Enhanced Seismic Protection System for an Emergency Diesel Generator Unit

Abstract

:1. Introduction

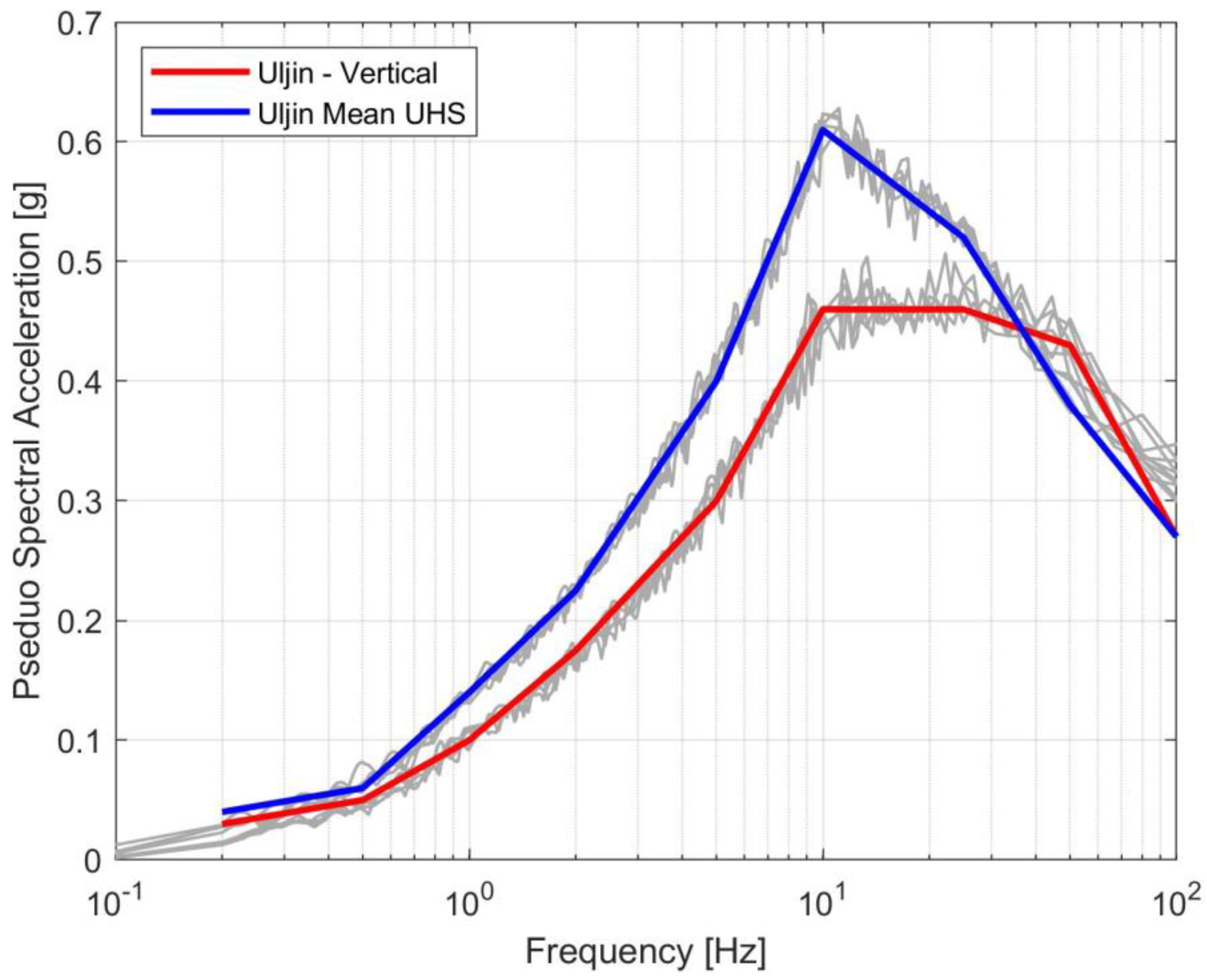

2. Seismic Hazard and Expected Seismic Performance

3. Design of Seismic Protection System

4. Results

4.1. Response for Target Seismic Hazard Intensity

4.2. Scaled Ground Motion Record

4.3. Incremental Dynamic Analysis

4.3.1. Base Isolation System Lateral Displacement

4.3.2. EDG Acceleration

4.4. Fragility Curves

4.4.1. Base Isolation System Lateral Displacement

4.4.2. EDG Acceleration

4.4.3. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ebisawa, K.; Ando, K.; Shibata, K. Progress of a research program on seismic base isolation of nuclear components. Nucl. Eng. Des. 2000, 198, 61–74. [Google Scholar] [CrossRef]

- JAERI. Characteristics and Dynamic Response Analysis of 3-D Component Base Isolation System Using Ball Bearings and Air Springs; Japan Atomic Energy Research Institute: Tokyo, Japan, 2000. [Google Scholar]

- Choun, Y.-S.; Kim, M.-K.; Ohtori, Y. The use of a base isolation system for an emergency diesel generator to reduce the core damage frequency caused by a seismic event. In Proceedings of the SMiRT 19, Toronto, ON, Canada, 12–17 August 2007; Volume 19, pp. 1–8. [Google Scholar]

- Furukawa, S.; Sato, E.; Shi, Y.; Becker, T.; Nakashima, M. Full-scale shaking table test of a base-isolated medical facility subjected to vertical motions. Earthq. Eng. Struct. Dyn. 2013, 42, 1931–1949. [Google Scholar] [CrossRef]

- Najafijozani, M.; Becker, T.C.; Konstantinidis, D. Evaluating adaptive vertical seismic isolation for equipment in nuclear power plants. Nucl. Eng. Des. 2020, 358, 110399. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Whittaker, A.S.; Constantinou, M.C. Seismic isolation of nuclear power plants. Nucl. Eng. Technol. 2015, 46, 569–580. [Google Scholar] [CrossRef] [Green Version]

- Medel-Vera, C.; Ji, T. Seismic protection technology for nuclear power plants: A systematic review. J. Nucl. Sci. Technol. 2015, 52, 607–632. [Google Scholar] [CrossRef]

- Tsutsumi, H.; Ebisawa, K.; Suzuki, M.; Yamada, H.; Fujimoto, S. Development of the Methodology for Evaluating the Probability of Failure of Seismic Isolation System for Nuclear Components. In Proceedings of the SMiRT, Manchester, UK, 10–14 August 2015. [Google Scholar]

- Inoue, K.; Fushimi, M.; Moro, S.; Morishita, M.; Kitamura, S.; Fujita, T. Development of Three-Dimensional Seismic Isolation System for Next Generation Nuclear Power Plant. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. No. 1537. [Google Scholar]

- Suhara, J.; Tamura, T.; Ohta, K.; Okada, Y.; Moro, S. Research on 3-D Base Isolation System Applied to New Power Reactor 3-D Seismic Isolation Device with Rolling Seal Type Air Spring: Part 1. In Proceedings of the Transactions of the 17th International Conference on Structural Mechanics in Reactor Technology (SMiRT 17), Prague, Czech Republic, 17–22 August 2003; pp. 1–6. [Google Scholar]

- Nawrotzki, P.; Siepe, D. Structural challenges of power plants in high seismic areas. In Proceedings of the Second European Conference on Earthquake Engineering and Seismology, Istanbul, Turkey, 25–29 August 2014; pp. 25–29. [Google Scholar]

- Choun, Y.; Kim, M.; Seo, J. Seismic and Vibration Isolation of an Emergency Diesel Generator by Using a Spring-Viscous Damper System. In Proceedings of the SMiRT 19, Toronto, ON, Canada, 12–17 August 2007; p. 8. [Google Scholar]

- Kančev, D.; Duchac, A.; European Commission; Joint Research Centre; Institute for Energy and Transport. European Clearinghouse: Events Related to Emergency Diesel Generators; Publications Office of the European Union: Luxembourg, 2013. [Google Scholar]

- Gregory, N.; Simon, R.; Branden, D.; Kermin, C. Practical Implementation of ASCE-41 and NLRHA Procedures for the Design of the LLUMC Replacement Hospital. In Proceedings of the 2017 SEAOC Conference Proceedings, San Diego, CA, USA, 13–15 September 2017; pp. 1–8. [Google Scholar]

- Tomizawa, T.; Takahashi, O.; Suhara, J.; Okada, K.; Tsuyuki, Y.; Fujita, T. Vibration test in a building named ‘ Chisuikan’ using three-dimensional seismic isolation system. In Proceedings of the ISEC 2013—7th International Structural Engineering and Construction Conference: New Developments in Structural Engineering and Construction, Honolulu, HI, USA, 18–23 June 2013; pp. 791–796. [Google Scholar] [CrossRef]

- Vamvatsikos, D.; Cornell, C.A. Incremental dynamic analysis. Earthq. Eng. Struct. Dyn. 2002, 31, 491–514. [Google Scholar] [CrossRef]

- Budnitz, R.J. Current status of methodologies for seismic probabilistic safety analysis. Reliab. Eng. Syst. Saf. 1998, 62, 71–88. [Google Scholar] [CrossRef]

- DIS. DIS 3D Isolation System. Available online: http://dis-inc.com/pdf_files/DIS%203D%20Isolation%20Systems.pdf (accessed on 15 October 2020).

- KAERI. Generation of Input Ground Acceleration for Analysis of Nuclear Plant Structures Reflecting Site Characteristics in Korea; KAERI: Pusan, Korea, 2018. [Google Scholar]

- Choi, I.-K.; Nakajima, M.; Choun, Y.-S.; Ohtori, Y. Development of the site-specific uniform hazard spectra for Korean nuclear power plant sites. Nucl. Eng. Des. 2009, 239, 790–799. [Google Scholar] [CrossRef]

- ASCE43-05; Seismic Design Criteria for Structures, System, and Components in Nuclear Facilities. American Society of Civil Engineers: Reston, VA, USA, 2006.

- U.S. Nuclear Regulatory Commission. NUREG/CR-4334—An Approach to the Quantification of Seismic Margins in Nuclear Power Plants; U.S. Nuclear Regulatory Commission: Rockville, MD, USA, 1985. [Google Scholar]

- U.S. Nuclear Regulatory Commission. Risk Assessment Standardization Project (RASP) Handbook-External Events: Seismic Event Modeling and Seismic Risk Quantification Seismic Event Modeling and Seismic Risk Quantification; U.S. Nuclear Regulatory Commission: Rockville, MD, USA, 2017. [Google Scholar]

- Liu, W.; Aziz, T.S. Seismic Capacity of Emergency Power Supply Diesel Generator Set for Candu 6. In Proceedings of the SMiRT 19, Toronto, ON, Canada, 12–17 August 2007; pp. 1–8. [Google Scholar]

- Jeong, Y.S.; Baek, E.R.; Jeon, B.G.; Chang, S.J.; Park, D.-U. Seismic performance of emergency diesel generator for high frequency motions. Nucl. Eng. Technol. 2019, 51, 1470–1476. [Google Scholar] [CrossRef]

- Jeon, B.-G.; Choi, H.-S.; Hahm, D.-G. Seismic Fragility Estimates of Piping System of Base-isolated Nuclear Power Plant. In Proceedings of the Transactions of the 17th International Conference on Structural Mechanics in Reactor Technology (SMiRT 23), Manchester, UK, 10–14 August 2015; pp. 1–10. [Google Scholar]

- JNES. Proposal of Technical Review Guidelines for Structures with Seismic Isolation; JNES: Tokyo, Japan, 2013. [Google Scholar]

- Touboul, F.; Sollogoub, P.; Blay, N. Seismic behaviour of piping systems with and without defects: Experimental and numerical evaluations. Nucl. Eng. Des. 1999, 192, 243–260. [Google Scholar] [CrossRef]

- Zhang, T.; Brust, F.W.; Wilkowski, G.; Shim, D.-J.; Nie, J.; Hofmayer, C.H.; Ali, S.A. Analysis of JNES seismic tests on degraded piping. In Proceedings of the Pressure Vessels and Piping Conference, Bellevue, WA, USA, 18–22 July 2010. [Google Scholar] [CrossRef]

- Choun, Y.S.; Kim, M.K. A performance assessment of a base isolation system for an emergency diesel generator in a nuclear power plant. Nucl. Eng. Technol. 2008, 40, 285–298. [Google Scholar] [CrossRef] [Green Version]

- Kawakami, K.; Hara, S.; Shibata, F.; Ohno, H.; Horimizu, T.; Ichimashi, Y.; Uchiyama, I.; Niino, Y.; Takayanagi, T.; Kajimura, M.; et al. Seismic Proving Test of Emergency Diesel Generator System. In Proceedings of the SMiRT, Stuttgart, Germany, 15–20 August 1993. [Google Scholar]

- Kim, M.K.; Choun, Y.S.; Seo, J.M. Demonstration of the vibration control performance of coil spring-viscous damper systems by measuring the vibration of an emergency diesel generator. JVC J. Vib. Control 2010, 16, 207–229. [Google Scholar] [CrossRef]

- FEMA. FEMA P-751—NEHRP Recommended Seismic Provisions for New Buildings and Other Structures; FEMA: New York, NY, USA, 2009. [Google Scholar]

- Christopoulos, C.; Filiatrault, A. Principles of Passive Supplemental Damping and Seismic Isolation; IUSS Press: Pavia, Italy, 2006; Volume 133, p. 1192. [Google Scholar]

- Kelly, J.M.; Konstantinidis, D.A. Mechanics of Rubber Bearings for Seismic and Vibration Isolation; Wiley: Chichester, UK, 2011. [Google Scholar]

- Naeim, F.; Kelly, J.M. Design of Seismic Isolated Structures: From Theory to Practice; Wiley: Chichester, UK, 1999. [Google Scholar]

- PEER. OpenSees: A Framework for Earthquake Engineering Simulation; University of California: Berkeley, CA, USA, 2020. [Google Scholar]

- Kafali, C.; Grigoriu, M. Seismic fragility analysis: Application to simple linear and nonlinear systems. Earthq. Eng. Struct. Dyn. 2007, 36, 1885–1900. [Google Scholar] [CrossRef]

- Zhao, C.; Yu, N.; Peng, T. Probabilistic seismic fragility assessment of isolated nuclear power plant structure using IDA and MSA methods. Structures 2021, 34, 1300–1311. [Google Scholar] [CrossRef]

- Pang, R.; Xu, B.; Zhou, Y.; Song, L. Seismic time-history response and system reliability analysis of slopes considering uncertainty of multi-parameters and earthquake excitations. Comput. Geotech. 2021, 136, 104245. [Google Scholar] [CrossRef]

- Prassinos, P.G.; Murray, R.C.; Cummings, G.E. Seismic Margin Review of the Maine Yankee Atomic Power Station; Lawrence Livermore National Laboratory: Livermore, CA, USA, 1987; Volume 1. [Google Scholar]

- Shang, Q.; Wang, T.; Li, J. Seismic fragility of flexible pipeline connections in a base isolated medical building. Earthq. Eng. Eng. Vib. 2019, 18, 903–916. [Google Scholar] [CrossRef]

| EDP | Label | Limit State | Value | Reference |

|---|---|---|---|---|

| EDG Acceleration | DS1-A | EDG LS1 | 0.40 g | [25] |

| Isolation Lateral Displacement | DS1-D | Pipeline LS1 | 127 mm | [26] |

| DS2-D | Bearing LS2 | 320 mm (γs = 250%) | [27] | |

| DS3-D | Bearing LS3 | 576 mm (γs = 450%) | [27] |

| Isolation Level | Horizontal Vibration Frequency (Hz) | Vertical Vibration Frequency (Hz) | Primary Horizontal Frequency (Hz) |

|---|---|---|---|

| IsoH | [0.25–4.0] | >10 | 11 |

| IsoV | - | ~2.0 | [8,9,10,11,12,13,14,15,16,17,18,19,20] |

| Type | Diameter (mm) | Lead Core (mm) | Rubber Thickness (mm) | Shear Modulus (MPa) | Rubber Layers - | fH (Hz) | fV (Hz) |

|---|---|---|---|---|---|---|---|

| Lead Rubber | 405 | 40 | 8 | 0.4 | 16 | 0.7 | 13.8 |

| Type | Direction | Value | f (Hz) | Damping (%) |

|---|---|---|---|---|

| Stiffness | Horizontal | 16.4 (kN/mm) | 2.5 | - |

| Vertical | 28.4 (kN/mm) | 2.0 | - | |

| Damping coefficient | Horizontal | 1.55 (kN s/mm) | - | 12.0 |

| Vertical | 5.37 (kN s/mm) | - | 11.0 |

| EDP | Label | Limit State | Value (mm) | Median PGA (g) | βR |

|---|---|---|---|---|---|

| Isolation Lateral Displacement | DS1-D | Pipeline LS1 | 127 | 0.94 | 0.07 |

| DS2-D | Bearing LS2 | 320 | 1.75 | 0.10 | |

| DS3-D | Bearing LS3 | 576 | 2.23 | 0.17 |

| EDP | Label | Limit State | Value (g) | Median PGA (g) | βR |

|---|---|---|---|---|---|

| EDG Acceleration | DS1-A | EDG LS1 | 0.40 | 1.80 | 0.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bustamante, R.; Mosqueda, G.; Kim, M. Enhanced Seismic Protection System for an Emergency Diesel Generator Unit. Energies 2022, 15, 1728. https://doi.org/10.3390/en15051728

Bustamante R, Mosqueda G, Kim M. Enhanced Seismic Protection System for an Emergency Diesel Generator Unit. Energies. 2022; 15(5):1728. https://doi.org/10.3390/en15051728

Chicago/Turabian StyleBustamante, Ricardo, Gilberto Mosqueda, and Minkyu Kim. 2022. "Enhanced Seismic Protection System for an Emergency Diesel Generator Unit" Energies 15, no. 5: 1728. https://doi.org/10.3390/en15051728

APA StyleBustamante, R., Mosqueda, G., & Kim, M. (2022). Enhanced Seismic Protection System for an Emergency Diesel Generator Unit. Energies, 15(5), 1728. https://doi.org/10.3390/en15051728