Optimization Control of Oilfield Waterflooding Systems Based on Different Zone and Pressure

Abstract

:1. Introduction

2. Methodology

2.1. Different Pressure Design of Pipe Network Based on Fuzzy Logic

2.1.1. Prior Knowledge of Fuzzy Logic Reasoning

- (1)

- Taking the pressure of a well as a judgment principle, the high-pressure well will be classified into the high-pressure area.

- (2)

- The differential pressure of two adjacent wells on the same pipeline is taken as the judgment principle. If the pressure difference between two wells is relatively high, the separation can be executed through fuzzy logic.

- (3)

- Taking the operability of wells as the judgment principle, we will judge whether there is a cut-off valve on the pipeline around the well and whether the cut-off valve is near the road, which can be easily shut down. If the normal water supply of other wells is not affected after cutting off the water supply pipeline, it is considered to have high operability.

- (4)

- In the case of several high-pressure wells in the low-pressure area or several low-pressure wells in the high-pressure area, it is not necessary to delineate them; there is no practical significance. If this is in the isolated low-pressure area, it needs to be merged into the surrounding high-pressure area.

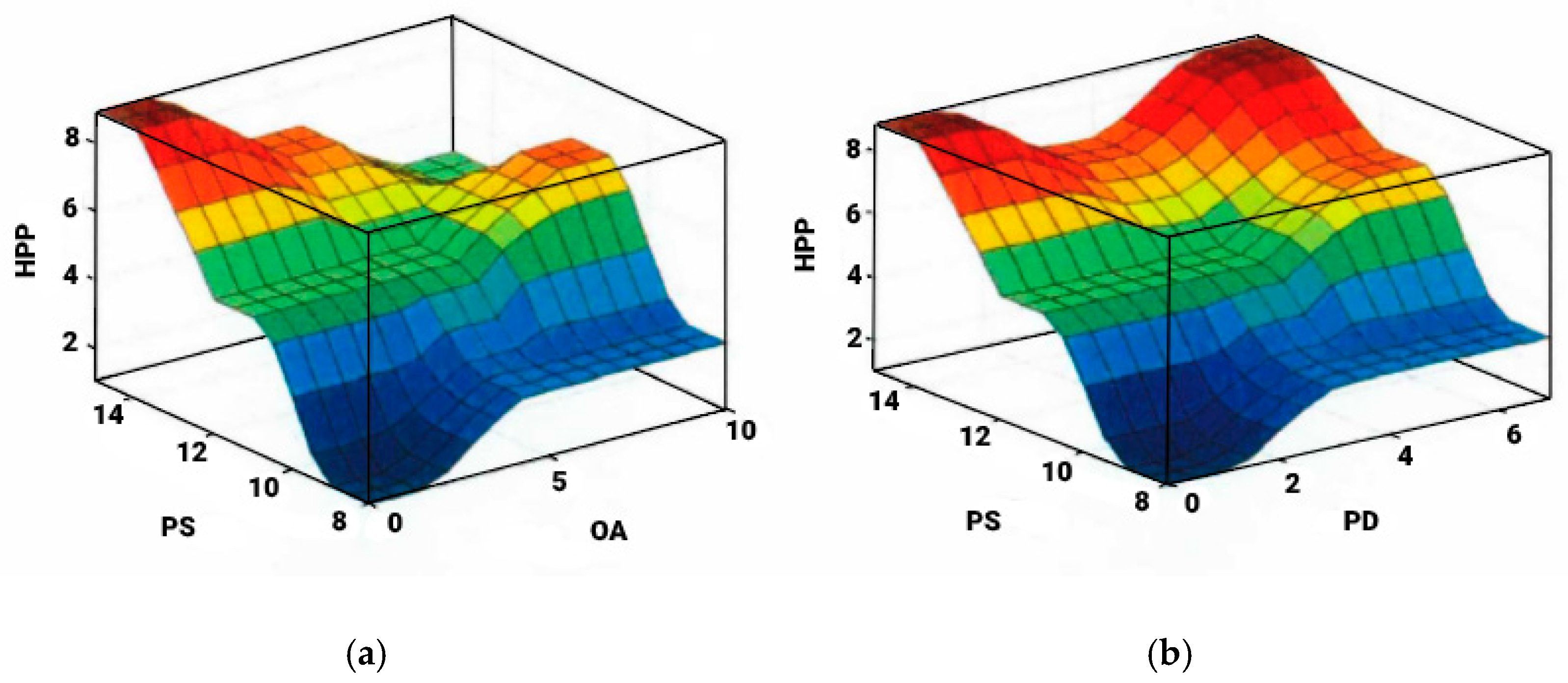

2.1.2. The Model of Fuzzy Reasoning System

- (1)

- The fuzzy set of PS is (low, middle, high). The domain is (8, 15). The domain value is different for different oil fields or production blocks.

- (2)

- The fuzzy set of PD is (low, middle, high). The domain is (0, 7). The domain value is different for different oil fields or production blocks.

- (3)

- The fuzzy set of OA is (low, middle, high). The domain is (0, 10).

- (4)

- The fuzzy set of HPP is (low, lower, middle, higher, high). The domain is (0, 10). If the fuzzy set of HPP is above higher, it can be included in the high-pressure area.

2.1.3. Design of Fuzzy Reasoning Rules

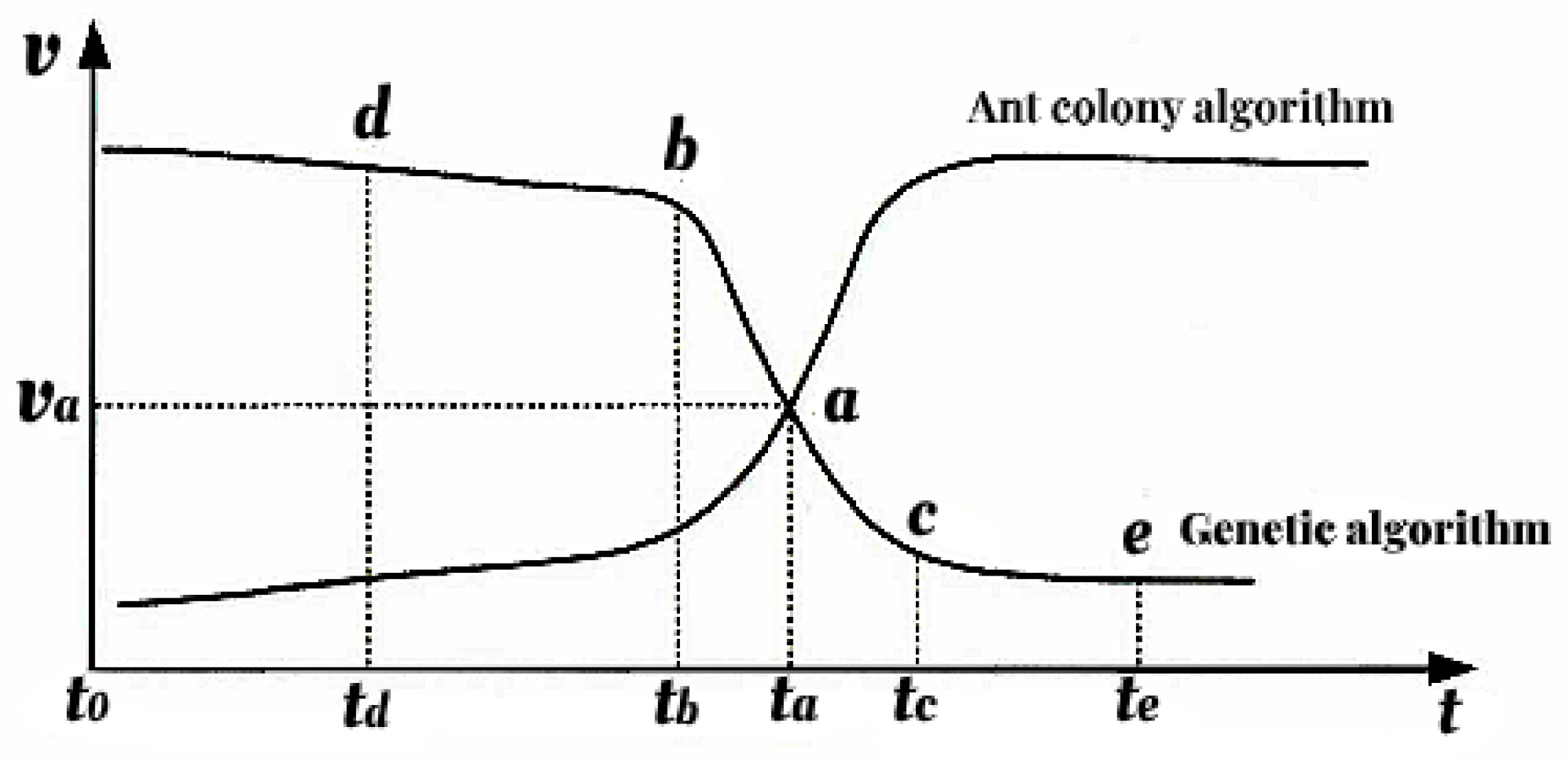

2.2. A New Adaptive Ant Colony Genetic Hybrid Algorithm

2.2.1. Fusion of the Genetic Algorithm and Ant Colony Algorithm

- (1)

- An adaptive control strategy for pheromone volatilization coefficient is proposed in order to improve the solution efficiency of the ant colony algorithm and prevent the results from falling into the local optimization.

- (2)

- The maximum and minimum ant systems are introduced to limit the residual pheromones in each subspace to a certain range in order to prevent stagnation and diffusion.

2.2.2. Adaptive Ant Colony Genetic Hybrid Algorithm

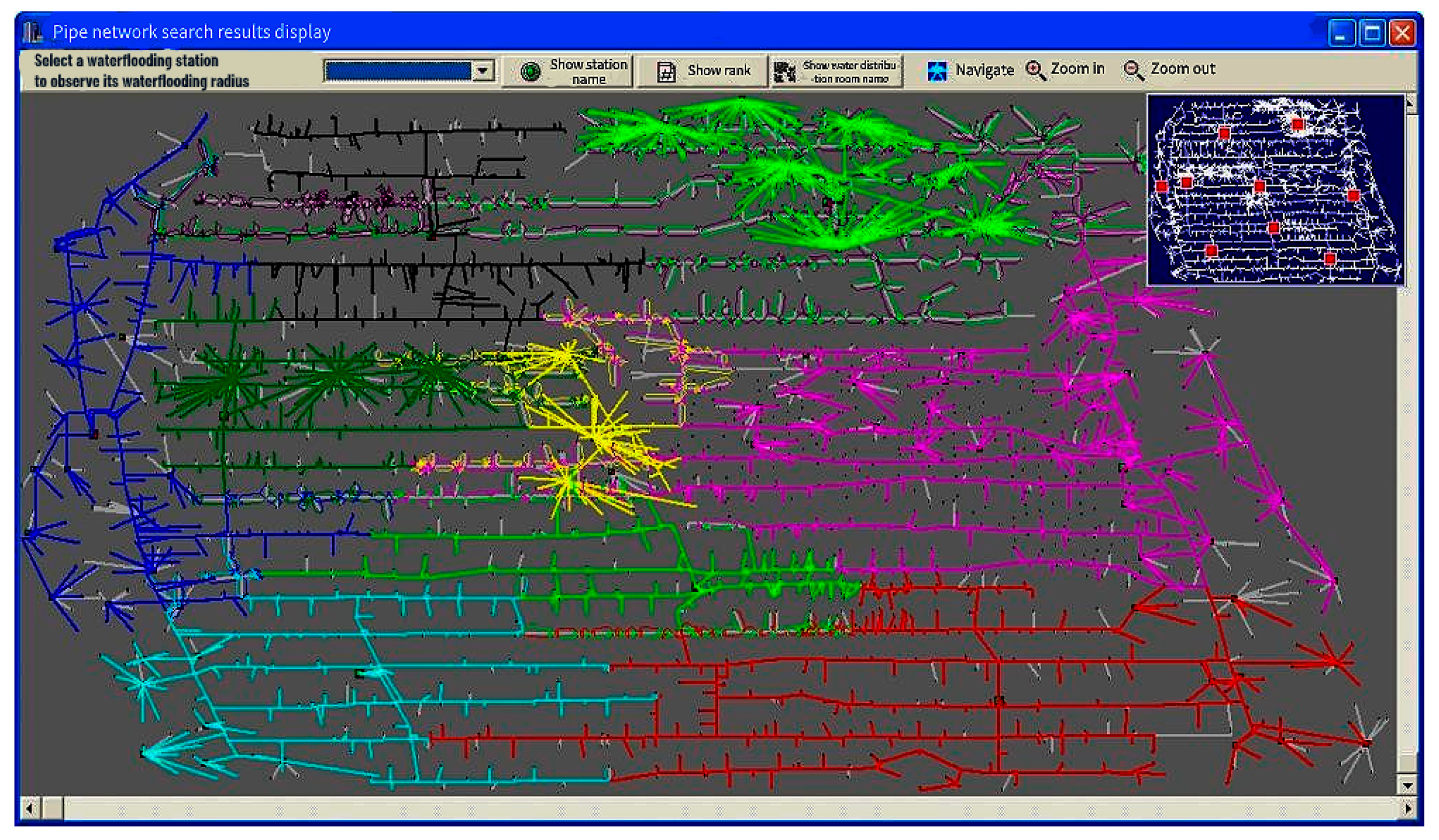

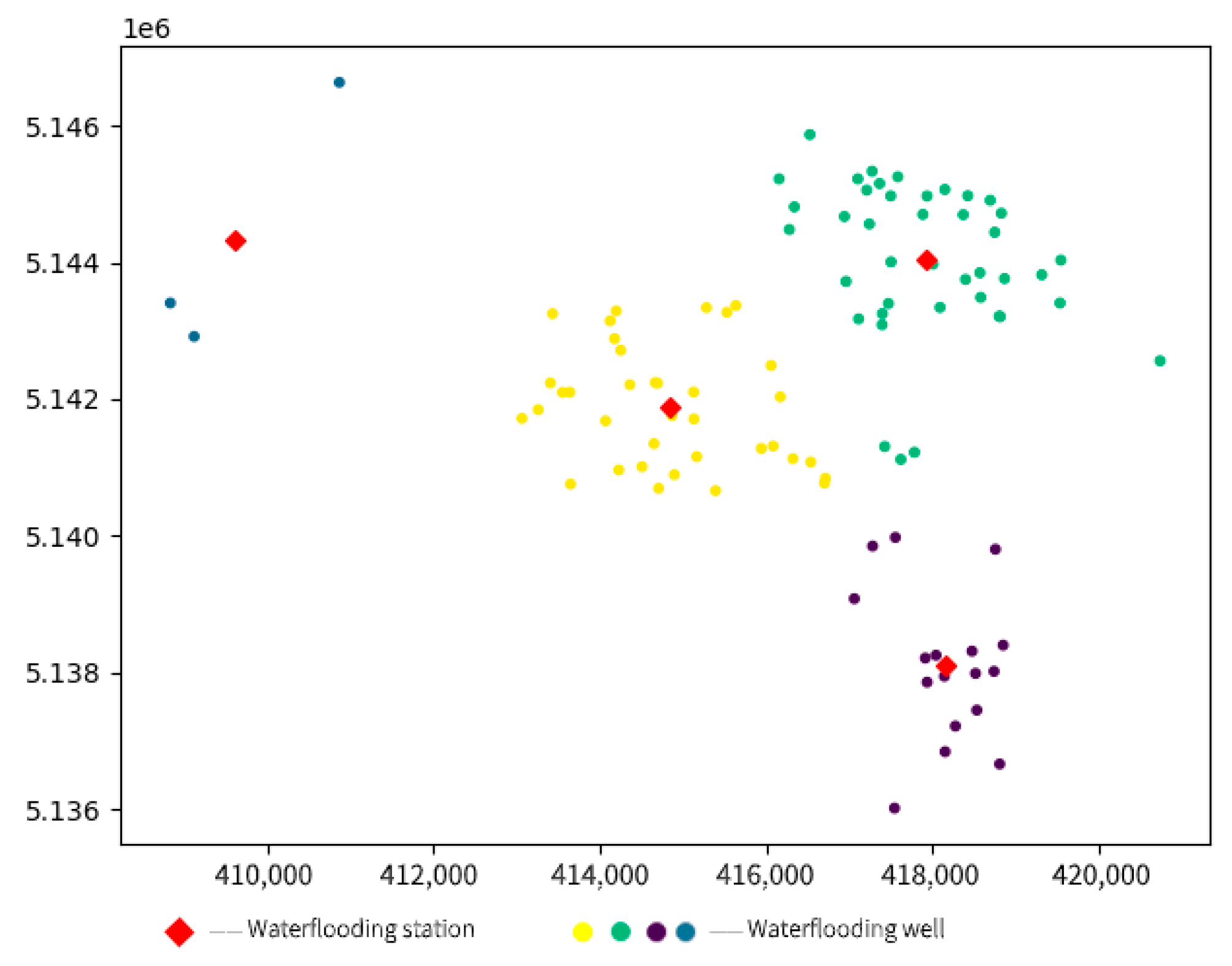

2.3. K-Means Algorithm for High Pressure Zone Topology

3. Results and Discussion

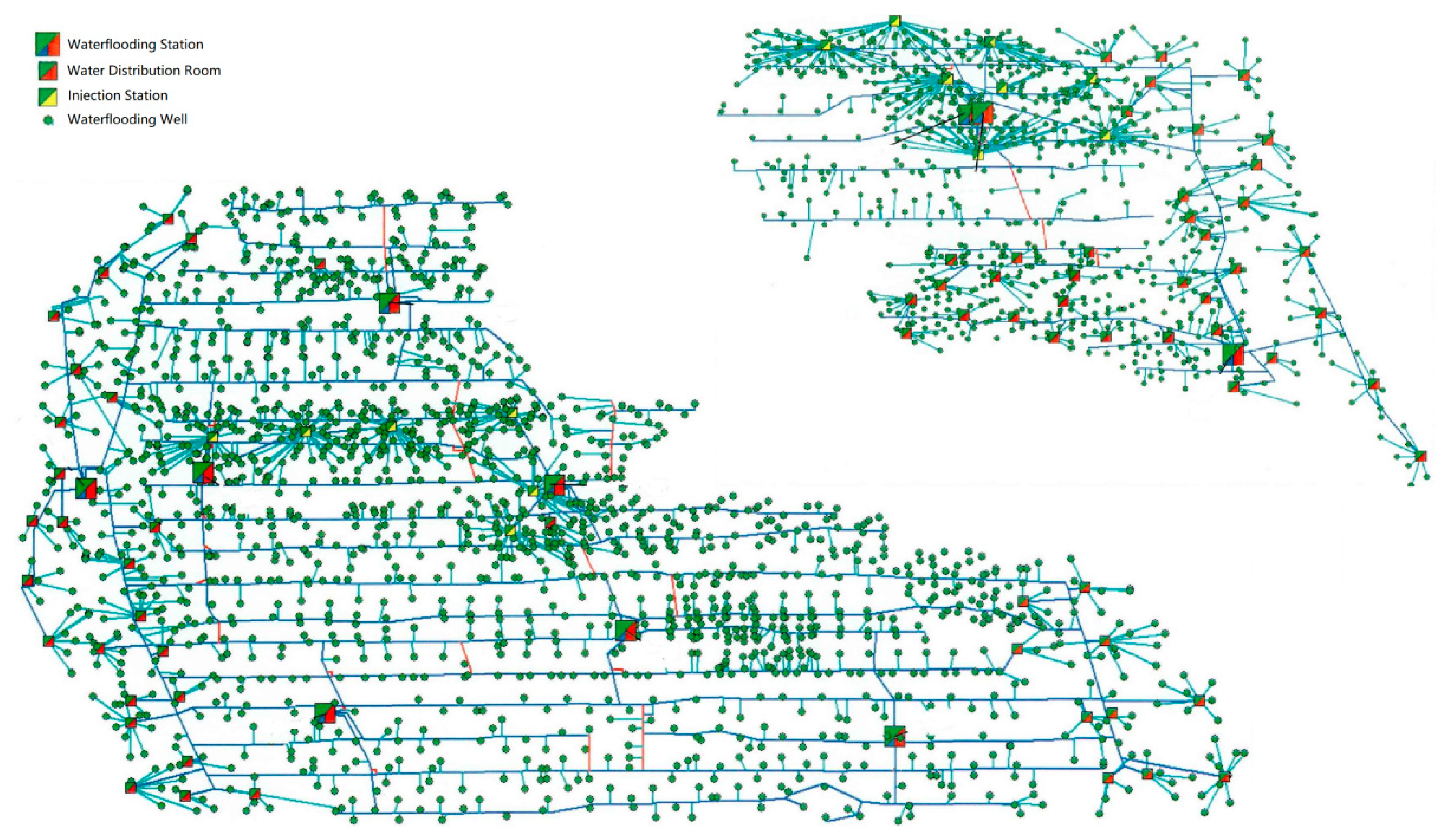

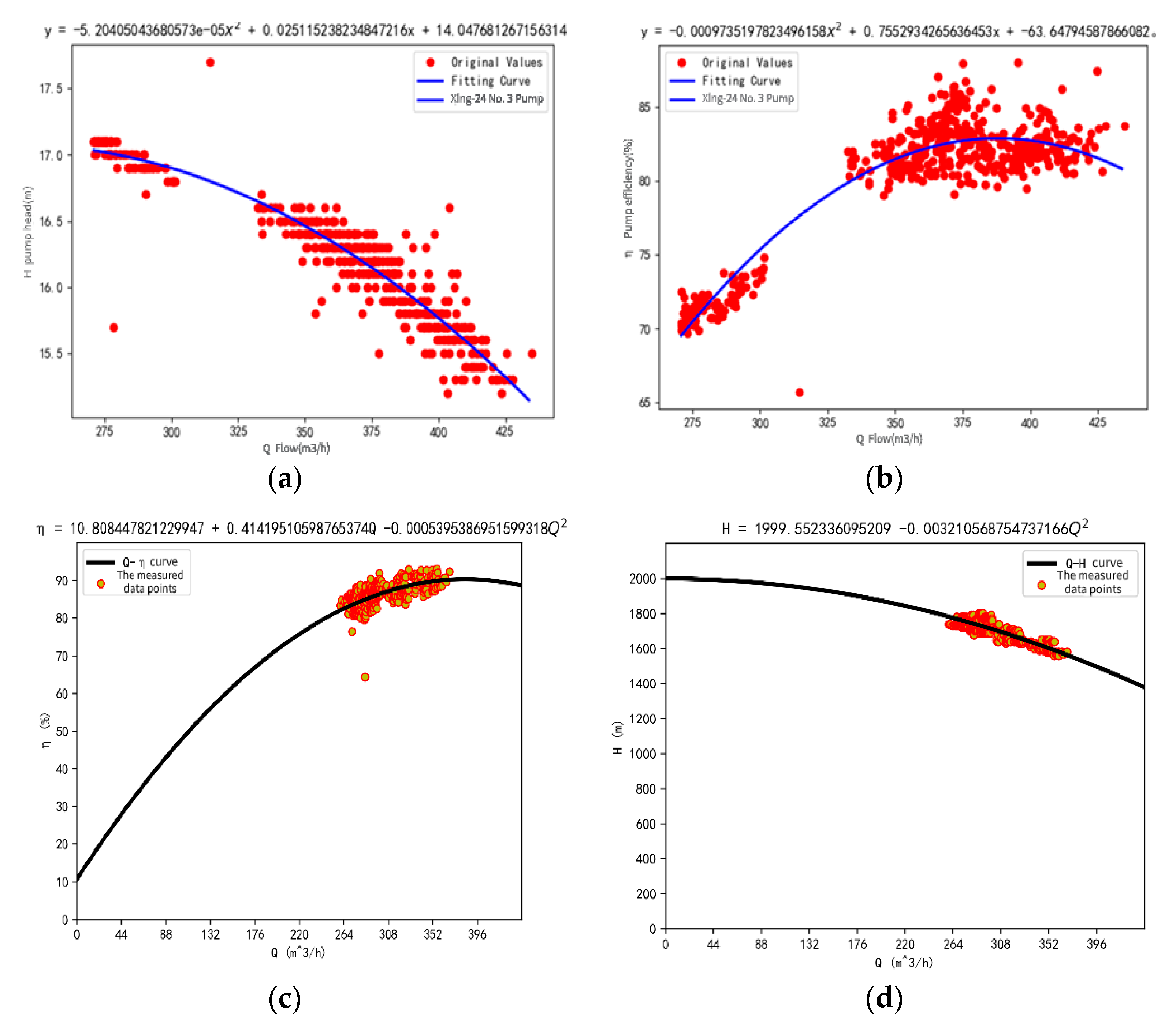

3.1. Simulation and Analysis of System

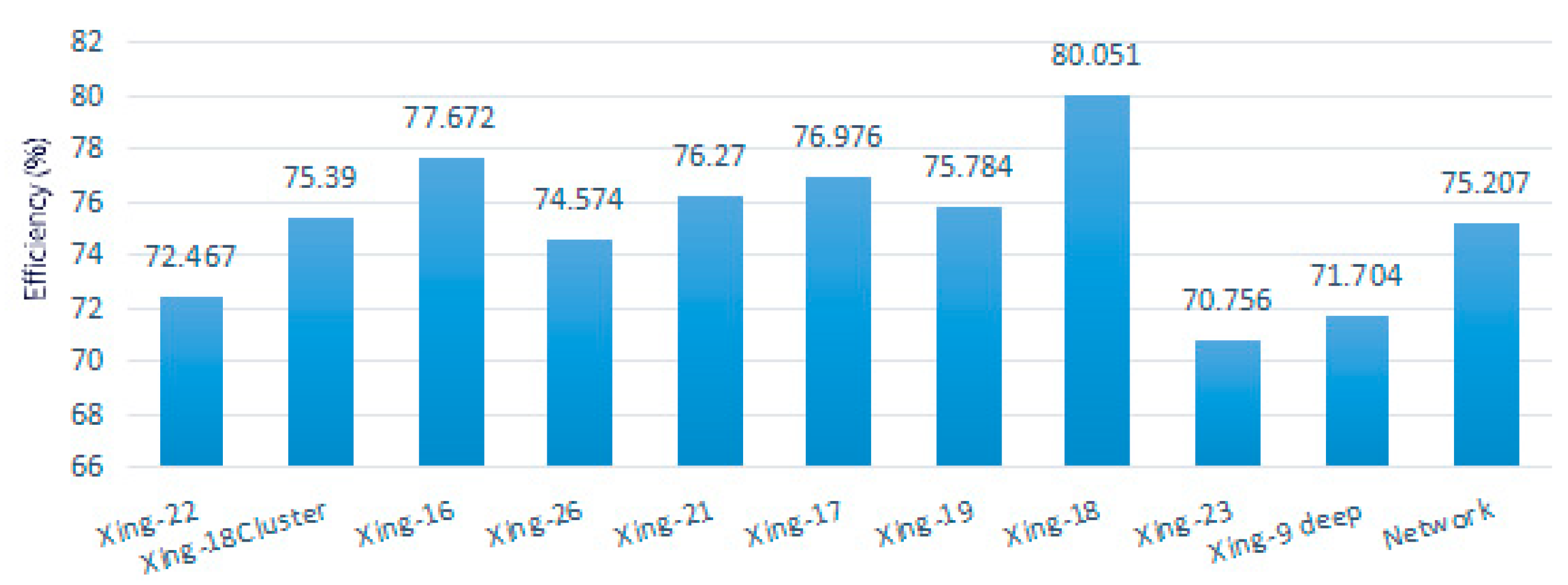

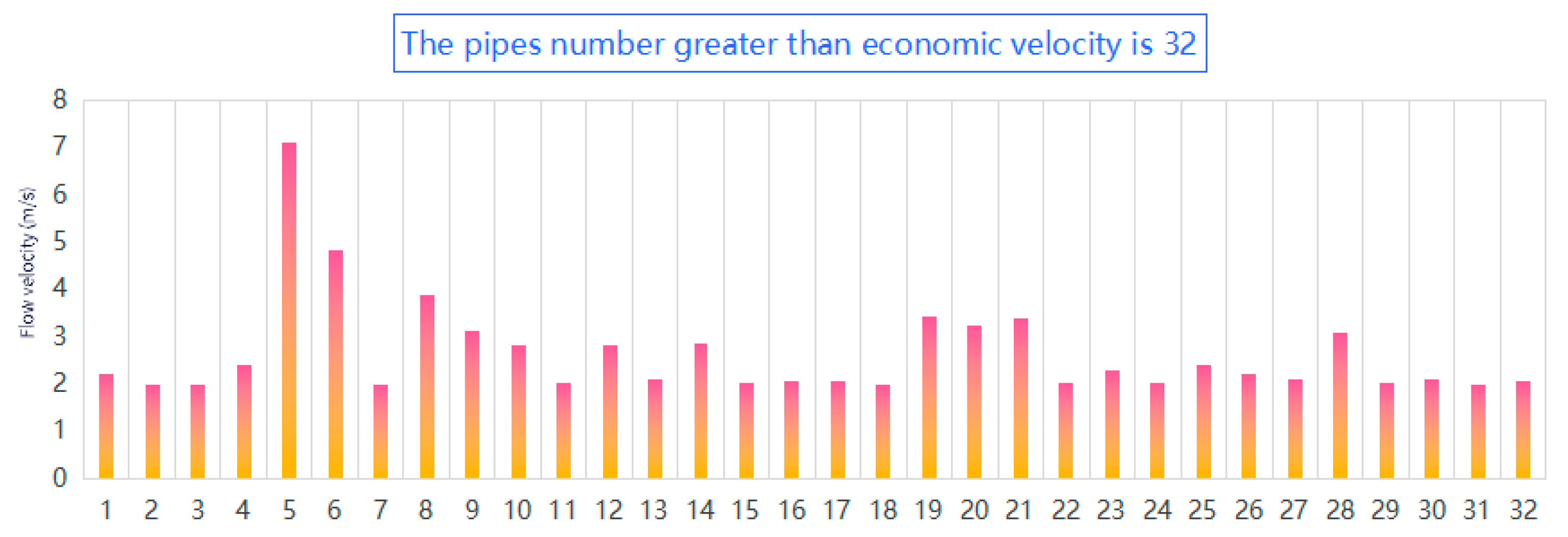

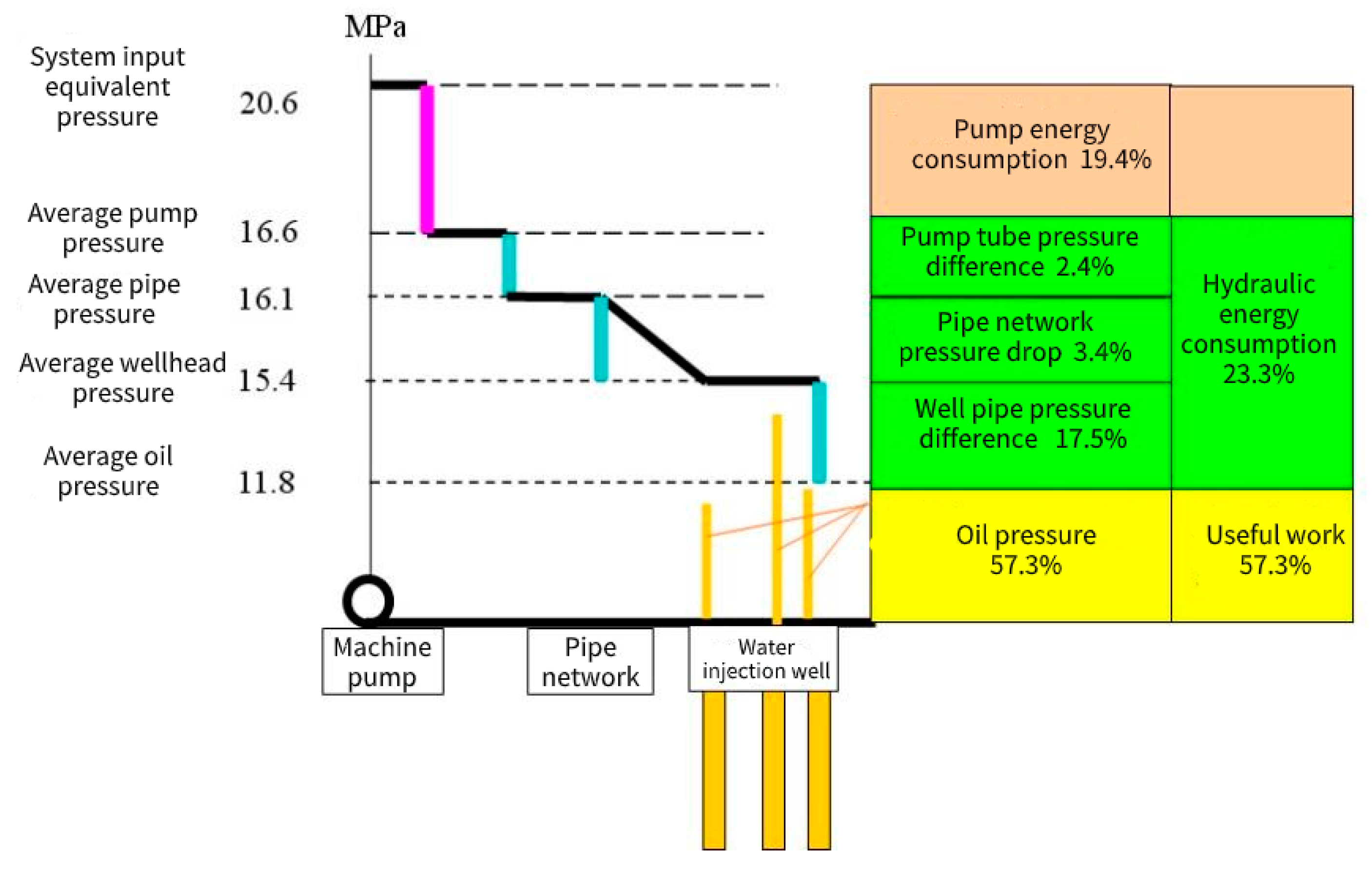

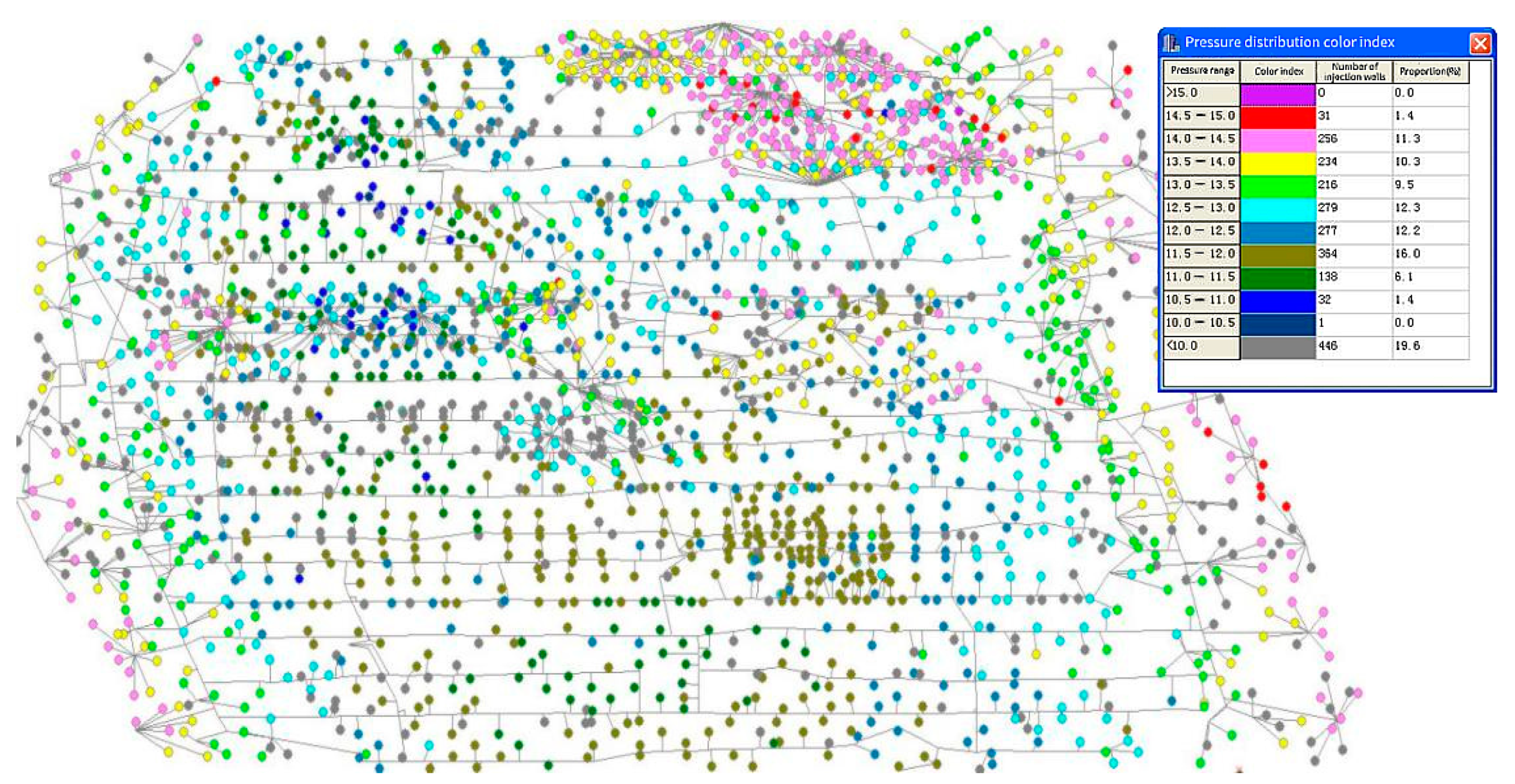

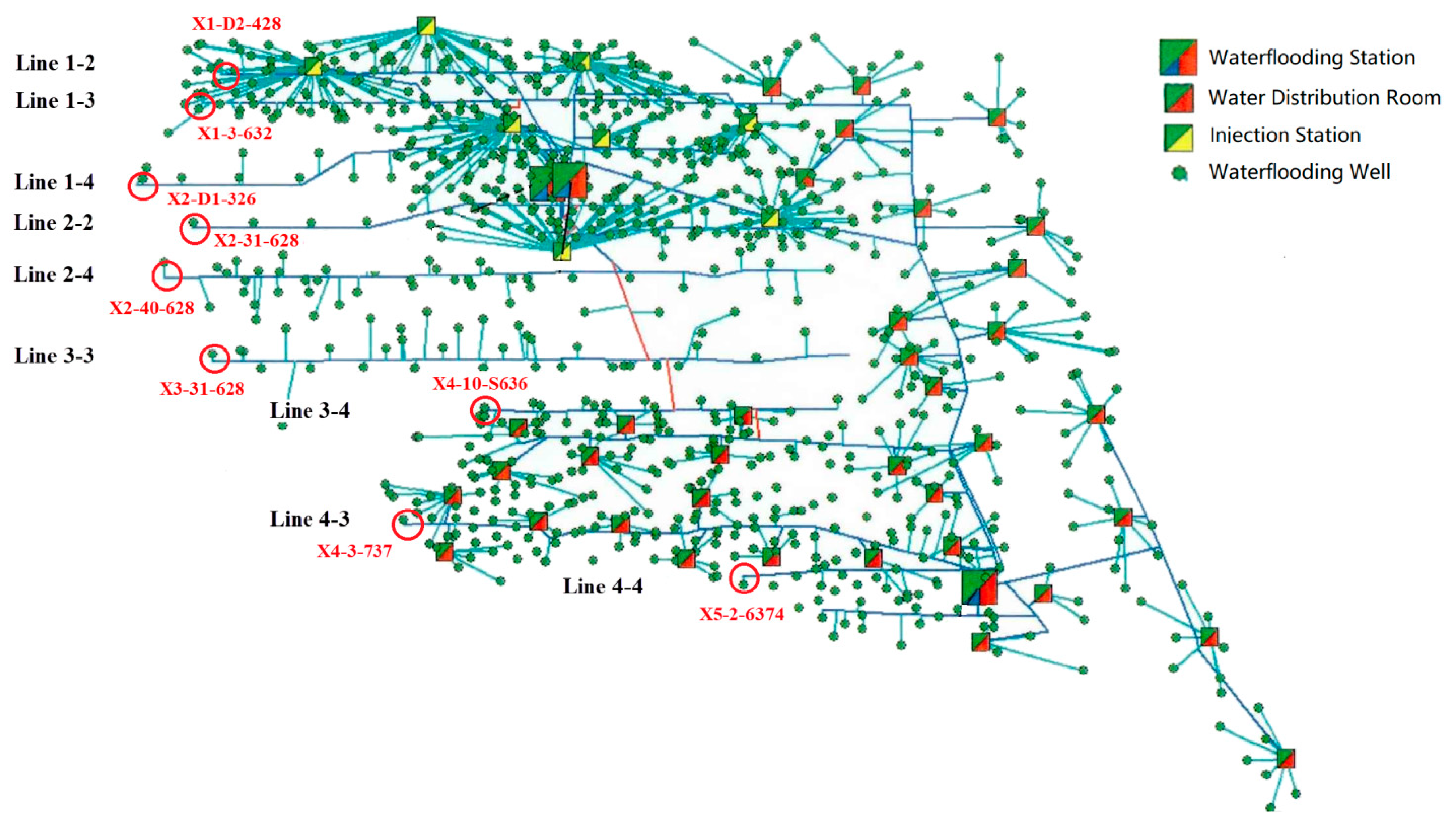

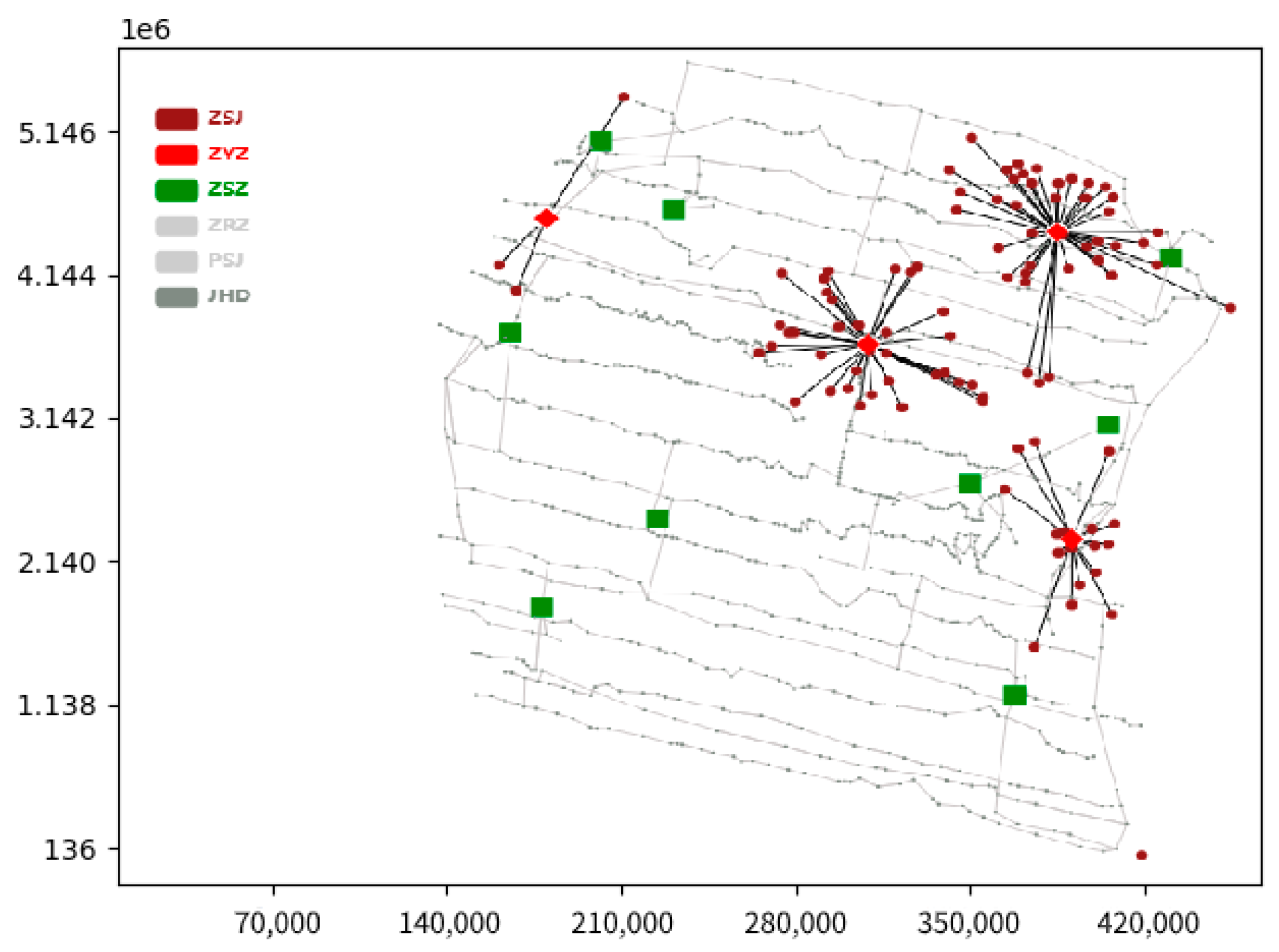

3.2. Different Zone and Pressure of System

3.3. Operation Effect of Low-Pressure Area

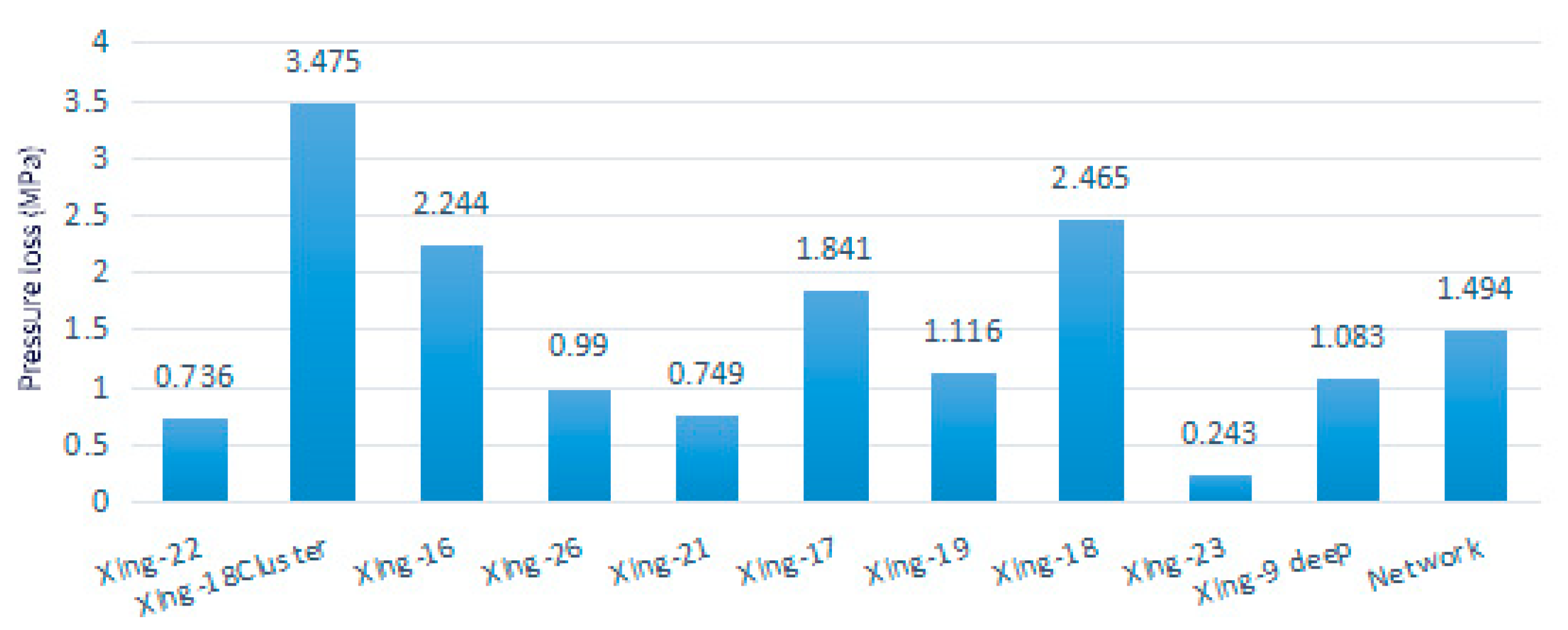

3.4. Operation Effect of High-Pressure Area

4. Conclusions

- (1)

- According to the characteristics of mixed distribution for high–low pressure wells in oilfields and based on the fuzzy logic theory, a different pressure model is established; well pressure, the pressure difference of adjacent wells and operability are its variables. The fuzzy logic theory domain and reasoning rules are established. As an example, the different pressure design of the waterflooding system is carried out with the X oilfield including 2200 wells and 10 waterflooding stations in a site in China. It is proven that the theory and method can effectively divide wells into high–low pressure areas through simulation and application research.

- (2)

- A new adaptive ant colony genetic hybrid algorithm is proposed based on the analysis of the genetic algorithm and ant colony algorithm and the characteristics of operation optimization for the waterflooding system. This method is used to calculate the operation optimization problem after separating pressure. The energy saving effect is remarkable through the application of the optimization results in the X oilfield. Its unit consumption decreased to 0.27 kWh/ and the efficiency of the system increased 2–3 percentage points.

- (3)

- The K-means algorithm is introduced into the station layout in the high-pressure area. The objective function is to minimize the investment of the waterflooding system. The flooding requirements of the waterflooding wells are the constraints. The model is established and solved. The results show that the energy saving effect of the high-pressure area is remarkable after the renovation. Its unit consumption decreased to 0.45 kWh/.

- (4)

- The research results show the new method of classifying high–low pressure wells has great significance for solving high–low pressure mixed flooding in old oilfields and the increase in system energy consumption from the perspective of different pressure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Export pressure at the outlet of the i-th pump | |

| Incoming pressure at the inlet of the i-th pump | |

| The output volume of the i-th pump, which is the optimization variable that constitutes a vector Q | |

| Operating efficiency of the i-th pump | |

| Motor efficiency of the i-th pump | |

| n | Number of pumps in operation |

| Unit conversion factor, which is a constant | |

| The lower limit of the value of the i-dimensional variable | |

| The upper limit of the value of the i-dimensional variable | |

| C | Volatilization constraint |

| Lower bound of pheromone residue coefficient |

References

- Naevdal, G.; Brouwer, D.R.; Jansen, J.D. Waterflooding Using Closed-loop Control. Comput. Geosci. 2006, 10, 37–60. [Google Scholar] [CrossRef]

- Tang, L.; Li, J.; Lu, W.; Lian, P.; Wang, H.; Jiang, H.; Wang, F.; Jia, H. Well Control Optimization of Waterflooding Oilfield Based on Deep Neural Network. Geofluids 2021. [Google Scholar] [CrossRef]

- Seddiqi, K.N.; Mahdi, Z. Application of waterflooding technique to the Angut oilfield in the northern part of Afghanistan. J. Pet. Explor. Prod. Technol. 2018, 8, 939–946. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Liang, Y.; Zhou, X.; Yan, X.; Qian, C.; Liao, Q. Sensitivity analysis and optimal operation control for large-scale waterflooding pipeline network of oilfield. J. Pet. Sci. Eng. 2017, 154, 38–48. [Google Scholar] [CrossRef]

- Zhou, X.; Liang, Y.; Xin, S.; Di, P.; Yan, Y.; Zhang, H. A MINLP model for the optimal waterflooding strategy and operation control of surface waterflooding pipeline network considering reservoir characteristics. Comput. Chem. Eng. 2019, 129, 106512. [Google Scholar] [CrossRef]

- Liang, H.B.; Li, M.; Tan, X.Q. Discussion on simulated annealing algorithm for optimal scheduling of water supply system. Water Supply Drain. 1999, 25, 30–33. [Google Scholar]

- Orr, C.H.; Ulanicki, B.; Rance, J.P. Computer control of operations at a large distribution systems. J. Am. Water Wastewater Assoc. 1992, 84, 68–74. [Google Scholar] [CrossRef]

- Liu, W.G. Research on modeling and optimization of large centrifugal pumping station system in oilfield. China Equip. Eng. 2007, 5, 10–12. [Google Scholar]

- Li, L.; Zhang, C.G.; Lin, J.H.; Li, H.B. Optimal scheduling of pumping station based on cell exclusion double population genetic algorithm. Control. Theory Appl. 2004, 1, 63–69. [Google Scholar]

- Yang, P.; Ji, X.H.; Shi, W.W. An improved genetic algorithm for optimal scheduling of pumping stations considering variable frequency speed regulation. J. Yangzhou Univ. 2002, 5, 67–70. [Google Scholar]

- Ning, Y.B.; Ming, Z.F.; Zhong, Y.R. Principle and realization of variable frequency speed regulation and constant pressure water supply system. J. Xi’an Univ. Technol. 2001, 17, 305–309. [Google Scholar]

- Ilich, N.; Simonovic, S.P. Evolutionary Algorithm for Minimization of Pumping Cost. J. Comput. Civ. Eng. 1998, 12, 232–240. [Google Scholar] [CrossRef]

- Hou, D.Y.; Sun, S.G. Optimal scheduling of water supply pump station based on genetic algorithm. J. Shandong Univ. (Eng. Ed.) 2003, 33, 25–28. [Google Scholar]

- Yao, Z.Q. Discussion on several issues in frequency control and constant pressure water supply. J. Xi’an Highw. Univ. 1997, 17, 80–82. [Google Scholar]

- Yang, X.X.; Li, L.; Lin, J.H. Research on optimal control of water supply pump station based on genetic algorithm. J. Appl. Basic Eng. Sci. 1999, 7, 209–214. [Google Scholar]

- Yang, P.; Ji, X.H.; Shi, W.W. Optimal scheduling of pumping stations based on genetic algorithm. J. Yangzhou Univ. 2001, 4, 72–74. [Google Scholar]

- Chen, H.; Liu, Z.Y.; Shi, W.W. Optimal scheduling of water supply pump station based on simulated annealing algorithm. Drain. Irrig. Mach. 2003, 21, 34–37. [Google Scholar]

- Guan, X.J.; Wei, L.X.; Yang, J.J. Optimization model of oilfield waterflooding system operation scheme based on hybrid genetic algorithm. Chin. J. Pet. 2005, 26, 114–117. [Google Scholar]

- Yang, J.J.; Liu, Y.; Wei, L.X.; Zhan, H. Double coding hybrid genetic algorithm for optimal scheduling of pump station in multi-source waterflooding system. J. Autom. 2006, 32, 154–160. [Google Scholar]

- Wei, L.X.; Liu, Y.; Sun, H.Z. Optimization of operation and scheduling of waterflooding system in multi-source oilfield. Pet. Extr. Technol. 2007, 29, 59–62. [Google Scholar]

- Yang, J.J.; Liu, Y.; Wei, L.X.; Zhan, H.; Zeng, W. Operation optimization of waterflooding system based on dual coding genetic algorithm. Pet. Mine Mach. 2006, 35, 8–11. [Google Scholar]

- Rodriguez, A.X.; Aristizábal, J.; Cabrales, S.; Gómez, J.M.; Medaglia, A.L. Optimal waterflooding management using an embedded predictive analytical model. J. Pet. Sci. Eng. 2022, 208, 109419. [Google Scholar] [CrossRef]

- Zhang, M. The adjustment method of centrifugal pump and its energy consumption analysis. Coal Technol. 2005, 24, 18–20. [Google Scholar]

- Guo, Z.Y.; Reynolds, A.C.; Zhao, H. Waterflooding optimization with the INSIM-FT data-driven model. Comput. Geosci. 2018, 22, 745–761. [Google Scholar] [CrossRef]

- Zhang, R.J. Research on Intelligent Analysis and Operation Optimization Technology of Waterflooding System Production State; Northeast Petroleum University: Daqing, China, 2011. [Google Scholar]

- Zhang, K.; Zhao, X.G.; Chen, G.D.; Zhao, M.J.; Wang, J.; Yao, C.J.; Sun, H.; Yao, J.; Wang, W.; Zhang, G.D. A double-model differential evolution for constrained waterflooding production optimization. J. Pet. Sci. Eng. 2021, 207, 109059. [Google Scholar] [CrossRef]

- Marotto, T.A.; Pires, A.P. Mathematical modeling of hot carbonated waterflooding as an enhanced oil recovery technique. Int. J. Multiph. Flow 2019, 115, 181–195. [Google Scholar] [CrossRef]

- VATTANI; ANDREA. K-means requires exponentially many iterations even in the plane. Discret. Comput. Geom. 2011, 45, 596–616. [Google Scholar] [CrossRef] [Green Version]

- INABA; MARY; Katoh, N.; Imai, H. Applications of weighted Voronoi diagrams and randomization to variance-based k-clustering. In Proceedings of the Tenth Annual Symposium on Computational Geometry, New York, NY, USA, 6–8 June 1994. [Google Scholar]

- Wu, F. Introduction to Artificial Intelligence: Models and Algorithms; Higher Education Press: Beijing, China, 2020. [Google Scholar]

| Rule Number | PS | PD | OA | HPP |

|---|---|---|---|---|

| 1 | Low | Low | Low | Low |

| 2 | Low | Low | Middle | Low |

| 3 | Low | Low | High | Low |

| 4 | Low | Middle | Low | Low |

| 5 | Low | Middle | Middle | Lower |

| 6 | Low | Middle | High | Lower |

| 7 | Low | High | Low | Lower |

| 8 | Low | High | Middle | Lower |

| 9 | Low | High | High | Middle |

| 10 | Middle | Low | Low | Middle |

| 11 | Middle | Low | Middle | Middle |

| 12 | Middle | Low | High | Higher |

| 13 | Middle | Middle | Low | Middle |

| 14 | Middle | Middle | Middle | Middle |

| 15 | Middle | Middle | High | Higher |

| 16 | Middle | High | Low | Lower |

| 17 | Middle | High | Middle | Higher |

| l8 | Middle | High | High | Higher |

| 19 | High | Low | Low | High |

| 20 | High | Low | Middle | High |

| 21 | High | Low | High | High |

| 22 | High | Middle | Low | High |

| 23 | High | Middle | Middle | Higher |

| Station Number | Available Pump Numbers | Current Operation Scheme | Optimized Operation Scheme | ||

|---|---|---|---|---|---|

| Running Pump Number | External Volume of Water (m3/d) | Running Pump Number | External Volume of Water (m3/d) | ||

| 1# | 1, 2, 3 | 1, 2 | 81,066,008 | 1 | 9129 |

| 2# | 1, 2 | 2 | 6753 | 1 | 6749 |

| 3# | 1, 2, 3 | 3 | 6677 | 3 | 9508 |

| 4# | 1, 2, 3 | 1 | 6714 | 2 | 8000 |

| 5# | 1, 2, 3 | 1 | 9293 | 1 | 9503 |

| 6# | 1, 2, 3 | 2 | 10,981 | 2 | 10,996 |

| 7# | 1, 2, 3 | 2, 3 | 75,446,939 | 2, 3 | 76,297,501 |

| Low Pressure Area | Volume of Water Daily (m3/d) | Average Pump Pressure (MPa) | Average Pipe Pressure (MPa) | Unit Consumption (kWh/m3) |

|---|---|---|---|---|

| before different pressure | 63237 | 16.23 | 15.68 | 5.69 |

| after different pressure | 61411 | 15.36 | 14.69 | 5.48 |

| Name of Booster Station | Booster Station 1 | Booster Station 2 | Booster Station 3 | Booster Station 4 |

|---|---|---|---|---|

| Number of high-pressure wells | 17 | 3 | 41 | 36 |

| Volume of water in flooding (m3) | 640 | 135 | 1160 | 1780 |

| Well pressure (MPa) | 13.6–14.2 | 13.8–14.1 | 13.8–14.6 | 13.6–14.5 |

| Daily Waterflooding (m3/d) | Average Pump Pressure (MPa) | Average Pipe Pressure (MPa) | Pump Water Consumption (kWh/m3) | |

|---|---|---|---|---|

| Before the downgrade pump is put into operation | 23,800 | 16.13 | 15.63 | 5.64 |

| After the downgrade pump is put into operation | 25,772 | 15.90 | 15.40 | 5.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wen, J.; Zhang, R.; Gao, S.; Ren, Y. Optimization Control of Oilfield Waterflooding Systems Based on Different Zone and Pressure. Energies 2022, 15, 1444. https://doi.org/10.3390/en15041444

Wang Y, Wen J, Zhang R, Gao S, Ren Y. Optimization Control of Oilfield Waterflooding Systems Based on Different Zone and Pressure. Energies. 2022; 15(4):1444. https://doi.org/10.3390/en15041444

Chicago/Turabian StyleWang, Yan, Jingqiang Wen, Ruijie Zhang, Sheng Gao, and Yongliang Ren. 2022. "Optimization Control of Oilfield Waterflooding Systems Based on Different Zone and Pressure" Energies 15, no. 4: 1444. https://doi.org/10.3390/en15041444

APA StyleWang, Y., Wen, J., Zhang, R., Gao, S., & Ren, Y. (2022). Optimization Control of Oilfield Waterflooding Systems Based on Different Zone and Pressure. Energies, 15(4), 1444. https://doi.org/10.3390/en15041444