Meso-Mechanical Characteristics of Granite with Natural Cracks after Mud Acid Corrosion

Abstract

:1. Introduction

2. Mud Acid Corrosion on the Microstructure of Granite

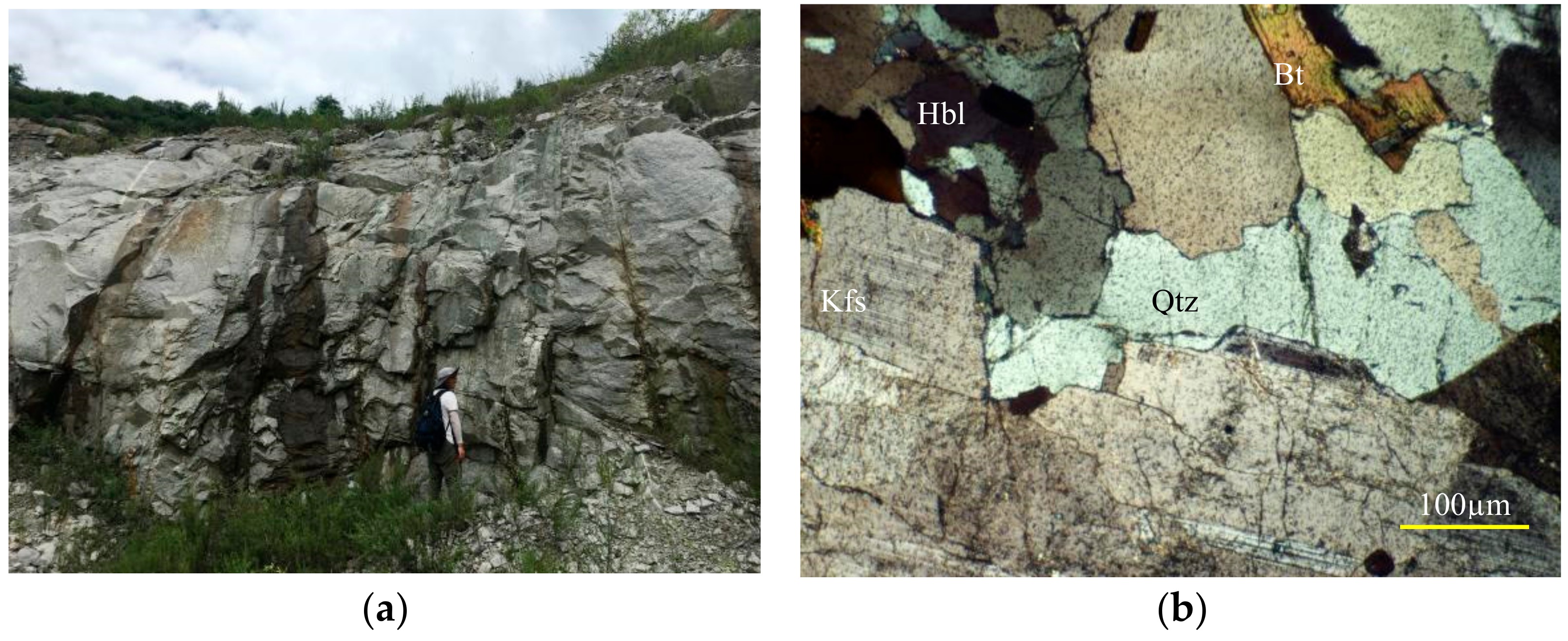

2.1. Sampling Location and Mineral Composition of Granite

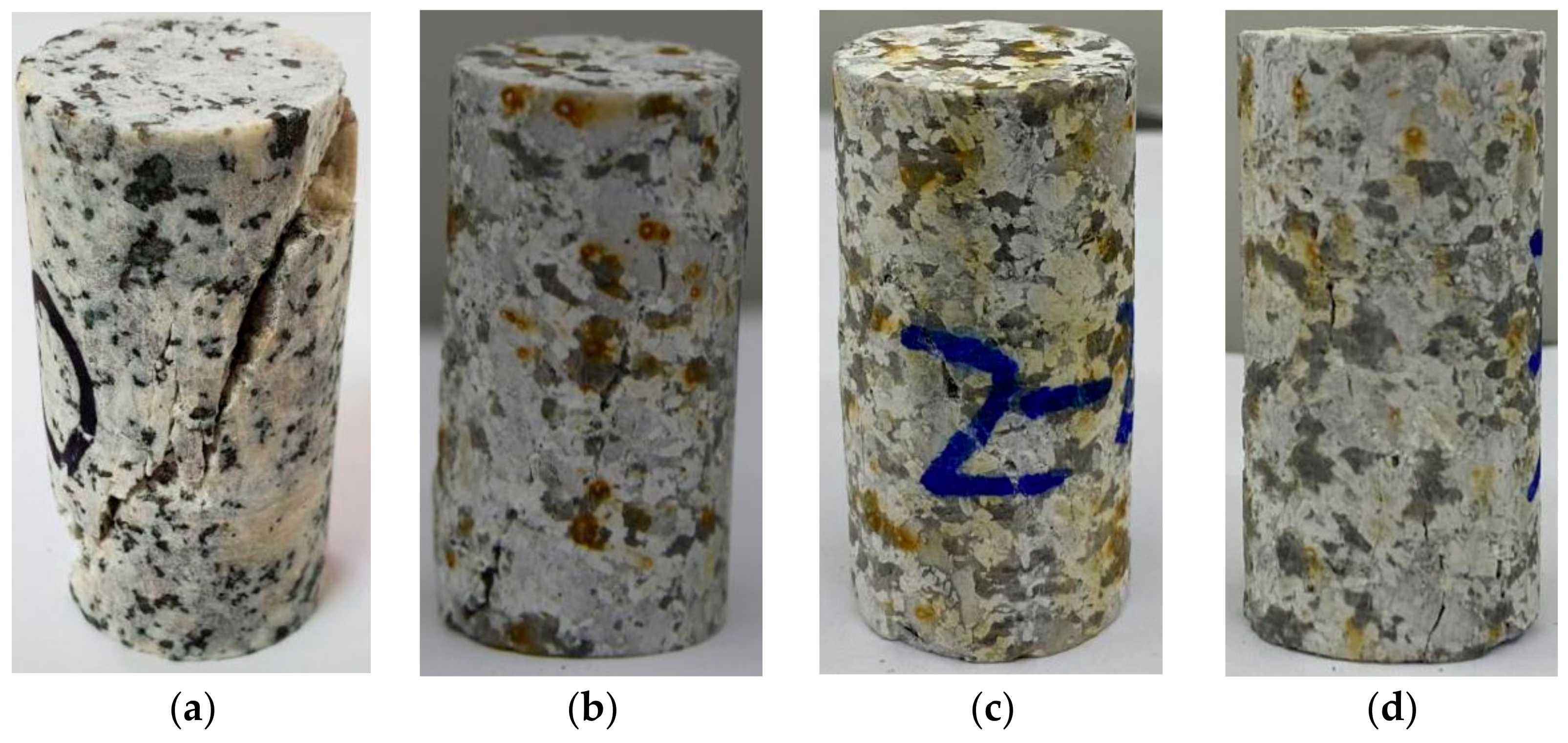

2.2. Mud Acid Corrosion and Triaxial Compression Mechanical Tests

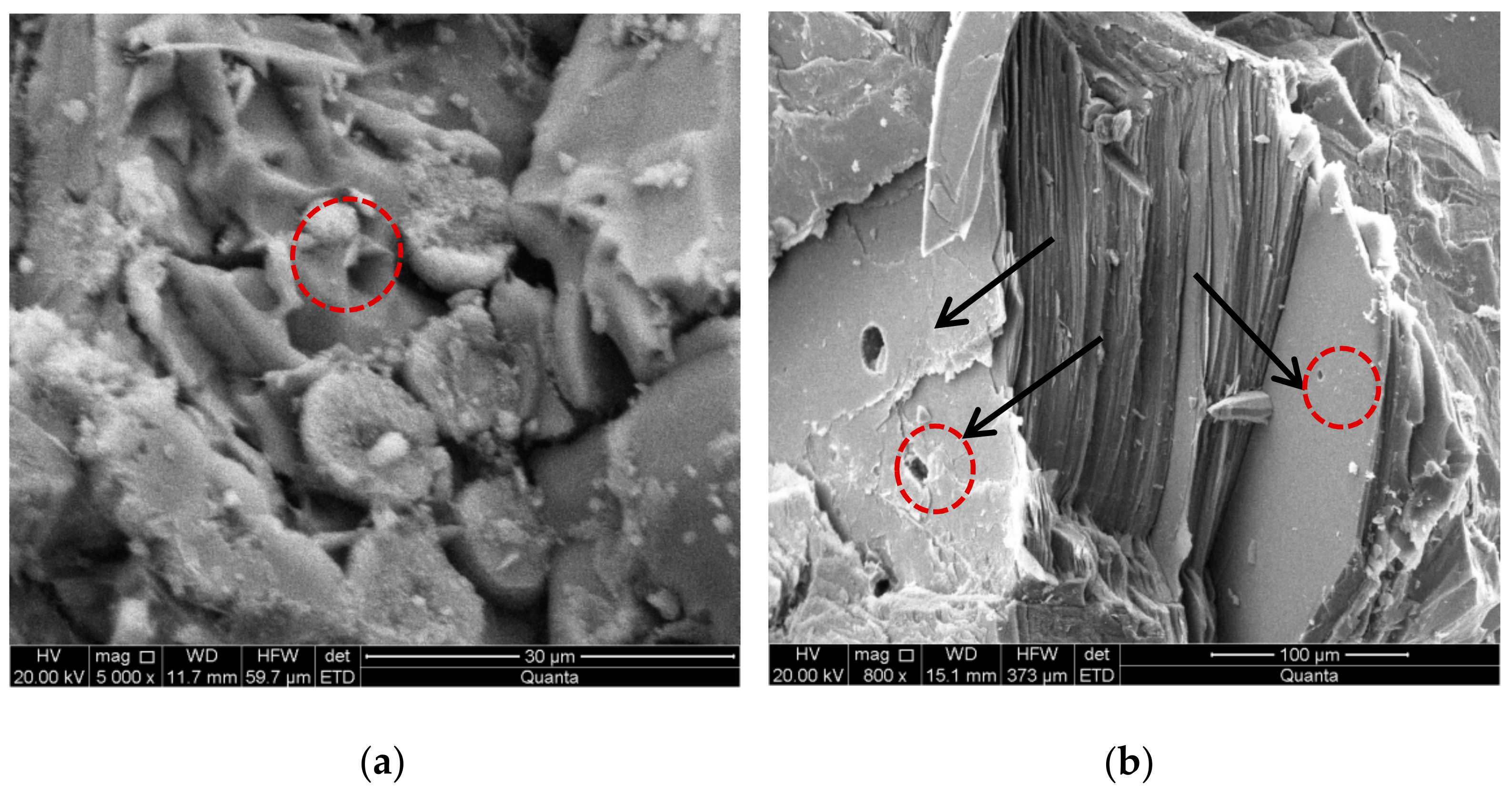

2.3. Experimental Analysis of Mud Acid Corrosion on Microstructure

2.4. Mechanical Characteristics of Granite after Mud Acid Corrosion in the Triaxial Compression Tests

3. Numerical Model Establishment and Parameters Input

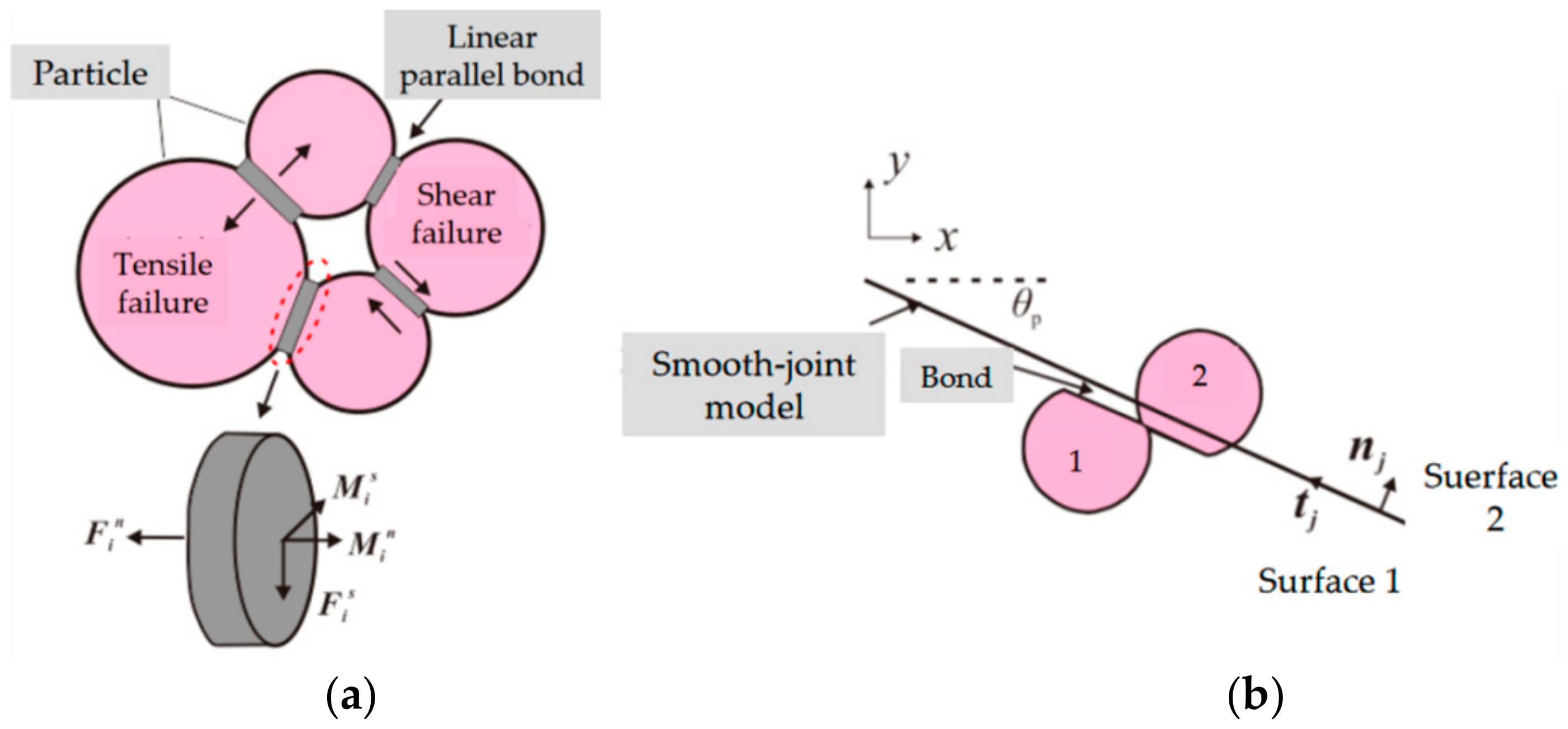

3.1. Theory of Discrete Element Method and Contact Models Used in the PFC2D Simulater

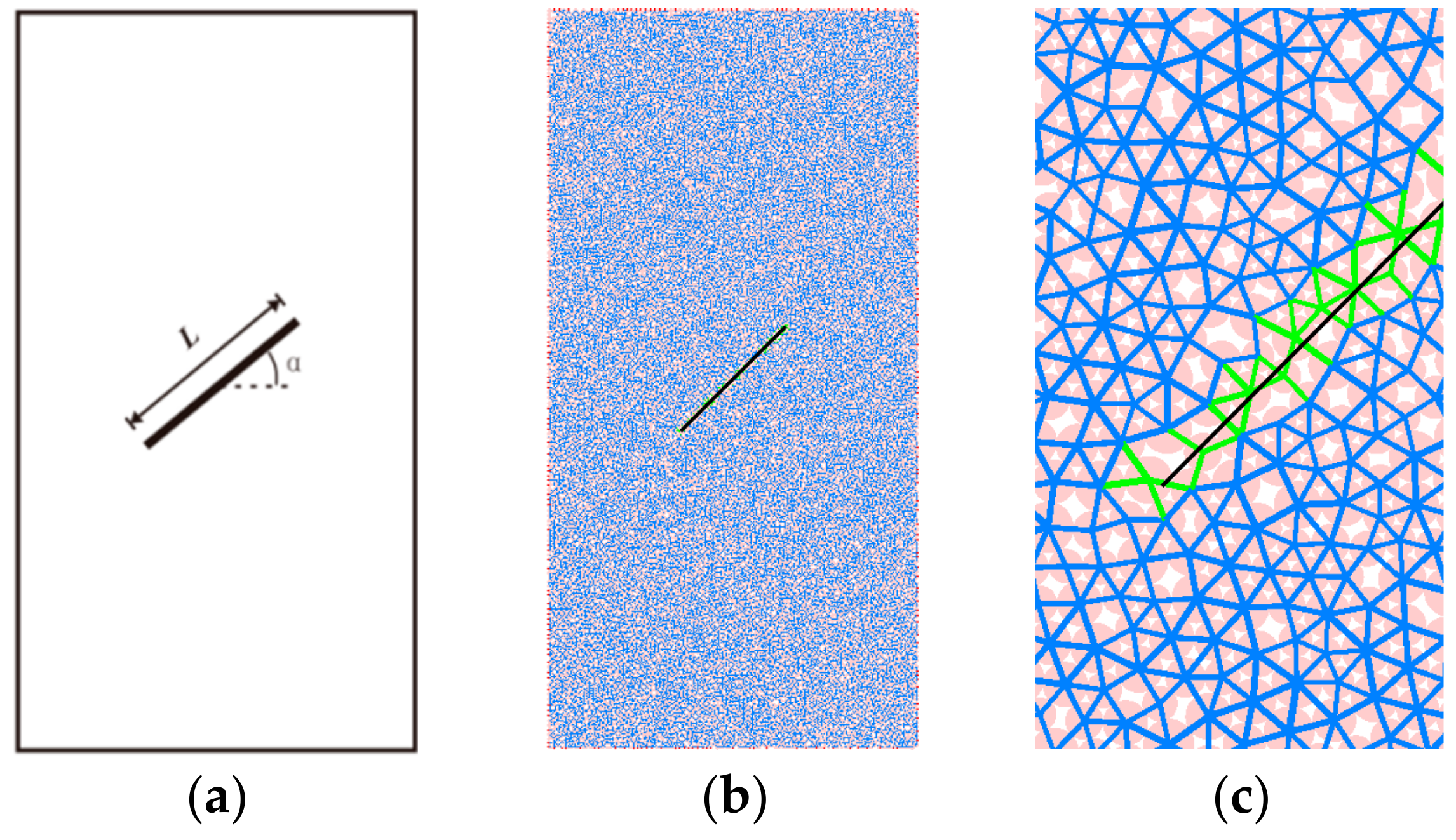

3.2. Establishment of Geometry

3.3. Calibration of Micro-Parameters Based on Experimental Data

3.3.1. Adjustment of Micro-Parameters for the Granite Matrix

3.3.2. Adjustment of Micro-Parameters for Single Main Closed Crack in Granite

3.3.3. Boundary Conditions

4. Results

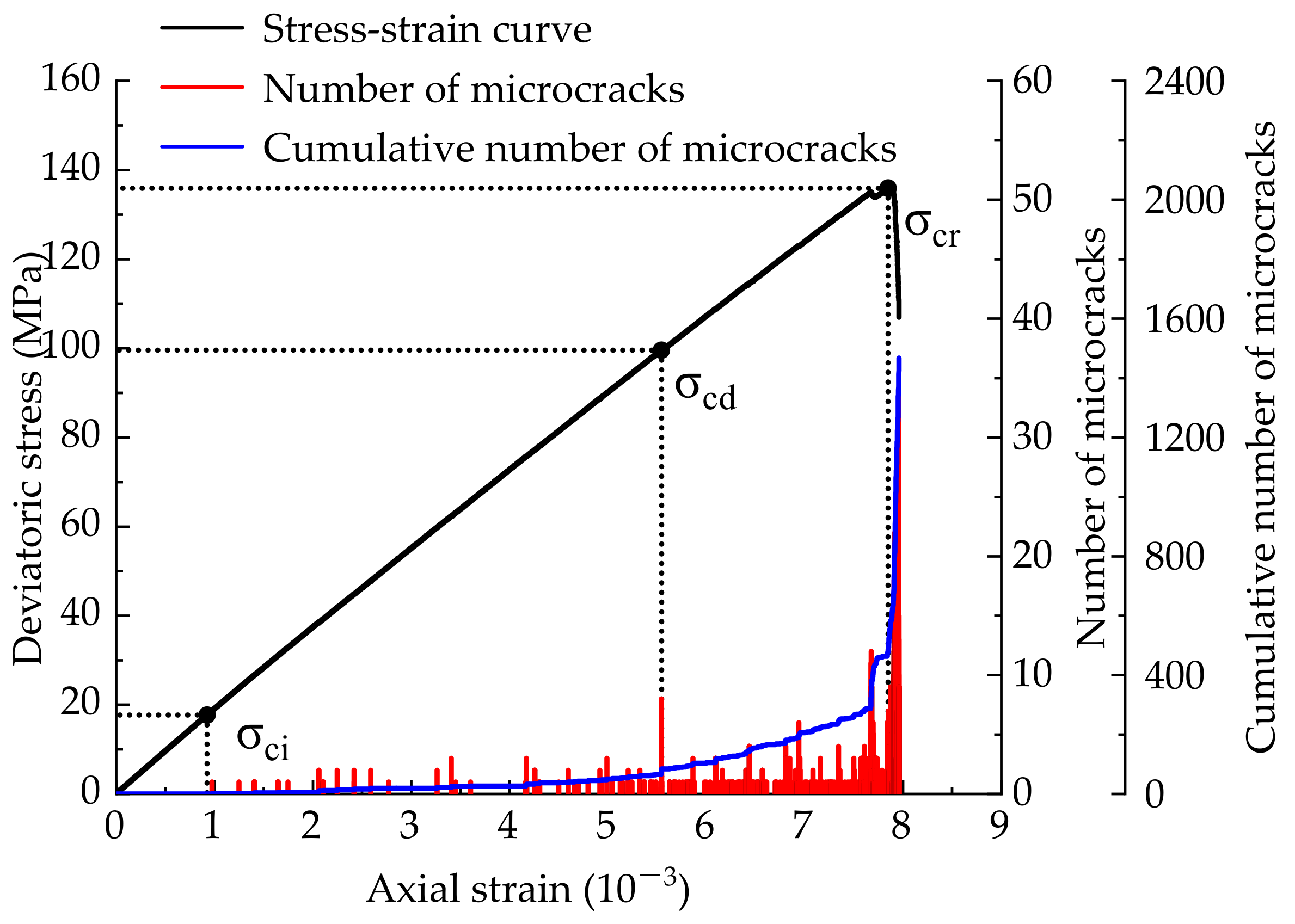

4.1. Characteristic Strength Analysis of the Fractured Rock during Loading

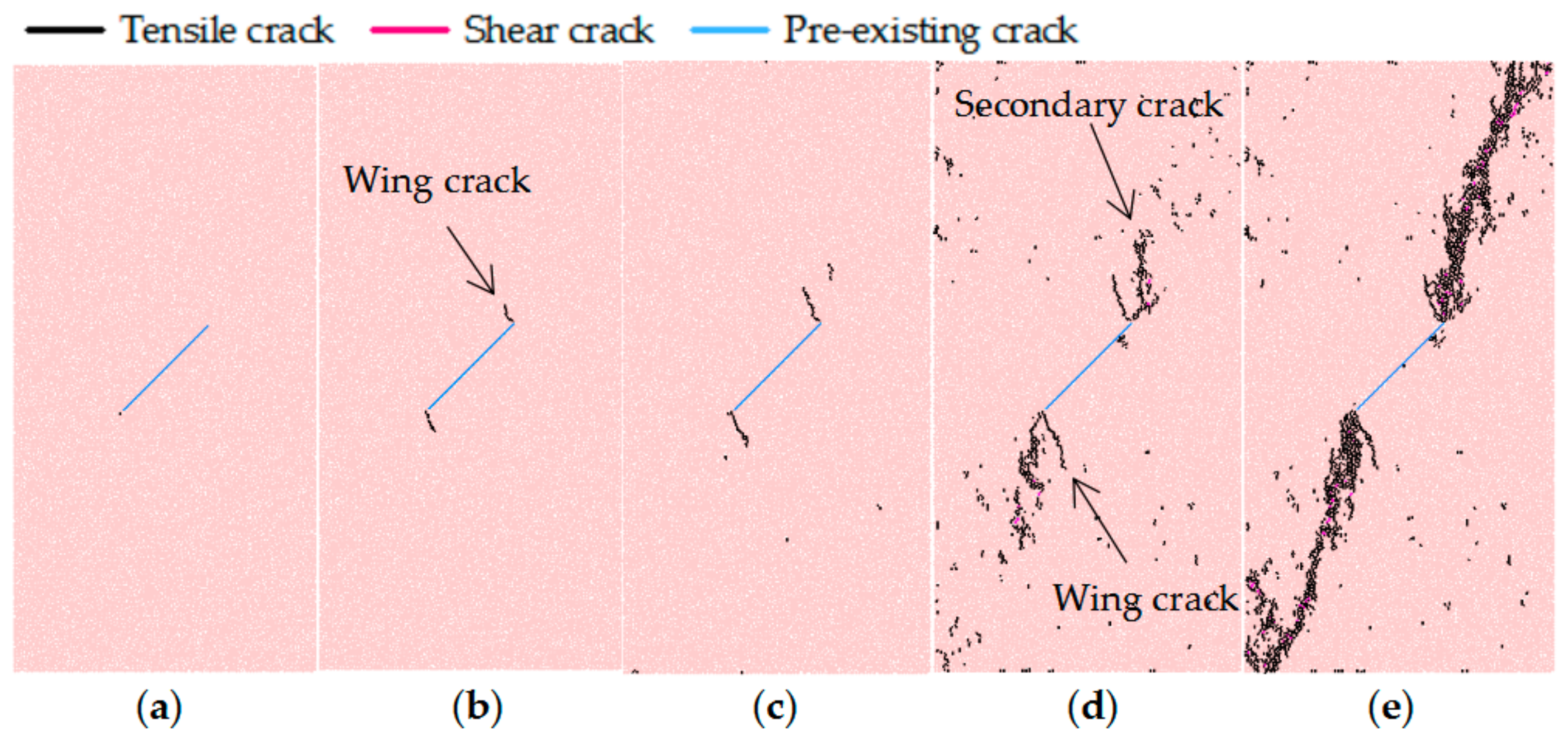

4.2. Damage Mechanism Analysis

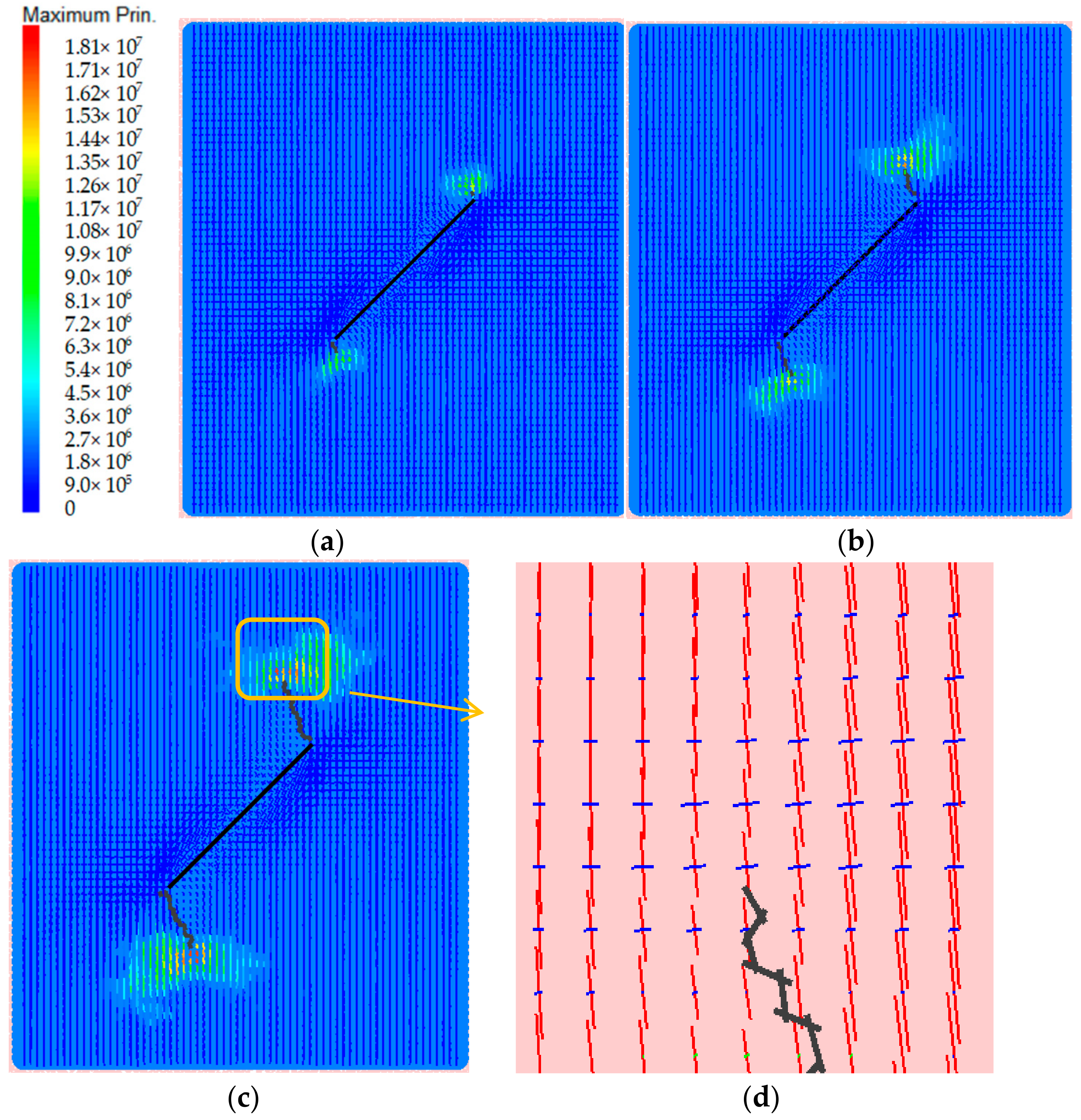

4.3. Local Stress Distribution in the Granite with a Single Main Crack

5. Discussion

5.1. Failure Modes of Granite under Different Conditions

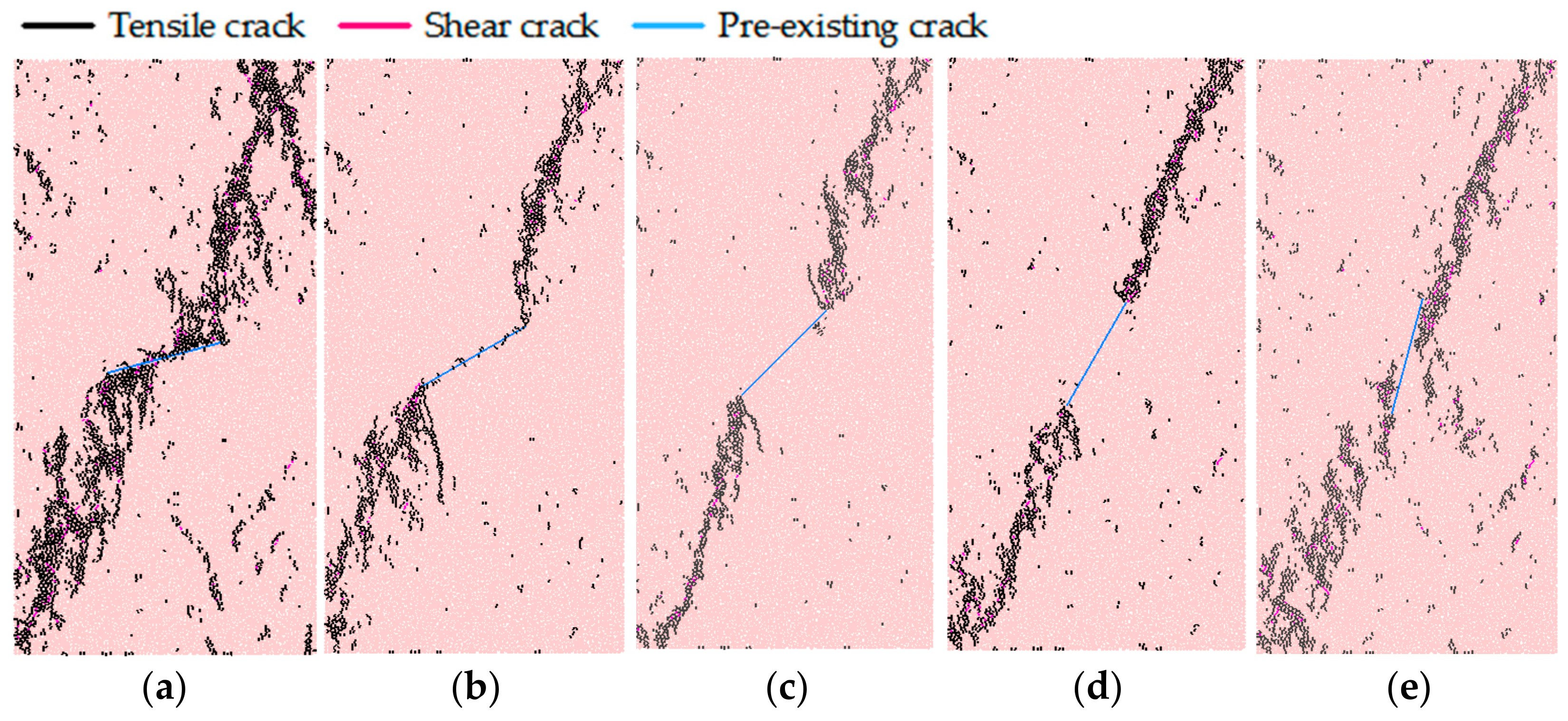

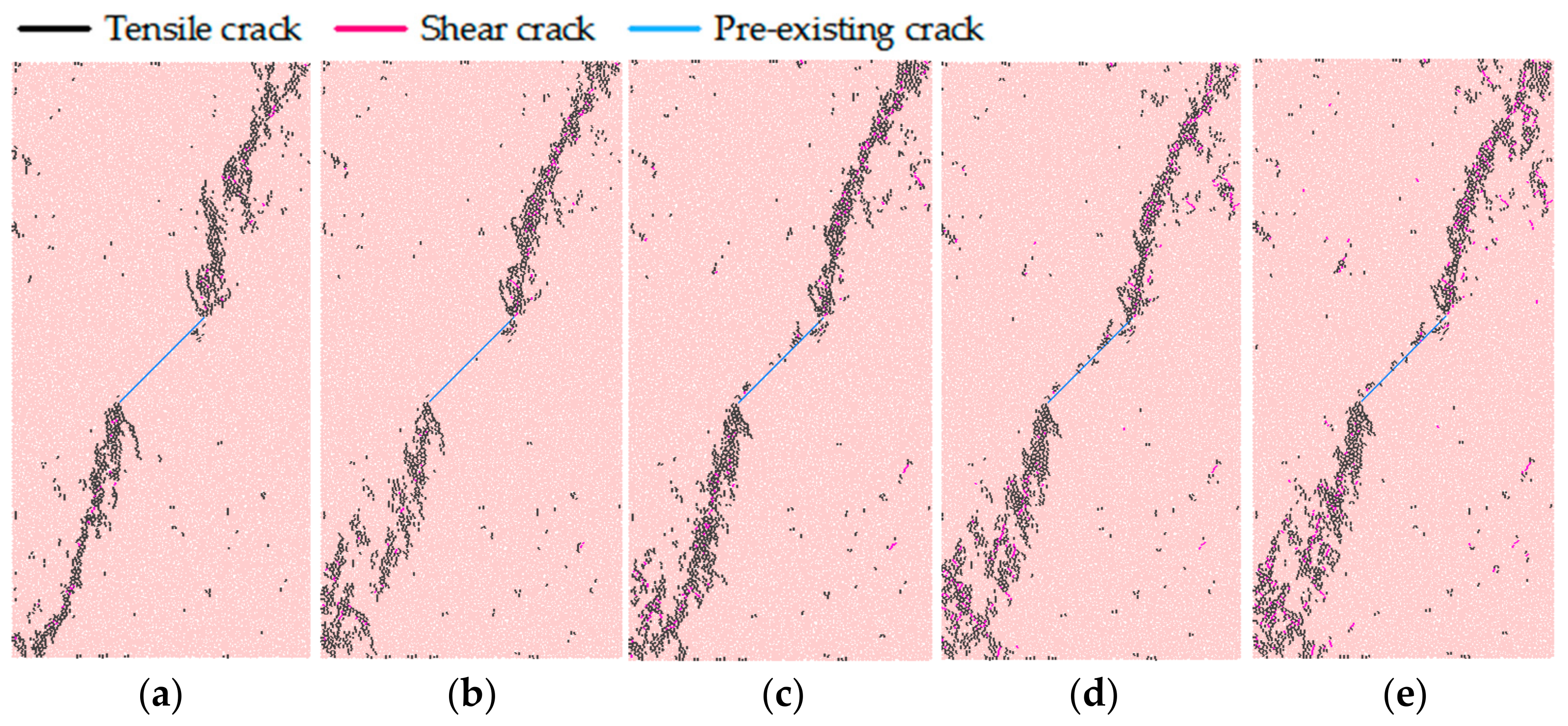

5.1.1. Influence of Pre-Existing Crack Inclination Angle

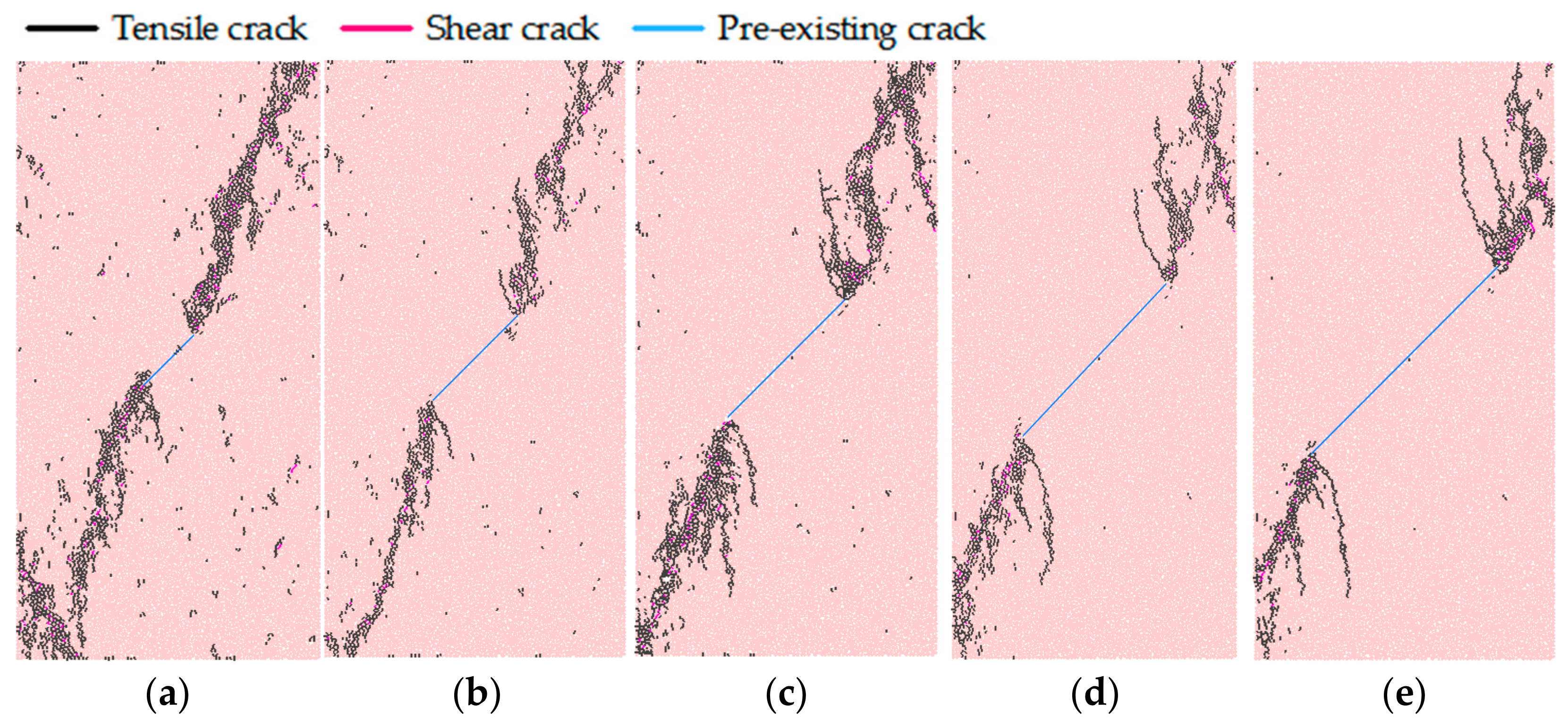

5.1.2. Influence of Main Crack Length

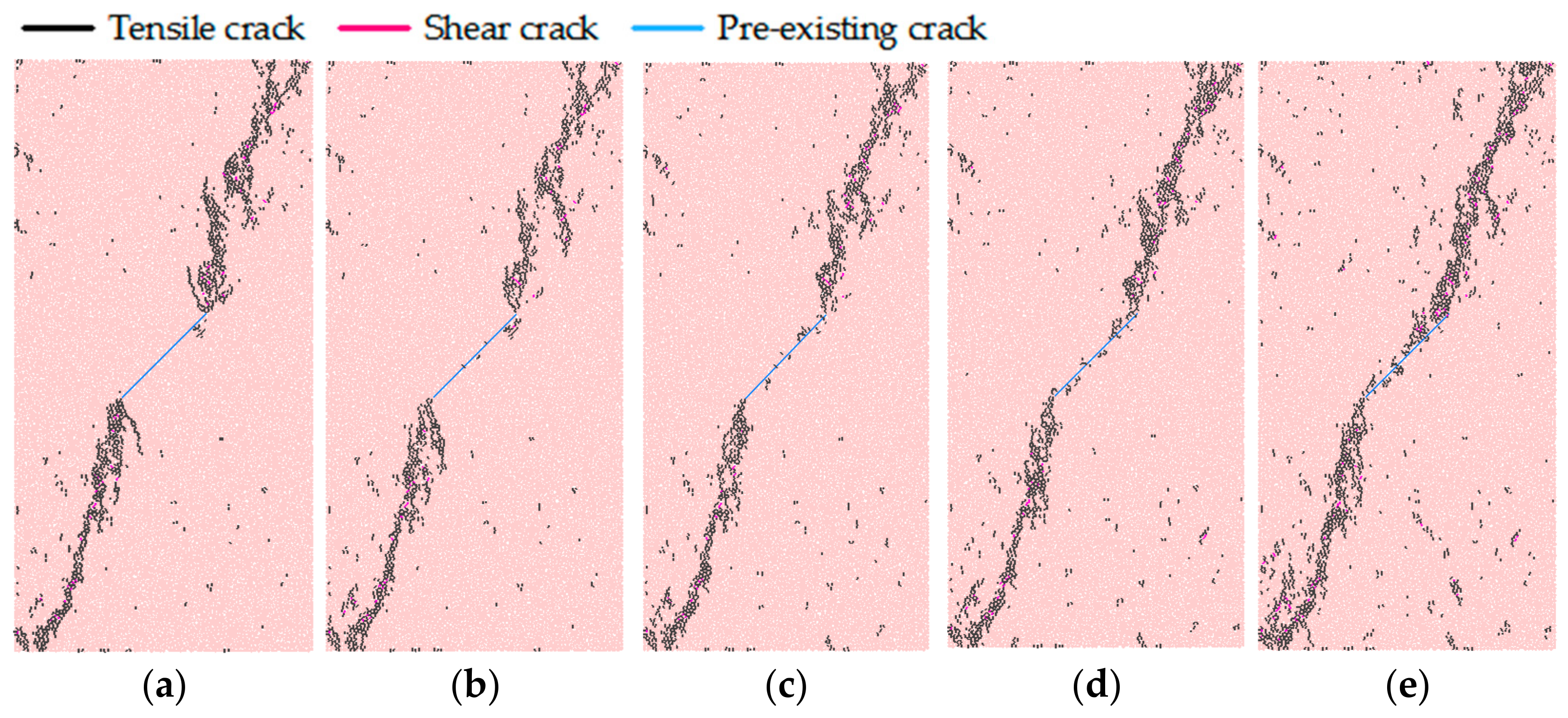

5.1.3. Influence of Crack Surface Friction Coefficient

5.1.4. Influence of Confining Pressure

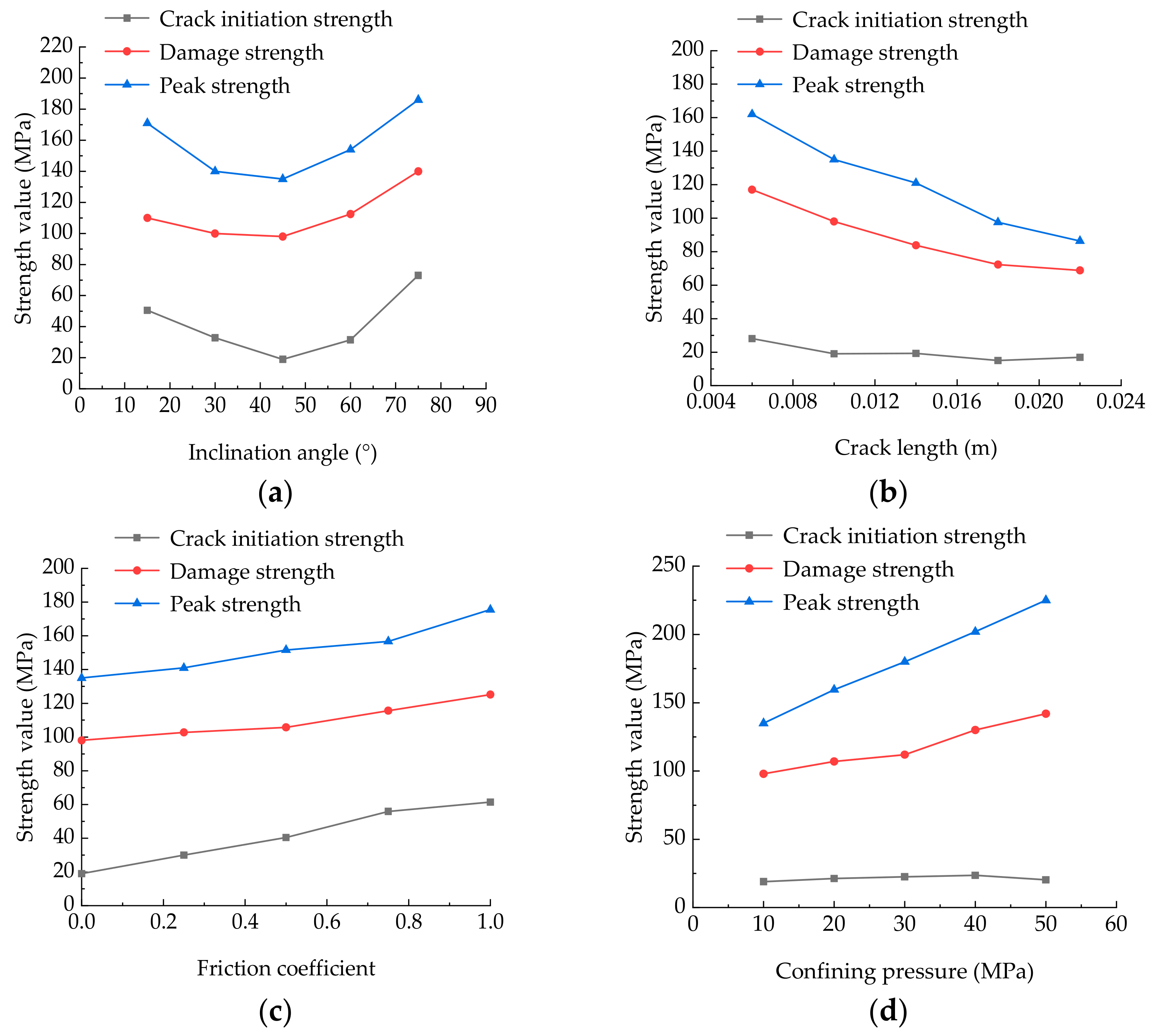

5.2. Analysis of Characteristic Strength

6. Conclusions

- (1)

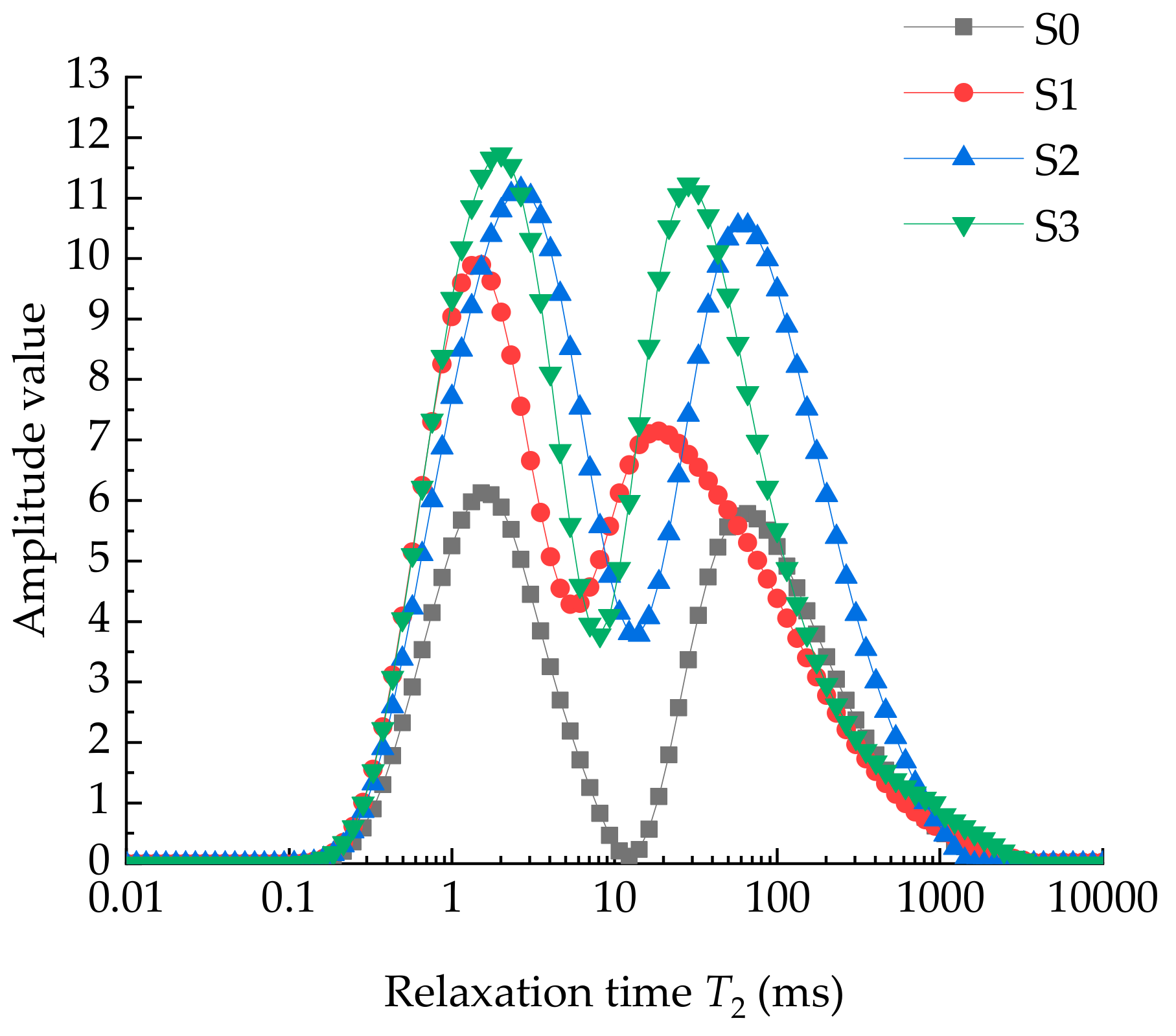

- With the increase of the concentration of mud acid solution from 8 wt% HCl + 1 wt% HF to 12 wt% HCl + 3 wt% HF, the amplitudes of two peaks in the T2 spectrum curve increase, indicating that the number of micropores is significantly increased and the corrosion effect is strengthened. In the compression process, the elastic modulus of granite samples after mud acid corrosion are seriously deteriorated from 29.6 GPa to 24.7 GPa, and the compressive strengths are deteriorated from 258 MPa to 194.2 MPa.

- (2)

- The triaxial compression simulation tests show that, when the deviatoric stress reaches the crack initiation strength , the wing cracks initiate in the tensile stress area at both ends of the main crack and expand perpendicularly to the main crack. The number of microcracks increases steadily, which is basically linearly related to the axial strain. When the deviatoric stress reaches the damage strength of granite, secondary cracks occur at the tip of the main crack and continue to propagate towards the top and bottom edge of the rock. At the same time, the relationship between the number of microcracks and axial strain changes from linear growth trend in the previous stage to exponential growth state. Until the deviatoric stress reaches the peak strength , the macroscopic shear surface is completely formed and the specimen is destroyed.

- (3)

- The effects of main closed crack inclination angle, crack length, crack surface friction coefficient and confining pressure on the three characteristic strengths are different. With the increase of inclination angle, all three characteristic strengths decrease at first and then increase. They decrease with inclination angle that is smaller than 45°, while increase with the inclination angle that is larger than 45°. When the length of the main pre-existing crack increases from 6 mm to 22 mm, these three characteristic strengths (//) decrease 60%, 59% and 53%, respectively. The increase of main crack surface friction coefficient from 0 to 1.0 will improve these three characteristic strengths, and their increments are similar. , and have a good linear relationship with confining pressure. The crack initiation strength is hardly affected by the confining pressure, and the peak strength will increase significantly with the increase of confining pressure from 10 to 50 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soltani, M.; Farshad, M.K.; Mohammd, S.; Behnam, R.; Mohammad, J.; Kobra, G.; Jatin, S.N. Environmental, economic, and social impacts of geothermal energy systems. Renew. Sustain. Energy Rev. 2021, 140, 110750. [Google Scholar] [CrossRef]

- Ramos-Escudero, A.; García-Cascales, M.S.; Urchueguía, J.F. Evaluation of the shallow geothermal potential for heating and cooling and its integration in the socioeconomic environment: A case study in the region of Murcia, Spain. Energies 2021, 14, 5740. [Google Scholar] [CrossRef]

- Knoblauch, T.; Stauffacher, M.; Trutnevyte, E. Communicating low-probability high-consequence risk, uncertainty and expert confidence: Induced seismicity of deep geothermal energy and shale gas. Risk Anal. 2018, 38, 694–709. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G. A systematic review of enhanced (or engineered) geothermal systems: Past, present and future. Geotherm. Energy 2013, 1, 4. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.R.; Li, M.L.; Wang, S.Y.; Guo, Q.Q.; Guo, L.; Wang, G.L.; Wang, X.Y. Present situation and prospect of hot dry rock exploration and development. Oil Drill. Prod. Technol. 2018, 40, 526–540. [Google Scholar]

- Hofmann, H.; Babadagli, T.; Zimmermann, G. Hot water generation for oil sands processing from enhanced geothermal systems:process simulation for different hydraulic fracturing scenarios. Appl. Energy 2014, 2014, 524–547. [Google Scholar] [CrossRef]

- Rodriguez, V.O.; Valdez, A.V.; Borderie, C.L.; Pijaudier, C.G.; Rivera, M.H. Estimation of fracture energy from hydraulic fracture tests on mortar and rocks at geothermal reservoir temperatures. Rock Mech. Rock Eng. 2021, 54, 4111–4119. [Google Scholar] [CrossRef]

- Timothy, K. The EGS Collab Project: An intermediate scale field test to address enhanced geothermal system challenges. E3S Web Conf. 2020, 205, 01002. [Google Scholar] [CrossRef]

- Yutkin, M.P.; Radke, C.J.; Patzek, T.W. Chemical compositions in salinity waterflooding of carbonate reservoirs: Theory. Transp. Porous Media 2021, 136, 411–429. [Google Scholar] [CrossRef]

- Talukdar, M.; Roy, D.G.; Singh, T.N. Correlating mode-I fracture toughness and mechanical properties of heat-treated crystalline rocks. J. Rock Mech. Geotech. Eng. 2018, 10, 91–101. [Google Scholar] [CrossRef]

- Wojtacki, K.; Daridon, L.; Monerie, Y. Computing the elastic properties of sandstone submitted to progressive dissolution. Int. J. Rock Mech. Min. Sci. 2017, 95, 16–25. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Ling, S.; Wu, X.; Chen, J.; Jiang, W. Oxidation of black shale and its deterioration mechanism in the slip zone of the Xujiaping landslide in Sichuan Province, Southwestern China. Catena 2021, 200, 105139. [Google Scholar] [CrossRef]

- Miao, S.J.; Cai, M.F.; Guo, Q.F.; Wang, P.T.; Liang, M.C. Damage effects and mechanisms in granite treated with acidic chemical solutions. Int. J. Rock Mech. Min. Sci. 2016, 88, 77–86. [Google Scholar] [CrossRef]

- Miao, Z.; Li, S.; Xie, J.; Huo, R.; Li, X. Three-dimensional reconstruction and numerical simulation analysis of acid-corroded sandstone based on CT. Shock. Vib. 2021, 2021, 1–14. [Google Scholar] [CrossRef]

- Paccaloni, G.; Tambini, M. Advances in matrix stimulation technology. J. Pet. Technol. 1993, 45, 256–263. [Google Scholar] [CrossRef]

- Portier, S.; Vuataz, F.D.; Nami, P.; Sanjuan, B.; Gerard, A. Chemical stimulation techniques for geothermal wells: Experiments on the three-well EGS system at Soultz-sous-Forêts, France. Geothermics 2009, 38, 349–359. [Google Scholar] [CrossRef]

- Schill, E.; Genter, A.; Cuenot, N.; Kohl, T. Hydraulic performance history at the Soultz EGS reservoirs from stimulation and long-term circulation tests. Geothermics 2017, 70, 110–124. [Google Scholar] [CrossRef]

- Luo, J.; Zhu, Y.; Guo, Q.; Tan, L.; Zhuang, Y.; Liu, M.; Zhang, C.; Zhu, M.; Xiang, W. Chemical stimulation on the hydraulic properties of artificially fractured granite for enhanced geothermal system. Energy 2018, 142, 754–764. [Google Scholar] [CrossRef]

- Lin, C.; Mao, J.; Yang, X.; Zhao, J. Experimental study on the strength and failure mechanism of hollow hot dry rocks under brazilian splitting tests. Arab. J. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Liu, X.; Wu, L.; Zhang, Y.; Wu, X. The characteristics of crack existence and development during rock shear fracturing evolution. Bull. Eng. Geol. Environ. 2020, 80, 1671–1682. [Google Scholar] [CrossRef]

- Misra, S.; Mandal, N.; Dhar, R.; Chakraborty, C. Mechanisms of deformation localization at the tips of shear fractures: Findings from analogue experiments and field evidence. J. Geophys. Res. Solid Earth 2009, 114. [Google Scholar] [CrossRef]

- Willemse, E.J.M.; Pollard, D.D. On the orientation and patterns of wing cracks and solution surfaces at the tips of a sliding flaw or fault. J. Geophys. Res. Solid Earth 1998, 103, 2427. [Google Scholar] [CrossRef]

- Einstein, A.B.H. Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1998, 35, 863–888. [Google Scholar]

- Lee, H.; Jeon, S. An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int. J. Solids Struct. 2011, 48, 979–999. [Google Scholar] [CrossRef] [Green Version]

- Wong, R.; Chau, K.T. Crack coalescence in a rock-like material containing two cracks. Int. J. Rock Mech. Min. Sci. 1998, 35, 147–164. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, Q.; Lu, Z.; Wan, L.; Gao, G. Numerical simulation of conical pick cutting arc rock plate fracture based on ANSYS/LS-DYNA. Adv. Mater. Sci. Eng. 2020, 2020, 6563520. [Google Scholar] [CrossRef]

- Zhang, W. Numerical and theoretical analysis on hydraulic fracture of rock masses based on contour integral and auto-remeshing technology. Geotech. Geol. Eng. 2020, 38, 4675–4684. [Google Scholar] [CrossRef]

- Fu, J.W.; Chen, K.; Zhu, W.S.; Zhang, X.Z.; Li, X.J. Progressive failure of new modelling material with a single internal crack under biaxial compression and the 3-D numerical simulation. Eng. Fract. Mech. 2016, 165, 140–152. [Google Scholar] [CrossRef]

- Mei, W.; Li, M.; Pan, P.Z.; Pan, J.; Liu, K. Blasting induced dynamic response analysis in a rock tunnel based on combined inversion of Laplace transform with elasto-plastic cellular automaton. Geophys. J. Int. 2021, 225, 699–710. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Hadjigeorgiou, J.; Esmaieli, K.; Grenon, M. Stability analysis of vertical excavations in hard rock by integrating a fracture system into a PFC model. Tunn. Undergr. Space Technol. 2009, 24, 296–308. [Google Scholar] [CrossRef]

- Shemirani, A.B.; Sarfarazi, V.; Haeri, H. Direct and indirect methods for determination of mode I fracture toughness using PFC2D. Comput. Concr. 2017, 20, 57–63. [Google Scholar]

- Li, S.; Liu, J.; Zhao, G.; Wu, F.; Han, Z.; Yang, Z. Key geochronology of Mesozoic deformation in the eastern block of the North China Craton and its constraints on regional tectonics: A case of Jiaodong and Liaodong Peninsula. Acta Petrol. Sin. 2004, 2, 633–646. [Google Scholar]

- Liu, J.L.; Mo, J.I.; Shen, L.; Guan, H.M.; Davis, G.A. Early Cretaceous extensional structures in the Liaodong Peninsula:Structural associations, geochronological constraints and regional tectonic implications. Sci. China 2011, 54, 823–842. [Google Scholar] [CrossRef]

- Liu, H.J.; Wang, H.W.; Lei, H.W.; Zhang, L.W.; Zhou, L. Numerical modeling of thermal breakthrough induced by geothermal production in fractured granite. J. Rock Mech. Geotech. Eng. 2020, 12, 900–916. [Google Scholar] [CrossRef]

- Claudio, D.P.; Alessio, A.; Joel, S.; Lionel, E.; Emilie, C. Micro-crack enhanced permeability in tight rocks: An experimental and microstructural study. Tectonophysics 2015, 665, 149–156. [Google Scholar]

- Liu, H.J.; Shi, Y.K.; Fang, Z.M.; Liu, J.F.; Zhang, L.W.; Tong, R.C. Seepage characteristics of thermally and chemically treated Mesozoic granite from geothermal region of Liaodong Peninsula. Environ. Earth Sci. 2021, 80, 599. [Google Scholar] [CrossRef]

- Crundwell, F.K. The mechanism of dissolution of minerals in acidic and alkaline solutions: Part II application of a new theory to silicates, aluminosilicates and quartz. Hydrometallurgy 2014, 149, 265–275. [Google Scholar] [CrossRef]

- Tsomaia, N.; Brantley, S.L.; Hamilton, J.P.; Pantano, C.G.; Mueller, K.T. NMR evidence for formation of octahedral and tetrahedral Al and repolymerization of the Si network during dissolution of aluminosilicate glass and crystal. Am. Mineral. 2003, 88, 54–67. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, X.; Zhang, S.F. Multi-peak deformation behavior of jointed rock mass under uniaxial compression: Insight from particle flow modeling. Eng. Geol. 2016, 213, 25–45. [Google Scholar] [CrossRef]

- Fakhimi, A.; Villegas, T. Application of dimensional analysis in calibration of a discrete element model for rock deformation and fracture. Rock Mech. Rock Eng. 2007, 40, 193–211. [Google Scholar] [CrossRef]

- Yoon, J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int. J. Rock Mech. Min. Sci. 2007, 44, 871–889. [Google Scholar] [CrossRef]

- Li, W.H.H. Relationship between the deformation characteristics and microscopic properties of sandstone explored by the bonded-particle model. Int. J. Rock Mech. Min. Sci. 2012, 56, 34–43. [Google Scholar]

- Bai, S.; Ren, W.; Feng, D.; Chen, J.; Chia, J. Failure mechanism and strength properties of rockmass containing close intermittent joints under plane stress condition. Chin. J. Rock Mech. Eng. 1999, 18, 635–640. [Google Scholar]

- Xian, W.P.; Li, X.B.; Zhao, Q.; Han, G. Strength and deformation characteristics of rock with single pre-existing fissure under different loading conditions. China Meas. Test. 2017, 43, 124–129. [Google Scholar]

- Bian, K.; Chen, Y.A.; Liu, J.; Cui, D.S.; Li, Y.R.; Liang, W.D.; Han, X. The unloading failure characteristics of shale under different water absorption time using the PFC numerical method. Rock Soil Mech. 2020, 41, 355–367. [Google Scholar]

- Zhou, F.X.; Zhao, M.; Ying, S. Analysis of mechanical behavior for unsaturated soil by three-dimensional discrete element method. J. Fuzhou Univ. 2020, 48, 779–785. [Google Scholar]

- Shen, H.M.; Li, Q.; Li, X.Y.; Ma, J.L. Laboratory experiment and numerical simulation on brittle failure characteristics of Longmaxi formation shale in Southern Sichuan under different stress conditions. Rock Soil Mech. 2018, 39, 254–262. [Google Scholar]

- Huang, D.; Li, X.Q.; Zou, J.Z.; Song, W.C. Crack evolution and energy dissipation of marble containing flaws. J. Yangtze River Sci. Res. Inst. 2020, 37, 130–136. [Google Scholar]

- Li, X.; He, X.; Chen, H. Crack initiation characteristics of opening-mode crack embedded in rock-like material under seepage pressure. Chin. J. Rock Mech. Eng. 2012, 31, 1317–1324. [Google Scholar]

- Yang, S.Q.; Jing, H.W. Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int. J. Fract. 2011, 168, 227–250. [Google Scholar] [CrossRef]

- Wong, R.; Chau, K.T.; Tang, C.A.; Lin, P. Analysis of crack coalescence in rock-like materials containing three flaws—Part I: Experimental approach. Int. J. Rock Mech. Min. Sci. 2001, 38, 909–924. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.P.; Li, Z.H.; Dou, R. Experimental investigation on the crack propagation behaviors of sandstone under different loading and unloading conditions. Int. J. Rock Mech. Min. Sci. 2020, 130, 104310. [Google Scholar] [CrossRef]

| Potassium Feldspar | Albite | Quartz | Biotite | Amphibole | Clinochlore |

|---|---|---|---|---|---|

| 39.76% | 26.08% | 17.7% | 9.2% | 5.57% | 1.69% |

| Sample Number | Peak Stress /MPa | Young’s Modulus/GPa | Poisson’s Ratio |

|---|---|---|---|

| S0 | 258 | 29.6 | 0.216 |

| S1 | 224.1 | 26.5 | 0.218 |

| S2 | 216.1 | 25 | 0.221 |

| S3 | 194.2 | 24.7 | 0.22 |

| Parameter Class | Parameter Name | Value |

|---|---|---|

| Particles | Minimum particle radius/mm | 0.12 |

| Particle radius ratio | 1.66 | |

| Effective modulus of particles/GPa | 11.3 | |

| Ratio of the normal to shear stiffness of particles | 1.8 | |

| Friction coefficient | 0.6 | |

| Parallel bond contact model | Effective modulus of bonds/GPa | 11.3 |

| Ratio of the normal to shear stiffness of bonds | 1.8 | |

| Tensile strength of bonds/MPa | 39 | |

| Cohesion strength of bonds/MPa | 65 | |

| Local friction angle/(°) | 20 |

| Parameters in SJ Model | Value |

|---|---|

| normal stiffness (GPa/m) | 50,000 |

| shear stiffness (GPa/m) | 20,000 |

| friction coefficient | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, R.; Liu, H.; Liu, J.; Shi, Y.; Xie, L.; Ban, S. Meso-Mechanical Characteristics of Granite with Natural Cracks after Mud Acid Corrosion. Energies 2022, 15, 721. https://doi.org/10.3390/en15030721

Tong R, Liu H, Liu J, Shi Y, Xie L, Ban S. Meso-Mechanical Characteristics of Granite with Natural Cracks after Mud Acid Corrosion. Energies. 2022; 15(3):721. https://doi.org/10.3390/en15030721

Chicago/Turabian StyleTong, Rongchen, Hejuan Liu, Jianfeng Liu, Yingkun Shi, Lihuan Xie, and Shengnan Ban. 2022. "Meso-Mechanical Characteristics of Granite with Natural Cracks after Mud Acid Corrosion" Energies 15, no. 3: 721. https://doi.org/10.3390/en15030721

APA StyleTong, R., Liu, H., Liu, J., Shi, Y., Xie, L., & Ban, S. (2022). Meso-Mechanical Characteristics of Granite with Natural Cracks after Mud Acid Corrosion. Energies, 15(3), 721. https://doi.org/10.3390/en15030721