Correction Mechanism for Balancing Driving Torques in an Opencast Mining Stacker with an Induction Motor and Converter Drive System

Abstract

:1. Introduction

2. Materials and Methods

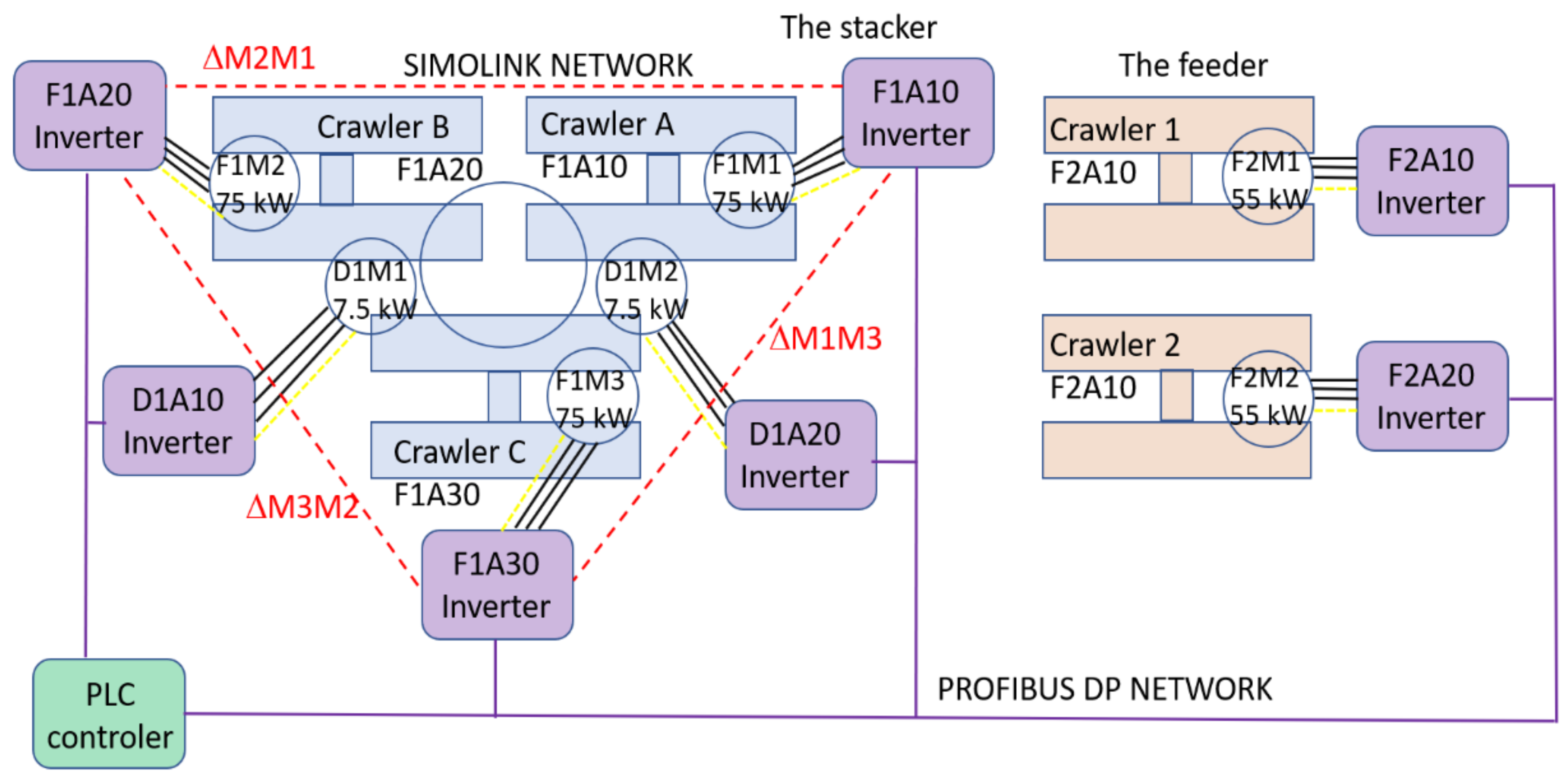

2.1. Structure of the Control System

2.2. Control Algorithm for Electrical Inverter Drives

2.3. Basic Equation for Motor and Drive Control

3. Results

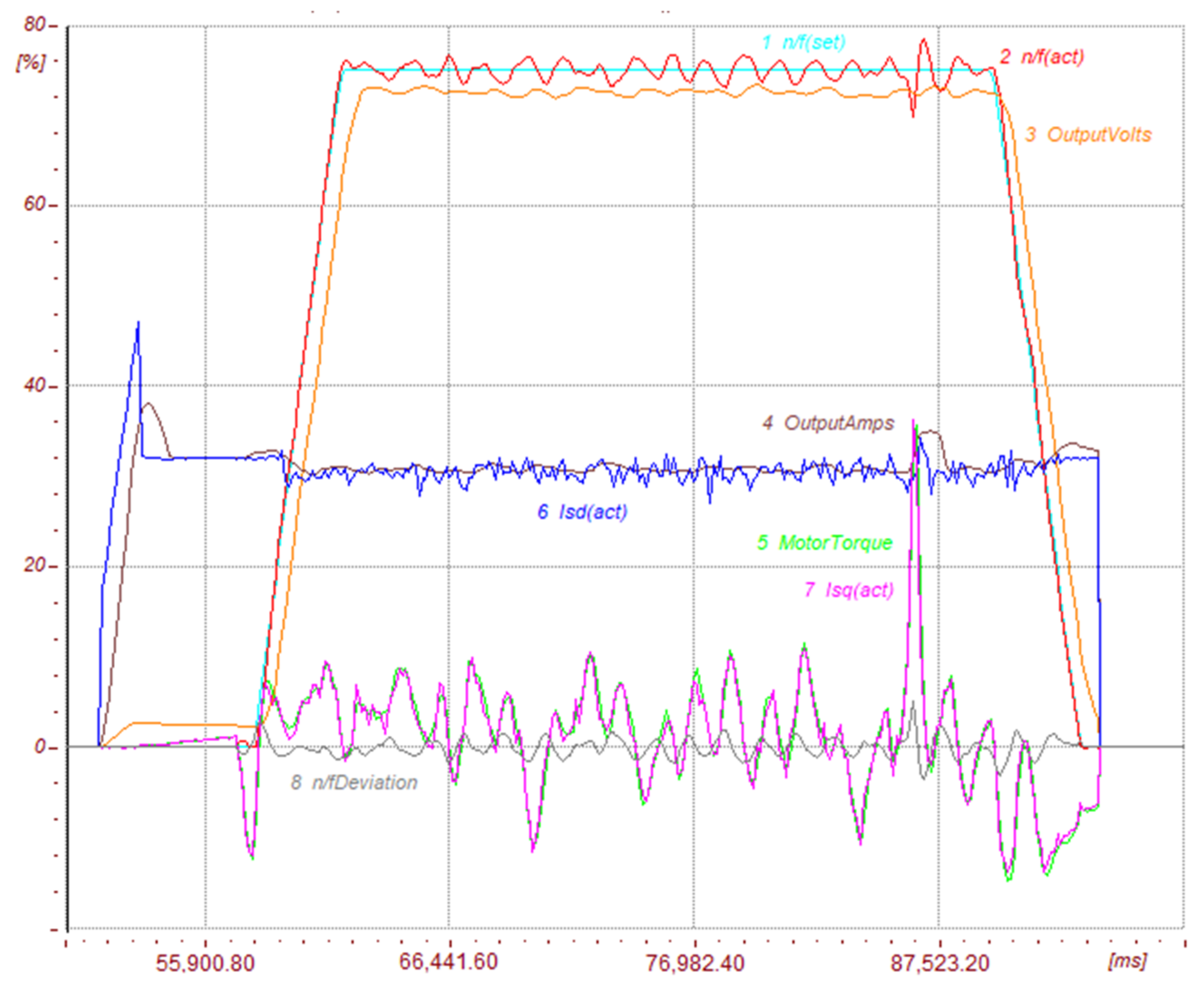

3.1. Investigation of Inverter Drive Systems in an Opencast Mining Stacker

- -

- by changing the frequency of dumps

- -

- by changing the weight of the body

- -

- by increasing the stiffness of the body

3.2. Correction Mechanism for the Balancing Driving Torques

- Speed control mode (Figure 3), where each inverter receives a set speed value from the PLC controller, resulting from the geometry of the current track alignment, and the driving speed is given by the operator.

- Speed control mode, with torque corrections (Figure 6 colored in red), where each inverter receives a set speed value from the controller, resulting from the geometry of the current track settings, and the driving speed is set by the operator. Based on the deviation of the actual drive torque from the average value of all drives, each inverter generates an appropriate correction of the set speed to equalize the torques. The amount of the correction related to the controller setpoint is set at ± 10% (empirically selected during start-up). The mean torque value for all drives was calculated, using the SIMOLINK network in the F1A10 inverter for sending process data. The average torque value from the F1A10 inverter is transferred to all other inverters via the SIMOLINK network.

- Torque boost mode, where by changing the torque limitations the torque boost function is additionally provided. This mode is realized by transmitting the torque limit value from the PLC to the inverter control algorithm. The torque limit values for normal and forced operation were established based on documentation and tests, then stored in the PLC (Figure 7).

4. Discussion and Verification of Method Implementation

5. Conclusions

- -

- The analyzed machine has a triangular drive system, which is asymmetrical. This affects the stability of the machine and the load distribution in the system.

- -

- The implementation of the torque balancing load mechanism improved the drive parameters of the machine.

- -

- Model parameters responsible for electromagnetic transient processes were improved and the settings of the regulators and limits were selected.

- -

- The machine is not subject to vibrations resulting from the influence of the frequency of the control system.

- -

- Failure to take into account the dynamic overloads when estimating the durability of a gear train may cause its premature failure.

- -

- Application of the objective function that lowers the maximum contact stresses and stresses at the base of the mechanical teeth of the band in the optimization process effectively increases the durability and reliability of the driveline.

- -

- A whole problem-oriented control algorithm could be designed using the main FOC principles and for example a fuzzy or neuron controller. It is very important to select the control settings and limits for the measured signals. The mechanism should be calculated, simulated, and tested before its practical implementation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hertel, L. Technika przekształtnikowa w napędach jazdy i obrotu na maszynach podstawowych—doświadczenia eksploatacyjne. Górnictwo Odkryw. 2008, 49, 38–41. (In Polish) [Google Scholar]

- Jabłoński, M.; Borkowski, P. Wymiana systemów sterowania wraz z implementacją cyfrowej falownikowej techniki napędowej w maszynach górnictwa odkrywkowego. Praca zbiorowa. Monografia. KOMTECH 2020, 1, 6–22. (In Polish) [Google Scholar]

- Jabłoński, M.; Borkowski, P. Industrial implementations of control algorithms for voltage inverters supplying induction motors. Arch. Electr. Eng. 2021, 70, 475–491. (In English) [Google Scholar]

- Jabłoński, M. The Analysis of Functional Parameters and Modification of Steering Algorithms in Vector Control Converter drive with an Induction Motor; Technical University of Łódź: Łódź, Poland, 2007. (In English) [Google Scholar]

- Siemens-Technical Documentation, Engineering Manual and Compendium for SIMOVERT MASTERDRIVES, Automation and Drives, Variable-Speed Drive Systems, Erlangen 1999–2012, Siemens AG (2020). (In English). Available online: https://support.industry.siemens.com/cs/attachments/109736629/vc34_kompend_f.pdf?download=true (accessed on 30 November 2021).

- Borczyk, Z.; Trajdos, M. Sterowanie jazdą maszyn górniczych regulacja prędkości z korekcją momentu. Górnictwo Odkrywkowe 2008, 49, 21–25. (In Polish) [Google Scholar]

- Hertel, L.; Nowacki, H. Algorytmy sterowania napędami na modernizowanych koparkach. Czas. Górnictwo Odkryw. 2014, 55, 39–43. (In Polish) [Google Scholar]

- Huss, W. Problems of Bucket-Wheel Excavators Body in Hardly-Workable Grounds in Polish Open Pit Mines. In Proceedings of the 12th International Symposium Continuous Surface Mining; Aachen, Germany, 24–27 September 2014, Niemann-Delius, C., Ed.; Lecture Notes in Production Engineering; Springer: Cham, Switzerland, 2015. (In English) [Google Scholar]

- Blaschke, F. Das Verfahren der Feldorientierung zur Regelung der Asynchronenmaschine. Siemens Forsch. Und Entwickl. 1972, 1, 184–193. (In German) [Google Scholar]

- Jabłoński, M.; Borkowski, P. Metody poprawy algorytmów sterowania systemów napędów maszyn górnictwa odkrywkowego. KOMTECH 2021, 1, 139–148. (In Polish) [Google Scholar]

- Wocka, N. Możliwości zaspokojenia popytu na wysokowydajne krajowe maszyny podstawowe dla przyszłych potrzeb górnictwa węgla brunatnego. Górnictwo I Geoinżynieria 2010, 4, 537–546. (In Polish) [Google Scholar]

- Trajdos, M.; Leśniewski, K. Zastosowanie napędów regulowanej prędkości w odkrywkowych zakładach górniczych—Zagadnienia wybrane. Górnictwo Odkryw. 2012, 53, 9–13. (In Polish) [Google Scholar]

- Jabłoński, M. Ekspertyza Przenośnika Samojezdnego PGOT-4500. Protokół z Wykonanych Prac Zlecenie HP/AG-W26/09; PGE KWB Turów S.A.: Bogatynia, Poland, 2021. (In Polish) [Google Scholar]

- Paszek, W. Dynamika Maszyn Elektrycznych Prądu Przemiennego; Helion: Gliwice, Poland, 2011. (In Polish) [Google Scholar]

- Kalus, M.; Skoczkowski, T. Sterowanie Napędami Asynchronicznymi I Prądu Stałego; Pracownia Komputerowa J. Skalmierskiego: Gliwice, Poland, 2003. (In Polish) [Google Scholar]

- Pełczewski, W.; Krynke, M. Metoda Zmiennych Stanu W Analizie Dynamiki Układów Napędowych; WNT: Warsawa, Poland, 1984. (In Polish) [Google Scholar]

- Tunia, H.; Kaźmierkowski, M. Automatyka Napędu Przekształtnikowego; PWN: Warszawa, Poland, 1987. (In Polish) [Google Scholar]

- Vas, P. Sensorless Vector and Direct Torque Control; Oxford University Press: Oxford, UK, 1998. (In English) [Google Scholar]

- Leśniewski, K. Hamowanie dynamiczne silników indukcyjnych na przenośnikach taśmowych o ujemnym kącie nachylenia w PGE GiEK S.A. Oddział KWB Turów. Górnictwo Odkryw. 2011, 52, 45–54. (In Polish) [Google Scholar]

- Szewerda, K.; Świder, J.; Herbuś, K. Control algorithm concept conveyor capacity longwall. Control, monitoring and diagnostics system. Masz. Górnicze 2016, 4, 93–103. (In Polish) [Google Scholar]

- Świtoński, E.; Chuchnowski, W. Optymalizacja cech konstrukcyjnych mechatronicznych układów napędowych maszyn górniczych. Masz. Górnicze 2008, 4, 23–30. (In Polish) [Google Scholar]

- Drwięga, A.; Szewerda, K.; Tytko, S. Zagadnienia regulacji obciążeń napędów w wysokowydajnym przenośniku zgrzebłowym kompleksu ścianowego. In Nowoczesne Metody Eksploatacji Węgla I Skał Zwięzłych; Monografia, Akademia Górniczo-Hutnicza im Stanisława Staszica: Kraków, Poland, 2013; pp. 375–384. (In Polish) [Google Scholar]

- Herbuś, K.; Ociepka, P. Mapping of the Characteristics of a Drive Functioning in the System of CAD Class Using the Integration of a Virtual Controller with a Virtual Model of a Drive. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Baech, Switzerland, 2015; pp. 1249–1254. (In English) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jabłoński, M.; Borkowski, P. Correction Mechanism for Balancing Driving Torques in an Opencast Mining Stacker with an Induction Motor and Converter Drive System. Energies 2022, 15, 1282. https://doi.org/10.3390/en15041282

Jabłoński M, Borkowski P. Correction Mechanism for Balancing Driving Torques in an Opencast Mining Stacker with an Induction Motor and Converter Drive System. Energies. 2022; 15(4):1282. https://doi.org/10.3390/en15041282

Chicago/Turabian StyleJabłoński, Mariusz, and Piotr Borkowski. 2022. "Correction Mechanism for Balancing Driving Torques in an Opencast Mining Stacker with an Induction Motor and Converter Drive System" Energies 15, no. 4: 1282. https://doi.org/10.3390/en15041282

APA StyleJabłoński, M., & Borkowski, P. (2022). Correction Mechanism for Balancing Driving Torques in an Opencast Mining Stacker with an Induction Motor and Converter Drive System. Energies, 15(4), 1282. https://doi.org/10.3390/en15041282