; Zhao, H.; Yu, R.; Li, D.; Luo, Y.; Meng, Q. Highly efficient core–shell CuInS2–Mn doped CdS quantum dot sensitized solar cells. Chem. Commun. 2013, 49, 3881–3883. [Google Scholar] [CrossRef] [Green Version]

- Zhao, K.; Pan, Z.; Mora-Seró, I.n.; Cánovas, E.; Wang, H.; Song, Y.; Gong, X.; Wang, J.; Bonn, M.; Bisquert, J. Boosting power conversion efficiencies of quantum-dot-sensitized solar cells beyond 8% by recombination control. J. Am. Chem. Soc. 2015, 137, 5602–5609. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, Z.; Wang, R.; Pan, Z.; Gong, X.; Zhong, X. Effects of metal oxyhydroxide coatings on photoanode in quantum dot sensitized solar cells. Chem. Mater. 2016, 28, 2323–2330. [Google Scholar] [CrossRef]

- González-Pedro, V.; Sima, C.; Marzari, G.; Boix, P.P.; Giménez, S.; Shen, Q.; Dittrich, T.; Mora-Seró, I. High performance PbS Quantum Dot Sensitized Solar Cells exceeding 4% efficiency: The role of metal precursors in the electron injection and charge separation. Phys. Chem. Chem. Phys. 2013, 15, 13835–13843. [Google Scholar] [CrossRef] [Green Version]

- Pan, Z.; Mora-Seroó, I.n.; Shen, Q.; Zhang, H.; Li, Y.; Zhao, K.; Wang, J.; Zhong, X.; Bisquert, J. High-efficiency “green” quantum dot solar cells. J. Am. Chem. Soc. 2014, 136, 9203–9210. [Google Scholar] [CrossRef] [PubMed]

- Jiao, S.; Shen, Q.; Mora-Sero, I.; Wang, J.; Pan, Z.; Zhao, K.; Kuga, Y.; Zhong, X.; Bisquert, J. Band engineering in core/shell ZnTe/CdSe for photovoltage and efficiency enhancement in exciplex quantum dot sensitized solar cells. ACS Nano 2015, 9, 908–915. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Kang, M.; Kim, S.; Heo, J.-H.; Noh, J.H.; Im, S.H.; Seok, S.I.; Kim, S.-W. Fabrication of CuInTe2 and CuInTe2–x Sex Ternary Gradient Quantum Dots and Their Application to Solar Cells. ACS Nano 2013, 7, 4756–4763. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Guo, X.; Huang, X.; Huang, S.; Li, D.; Luo, Y.; Shen, Q.; Toyoda, T.; Meng, Q. Highly efficient CdS/CdSe-sensitized solar cells controlled by the structural properties of compact porous TiO2 photoelectrodes. Phys. Chem. Chem. Phys. 2011, 13, 4659–4667. [Google Scholar] [CrossRef]

- Yang, X.; Wang, K.; Gu, Y.; Ni, H.; Wang, X.; Yang, T.; Wang, Z. Improved efficiency of InAs/GaAs quantum dots solar cells by Si-doping. Sol. Energy Mater. Sol. Cells 2013, 113, 144–147. [Google Scholar] [CrossRef]

| S.No | Cell Architecture | Inference | Voc (V) | Jsc (mA cm−2) | FF (%) | Eff (%) | Ref |

|---|---|---|---|---|---|---|---|

| 1. | Mo-N back contact diffusion barrier deposition in CIGS SC | 0.622 | 28.67 | 67.53 | 12.05 | [57] | |

| 2. | alkali post deposition treatment of RbF | 0.741 | 37.8 | 80.6 | 22.66 | [58] | |

| 3. | glass/Mo/CIGS/CdS/i-ZnO/TCO/Au | CdS buffer layer deposition through chemical bath method, effect of i-ZnO high resistive layer | 0.661 | 32.08 | 78.9 | 15.50 | [59] |

| 4. | high mobility TCO with 1 eV absorbers | 0.609 | 42.3 | 74.6 | 19.20 | [60] | |

| 5. | Mo/Si/CIGS/ZnS/ZnO | impact of silicon inclusion to reduce the cell thickness and influence of thickness and gallium concentration of the CIGS absorber layer on the performance | 0.6903 | 37.57 | 81.03 | 21.08 | [61] |

| 6. | ZnO NWs/AZO/ZnS/CIGS/Mo/Thermal electric generator | enhanced performance achieved by ZnO NWs with CIGS SC along with series connection of Thermal electric generator | 0.85 | 38.55 | 67.2 | 22.02 | [62] |

| 7. | (Ni/Al)/MgF2/Al:ZnO/CdS/(KF-PDT/CIGS)/Mo/SLG | influence of light-soaking, heat-soaking, and combined LS and HS on KF-treated and KF-free CIGS SCs with CBD-CdS buffer layer | [63] | ||||

| 8. | ZnO/Buffer n-ZnS/p-CIGS/Mo | effect of ZnS buffer layer | 0.804 | 35.66 | 82.14 | 23.54 | [64] |

| 9. | Al2O3/MgF2)/AZO/i-ZnO/CdS/CIGS/Mo | effect of thickness of ARC over CIGS cell | 31.22 | [65] | |||

| 10. | (Al/Ni)/TCO/CdS/GaOx/CIGS/Mo/Soda-lime glass | gallium oxide deposited by plasma-enhanced atomic layer deposition, as a surface passivation material at the interface of CdS buffer layer of CIGS SC | 0.056 | 1 | 8.22 | 2.60 | [66] |

| 11. | (glass/stainless steel)/Mo/CIGS/CdS/ZnO NWs/ITO | ZnO NWS incorporated in CIGS and the effect of externally applied stress (rigid) and strain (flexible) | 11.40 (stress) 5.96 (strain) | [67] |

| S.no | Cell Architecture | Voc (mV) | Jsc (mAcm−2) | FF | η (%) | Ref. |

|---|---|---|---|---|---|---|

| 1. | Glass/FTO/n-CdS/n-CdTe/p-CdTe/Au | 730 | 33.8 | 0.62 | 15.30 | [83] |

| 2. | Glass/FTO/CdS/CdTe | 838 | 25 | 0.72 | 15.20 | [84] |

| 3. | glass/FTO/CdS/CdSe/CdTe/ZnTe:Cu/Au | 791 | 27.4 | 13.47 | [85] | |

| 4 | 861 | 26.9 | 0.754 | 17.50 | [71] | |

| 5. | 863 | 28.6 | 0.781 | 19.25 | [86] | |

| 6. | Glass/ZnO:Al/n-CdS/p-CdTe/ZnTe | 1528.5 | 28.355 | 0.497 | 21.57 | [87] |

| 7. | Glass/n-FTO/n-Cd(S,O)/p-CdTe/p-CuZnTe/Au | 848 | 26.6 | 0.733 | 16.60 | [88] |

| 8. | ZnO/CdS/CdTe (0.25/0.05/2.5 micrometers) | 859 | 28.4 | 0.737 | 17.66 | [89] |

| 9. | Quartz/Ti/SiO2/CdTe/ITO | 40.36 | [90] | |||

| 10. | Sodalime glass/SnO2:F/SnO2/CdS:O/CdTe/(Cu/Au) | 857 | 23.6 | 0.672 | 14.10 | [91] |

| 11. | SiO2/Si(DBR)/ZnTe (BSF)/CdTe/CdS/ZnO/FTO. | 109,820 | 1201 | 0.8203 | 10.39 | [92] |

| 12. | glass/SnO2:F(FTO)/n-CdS/p-CdTe/Cu/V2O5/Cu/Au | 806 | 24.8 | 0.7 | 14 | [84] |

| S.No | Material | HOMO Energy Level (eV) | LUMO Energy Level (eV) | Energy Bandgap (eV) |

|---|---|---|---|---|

| 1 | MAPbBr3 | −5.68 | −3.38 | 2.3 |

| 2 | MAPbI3 | −5.43 | −3.88 | 1.55 |

| 3 | FAPbI3 | −5.42 | −3.92 | 1.5 |

| 4 | MAPb1-x SnxI3 (x = 0.25) | −5.48 | −4.24 | 1.24 |

| 5 | MAPb1-x SnxI3 (x = 0.5) | −5.61 | −4.44 | 1.17 |

| 6 | MAPb1-x SnxI3 (x = 0.75) | −5.77 | −4.60 | 1.17 |

| 7 | MASnI3 | −5.47 | −4.17 | 1.3 |

| Various Interfacial Layers | Commonly Used Materials | |

|---|---|---|

| Metal Contacts | Al, Au, Ag | |

| Hole Transport Materials | Small molecules HTM | Spiro-OMeTAD, TPBC, OMe TPA-FA |

| Polymer Based HTM | P3HT, PTAA, PEDOT:PSS | |

| Inorganic HTM | CuSCN, CuI, NiO, CuO | |

| Perovskite materials | MAPb(I3,Br3), Cs2AgBiBr6, FAPbI3, MASnI3 | |

| Electron transport materials | ZnO, TiO2, PCBM, SnO2 | |

| Conducting Oxide | ITO | |

| Element | Structural Change with Respect to the Temperature Variation (°C) | ||

|---|---|---|---|

| Cubic | Tetragonal | Orthogonal | |

| Iodine | >54.25 | From 54.25 to −110.95 | <−110.95 |

| Bromine | >−36.25 | From −36.25 to −123.65 | <−123.65 |

| Chlorine | >−94.35 | From −94.35 to −200.25 | <−200.25 |

| S.No | Type of Material | Density of States | Motion of Electron |

|---|---|---|---|

| 1 | 3D (Bulk material) | Free to move in all directions | |

| 2 | 2D (Quantum Well) | Restricted to two directions | |

| 3 | 1D (Quantum Wire) | Restricted to one direction | |

| 4 | 0D (QD) | Restricted in all directions |

| S.No | QD Material | Voc | Jsc | FF | Eff (%) | Ref. |

|---|---|---|---|---|---|---|

| 1 | CdSe | 710 | 7.51 | 0.5 | 2.7 | [194] |

| 2 | CuInS2–Mn doped CdS | 581 | 19.29 | 0.48 | 5.38 | [195] |

| 3 | CdSeTe | 653 | 20.78 | 0.605 | 8.21 | [196] |

| 4 | CdSeTe with ZrOCl2 treatment | 21.04 | 72 | 0.642 | 9.73 | [197] |

| 5 | PbS/CdS | 416 | 22 | 0.453 | 4.2 | [198] |

| 6 | CIS | 586 | 20.65 | 0.581 | 7.04 | [199] |

| 7 | ZnTe/CdSe | 642 | 19.65 | 0.57 | 7.17 | [200] |

| 8 | Cu0.23In0.36Te0.19Se0.22 | 400 | 17.4 | 0.44 | 3.1 | [201] |

| 9 | CdS/CdSe | 575 | 13.68 | 0.63 | 4.92 | [202] |

| 10 | InAs/GaAs with Si doping | 840 | 27.6 | 0.734 | 17 | [203] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivaraj, S.; Rathanasamy, R.; Kaliyannan, G.V.; Panchal, H.; Jawad Alrubaie, A.; Musa Jaber, M.; Said, Z.; Memon, S. A Comprehensive Review on Current Performance, Challenges and Progress in Thin-Film Solar Cells. Energies 2022, 15, 8688. https://doi.org/10.3390/en15228688

Sivaraj S, Rathanasamy R, Kaliyannan GV, Panchal H, Jawad Alrubaie A, Musa Jaber M, Said Z, Memon S. A Comprehensive Review on Current Performance, Challenges and Progress in Thin-Film Solar Cells. Energies. 2022; 15(22):8688. https://doi.org/10.3390/en15228688

Chicago/Turabian StyleSivaraj, Santhosh, Rajasekar Rathanasamy, Gobinath Velu Kaliyannan, Hitesh Panchal, Ali Jawad Alrubaie, Mustafa Musa Jaber, Zafar Said, and Saim Memon. 2022. "A Comprehensive Review on Current Performance, Challenges and Progress in Thin-Film Solar Cells" Energies 15, no. 22: 8688. https://doi.org/10.3390/en15228688

APA StyleSivaraj, S., Rathanasamy, R., Kaliyannan, G. V., Panchal, H., Jawad Alrubaie, A., Musa Jaber, M., Said, Z., & Memon, S. (2022). A Comprehensive Review on Current Performance, Challenges and Progress in Thin-Film Solar Cells. Energies, 15(22), 8688. https://doi.org/10.3390/en15228688