Hybrid Research Platform for Fundamental and Empirical Modeling and Analysis of Energy Management of Shared Electric Vehicles

Abstract

:1. Introduction

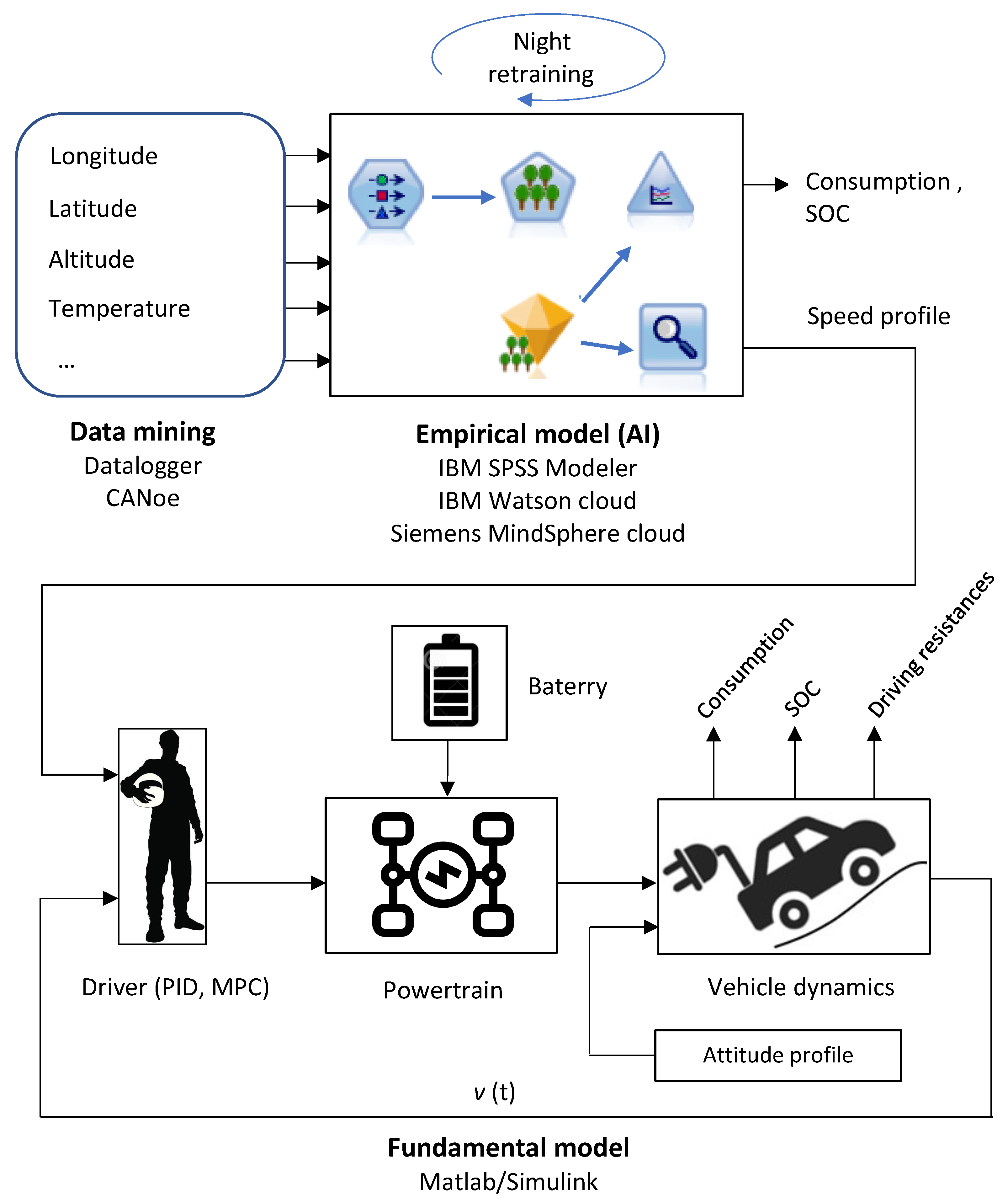

2. Biro Electric Vehicle Hybrid Research Model

2.1. Data Mining

2.2. Empirical Model

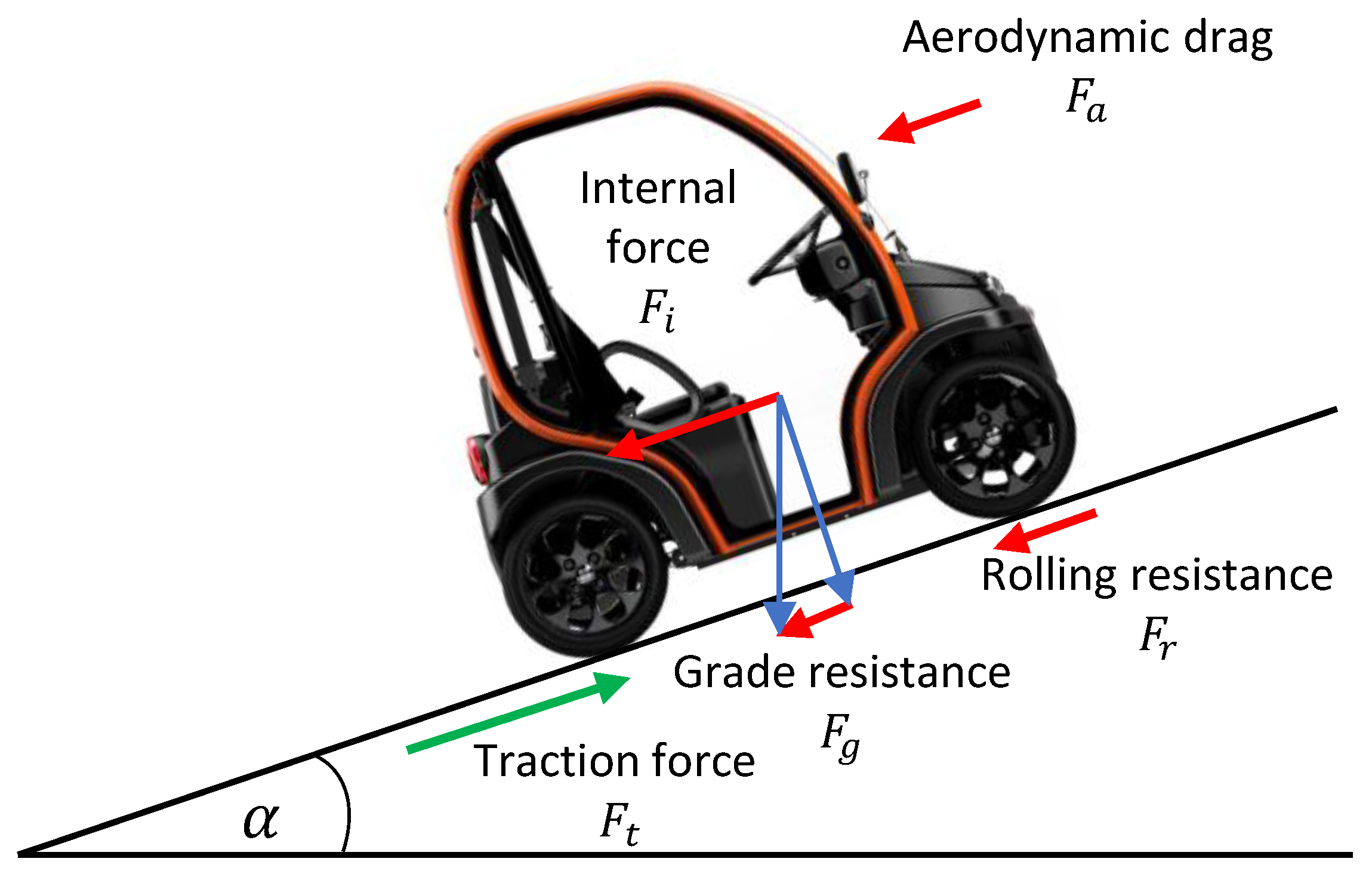

2.3. Fundamental Model

3. Results of Experiments

3.1. Elevation Profile of the Route

3.1.1. Route Elevation Profile Determined from BME280 Barometric Pressure Sensor Data

3.1.2. Route Elevation Profile Determined from GNSS Receiver uBlox Neo-M8N

3.1.3. Route Elevation Profile Determined from a Czech Republic Digital Relief Model

3.1.4. Route Elevation Profile Determined from the Mapy.cz Planner

3.1.5. Comparison of the Results of Height Profile Measurements Using the above Methods

3.2. Determining Aerodynamic and Rolling Resistance Coefficients

3.3. Verification of Driver Block Functionality

3.4. Comparison of Real and Simulated Consumption

3.5. Distribution of Consumption According to Driving Resistance

3.6. Measurement of Motor and Inverter Losses

3.7. Evaluation Metrics of the Best Machine Learning Algorithms for Speed and Consumption Prediction in SPSS Modeler

3.8. Speed Prediction Using Machine Learning

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Electric Vehicle Overview Database. EV Database-v4.1. Available online: https://ev-database.org (accessed on 4 July 2020).

- De cauwer, C.; Verbeke, W.; Coosemans, T.; Faid, S.; Mierlo, J.V. A Data-Driven Method for Energy Consumption Prediction and Energy-Efficient Routing of Electric Vehicles in Real-World Conditions. Energies 2017, 10, 608. [Google Scholar] [CrossRef] [Green Version]

- Vajedi, M.; Azad, N.L. Ecological Adaptive Cruise Controller for Plug-In Hybrid Electric Vehicles Using Nonlinear Model Predictive Control. IEEE Trans. Intell. Transp. Syst. 2016, 17, 113–122. [Google Scholar] [CrossRef]

- Zhang, Y.; Chu, L.; Fu, Z.; Xu, N.; Guo, C.; Zhang, X.; Chen, Z.; Wang, P. Optimal energy management strategy for parallel plug-in hybrid electric vehicle based on driving behavior analysis and real time traffic information prediction. Mechatronics 2017, 46, 177–192. [Google Scholar] [CrossRef]

- Gilman, E.; Keskinarkaus, A.; Tamminen, S.; Pirttikangas, S.; Röning, J.; Riekki, J. Personalised assistance for fuel-efficient driving. Transp. Res. Part C: Emerg. Technol. 2015, 58, 681–705. [Google Scholar] [CrossRef] [Green Version]

- Magaña, V.C.; Organero, M.M. Artemisa: Using an Android device as an Eco-Driving assistant. J. Sel. Areas Mechatron. (JMTC) 2011, 1–8. [Google Scholar]

- Magana, V.C.; Muñoz-Organero, M. Artemisa: An eco-driving assistant for Android Os. In Proceedings of the 2011 IEEE International Conference on Consumer Electronics-Berlin (ICCE-Berlin), Berlin, Germany, 6–8 September 2011; pp. 211–215. [Google Scholar]

- Magana, V.C.; Organero, M.M. Artemisa: A Personal Driving Assistant for Fuel Saving. IEEE Trans. Mob. Comput. 2016, 15, 2437–2451. [Google Scholar] [CrossRef] [Green Version]

- Kural, E.; Jones, S.; Parrilla, A.F.; Grauers, A. Traffic light assistant system for optimized energy consumption in an electric vehicle. In Proceedings of the 2014 IEEE International Conference on Connected Vehicles and Expo (ICCVE), Vienna, Austria, 3–7 November 2014; pp. 604–611. [Google Scholar]

- Sun, C.; Sun, F.; He, H. Investigating adaptive-ECMS with velocity forecast ability for hybrid electric vehicles. Appl. Energy 2017, 185, 1644–1653. [Google Scholar] [CrossRef]

- Sun, C.; He, H.; Sun, F. The Role of Velocity Forecasting in Adaptive-ECMS for Hybrid Electric Vehicles. Energy Procedia 2015, 75, 1907–1912. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; He, H.; Peng, J.; Zhou, N. A novel MPC-based adaptive energy management strategy in plug-in hybrid electric vehicles. Energy 2019, 175, 378–392. [Google Scholar]

- Trommer, S.; Holtl, A. Perceived usefulness of eco-driving assistance systems in Europe. IET Intell. Transp. Syst. 2012, 6, 145–152. [Google Scholar] [CrossRef]

- Magana, V.C.; Munoz-Organero, M. GAFU: Using a Gamification Tool to Save Fuel. IEEE Intell. Transp. Syst. Mag. 2015, 7, 58–70. [Google Scholar] [CrossRef] [Green Version]

- Jamson, S.L.; Hibberd, D.L.; Jamson, A.H. Drivers’ ability to learn eco-driving skills; effects on fuel efficient and safe driving behaviour. Transp. Res. Part C Emerg. Technol. 2015, 58, 657–668. [Google Scholar] [CrossRef]

- Report on Updating and Status Records of Fuel Filling Stations in the Czech Republic as of 9 April 2021. MPO. 2021. Available online: https://www.mpo.cz/cz/energetika/statistika/statistika-a-evidence-cerpacich-a-dobijecich-stanic/zprava-o-aktualizaci-a-stavu-evidence-cerpacich-stanic-pohonnych-hmot-v-cr-k-9–4–2021–260737/ (accessed on 17 July 2020).

- List of Public Charging Stations-Status as of 31 March 2021. MPO. 2021. Available online: https://www.mpo.cz/cz/energetika/statistika/statistika-a-evidence-cerpacich-a-dobijecich-stanic/seznam-verejnych-dobijecich-stanic-_-stav-k-31–3–2021–260994/ (accessed on 17 July 2020).

- Introduction to Machine Learning, Part 1: Machine Learning Fundamentals. MathWorks. 2020. Available online: https://www.mathworks.com/videos/introduction-to-machine-learning-part-1-machine-learning-fundamentals-1542879625034.html (accessed on 17 July 2020).

- IBM SPSS Modeler V18.2.1 Documentation. IBM. 2020. Available online: https://www.ibm.com/support/knowledgecenter/cs/SS3RA7_18.2.1/modeler.kc.doc/clementine/knowledge_center/product_landing.html (accessed on 17 July 2020).

- Cortez, P.; Silva, A. Using Data Mining to Predict Secondary School Student Performance. Proceedings of 5th FUture BUsiness TEChnology Conference (FUBUTEC 2008), Porto, Portugal, 5–12 April 2008; pp. 5–7. [Google Scholar]

- Ozana, S.; Pies, M.; Hajovsky, R.; Koziorek, J.; Horacek, O. Application of PIL Approach for Automated Transportation Center. In Computer Information Systems and Industrial Management; Springer: Heidelberg, Germany, 2014; pp. 501–513. ISBN 978-3-662-45236-3. [Google Scholar]

- MATLAB and Simulink Racing Lounge: Vehicle Modeling. MathWorks. 2020. Available online: https://www.mathworks.com/matlabcentral/fileexchange/63823-matlab-and-simulink-racing-lounge-vehicle-modeling (accessed on 8 July 2020).

- Zou, Y.; Li, J.; Hu, X.; Chamaillard, Y. Modeling and Control of Hybrid Propulsion System for Ground Vehicles; Beijing Institute of Technology Press: Beijing, China; Springer: Berlin, Gemany, 2018; ISBN 978-3-662-53673-5. [Google Scholar]

- Hedengren, J.D.; Shishavan, R.A.; Powell, K.M.; Edgar, T.F. Nonlinear modeling, estimation and predictive control in APMonitor. Comput. Chem. Eng. 2014, 70, 133–148. [Google Scholar] [CrossRef] [Green Version]

- Vlk, F. Dynamics of Motor Vehicles, 2nd ed.; Prof. Ing. Frantisek Vlk, DrSc.: Brno, Czech Republic, 2003; ISBN 80-239-0024-2. [Google Scholar]

- Sciarretta, A.; Vahidi, A. Energy-Efficient Driving of Road Vehicles Toward Cooperative, Connected, and Automated Mobility; Springer: Cham, Switzerland, 2020; ISBN 978-3-030-24127-8. [Google Scholar]

- Neborak, I.; Simonik, P.; Odlevak, P. Electric Vehicle Modelling and Simulation. In Proceedings of the 14th International Scientific Conference on Electric Power Engineering, Kouty nad Desnou, Czech Republic, 28–30 May 2013; pp. 693–696. [Google Scholar]

- Rapant, P. Satellite Positioning Systems; Vysoka Skola Banska-Technicka Univerzita: Ostrava, Czech Republic, 2002; ISBN 80-248-0124-8. [Google Scholar]

- Digital Relief Model of the Czech Republic 5th Generation (DMR 5G). CUZK. 2018. Available online: https://geoportal.cuzk.cz/(S(4rwf2xubg35yvuzr4xlj2fyx))/Default.aspx?mode=TextMeta&side=vyskopis&metadataID=CZ-CUZK-DMR5G-V&head_tab=sekce-02-gp&menu=302 (accessed on 4 July 2020).

- Tools for Working with the Route. Seznam.cz a.s. 2020. Available online: https://napoveda.seznam.cz/cz/nastroje-pro-praci-s-trasou/ (accessed on 4 July 2020).

- Comparison of Aerodynamic Drag Determination Procedures for HDV CO2 Certification. ICCT. 2019. Available online: https://theicct.org/sites/default/files/publications/ICCT_aero_drag_briefing_20190814.pdf (accessed on 4 July 2020).

- APMonitor Documentation. 2020. Available online: http://apmonitor.com/wiki/ (accessed on 25 December 2020).

- Lever, J.; Kryzwinki, M.; Altman, N. Classification evaluation. Nat. Methods 2016, 13, 603–604. [Google Scholar] [CrossRef]

| Tire Pressure (kPa) | Sample Time (ms) | Simulation Time (s) | (−) | (−) |

|---|---|---|---|---|

| 300 | 20 | 45.657 | 0.482 | 0.032 |

| 300 | 200 | 0.409 | 0.460 | 0.032 |

| 260 | 20 | 41.786 | 0.442 | 0.033 |

| 260 | 200 | 0.389 | 0.471 | 0.033 |

| 200 | 20 | 38.697 | 0.437 | 0.035 |

| 200 | 200 | 0.378 | 0.423 | 0.035 |

| v (km/h) | F (N) | M (Nm) | P (kW) | (V) | (A) | (kW) | (kW) | (kW) | (−) |

|---|---|---|---|---|---|---|---|---|---|

| 15 | 100 | 25 | 0.4 | 44.65 | 23 | 1.03 | 1.03 | 0.35 | 0.66 |

| 15 | 200 | 50 | 0.9 | 44.52 | 35 | I.56 | 1.56 | 0.38 | 0.75 |

| 15 | 300 | 76 | 1.3 | 44.3 | 48 | 2.13 | 2.13 | 0.55 | 0.74 |

| 15 | 400 | 101 | 1.8 | 44.1 | 61 | 2.69 | 2.69 | 0.61 | 0.77 |

| 15 | 500 | 126 | 2.1 | 43.8 | 75 | 3.29 | 3.29 | 0.91 | 0.72 |

| 15 | 760 | 192 | 3.2 | 42.5 | 120 | 5.10 | 5.10 | 1.62 | 0.68 |

| 25 | 50 | 13 | 0.4 | 44.3 | 29 | 1.28 | 1.28 | 0.43 | 0.67 |

| 25 | 100 | 25 | 0.8 | 44.21 | 37 | 1.64 | 1.64 | 0.38 | 0.77 |

| 25 | 200 | 50 | 1.4 | 43.9 | 55 | 2.41 | 2.41 | 0.56 | 0.77 |

| 25 | 300 | 76 | 2.1 | 43.6 | 74 | 3.23 | 3.23 | 0.67 | 0.79 |

| 25 | 505 | 127 | 3.5 | 42.6 | 118 | 05.03 | 05.03 | 11.07 | 0.79 |

| 30 | 60 | 15 | 0.5 | 44 | 35 | 1.54 | 1.54 | 0.49 | 0.68 |

| 30 | 100 | 25 | 0.9 | 43.8 | 44 | 1.93 | 1.93 | 0.48 | 0.75 |

| 30 | 200 | 50 | 1.7 | 43.6 | 66 | 2.88 | 2.88 | 0.63 | 0.78 |

| 30 | 246 | 62 | 2 | 43.3 | 75 | 3.25 | 3.25 | 0.70 | 0.79 |

| 30 | 420 | 106 | 3.5 | 42.7 | 120 | 5.12 | 5.12 | 1.07 | 0.79 |

| 40 | 62 | 16 | 0.7 | 43.6 | 50 | 2.18 | 2.18 | 0.75 | 0.66 |

| 40 | 94 | 24 | 1 | 43.38 | 57 | 2.47 | 2.47 | 0.74 | 0.70 |

| 40 | 165 | 42 | 1.8 | 43.07 | 77 | 3.32 | 3.32 | 0.78 | 0.76 |

| 40 | 293 | 74 | 3.2 | 42.8 | 120 | 5.14 | 5.14 | 1.20 | 0.77 |

| Training 80% | Training 70% | Training 50% | ||||

|---|---|---|---|---|---|---|

| Testing 20% | Testing 30% | Testing 50% | ||||

| LC | RE | LC | RE | LC | RE | |

| KNN | 0.935 | 0.134 | 0.935 | 0.131 | 0.928 | 0.143 |

| XGBoost Tree | 0.948 | 0.148 | 0.950 | 0.142 | 0.950 | 0.122 |

| CHAID | 0.906 | 0.179 | 0.884 | 0.223 | 0.844 | 0.290 |

| C&R Tree | 0.874 | 0.238 | 0.850 | 0.279 | 0.889 | 0.211 |

| Neural Net | 0.783 | 0.390 | 0.792 | 0.379 | 0.726 | 0.482 |

| Training 80% | Training 70% | Training 50% | ||||

|---|---|---|---|---|---|---|

| Testing 20% | Testing 30% | Testing 50% | ||||

| LC | RE | LC | RE | LC | RE | |

| KNN | 0.999 | 0.001 | 0.999 | 0.001 | 0.998 | 0.005 |

| Neural Net | 0.999 | 0.001 | 0.999 | 0.001 | 0.999 | 0.002 |

| CHAID | 0.999 | 0.003 | 0.998 | 0.004 | 0.999 | 0.003 |

| Linear | 0.999 | 0.003 | 0.999 | 0.003 | 0.999 | 0.003 |

| Regression | 0.999 | 0.003 | 0.999 | 0.003 | 0.998 | 0.003 |

| XGBoost Tree | 0.997 | 0.031 | 0.997 | 0.031 | 0.996 | 0.042 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koreny, M.; Simonik, P.; Klein, T.; Mrovec, T.; Ligori, J.J. Hybrid Research Platform for Fundamental and Empirical Modeling and Analysis of Energy Management of Shared Electric Vehicles. Energies 2022, 15, 1300. https://doi.org/10.3390/en15041300

Koreny M, Simonik P, Klein T, Mrovec T, Ligori JJ. Hybrid Research Platform for Fundamental and Empirical Modeling and Analysis of Energy Management of Shared Electric Vehicles. Energies. 2022; 15(4):1300. https://doi.org/10.3390/en15041300

Chicago/Turabian StyleKoreny, Martin, Petr Simonik, Tomas Klein, Tomas Mrovec, and Joy Jason Ligori. 2022. "Hybrid Research Platform for Fundamental and Empirical Modeling and Analysis of Energy Management of Shared Electric Vehicles" Energies 15, no. 4: 1300. https://doi.org/10.3390/en15041300

APA StyleKoreny, M., Simonik, P., Klein, T., Mrovec, T., & Ligori, J. J. (2022). Hybrid Research Platform for Fundamental and Empirical Modeling and Analysis of Energy Management of Shared Electric Vehicles. Energies, 15(4), 1300. https://doi.org/10.3390/en15041300