Modelling a Turbulent Non-Premixed Combustion in a Full-Scale Rotary Cement Kiln Using reactingFoam

Abstract

:1. Introduction

2. Computational Fluid Dynamics of Turbulent Non-Premixed Combustion

2.1. Unsteady Compressible Turbulent Flow of the Gas Mixture

2.2. Non-Premixed Combustion of Gaseous Fuels

2.3. Radiative Heat Transfer in Gas Mixture

2.4. Zeldovich Thermal Nitric Oxide Post-Processing

2.5. Implementation in chtMultiRegionFoam and reactingFoam

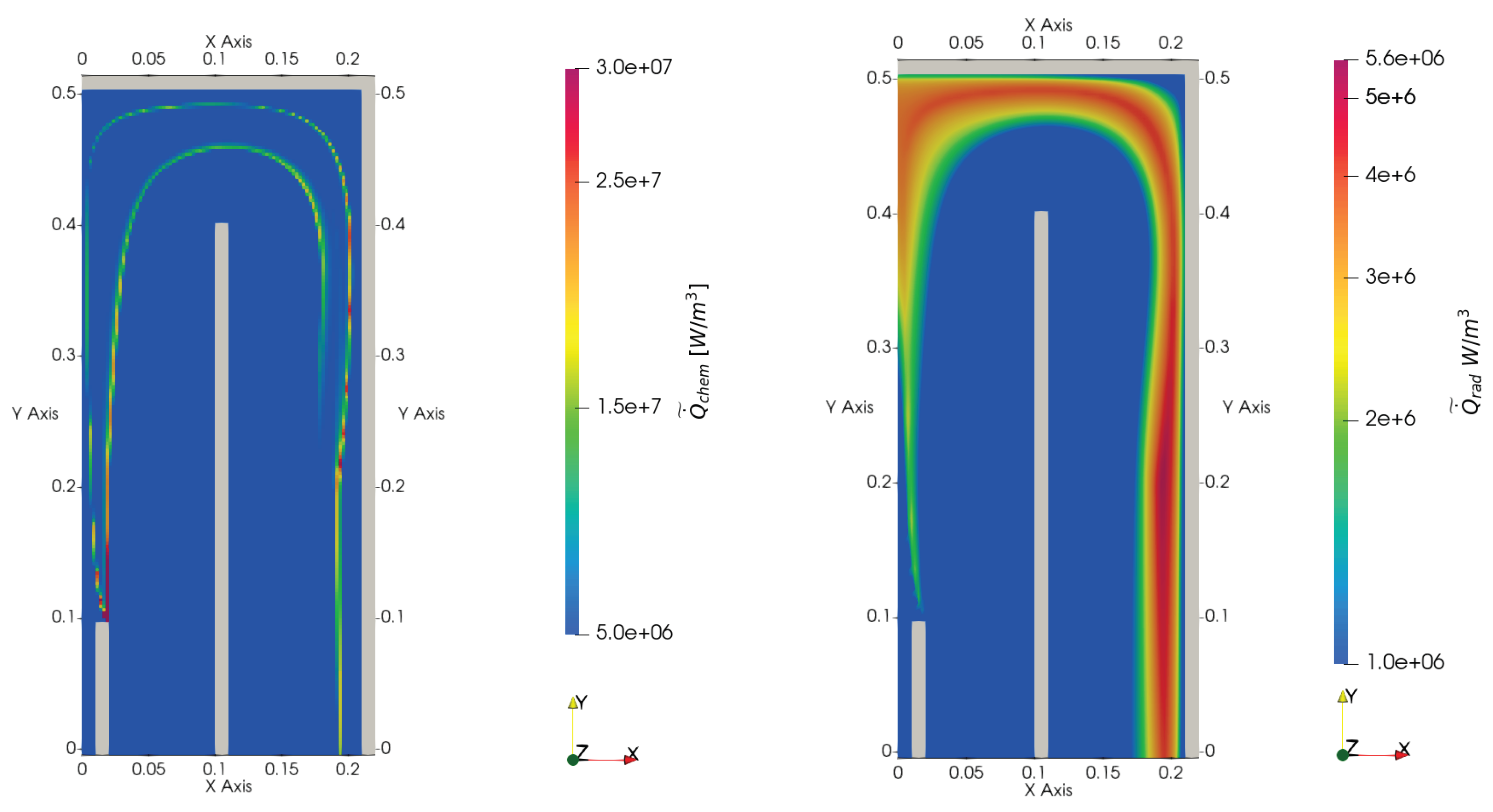

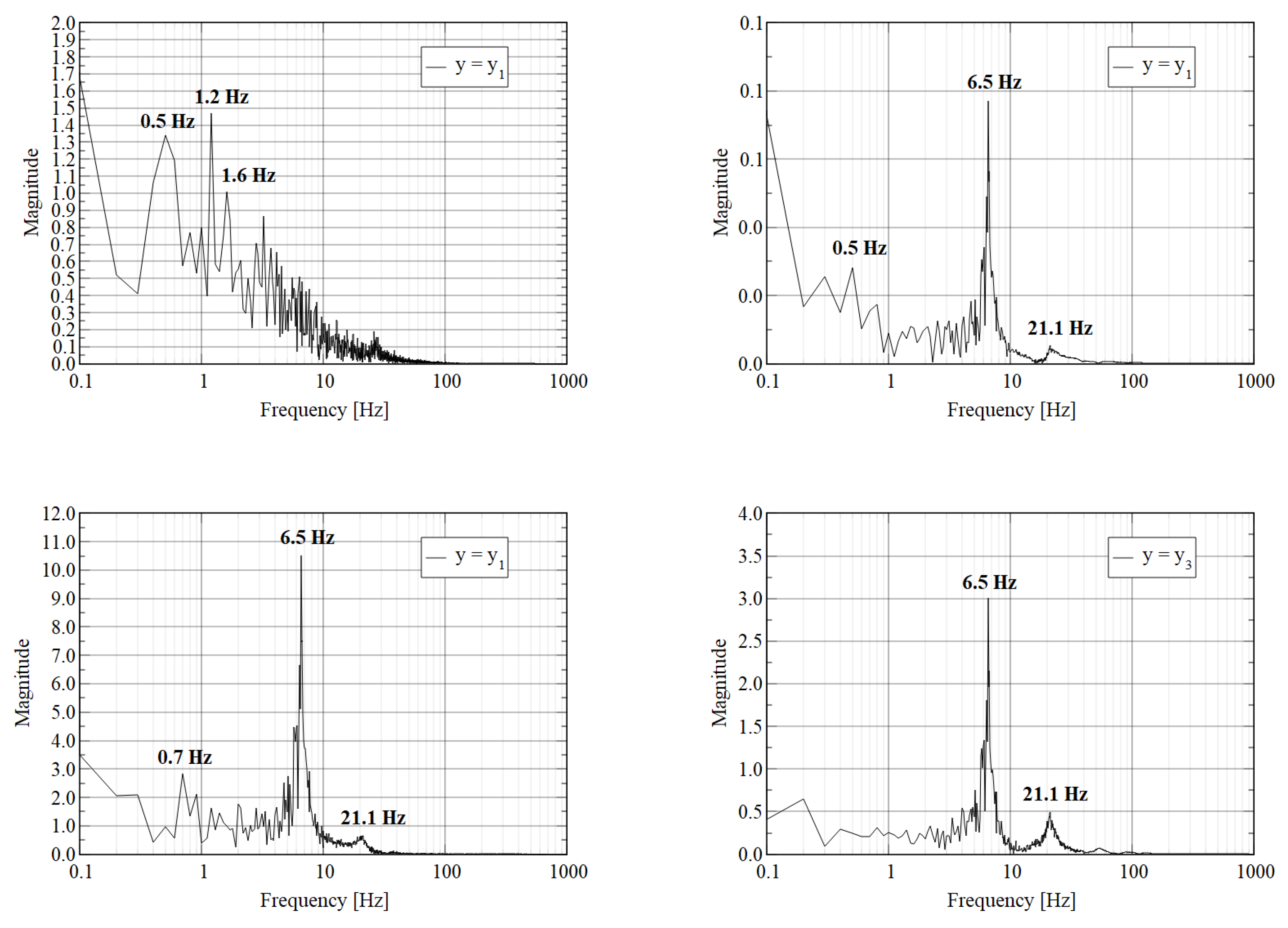

3. The reverseBurner Tutorial Case for Non-Premixed Turbulent Combustion

4. Cement Kiln: Geometry Definition, Mesh Generation, and Boundary Conditions Imposed

4.1. Geometry Definition

4.2. Mesh Generation

4.3. Imposed Boundary Conditions

5. Numerical Results

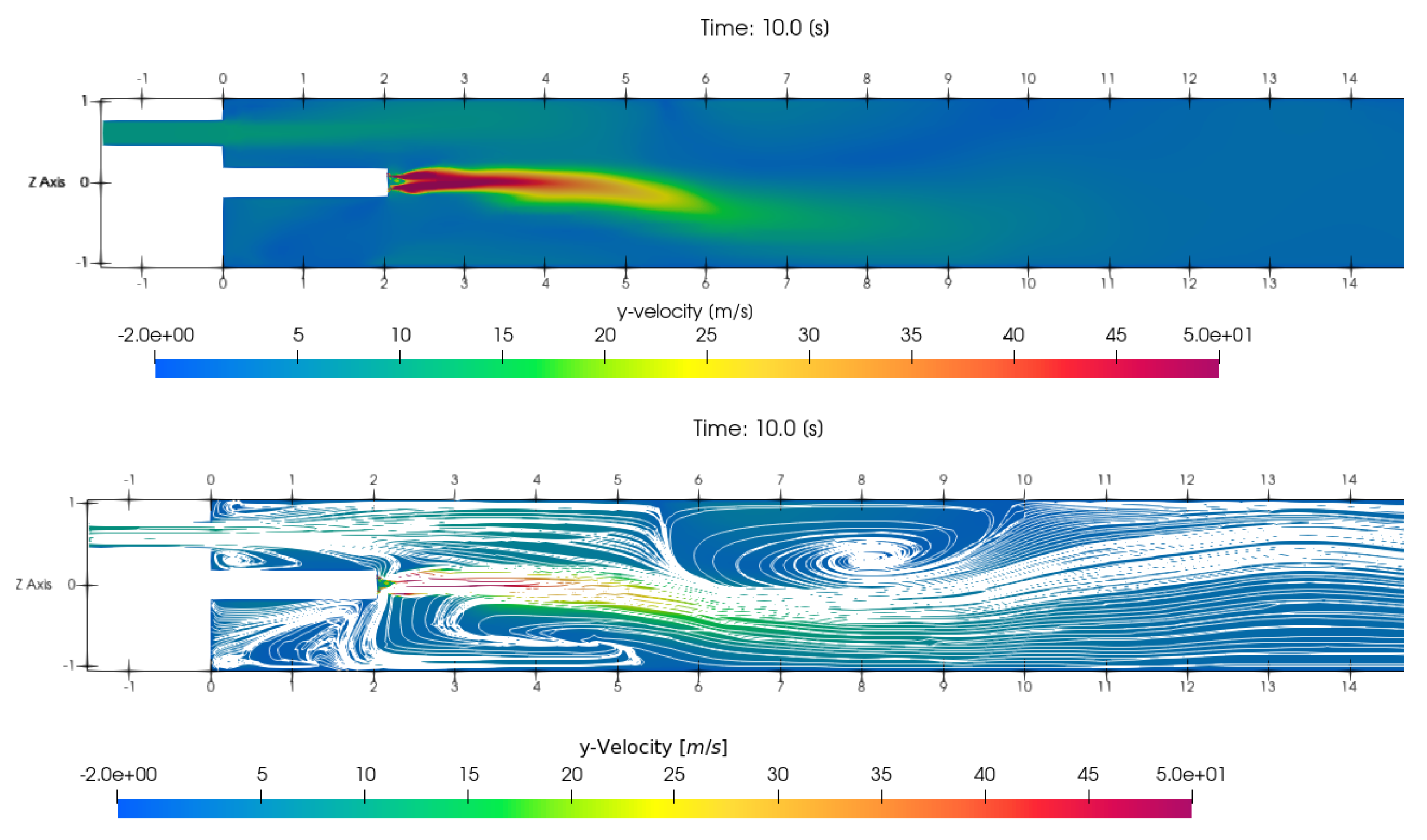

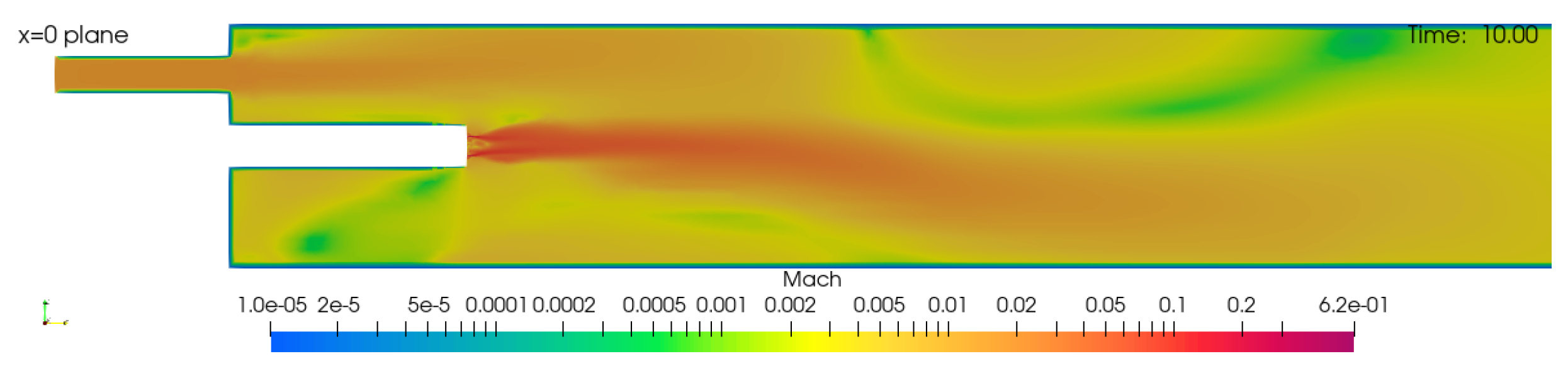

5.1. Results for the Flow Field

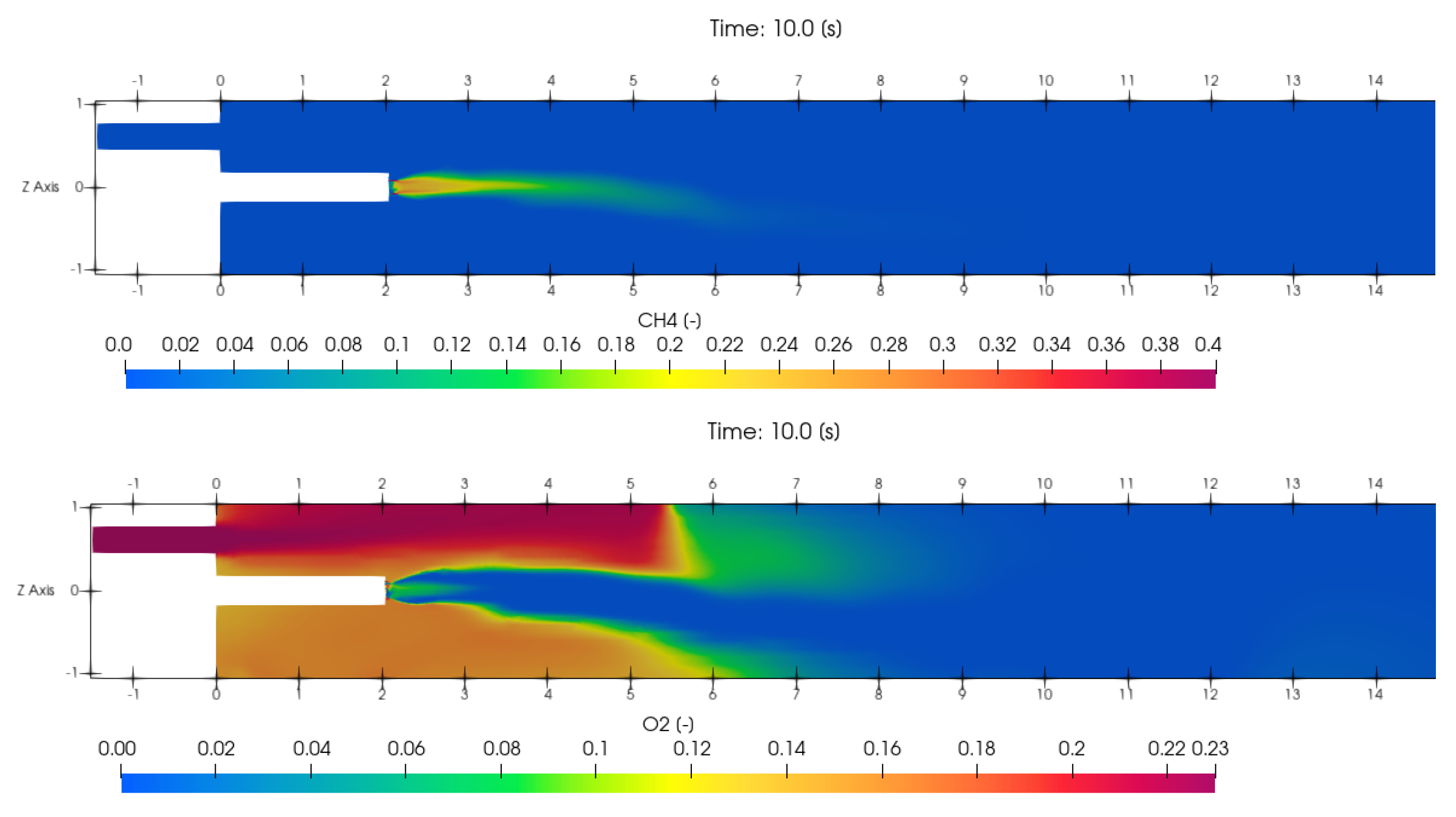

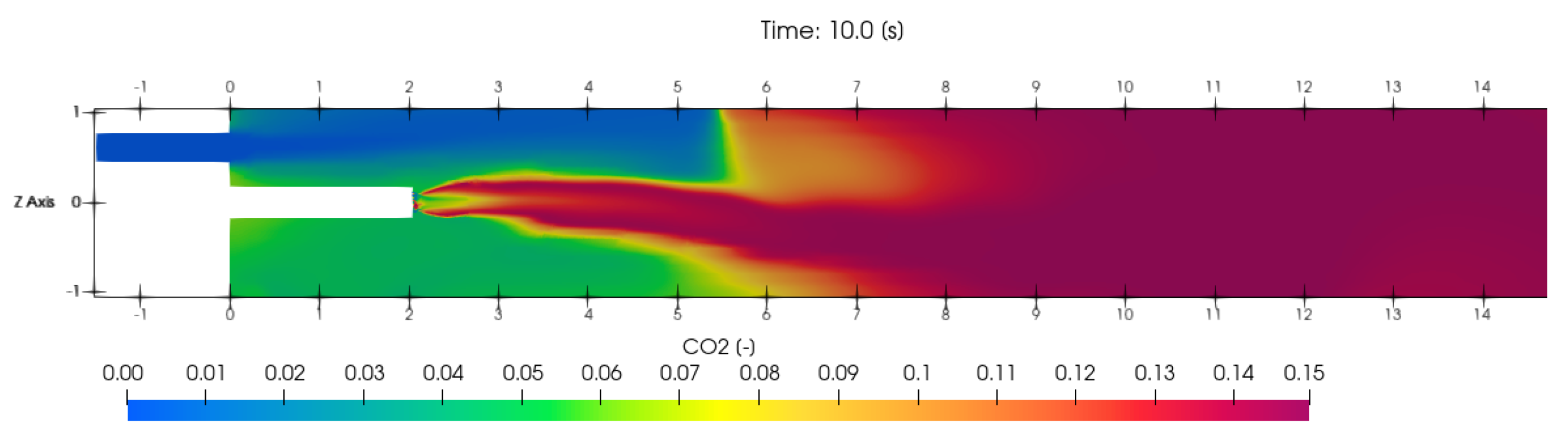

5.2. Results for Species Concentration

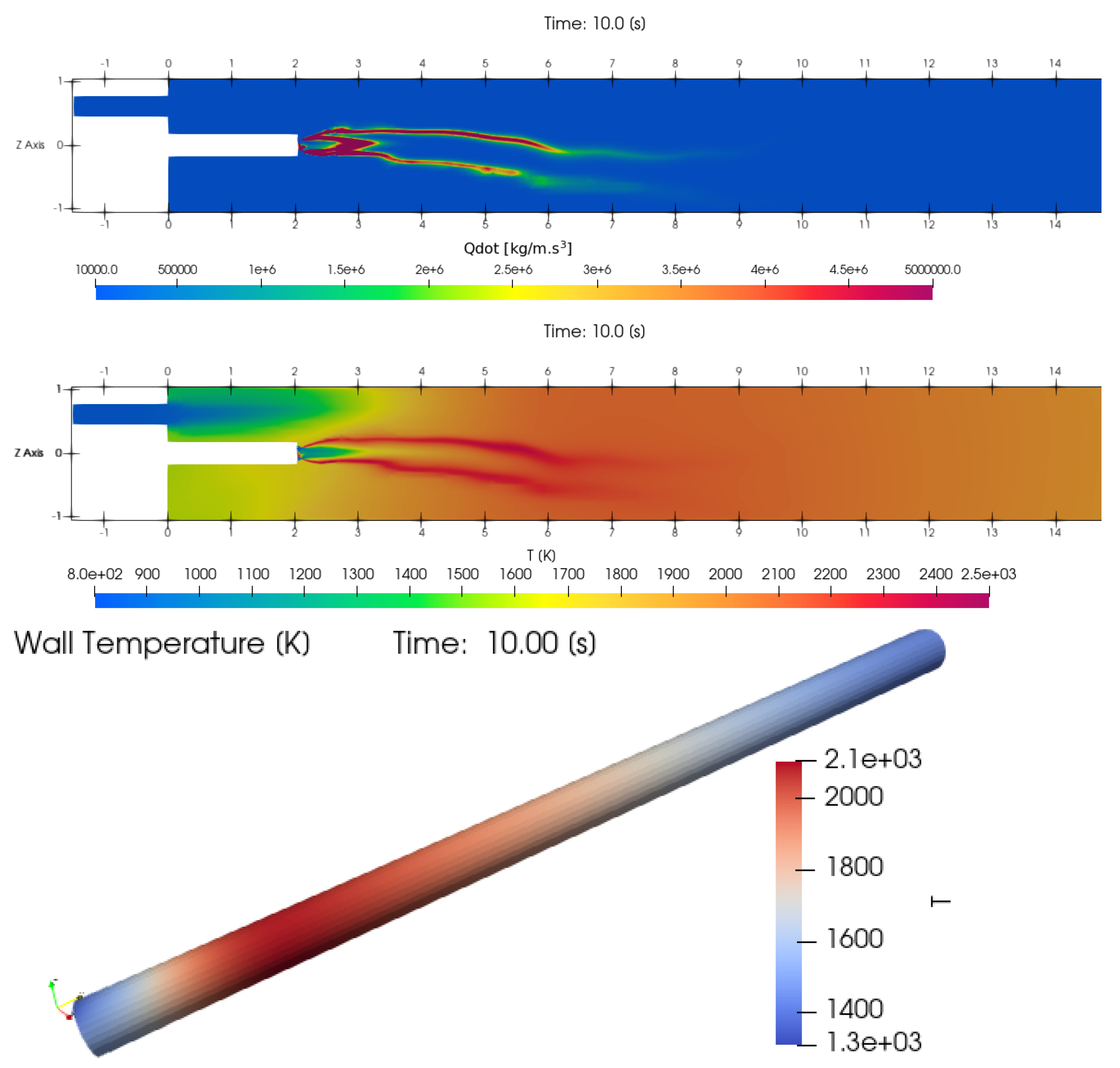

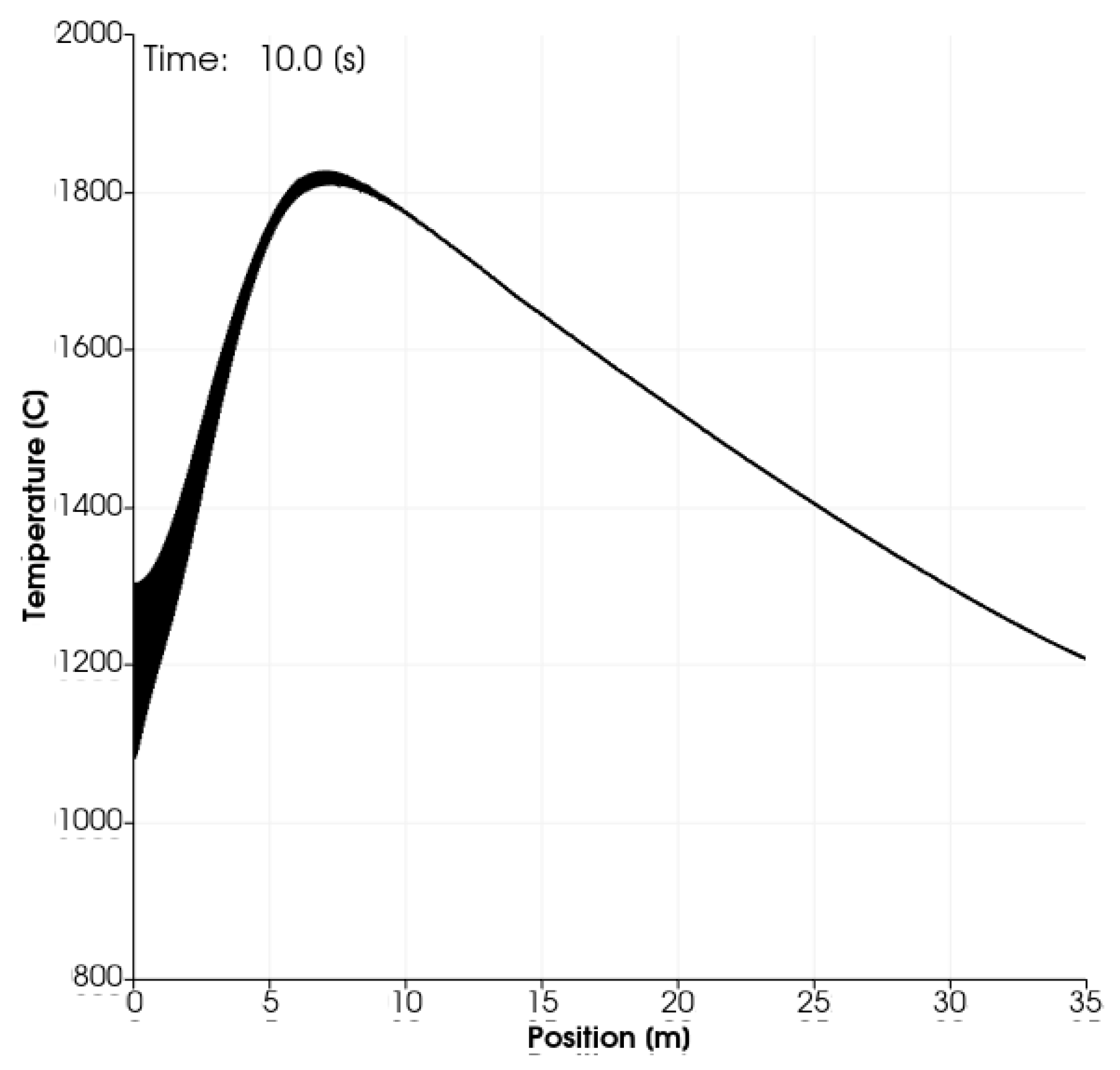

5.3. Results for Temperature

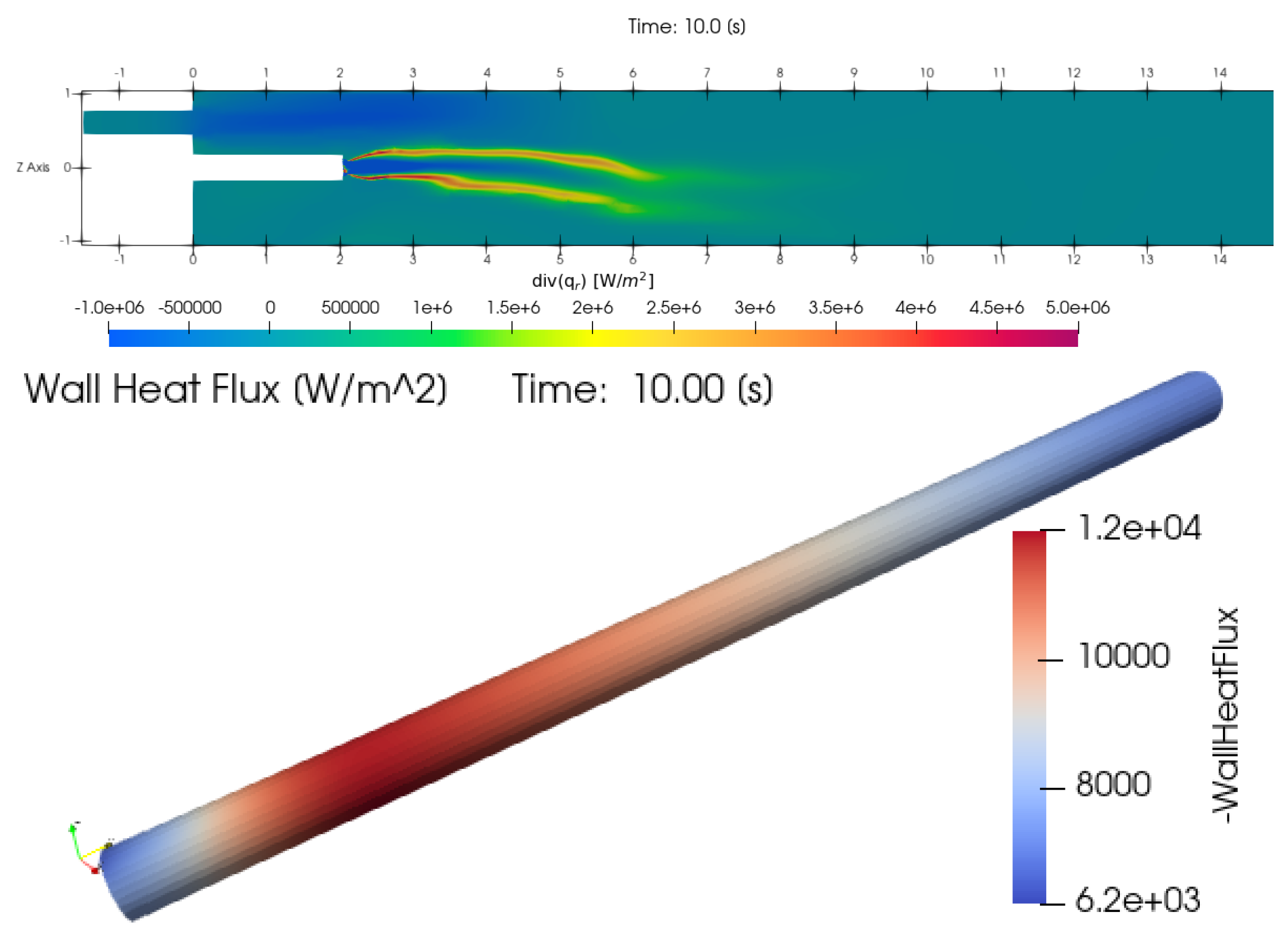

5.4. Results for Radiative Heat Transfer Quantities

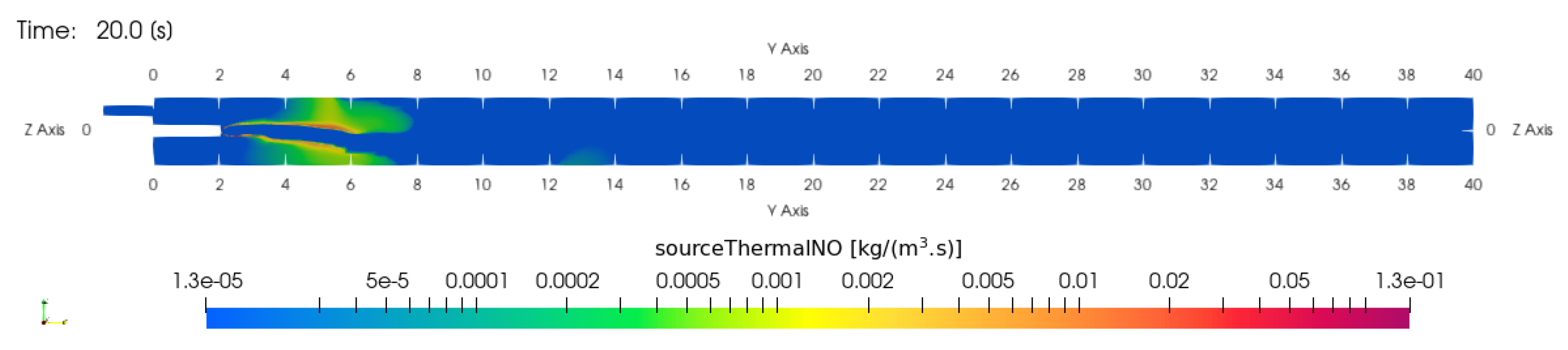

5.5. Results for Thermal NO Concentration

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boateng, A. Rotary Kilns: Transport Phenomena and Transport Processes; Elsevier Science: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Giannopoulos, D.; Kolaitis, D.; Togkalidou, A.; Skevis, G.; Founti, M. Quantification of Emissions from the Co-Incineration of Cutting Oil Emulsions in Cement Plants: Part I: NOx, CO and VOC. Fuel 2007, 86, 1144–1152. [Google Scholar] [CrossRef]

- Larsson, I.S.; Lundström, T.S.; Marjavaara, B.D. Calculation of kiln aerodynamics with two RANS turbulence models and by DDES. Flow Turbul. Combust. 2015, 94, 859–878. [Google Scholar] [CrossRef]

- Elattar, H.F.; Specht, E.; Fouda, A.; Rubaiee, S.; Al-Zahrani, A.; Nada, S.A. Swirled Jet Flame Simulation and Flow Visualization Inside Rotary Kiln?CFD with PDF Approach. Processes 2020, 8, 159. [Google Scholar] [CrossRef] [Green Version]

- Gunnarsson, A.; Bckstrm, D.; Johansson, R.; Fredriksson, C.; Andersson, K. Radiative heat transfer conditions in a rotary kiln test furnace using coal, biomass, and cofiring burners. Energy Fuels 2017, 31, 7482–7492. [Google Scholar] [CrossRef]

- Edland, R.; Smith, N.; Allgurén, T.; Fredriksson, C.; Normann, F.; Haycock, D.; Johnson, C.; Frandsen, J.; Fletcher, T.H.; Andersson, K. Evaluation of NOx-Reduction Measures for Iron-Ore Rotary Kilns. Energy Fuels 2020, 34, 4934–4948. [Google Scholar] [CrossRef]

- Chen, Z.X.; Langella, I.; Swaminathan, N.; Stöhr, M.; Meier, W.; Kolla, H. Large Eddy Simulation of a dual swirl gas turbine combustor: Flame/flow structures and stabilisation under thermoacoustically stable and unstable conditions. Combust. Flame 2019, 203, 279–300. [Google Scholar] [CrossRef] [Green Version]

- Tekgül, B.; Peltonen, P.; Kahila, H.; Kaario, O.; Vuorinen, V. DLBFoam: An open-source dynamic load balancing model for fast reacting flow simulations in OpenFOAM. Comput. Phys. Commun. 2021, 267, 108073. [Google Scholar] [CrossRef]

- Sforza, L.; Abdelwahid, S.; Lucchini, T.; Onorati, A. Ultra-Lean Premixed Turbulent Combustion: Challenges of RANS modeling. Energies 2022, 15, 5947. [Google Scholar] [CrossRef]

- Ge, W.; Marquez, R.; Modest, M.F.; Roy, S.P. Implementation of High-Order Spherical Harmonics Methods for Radiative Heat Transfer on OpenFoam. J. Heat Transf. 2015, 137, 052701. [Google Scholar] [CrossRef]

- Sun, Y.; Shen, H.; Zheng, S.; Jiang, L. A hybrid non-gray gas radiation heat transfer solver based on OpenFOAM. J. Quant. Spectrosc. Radiat. Transf. 2022, 281, 108105. [Google Scholar] [CrossRef]

- Wu, B.; Ihme, M.; Zhao, X. Limitations of flamelet formulation for modeling turbulent pool fires. Combust. Flame 2021, 227, 346–358. [Google Scholar] [CrossRef]

- Nguyen, D.N.; Jung, K.S.; Shim, J.W.; Yoo, C.S. Real-fluid thermophysicalModels: An OpenFOAM-based library for reacting flow simulations at high pressure. Comput. Phys. Commun. 2022, 273, 108264. [Google Scholar] [CrossRef]

- Zhang, Y.; Vanierschot, M. Modeling capabilities of unsteady RANS for the simulation of turbulent swirling flow in an annular bluff-body combustor geometry. Appl. Math. Model. 2021, 89, 1140–1154. [Google Scholar] [CrossRef]

- Moukalled, F.; Mangani, L.; Darwish, M. The Finite Volume Method in Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2016; Volume 113. [Google Scholar]

- Poinsot, T.; Lelef, S. Boundary conditions for direct simulations of compressible viscous flows. J. Comput. Phys. 1992, 101, 104–129. [Google Scholar] [CrossRef]

- Lahaye, D.; Nakate, P.; Vuik, K.; Juretić, F.; Talice, M. Modeling Conjugate Heat Transfer in an Anode Baking Furnace Using OpenFoam. Fluids 2022, 7, 124. [Google Scholar] [CrossRef]

- Lahaye, D.; Abbassi, M.E.; Vuik, K.; Talice, M.; Juretić, F. Mitigating Thermal NOx by Changing the Secondary Air Injection Channel: A Case Study in the Cement Industry. Fluids 2020, 5, 220. [Google Scholar] [CrossRef]

- Talice, M.; Juretić, F.; Lahaye, D. Turbulent Non-Stationary Reactive Flow in a Cement Kiln. Fluids 2022, 7, 205. [Google Scholar] [CrossRef]

- Law, C. Combustion Physics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Poinsot, T.; Veynante, D. Theoretical and Numerical Combustion, 2nd ed.; R.T. Edwards, Inc.: Spring Hope, NC, USA, 2005. [Google Scholar]

- Baukal, C. Industrial Combustion Pollution and Control; Environmental Science & Pollution; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Modest, M.F.; Haworth, D.C. Radiative Heat Transfer in Turbulent Combustion Systems: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Ferziger, J.; Perić, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Magnussen, B.F. The eddy dissipation concept: A bridge between science and technology. In Proceedings of the ECCOMAS Thematic Conference on Computational Combustion, Libson, Portugal, 21–24 June 2005; Volume 21, p. 24. [Google Scholar]

- Ertesvåg, I.S. Analysis of some recently proposed modifications to the Eddy Dissipation Concept (EDC). Combust. Sci. Technol. 2020, 192, 1108–1136. [Google Scholar] [CrossRef]

- Versteeg, H.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method, 2nd ed.; Pearson Education Limited: London, UK, 2007. [Google Scholar]

- Kadar, A.H. Modeling Turbulent Non-Premixed Combustion in Industrial Furnaces. Master’s Thesis, TU Delft, Delft, The Netherlands, 2015. [Google Scholar]

- Juretic, F. cfMesh Version 1.1 Users Guide. Available online: http://cfmesh.com/wp-content/uploads/2015/09/User_Guide-cfMesh_v1.1.pdf (accessed on 1 November 2020).

- Elattar, H.F.; Specht, E.; Fouda, A.; Bin-Mahfouz, A.S. Study of parameters influencing fluid flow and wall hot spots in rotary kilns using CFD. Can. J. Chem. Eng. 2016, 94, 355–367. [Google Scholar] [CrossRef]

- Pisaroni, M.; Sadi, R.; Lahaye, D. Counteracting ring formation in rotary kilns. J. Math. Ind. 2012, 2, 1–19. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lahaye, D.; Juretić, F.; Talice, M. Modelling a Turbulent Non-Premixed Combustion in a Full-Scale Rotary Cement Kiln Using reactingFoam. Energies 2022, 15, 9618. https://doi.org/10.3390/en15249618

Lahaye D, Juretić F, Talice M. Modelling a Turbulent Non-Premixed Combustion in a Full-Scale Rotary Cement Kiln Using reactingFoam. Energies. 2022; 15(24):9618. https://doi.org/10.3390/en15249618

Chicago/Turabian StyleLahaye, Domenico, Franjo Juretić, and Marco Talice. 2022. "Modelling a Turbulent Non-Premixed Combustion in a Full-Scale Rotary Cement Kiln Using reactingFoam" Energies 15, no. 24: 9618. https://doi.org/10.3390/en15249618

APA StyleLahaye, D., Juretić, F., & Talice, M. (2022). Modelling a Turbulent Non-Premixed Combustion in a Full-Scale Rotary Cement Kiln Using reactingFoam. Energies, 15(24), 9618. https://doi.org/10.3390/en15249618