1. Introduction

Availability of energy and electrical supplies are among the challenging issues in certain areas of the world. The development of efficient, flexible, and low-cost energy systems can contribute significantly to several social, industrial, and economical aspects in these regions. Microturbine MGT is a promising technology for small-scale combined heat and power CHP systems. It offers the advantages of high fuel flexibility, low operational costs, reduced vibration and noise levels, and clean emissions [

1]. The combustor is a crucially important component, where the chemical energy of the fuel is converted to thermal energy for electric power generation and space heating [

2].

The design of a microturbine combustor is a challenging task as it has to meet numerous performance and operational requirements in the compact space. Multi-fidelity combustor design tools are of great importance as they allow rapid design solutions exploration and avoid the “trial and error” that adds a great expense of time and cost to the product development process. In the public domain literature, the design tools have been developed for large aero combustors. Liu et al. developed a design tool for a lean-burn aero combustor. The tool combines with the genetic algorithm to enable multi-objective optimisations at the combustor early development stage [

3]. Angersbach et al. presented a combustor design tool that combines the industrial in-house design rules with a CFD solver. The tool provides 1D design feature and up to 3D combustor flow field for a rich burn aero combustor [

4]. Foust described the development of a twin-annular-premixing-swirler combustor. Design optimisation is performed using CFD analysis along with test validation to optimise pilot and main premixing for low NOx, and the mixer design to avoid autoignition and flashback [

5]. Pegemanyfar et al. developed a design system for a rich-burn low-emissions aero combustor. The detailed postprocessing CFD analysis was conducted on flow distribution and liner configuration to optimise the combustor altitude relight performance and emissions [

6]. Major engine manufacturers have developed proprietary design programs based on the tests and simulation data to assist their combustor development [

7].

Compared to larger combustors, the MGT combustor has a low Reynolds number but with a higher surface to volume ratio. In addition, it has a more stringent requirement for the maximum allowable pressure loss. Ji presented a systematic design methodology for a micro-gas-turbine-based range extender and explored its feasibility for electric vehicles. The power of the MGT is close to 12 kW and the combustor is an annular type [

8]. Visser et al. developed a recuperated MGT for micro-CHP applications. An aerodynamically stabilised flame combustor is designed to achieve high combustion completeness and low pressure loss. The common engineering method is used to conduct the preliminary design [

9]. Ibrahim designed an MGT combustion chamber through software simulations. The swirlers are not used in the initial design and the flame is sustained by the jet through the liner holes [

10]. Bazooyar presented a design procedure and conducted performance analysis for a trapped-vortex micro combustor. Empirical correlations are used in the MGT preliminary design [

11]. CR Liu reveals the design and modelling details of a micro can combustor supplied with methane and syngas fuels. The modified combustor geometry resolves the flame stabilisation and cooling issues [

12]. Abagnale et al. optimised the combustor configuration using a numerical method to control the NOx and CO emissions. The combustor is a reversed flow annular combustor [

13]. Research and development have also led to different types of micro gas turbine combustors using various numerical and experimental approaches. Swirl-stabilised flame MGT combustors are developed based on numerical modelling and experimental testing to investigate the emission and flame characteristics [

14,

15,

16]. There is another combustor concept: vaporiser-tube combustors used in MGT applications [

17]. The premixing chamber dimension is determined using the correlation-based approach. Numerical modelling is also used to support the research by investigating the temperature distribution at the combustor outlet [

18].

The shortage of conventional fossil fuels and the continued demand for energy supplies have led to the development of a micro-turbine system running renewable fuels. Nipey conducted the experimental test to evaluate MGT performance burning mixtures of biogas and natural gas. The test shows that the main MGT performances are not significantly changed with the biogas content in terms of power output and electric efficiency [

19]. The performance analysis of a biogas-fuelled MGT system is conducted based on a validated thermodynamic model. The results showed the viability of the MGT in biogas application [

20]. To realise a dual-fuel operation in MGT, a noninvasive and cost-effective approach was proposed to enable feeds of biogas to the premixed flames, and diffusion flames supplied with natural gas [

21].

In comparison with the previous studies, the contributions and motivation of the present research are as follows:

Studies usually rely on empirical-based approaches during the MGT combustor preliminary design phase. In this research, a combined analytical, parameter-based, physics-based, and empirical-based approach was developed and integrated into the whole design framework, which aims to shorten the design cycle and improve the accuracy of the MGT combustor modelling at the early design stage.

In the process of the MGT combustor design utilising the multi-fidelity approach, the underlying interactions between different approaches are not explored in great detail in the public domain literature. Specifically, the refinement process of the reduced-order method through high-fidelity methods are not greatly revealed. This is to be investigated in the research.

In this paper, a multi-fidelity design is performed on an MGT system that generates 12 kW of power and 200 kW of heat simultaneously. The developed combustor is a swirl-stabilised, multi-point injection type. The overall methodology for the combustor design and modelling is initially presented. The main preliminary design involves the definitions of design parameters, combustion chamber layout, flow distributions, and burner geometries. Combined approaches, as well as design procedures and criteria, are provided in detail. The high-fidelity numerical methods are also integrated to provide detailed modelling and analysis, which produces the optimum solution. The designed combustor is then manufactured, and an MGT system is constructed to test and verify the design. The experimental test is conducted and confirms that the designed combustor is successfully implemented at the desired working conditions. The developed design and modelling approach are then validated against the test data. Suggestions of refinement for low-order models are provided. The shortage of fossil fuels and continuous demand for energy supplies has led to the development of a microturbine system operating renewable fuels. The effects of renewable fuel on combustor performance and emissions are also investigated by the verified numerical approaches. The design strategies to address the flame stabilisation issue are explored.

2. Design Framework Overview

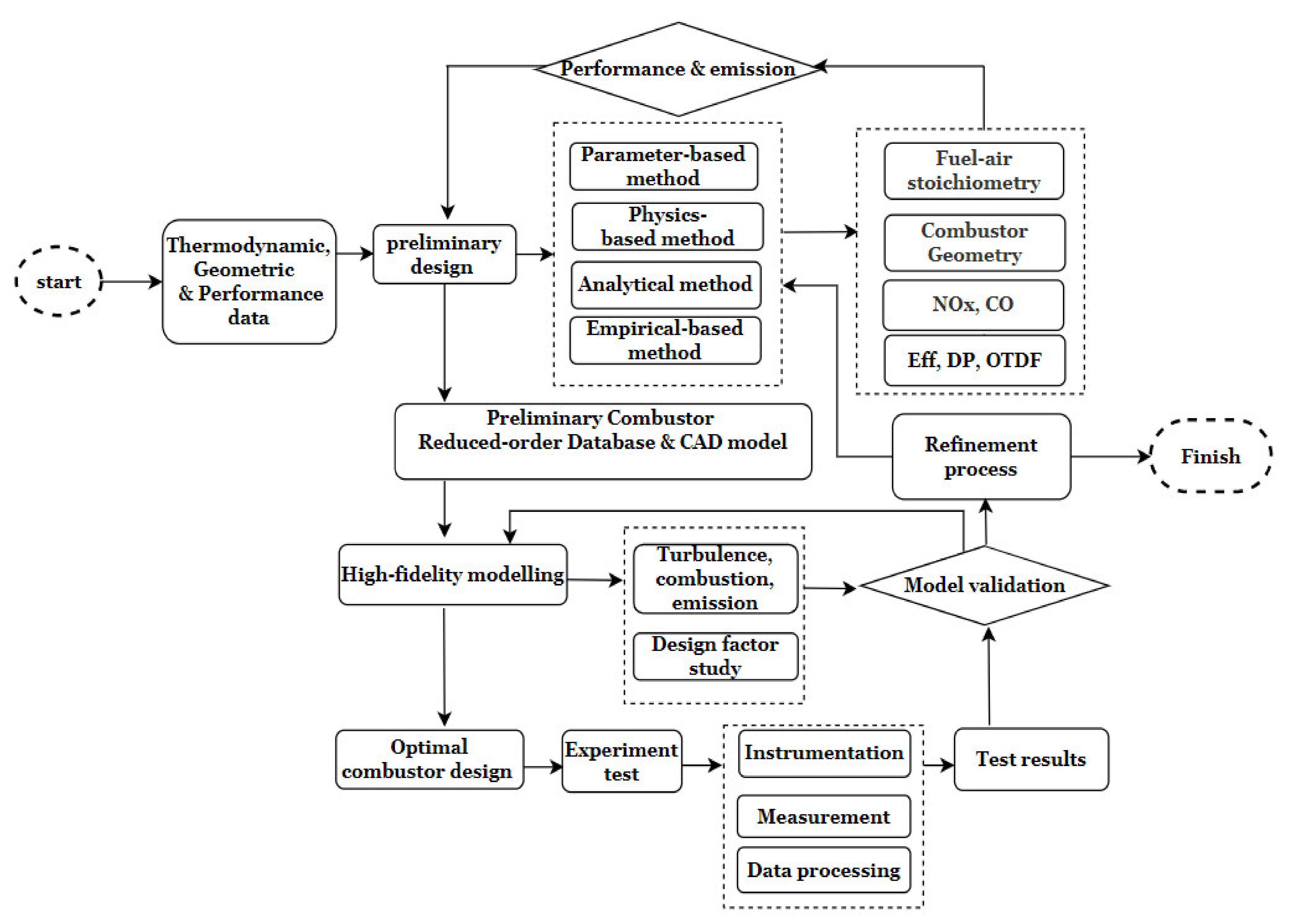

The overview of the multi-fidelity design and modelling approach is presented in

Figure 1. Three sets of input data are required to initialise the design process based on MGT thermodynamic cycle analysis, design targets, and geometric limitations. It starts with the preliminary design phase. An in-house preliminary design tool was developed. It defines the initial details of MGT combustor layout, fuel–air stoichiometry, liner hole, and fuel burner. Moreover, the integrated in-house design system including a physics-based method, analytical, and empirical approaches are coupled to evaluate emission, combustion efficiency, pressure drop, and outlet temperature distribution factor based on the flow distribution and geometric data. Adjustment of the design variables is necessary to ensure that for the combustor, the basic performance targets are achieved. Furthermore, the computed combustor dimensions are checked against the geometric constraints imposed by the turbomachinery design.

Once the preliminary design is completed, the resulting design and geometric information restored in the reduced-order model database is transferred to the CAD tool where a three-dimensional geometry is generated. Moreover, the database is further transferred to ANSYS 19.1 Fluent solver for a comprehensive high-fidelity analysis. It comprises the modelling of turbulence flow, mixing characteristics, combustion reaction, and emission formation. Moreover, the design factors that are not fully modelled in the preliminary stage are identified, and their effects on combustor performance are investigated in detail. Volumetric grids are generated on the defined computational domain. The boundary conditions are imposed based on predetermined thermodynamic information in the preliminary design phase. The governing equations are defined to solve for energy and mass balances. The insight provided by the high-fidelity modelling explores the effect of design parameters on combustor performance and enables the combustor tunning process.

In the final phase, the combustor design is evaluated through experimental testing. The MGT test bench is designed to allow it to be conducted at full scale and real microturbine operating conditions. Moreover, the designed test bench is flexible to enable testing of different combustor geometries (if required). The instrumentation techniques are applied to measure the combustor and MGT performance. In this case, the mass flow, temperature, pressure, and emissions are thoroughly evaluated. The data generated from the rig test are used to verify and validate the multi-physics approaches. At the same time, the refinement process on reduced-order models can be realised based on the insights acquired by verified high-fidelity models, which increases the model robustness and allows the first-order accurate design of an MGT combustor system at the early stage of the whole design process.

3. MGT Combustor Preliminary Design

A dedicated in-house preliminary design tool for the MGT combustor was developed. The detailed preliminary design procedure is shown in

Figure 2. Three categories of data are required to initialise the design process (

Table 1): Thermodynamic parameters: combustor air inlet/outlet pressure, temperature, and the mass flow determined by the MGT cycle calculations based on the power output requirement. The fuel type is also defined. The current MGT is fed by natural gas. Renewable fuel is also investigated. Geometric parameters: The inlet and outlet geometric boundary generated by the turbomachinery design. Moreover, the geometric constraints of the combustor design space are imposed based on the MGT size limitations. Performance parameters: The designed combustion chamber is expected to satisfy certain performance targets, including high combustion efficiency, low pressure drop, emissions, and outlet temperature distribution factor.

The type of the combustor is a primary design concern for initialising the layout definition. In the present work, a single-can version is developed based on manufacturing simplicity, ease of access to components, simple thermal management, and reduced cost requirements.

The design begins with fuel–air stoichiometry calculations. The actual flow distribution is determined based on the zonal equivalence ratio

in (1). The dome flow is divided into swirling air, head cooling, and primary mixing jet. The remaining flow splits include secondary jet and dilution air. The determination process considers a trade-off between the high combustion completeness and maximum permitted flame temperature for NOx production.

where

is the total air mass flow,

is fuel flow,

is the stoichiometric fuel–air ratio, and

is the zonal equivalence ratio.

The main procedure used for obtaining the chamber dimension is a parameter-based approach: intensity factor (2) that takes account of combustor thermodynamic parameters and fuel information. The length of the zonal chamber is computed based on sufficient length for primary zone recirculation flow establishment, the length required for secondary hole mixing, and the low outlet temperature distribution factor.

where

is the chamber volume and

is the fuel lower heating value.

The next design procedure concerns the fuel burner. To mitigate the risks of flame flashback and dynamic issues, diffusion-based combustion is considered in this design. The flame aims to be stabilised via a fuel burner that consists of a fuel nozzle and a swirl generator. A multi-point gas nozzle is designed to improve the fuel–air mixing and minimise emissions. The fuel nozzle orifices are arranged circumferentially, and the total orifice dimension is determined based on the fuel flow rate and fuel pressure differential. In this case, the fuel pressure differential is 10% of the combustor inlet total pressure. The single orifice dimension is then obtained based on the assumed orifice number.

A radial-type swirl generator is considered in this design. Flat vane blades are used and circumferentially mounted on the injector head with equal spacings. The gap between the swirler hub and the fuel nozzle is 1.5 mm. The swirler outer diameter is around 75% of the combustor inlet diameter. The geometries of the swirler area and the axial swirler width are defined based on the precalculated swirling flow, swirler arrangement, and permitted pressure drop. The main design objective is to achieve sufficient swirling strength to establish central recirculation flow to sustain the flame as well as enhance rapid fuel–air mixing. The swirling strength is characterised by swirl number

SN ((3) [

22]), which is mainly dependent on flow Reynolds number, vane blade

angle, and number

.

The liner holes design can be initiated as soon as the air and gas thermodynamic data become available. By specifying the hole type, the hole dimensions are determined based on the pressure drop and flow coefficient (4). For dilution holes design, the main design criteria are jet penetration and mixing that are governed by a crucial design parameter, momentum flux ratio,

[

23]. The liner hole geometry is updated with a new iterated air mass.

where

is the zonal air mass flow and

is the flow coefficient.

For the MGT emission evaluation at the preliminary design phase, the correlation-based approaches are not applicable: empirical terms are specific to certain combustor applications, and parameters used in the semi-empirical are challenging to fully define. CFD simulations require a long computational time and high cost. Instead, the physics-based method is deemed to be the most suitable approach. The modelling algorithm is developed and integrated into the current preliminary design framework. The method concerns the influence of different levels of flow mixing on a chemical reaction within the prescribed volume. Different types of reactors are developed based on the flow mixing characteristics. In the developed model, the perfectly stirred reactor (PSR) regards the mixing as instantaneous, uniform, and ideal. Thus, the temperature and species mass/concentration are computed based on the gas mixture fraction

and flow residence time inside the reactor.

The gas mixture fraction inside each reactor can be obtained from the flow distribution procedure defined in (1). is the gas mixture mass flow rate.

The partially stirred reactor (PaSR) assumes the mixing takes place at the micro-level with no intermixing between pockets and all fluid elements containing different speeds. Thus, this reactor is used to model the inhomogeneous mixing effect. Inside the PaSR, the mean quantities, including temperature and species mass/concentrations

can be computed from the probability density functions as an average over all of the states:

is the probability density function that is derived from clipped Gaussian distribution. To fully define the probability profile, the deviation

is required and obtained by an empirical mixing parameter

.

The reactor is then formulated at each liner zone, and a two-dimensional network is generated to link each element to represent the physical features and chemical reaction of the combustion chamber.

To model NOx emissions, the governing mechanism ((8)–(10)) for thermal NOx formation is specified as follows:

and prompt NOx formations where the main reaction routes ((11)–(14)) are expressed as

The formation of CO is initially originated from the combustion of the fuel that reacts to CO and H

2O. Then, the main reaction to govern the conversion rate of CO is given as

During the preliminary design phase, empirical correlations are widely used to evaluate combustion efficiency [

18,

24]. However, these well-known correlations are not applicable in the analysis of MGT burners, as they were developed for large aero combustors. The study aims to improve the modelling accuracy by performing detailed gas composition analysis. In this analysis, the volumetric concentrations of incomplete and complete combustion products (i.e., CO and CO

2) are computed at the combustor outlet using the physics-based method described above. CH

4 is set to be the fuel in this analysis. Thus, the efficiency level is expressed as:

where

,

are lower heating values in kJ/kmol.

The pressure loss analysis is conducted utilising the analytical approach. The overall combustor pressure loss consists of cold loss and fundamental loss due to combustion. In addition to the cold loss due to flow through the liner holes (17), in this MGT combustion chamber, a truncated divergent cone is added to accommodate the connections of combustor entry. Thus, the cold loss due to inlet duct geometric expansion is also taken into account (18). The fundamental loss is derived from the momentum considerations, and the density variation can be approximated by temperature variations (19). Therefore, the overall pressure loss is the sum of the losses specified as

where

is effective hole area.

where

is Mach number at the inlet section,

,

denotes inlet and casing area.

where

is flow density and velocity.

The uniformity of the temperature distribution at the outlet of the combustion chamber directly affects the durability of the turbine. The outlet temperature distribution factor (

OTDF) is used to quantify the temperature distribution and is defined in (20): the ratio of the difference between the peak and mass flow weighted mean temperature at the combustor outlet plane to the combustor mean temperature rise. To estimate OTDF at the preliminary design stage, the two parameters in (20), liner dimensions and pressure drop [

25], are utilized to estimate OTDF at the preliminary design stage.

where

is maximum outlet temperature,

and

are inlet and outlet mass flow weighted mean temperatures,

is the liner length,

is liner diameter,

is liner pressure drop, and

is the reference dynamic head.

Finally, the iteration loop is formed by adjusting the combustor geometric design variables and zonal fuel–air stoichiometry. The iterative process will proceed until the design meets the efficiency, pressure drop, emission, and OTDF requirements.

4. High-Fidelity Modelling

The detailed procedure for high-fidelity modelling is presented in

Figure 3.

The initial step is to gain more physical insight into the performance of the designed MGT combustor through the modelling approach of turbulence, combustion, and emission. In this study, the details of turbulent flow pattern, flame shape, fuel–air mixing characteristics, temperature/pressure distribution, and emission characteristics are investigated.

The three-dimensional steady-state Reynolds averaged Navier–Stokes (RANS) simulations are performed for high-fidelity modelling using ANSYS Fluent 19.1 solver. For turbulence modelling, the two-equation model was implemented to determine turbulence length and time scale by resolving two separated transport equations. The

k- model was considered since it is a robust and well-tested model that is widely applied in industrial flow simulations [

26].

The realizable

k- model was chosen as it provides superior performance to standard

k- in modelling flow separation, strong streamline curvature, and secondary flow features [

27]. Thus, the transport equations for

k and

in the model are expressed as:

where

,

are the generation of turbulence kinetic energy due to mean velocity gradient and buoyancy, respectively. The definition of

,

can be found in Ref. [

27].

For combustion modelling, a flamelet-generated manifold approach was implemented to model the chemistry in the reacting turbulent flow field. The chemistry is characterised by mixture fraction

and progress variable

c [

28]. Thus, the mean thermochemical quantities are computed from (23):

where

is the mean thermochemical quantities.

Therefore, governing equations are solved for mass, momentum, energy, mixture fraction, mixture fraction variance, reaction progress, and reaction progress variance. Non-adiabatic FGM was considered to take account of the heat loss effect. The GRImech 3.0 mechanism was used to initiate the flamelet generation and model the chemical reactions. The mechanism consists of 53 species and 352 reactions [

29].

For emissions modelling, the main governing formation mechanisms for NOx (thermal and prompt NOx) and CO remain similar to the physics-based approach in the preliminary design. For NOx modelling, the method suggests that NOx forms more slowly than other high energy-releasing reactions. Thus, NOx calculations can be decoupled from the main reacting flow simulations. In this case, the post-processing technique is adopted via the use of the decoupled NOx model in the Fluent solver, and the temperature and species are obtained from the converged reacting flow simulations.

The next procedure for high-fidelity modelling is to identify the design factors that are not fully modelled in the preliminary stage. Chamber dimension, dome front configuration, number of fuel nozzle orifice, and dilution hole arrangement are identified and their effects on combustor performance are investigated in detail. In the preliminary design model, the chamber dimension is derived using the parameter-based approach. High-fidelity modelling is conducted to determine the optimum value of the parameter by analysing the combustion completeness at the design point through the gas composition analysis. Moreover, combustion at the off-design point is also assessed to confirm whether the determined chamber dimension is able to sustain the combustion at lower temperatures/pressures. In the preliminary design phase, the effect of the dome front configuration is not taken into account. The high-fidelity analysis considers the different dome configurations that consist of various dome shapes and primary zone mixing hole arrangements. Flow patterns and combustion characteristics are examined. In the preliminary design model, the fuel nozzle orifice dimension is obtained based on the assumed orifice number.

To investigate the effect of orifice number on fuel–air mixing, a new nondimensional parameter

(24) is introduced to quantify the uniformity of the fuel distribution at defined surface locations. The higher the value of

, the more enhanced the degree of uniform mixing that can be attained. By definition, when the fuel and air are perfectly mixed, the value can reach up to 1. The effect of the orifice number on emission characteristics is also studied.

where

is the species variable, and

is averaged value of

at the entire surface

.

In the preliminary design model, dilution hole designs are performed based on two main design criteria: mixing and jet penetration. The two resulting dilution hole arrangements are to be assessed via the temperature and emission analysis in the high-fidelity modelling.

Then, the procedure proceeds with the detailed modelling strategy phase where computational domain, grid generation, and boundary conditions are all defined.

The computational domain was established via the creation of a three-dimensional combustor geometry. The airflow enters the combustor through the inlet circular section specified as the domain inlet. A fraction of the air enters the injector-swirler assembly and the remaining air passes through the annulus between the liner and air casing. Combustion is formed inside the liner, and the hot burned gas exits the truncated convergent conical section (domain outlet) to drive the turbine wheel. The entire computational domain was set to be fluid in the simulations.

A hybrid grid-generation strategy was implemented to discretise the computational domain. The tetrahedral elements were created in the zones of fuel injectors, swirlers, and combustor holes where the geometries are relatively complex. For regular geometry such as inlet duct, casing passage, and liner, the hexahedra grids were dominant. Grid sensitivity analysis was performed by examining different numbers of the grid. No significant changes in the results of simulations were observed with a grid number of 8 million. Thus, the number was used in the subsequent analysis.

The defined boundary conditions are listed in

Table 2. Mass flow inlet conditions were applied at air and fuel inlets. The mean mixture fraction at the fuel inlet is unity. The directions of inlet flow were set normal to the boundaries. At the combustor outlet, atmospheric static pressure was imposed. No-slip stationary wall condition was imposed at the walls.

The main performance criteria are then defined to determine the optimal combustor geometry. The details are listed below:

Combustion stability at design and off-design conditions; flame dynamic issues have to be controlled.

Low pressure loss to maintain the high MGT cycle efficiency.

Desired flow pattern (i.e., well-generated recirculation flow in the primary zone, etc.).

Desired flame shape (i.e., avoid direct flame contact to the liner wall to cause the liner cooling durability challenge).

Reduced emissions (NOx and CO).

Accepted outlet temperature distribution factor.

Based on the above criteria, the final optimal combustor design is produced. The validation of the modelling approach is then conducted by comparing the simulation results with the measured data obtained from the experimental test. The details of the rig setup are presented in

Section 6.

In the final phase, the results from the validated high-fidelity modelling are then used to generate customised methods to refine the low-order model in the initial preliminary design. The details are presented in

Section 7.2.

6. Experimental Test Rig

The combustor was fabricated and installed in the turbo-green MGT assembly designed by Samad Power Ltd. (Milton Keynes, UK). The MGT operates based on the Brayton cycle. It consists of a single-stage centrifugal air compressor/turbine, a combustion chamber, a heat exchanger, and an alternator. The system generates up to 12 kW of electricity and 200 kW of heat simultaneously.

The schematic drawing of the test rig setup is presented in

Figure 14. The single-shaft MGT assembly is fixed on the test bench with the combustor placed vertically. A natural gas tank is installed to supply the gaseous fuel to the MGT through an orange-coloured pipeline (shown in

Figure 15). For measurement of fuel mass flow rate, a gas mass flow controller is installed between the gas tank and the combustion chamber. To measure air mass flow rate, a flow duct is installed before the compressor inlet to ensure the inlet flow distortion effect is controlled to an acceptable level for reliable recording. The MAF sensor is placed between the duct and compressor inlet to monitor the airflow rate data. For temperature measurement, thermocouples are installed at the key locations, including compressor inlet and outlet, turbine inlet, and exhaust. Some additional thermocouples are also installed at other units, including the alternator, compressor, turbine housing, and bearing housing. The pressure sensors are also placed at the compressor outlet and turbine inlet to enable the combustor pressure drop measurement. A flue gas analyser probe is installed at the turbine outlet (

Figure 15) to measure the MGT combustion product. The sensors inside the analyser are capable of detecting the emissions of NOx, CO, and CO

2. To enable the ignition process, a full sequence automatic spark plug is placed near the combustor liner close to the primary zone. The tested MGT is expected to operate at various operating points. The test ambient pressure is 101.3 KPa, and the ambient temperature is 288 K. By finely tuning the gas valve setpoints, the turbine inlet temperature TIT level is maintained to be below the limit (i.e., <1200 K) to avoid damage to the turbine blade. In addition, other control parameters, such as turbine rotational speeds setpoints, during the test and all the measurement parameters are monitored using LabVIEW via connected hardware, datalogger, and relays.

8. Renewable Fuel

The combustor is designed to be fuel-flexible to enable the operation of supplementary and renewable fuels. After the verification and validation of the models, CFD analysis is carried out on the same combustor feeding biogas. For a comparable case study, the biogas mass flow was calculated so that the thermal power was the same as in the case of natural gas. Therefore, apart from the fuel composition and the fuel mass flow, the same boundary conditions (

Table 2) of the natural gas case are applied.

In the initial simulation, the biogas consists of 60% CH

4 and 40% CO

2. The fraction is given on a volumetric basis. The lower heating value of the fuel is 17.7 MJ/kg. For comparison purposes, the scale of temperature is presented in a nondimensional format, as indicated in

Figure 19. The temperatures for natural gas are set as reference. The combustor burning the biomass yields a lower flame temperature. In particular, the maximum temperature is 13% lower compared to the case of natural gas. The reacting flow velocity streamlines are also generated in the same plot to indicate the flow structures. For the two reacting flow cases, similar flow characteristics are noticed: flow recirculation is also established in the primary zone in the case of biogas. A large fraction of recirculation flow is formed in MRZ. A small fraction of the recirculation is observed in the corner region, which establishes the corner recirculation zone (CRZ).

NOx and CO concentrations maps are given in

Figure 20, with nondimensional scales applied for more visible comparisons. Due to the presence of CO

2 in the fuel content of the biogas, the reaction temperature decreases. Since NOx production is highly affected by the temperature, the lower temperature decreases the NOx level. At the exit plane of the combustor, the biogas combustor features a 66.7% NOx reduction in comparison with natural gas. A higher concentration of CO is noticed at the primary reaction zone when firing biogas due to lower combustion temperature and, hence, the slower consumption rate of CO. As a result, the level of CO produced by biogas is twice higher than that of natural gas.

Biogas typically consists of 50–75% methane, and the main remaining content is CO

2. The actual composition depends on the raw materials and production methods [

30]. Thus, there is an interest to investigate the effect of methane concentration on emissions. The calculated results are summarised in

Table 8. It can be observed that a significant NOx reduction is obtained in all cases. When the concentration of CH

4 is decreased from 75% to 55%, NOx emission is reduced by 78.3%.

When the biogas system is burned with a lower methane content (i.e., 50%), the simulation study indicates that it possesses challenges in maintaining flame stabilisation and cannot attain the required TIT level. To address this issue, a number of design strategies are initially proposed, with the parameters suggested being modified. These include (a) chamber diameter, (b) liner axial length, (c) the number of primary mixing holes, (d) axial position of primary mixing hole, and (e) swirling intensity. Since the current MGT combustor has a stringent size requirement, in particular, the length and diameter limits are imposed, and modifications of parameters (a) and (b) would also add the extra cost and weight to the system, these solutions are not primarily considered. The adjustment of design parameters of (c), (d), and (e) will not compromise the overall size requirement; however, the change of parameter (c) leads to the modifications of the FAR and flow distribution across the combustor chamber. Therefore, the design strategy is carried out by studying the axial position of the primary mixing hole and the swirling intensity characterised by the swirler blade angle. The original axial position is set as the baseline. The four additional locations are defined relative to the reference point: −5 mm, 5 mm, 10 mm, and 15 mm. The investigated swirler blade angles

are

,

,

,

, and

. Results are summarised in

Figure 21. On the y axis, five axial positions of the primary mixing hole are marked, with point 1 referring to −5 mm relative to point 2 (reference point). Points 3–5 are 5, 10, and 15 mm, relative to point 2. The analysis starts with

with axial position −5 mm relative to the reference point. Combustion is not sustained until

with the axial position reaching 5 mm relative to the baseline. For the two parameters, the combustion stabilisation is mainly governed by the swirl intensity, through the modification of the blade angle. The increase in blade angle enhances the flame stabilisation. The most effective method to maintain the flame stability is observed by increasing the swirler angle as well as shifting the primary hole axial position toward the turbine outlet. As a result, satisfactory combustion efficiency of 99.9% is obtained at point 5 with

. The design strategy is feasible to be adopted as it requires minor system modifications for dual fuel system operation.