Using Wood-Based Waste from Grapevine Cultivation for Energy Purposes

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roca, P. Statistical Report on World Vitiviniculture; International Organisation of Vine and Wine Intergovernmental Organisation. OIV: Paris, France, 2019; pp. 1–23. [Google Scholar]

- Lisek, J. Winter Hardiness of Thirty Grape Cultivar Buds (Vitis Sp.) under Conditions of Central Poland. Zesz. Probl. Postepow Nauk. Rol. 2004, 497, 405–410. [Google Scholar]

- Lisek, J. Climatic Factors Affecting Development and Yielding of Grapevine in Central Poland. J. Fruit Ornam. Plant Res. 2008, 16, 285–293. [Google Scholar]

- Lisek, J. Frost Damage of Buds on One-Year-Old Shoots of Wine and Table Grapevine Cultivars in Central Poland Following the Winter of 2008/2009. J. Fruit Ornam. Plant Res. 2009, 17, 149–161. [Google Scholar]

- Dobrowolska-Iwanek, J.; Gąstol, M.; Wanat, A.; Krośniak, M.; Jancik, M.; Zagrodzki, P. Wine of Cool-Climate Areas in South Poland. S. Afr. J. Enol. Vitic. 2014, 35, 1–9. [Google Scholar] [CrossRef]

- Kapłan, M.; Najda, A. Antioxidant Activity of Vine Fruits Depending on Their Colouring. Chemija 2014, 25, 51–55. [Google Scholar]

- Wino/Wine. Available online: https://www.kowr.gov.pl/interwencja/wino (accessed on 6 May 2021).

- De la Fuente Lloreda, M. Use of Hybrids in Viticulture. A Challenge for the OIV. OENO One 2018, 52, 231–234. [Google Scholar] [CrossRef]

- Raddova, J.; Stefkova, A.; Sotolar, R.; Baranek, M. Genetic Analysis of Vitis Interspecific Hybrids Occurring in Vineyards of the Czech Republic. Pak. J. Bot. 2016, 48, 681–688. [Google Scholar]

- Sinoquet, N. Piwi-Sorten: Die Zukunft Im Weinbau? Available online: https://academie-du-vin.ch/die-wichtigsten-traubensorten-weltweit/ (accessed on 8 May 2021).

- Caliari, V.; Burin, V.M.; Rosier, J.P.; BordignonLuiz, M.T. Aromatic Profile of Brazilian Sparkling Wines Produced with Classical and Innovative Grape Varieties. Food Res. Int. 2014, 62, 965–973. [Google Scholar] [CrossRef] [Green Version]

- De Bem, B.; Brighenti, E.; Bonin, B.F.; Allembrandt, R.; Araújo, L.; Brighenti, A.F.; Bogo, A. Downy Mildew Intensity in Tolerant Grapes Varieties in Highlands of Southern Brazil. In Proceedings of the BIO Web of Conferences, Bento Goncalves, Brazil, 24–28 October 2016; Volume 7, p. 01015. [Google Scholar]

- Spinelli, R.; Nati, C.; Pari, L.; Mescalchin, E.; Magagnotti, N. Production and Quality of Biomass Fuels from Mechanized Collection and Processing of Vineyard Pruning Residues. Appl. Energy 2012, 89, 374–379. [Google Scholar] [CrossRef]

- Choudhury, N.D.; Saha, N.; Phukan, B.R.; Kataki, R. Characterization and Evaluation of Energy Properties of Pellets Produced from Coir Pith, Saw Dust and Ipomoea Carnea and Their Blends. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–18. [Google Scholar] [CrossRef]

- Garita-Cambronero, J.; Paniagua-García, A.I.; Hijosa-Valsero, M.; Díez-Antolínez, R. Biobutanol Production from Pruned Vine Shoots. Renew. Energy 2021, 177, 124–133. [Google Scholar] [CrossRef]

- González-García, S.; Dias, A.C.; Clermidy, S.; Benoist, A.; Maurel, V.B.; Gasol, C.M.; Gabarrell, X.; Arroja, L. Comparative Environmental and Energy Profiles of Potential Bioenergy Production Chains in Southern Europe. J. Clean. Prod. 2014, 76, 42–54. [Google Scholar] [CrossRef]

- Manzone, M.; Paravidino, E.; Bonifacino, G.; Balsari, P. Biomass Availability and Quality Produced by Vineyard Management during a Period of 15 Years. Renew. Energy 2016, 99, 465–471. [Google Scholar] [CrossRef]

- Senila, L.; Tenu, I.; Carlescu, P.; Corduneanu, O.R.; Dumitrachi, E.P.; Kovacs, E.; Scurtu, D.A.; Cadar, O.; Becze, A.; Senila, M.; et al. Sustainable Biomass Pellets Production Using Vineyard Wastes. Agriculture 2020, 10, 501. [Google Scholar] [CrossRef]

- Rosúa, J.M.; Pasadas, M. Biomass Potential in Andalusia, from Grapevines, Olives, Fruit Trees and Poplar, for Providing Heating in Homes. Renew. Sustain. Energy Rev. 2012, 16, 4190–4195. [Google Scholar] [CrossRef]

- Burg, P.; Mašán, V.; Zemánek, P.; Rutkowski, K. Review of Energy Potential of the Wood Biomass of Orchards and Vineyards in the Czech Republic. Res. Agric. Eng. 2017, 63, S1–S7. [Google Scholar]

- van Dam, J.; Faaij, A.P.C.; Lewandowski, I.; Fischer, G. Biomass Production Potentials in Central and Eastern Europe under Different Scenarios. Biomass Bioenergy 2007, 31, 345–366. [Google Scholar] [CrossRef] [Green Version]

- Souček, J.; Burg, P.; Kroulik, M. Dřevo z Ovocnỳch Vỳsadeb Jako Potenciální Zdroj Energie. In Proceedings of the Sborník z Mezinárodní Konference Strom a Květina–Součást Života, Pruhonice, Czech Republic, 4–5 September 2007; Volume 4, p. 9. [Google Scholar]

- Di Blasi, C.; Tanzi, V.; Lanzetta, M. A Study on the Production of Agricultural Residues in Italy. Biomass Bioenergy 1997, 12, 321–331. [Google Scholar] [CrossRef]

- Mendívil, M.A.; Muñoz, P.; Morales, M.P.; Juárez, M.C.; García-Escudero, E. Chemical Characterization of Pruned Vine Shoots from La Rioja (Spain) for Obtaining Solid Bio-Fuels. J. Renew. Sustain. Energy 2013, 5, 033113. [Google Scholar] [CrossRef]

- Spinelli, R.; Lombardini, C.; Pari, L.; Sadauskiene, L. An Alternative to Field Burning of Pruning Residues in Mountain Vineyards. Ecol. Eng. 2014, 70, 212–216. [Google Scholar] [CrossRef]

- Scarlat, N.; Blujdea, V.; Dallemand, J.-F. Assessment of the Availability of Agricultural and Forest Residues for Bioenergy Production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- Magagnotti, N.; Nati, C.; Spinelli, R.; Vieri, M. Technical Protocol for the Utilization of Pruning Residues from Vineyards and Olive Groves. In The Forest-Wood-Energy Chain: Results from the International Project Woodland Energy; ARSIA di Regione Toscana: Florence, Italy, 2009. [Google Scholar]

- Keshtkar, H.; Ashbaugh, L.L. Size Distribution of Polycyclic Aromatic Hydrocarbon Particulate Emission Factors from Agricultural Burning. Atmos. Environ. 2007, 41, 2729–2739. [Google Scholar] [CrossRef]

- Chau, J.; Sowlati, T.; Sokhansanj, S.; Preto, F.; Melin, S.; Bi, X. Economic Sensitivity of Wood Biomass Utilization for Greenhouse Heating Application. Appl. Energy 2009, 86, 616–621. [Google Scholar] [CrossRef]

- Molcan, P.; Lu, G.; Le Bris, T.; Yan, Y.; Taupin, B.; Caillat, S. Characterisation of Biomass and Coal Co-Firing on a 3 MWth Combustion Test Facility Using Flame Imaging and Gas/Ash Sampling Techniques. Fuel 2009, 88, 2328–2334. [Google Scholar] [CrossRef]

- Corona, G.; Nicoletti, G. Renewable Energy from the Production Residues of Vineyards and Wine: Evaluation of a Business Case. New Medit 2010, 9, 41–47. [Google Scholar]

- Alves, J.L.F.; da Silva, J.C.G.; Mumbach, G.D.; Domenico, M.D.; da Silva Filho, V.F.; de Sena, R.F.; Machado, R.A.F.; Marangoni, C. Insights into the Bioenergy Potential of Jackfruit Wastes Considering Their Physicochemical Properties, Bioenergy Indicators, Combustion Behaviors, and Emission Characteristics. Renew. Energy 2020, 155, 1328–1338. [Google Scholar] [CrossRef]

- Borycka, B. Commodity Study on Food and Energy Utilization of Rich-Food Waste of the Fruit and Vegetables Industry. Monography; Radom University of Technology: Radom, Poland, 2008. [Google Scholar]

- Maj, G. Emission Factors and Energy Properties of Agro and Forest Biomass in Aspect of Sustainability of Energy Sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef] [Green Version]

- Kovacs, H.; Szemmelveisz, K.; Koós, T. Theoretical and Experimental Metals Flow Calculations during Biomass Combustion. Fuel 2016, 185, 524–531. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Serban, A.; Paraschiv, S. Calculation of Combustion Air Required for Burning Solid Fuels (Coal/Biomass/Solid Waste) and Analysis of Flue Gas Composition. Energy Rep. 2020, 6, 36–45. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion Characteristics of Different Biomass Fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Maj, G. Diversification and Environmental Impact Assessment of Plant Biomass Energy Use. Pol. J. Environ. Stud. 2015, 24, 2055–2061. [Google Scholar] [CrossRef]

- Yi, Q.; Qi, F.; Cheng, G.; Zhang, Y.; Xiao, B.; Hu, Z.; Liu, S.; Cai, H.; Xu, S. Thermogravimetric Analysis of Co-Combustion of Biomass and Biochar. J. Therm. Anal. Calorim. 2013, 112, 1475–1479. [Google Scholar] [CrossRef]

- Burnham, A.K. Van Krevelen Diagrams. In Encyclopedia of Petroleum Geoscience; Sorkhabi, R., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–5. ISBN 978-3-319-02330-4. [Google Scholar]

- Krysanova, K.; Krylova, A.; Zaichenko, V.; Lavrenov, V.; Khaskhachikh, V. Influence of the Parameters of the Hydrothermal Carbonization of the Biomass on the Biocoal Obtained from Peat. E3S Web Conf. 2019, 114, 07003. [Google Scholar] [CrossRef]

- Kalita, P.; Baruah, D. Investigation of Biomass Gasifier Product Gas Composition and Its Characterization. In Coal and Biomass Gasification; Springer: Singapore, 2018; pp. 115–149. ISBN 978-981-10-7334-2. [Google Scholar]

- Fernández-Puratich, H.; Hernández, D.; Tenreiro, C. Analysis of Energetic Performance of Vine Biomass Residues as an Alternative Fuel for Chilean Wine Industry. Renew. Energy 2015, 83, 1260–1267. [Google Scholar] [CrossRef]

- Gañán, J.; Al-Kassir Abdulla, A.; Cuerda Correa, E.M.; Macías-García, A. Energetic Exploitation of Vine Shoot by Gasification Processes: A Preliminary Study. Fuel Processing Technol. 2006, 87, 891–897. [Google Scholar] [CrossRef]

- Bilandzija, N. Energy Potential of Fruit Tree Pruned Biomass in Croatia. Span. J. Agric. Res. 2012, 292–298. [Google Scholar]

- Maj, G.; Najda, A.; Klimek, K.; Balant, S. Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry. Energies 2020, 13, 55. [Google Scholar] [CrossRef] [Green Version]

- Maj, G.; Piekut, J. Comparing Emission Factors and Physicochemical Properties of Waste-Biomass Leaves of Selected Species of Trees. Pol. J. Environ. Stud. 2018, 27, 2155–2162. [Google Scholar] [CrossRef]

- Zhang, T.; Wooster, M.J.; Green, D.C.; Main, B. New Field-Based Agricultural Biomass Burning Trace Gas, PM2.5, and Black Carbon Emission Ratios and Factors Measured in Situ at Crop Residue Fires in Eastern China. Atmos. Environ. 2015, 121, 22–34. [Google Scholar] [CrossRef] [Green Version]

- Mateos, E.; Ormaetxea, L. Sustainable Renewable Energy by Means of Using Residual Forest Biomass. Energies 2019, 12, 13. [Google Scholar] [CrossRef] [Green Version]

- Malaták, J.; Gürdil, G.A.K.; Jevic, P.; Selvi, K.Ç. Biomass Heat-Emission Characteristics of Energy Plants. AMA Agric. Mech. Asia Afr. Lat. Am. 2008, 39, 9–13. [Google Scholar]

- Brunerová, A.; Malaťák, J.; Müller, M.; Valášek, P.; Roubík, H. Tropical Waste Biomass Potential for Solid Biofuels Production. Agron. Res. 2017, 15, 359–368. [Google Scholar]

- Malaťák, J.; Passian, L. Heat-Emission Analysis of Small Combustion Equipments for Biomass. Res. Agric. Eng. 2011, 57, 37–50. [Google Scholar] [CrossRef] [Green Version]

- Malaťák, J.; Bradna, J.; Velebil, J. The Dependence of COx and NOx Emission Concentrations on the Excess Air Coefficient during Combustion of Selected Agricultural Briquetted By-Products. Agron. Res. 2017, 15, 1084–1093. [Google Scholar]

| Parameter | Equipment | Standard |

|---|---|---|

| Ash (A; %) | LECO TGA 701 | EN-ISO 18122 |

| Volatile matter (V; %) | EN-ISO 18123 | |

| Moisture (M; %) | EN-ISO 18134-3 | |

| Higher heat value (HHV; MJ·kg−1) | LECO AC 600 | EN-ISO 1928:2009 |

| Lower heat value (LHV; MJ·kg−1) | ||

| Fixed carbon (FC; %) [14] | - | FC=100-V-A-M |

| Carbon (C; %) | LECO CHNS 628 | EN-ISO 16948:2015-07 |

| Hydrogen (H; %) | ||

| Nitrogen (N; %) | ||

| Sulfur (S; %) | EN-ISO 16994:2016-10 | |

| Oxygen (O; %) [32] | - | O=100-A-H-C-S-N |

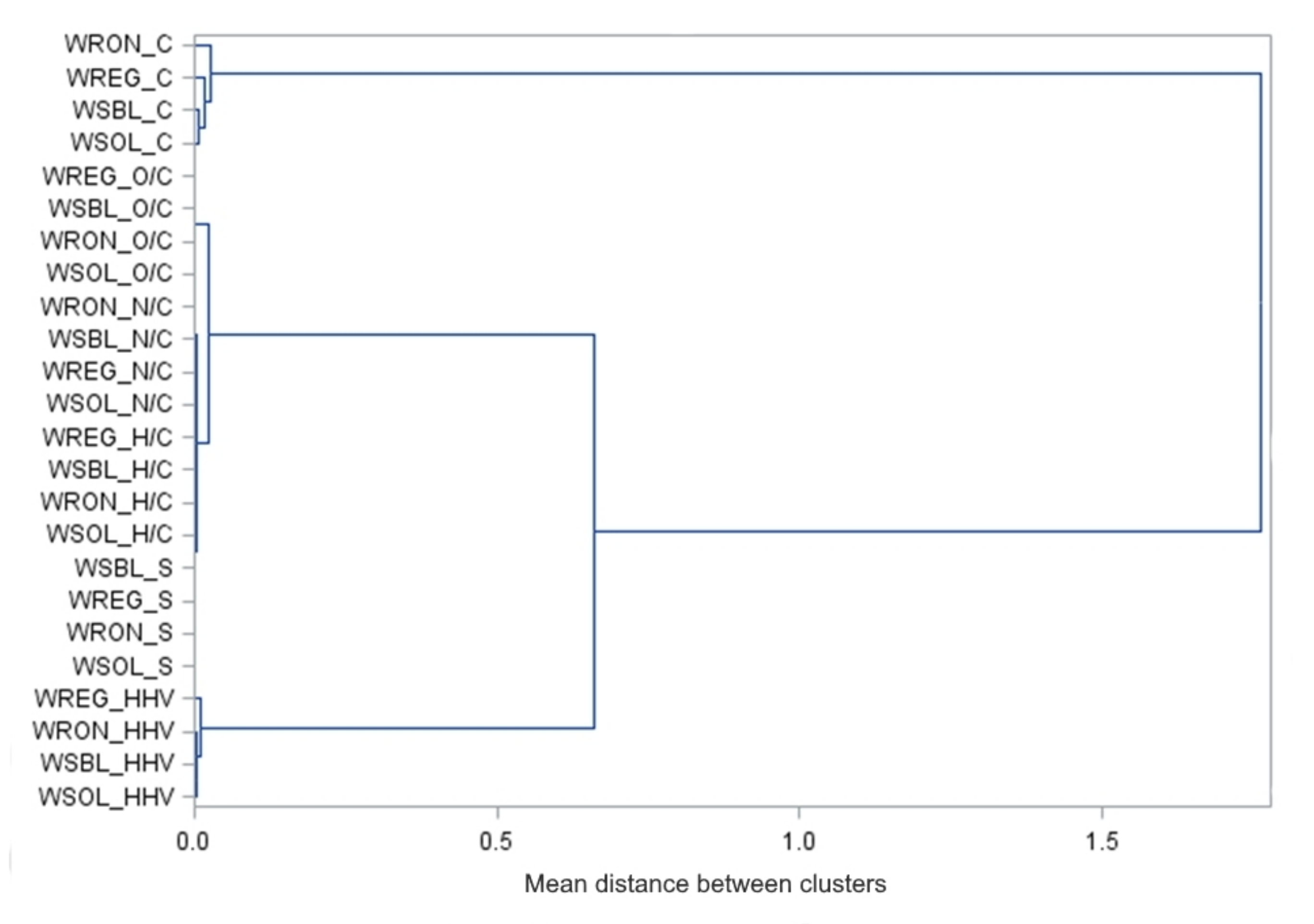

| Parameter | Unit | WSBL | WSOL | WREG | WRON | p-Value |

|---|---|---|---|---|---|---|

| N | pcs. | 12.0 b | 14.0 ab | 16.0 a | 14.0 ab | 0.004 * |

| ±Sd | ±1.0 | ±1.0 | ±1.0 | ±2.0 | ||

| Msh | kg·shrub−1 | 0.72 b | 0.67 b | 0.67 b | 0.93 a | 0.006 * |

| ±Sd | ±0.07 | ±0.02 | ±0.02 | ±0.24 | ||

| Mha | t·ha−1 | 3.61 b | 3.38 b | 3.36 b | 4.65 a | 0.006 * |

| ±Sd | ±0.08 | ±1.19 | ±0.34 | ±0.11 | ||

| D | mm | 8.72 a | 8.01 b | 8.13 b | 8.24 ab | 0.010 * |

| ±Sd | ±0.45 | ±0.06 | ±0.16 | ±0.49 |

| Parameter | Unit | WSOL | WRON | WSBL | WREG | p-Value |

|---|---|---|---|---|---|---|

| LHV ±Sd | MJ·kg−1 | 15.97 bc | 15.88 c | 16.04 b | 16.19 a | <0.001 * |

| ±0.05 | ±0.03 | ±0.05 | ±0.03 | |||

| HHV ± Sd | MJ·kg−1 | 17.36 bc | 17.18 c | 17.52 b | 17.60 a | <0.001 * |

| ±0.05 | ±0.04 | ±0.05 | ±0.03 | |||

| M ± Sd | % | 7.04 c | 6.60 d | 7.43 a | 7.05 b | <0.001 * |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| V ± Sd | % | 70.92 ab | 71.01 a | 70.52 bc | 70.41 c | 0.006 * |

| ±0.28 | ±0.19 | ±0.05 | ±0.04 | |||

| A ± Sd | % | 4.07 a | 4.21 a | 3.62 b | 3.68 b | <0.001 * |

| ±0.04 | ±0.07 | ±0.05 | ±0.09 | |||

| FC ± Sd | % | 17.98 c | 18.20 bc | 18.43 b | 18.86 a | <0.001 * |

| ±0.09 | ±0.09 | ±0.10 | ±0.10 | |||

| C ± Sd | % | 48.69 b | 48.22 c | 48.90 b | 49.19 a | <0.001 * |

| ±0.09 | ±0.03 | ±0.12 | ±0.13 | |||

| H ± Sd | % | 5.56 | 5.97 | 5.99 | 5.95 | 0.161 |

| ±0.48 | ±0.00 | ±0.00 | ±0.02 | |||

| N ± Sd | % | 0.50 | 0.51 | 0.51 | 0.50 | 0.976 |

| ±0.02 | ±0.03 | ±0.03 | ±0.03 | |||

| S ± Sd | % | 0.06 b | 0.07 ab | 0.07 a | 0.08 ab | 0.013 * |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| O ± Sd | % | 41.11 | 41.02 | 40.91 | 40.59 | 0.242 |

| ±0.53 | ±0.14 | ±0.17 | ±0.18 | |||

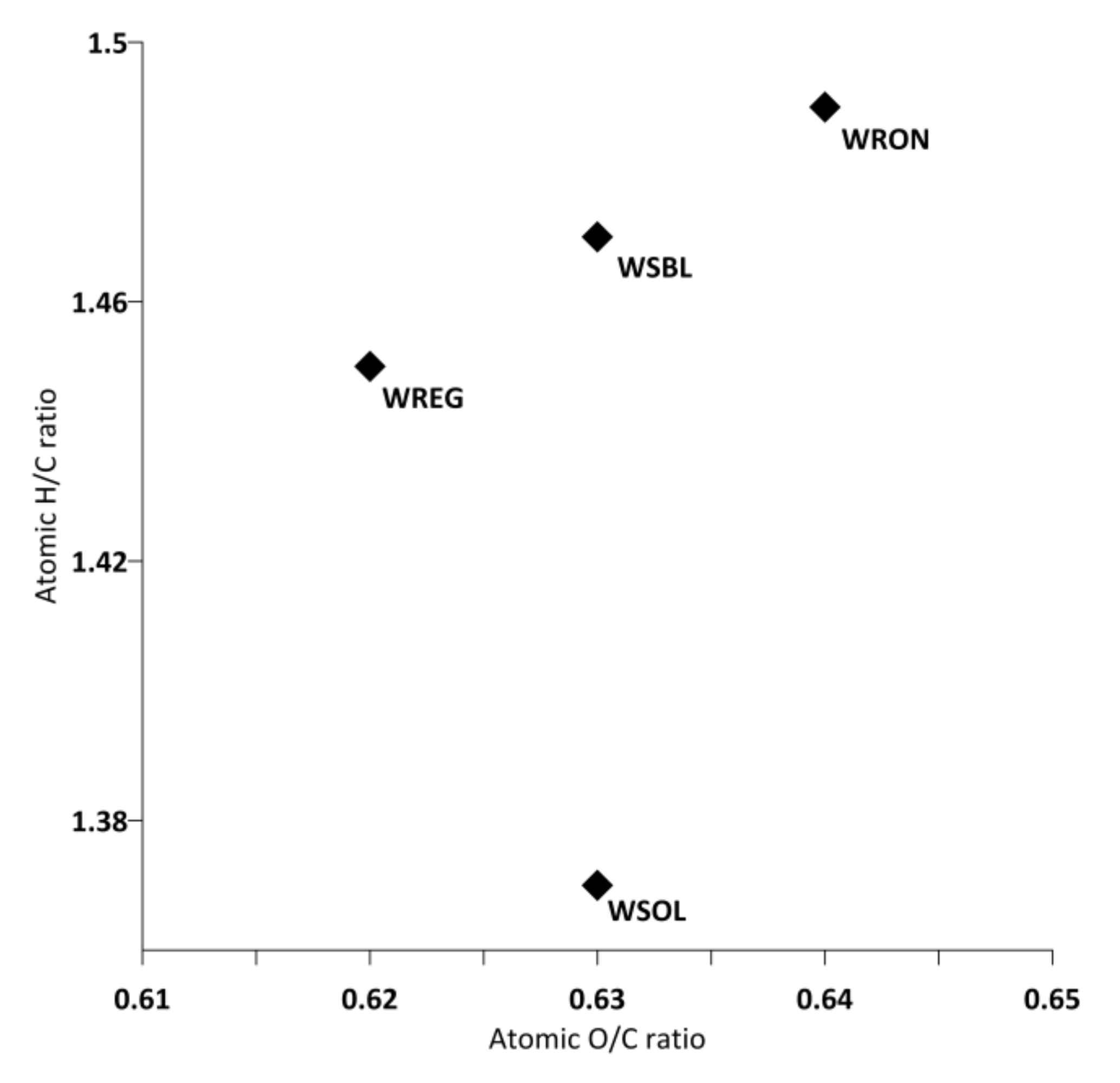

| H/C ± Sd | 1.37 | 1.49 | 1.47 | 1.45 | 0.146 | |

| ±0.12 | ±0.00 | ±0.00 | ±0.01 | |||

| N/C ± Sd | 0.01 | 0.01 | 0.01 | 0.01 | 0.987 | |

| ±0.00 | ±0.00 | ±0.00 | ±0.00 | |||

| O/C ± Sd | 0.63 ab | 0.64 a | 0.63 ab | 0.62 b | 0.015 * | |

| ±0.01 | ±0.00 | ±0.00 | ±0.00 |

| Material | LHV (MJ·kg−1) | HHV (MJ·kg−1) |

|---|---|---|

| Sauvignon blanc [43] | 17.3 | 18.7 |

| Pinot [43] | 15.1 | 16.5 |

| Cabernet sauvignon [43] | 16.2 | 17.6 |

| Chardonnay [43] | 16.2 | 17.6 |

| Carmenere [43] | 17.3 | 18.7 |

| Merlot [13] | - | 17.8 |

| Prosecco [13] | - | 18.5 |

| Verduzzo [13] | - | 18.9 |

| Parameter | Unit | WSOL | WRON | WSBL | WREG | p-Value |

|---|---|---|---|---|---|---|

| CO ±Sd | kg·Mg−1 | 59.98 b | 59.40 c | 60.25 b | 60.60 a | <0.0001 * |

| ±0.15 | ±0.04 | ±0.14 | ±0.11 | |||

| CO2 ±Sd | kg·Mg−1 | 1468.87 b | 1454.65 c | 1475.35 b | 1484.06 a | <0.0001 * |

| ±3.87 | ±0.99 | ±3.51 | ±2.62 | |||

| NOx ±Sx | kg·Mg−1 | 1.78 | 1.81 | 1.80 | 1.78 | 0.9763 |

| ±0.11 | ±0.11 | ±0.12 | ±0.07 | |||

| SO2 ±Sd | kg·Mg−1 | 0.12 b | 0.14 ab | 0.16 a | 0.14 ab | 0.0129 * |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| Dust ±Sd | kg·Mg−1 | 5.14 a | 5.31 a | 4.57 b | 4.65 b | <0.0001 * |

| ±0.11 | ±0.09 | ±0.06 | ±0.05 |

| Parameter | Unit | WSOL | WRON | WSBL | WREG | p-Value |

|---|---|---|---|---|---|---|

| CO ±Sd | kg·GJ−1 | 3.76 | 3.74 | 3.76 | 3.74 | 0.2168 |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| NOx ±Sd | kg·GJ−1 | 0.11 | 0.11 | 0.11 | 0.11 | 0.8971 |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| CO2 ±Sd | kg·GJ−1 | 91.98 | 91.60 | 91.98 | 91.67 | 0.2168 |

| ±0.38 | ±0.16 | ±0.11 | ±0.26 | |||

| SO2 ±Sd | kg·GJ−1 | 0.01 b | 0.01 ab | 0.01 a | 0.01 ab | 0.0198 * |

| ±0.01 | ±0.01 | ±0.016 | ±0.01 | |||

| dust ±Sd | kg·GJ−1 | 0.32 a | 0.33 a | 0.29 b | 0.29 b | <0.0001 * |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 |

| Nazwa | Unit | WSOL | WRON | WSBL | WREG | p-Value |

|---|---|---|---|---|---|---|

| VoO2 ±Sd | Nm3·kg−1 | 0.93 | 0.95 | 0.95 | 0.95 | 0.1461 |

| ±0.01 | ±0.01 | ±0.01 | ±0.03 | |||

| Voa ±Sd | Nm3·kg−1 | 4.44 | 4.53 | 4.53 | 4.52 | 0.1035 |

| ±0.01 | ±0.01 | ±0.01 | ±0.15 | |||

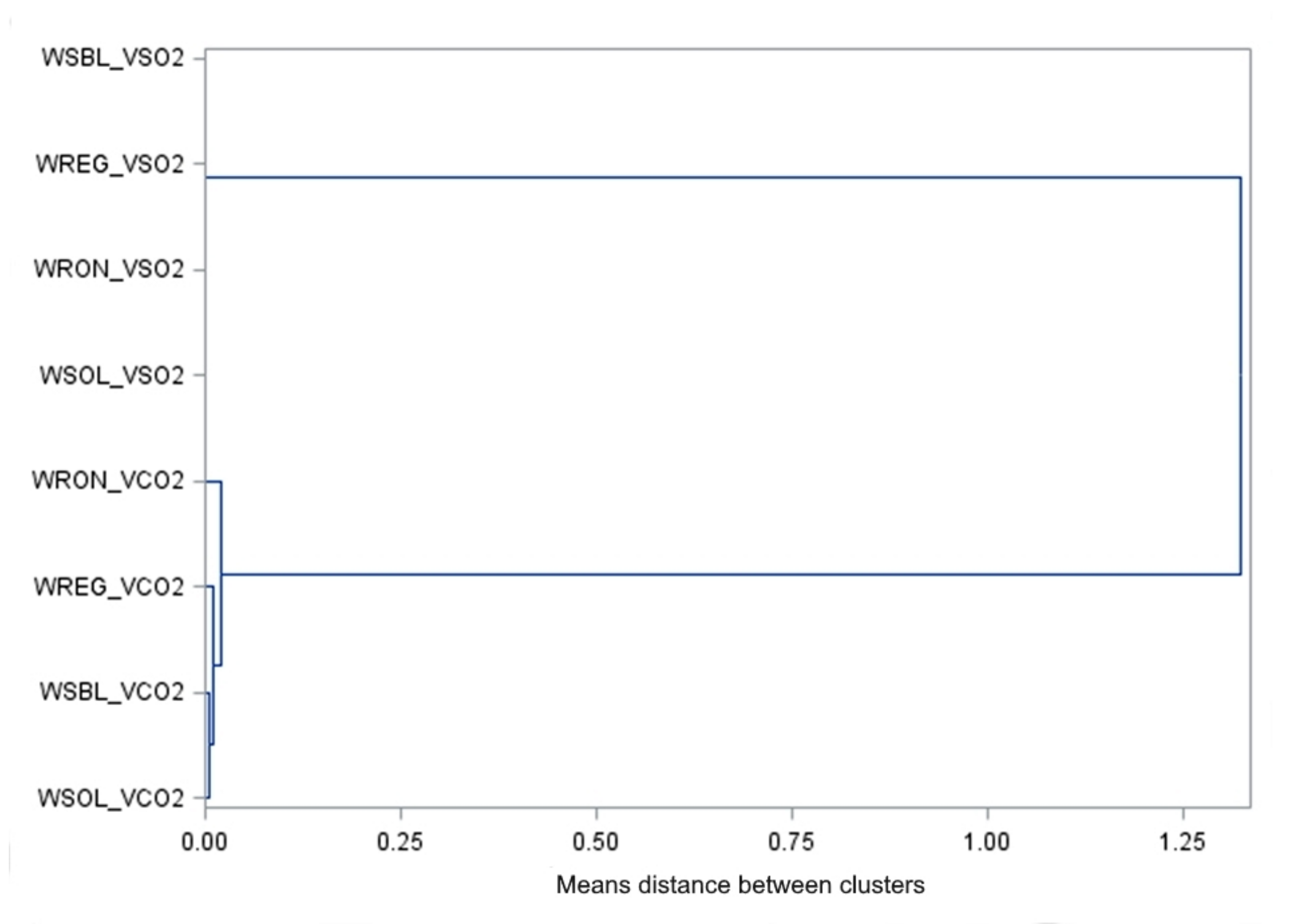

| VCO2 ±Sd | Nm3·kg−1 | 0.91 b | 0.91 c | 0.90 b | 0.90 a | <0.0001 * |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| VSO2 ±Sd | Nm3·kg−1 | 0.00 b | 0.00 ab | 0.00 a | 0.00 ab | 0.0129 * |

| ±0.01 | ±0.01 | ±0.01 | ±0.01 | |||

| VH2O ±Sd | Nm3·kg−1 | 1.43 | 1.47 | 1.48 | 1.48 | 0.1036 |

| ±0.01 | ±0.01 | ±0.01 | ±0.07 | |||

| VN2 ±Sd | Nm3·kg−1 | 3.91 | 3.99 | 3.98 | 3.98 | 0.1315 |

| ±0.02 | ±0.02 | ±0.03 | ±0.12 | |||

| Vgu ±Sd | Nm3·kg−1 | 4.82 | 4.90 | 4.89 | 4.88 | 0.1034 |

| ±0.02 | ±0.02 | ±0.03 | ±0.02 | |||

| Vga ±Sd | Nm3·kg−1 | 6.25 | 6.37 | 6.37 | 6.36 | 0.1173 |

| ±0.02 | ±0.02 | ±0.03 | ±0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maj, G.; Klimek, K.; Kapłan, M.; Wrzesińska-Jędrusiak, E. Using Wood-Based Waste from Grapevine Cultivation for Energy Purposes. Energies 2022, 15, 890. https://doi.org/10.3390/en15030890

Maj G, Klimek K, Kapłan M, Wrzesińska-Jędrusiak E. Using Wood-Based Waste from Grapevine Cultivation for Energy Purposes. Energies. 2022; 15(3):890. https://doi.org/10.3390/en15030890

Chicago/Turabian StyleMaj, Grzegorz, Kamila Klimek, Magdalena Kapłan, and Edyta Wrzesińska-Jędrusiak. 2022. "Using Wood-Based Waste from Grapevine Cultivation for Energy Purposes" Energies 15, no. 3: 890. https://doi.org/10.3390/en15030890

APA StyleMaj, G., Klimek, K., Kapłan, M., & Wrzesińska-Jędrusiak, E. (2022). Using Wood-Based Waste from Grapevine Cultivation for Energy Purposes. Energies, 15(3), 890. https://doi.org/10.3390/en15030890