Synthesis, Optimization, and Characterization of Fluorescent Particle Preformed Gel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

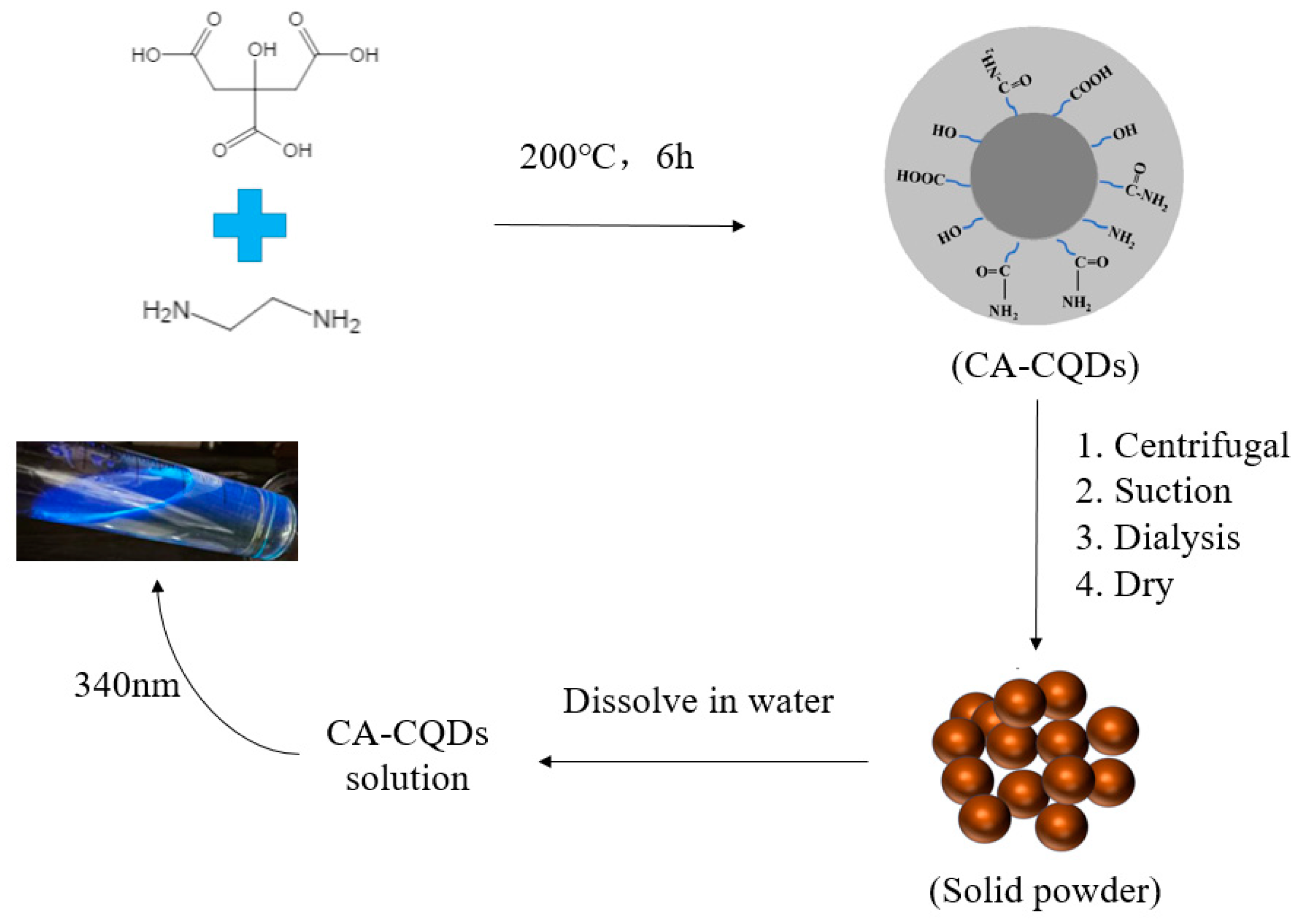

2.2. Synthesis of the Carbon Quantum Dots (CQDs)s

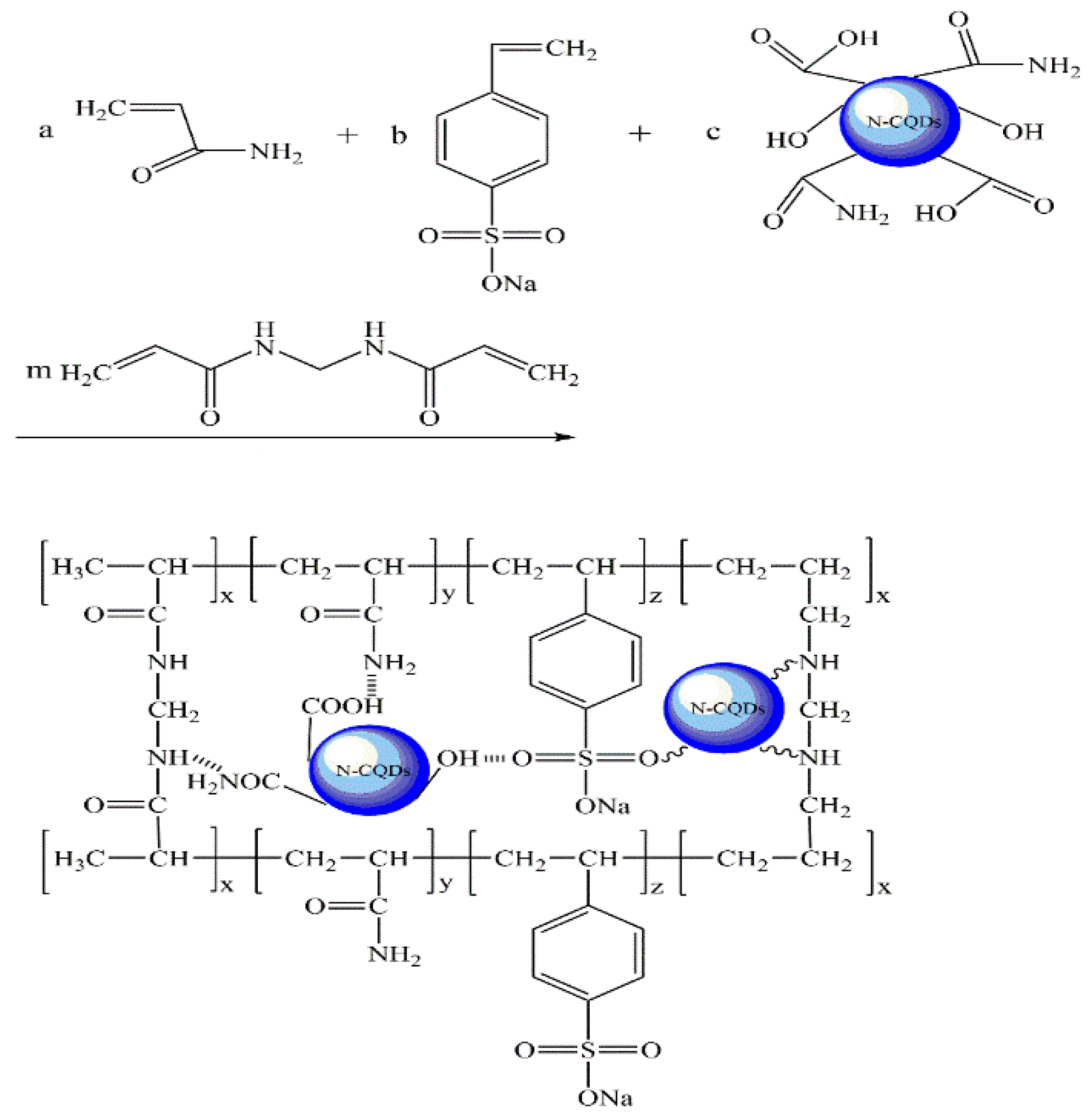

2.3. Synthesis of CQDs@PPG

- Oil phase: weigh 2.24 g of Span 80 and 0.56 g of Tween 80, and add them into 50 g of white oil in a four-necked flask, stirring well to make it evenly mixed.

- Aqueous phase: weigh 13.0 g of AA, 3.0 g of SSS, 0.8 g of dry CQDs, and 0.3 g of MBAA into 30 g of pure water, stir well to make it evenly mixed. Adjust pH to neutral with NaOH standard solution, then add 0.0313 g sodium bisulfite and stir well.

- Preparation of CQDs@PPG: After building the synthesis device, add a magnetic stirring bar to the four-necked flask containing the oil phase, turn on the stirring switch, and set the rotating speed to 400 r/min. Slowly drop the aqueous phase into the oil phase with a constant-pressure dropping funnel to obtain a W/O emulsion. Continue the stirring while injecting nitrogen for 30 min to remove oxygen altogether, and then add 0.0687 g of ammonium persulfate aqueous solution dropwise under nitrogen protection. Rising the environmental temperature to 45 °C for 4 h of reaction, and the CQDs@PPG emulsion was obtained by cooling the product to room temperature. Demulsify and wash it with acetone and absolute ethanol, and then the mixture was centrifuged at 6000 r/min. Remove the supernatant and wash with ethanol again, then filter to obtain CQDs@PPG precipitation. Finally, dehydrate the precipitation for 12 h in the oven to collect CQDs@PPG powder.

2.4. Optimized Synthesis of CQDs@PPG

Orthogonal Design

2.5. Influence of Single Factor on CQDs@PPG

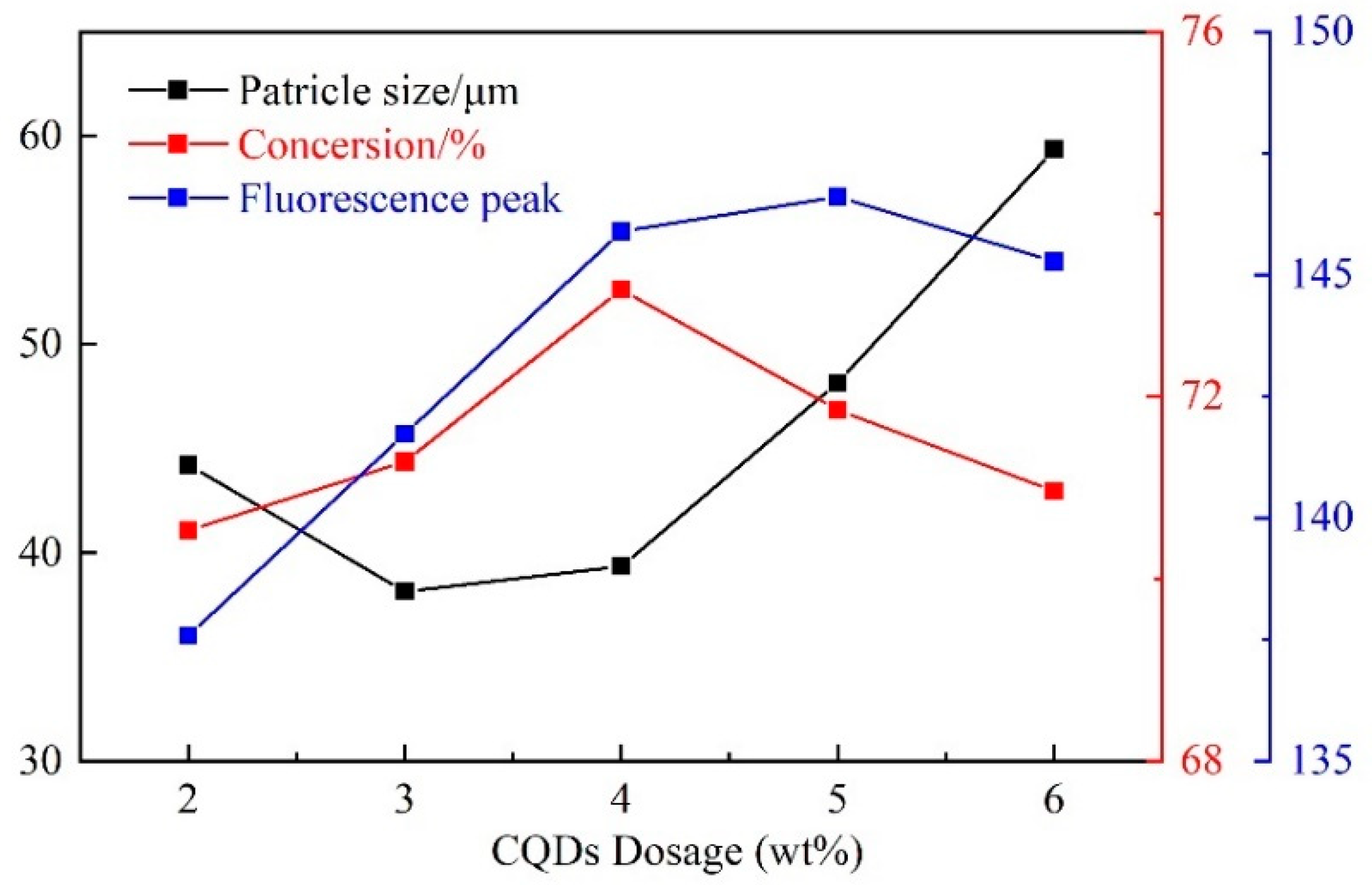

2.5.1. Influence of CQDs Dosage on CQDs@PPG

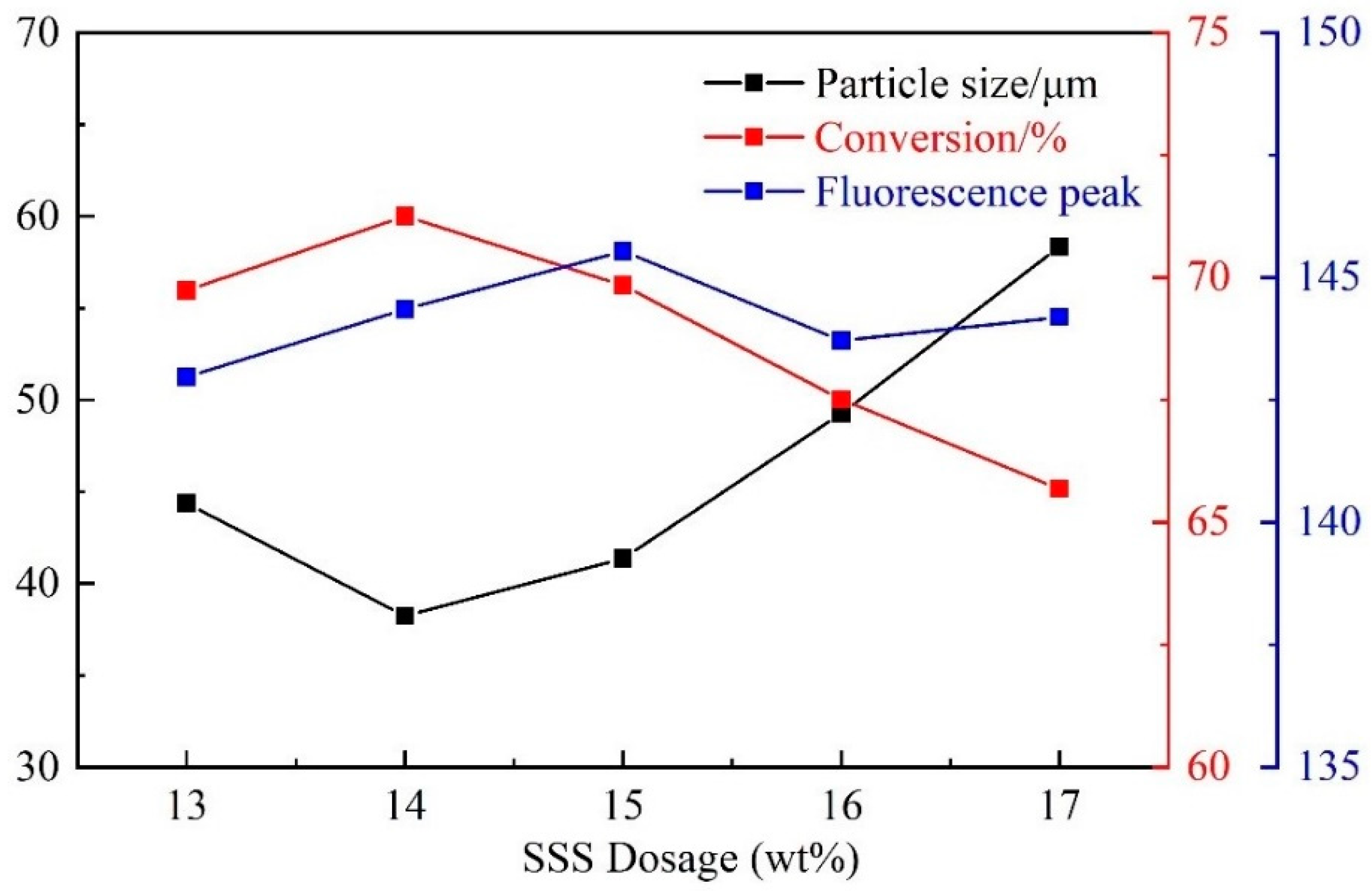

2.5.2. Influence of SSS Dosage on CQDs@PPG

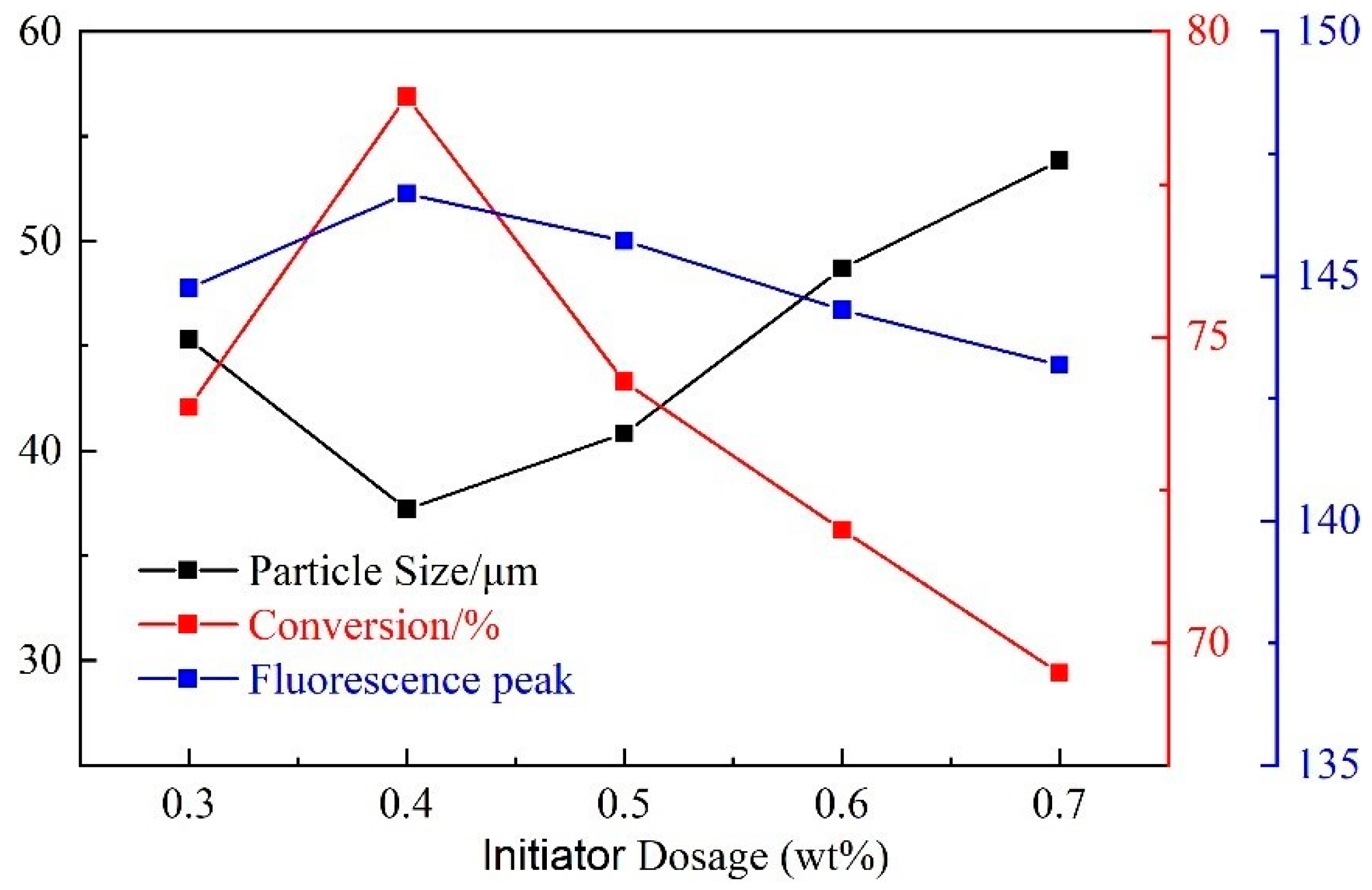

2.5.3. Influence of Initiator Dosage on CQDs@PPG

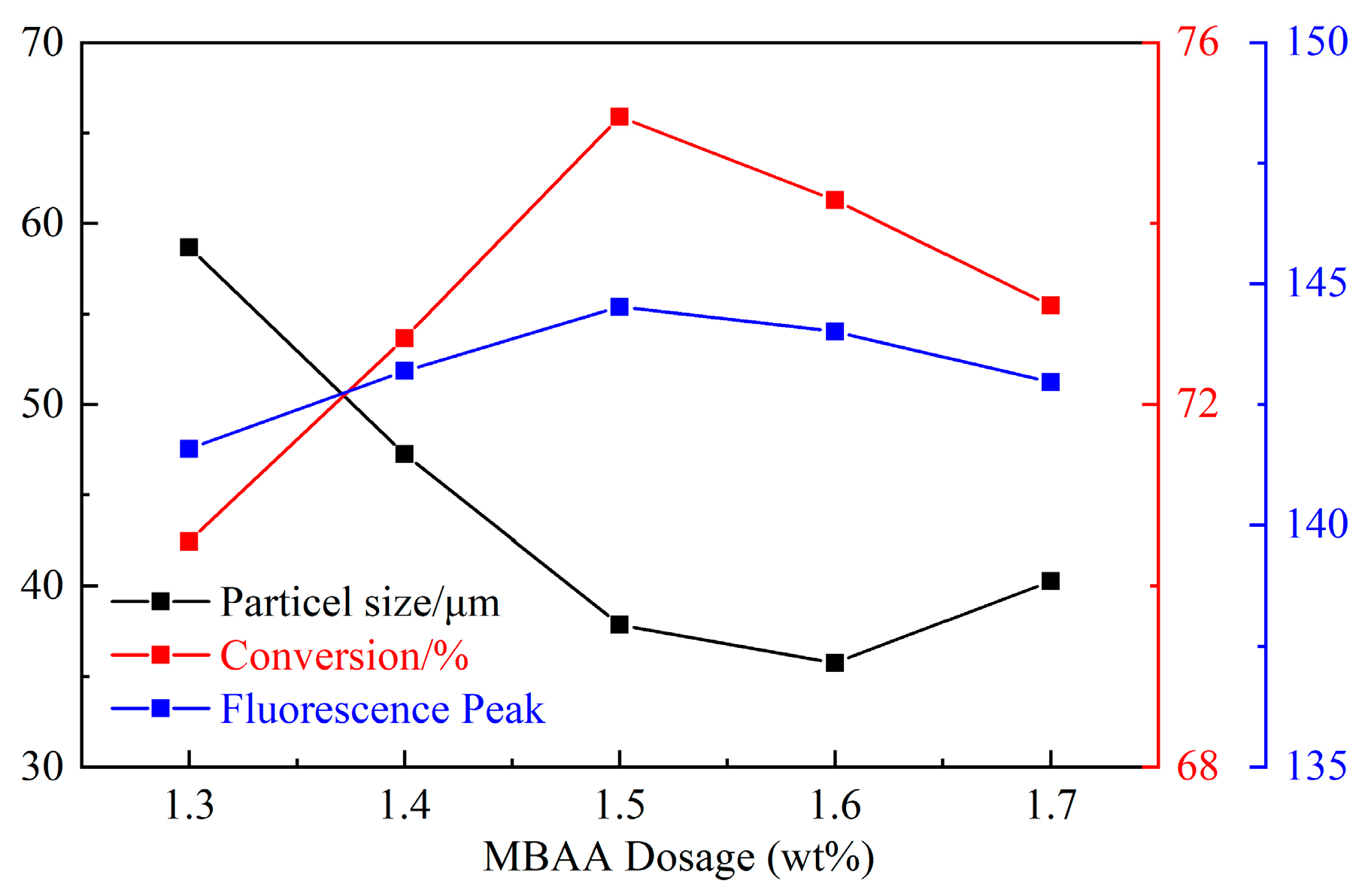

2.5.4. Influence of MBAA Dosage on CQDs@PPG

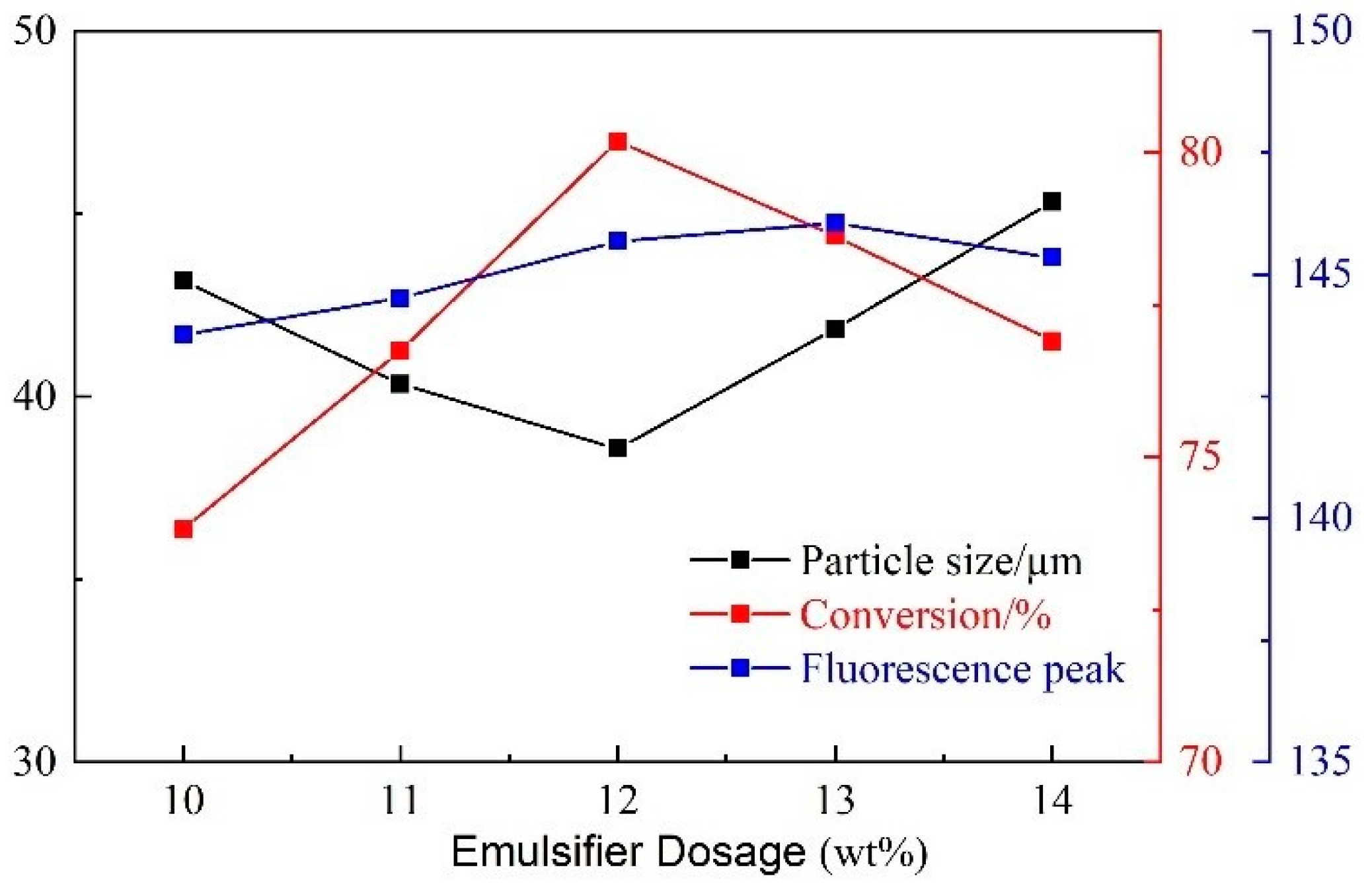

2.5.5. Influence of Emulsifier Dosage on CQDs@PPG

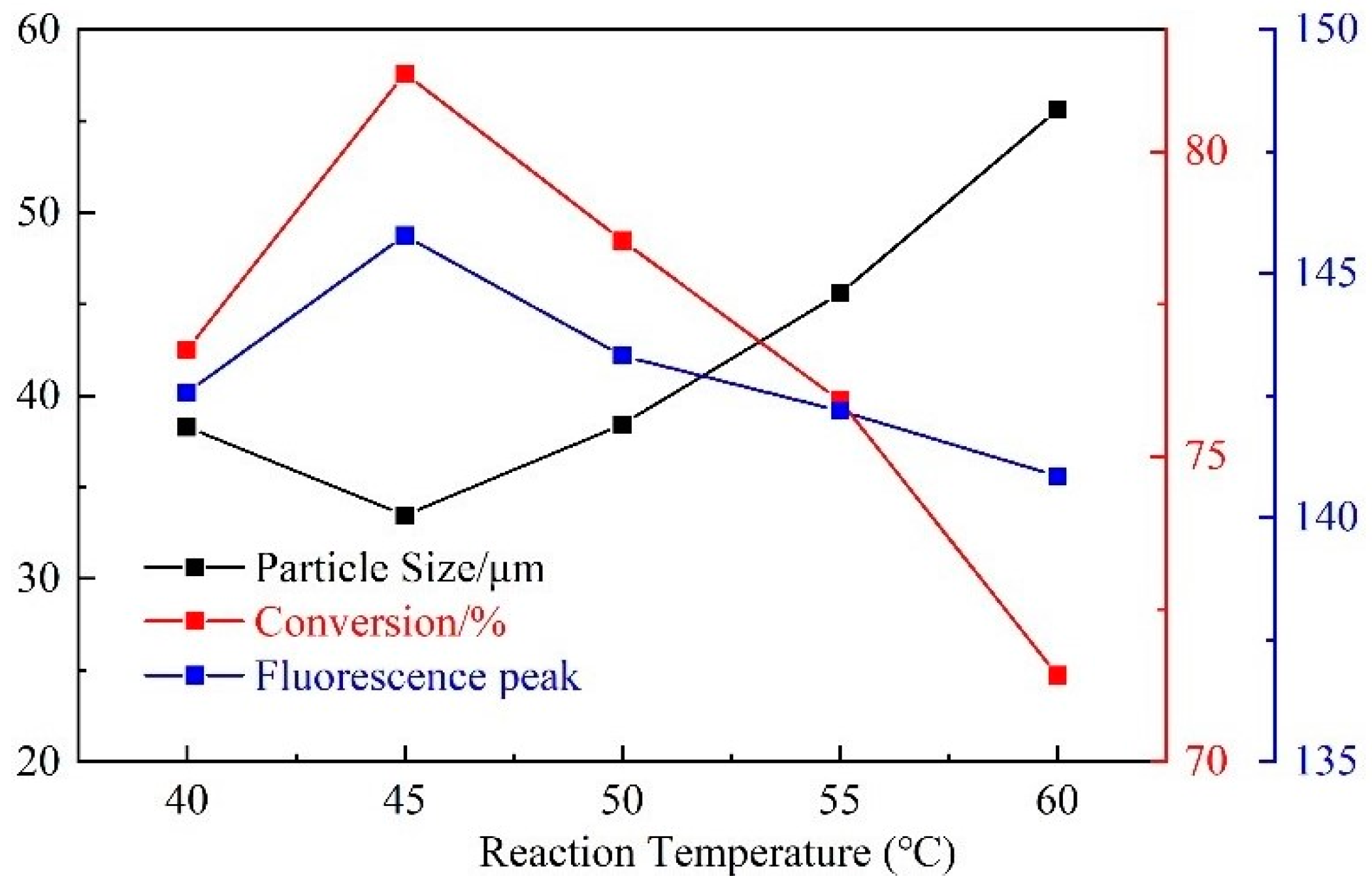

2.5.6. Influence of Synthesis Temperature on CQDs@PPG

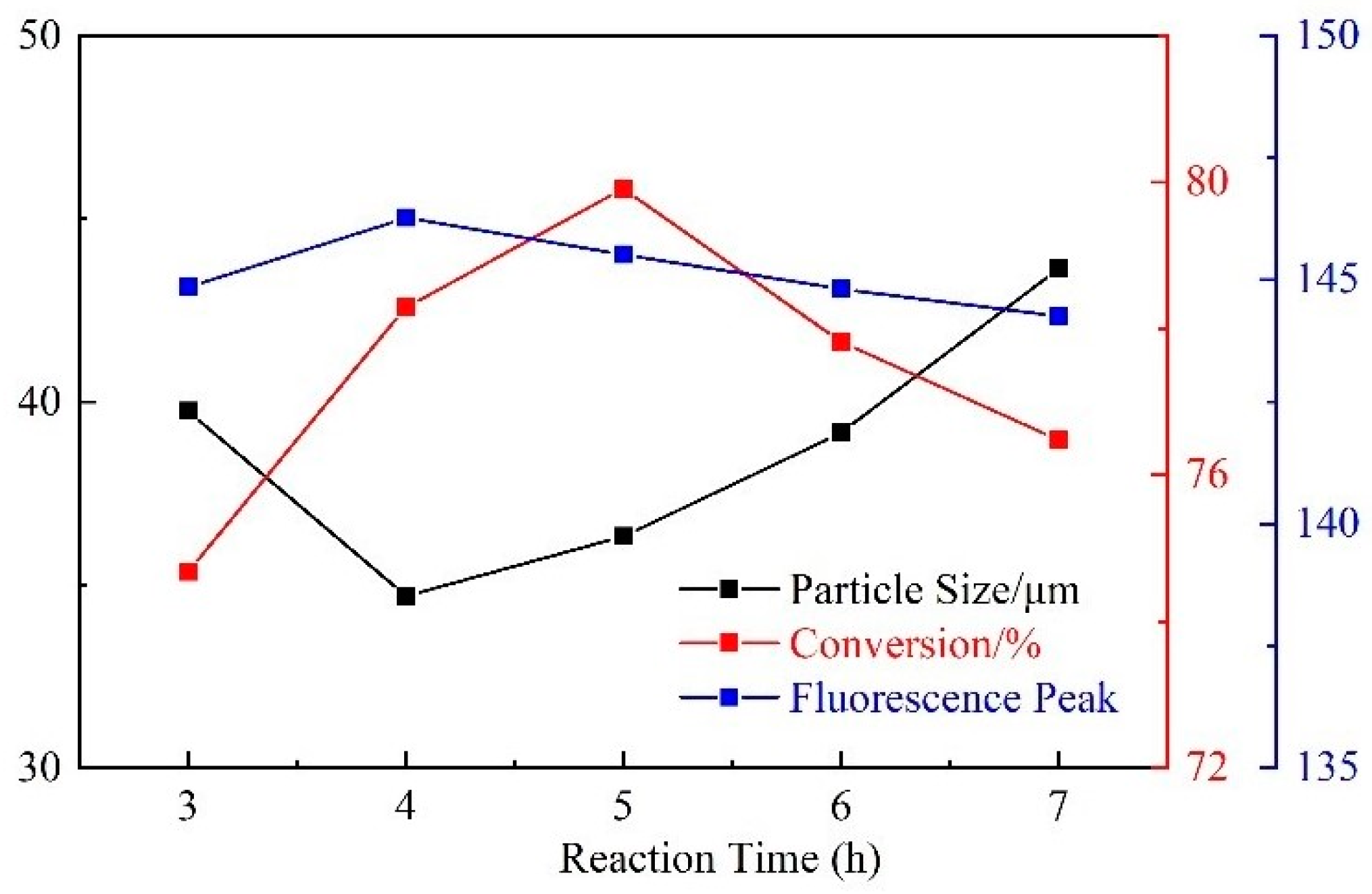

2.5.7. Influence of Reaction Duration Time on CQDs@PPG

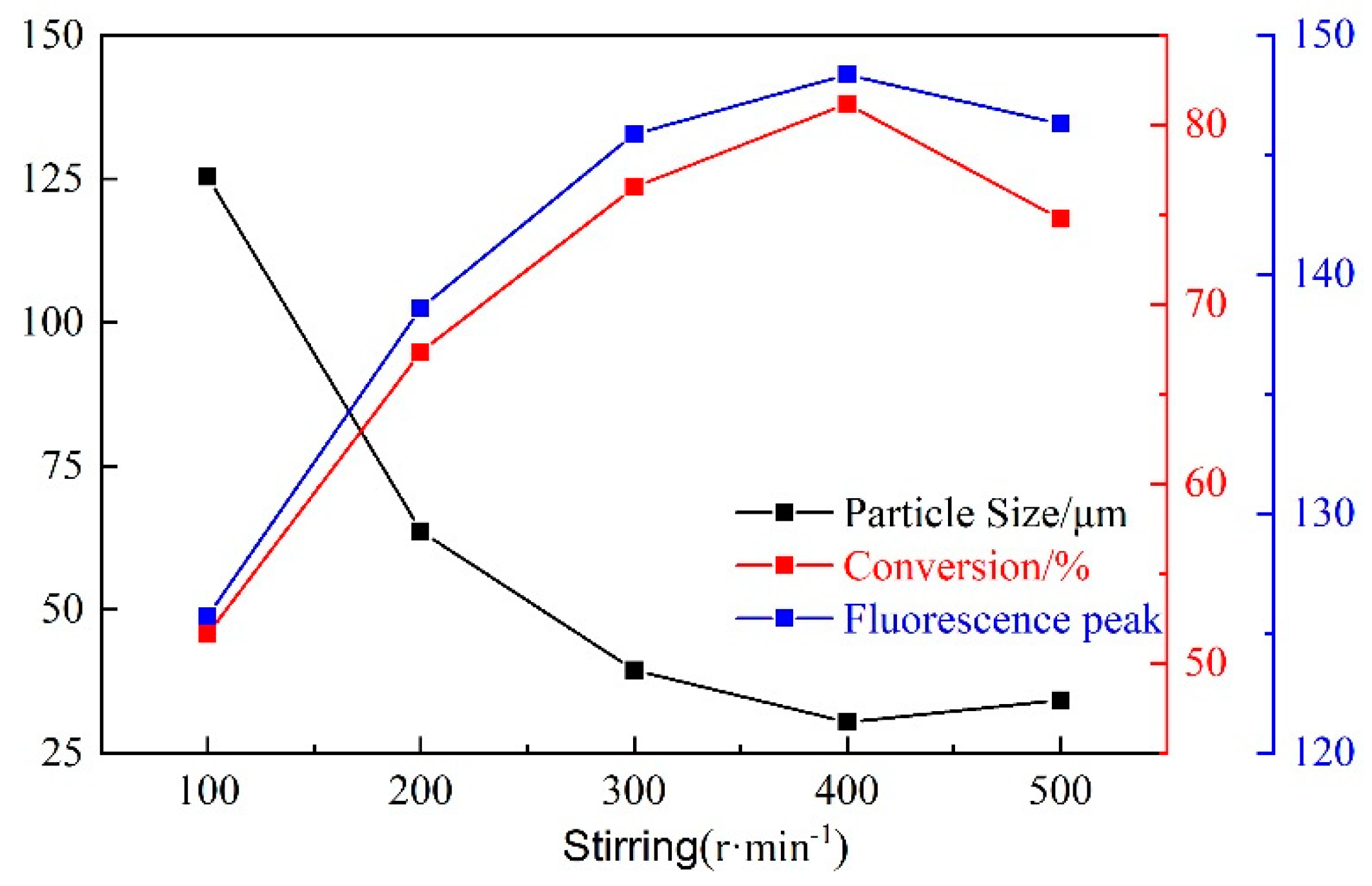

2.5.8. Influence of Stirring Speed on CQDs@PPG

2.5.9. Optimizing Synthetic Analysis Results

3. Results and Discussion

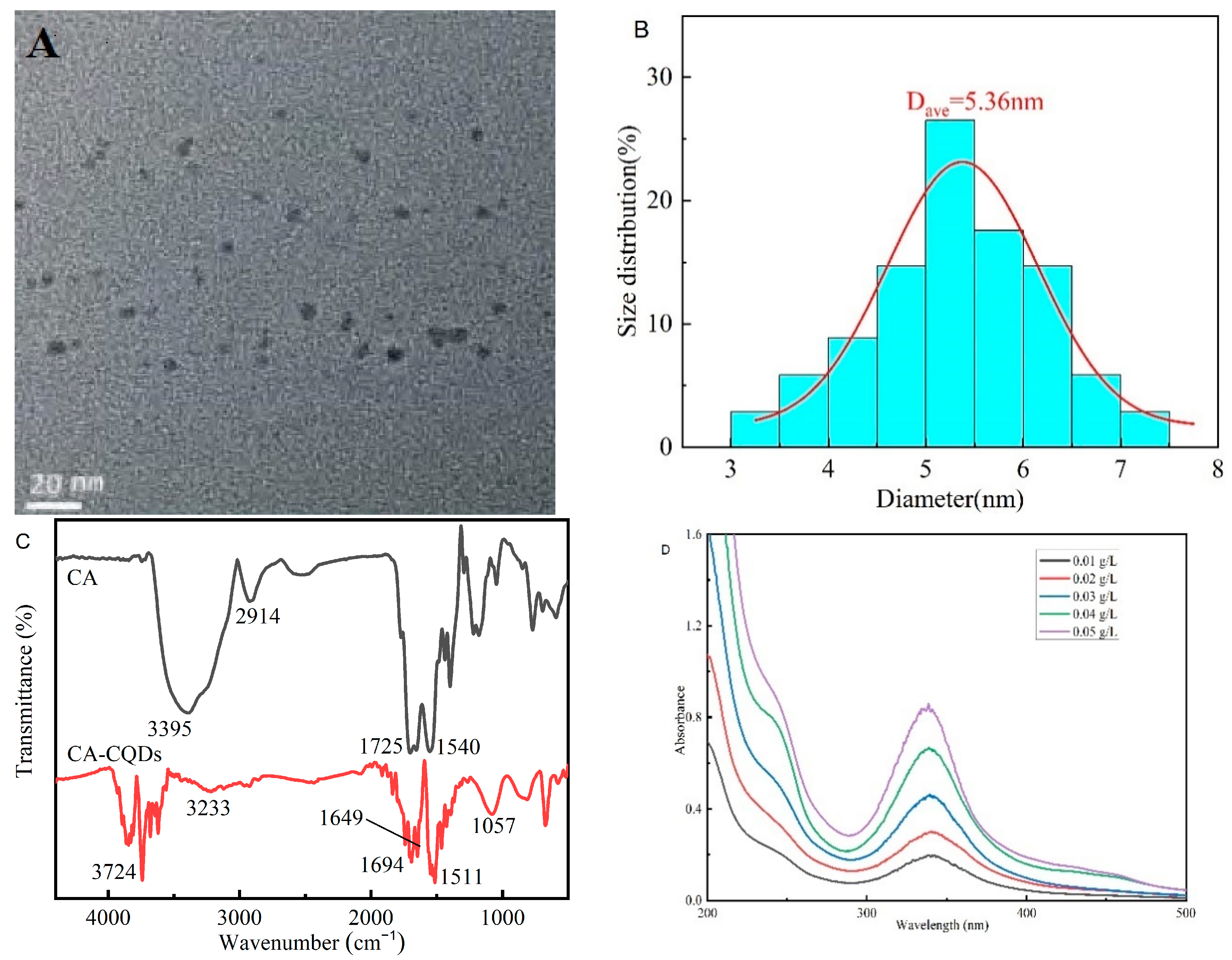

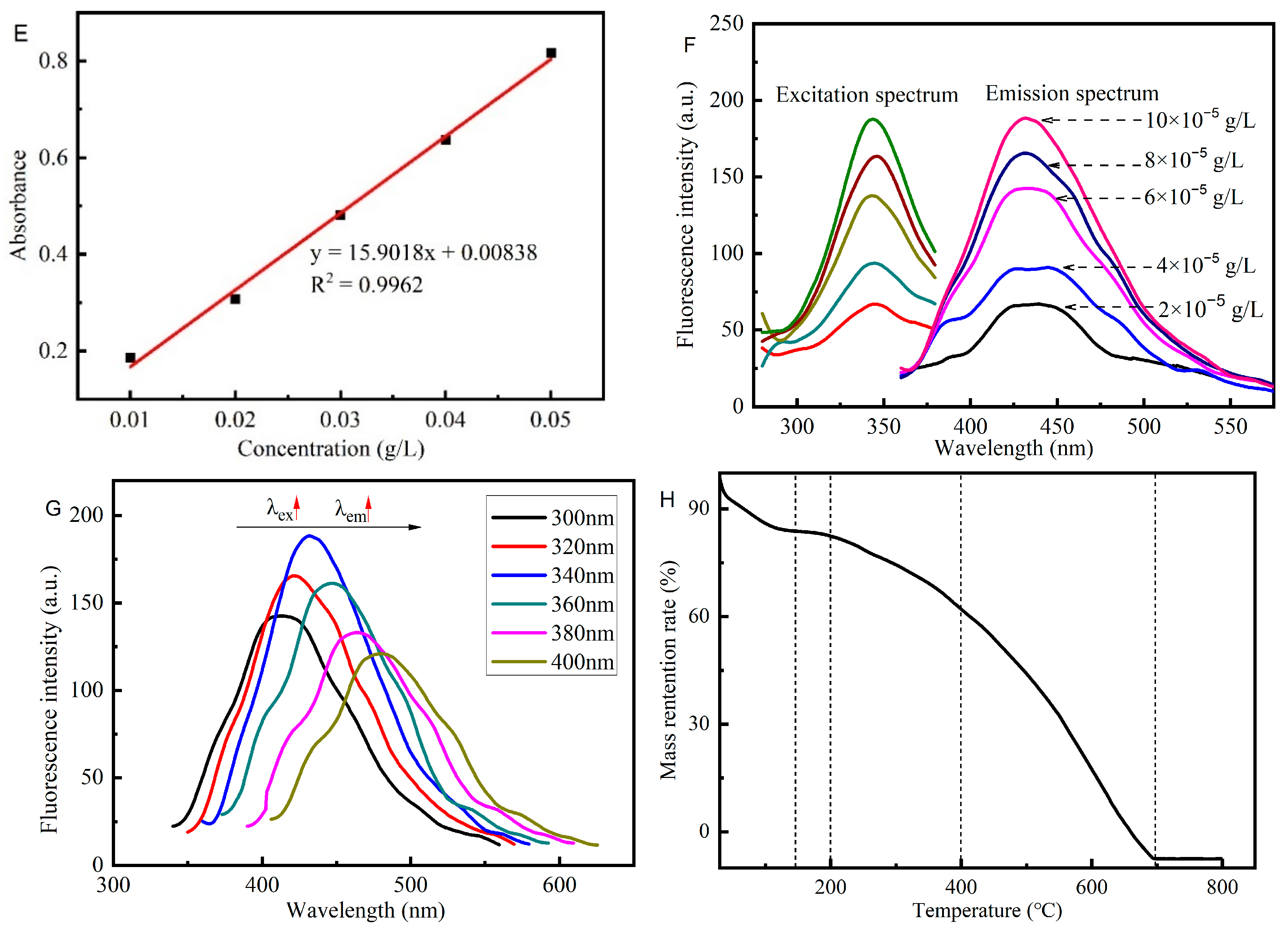

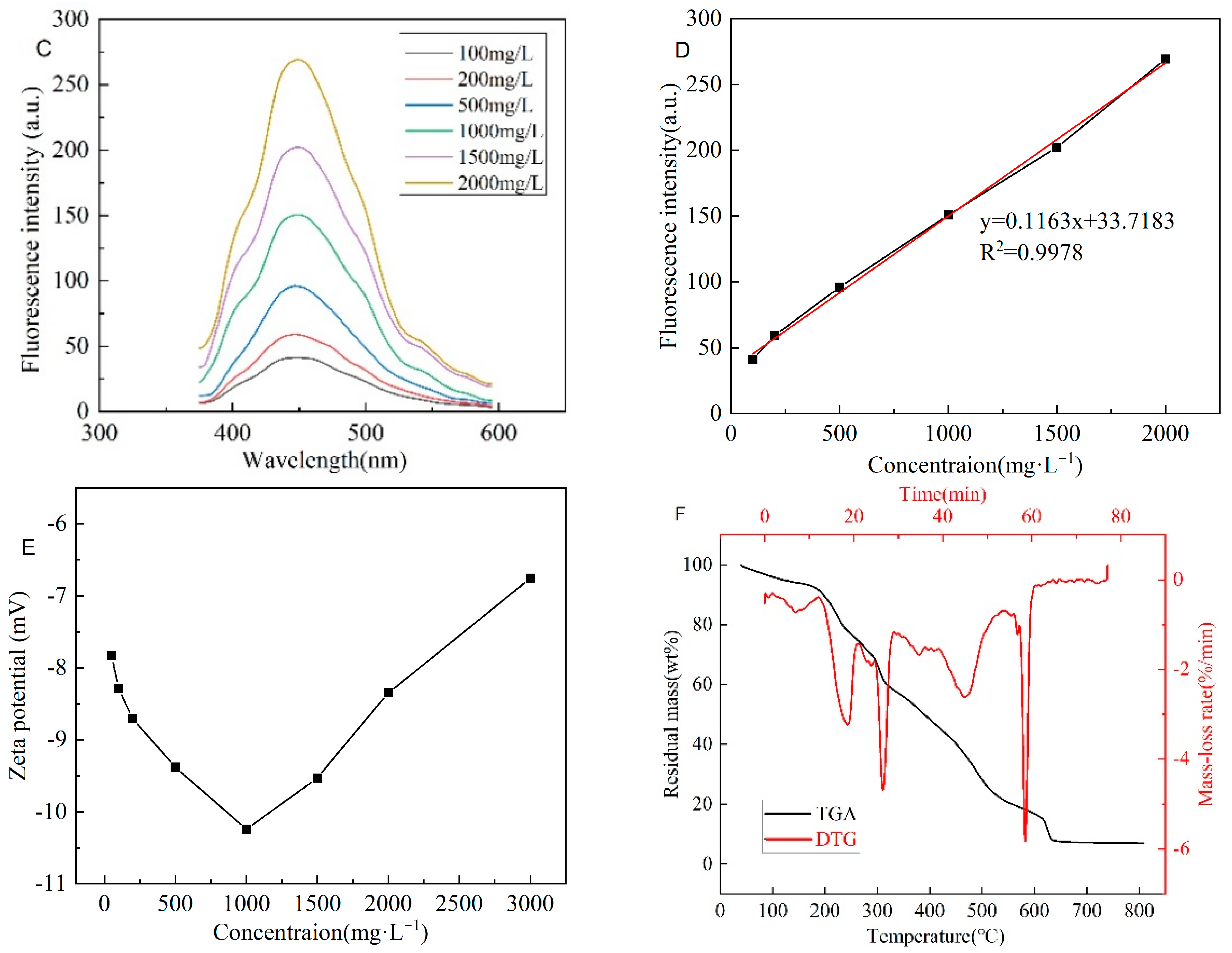

3.1. Characterization of CQDs

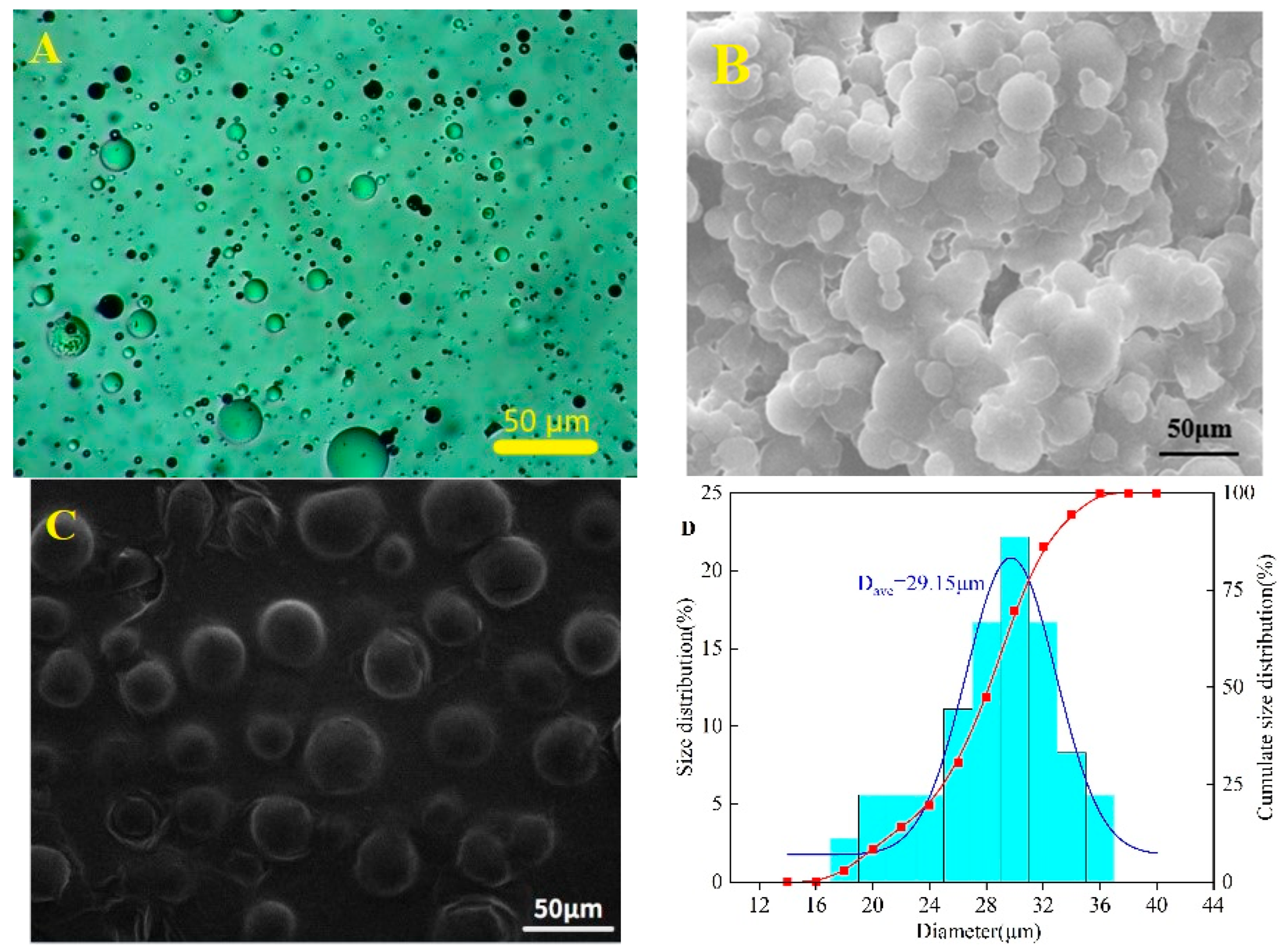

3.2. Characterization of CQDs@PPG

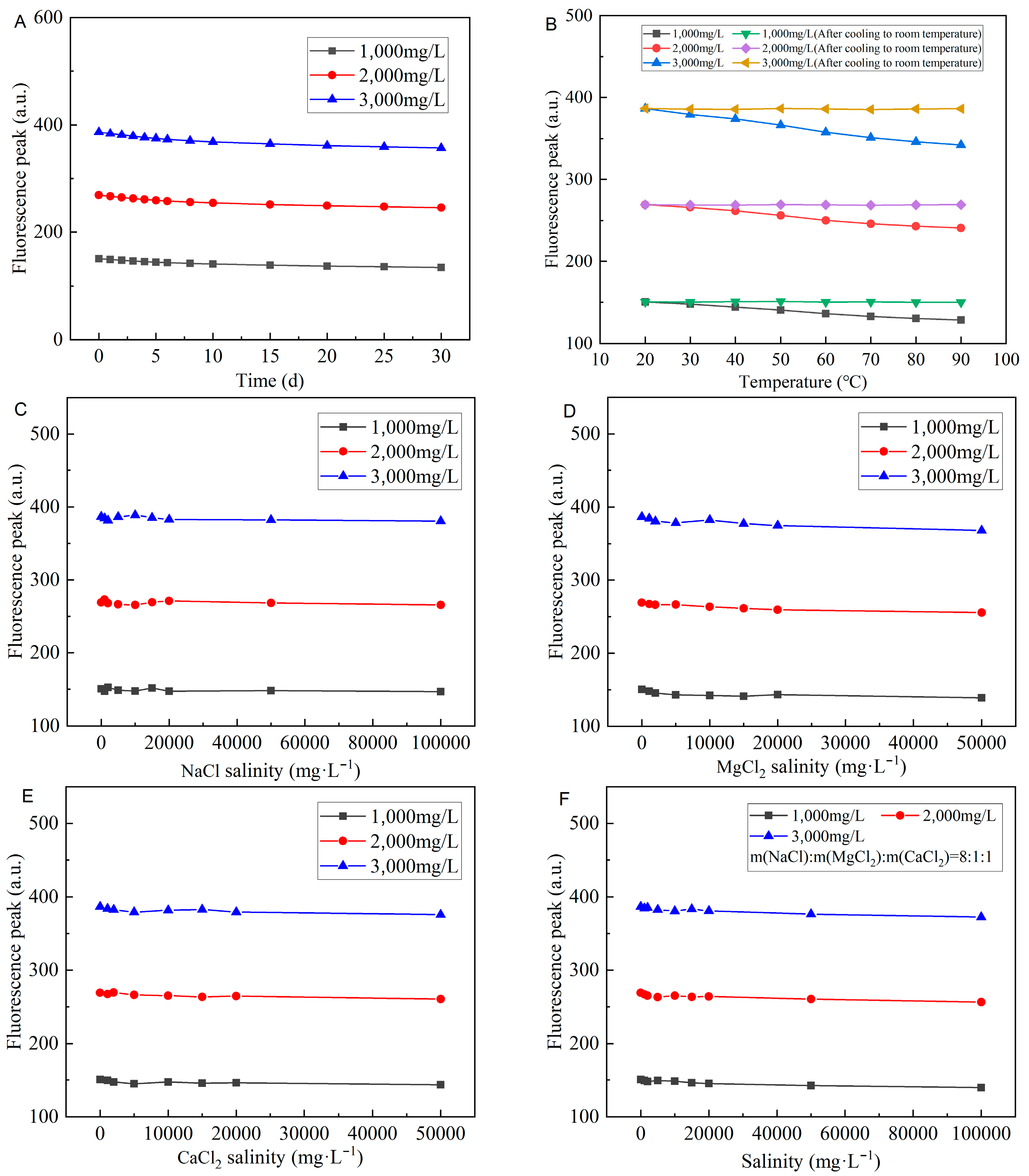

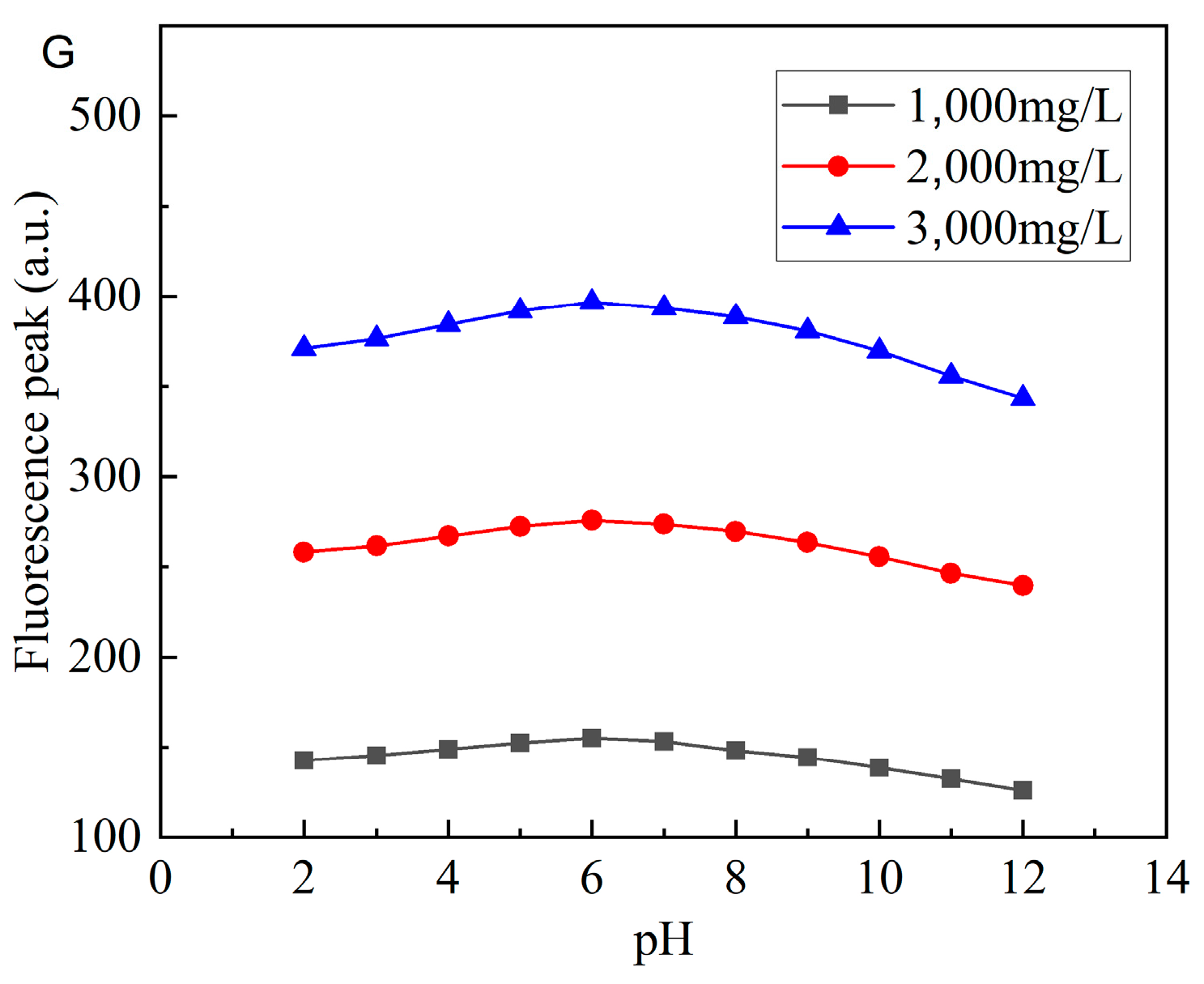

3.3. Fluorescence Performance Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, E.-B.; Peng, Y.; Peng, S.-B.; Yu, B.; Chen, Q.-K. Research on low carbon emission optimization operation technology of natural gas pipeline under multi-energy structure. Pet. Sci. 2022. [Google Scholar] [CrossRef]

- Fang, Y.; Yang, E.; Guo, S.; Cui, C.; Zhou, C. Study on micro remaining oil distribution of polymer flooding in Class-II B oil layer of Daqing Oilfield. Energy 2022, 254, 124479. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y.; Gan, Y.; Han, X.; Liu, W.; Xin, H. Micromechanism of partially hydrolyzed polyacrylamide molecule agglomeration morphology and its impact on the stability of crude oil−water interfacial film. J. Pet. Sci. Eng. 2022, 214, 110492. [Google Scholar] [CrossRef]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of polymer-flooding technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Frampton, H.; Morgan, J.C.; Cheung, S.K.; Munson, L.; Chang, K.T.; Williams, D. Development of a Novel Waterflood Conformance Control System. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 3–5 April 2004. [Google Scholar]

- Pritchett, J.; Frampton, H.; Brinkman, J.; Cheung, S.; Morgan, J.; Chang, K.T.; Williams, D.; Goodgame, J. Field Application of a New In-Depth Waterflood Conformance Improvement Tool. In Proceedings of the SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 20–21 October 2003. [Google Scholar]

- Chang, K.; Frampton, H.; Morgan, J. Composition for Recovering Hydrocarbon Fluids from a Subterranean Reservoir. U.S. Patent 7,300,973, 27 November 2007. [Google Scholar]

- Ohms, D.S.; McLeod, J.D.; Graff, C.J.; Frampton, H.; Morgan, J.C.; Cheung, S.K.; Chang, K.T. Incremental-Oil Success From Waterflood Sweep Improvement in Alaska. SPE Prod. Oper. 2010, 25, 247–254. [Google Scholar] [CrossRef]

- Burcik, E.J. Note on the flow behavior of polyacrylamide solutions in porous media. Prod. Mon. 1965, 29, 6. [Google Scholar]

- Burcik, E.J.; Walrond, W.K. Microgel in polyacrylamide solutions and its role in mobility control. Prod. Mon. 1968, 32. Available online: https://www.osti.gov/biblio/7299555 (accessed on 1 October 2022).

- Feng, Y.; Tabari, R.; Renard, M.; Le Bon, C.; Omari, A.; Chauveteau, G. Characteristics of HSPAM/Zr(IV) microgels designed for oilwell water shut-off and profile control. In Proceedings of the Society of Petroleum Engineers (SPE) 2003 Oilfield Chemistry Symposium, Houston, TX, USA, 5–7 February 2003. [Google Scholar]

- Al-Anazi, H.A.; Sharma, M.M. Use of a pH Sensitive Polymer for Conformance Control. In Proceedings of the International Symposium & Exhibition on Formation Damage Control, Lafayette, LA, USA, 23–24 February 2002. [Google Scholar]

- Huh, C.; Choi, S.K.; Sharma, M.M. A Rheological Model for pH-Sensitive Ionic Polymer Solutions for Optimal Mobility Control Applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Roussennac, B.; Toschi, C. Brightwater Trial in Salema Field (Campos Basin, Brazil). In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, 6–9 June 2010. [Google Scholar]

- Spildo, K.; Skauge, A.; Aarra, M.G.; Tweheyo, M.T. A New Polymer Application for North Sea Reservoirs. SPE Reserv. Evaluation Eng. 2009, 12, 427–432. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, B.; Wang, Y. Applied Technologies and Prospects of Conformance Control Treatments in China. Oil Gas Sci. Technol. 2010, 65, 859–878. [Google Scholar] [CrossRef]

- Bai, B.; Li, L.; Liu, Y.; Liu, H.; Wang, Z.; You, C. Preformed Particle Gel for Conformance Control: Factors Affecting Its Properties and Applications. SPE Reserv. Eval. Eng. 2007, 10, 415–422. [Google Scholar] [CrossRef]

- Bai, B.; Liu, Y.; Coste, J.-P.; Li, L. Preformed Particle Gel for Conformance Control: Transport Mechanism through Porous Media. SPE Reserv. Eval. Eng. 2007, 10, 176–184. [Google Scholar] [CrossRef]

- Chauveteau, G.; Tabary, R.; Le Bon, C.; Renard, M.; Feng, Y.; Omari, A. In-Depth Permeability Control by Adsorption of Soft Size-Controlled Microgels. In Proceedings of the SPE European Formation Damage Conference, Hague, The Netherlands, 13–14 May 2003. [Google Scholar]

- Salehi, M.B.; Moghadam, A.M.; Jarrahian, K. Effect of Network Parameters of Preformed Particle Gel on Structural Strength for Water Management. SPE Prod. Oper. 2020, 35, 362–372. [Google Scholar] [CrossRef]

- Zhu, D.; Bai, B.; Hou, J. Polymer Gel Systems for Water Management in High-Temperature Petroleum Reservoirs: A Chemical Review. Energy Fuels 2017, 31, 13063–13087. [Google Scholar] [CrossRef]

- Bai, B.; Zhou, J.; Yin, M. A comprehensive review of polyacrylamide polymer gels for conformance control. Pet. Explor. Dev. 2015, 42, 525–532. [Google Scholar] [CrossRef]

- Esfahlan, M.S.; Khodapanah, E.; Tabatabaei-Nezhad, S.A. Comprehensive review on the research and field application of preformed particle gel conformance control technology. J. Pet. Sci. Eng. 2021, 202, 108440. [Google Scholar] [CrossRef]

- O’Brien, J.; Sayavedra, L.; Mogollon, J.L.; Lokhandwala, T.; Lakani, R. Maximizing Mature Field Production - A Novel Approach to Screening Mature Fields Revitalization Options. In Proceedings of the SPE Europec Featured at 78th EAGE Conference and Exhibition, Vienna, Austria, 30 May–2 June 2016. [Google Scholar] [CrossRef]

- Chauveteau, G.; Tabary, R.; Blin, N.; Renard, M.; Rousseau, D.; Faber, R. Disproportionate Permeability Reduction by Soft Preformed Microgels. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 3–5 April 2004. [Google Scholar] [CrossRef]

- Duranvalencia, C.D.L.A.; Bai, B.; Reyes-Perez, H.; Fajardo-López, R.; Barragán-Aroche, J.F.; Lopez-Ramirez, S. Development of enhanced nanocomposite preformed particle gels for conformance control in high-temperature and high-salinity oil reservoirs. Polym. J. 2014, 46, 277–284. [Google Scholar] [CrossRef]

- Tang, X.; Yang, H.; Gao, Y.; Lashari, Z.A.; Cao, C.; Kang, W. Preparation of a micron-size silica-reinforced polymer microsphere and evaluation of its properties as a plugging agent. Colloids Surf. A Phys. Eng. Asp. 2018, 547, 8–18. [Google Scholar] [CrossRef]

- Li, X.; Li, W.; Yang, Q.; Gong, X.; Guo, W.; Dong, C.; Liu, J.; Xuan, L.; Chang, J. Rapid and Quantitative Detection of Prostate Specific Antigen with a Quantum Dot Nanobeads-Based Immu-nochromatography Test Strip. ACS Appl. Mater. Interfaces 2014, 6, 6406–6414. [Google Scholar] [CrossRef]

- Rosi, N.L.; Mirkin, C.A. Nanostructures in Biodiagnostics. Chem. Rev. 2005, 105, 1547–1562. [Google Scholar] [CrossRef]

- Guo, W.; Chen, N.; Tu, Y.; Dong, C.; Zhang, B.; Hu, C.; Chang, J. Synthesis of Zn-Cu-In-S/ZnS core/shell quantum dots with inhibited blue-shift photoluminescence and appli-cations for tumor targeted bioimaging. Theranostics 2013, 3, 99–108. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, A. Carbon quantum dots: Synthesis, properties and applications. J. Mater. Chem. C 2014, 2, 6921–6939. [Google Scholar] [CrossRef]

- Vanderhoff, J.W.; Bradford, E.B.; Tarkowski, H.L.; Shaffer, J.B.; Wiley, R.M. Inverse Emulsion Polymerization. In Polymerization and Polycondensation Processes; American Chemical Society: Washington, DC, USA, 1962; pp. 32–51. [Google Scholar]

| Polymerization | Inverse Emulsion Polymerization |

|---|---|

| Monomer | AA |

| Temperature and salt resistants | SSS |

| Fluorescences | CQD |

| Crosslinking agent | MBAA |

| Initiator | Ammonium sulfate and Sodium bisulfite |

| Emulsifier | Span 80 and Tween 80 |

| A | B | C | D | E |

|---|---|---|---|---|

| SSS Dosage /(wt%) | CQDs Dosage /(wt%) | MBAA Dosage/(wt%) | Initiator Dosage/(wt%) | Emulsifier Dosage/(wt%) |

| 10 | 3 | 1.5 | 0.6 | 18 |

| 15 | 4 | 1 | 0.4 | 14 |

| 20 | 5 | 0.5 | 0.5 | 16 |

| 25 | 2 | 2 | 0.3 | 12 |

| SSS Dosage/(wt%) | CQDs Dosage/(wt%) | MBAA Dosage/(wt%) | Initiator Dosage/(wt%) | Emulsifier Dosage/(wt%) | Particle Size/(μm) | Conversion /(%) | Fluorescence Peak/(a.u.) | |

|---|---|---|---|---|---|---|---|---|

| 1 | 10 | 3 | 1.5 | 0.6 | 18 | 56.36 | 65.83 | 133.75 |

| 2 | 10 | 4 | 1 | 0.4 | 14 | 83.65 | 68.31 | 140.68 |

| 3 | 10 | 5 | 0.5 | 0.5 | 16 | 122.17 | 73.49 | 142.52 |

| 4 | 10 | 2 | 2 | 0.3 | 12 | 45.85 | 59.72 | 137.61 |

| 5 | 15 | 3 | 2 | 0.5 | 12 | 36.42 | 74.15 | 139.43 |

| 6 | 15 | 4 | 1.5 | 0.3 | 16 | 39.58 | 75.48 | 145.49 |

| 7 | 15 | 5 | 0.5 | 0.6 | 14 | 108.94 | 67.53 | 148.36 |

| 8 | 15 | 2 | 1 | 0.4 | 18 | 67.35 | 68.62 | 137.21 |

| 9 | 20 | 3 | 1 | 0.3 | 14 | 95.84 | 63.49 | 132.67 |

| 10 | 20 | 4 | 2 | 0.5 | 18 | 49.29 | 71.58 | 138.49 |

| 11 | 20 | 5 | 1.5 | 0.4 | 12 | 60.71 | 61.83 | 137.38 |

| 12 | 20 | 2 | 0.5 | 0.6 | 16 | 135.43 | 63.59 | 133.42 |

| 13 | 25 | 3 | 2 | 0.4 | 16 | 62.53 | 69.72 | 127.53 |

| 14 | 25 | 4 | 1 | 0.6 | 12 | 109.87 | 65.36 | 136.79 |

| 15 | 25 | 5 | 0.5 | 0.3 | 18 | 158.46 | 56.83 | 138.27 |

| 16 | 25 | 2 | 1.5 | 0.5 | 14 | 76.51 | 62.43 | 131.35 |

| Indicators | SSS Dosage (A) | CQDs Dosage (B) | MBAA Dosage (C) | Initiator Dosage (D) | Emulsifier Dosage (E) | |

|---|---|---|---|---|---|---|

| particle size/(μm) | K1 | 308.04 | 251.16 | 233.16 | 410.61 | 331.48 |

| K2 | 252.28 | 282.36 | 413.96 | 274.24 | 364.96 | |

| K3 | 341.28 | 450.28 | 395.24 | 284.36 | 359.72 | |

| K4 | 407.36 | 325.12 | 266.61 | 339.72 | 252.84 | |

| k1 | 77.01 | 62.79 | 58.29 | 102.65 | 82.87 | |

| k2 | 63.07 | 70.59 | 103.49 | 68.56 | 91.24 | |

| k3 | 85.32 | 112.57 | 98.81 | 71.09 | 89.93 | |

| k4 | 101.84 | 81.28 | 66.65 | 84.93 | 63.21 | |

| R | 38.77 | 49.78 | 45.20 | 34.09 | 28.03 | |

| Orders | B > C > A > D > E | |||||

| Optimum | B1C1A2D2E4 | |||||

| Conversion /(%) | K1 | 267.35 | 273.19 | 265.57 | 262.31 | 262.86 |

| K2 | 285.78 | 280.73 | 265.78 | 268.48 | 261.76 | |

| K3 | 260.49 | 259.68 | 261.44 | 281.65 | 282.28 | |

| K4 | 254.34 | 254.36 | 275.17 | 255.52 | 261.06 | |

| k1 | 66.84 | 68.30 | 66.39 | 65.58 | 65.72 | |

| k2 | 71.45 | 70.18 | 66.45 | 67.12 | 65.44 | |

| k3 | 65.12 | 64.92 | 65.36 | 70.41 | 70.57 | |

| k4 | 63.59 | 63.59 | 68.79 | 63.88 | 65.27 | |

| R | 7.86 | 6.59 | 3.43 | 6.53 | 5.3 | |

| Orders | A > B > D > E > C | |||||

| Optimum | A2B2D3E3C4 | |||||

| fluorescence peak/(a.u.) | K1 | 554.56 | 533.38 | 547.97 | 552.32 | 547.72 |

| K2 | 570.49 | 561.45 | 547.35 | 542.8 | 553.06 | |

| K3 | 541.96 | 566.53 | 562.57 | 551.79 | 548.96 | |

| K4 | 533.94 | 539.59 | 543.06 | 554.04 | 551.21 | |

| k1 | 138.64 | 133.35 | 136.99 | 138.08 | 136.93 | |

| k2 | 142.62 | 140.36 | 136.84 | 135.7 | 138.27 | |

| k3 | 135.49 | 141.63 | 140.64 | 137.95 | 137.24 | |

| k4 | 133.49 | 134.90 | 135.77 | 138.51 | 137.80 | |

| R | 9.13 | 8.28 | 4.87 | 2.81 | 1.34 | |

| Orders | A > B > C > D > E | |||||

| Optimum | A2B3C3D4E2 | |||||

| Exp. No. | CQDs Dosage/(wt%) | Particle Size/(μm) | Conversion/(%) | Fluorescence Peak /(a.u.) |

|---|---|---|---|---|

| 1 | 2 | 44.21 | 70.53 | 137.58 |

| 2 | 3 | 38.13 | 71.28 | 141.72 |

| 3 | 4 | 39.35 | 73.17 | 145.89 |

| 4 | 5 | 48.14 | 71.85 | 146.61 |

| 5 | 6 | 59.36 | 70.96 | 145.27 |

| Exp. No. | SSS Dosage/(wt%) | Particle Size/(μm) | Conversion/(%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 13 | 44.37 | 69.73 | 142.97 |

| 2 | 14 | 38.23 | 71.25 | 144.35 |

| 3 | 15 | 41.36 | 69.84 | 145.54 |

| 4 | 16 | 49.25 | 67.51 | 143.71 |

| 5 | 17 | 58.34 | 65.68 | 144.19 |

| Exp. No. | Initiator Dosage/(wt%) | Particle Size/(μm) | Conversion/(%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 0.3 | 45.33 | 73.86 | 144.75 |

| 2 | 0.4 | 37.21 | 78.93 | 146.68 |

| 3 | 0.5 | 40.82 | 74.27 | 145.72 |

| 4 | 0.6 | 48.69 | 71.85 | 144.31 |

| 5 | 0.7 | 53.83 | 69.51 | 143.18 |

| Exp. No. | MBAA Dosage/(wt%) | Particle Size/(μm) | Conversion/(%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 1.3 | 58.68 | 70.49 | 141.85 |

| 2 | 1.4 | 47.24 | 72.73 | 143.19 |

| 3 | 1.5 | 37.85 | 75.18 | 144.52 |

| 4 | 1.6 | 35.74 | 74.26 | 144.01 |

| 5 | 1.7 | 40.28 | 73.09 | 142.96 |

| Exp. No. | Emulsifier Dosage/(wt%) | Particle Size/(μm) | Conversion/(%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 10 | 43.16 | 73.82 | 143.76 |

| 2 | 11 | 40.34 | 76.75 | 144.52 |

| 3 | 12 | 38.57 | 80.19 | 145.68 |

| 4 | 13 | 41.85 | 78.63 | 146.05 |

| 5 | 14 | 45.32 | 76.91 | 145.35 |

| Exp. No. | Reaction Temperature/ (°C) | Particle Size/(μm) | Conversion/ (%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 40 | 38.27 | 76.75 | 142.57 |

| 2 | 45 | 33.46 | 81.27 | 145.78 |

| 3 | 50 | 38.43 | 78.54 | 143.32 |

| 4 | 55 | 45.58 | 75.92 | 142.19 |

| 5 | 60 | 55.62 | 71.42 | 140.85 |

| Exp. No. | Reaction Duration Time/(h) | Particle Size/(μm) | Conversion/(%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 3 | 39.75 | 74.68 | 144.85 |

| 2 | 4 | 34.69 | 78.29 | 146.27 |

| 3 | 5 | 36.32 | 79.91 | 145.52 |

| 4 | 6 | 39.15 | 77.82 | 144.81 |

| 5 | 7 | 43.64 | 76.48 | 144.26 |

| Exp. No. | Stirring Speed/(r/min) | Particle Size/(μm) | Conversion/ (%) | Fluorescence Peak/(a.u.) |

|---|---|---|---|---|

| 1 | 100 | 125.28 | 51.62 | 125.73 |

| 2 | 200 | 63.61 | 67.35 | 138.61 |

| 3 | 300 | 39.48 | 76.51 | 145.85 |

| 4 | 400 | 30.39 | 81.17 | 148.34 |

| 5 | 500 | 34.23 | 74.75 | 146.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, N.; Wang, D.; Wang, J.; Tang, L. Synthesis, Optimization, and Characterization of Fluorescent Particle Preformed Gel. Energies 2022, 15, 8712. https://doi.org/10.3390/en15228712

Lai N, Wang D, Wang J, Tang L. Synthesis, Optimization, and Characterization of Fluorescent Particle Preformed Gel. Energies. 2022; 15(22):8712. https://doi.org/10.3390/en15228712

Chicago/Turabian StyleLai, NanJun, Dongdong Wang, Junqi Wang, and Lei Tang. 2022. "Synthesis, Optimization, and Characterization of Fluorescent Particle Preformed Gel" Energies 15, no. 22: 8712. https://doi.org/10.3390/en15228712

APA StyleLai, N., Wang, D., Wang, J., & Tang, L. (2022). Synthesis, Optimization, and Characterization of Fluorescent Particle Preformed Gel. Energies, 15(22), 8712. https://doi.org/10.3390/en15228712