Efficiency and Slippage in Draw Gears with Flat Belts

Abstract

:1. Introduction

2. Materials and Methods

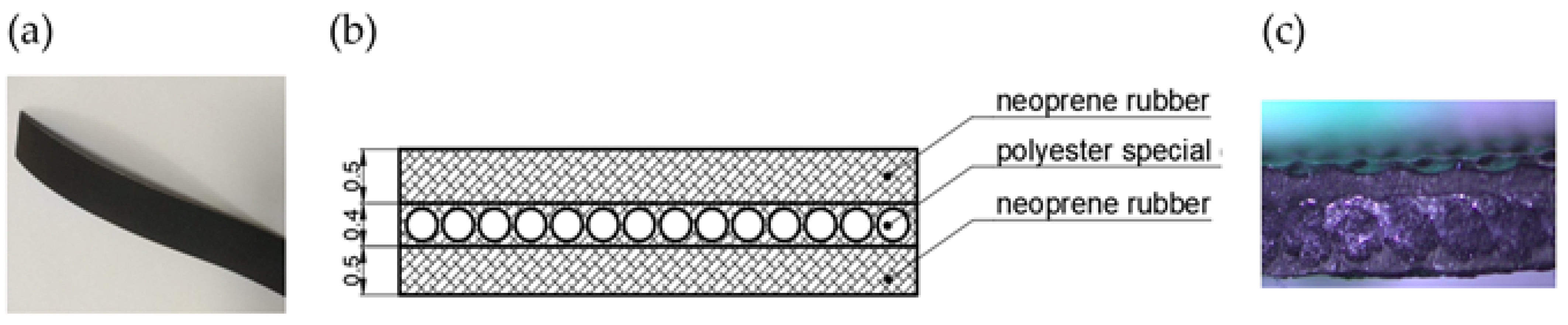

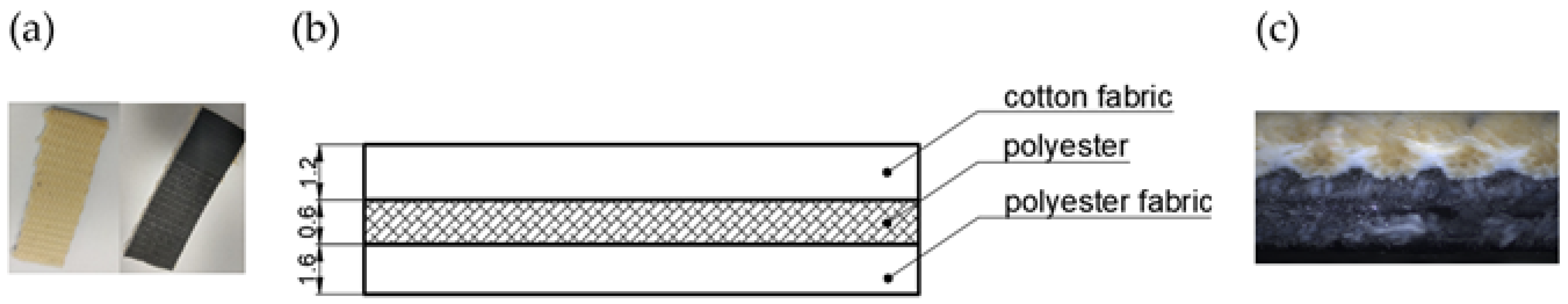

2.1. Materials

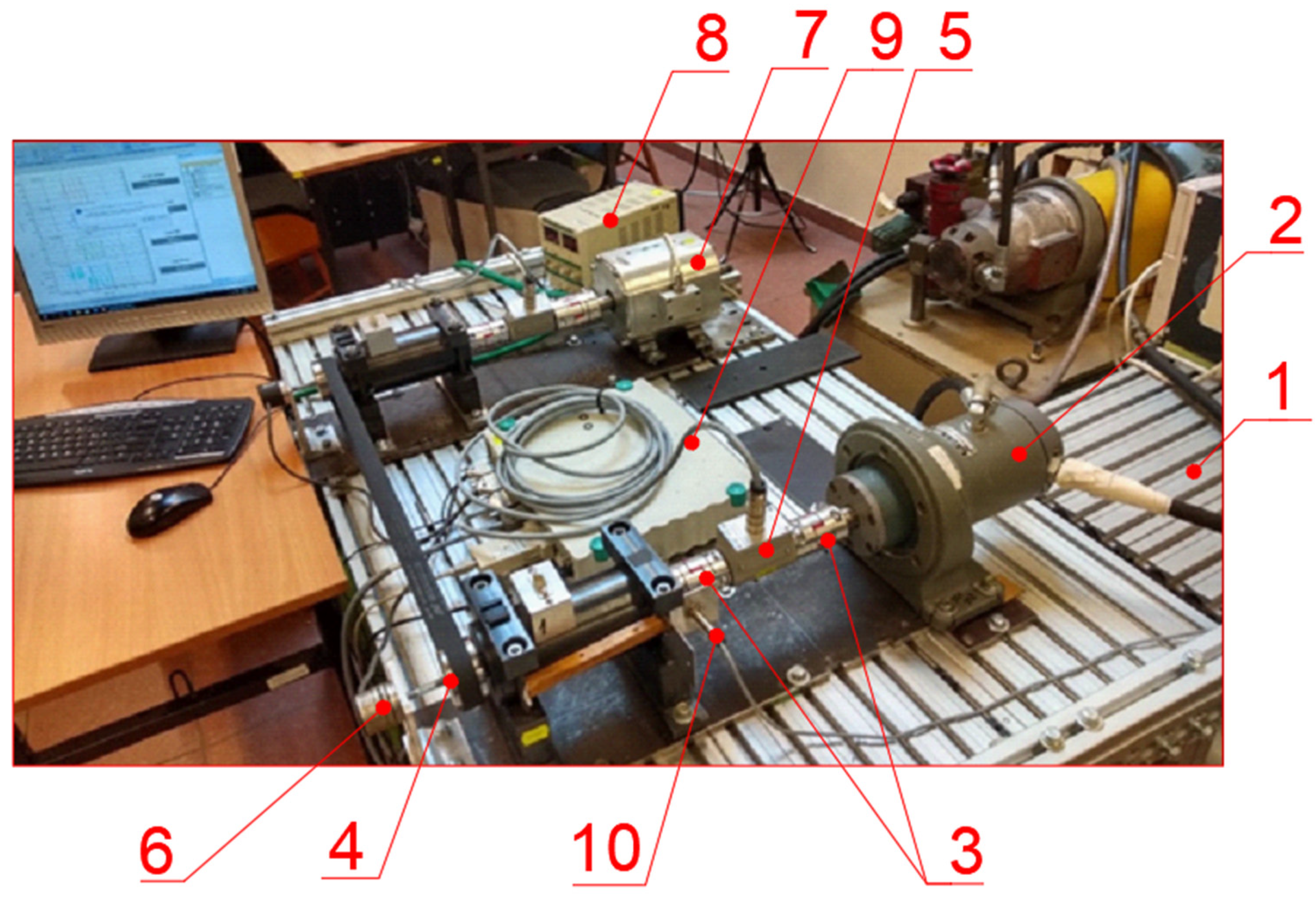

2.2. Test Stand

2.3. Research Methodology

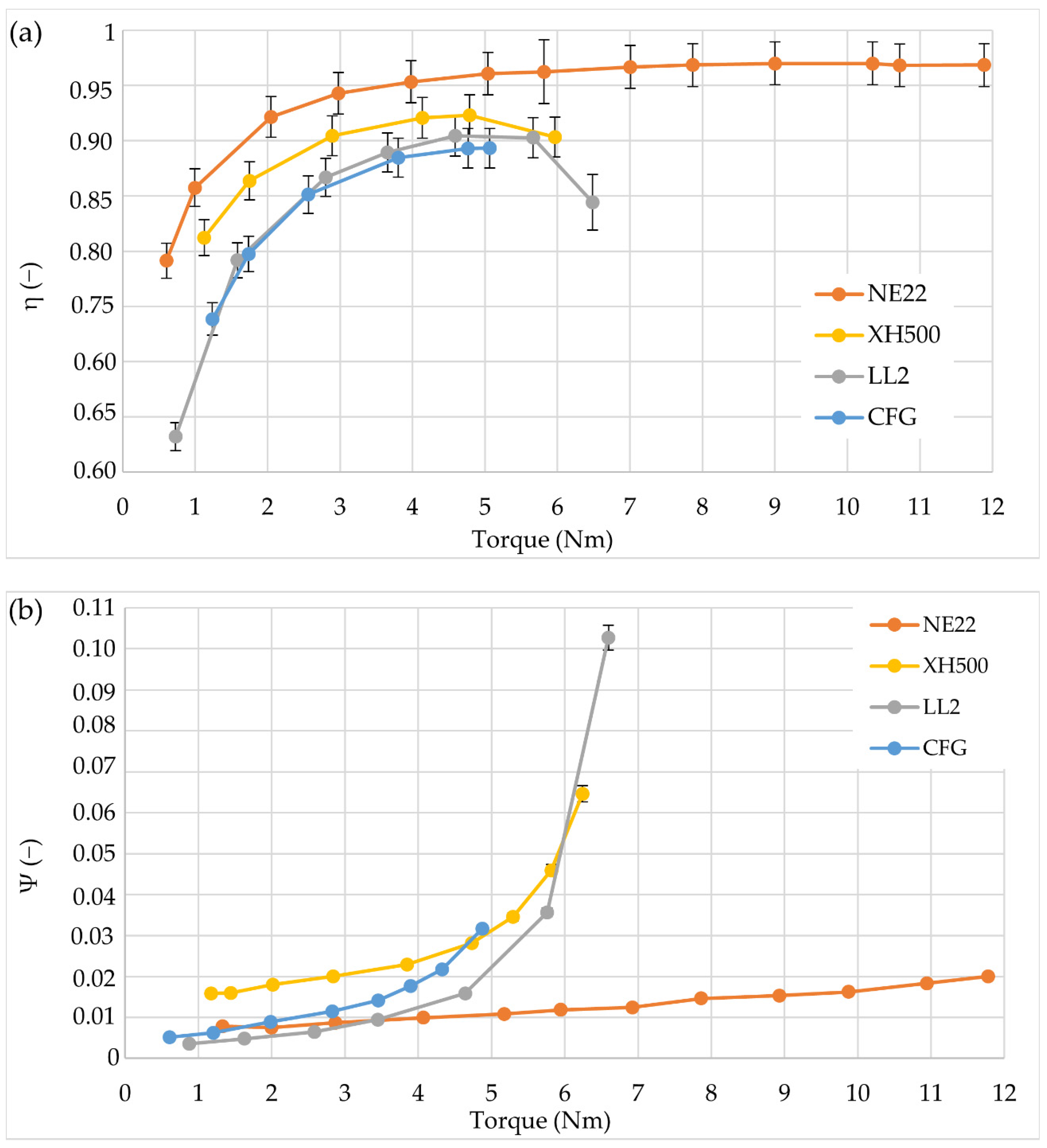

3. Results and Discussion

4. Conclusions

- -

- Belts with high efficiency had the lowest belt slippage. For this reason, materials with a high coefficient of friction concerning the wheel material are used on the running side of the belts, and this layer is made as thin as possible;

- -

- The thinner the layer, the higher the belt transmission efficiency;

- -

- Excessive increases in braking torque resulted in a significant increase in slippage and, consequently, in the belt falling off the wheels. This effect was mitigated by sufficiently high belt preload;

- -

- The NE22 has the most favorable characteristics of the belts tested, with the broadest torque transmission range of 0.7 Nm to 12 Nm. This belt had an efficiency of 97%, while slippage ranged from 0.005 to 0.02;

- -

- The highest energy loss was recorded for the CFG belt, the torque range was comparable to that of the XH500 and LL2 belts, and efficiency was around 90% in the very low torque range;

- -

- XH500 and LL2 belts showed similar transferable torque, slippage and efficiency values.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hrabovský, L.; Fries, J. Transport Performance of a Steeply Situated Belt Conveyor. Energies 2021, 14, 7984. [Google Scholar] [CrossRef]

- Stehlikova, B.; Molnar, V.; Fedorko, G.; Michalik, P.; Paulikova, A. Research about influence of the tension forces, asymmetrical tensioning and filling rate of pipe conveyor belt filled with the material on the contact forces of idler rolls in hexagonal idler housing. Measurement 2020, 156, 107598. [Google Scholar] [CrossRef]

- Gierz, Ł.; Warguła, Ł.; Kukla, M.; Koszela, K.; Zwiachel, T.S. Computer aided modeling of wood chips transport by means of a belt conveyor with use of discrete element method. Appl. Sci. 2020, 10, 9091. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnar, V.; Vasil, M.; Salai, R. Proposal of digital twin for testing and measuring of transport belts for pipe conveyors within the concept Industry 4.0. Measurement 2021, 174, 10897. [Google Scholar] [CrossRef]

- Wozniak, D.; Hardygora, M. Method for laboratory testing rubber penetration of steel cords in conveyor belts. Min. Sci. 2020, 27, 105–117. [Google Scholar] [CrossRef]

- Marasova, D.; Ambrisko, L.; Caban, L. Determination of the Quality of Rubber Composites Based on their Testing. Qual. Access Success 2019, 20, 18–21. [Google Scholar]

- Czarnecka-Komorowska, D.; Sterzynski, T.; Dutkiewicz, M. Polyoxymethylene/Polyhedral Oligomeric Silsesquioxane Composites: Processing, Crystallization, Morphology and Thermo-Mechanical Behavior. Int. Polym. Process. 2016, 31, 598–606. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Sterzynski, T.; Andrzejewski, J. Evaluation of structure and thermomechanical properties of polyoxymethylene modified with polyhedral oligomeric silsesquioxanes (POSS). Przem. Chem. 2013, 92, 2129–2132. [Google Scholar]

- Sika, R.; Rogalewicz, M.; Popielarski, P.; Czarnecka-Komorowska, D.; Przestacki, D.; Gawdzińska, K.; Szymański, P. Decision support system in the field of defects assessment in the metal matrix composites castings (Open Access). Materials 2020, 13, 3552. [Google Scholar] [CrossRef]

- Krawiec, P.; Grzelka, M.; Kroczak, J.; Domek, G.; Kołodziej, A. A proposal of measurement methodology and assessment of manufacturing methods of nontypical cog belt pulleys. Measurement 2019, 132, 182–190. [Google Scholar] [CrossRef]

- Krawiec, A.; Marlewski, A. Profile design of noncircular belt pulleys. J. Theor. Appl. Mech. 2016, 54, 561–570. [Google Scholar] [CrossRef] [Green Version]

- Krawiec, P. Analysis of selected dynamic features of a two-whwwled transmission system. J. Theor. Appl. Mech. 2017, 55, 461–467. [Google Scholar] [CrossRef]

- Kujawski, M.; Krawiec, P. Analysis of Generation Capabilities of Noncircular Cog belt Pulleys on the Example of a Gear with an Elliptical Pitch Line. J. Manuf. Sci. Eng. -Trans. ASME 2011, 133, 051006. [Google Scholar] [CrossRef]

- Wałęsa, K.; Malujda, I.; Górecki, J. Experimental research of the mechanical properties of the round drive belts made of thermoplastic. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012107-1–012107-11. [Google Scholar] [CrossRef]

- Wojtkowiak, D.; Talaśka, K. The influence of the piercing punch profile on the stress distribution on its cutting edge. MATEC Web Conf. 2019, 254, 02001. [Google Scholar] [CrossRef]

- Berdychowski, M.; Malujda, I.; Wałęsa, K.; Fierek, A. Analysis of angular deflection of bearing node in machine with toothed transport belt. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012019. [Google Scholar] [CrossRef] [Green Version]

- Bajda, M.; Hardygóra, M. Analysis of the Influence of the Type of Belt on the Energy Consumption of Transport Processes in a Belt Conveyor. Energies 2021, 14, 6180. [Google Scholar] [CrossRef]

- Sága, M.; Jakubovičová, L. Simulation of vertical vehicle non-stationary random vibrations considering various speeds. Sci. J. Sil. Univ. Technol. Ser. Transp. 2014, 84, 113–118. [Google Scholar]

- Kuric, I.; Bulej, V.; Saga, M.; Pokorny, P. Development of simulation software for mobile robot path planning within multilayer map system based on metric and topological maps. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417743029. [Google Scholar] [CrossRef] [Green Version]

- Xiao, H.; Chuang, H.C.; Yang, Z.H.; Lee, C.T. The efciency improvement of induction motor with constant speed for belt drive mechanism. Energy Effic. 2021, 14, 87. [Google Scholar] [CrossRef]

- Elahi, M.; Afolaranmi, S.O.; Mohammed, W.M.; Martinez Lastra, J.L. Energy-Based Prognostics for Gradual Loss of Conveyor Belt Tension in Discrete Manufacturing Systems. Energies 2022, 15, 4705. [Google Scholar] [CrossRef]

- Kubas, K. Measurement of the friction parameters of a belt transmission under heavy load. Arch. Motoryz. 2022, 95, 18–31. [Google Scholar] [CrossRef]

- Kubas, K. A model for the dynamic analysis of a belt transmission using the Dahl friction model. J. Theor. Appl. Mech. 2017, 55, 1423–1435. [Google Scholar] [CrossRef]

- Balta, B.; Sonmez, F.O.; Cengiz, A. Speed losses in V-ribbed belt drives. Mech. Ma-Chine Theory 2015, 86, 1–14. [Google Scholar] [CrossRef]

- Balta, B.; Sonmez, F.O.; Cengiz, A. Experimental identification of the torque losses in V-ribbed belt drives using the response surface method. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 1070–1082. [Google Scholar] [CrossRef]

- Bucchi, F.; Frendo, F. Analysis of belt transmissions capabilities using the brush model. Inst. Phys. Conf. Ser. Mater. Sci. Eng. 2021, 1038, 012076. [Google Scholar] [CrossRef]

- Frendo, F.; Bucchi, F. “Brush model” for the analysis of flat belt transmissions in steady-state conditions. Mech. Mach. Theory 2020, 143, 103653. [Google Scholar] [CrossRef]

- Mascenik, J.; Murcinkowa, Z. Experimental determination of the belt transmission slip. Manag. Syst. Prod. Eng. 2019, 4, 205–210. [Google Scholar] [CrossRef] [Green Version]

- Oborin, E. Belt–pulley interaction: Role of the action line of friction forces. Acta Mech. 2020, 231, 3979–3987. [Google Scholar] [CrossRef]

- Gawrońska, E.; Domek, G.; Krawiec, P.; Kołodziej, A. Modeling the damages of belt gears. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1199, 012017. [Google Scholar]

- Blatnická, M.; Sága, M.; Blatnický, M. Design of pallet, frame and chain of soldering station conveyor. MATEC Web Conf. 2018, 157, 0100122. [Google Scholar] [CrossRef]

- Nikonova, T.; Zharkevich, O.; Dandybaev, E.; Baimuldin, M.; Daich, L.; Sichkarenko, A.; Kotov, E. Developing a Measuring System for Monitoring the Thickness of the 6 m Wide HDPE/LDPE Polymer Geomembrane with Its Continuous Flow Using Automation Equipment. Appl. Sci. 2021, 11, 10045. [Google Scholar] [CrossRef]

- Kuric, I.; Tlach, V.; Sága, M.; Císar, M.; Zajačko, I. Industrial Robot Positioning Performance Measured on Inclined and Parallel Planes by Double Ballbar. Appl. Sci. 2021, 11, 1777. [Google Scholar] [CrossRef]

- Blatnický, M.; Dižo, J.; Gerlici, J.; Sága, M.; Lack, T.; Kuba, E. Design of a robotic manipulator for handling products of automotive industry. Int. J. Ofdvanced Robot. Syst. 2020, 17, 1729881420906290. [Google Scholar] [CrossRef]

| Belt | Vibration Frequency [Hz] |

|---|---|

| NE22 | 58 |

| XH500 | 28 |

| LL2 | 39 |

| CFG | 36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krawiec, P.; Warguła, Ł.; Waluś, K.J.; Gawrońska, E.; Ságová, Z.; Matijošius, J. Efficiency and Slippage in Draw Gears with Flat Belts. Energies 2022, 15, 9184. https://doi.org/10.3390/en15239184

Krawiec P, Warguła Ł, Waluś KJ, Gawrońska E, Ságová Z, Matijošius J. Efficiency and Slippage in Draw Gears with Flat Belts. Energies. 2022; 15(23):9184. https://doi.org/10.3390/en15239184

Chicago/Turabian StyleKrawiec, Piotr, Łukasz Warguła, Konrad Jan Waluś, Elżbieta Gawrońska, Zuzana Ságová, and Jonas Matijošius. 2022. "Efficiency and Slippage in Draw Gears with Flat Belts" Energies 15, no. 23: 9184. https://doi.org/10.3390/en15239184

APA StyleKrawiec, P., Warguła, Ł., Waluś, K. J., Gawrońska, E., Ságová, Z., & Matijošius, J. (2022). Efficiency and Slippage in Draw Gears with Flat Belts. Energies, 15(23), 9184. https://doi.org/10.3390/en15239184