Heat Exchanging Grid Structures Based on Laser-Based Powder Bed Fusion: Formation Process and Boiling Heat Transfer Performance

Abstract

:1. Introduction

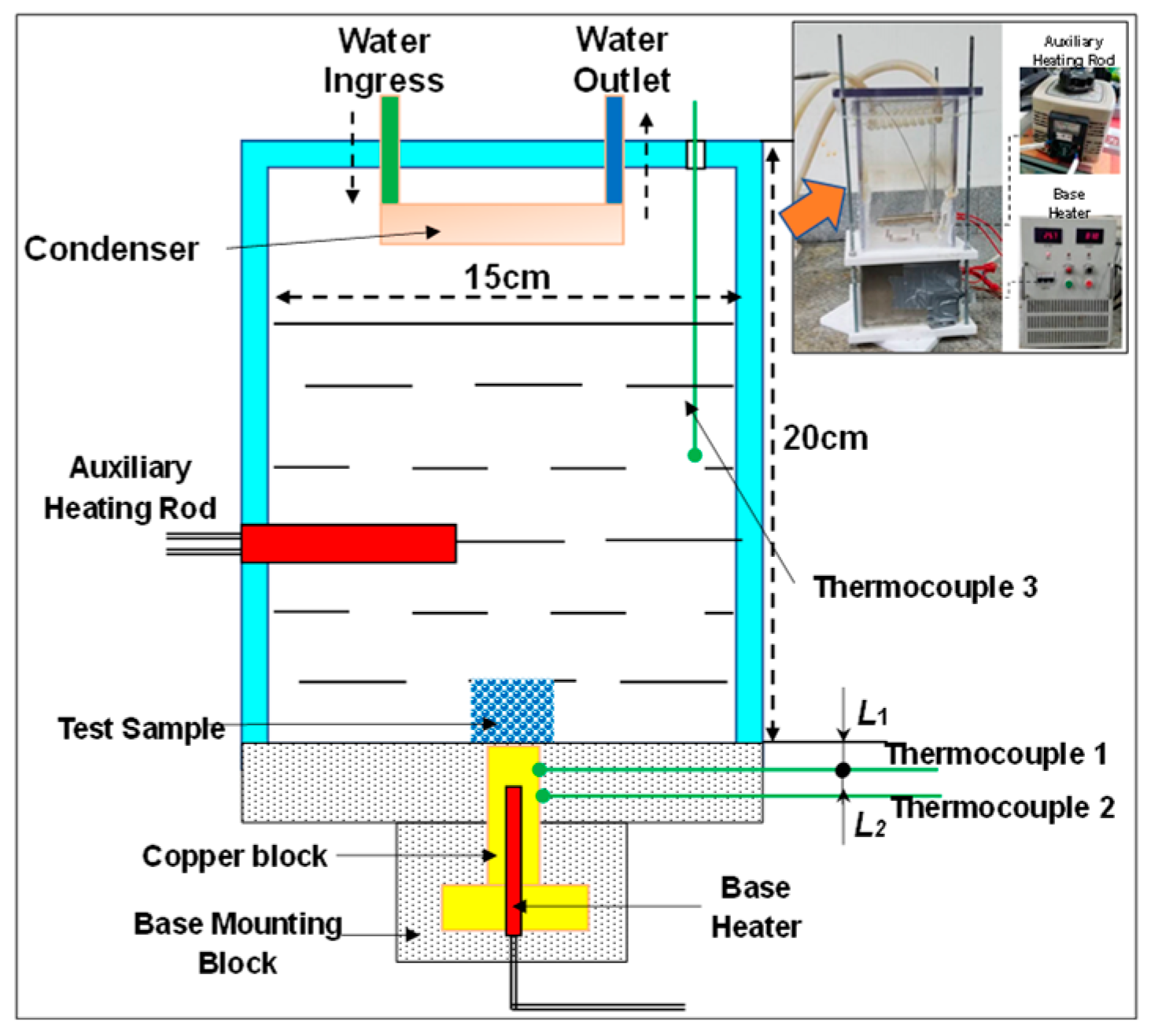

2. Methods, Experimental Platform and Materials

2.1. Principle of the Formation of the Grid Structure

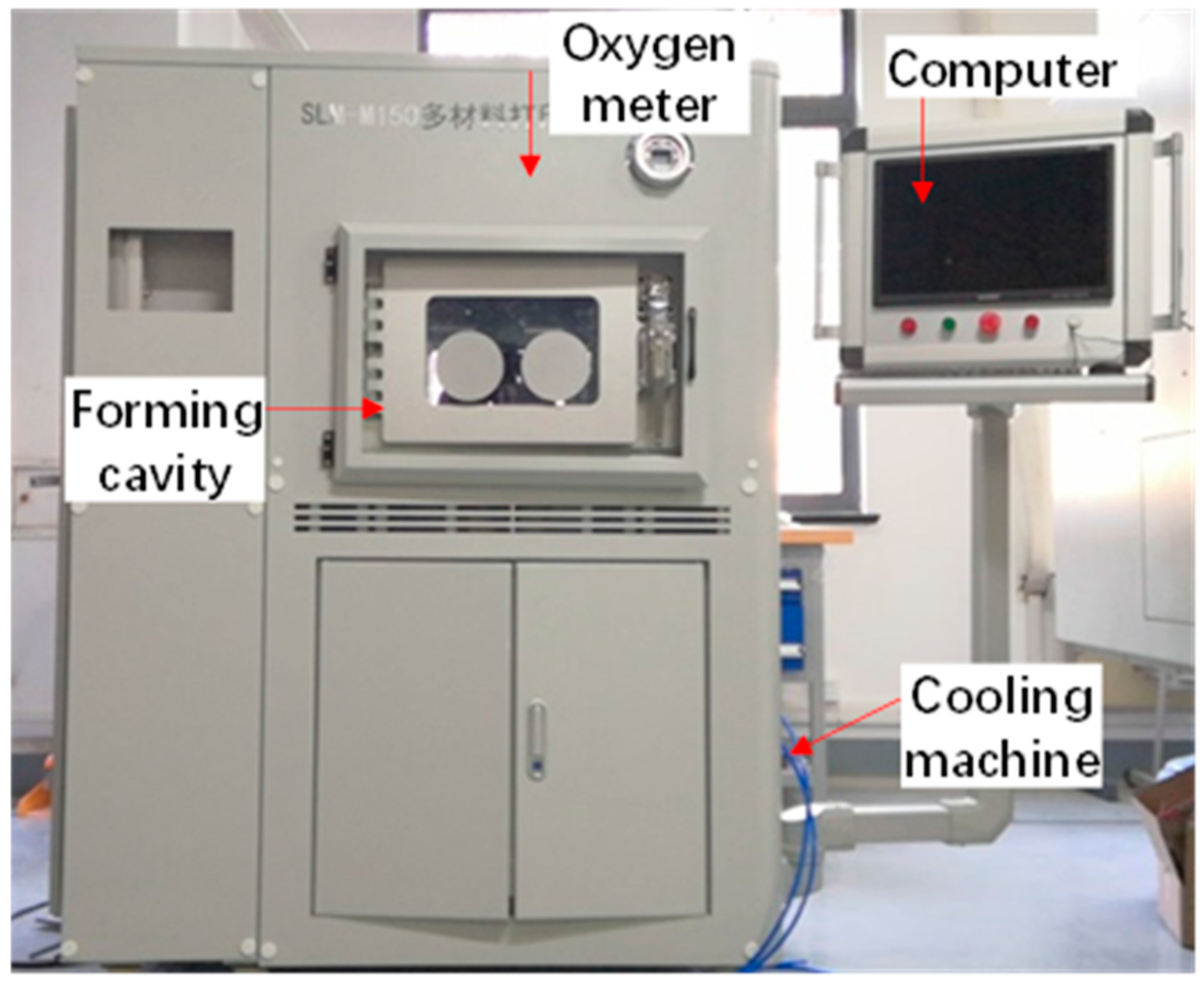

2.2. L-PBF Experimental Facility

- (1)

- Design the 3D structural model and convert it to STL format file.

- (2)

- Use special model processing software to transform the STL model into contour paths and laser scanning paths layer by layer; calculate the scanning paths according to the structural properties of G-surface structure.

- (3)

- Use the scraper to spread the powder on the substrate of the working platform, and then use the scan system XY mirrors to reflect the laser in order to scan and melt selected regions of the slicing layer.

- (4)

- After the scanning is completed, the working platform substrate decreases layer thickness, and the powder spreading and laser scanning are performed again. Repeat the above steps until the part is printed.

- (5)

- Remove the working platform substrate and use a cutting machine to separate the parts from the base substrate.

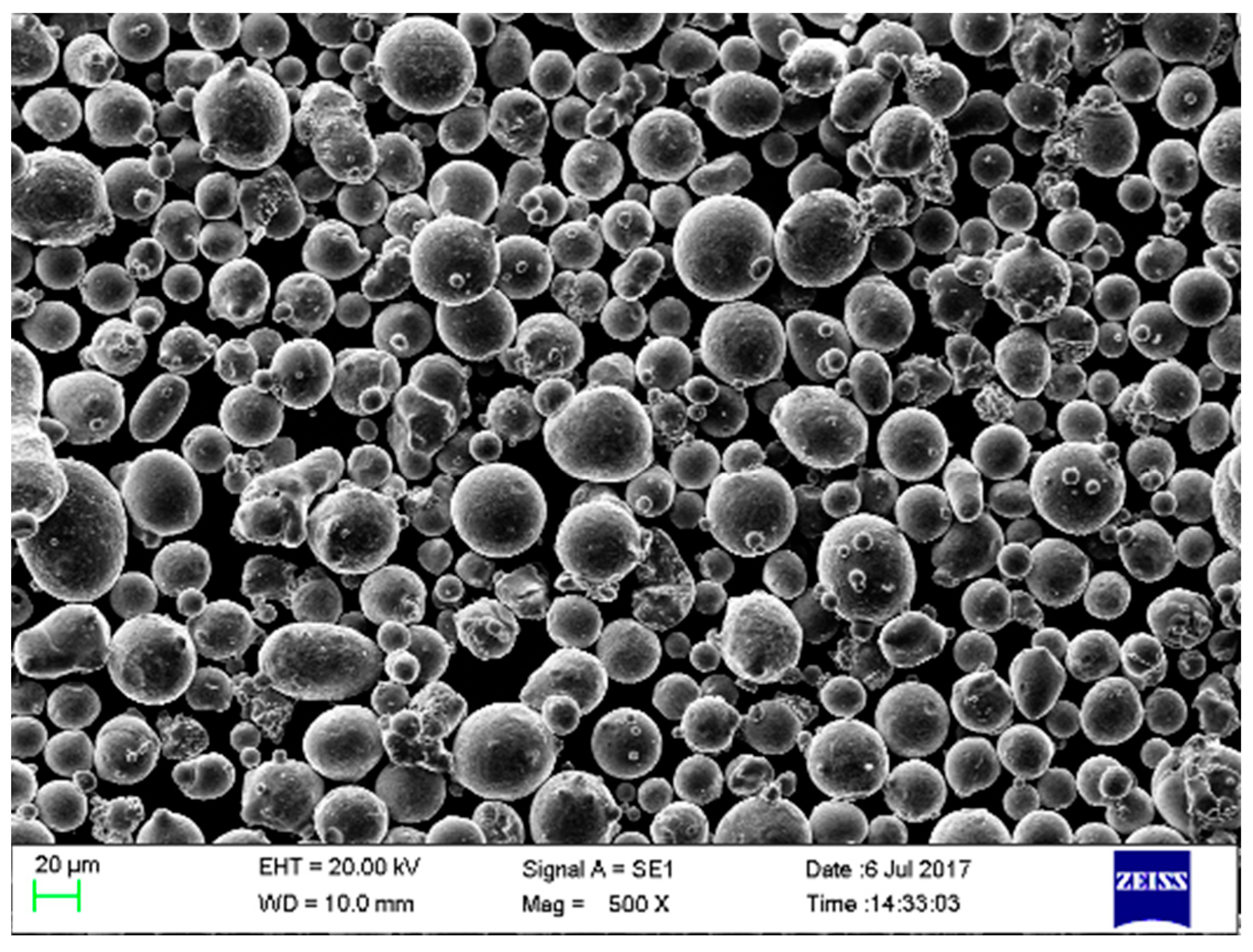

2.3. Experimental Material

2.4. Forming Process Parameters for the Grid Structures

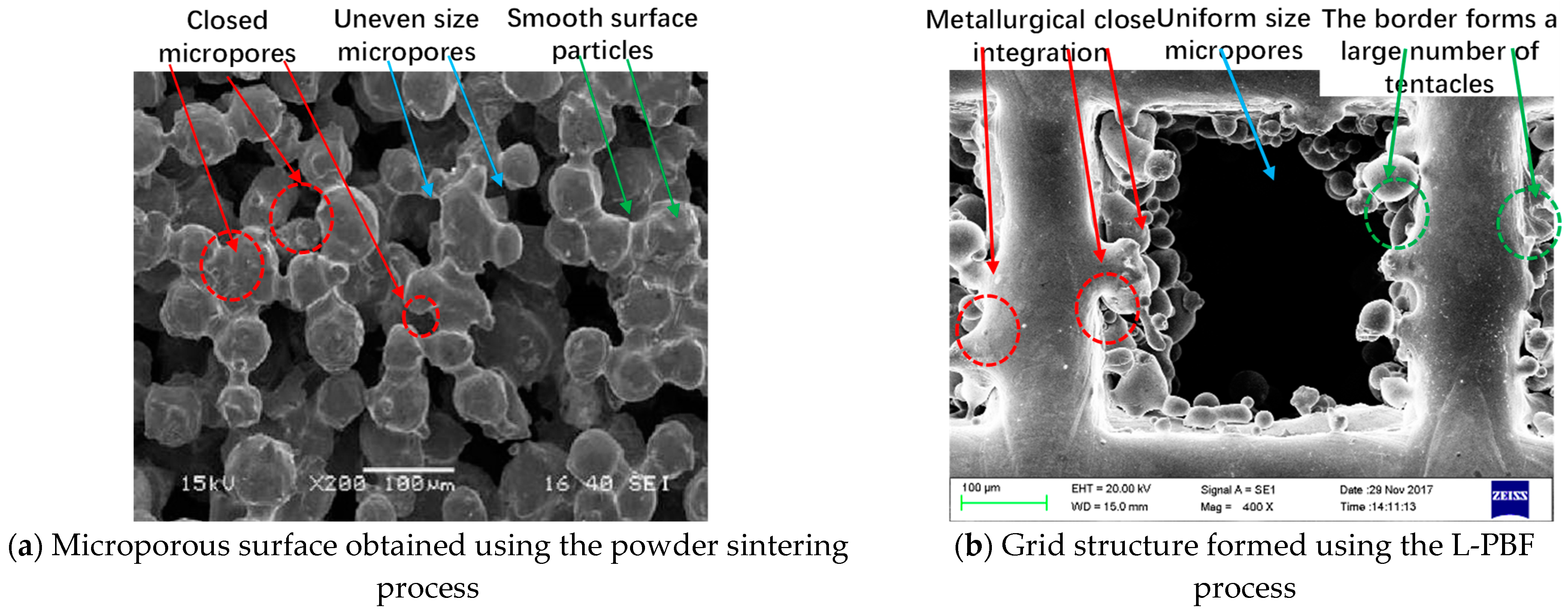

3. Pore Morphology and Structure Analysis of the Grid Structure

3.1. Influence of Scan Spacing on Pore Morphology

3.2. Influence of Laser Power on Pore Morphology

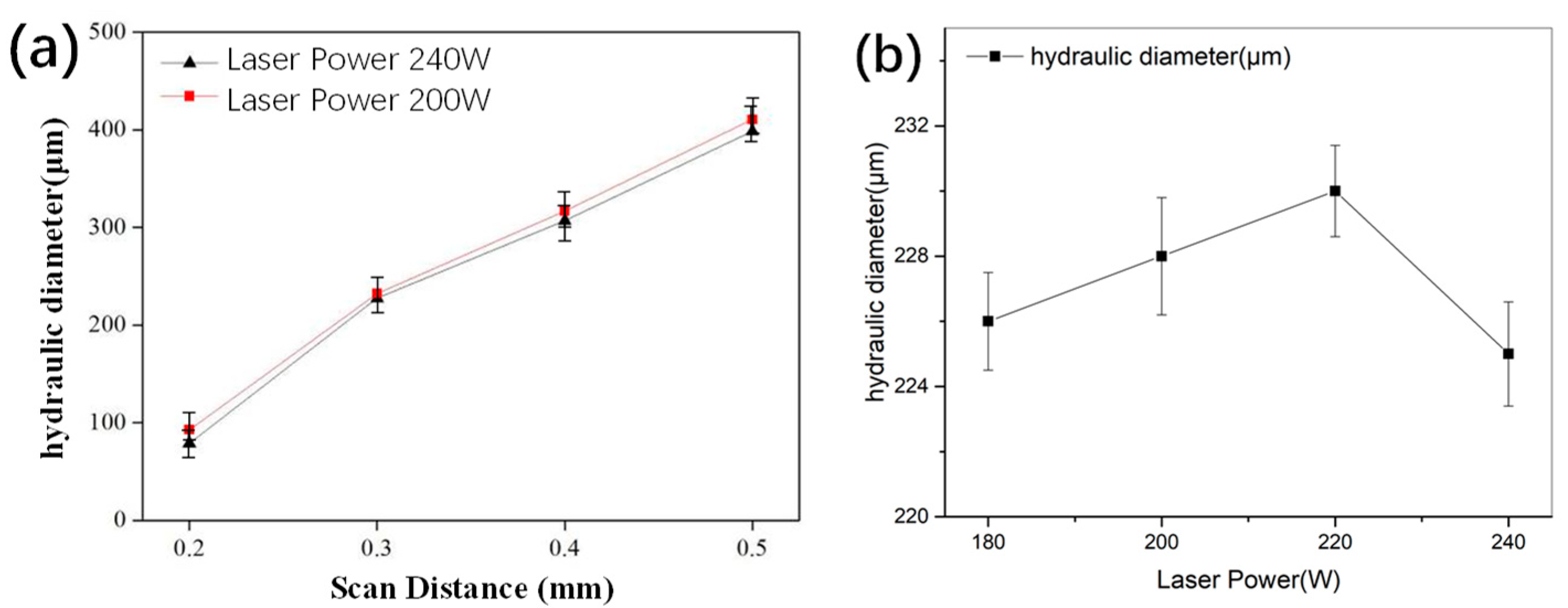

3.3. Analysis of the Hydraulic Diameters of Different Grid Structures

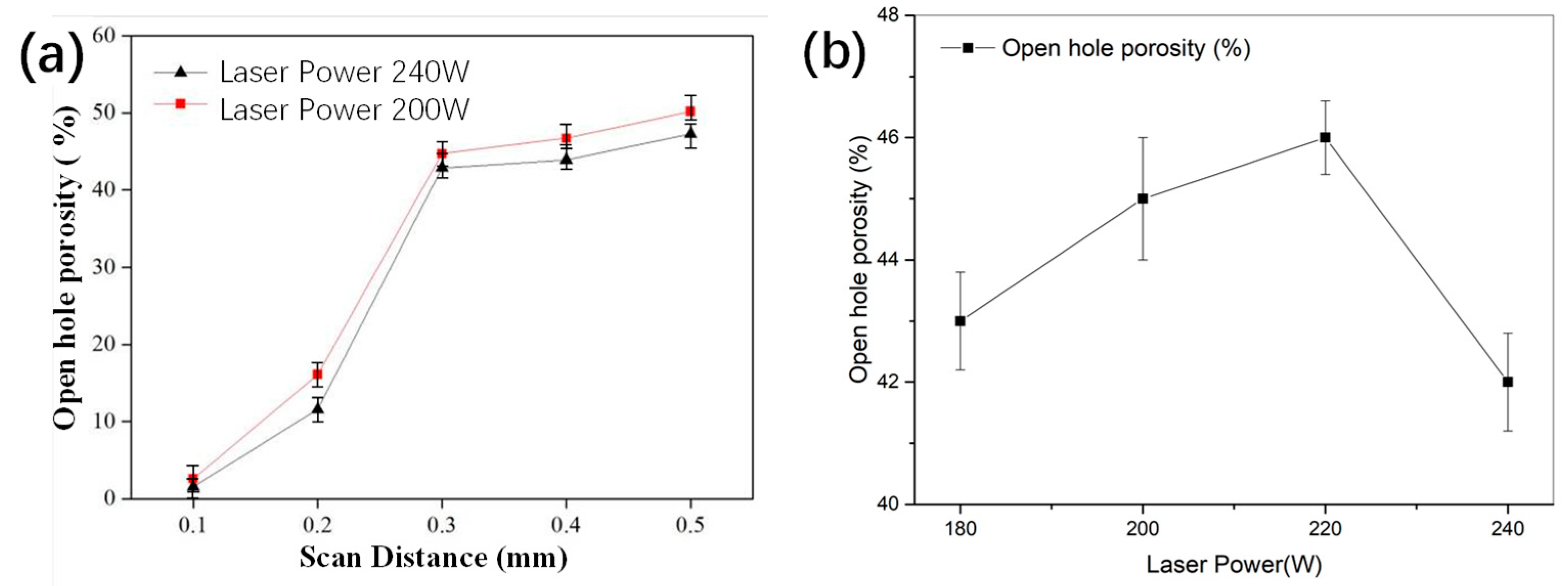

3.4. Open Porosity Analysis for Grid Structures

4. Experimental Details and Analysis of the Boiling Heat Transfer Characteristics of the Grid Structures

4.1. Experimental Platform and Calculation Method for Boiling Heat Exchange

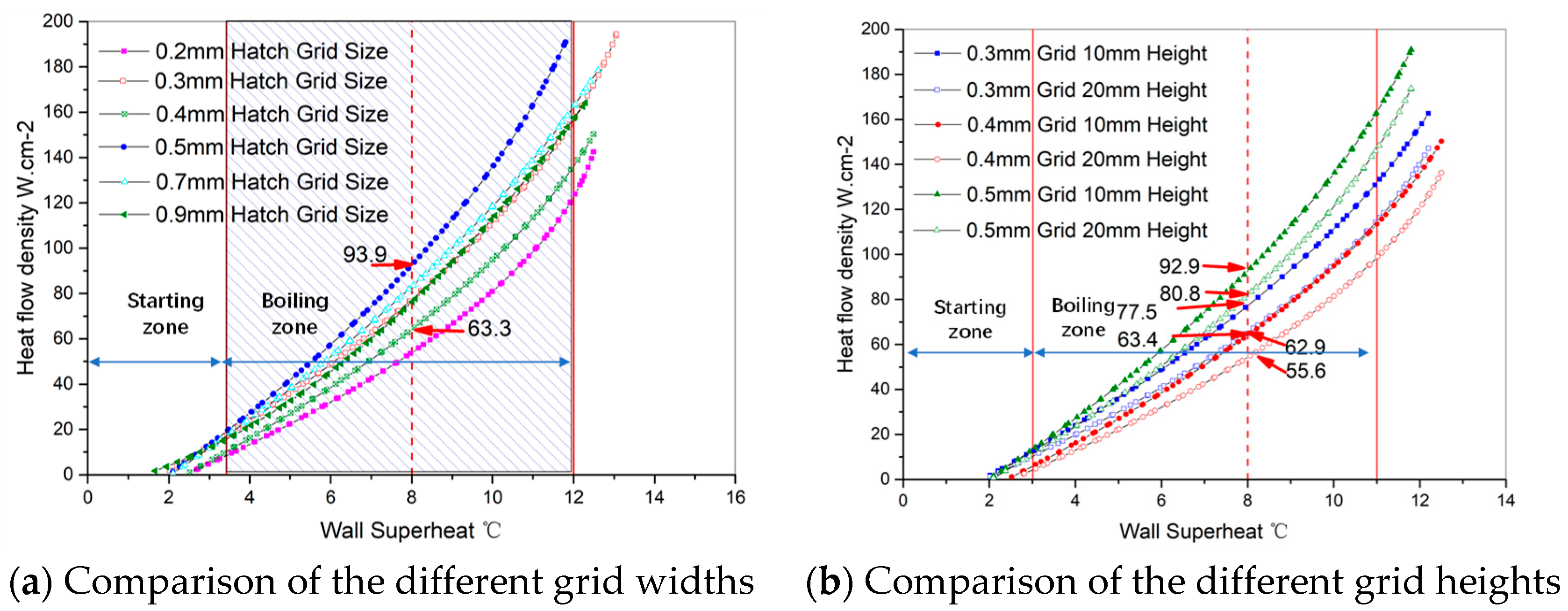

4.2. Comparative Analysis of the Grid Structure Samples of Different Widths and Heights

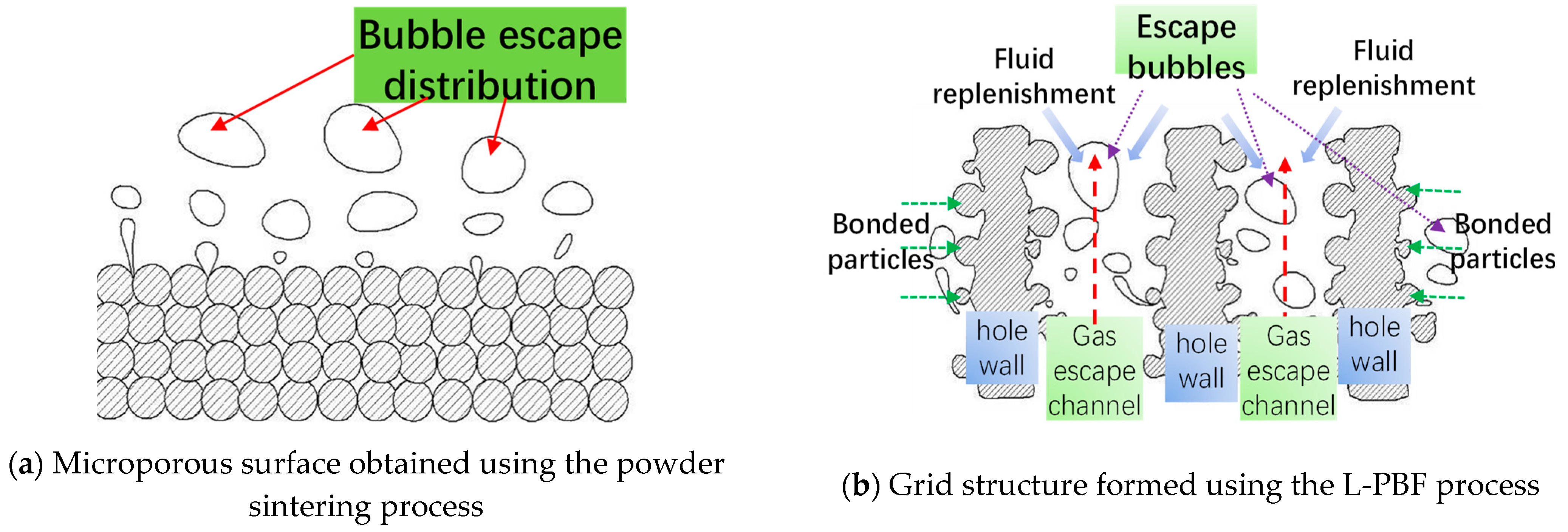

4.3. Comparison of the Boiling Heat Transfer Mechanisms of Grid Structure Samples and Powder-Sintered Samples

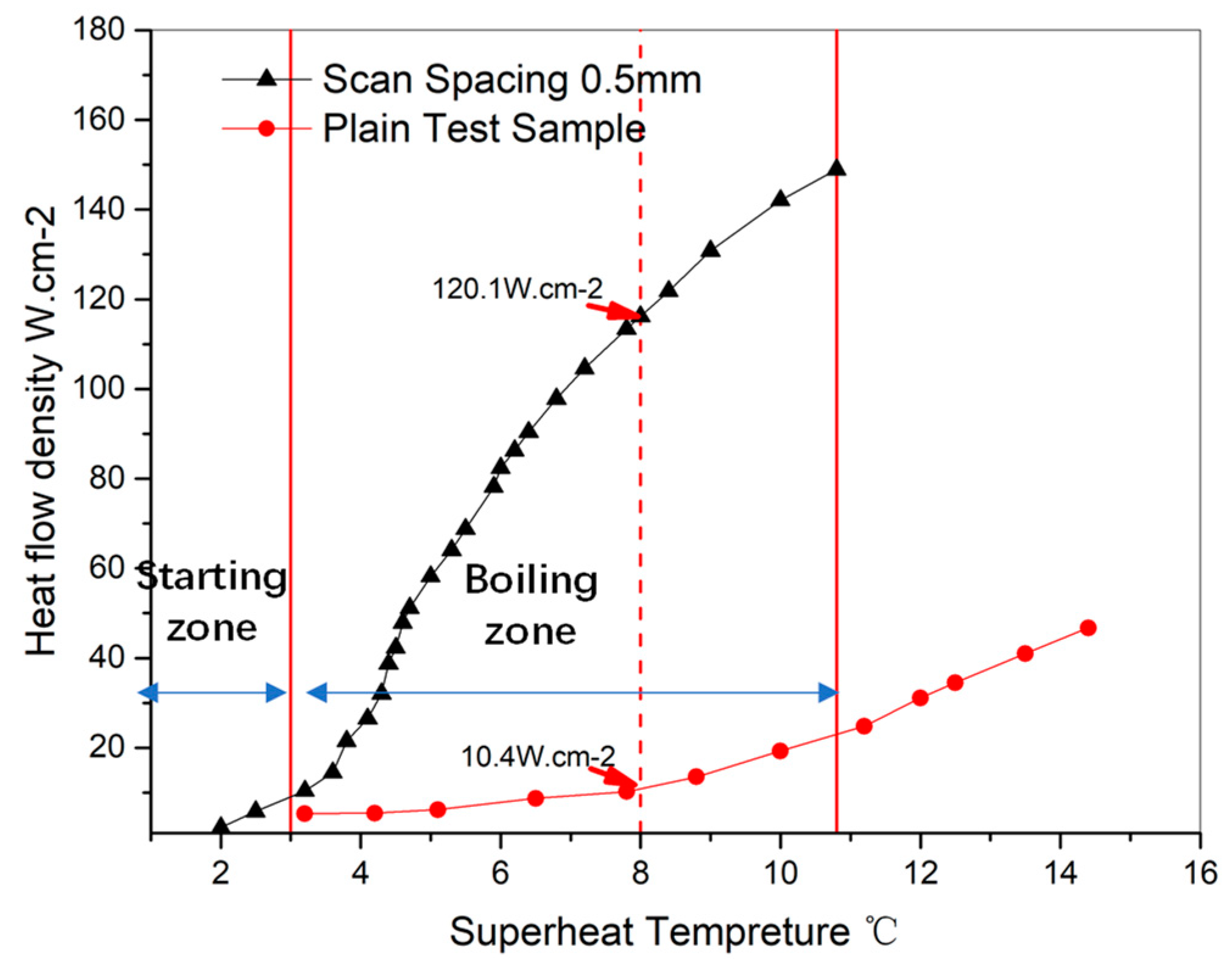

4.4. Comparison of the Boiling Heat Transfer Characteristics between a Grid Structure and Plain Test Sample

5. Conclusions

- (1)

- Using 316 L stainless steel powder, an L-PBF-forming experiment of grid structures was conducted. The pore morphology and structural parameters of the grid structures, formed using different processing parameters, were obtained via microscopic observation and image processing. The effects of the scan spacing and laser power on the pore morphology, hydraulic diameter, and open porosity of the grid structure were studied. According to the characteristics of the macroporous structure of the grid parts, the internal porosity of the metal grid parts varied from 5% to 50% depending on the scanning spacing. The macroporosity of the surface was consistent with the macroporosity of the internal grid structure.

- (2)

- Grid samples with different scan spacings were experimentally compared, demonstrating that among different widths, the 0.5 mm sample exhibited the best critical heat transfer performance with a CHF of 10–27% higher than those of the other four samples (minimum of 63.3 W·cm−2 and maximum of 93.9 W·cm−2) at the wall superheat temperature of 8 °C. For samples with a grid width greater than 0.5 mm, the boiling slightly decreased by <5%. This was because when the grid width exceeded 0.5 mm, the flow resistance decreased, the high-temperature flow rate increased, and the bubbles produced by the wall synapses reduced, thus causing a decrease in the heat flux carried away by the bubbles.

- (3)

- When the grid width was further increased, the flow resistance and the bubble synapse generation effects tended to converge where the boiling heat transferred in only a single phase along the medium wall thickness direction and the optimal two-phase heat transfer effect could not occur by bubble growth and collapse.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qu, Y.; Wang, S.; Tian, Y. A review of thermal performance in multiple evaporators loop heat pipe. Appl. Therm. Eng. 2018, 143, 209–224. [Google Scholar] [CrossRef]

- Vasiliev, L.L. Micro and miniature heat pipes-Electronic component coolers. Appl. Therm. Eng. 2008, 28, 266–273. [Google Scholar] [CrossRef]

- Mudawar, I. Recent Advances in High-Flux, Two-Phase Thermal Management. J. Therm. Sci. Eng. Appl. 2013, 5, 021012. [Google Scholar] [CrossRef]

- Das, A.K.; Das, P.K.; Saha, P. Performance of different structured surfaces in nucleate pool boiling. Appl. Therm. Eng. 2009, 29, 3643–3653. [Google Scholar] [CrossRef]

- Dong, L.; Quan, X.; Cheng, P. An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano-structures. Int. J. Heat Mass Transf. 2014, 71, 189–196. [Google Scholar] [CrossRef]

- Xu, P.; Li, Q.; Xuan, Y. Enhanced boiling heat transfer on composite porous surface. Int. J. Heat Mass Transf. 2015, 80, 107–114. [Google Scholar] [CrossRef]

- Surtaev, A.S. Heat transfer and crisis phenomena at pool boiling of liquid nitrogen on the surfaces with capillary-porous coatings. Int. J. Heat Mass Transf. 2017, 108, 146–155. [Google Scholar] [CrossRef]

- Surtaev, A. Structured capillary-porous coatings for enhancement of heat transfer at pool boiling. Appl. Therm. Eng. 2018, 133, 532–542. [Google Scholar] [CrossRef]

- Kotthoff, S.; Gorenflo, D.; Danger, E.; Luke, A. Heat transfer and bubble formation in pool boiling: Effect of basic surface modifications for heat transfer enhancement. Int. J. Therm. Sci. 2006, 45, 217–236. [Google Scholar] [CrossRef]

- Chang, J.Y.; You, S.M. Boiling heat transfer phenomena from microporous and porous surfaces in saturated FC-72. Int. J. Heat Mass Transf. 1997, 40, 4437–4447. [Google Scholar] [CrossRef]

- Mohamed, S.E.; Amir, F.A. Enhanced nucleate boiling on copper microporous surfaces. Int. J. Multiph. Flow 2010, 36, 780–792. [Google Scholar]

- Suazlan, M.A.; Shoji, M.; Fumiki, S. Effects of heater orientation on critical heat flux for nanoparticle-deposited surface with honeycomb porous plate attachment in saturated pool boiling of water. Int. J. Heat Mass Transf. 2016, 102, 1345–1355. [Google Scholar]

- Deng, D.X.; Feng, J.Y.; Huang, Q.S.; Tang, Y.; Lian, Y. Pool boiling heat transfer of porous structures with reentrant cavities. Int. J. Heat Mass Transf. 2016, 99, 556–568. [Google Scholar] [CrossRef]

- Liu, H.L.; Zhang, C.; Wang, J.; Zhang, L. Critical heat flux enhancement using composite porous structure produced by selective laser melting. Appl. Therm. Eng. 2021, 197, 117396. [Google Scholar] [CrossRef]

- Li, C.H.; Li, T.; Hodgins, P.; Hunter, C.N.; Voevodin, A.A.; Jones, J.G.; Peterson, G.P. Comparison study of liquid replenishing impacts on critical heat flux and heat transfer coefficient of nucleate pool boiling on multiscale modulated porous structures. Int. J. Heat Mass Transf. 2011, 54, 3146–3155. [Google Scholar] [CrossRef]

- Arvind, J.; Satish, G.K. Enhanced pool boiling for electronics cooling using porous fin tops on open microchannels with FC-87. Appl. Therm. Eng. 2015, 91, 426–433. [Google Scholar]

- Seol, H.K.; Gi, C.L.; Jun, Y.K.; Moriyama, K.; Kim, M.H.; Park, H.S. Boiling heat transfer and critical heat flux evaluation of the pool boiling on micro structured surface. Int. J. Heat Mass Transf. 2015, 91, 1140–1147. [Google Scholar]

- Ji, X.B.; Xu, J.L.; Zhao, Z.W.; Yang, W. Pool boiling heat transfer on uniform and non-uniform porous coating surfaces. Exp. Therm. Fluid Sci. 2013, 48, 198–212. [Google Scholar] [CrossRef]

- Scott, G.L.; Massoud, K. Pool-boiling CHF enhancement by modulated porous-layer coating: Theory and experiment. Int. J. Heat Mass Transf. 2001, 44, 4287–4311. [Google Scholar]

- Min, D.H.; Hwang, G.S.; Usta, Y.; Cora, O.N.; Koc, M.U.; Kaviany, M. 2-D and 3-D modulated porous coatings for enhanced pool boiling. Int. J. Heat Mass Transf. 2009, 52, 2607–2613. [Google Scholar] [CrossRef]

- Ahn, H.S.; Gunyeop, P.; Kim, J.M. The effect of water absorption on critical heat flux enhancement during pool boiling. Exp. Therm. Fluid Sci. 2012, 42, 187–195. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Shishkovsky, I.; Bertrand, P.; Smurov, I. Manufacturing of finestructured 3D porous filter elements by selective laser melting. Appl. Surf. Sci. 2009, 255, 5523–5527. [Google Scholar] [CrossRef]

- Wong, K.K.; Leong, K.C. Saturated pool boiling enhancement using porous lattice structures produced by Selective Laser Melting. Int. J. Heat Mass Transf. 2018, 121, 46–63. [Google Scholar] [CrossRef]

- Chi, Z.; Li, Z.; Hong, X.; Pei, L.; Bo, Q. Performance of pool boiling with 3D grid structure manufactured by selective laser melting technique. Int. J. Heat Mass Transf. 2019, 128, 570–580. [Google Scholar]

- Bagheri, Z.S.; Melancon, D.; Liu, L.; Johnston, R.B.; Pasini, D. Compensation strategy to reduce geometry and mechanics mismatches in porous biomaterials built with Selective Laser Melting. J. Mech. Behav. Biomed. Mater. 2016, 70, 17–27. [Google Scholar] [CrossRef] [Green Version]

- Ameli, M.; Agnew, B.; Leung, P.S.; Ng, B.; Sutcliffe, C.J.; Singh, J.; McGlen, R. A novel method for manufacturing sintered aluminium heat pipes (SAHP). Appl. Therm. Eng. 2013, 52, 498–504. [Google Scholar] [CrossRef]

- Xu, Z.G.; Qu, Z.G.; Zhao, C.Y.; Tao, W.Q. Experimental correlation for pool boiling heat transfer on metallic foam surface and bubble cluster growth behavior on grooved array foam surface. Int. J. Heat Mass Transf. 2014, 77, 1169–1182. [Google Scholar] [CrossRef]

- Qian, B.; Fan, H.R.; Liu, G.; Zhang, J.; Li, P. Self-Supporting Microchannel Liquid-Cooled Plate for T/R Modules Based on Additive Manufacturing: Study on Its Pass Design, Formation Process and Boiling Heat Transfer Performance. Metals 2021, 11, 1731. [Google Scholar] [CrossRef]

- Qian, B.; Fan, H.R.; Liu, G.; Zhang, J.; Li, P. Microchannel Liquid-Cooled Heat Exchanger Based on a Nonuniform Lattice: Study on Structure Calculation, Formation Process, and Boiling Heat Transfer Performance. Materials 2021, 14, 7248. [Google Scholar] [CrossRef]

| Parameter | Setting |

|---|---|

| Rated output power (W) | 250 |

| Working mode | Continuous/Modulated |

| Center wavelength (nm) | 1080 |

| Output power fluctuation | <3% |

| Minimum spot diameter (mm) | 0.06 |

| Element | Assay Value/wt. % | Element | Assay Value/wt. % | Particle Size Distribution | Assay Value/wt. % |

|---|---|---|---|---|---|

| Cr | 16.79 | Mn | 0.20 | D10 | 23.1 |

| Mo | 2.42 | S | 0.011 | D50 | 35.3 |

| Ni | 10.66 | P | 0.025 | D90 | 53.3 |

| Si | 1.00 | O | 0.0247 |

| No. | Laser Power (W) | Scan Spacing (mm) | Scanning Speed (mm∙s−1) | Layer Thickness (mm) |

|---|---|---|---|---|

| 1 | 200 | 0.1 | 550 | 0.03 |

| 2 | 200 | 0.2 | ||

| 3 | 200 | 0.4 | ||

| 4 | 200 | 0.5 | ||

| 5 | 180 | 0.3 | ||

| 6 | 200 | 0.3 | ||

| 7 | 220 | 0.3 | ||

| 8 | 240 | 0.3 | ||

| 9 | 240 | 0.1 | ||

| 10 | 240 | 0.2 | ||

| 11 | 240 | 0.4 | ||

| 12 | 240 | 0.5 | ||

| 13 | 200 | 0.7 | ||

| 14 | 220 | 0.9 | ||

| 15 | 240 | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, B.; Fan, H.; Zhang, J.; Liu, G.; Li, P. Heat Exchanging Grid Structures Based on Laser-Based Powder Bed Fusion: Formation Process and Boiling Heat Transfer Performance. Energies 2022, 15, 1779. https://doi.org/10.3390/en15051779

Qian B, Fan H, Zhang J, Liu G, Li P. Heat Exchanging Grid Structures Based on Laser-Based Powder Bed Fusion: Formation Process and Boiling Heat Transfer Performance. Energies. 2022; 15(5):1779. https://doi.org/10.3390/en15051779

Chicago/Turabian StyleQian, Bo, Hongri Fan, Jianrui Zhang, Gang Liu, and Pei Li. 2022. "Heat Exchanging Grid Structures Based on Laser-Based Powder Bed Fusion: Formation Process and Boiling Heat Transfer Performance" Energies 15, no. 5: 1779. https://doi.org/10.3390/en15051779