Optimization of Heat Exchange Plate Geometry by Modeling Physical Processes Using CAD

Abstract

:1. Introduction

- Determination of average useful temperature difference of heat transfer fluids and surfaces.

- Determination of the mode of movement of heat transfer fluids in the channel by using Reynolds number:where

- —Linear speed of the coolant in the channel (m/s);

- —Determining size of the channel through which the coolant moves (m);

- —Kinematic viscosity of the coolant (m/s2);

- —Density of the coolant (kg/m3);

- —Dynamic viscosity of the coolant (Pa/s).

- On the basis of the theory of similarity, we select the criterion Nusselt equation for a certain mode of motion of the coolant in the channel between corrugated plates [3]:where

- Nu—Nusselt number:

- Re—Reynolds number (1);

- Pr—Prandtl number:

- Prf, Prw—Prandtl number at fluid flow temperature and at plate wall temperature, respectively;

- C, n, m—Coefficients selected depending on the mode of motion of the coolant and the surface of the plate;

- α—Heat transfer coefficient (W/m2 K);

- c—Specific heat capacity of the coolant (J/kg K);

- λ—Thermal conductivity coefficient (W/m K).

- The value of the Nusselt number from Equation (2) is substituted in (3) to determine the heat transfer coefficient between the coolant and the plate:

- Construct the geometry of the internal cavity of the heat exchanger;

- Build a computer model of the process of the convective flow between plates for different designs of the surfaces;

- Analyze the influence of the geometry of the heat plates on the efficiency of heat transfer.

2. Materials and Methods

- Simulation of heat exchange when moving a liquid in a flat wall channel.

- Simulation of heat exchange during fluid movement in the channel formed by chevron plates.

- Simulation of heat exchange when moving fluid in a channel formed by plates with conical stamping.

- Optimization of heat exchange plate design with conical stamping.

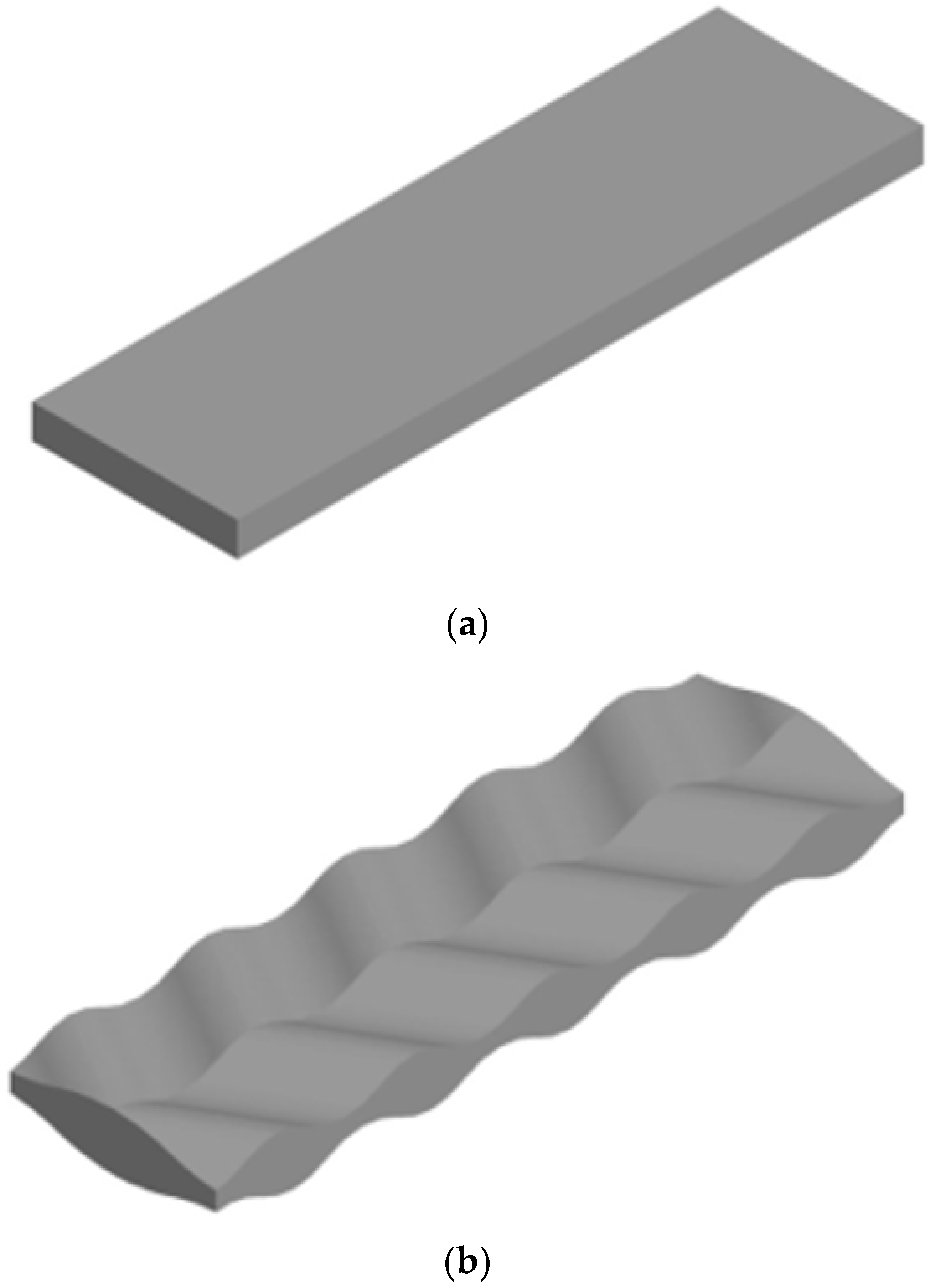

- Flat heat plate;

- Chevron plate;

- Plate with conical stamping.

- Mesh consists of tetrahedra (function Method control: Tetrahedrons);

- When constructing a grid, the function is included «Use Adaptive Sizing» setting the parameter «Resolution» equal to 7.

- Water enters through the front end with speed w = 0.5 m/s and temperature t = 20 °C, boundary condition «Inlet» (Figure 6, position 1);

- The water output is located on the opposite side of the volume, boundary condition «Outlet», pressure at the exit of the volume P = 105 Pa (Figure 6, position 2);

- For the side ends, the border type is set to «Symmetry» to reduce the resources and time for modeling (Figure 6, position 3);

- The upper and lower surfaces of the volume model contact with heat exchange plates having temperature tw = 60 °C and boundary condition «Wall» (Figure 6, position 4).

3. Validation

4. Results and Discussion

5. Conclusions

- For each case, the change in temperature and pressure in the middle flow between the plates and the average values of heat transfer coefficients from the wall to the liquid were determined. Temperature, pressure drop, and heat transfer coefficients follow for three types of stamping: flat heat exchange plate—t = 22.2 °C, P = 40 Pa, α = 2472 W/m2; chevron heat exchange plate—t = 22.4 °C, P = 250 Pa, α = 3340 W/m2; and plate with conical stamps—t = 27.8 °C, P = 1060 Pa, α = 5339 W/m2. After analyzing the data, a heat exchange plate with conical stamps was selected, which has the highest parameters of heat transfer and temperature difference.

- The peculiarities of the process of convective heat transfer in the channel formed by plates with conical stamping are established. The trajectory of the particles is small waves with significant areas of flow turbulence. The velocity of the coolant is much lower because the plates form much smaller channels for fluid movement than in the case of other plates. However, the liquid in this case is heated more intensely in the middle of the stream. Stagnant zones occur closer to the coolant outlet.

- The more complex the configuration of the channel, the greater the heat transfer coefficient. This is due to the fact that the characteristic of turbulent motion is the pulsation of pressures and velocities. The complex configuration of the stamping plates forms a channel of variable cross section, in which the fluid constantly changes the modulus and direction of the velocity vector and, according to Bernoulli’s law, it affects the local pressure change.

- Optimization of heat exchange plate design with conical stamps was carried out for the following parameters: the angle of inclination of the tilt changed in the range from 50° to 65° with a 5° step and the height of the stamping ranged from 1 to 2.5 mm with a 0.5 mm step. A heat exchange plate with conical stamps with a cone height of equal to 1.5 mm and an angle of inclination of the tilting cone of 55° was selected.

Author Contributions

Funding

Conflicts of Interest

References

- Bart, H.-J.; Scholl, S. Innovative Heat Exchangers; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–394. [Google Scholar] [CrossRef]

- Popov, D.; Fikiin, K.; Stankov, B.; Alvarez, G.; Youbi-Idrissi, M.; Damas, A.; Evans, J.; Brown, T. Cryogenic heat exchangers for process cooling and renewable energy storage: A review. Appl. Therm. Eng. 2019, 153, 275–290. [Google Scholar] [CrossRef]

- Ioffe, I. Design of Processes and Apparatuses of Chemical Technology; Chemistry: Leningrad, Russia, 1991. [Google Scholar]

- Datta, N.; Zhuang, Z.; Qin, W. Experimental study of a liquid desiccant regeneration system: Performance analysis for high feed concentrations. Clean Technol. Environ. Policy 2020, 22, 1255–1267. [Google Scholar] [CrossRef]

- Prun, O.E.; Garyaev, A.B. Method for Optimization of Heat-Exchange Units Working in Heat Recovery Systems. Therm. Eng. 2020, 67, 560–566. [Google Scholar] [CrossRef]

- Lin, W.; Ling, Z.; Fang, X.; Zhang, Z. Research progress on heat transfer of phase change material heat storage technology. HuagongJinzhan/Chem. Ind. Eng. Prog. 2021, 40, 5166–5179. [Google Scholar] [CrossRef]

- Piper, M.; Zibart, A.; Kenig, E.Y. New design equations for turbulent forced convection heat transfer and pressure loss in pillow-plate channels. Int. J. Therm. Sci. 2017, 120, 459–468. [Google Scholar] [CrossRef]

- Pfortner, B.; Hadad, W.A.; Schick, V.; Maillet, D.; Zacharie, C.; Rémy, B. Transient detection of either maldistribution or flowrate change in a counter current plate-fin heat exchanger using an ARX model. Int. J. Heat Mass Transf. 2022, 182, 121987. [Google Scholar] [CrossRef]

- Korobiichuk, I.; Bezvesilna, O.; Ilchenko, A.; Shadura, V.; Nowicki, M.; Szewczyk, R. A Mathematical Model of the Thermo-Anemometric Flowmeter. Sensors 2015, 15, 22899–22913. [Google Scholar] [CrossRef] [Green Version]

- Klugmann, M.; Dąbrowski, P.; Mikielewicz, D. Flow distribution and heat transfer in minigap and minichannel heat exchangers during flow boiling. Appl. Therm. Eng. 2020, 181, 116034. [Google Scholar] [CrossRef]

- Gusew, S. Heat transfer in plate heat exchangers in the transition flow regime. J. Enhanc. Heat Transf. 2015, 22, 441–455. [Google Scholar] [CrossRef]

- Jiang, C.; Zhou, W.; Tang, X.; Bai, B. Influence of capsule length and width on heat transfer in capsule-type plate heat exchangers. Adv. Mech. Eng. 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Savvin, N.Y.; Kushchev, L.A.; Feoktistov, A.Y.; Roshchubkin, P.V. The enhanced plate heat exchanger for systems of housing and communal services. J. Phys. Conf. Ser. 2020, 1679, 052079. [Google Scholar] [CrossRef]

- Arsenyeva, O.; Kapustenko, P.; Tovazhnyanskyy, L.; Khavin, G. The influence of plate corrugations geometry on plate heat exchanger performance in specified process conditions. Energy 2013, 57, 201–207. [Google Scholar] [CrossRef] [Green Version]

- Korobiichuk, I.; Bezvesilna, O.; Ilchenko, A.; Trostenyuk, Y. Thermoanemometricflowmeter of biofuels for motor transport. Adv. Intell. Syst. Comput. 2017, 519, 443–448. [Google Scholar] [CrossRef]

- Korobiichuk, I.; Kachniarz, M.; Shavursky Yu Nowicki, M.; Szewczyk, R. Algorithms on Improvement of Accuracy of Biofuel Temperature Measurement in Thermo-anemometric Flowmeter. In Proceedings of the 2017 4th International Conference on Control, Decision and Information Technologies (CoDIT), Barcelona, Spain, 5–7 April 2017; pp. 0964–0968. [Google Scholar] [CrossRef]

- Tran, J.M.; Linnemann, M.; Piper, M.; Kenig, E.Y. On the coupled condensation-evaporation in pillow-plate condensers: Investigation of cooling medium evaporation. Appl. Therm. Eng. 2017, 124, 1471–1480. [Google Scholar] [CrossRef]

- Jung, J.H.; Ko, Y.M.; Kang, Y.T. Condensation heat transfer characteristics and energy conversion performance analysis for low GWP refrigerants in plate heat exchangers. Int. J. Heat Mass Transf. 2021, 166, 120727. [Google Scholar] [CrossRef]

- Gupta, A.K.; Kumar, M.; Sahoo, R.K.; Sarangi, S.K. Analytical and experimental investigation of a plate fin heat exchanger at cryogenics temperature. Int. J. Heat Technol. 2021, 39, 1225–1235. [Google Scholar] [CrossRef]

- Rauber, W.K.; Silva, U.F.; VazJr, M.; Alves, M.V.C.; Zdanski, P.S.B. Investigation of the effects of fin perforations on the thermal-hydraulic performance of Plate-Finned heat exchangers. Int. J. Heat Mass Transf. 2022, 185, 122561. [Google Scholar] [CrossRef]

- Payambarpoura, S.A.; Shokouhmanda, H.; Ahmadib, M.H.; Assadc, M.E.H.; Chend, L. Effect of wetness pattern on the fin-tube heat exchanger performance under partially wet-surface condition. Therm. Sci. Eng. Prog. 2020, 19, 100619. [Google Scholar] [CrossRef]

- Payambarpoura, S.A.; Nazari, M.A.; Ahmadib, M.H.; Chamkha, A.J. Effect of partially wet-surface condition on the performance of fin-tube heat exchanger. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 3938–3958. [Google Scholar] [CrossRef]

- Aljubaili, D.; Chan, L.; Lu, W.; Ooi, A. Numerical investigations of the wake behind a confined flat plate. Int. J. Heat Fluid Flow 2022, 94, 108924. [Google Scholar] [CrossRef]

- Baran, B.; Machaj, K.; Malecha, Z.; Tomczuk, K. Numerical Study of Baroclinic Acoustic Streaming Phenomenon for Various Flow Parameters. Energies 2022, 15, 854. [Google Scholar] [CrossRef]

- Lisowski, F.; Lisowski, E. Influence of Fins Number and Frosting on Heat Transfer through Longitudinal Finned Tubes of LNG Ambient Air Vaporizers. Energies 2022, 15, 280. [Google Scholar] [CrossRef]

- AboulKhail, A.; Erişen, A. Improvement of Plate Heat Exchanger Performance Using a New Plate Geometry. Arab. J. SciEng. 2021, 46, 2877–2889. [Google Scholar] [CrossRef]

- Kostyk, S.; Shybetskyy, V.; Fesenko, S.; Povodzinskiy, V. Revealing special features of hydrodynamics in a rotor-disk film vaporizing plant. East.-Eur. J. Enterp. Technol. 2019, 1, 28–33. [Google Scholar] [CrossRef] [Green Version]

- Vargaftik, N.B. Handbook on the Thermophysical Properties of Water and Gases; Nauka: Moscow, Russia, 1972. [Google Scholar]

- Korobiichuk, I.; Shybetska, N.; Shybetskyi, V.; Kostyk, S. Modeling of Systems of Automated Auxiliary Processes in Pharmaceutical Industry. In Automation 2021: Recent Achievements in Automation, Robotics and Measurement Techniques. AUTOMATION 2021. Advances in Intelligent Systems and Computing; Szewczyk, R., Zieliński, C., Kaliczyńska, M., Eds.; Springer: Cham, Switzerland, 2021; Volume 1390. [Google Scholar]

- Shybetskiy, V.; Semeniuk, S.; Kostyk, S. Design of consrtuction and hydrodynamic modeling in a roller bioreactor with surface cultivation of cell cultures. ScienceRise 2017, 7, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Korobiichuk, I.; Mel’nick, V.; Karachun, V.; Shybetskyi, V.; Kostyk, S. Numerical modeling of the possibility of scale power growth of the internal combustion engine in real time. In Proceedings of the 2021 25th International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 23–26 August 2021; pp. 309–314. [Google Scholar]

- Pankaj, S.; Gautam, B.; Subrata, S. Comparison of winglet-type vortex generators periodically deployed in a plate-fin heat exchanger—A synergy based analysis. Int. J. Heat Mass Transf. 2014, 74, 292–305. [Google Scholar]

- Deeb, R. Effect of angle of attack on heat transfer and hydrodynamic characteristics for staggered drop-shaped tubes bundle in cross-flow. Proc. Russ. High. Sch. Acad. Sci. 2020, 48, 21–36. [Google Scholar] [CrossRef]

| № | Angle of Inclination for the Concave, ° | Inlet Temperature, °C | Output Temperature, °C | Temperature Difference, °C |

|---|---|---|---|---|

| 1 | 50 | 20 | 25.3 | 5.3 |

| 2 | 55 | 20 | 27.1 | 7.1 |

| 3 | 60 | 20 | 27.9 | 7.9 |

| 4 | 65 | 20 | 28.7 | 8.7 |

| № | Angle of Inclination for the Concave, ° | Average Values of Heat Transfer Coefficient, W/m2 K |

|---|---|---|

| 1 | 50 | 4922 |

| 2 | 55 | 5722 |

| 3 | 60 | 5207 |

| 4 | 65 | 5216 |

| № | Cone Height, mm | Inlet Temperature, °C | Output Temperature, °C | Temperature Difference, °C |

|---|---|---|---|---|

| 1 | 1 | 20 | 22.8 | 2.8 |

| 2 | 1.5 | 20 | 24.5 | 4.5 |

| 3 | 2 | 20 | 25.8 | 5.8 |

| 4 | 2.5 | 20 | 26 | 6 |

| № | Cone Height, mm | Mean Heat Transfer Coefficient, W/m2 K |

|---|---|---|

| 1 | 1 | 3720 |

| 2 | 1.5 | 4366 |

| 3 | 2 | 5026 |

| 4 | 2.5 | 5993 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korobiichuk, I.; Mel’nick, V.; Shybetskyi, V.; Kostyk, S.; Kalinina, M. Optimization of Heat Exchange Plate Geometry by Modeling Physical Processes Using CAD. Energies 2022, 15, 1430. https://doi.org/10.3390/en15041430

Korobiichuk I, Mel’nick V, Shybetskyi V, Kostyk S, Kalinina M. Optimization of Heat Exchange Plate Geometry by Modeling Physical Processes Using CAD. Energies. 2022; 15(4):1430. https://doi.org/10.3390/en15041430

Chicago/Turabian StyleKorobiichuk, Igor, Viktorij Mel’nick, Vladyslav Shybetskyi, Sergii Kostyk, and Myroslava Kalinina. 2022. "Optimization of Heat Exchange Plate Geometry by Modeling Physical Processes Using CAD" Energies 15, no. 4: 1430. https://doi.org/10.3390/en15041430