Power-to-Methane to Integrate Renewable Generation in Urban Energy Districts

Abstract

1. Introduction

1.1. Methanion Reactors in Brief

1.2. Scope of the Work

2. Materials and Methods

2.1. Case Study

2.2. Energy Model

2.3. Technical and Economic Indicators

2.4. Technical and Economic Assumptions

3. Results and Discussion

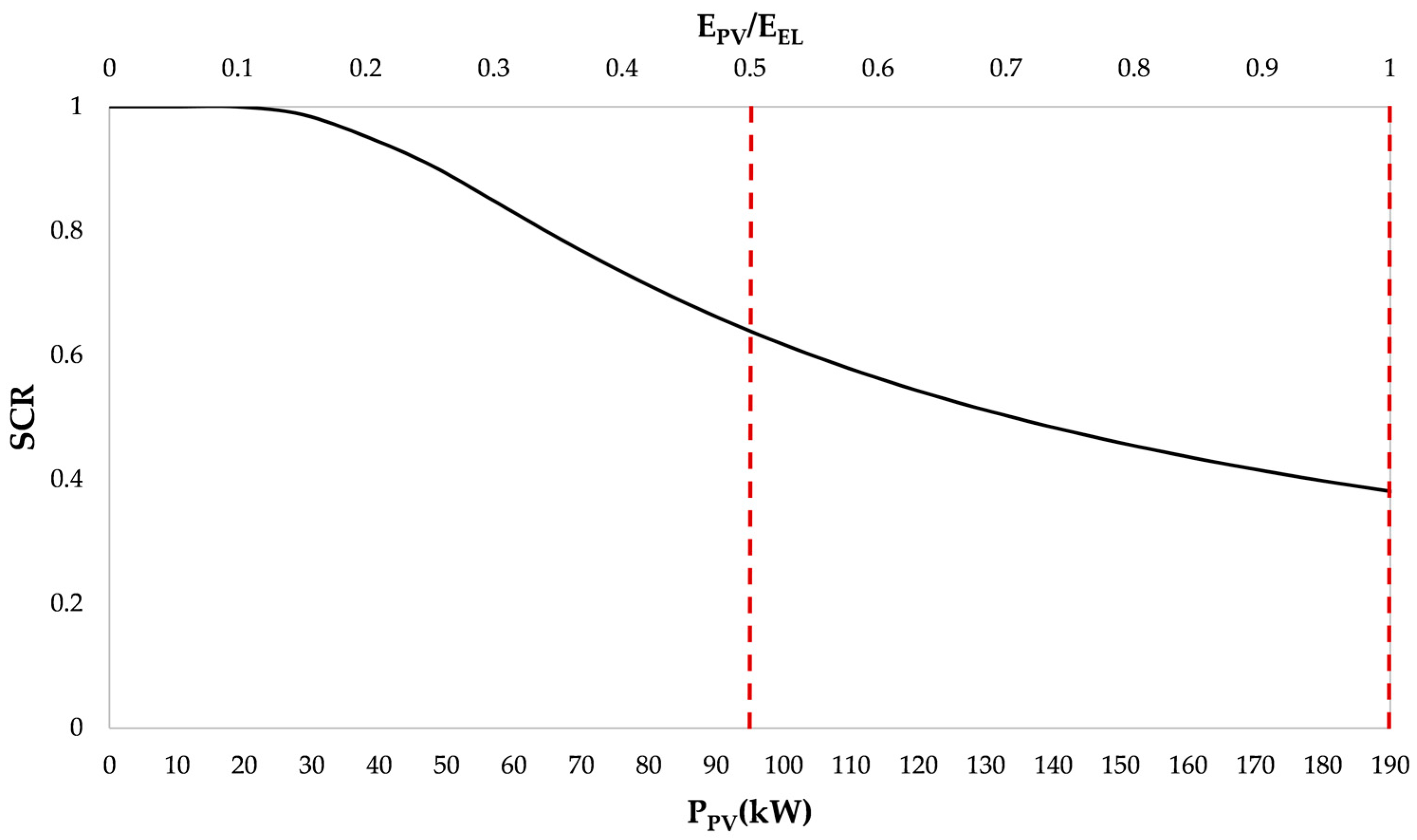

3.1. Preliminary Analysis

- EPV/EEL = 0.5, corresponding to a PPV of approximately 95 kW

- EPV/EEL = 1, corresponding to a PPV of approximately 190 kW

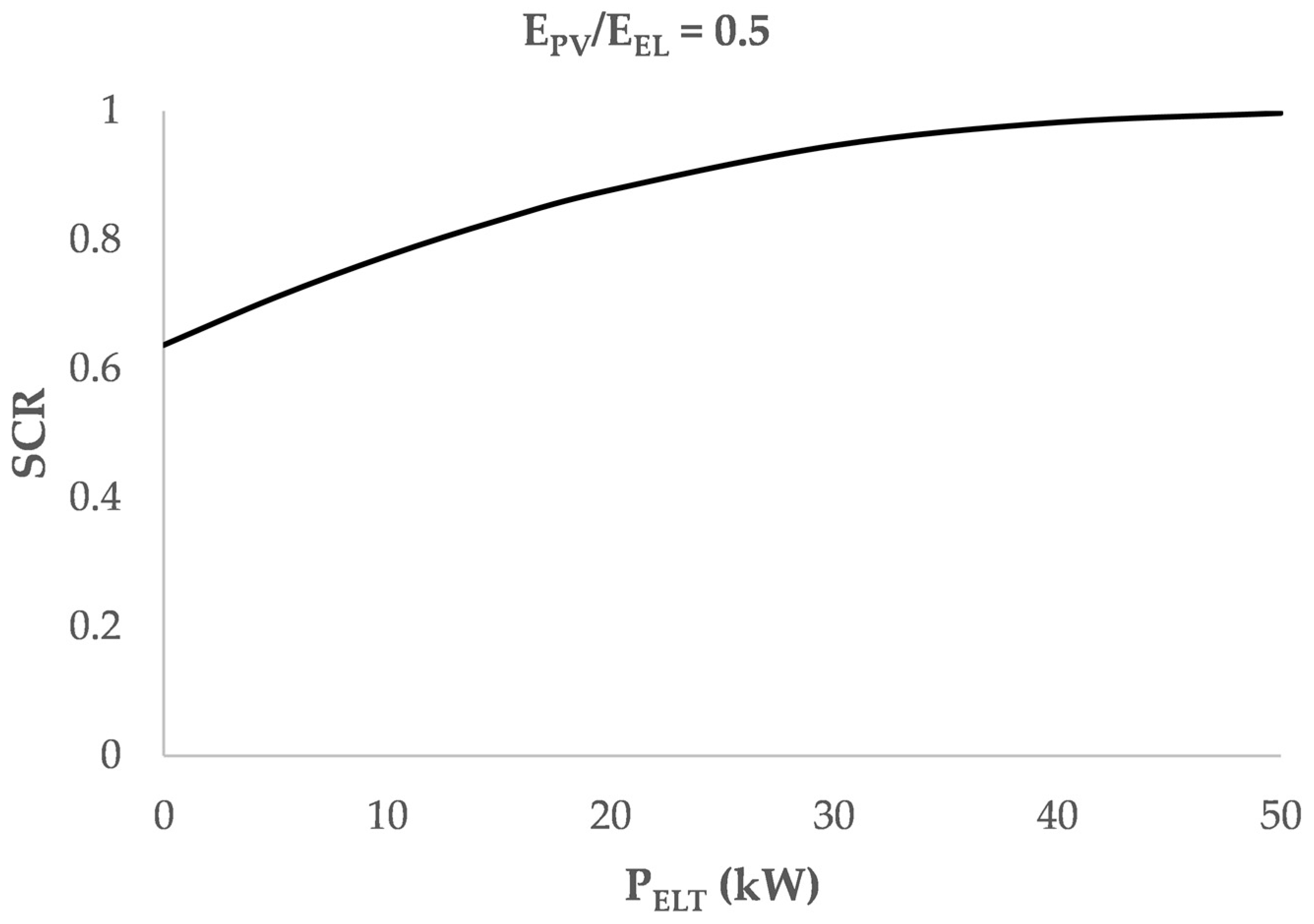

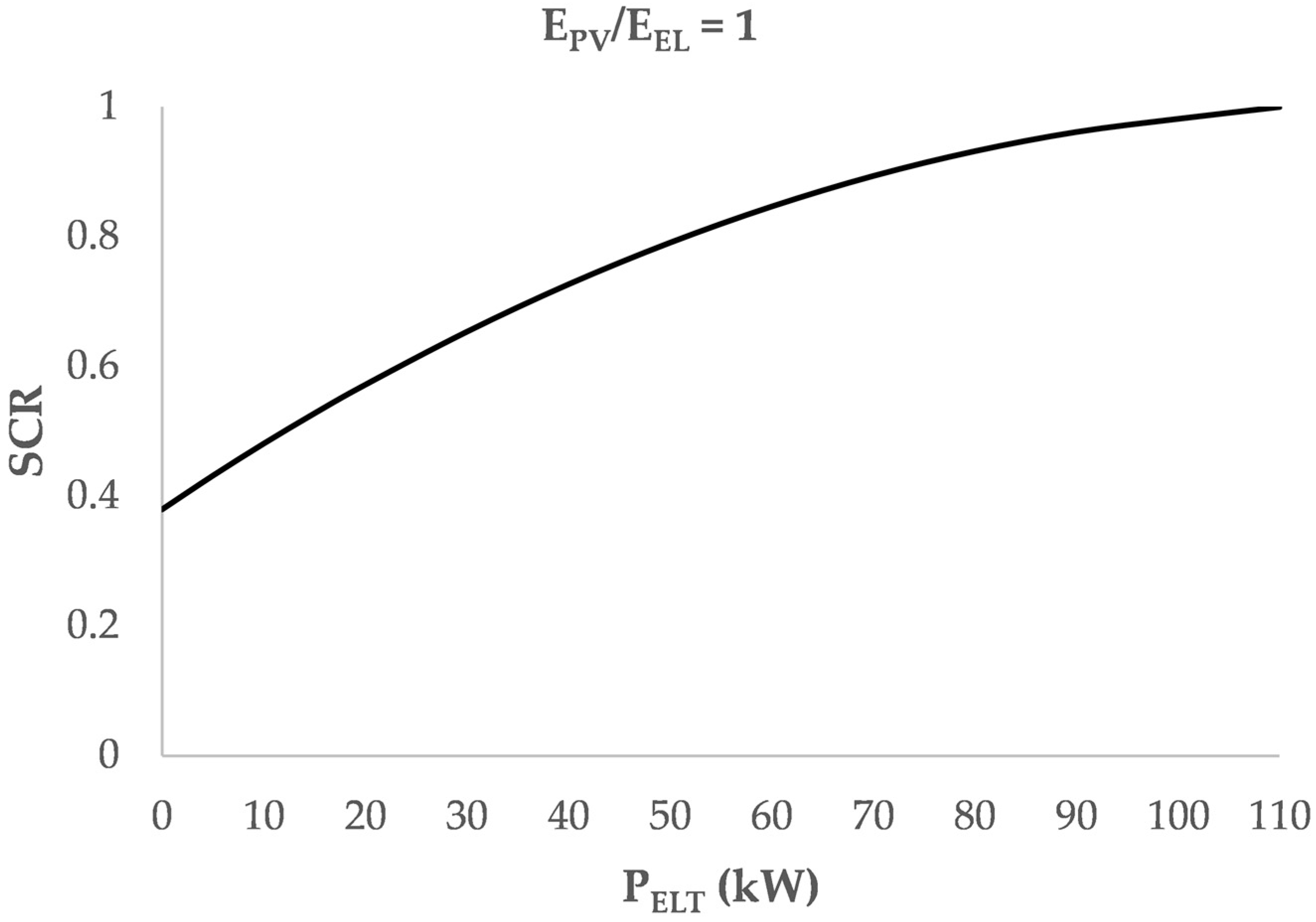

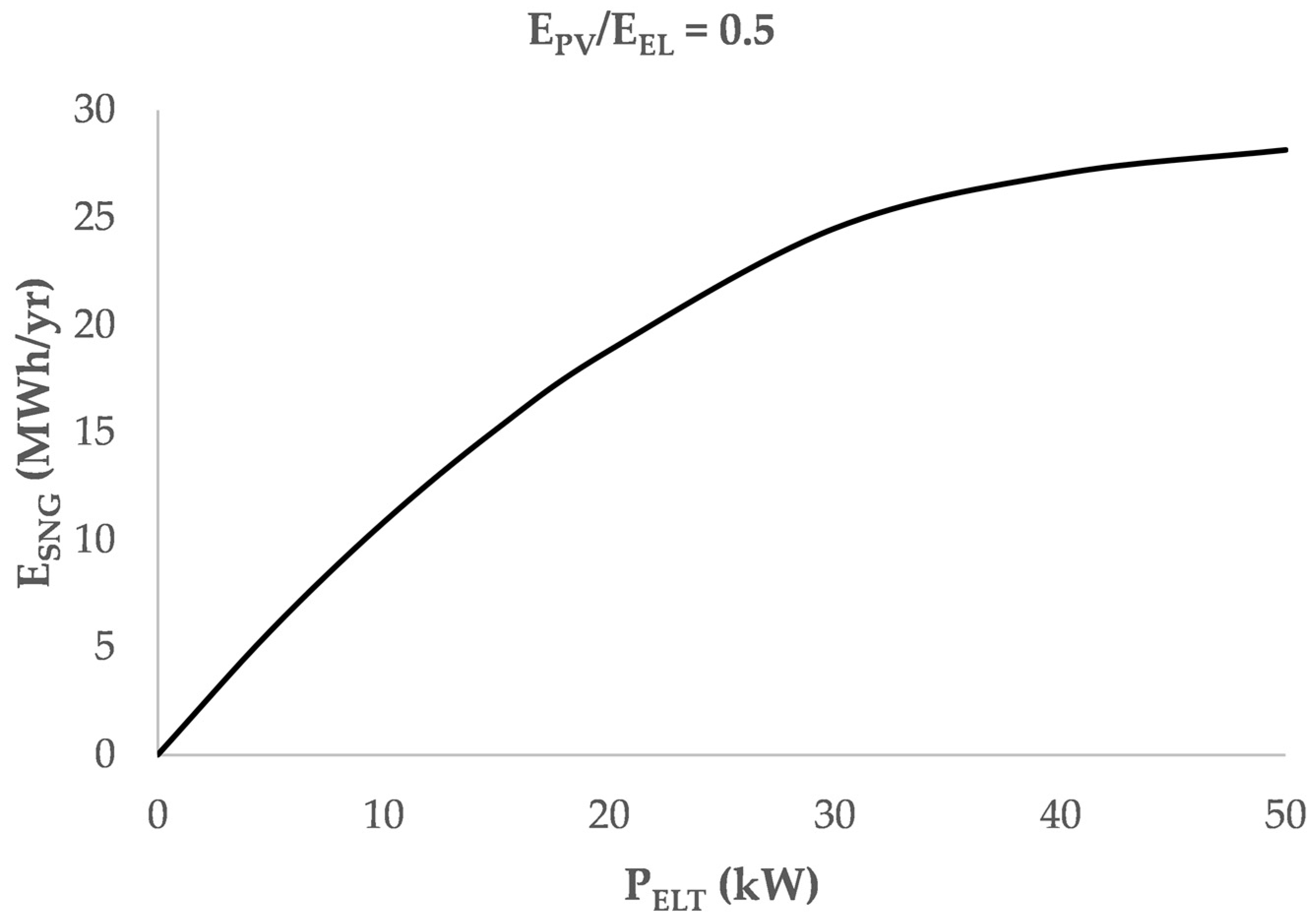

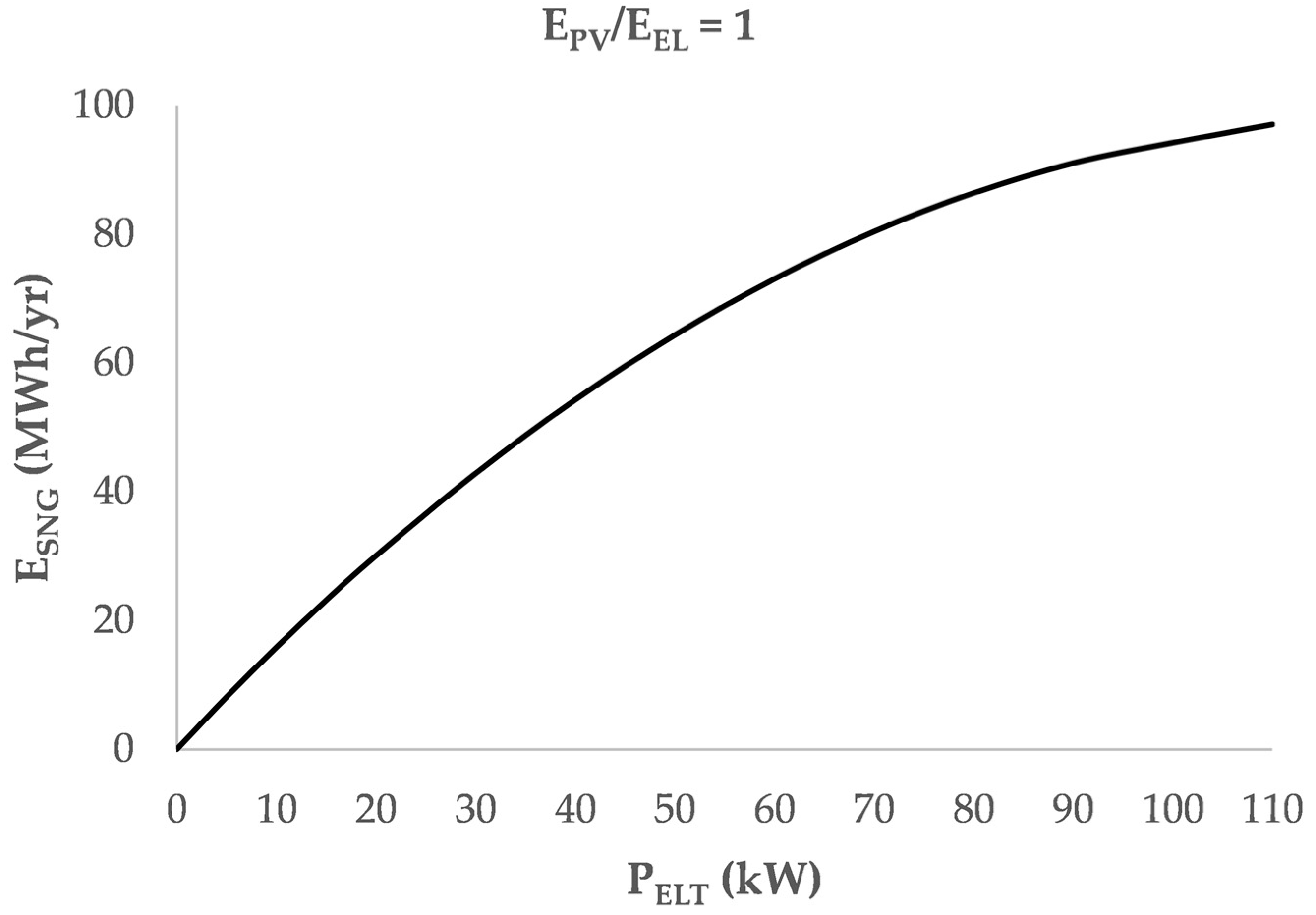

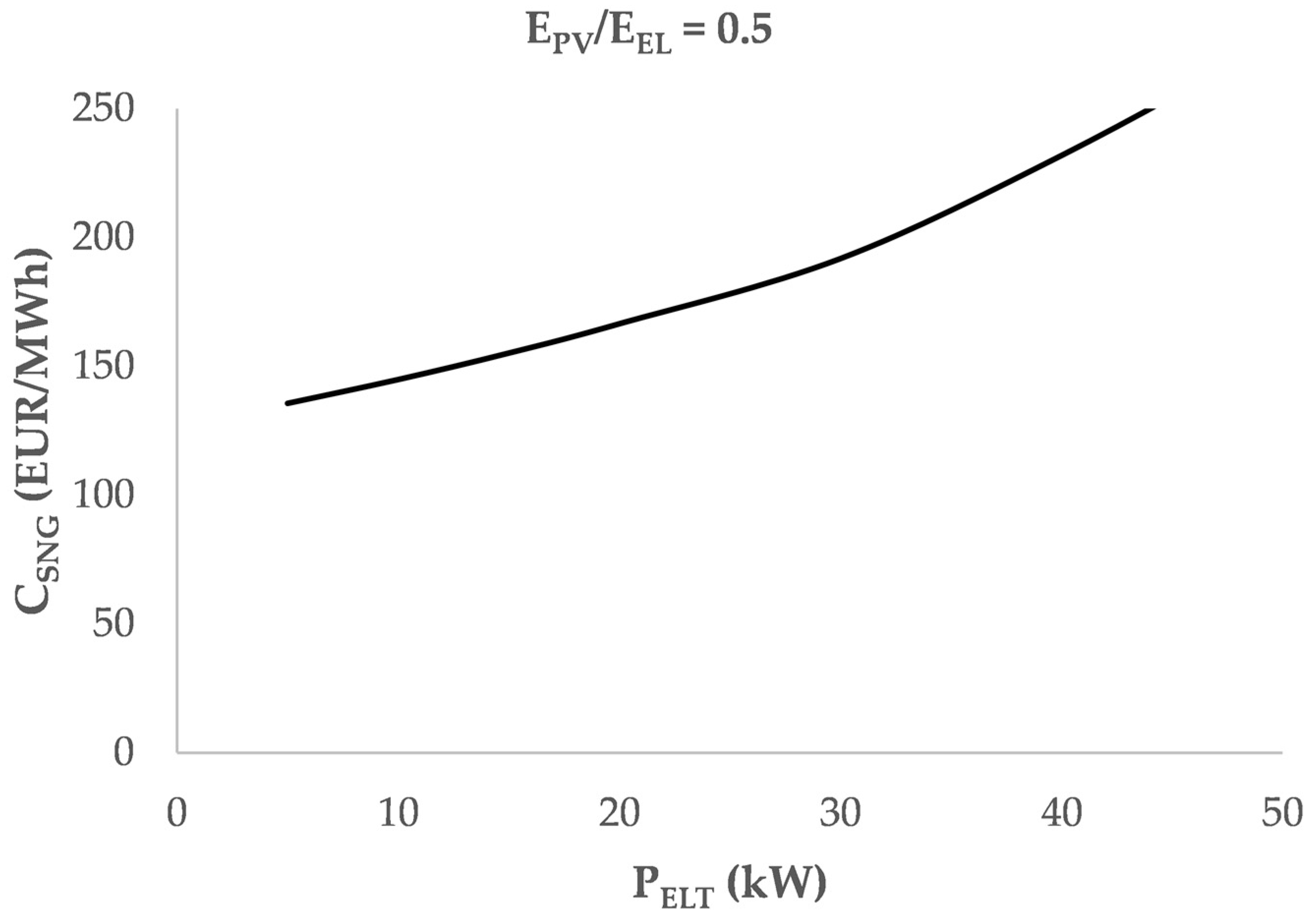

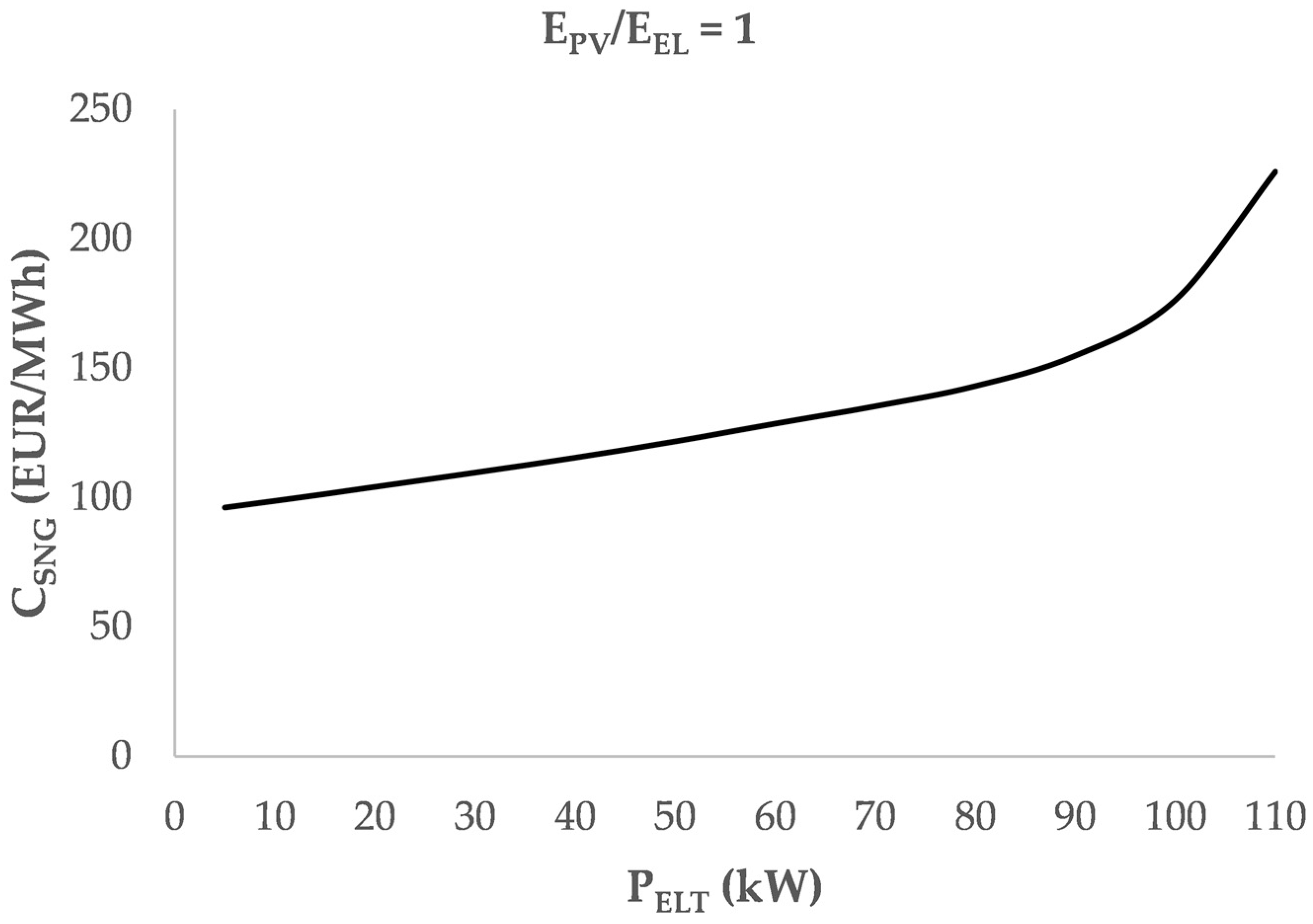

3.2. Power-to-Methane

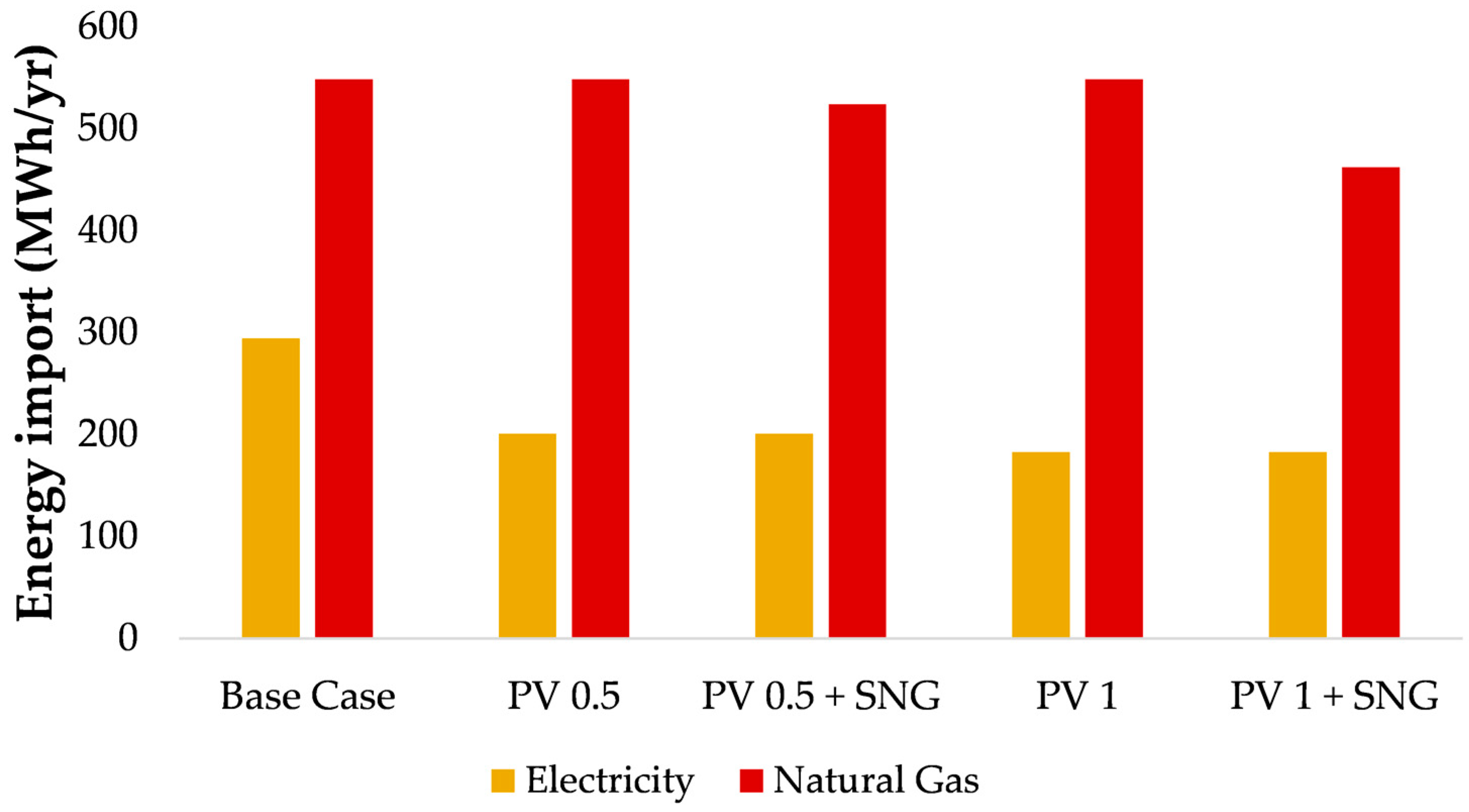

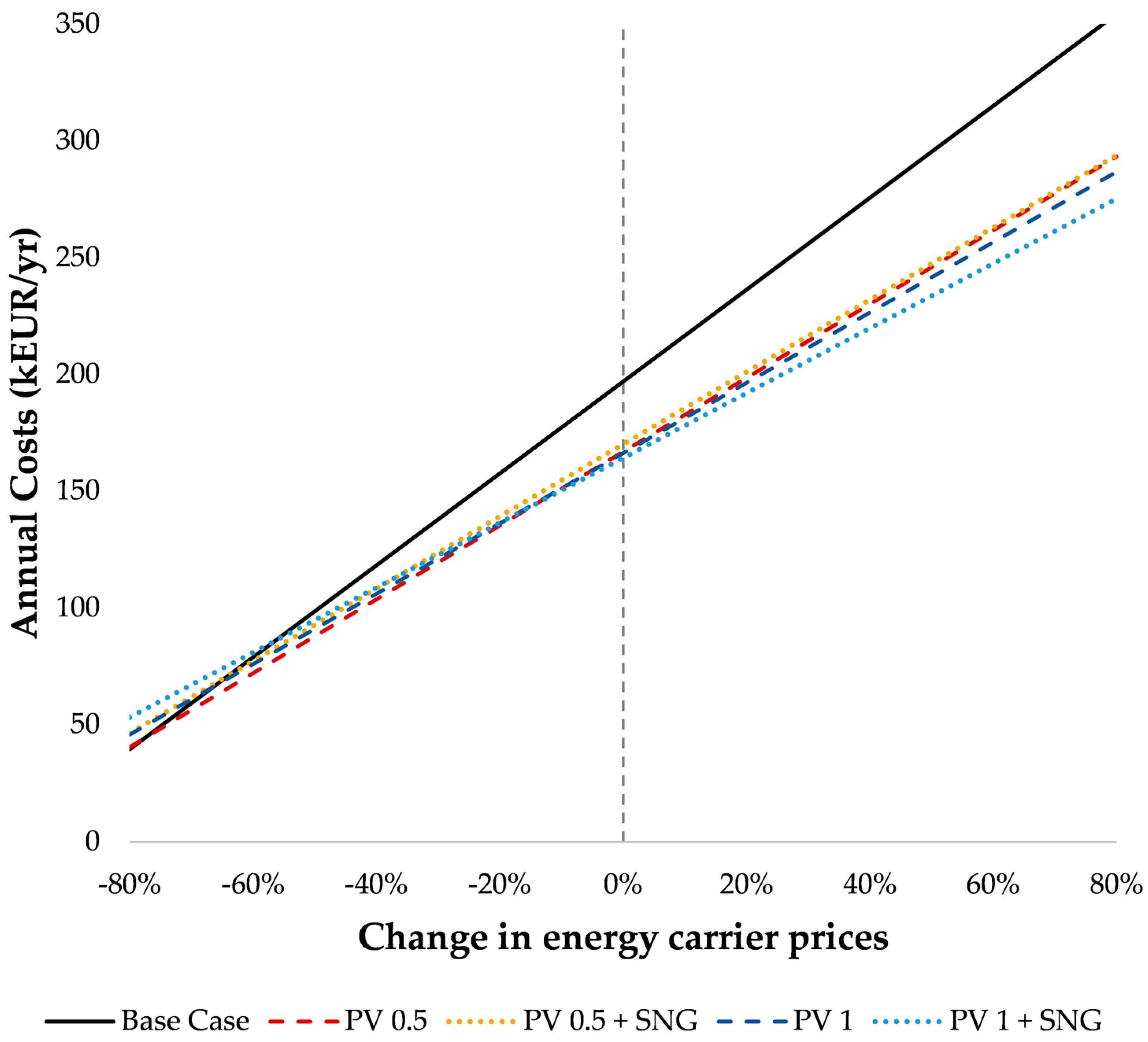

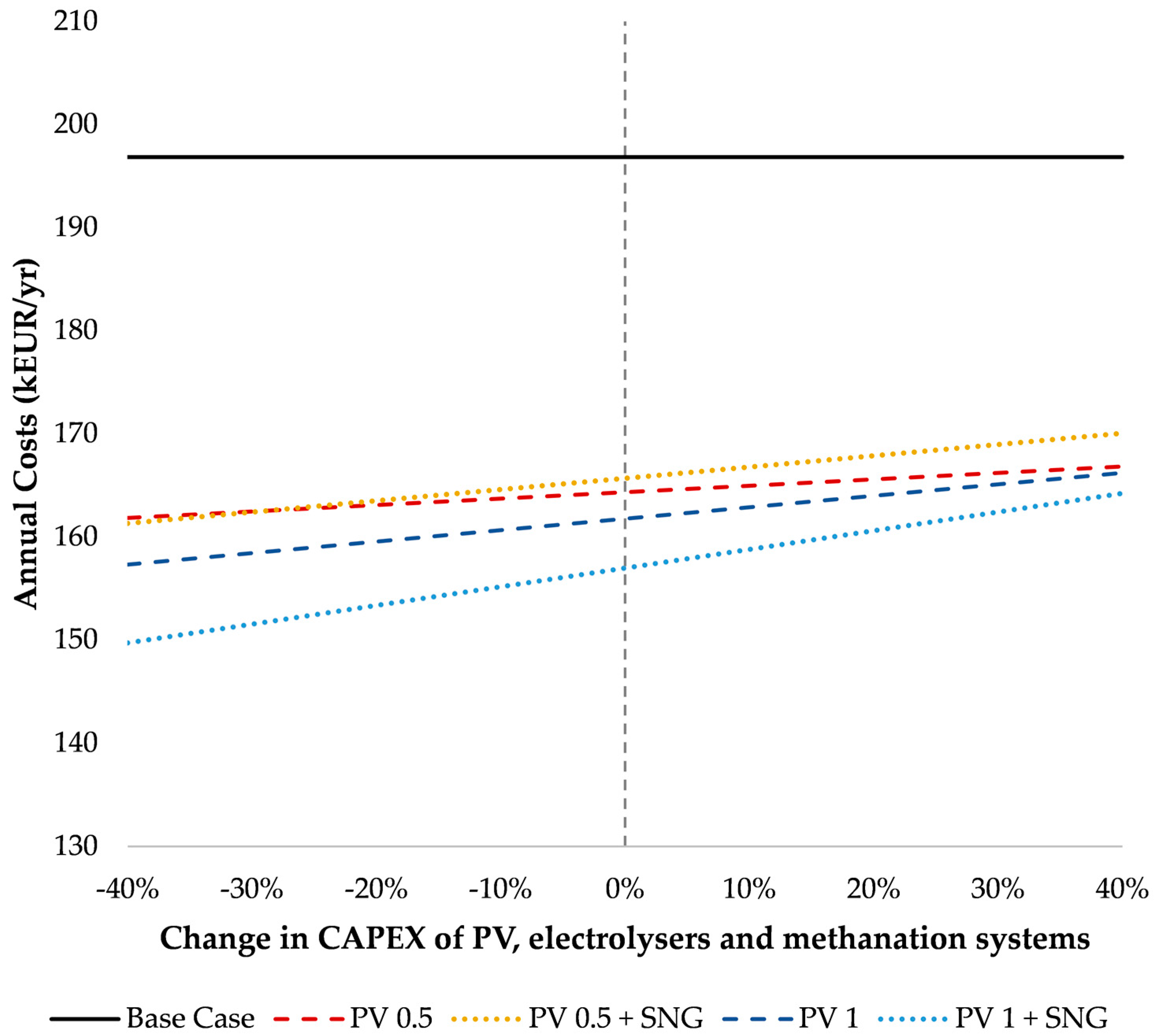

3.3. Comparison between Scenarios and Sensitivity Analysis

- Base Case: in the reference scenario, the electricity and natural gas demands are completely supplied by the grids; no PV systems are implemented;

- PV 0.5: A PV system with a rated power equal to 95 kW is considered;

- PV 0.5 + SNG: A PV system with a rated power equal to 95 kW and a Power-to-Methane system characterised by an electrolyser of 30 kW are considered;

- PV 1: A PV system with a rated power equal to 190 kW is considered;

- PV 1 + SNG: A PV system with a rated power equal to 190 kW and a Power-to-Methane system characterised by an electrolyser of 80 kW are considered.

3.4. Limitations of the Present Work

4. Conclusions

- Without energy storage systems, low SCR levels are achieved when large PV sizes are installed. Furthermore, when the energy annually produced by the PV system matches the electricity demand of the community, the SCR is approximately 0.4.

- The Power-to-Methane strategy can exploit all the RES excess, since there is no limit linked to the storage system size. Indeed, all the SNG produced can be fed into the gas grid, thus avoiding storage volume constraints.

- In the scenario characterised by the ratio EPV/EEL equal to 1, under high-RES excess conditions, the Power-to-Methane strategy allows almost twice as much renewable generation to be integrated within the energy district, compared to the same PV configuration without energy storage systems.

- The SNG production costs raise as the size of the Power-to-Methane system increases. This is due to the fact that an increase in size reduces the system’s full load hours.

- The SNG production cost is between 100 and 200 EUR/MWh in almost all the analysed configurations. Those values are higher than the average cost of natural gas in the period from 2015 to 2020. However, they are comparable to or lower than current gas prices for end-users. Therefore, the current energy crisis can make SNG’s local self-production cost-effective for urban energy districts.

- The annual costs of the urban energy district can be reduced by means of the PV array implementation along with the Power-to-Methane strategy. At current energy carrier prices, investments are more than repaid by savings in gas and electricity purchase from the grid, even in the PV 1 + SNG scenario.

- Considering the energy prices before the current crisis, SNG production is correlated with higher annual costs for the community. On the contrary, at current energy carrier prices, the proposed systems provide economic benefits, as well as they decarbonise the energy district.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ACs | Annual Costs |

| ALK | Alkaline |

| Energy vectors’ purchase | |

| Operation and maintenance costs | |

| CSNG | SNG production cost |

| DME | Dimethyl ether |

| E | Energy |

| EL | Electricity |

| ELT | Electrolyser |

| η | Efficiency [-] |

| LCOE | Levelized Cost of Energy |

| LCOH | Levelized Cost of Hydrogen |

| LCOS | Levelized Cost of Storage |

| METH | Methanation Reactor |

| NG | Natural Gas |

| P | Power |

| PV | Photovoltaic |

| RES | Renewable Energy Sources |

| SNG | Substitute Natural Gas |

References

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2022: Mitigation of Climate Change; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- Connolly, D.; Lund, H.; Mathiesen, B.V. Smart Energy Europe: The technical and economic impact of one potential 100% renewable energy scenario for the European Union. Renew. Sustain. Energy Rev. 2016, 60, 1634–1653. [Google Scholar] [CrossRef]

- Møller Sneum, D. Barriers to flexibility in the district energy-electricity system interface—A taxonomy. Renew. Sustain. Energy Rev. 2021, 145, 111007. [Google Scholar] [CrossRef]

- Pastore, L.M.; Lo Basso, G.; Sforzini, M.; De Santoli, L. Heading towards 100% of Renewable Energy Sources Fraction: A critical overview on Smart Energy Systems planning and flexibility measures. E3S Web Conf. 2020, 197, 01003. [Google Scholar] [CrossRef]

- Luthander, R.; Widén, J.; Nilsson, D.; Palm, J. Photovoltaic self-consumption in buildings: A review. Appl. Energy 2015, 142, 80–94. [Google Scholar] [CrossRef]

- Gallego-Castillo, C.; Heleno, M.; Victoria, M. Self-consumption for energy communities in Spain: A regional analysis under the new legal framework. Energy Policy 2021, 150, 112144. [Google Scholar] [CrossRef]

- Li, H.; Wang, Z.; Hong, T.; Piette, M.A. Energy flexibility of residential buildings: A systematic review of characterization and quantification methods and applications. Adv. Appl. Energy 2021, 3, 100054. [Google Scholar] [CrossRef]

- Heydari, A.; Astiaso Garcia, D.; Keynia, F.; Bisegna, F.; De Santoli, L. Hybrid intelligent strategy for multifactor influenced electrical energy consumption forecasting. Energy Sources Part B Econ. Plan. Policy 2019, 14, 341–358. [Google Scholar] [CrossRef]

- Panda, S.; Mohanty, S.; Rout, P.K.; Sahu, B.K.; Bajaj, M.; Zawbaa, H.M.; Kamel, S. Residential Demand Side Management model, optimization and future perspective: A review. Energy Rep. 2022, 8, 3727–3766. [Google Scholar] [CrossRef]

- Mattoni, B.; Pagliaro, F.; Gugliermetti, L.; Bisegna, F.; Cellucci, L. A territorial based strategy for the distribution of sensor networks in smart cities. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering, EEEIC 2015-Conference Proceedings, Rome, Italy, 10–13 June 2015; pp. 653–658. [Google Scholar]

- Lund, P.D.; Lindgren, J.; Mikkola, J.; Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 2015, 45, 785–807. [Google Scholar] [CrossRef]

- Pfeifer, A.; Dobravec, V.; Pavlinek, L.; Krajačić, G.; Duić, N. Integration of renewable energy and demand response technologies in interconnected energy systems. Energy 2018, 161, 447–455. [Google Scholar] [CrossRef]

- Jülch, V. Comparison of electricity storage options using levelized cost of storage (LCOS) method. Appl. Energy 2016, 183, 1594–1606. [Google Scholar] [CrossRef]

- Rahman, M.M.; Oni, A.O.; Gemechu, E.; Kumar, A. Assessment of energy storage technologies: A review. Energy Convers. Manag. 2020, 223, 113295. [Google Scholar] [CrossRef]

- Baumann, M.; Peters, J.F.; Weil, M.; Grunwald, A. CO2 Footprint and Life-Cycle Costs of Electrochemical Energy Storage for Stationary Grid Applications. Energy Technol. 2017, 5, 1071–1083. [Google Scholar] [CrossRef]

- Child, M.; Breyer, C. Vision and initial feasibility analysis of a recarbonised Finnish energy system for 2050. Renew. Sustain. Energy Rev. 2016, 66, 517–536. [Google Scholar] [CrossRef]

- Pastore, L.M.; Basso, G.L.; Cristiani, L.; Santoli, L. De Rising targets to 55 % GHG emissions reduction–The smart energy systems approach for improving the Italian energy strategy Italian Manager of Energy Services. Energy 2022, 259, 125049. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart energy and smart energy systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- Mattoni, B.; Nardecchia, F.; Bisegna, F. Towards the development of a smart district: The application of an holistic planning approach. Sustain. Cities Soc. 2019, 48, 101570. [Google Scholar] [CrossRef]

- Weiss, R. Decarbonised district heat, electricity and synthetic renewable gas in wind-and solar-based district energy systems. J. Sustain. Dev. Energy Water Environ. Syst. 2021, 9, 1080340. [Google Scholar] [CrossRef]

- Finck, C.; Li, R.; Kramer, R.; Zeiler, W. Quantifying demand flexibility of power-to-heat and thermal energy storage in the control of building heating systems. Appl. Energy 2018, 209, 409–425. [Google Scholar] [CrossRef]

- Gjorgievski, V.Z.; Markovska, N.; Abazi, A.; Duić, N. The potential of power-to-heat demand response to improve the flexibility of the energy system: An empirical review. Renew. Sustain. Energy Rev. 2021, 138, 110489. [Google Scholar] [CrossRef]

- Pastore, L.M.; Lo Basso, G.; Ricciardi, G.; de Santoli, L. Synergies between Power-to-Heat and Power-to-gas in renewable energy communities. Renew. Energy 2022, 198, 1383–1397. [Google Scholar] [CrossRef]

- Fonseca, J.D.; Camargo, M.; Commenge, J.M.; Falk, L.; Gil, I.D. Trends in design of distributed energy systems using hydrogen as energy vector: A systematic literature review. Int. J. Hydrog. Energy 2019, 44, 9486–9504. [Google Scholar] [CrossRef]

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Khalid, F.; Aydin, M.; Dincer, I.; Rosen, M.A. Comparative assessment of two integrated hydrogen energy systems using electrolyzers and fuel cells. Int. J. Hydrog. Energy 2016, 41, 19836–19846. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H.; Connolly, D.; Wenzel, H.; Ostergaard, P.A.; Möller, B.; Nielsen, S.; Ridjan, I.; KarnOe, P.; Sperling, K.; et al. Smart Energy Systems for coherent 100% renewable energy and transport solutions. Appl. Energy 2015, 145, 139–154. [Google Scholar] [CrossRef]

- Qadrdan, M.; Abeysekera, M.; Chaudry, M.; Wu, J.; Jenkins, N. Role of power-to-gas in an integrated gas and electricity system in Great Britain. Int. J. Hydrog. Energy 2015, 40, 5763–5775. [Google Scholar] [CrossRef]

- Stančin, H.; Mikulčić, H.; Wang, X.; Duić, N. A review on alternative fuels in future energy system. Renew. Sustain. Energy Rev. 2020, 128, 109927. [Google Scholar] [CrossRef]

- Pastore, L.M.; Lo Basso, G.; de Santoli, L. Can the renewable energy share increase in electricity and gas grids takes out the competitiveness of gas-driven CHP plants for distributed generation? Energy 2022, 256, 124659. [Google Scholar] [CrossRef]

- Pastore, L.M.; Lo Basso, G.; de Santoli, L. Towards a dramatic reduction in the European Natural Gas consumption: Italy as a case study. J. Clean. Prod. 2022, 369, 133377. [Google Scholar] [CrossRef]

- Ghaib, K.; Ben-Fares, F.Z. Power-to-Methane: A state-of-the-art review. Renew. Sustain. Energy Rev. 2018, 81, 433–446. [Google Scholar] [CrossRef]

- Strakey, J.P.; Forney, A.J.; Haynes, W.P. Methanation in Coal Gasification Processes. 1975. Available online: https://www.osti.gov/biblio/5101832 (accessed on 24 November 2022).

- Höhlein, B. Methanation-Pilot Plant ADAM I (NFE Proiect) and Other Methanation Pilot Plants. 1978. Available online: http://juser.fz-juelich.de/record/811153/files/J%C3%BCl_1512_H%C3%B6hlein_1978.pdf (accessed on 24 November 2022).

- Haynes, W.; Forney, A. High BTU Gas from Coal: Status and Prospects. 1976. Available online: https://www.osti.gov/biblio/7194589 (accessed on 24 November 2022).

- Alarcón, A.; Busqué, R.; Andreu, T.; Guilera, J. Design of a Multi-Tubular Catalytic Reactor Assisted by CFD Based on Free-Convection Heat-Management for Decentralised Synthetic Methane Production. Catalysts 2022, 12, 1053. [Google Scholar] [CrossRef]

- Kiendl, I.; Klemm, M.; Clemens, A.; Herrman, A. Dilute gas methanation of synthesis gas from biomass gasification. Fuel 2014, 123, 211–217. [Google Scholar] [CrossRef]

- Köchermann, J.; Schneider, J.; Matthischke, S.; Rönsch, S. Sorptive H2S removal by impregnated activated carbons for the production of SNG. Fuel Process. Technol. 2015, 138, 37–41. [Google Scholar] [CrossRef]

- Kiewidt, L.; Thöming, J. Predicting optimal temperature profiles in single-stage fixed-bed reactors for CO2-methanation. Chem. Eng. Sci. 2015, 132, 59–71. [Google Scholar] [CrossRef]

- Mancini, F.; Romano, S.; Basso, G.L.; Cimaglia, J.; De Santoli, L. How the italian residential sector could contribute to load flexibility in demand response activities: A methodology for residential clustering and developing a flexibility strategy. Energies 2020, 13, 3359. [Google Scholar] [CrossRef]

- Mancini, F.; Salvo, S.; Piacentini, V. Issues of Energy Retrofitting of a Modern Public Housing Estates: The “Giorgio Morandi” Complex at Tor Sapienza, Rome, 1975–1979. In Proceedings of the Energy Procedia; Elsevier: Amsterdam, The Netherlands, 2016; Volume 101, pp. 1111–1118. [Google Scholar]

- European Commission HotMaps, the Open Source Mapping and Planning Tool for Heating and Cooling. Available online: https://www.hotmaps-project.eu/ (accessed on 10 February 2022).

- Merei, G.; Moshövel, J.; Magnor, D.; Sauer, D.U. Optimization of self-consumption and techno-economic analysis of PV-battery systems in commercial applications. Appl. Energy 2016, 168, 171–178. [Google Scholar] [CrossRef]

- Pastore, L.M.; Basso, G.L.; Quarta, M.N. Power-to-gas as an option for improving energy self-consumption in renewable energy communities. Int. J. Hydrog. Energy 2022, 47, 29604–29621. [Google Scholar] [CrossRef]

- Ram, M.; Child, M.; Aghahosseini, A.; Bogdanov, D.; Lohrmann, A.; Breyer, C. A comparative analysis of electricity generation costs from renewable, fossil fuel and nuclear sources in G20 countries for the period 2015-2030. J. Clean. Prod. 2018, 199, 687–704. [Google Scholar] [CrossRef]

- Pastore, L.M.; Basso, G.L.; Sforzini, M.; de Santoli, L. Technical, economic and environmental issues related to electrolysers capacity targets according to the Italian Hydrogen Strategy: A critical analysis. Renew. Sustain. Energy Rev. 2022, 166, 112685. [Google Scholar] [CrossRef]

- Mayyas, A.; Wei, M.; Levis, G. Hydrogen as a long-term, large-scale energy storage solution when coupled with renewable energy sources or grids with dynamic electricity pricing schemes. Int. J. Hydrog. Energy 2020, 45, 16311–16325. [Google Scholar] [CrossRef]

- EU Science Hub Photovoltaic Geographical Information System (PVGIS). Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 4 January 2022).

- International Renewable Energy Agency. IRENA (2021), Renewable Power Generation Costs in 2020; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- IEA. The Future of Hydrogen; IEA: Paris, France, 2019. [Google Scholar]

- Minutillo, M.; Perna, A.; Forcina, A.; Di Micco, S.; Jannelli, E. Analyzing the levelized cost of hydrogen in refueling stations with on-site hydrogen production via water electrolysis in the Italian scenario. Int. J. Hydrog. Energy 2021, 46, 13667–13677. [Google Scholar] [CrossRef]

- Nami, H.; Rizvandi, O.B.; Chatzichristodoulou, C.; Hendriksen, P.V.; Frandsen, H.L. Techno-economic analysis of current and emerging electrolysis technologies for green hydrogen production. Energy Convers. Manag. 2022, 269, 116162. [Google Scholar] [CrossRef]

- Heat Roadmap Europe 4 (HRE4) | EnergyPLAN. Available online: https://www.energyplan.eu/hre4/ (accessed on 3 November 2021).

- Baena-Moreno, F.M.; Sebastia-Saez, D.; Pastor-Pérez, L.; Reina, T.R. Analysis of the potential for biogas upgrading to syngas via catalytic reforming in the United Kingdom. Renew. Sustain. Energy Rev. 2021, 144, 110939. [Google Scholar] [CrossRef]

- ARERA-Dati Statistici. Available online: https://www.arera.it/it/dati/elenco_dati.htm (accessed on 3 April 2021).

- Elexis Spot TTF. Available online: https://my.elexys.be/MarketInformation/SpotTtf.aspx (accessed on 6 April 2021).

| Dwelling Archetype | Number of Dwellings | Inhabitants (n° of People) | Surface (m2) | Electricity Demand (MWh/Year) | Heating Demand (MWh/Year) |

|---|---|---|---|---|---|

| A | 70 | 1 | 50 | 1.01 | 2.62 |

| B | 70 | 2 | 60 | 1.52 | 3.15 |

| C | 30 | 4 | 100 | 2.49 | 5.25 |

| D | 30 | 2 | 124 | 1.43 | 6.51 |

| District | 200 | 600 | 19,900 | 295 | 505 |

| PV System | ALK Electrolyser | Methanation Reactor | |

|---|---|---|---|

| Efficiency/producibility | 1524 kWh/kW/yr | 64% | 77% |

| CAPEX | 895 | 900 | 845 |

| Unit for CAPEX | EUR/kW | EUR/kWel | EUR/kWhSNG |

| O&M costs (% of INV) | 1.58% | 2% | 3% |

| Lifetime (years) | 25 | 20 | 30 |

| Ref. | [44,48,49] | [50,51] | [50] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lo Basso, G.; Pastore, L.M.; de Santoli, L. Power-to-Methane to Integrate Renewable Generation in Urban Energy Districts. Energies 2022, 15, 9150. https://doi.org/10.3390/en15239150

Lo Basso G, Pastore LM, de Santoli L. Power-to-Methane to Integrate Renewable Generation in Urban Energy Districts. Energies. 2022; 15(23):9150. https://doi.org/10.3390/en15239150

Chicago/Turabian StyleLo Basso, Gianluigi, Lorenzo Mario Pastore, and Livio de Santoli. 2022. "Power-to-Methane to Integrate Renewable Generation in Urban Energy Districts" Energies 15, no. 23: 9150. https://doi.org/10.3390/en15239150

APA StyleLo Basso, G., Pastore, L. M., & de Santoli, L. (2022). Power-to-Methane to Integrate Renewable Generation in Urban Energy Districts. Energies, 15(23), 9150. https://doi.org/10.3390/en15239150