Research on Oil Mist Leakage of Bearing in Hydropower Station: A Review

Abstract

:1. Introduction

2. The Generation, Classification, and Damage of Oil Mist Leakage

2.1. The Generation Mechanism of Oil Mist Leakage

2.2. Classification of Bearing oil Throwing Problem

2.2.1. Internal Oil Throwing

- The gap between the thrust oil-retaining tube and the shaft is excessive [43];

- There is no oil-receiving box between the oil-retaining tube and the shaft, thereby forming an oil mist leakage channel [48];

- Operation of the air cooler to minimize the temperature effects of a high-speed generator. This is because the continuous blow and change of flow velocity will produce low pressure in the upper and lower regions of the central body of the generator rotor. The low-pressure zone will increase the oil level height, inducing oil droplets and mist leakage [50]. The path of the blast is shown in Figure 4.

- An eccentricity between the thrust head and the oil-retaining tube or the inner wall of the tank is produced during the installation. The effect of the uneven oil ring and pump are similar, resulting in oil pumping and internal throwing [51].

2.2.2. External Oil Throwing

- Considerable space limitation of the volume of the tank, and thus of the oil mist condensation [48];

- The sealing structure of the oil tank seal cover is unreasonable, forming the main channel of the oil leakage [48];

- The viscous shear action of the oil during high-speed operation, thereby converting substantial mechanical into heat energy [52]. As the lubricating oil expands, the internal pressure becomes greater than the external’s, developing the leakage of the oil mist. This leakage can be worsened if the low-pressure zone is close to the sealing cover plate [6,48].

- Oil leakage exists on the bearing assembly surface and pipeline, worsening the problem [48];

- The generator structure manufacturing is unconventional, or the installation and debugging are inaccurate. For example, the offset distance between the rotating part and the geometric center of the oil tank can be excessive, resulting in violent oil fluctuations and collisions [53];

- Augmentation of the clearance between the bearing seal cover shaft results in oil mist leakage [54]. This clearance can easily misalign due to the large vibration of the high-head suspension unit.

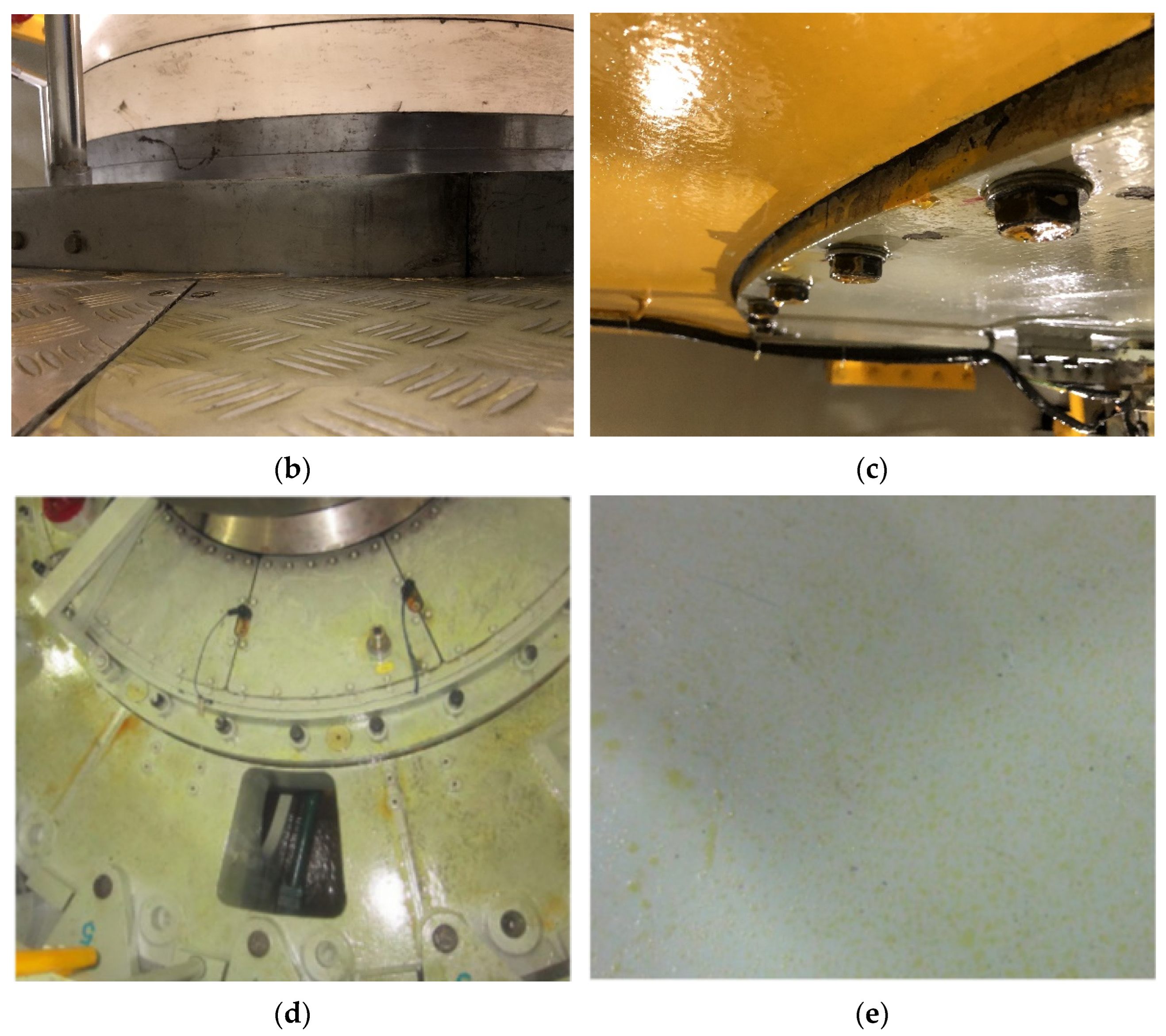

2.3. Damage Caused by Oil Mist Leakage

2.3.1. Pollution to the Power Plant and Its Watershed Environment

2.3.2. Damage to the Insulating Performance of Electrical Equipment

2.3.3. Disruption of the Safe and Stable UNIT Operation

2.3.4. Intensification of the Costs and Workload of Unit Maintenance

2.3.5. Negative Effects on the Health of Operations Personnel

3. Examples of Engineering Research and Some Common Solutions

3.1. Reduction in the Operating Pad and Oil Temperature

3.1.1. Optimization of the Structure of the Pad

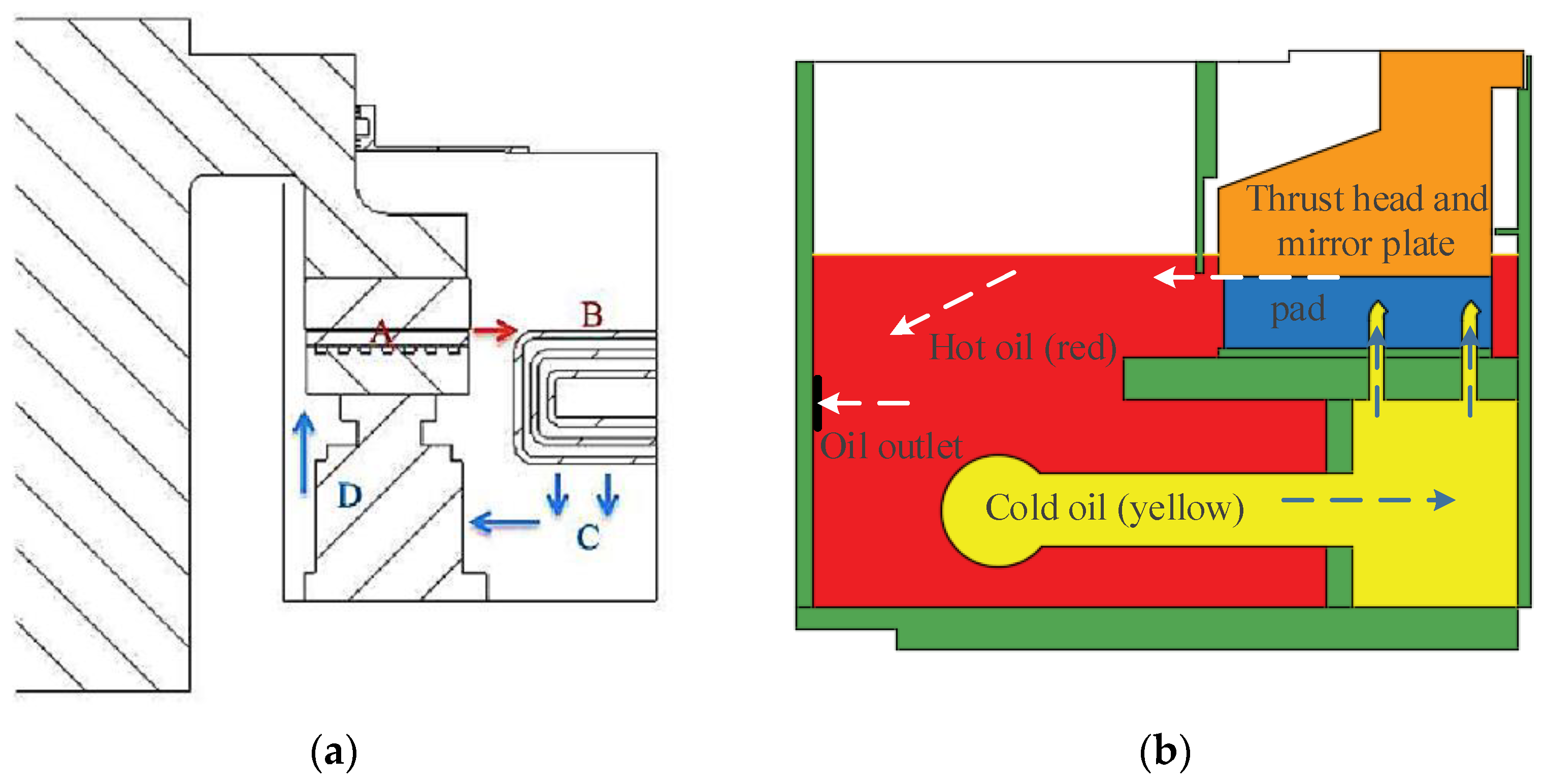

3.1.2. Improvement on the Cooling Cycle Efficiency of the Lubricating Oil

3.2. Optimization of the Oil Circulation Loop in the Oil Tank

3.3. Improvement of the Sealing Performance

3.4. Design of Oil Mist Emission Device

| Hydropower Station | Measures | Country |

|---|---|---|

| Ertan [95,96] | Raise the oil retaining ring, replace the contact seal, and install the oil slinger and mist respirator | China |

| Dalanshan [55] | Replace the oil mist absorption device, the oil tank cover, and seal | China |

| Longtan [87,97] | Increase the power of the oil mist absorption device. Add oil breathing device; an oil mist suction pipe is arranged in the sealing tooth cavity | China |

| Xiluodu [98,99] | Renovate the sealing cover structure, increase the oil slinger, and replace the oil tank seal | China |

| Shilong [100] | Add comb labyrinth oil-retaining tube, connecting pipes, and oil-return holes in upper and lower oil tanks. Install oil baffle plate | China |

| Shuibuya [101] | Increase the height of the oil-retaining tube and the number of oil respirators. Install the oil-pressing vane on the inner wall of the thrust head and adopt the contact seal | China |

| Xiaolangdi [24,102,103] | Increase the height of the oil-retaining tube, lower the oil level of the oil tank, and increase the number and diameter of oil-return holes | China |

4. General Thinking and Some Critical Issues of Numerical Simulation

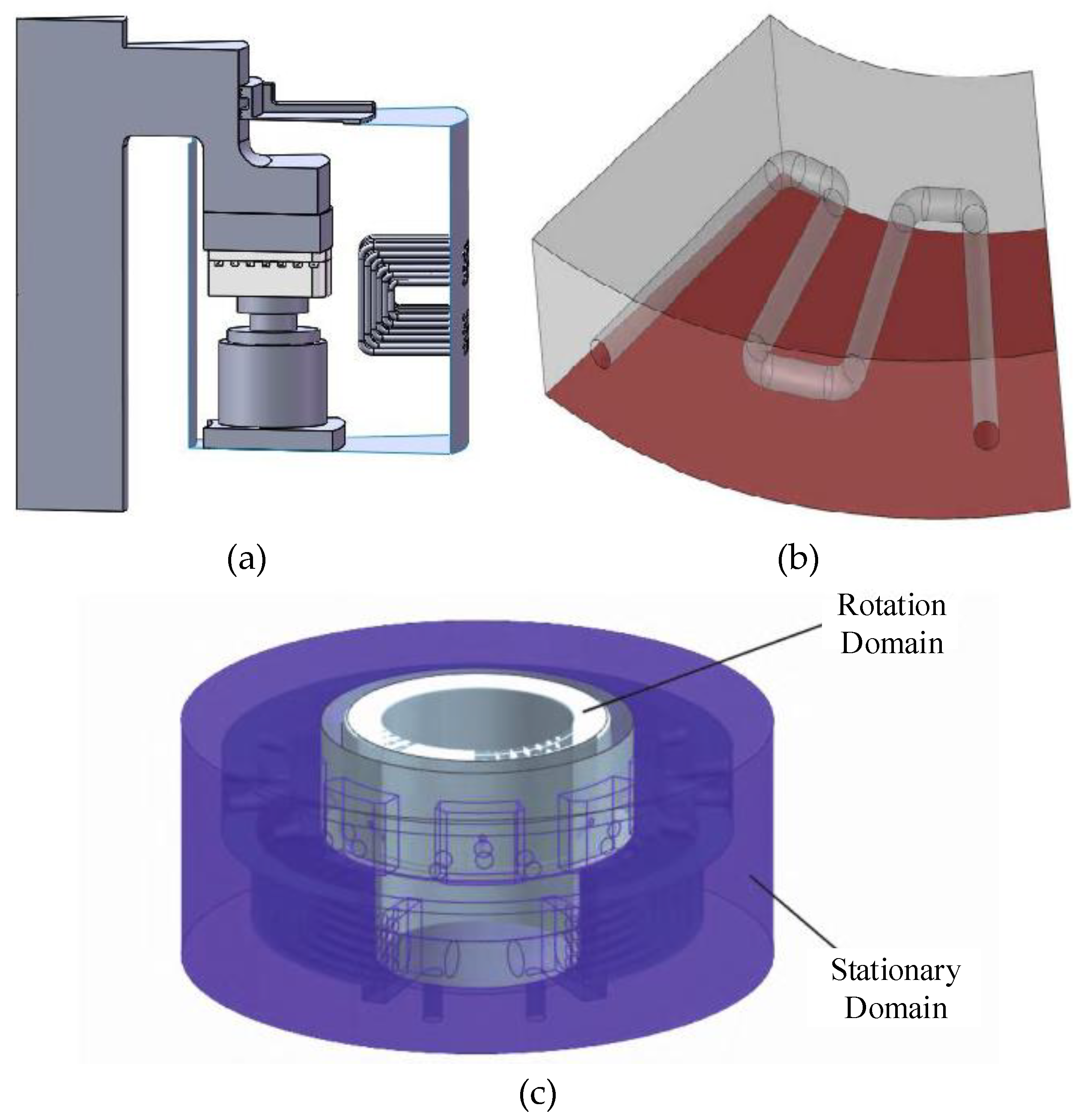

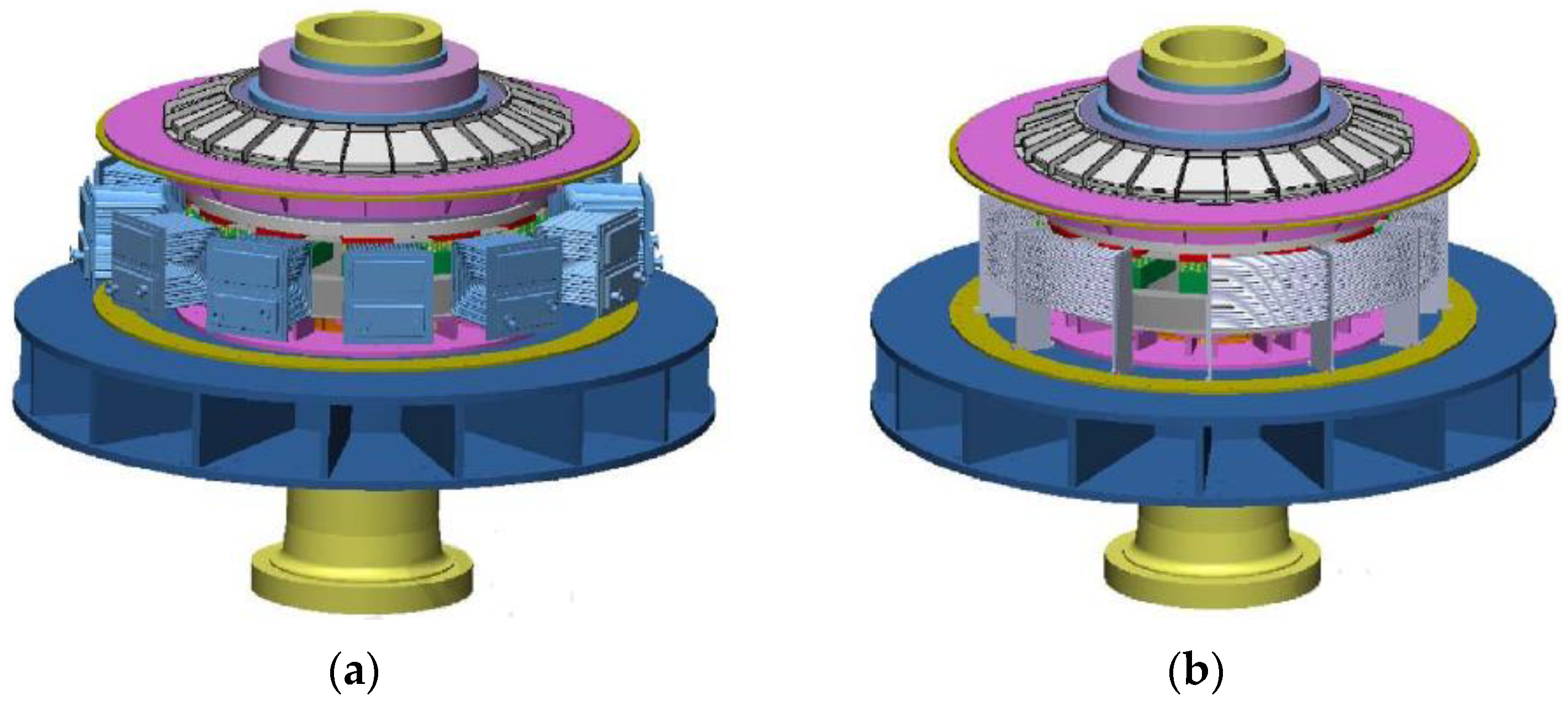

4.1. Research on Simplification of Modeling

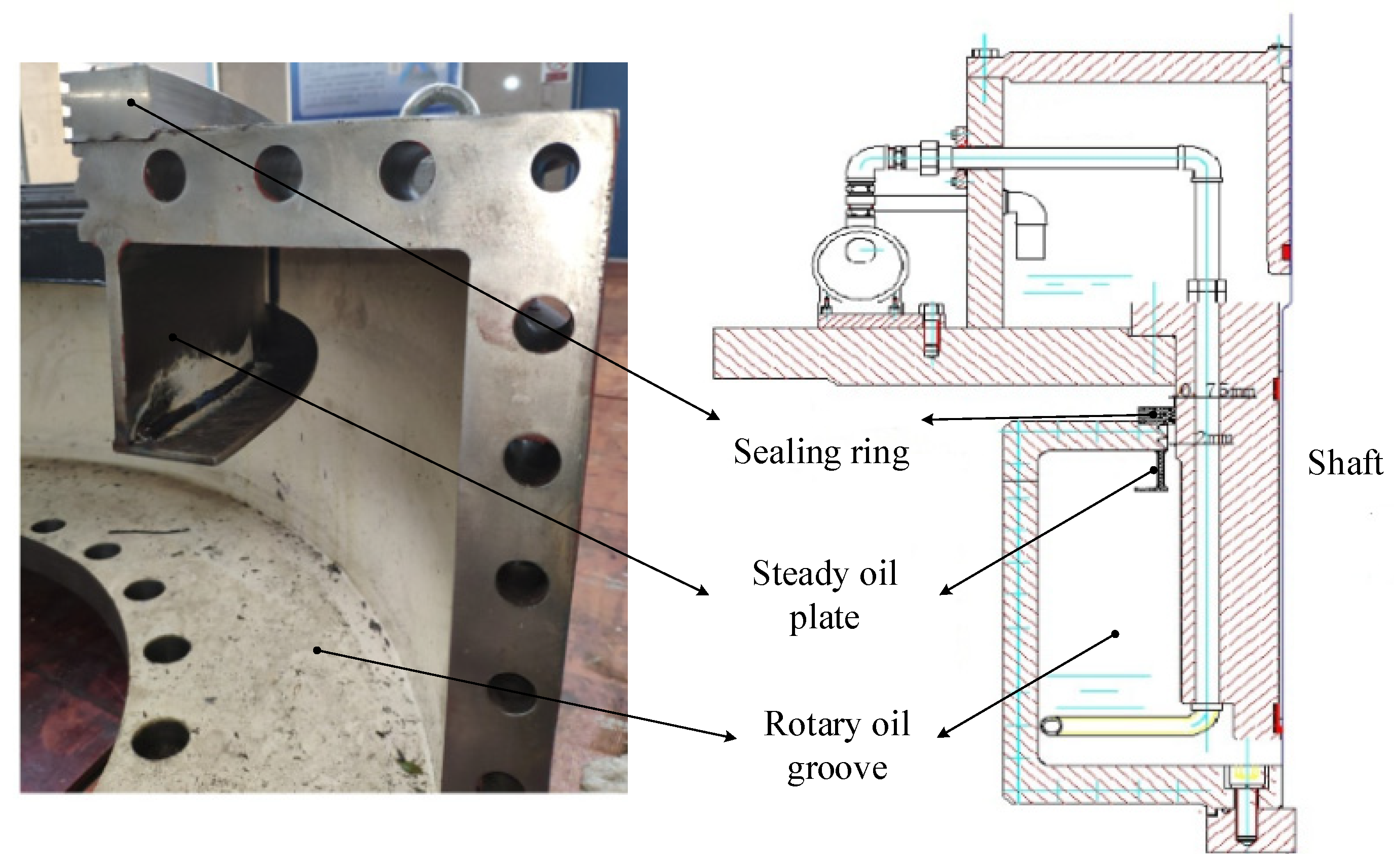

4.2. The Tackling Method of Bearing Dynamic and Static Clearance

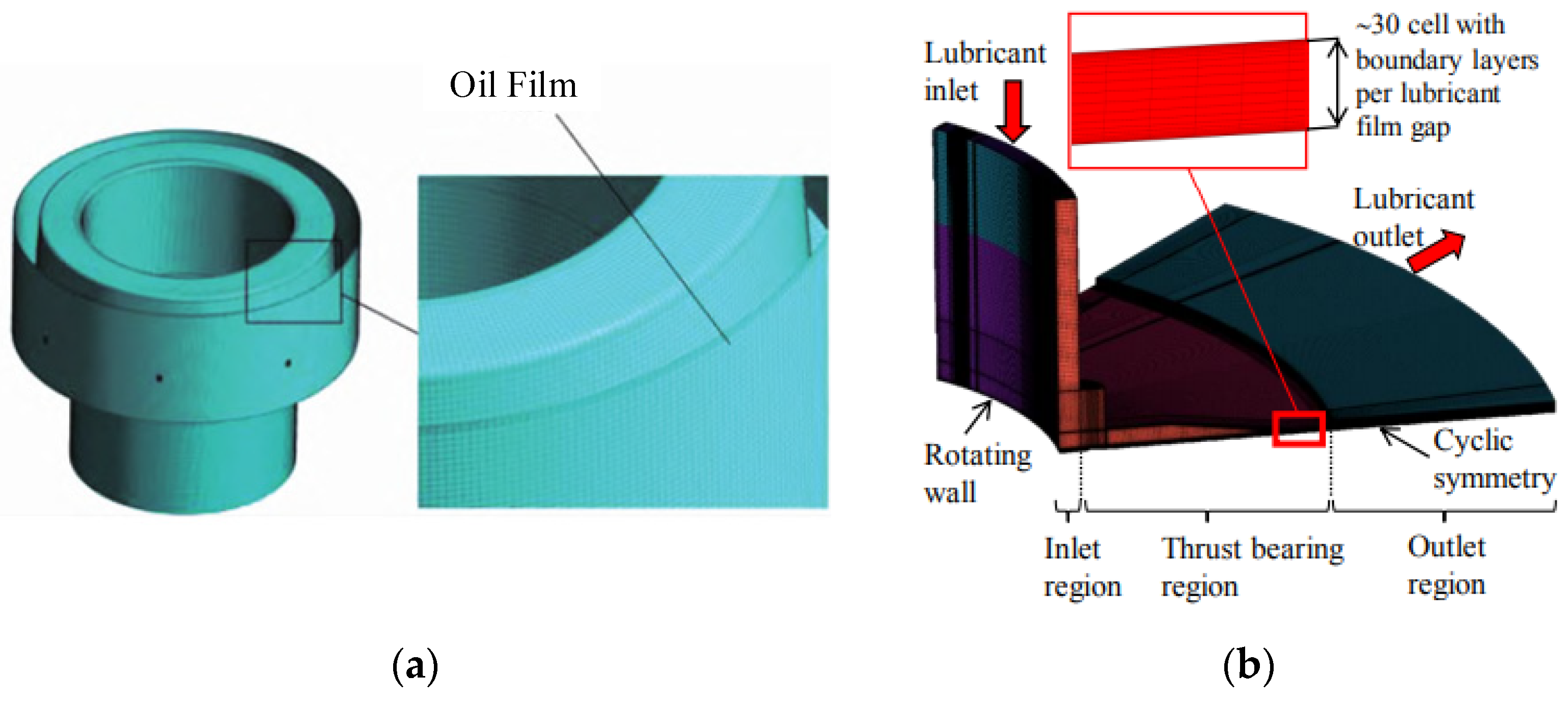

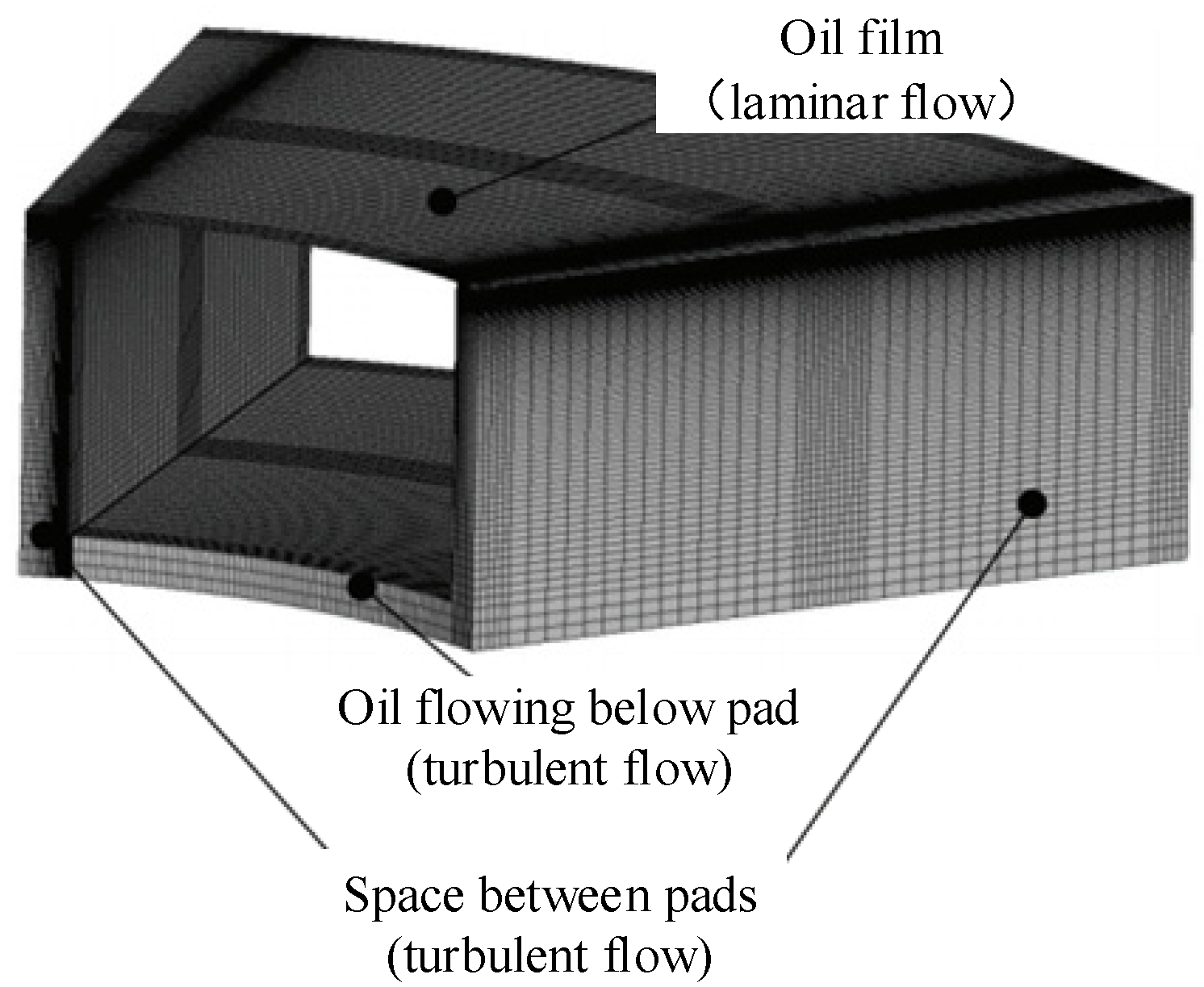

4.2.1. Dynamic and Static Clearance with the Pressure Oil Film

4.2.2. Clearance between the Shaft and Seal Cover

4.2.3. Clearance between the Oil-Retaining Tube and the Shaft

4.3. Selections of Calculation Models

4.3.1. Rotation Model

4.3.2. The Turbulence Model

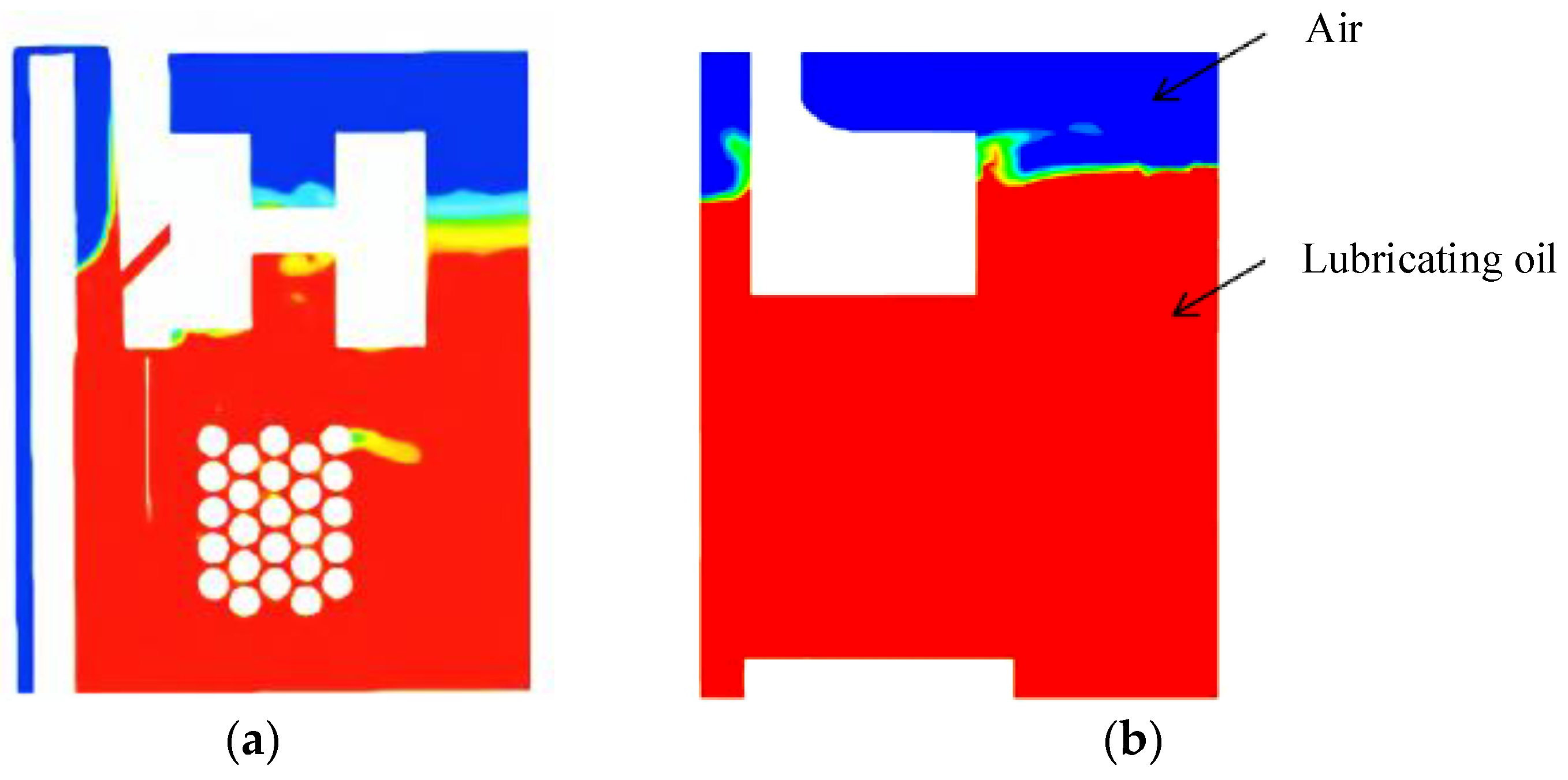

4.3.3. Multi-Phase Flow Model

4.3.4. Evaporation-Condensation Model

4.4. Setting of Boundary Conditions for Different Types of Bearings

5. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jadoon, T.R.; Ali, M.K.; Hussain, S.; Wasim, A.; Jahanzaib, M. Sustaining power production in hydropower stations of developing countries. Sustain. Energy Technol. Assess. 2020, 37, 100637. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Elliott, R.J.R.; Strobl, E.A. Hydropower generation, flood control and dam cascades: A national assessment for Vietnam. J. Hydrol. 2018, 560, 109–126. [Google Scholar] [CrossRef] [Green Version]

- Liming, Z.; Yongyao, L.; Zhengwei, W.; Xin, L.; Yexiang, X. A review on the large tilting pad thrust bearings in the hydropower units. Renew. Sustain. Energy Rev. 2017, 69, 1182–1198. [Google Scholar] [CrossRef]

- De Sousa, F.M.M.M. Study of a Hydrodynamic Thrust Bearing for Hydroelectric Power Stations; Universidade do Porto: Porto, Portugal, 2016. [Google Scholar]

- Zabawski, E. Tilting pad bearing history. Tribol. Lubr. Technol. 2020, 76, 8. [Google Scholar]

- Wang, W.; Sun, W.; Fan, J.; Lei, X. Analysis and Treatment of Oil Mist Problem for Large-scale Hydro-turbine Generator Units. Hydropower New Energy 2017, 4, 74–77. (In Chinese) [Google Scholar]

- Cao, S. Research and Implementation of Oil Mist Emission Control Technology for Hydropower Station Units; Harbin Engineering University: Harbin, China, 2020. (In Chinese) [Google Scholar]

- Ashour, N.M. An investigation on large thrust bearings. In Proceedings of the 13th International Conference on Aerospace Sciences & Aviation Technology, Cairo, Egypt, 26–28 May 2009. [Google Scholar]

- Nurbanasari, M.; Purwanto, T.S.; Kristyadi, T.; Syamsurizal, D. Failure on Bearing Cooler Coils Connector of Hydroelectric Power Plant. Key Eng. Mater. 2019, 805, 185–190. [Google Scholar] [CrossRef]

- Hu, J. Analysis and treatment of bearing oil mist pollution in hydropower station. Mech. Electr. Tech. Hydropower Stn. 1993, 4, 32–37. (In Chinese) [Google Scholar]

- Liu, C.; Huang, K.; An, G. Analysis and treatment of oil throwing by water guide for unit of Bulunkou-Gongeer hydropower Station. Mech. Electr. Tech. Hydropower Stn. 2016, 39, 70–71. (In Chinese) [Google Scholar]

- Baiborodov, Y.I.; Tereshchenko, A.V.; Aleksandrov, A.E.; Shchetkin, V.S.; Pokrovskii, I.B.; Tukmakov, V.P.; Gurbanov, I.S. Results of full-scale tests of the thrust bearing with elastic metal-plastic segments for the turbine-generator unit at the Bratsk hydroelectric station. Hydrotech. Constr. 1982, 16, 348–353. [Google Scholar] [CrossRef]

- Haroun, M.A. Effect of Roseires Dam Heightening on Thrust Bearing of the Power Generation Units; Sudan University of Science and Technology: Khartoum, Sudan, 2017. [Google Scholar]

- Tang, X.; Zhang, C.; Sun, L. Analysis on tile burning accident of guide bearing of generator in a hydropower station in Pakistan. Small Hydro Power 2016, 4, 48–50. (In Chinese) [Google Scholar]

- Ma, D.; Hu, C.; Rao, J. Analysis and treatment of tile burning reason of water guide bearing in Aolujie hydropower Station. Small Hydro Power 2014, 4, 67–69. (In Chinese) [Google Scholar]

- Huang, Q. Analysis and Treatment of Abnormal Internal Oil Spill and High Bushing Temperature of the Lower Guide Bearing in Sanliping Hydropower Station. Hydropower New Energy 2018, 32, 48–50. (In Chinese) [Google Scholar]

- Plante, P.; Soule, E.D.; Energy, F.P.L.; Dupuis, M. Thrust Bearing Retrofit: A Case Study of the Cataract Generating Station; Hydro Tech: Quebec City, QC, Canada; pp. 1–9. Available online: https://www.electrisa.com.br/fornecedores/hydrotech/mancais-de-escora-informacoes-tecnicas-ingles.pdf (accessed on 1 February 2022).

- Yu, F. Fault analysis of oil-throwing ring of hydraulic guide bearing in Caijiazhou Hydropower Station. Mech. Electr. Inf. 2021, 4, 27–28. (In Chinese) [Google Scholar]

- Zhu, Y.; Lin, F. Analysis and treatment of oil throwing defect of hydraulic guide bearing in Unit 2 of Gutianxi Power Plant. Fujian Water Power 2020, 4, 23–25. (In Chinese) [Google Scholar]

- Zeng, Z. Analysis and treatment of oil throwing in hydraulic guide rotating oil basin of longmentan Secondary hydropower station. Small Hydro Power 2020, 4, 57–58. (In Chinese) [Google Scholar]

- Wu, J. Analysis and treatment of oil dumping by water guide in unit 2 of Zhouning power Station. Fujian Water Power 2017, 4, 13–16. (In Chinese) [Google Scholar]

- Lan, R.; Wei, H.; Wu, F. Causes and Control Measures of Dust and Oil Mist from Generators in Yantan Hydropower Station. Hongshui River 2016, 35, 96–97. (In Chinese) [Google Scholar]

- Liu, J.; Deng, G. Oil Splashing Treatment for Thrust Bearing of The No. 2 Unit at Dafa Hydropower Station on Tianwanhe River. Sichuan Water Power 2010, 29, 120–122. (In Chinese) [Google Scholar]

- Luo, Y. Remedial Treatment of Oil Leakage from Thrust Bearing Oil Retaining Tube in Xiaolangdi Hydroelectric Power Station. Des. Hydroelectr. Power Stn. 2003, 4, 86–89. (In Chinese) [Google Scholar]

- Mahesh, A.; Sahoo, S.; Panigrahi, A. Impact of contamination by bamboo decomposition and lubricant oil leak and deterioration of Balimela reservoir water standard at Malkangiri of Odisha. Nat. J. Life Sci. 2014, 11, 1–6. [Google Scholar]

- Jin, C.; Bao, Z. Environmental protection transformation of unit of Baoku river hydropower station. Small Hydro Power 2017, 44, 45–65. [Google Scholar]

- Peng, S.; Yu, Y. Analysis and treatment of thrust tank oil dumping in Ahai Hydropower Station. Yunnan Water Power 2018, 34, 31–32. [Google Scholar]

- Inoue, K.; Deguchi, K.; Okude, K.; Fujimoto, R. Development of the water-lubricated thrust bearing of the hydraulic turbine generator. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 072022. [Google Scholar] [CrossRef]

- Sanz-Bobi, M.A.; Welte, T.M.; Eilertsen, L. Anomaly indicators for Kaplan turbine components based on patterns of normal behavior. In Safety and Reliability–Safe Societies in a Changing World; CRC Press: Boca Raton, FL, USA, 2018; pp. 1003–1010. [Google Scholar]

- Olszewski, A.; Litwin, W.; Wodtke, M. Influence of shaft misalignment on water lubricated turbine sliding bearings with various bush modules of elasticity. Key Eng. Mater. 2011, 1390, 128. [Google Scholar]

- Ramachandran, D.; Krishnamoorthy, S.; Kannan, R.; Boolingam, S. Oil flow simulations in the lubrication system of a turbocharger. In Proceedings of the Gas Turbine India Conference, Bangalore, India, 7–8 December 2017; American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 58509, p. V001T04A014. [Google Scholar]

- Hashish, E.; Mistry, R.; Kreitzer, S.; Finley, B. Oil leak causes and prevention in large electric motors. In Proceedings of the 2014 Petroleum and Chemical Industry Conference Europe, Amsterdam, The Netherlands, 3–5 June 2014; pp. 1–8. [Google Scholar]

- Untaroiu, A.; Fu, G. An optimum design approach for textured thrust bearing with elliptical-shape dimples using computational fluid dynamics and design of experiments including cavitation. J. Eng. Gas Turbines Power 2017, 139, 092502. [Google Scholar]

- Jiang, S.; Zhang, S.; Lin, X. Static and dynamic characteristics of high-speed water-lubricated spiral-groove thrust bearing considering cavitating and centrifugal effects. Tribol. Int. 2020, 145, 106159. [Google Scholar]

- De Pellegrin, D.V.; Hargreaves, D.J. An isoviscous, isothermal model investigating the influence of hydrostatic recesses on a spring-supported tilting pad thrust bearing. Tribol. Int. 2012, 51, 25–35. [Google Scholar] [CrossRef] [Green Version]

- New, N.H. experimental comparison of ooded, directed, and inlet ori ce type of lubrication for a tilting pad thrust bearing. J. Lubr. Technol. 1974, 96, 22–27. [Google Scholar] [CrossRef]

- New, N.H. Comparison of flooded and directed lubrication tilting pad thrust bearings. TRIBOLOGY Int. 1979, 12, 251–254. [Google Scholar] [CrossRef]

- Yuan, B.; Zhang, L.; Wang, W. Oil Vapor Treatment of Vertical Hydro-generator Bearing. Hydropower Autom. Dam Monit. 2015, 1, 43–48. [Google Scholar]

- Jang, G.; Jung, K.; Kim, J. Behavior of fluid lubricant and air–oil interface of operating FDBs due to operating condition and seal design. Microsyst. Technol. 2012, 18, 1373–1381. (In Chinese) [Google Scholar] [CrossRef]

- Huo, X.; Wang, S.; Wu, Z.; Fan, S.; Liu, Q. Measures to prevent oil throwing in thrust bearing oil tank of hydro-generator. Heilongjiang Electr. Power 2020, 42, 471–473. (In Chinese) [Google Scholar]

- Zhang, C. Size Optimization of Thrust Bearing Oil Groove of Hydro-Generator Unit Based on CFD; Changchun Institute of Technology: Changchun, China, 2020. (In Chinese) [Google Scholar]

- Liu, J. Cause Analysis and Treatment of Oil Mist Leakage of Generator Bearing in Longtan Hydropower Station. Water Power 2017, 43, 65–68. (In Chinese) [Google Scholar]

- Zhao, Y. Research on Anti-Oil Mist Escape Device of Thrust Bearing of Mianhuatan Hydropower Station; Changchun Institute of Technology: Changchun, China, 2020. (In Chinese) [Google Scholar]

- Li, D. The design of oil mist seal structure for thrust bearing of hydrogenerator discussed. Sci. Technol. Innov. 2020, 24, 31–32. (In Chinese) [Google Scholar]

- Isić, S.; Leto, A.; Đidelija, M.; Šunje, E. Development of the System for Oil Vapor Drainage from Bearing Housings of Big Hydroaggregates. In Proceedings of the International Conference “New Technologies, Development and Applications”, Sarajevo, Bosnia and Herzegovina, 27–29 June 2019; Springer: Cham, Switzerland, 2019; pp. 486–493. [Google Scholar]

- Huo, Z. Analysis of oil throwing fault of hydrogenerator and its treatment strategy. Technol. Enterp. 2013, 4, 327. (In Chinese) [Google Scholar]

- Song, H. Analysis on Vertical Hydro-Generator Bearing Structure of Preventing Oil Throwing and Oil Mist Spilling. Explos.-Proof Electr. Mach. 2012, 47, 11–14. (In Chinese) [Google Scholar]

- Wu, B.; Ren, Z.; Jing, Y. Research and Application of Oil Fog Treatment of Hydrogenerator at Pubugou Hydropower Station. Large Electr. Mach. Hydraul. Turbine 2016, 5, 52–55. (In Chinese) [Google Scholar]

- Ou, S.; Feng, J. Analysis and Solution of Bearing Oil Dumping in Chongqing Jiangkou Hydropower Station No.3 Unit. Mech. Eng. 2020, 4, 122–123. (In Chinese) [Google Scholar]

- Huang, Y. Cause Analysis and Treatment of Oil Rejection of Guide Bearing of Unit #1 in Goupitan Power Plant. Enterp. Technol. Dev. 2019, 38, 93–95. (In Chinese) [Google Scholar]

- Liu, Q. Failure and treatment of generator oil dump. Heilongjiang Sci. (In Chinese). 2014, 5, 187. [Google Scholar]

- Byrne, J.; He, M. Fundamentals of fluid film thrust bearing operation and modeling. In Asia Turbomachinery & Pump Symposium 2018; Turbomachinery Laboratory, Texas A&M Engineering Experiment Station: College Station, TX, USA, 2018; pp. 1–26. [Google Scholar]

- Yang, M. Mist prevention and control for thrust-bearing oil sump of large hydroelectric generating set. Mech. Electr. Tech. Hydropower Stn. 2005, 6, 14–16, 61. (In Chinese) [Google Scholar]

- Hu, X. Optimization of bearing seal cover for Shawan Hydropower Station. Mech. Electr. Tech. Hydropower Stn. 2015, 38, 53–56. (In Chinese) [Google Scholar]

- Liu, B.; Yang, J.; Liu, J.; Song, L. Research and treatment of engine oil mist in Dagangshan Power Station. Mech. Electr. Tech. Hydropower Stn. 2020, 43, 49–50. (In Chinese) [Google Scholar]

- Zhao, H.; Zhang, L.; Zhao, Z. Analysis and Treatment of Bearing Oil Mist in Xianju Pumped Storage Power Station. Pumped Storage Power Station Engineering Construction Collection 2018; Power Grid Peaking and Pumped Storage Professional Committee of China Hydropower Engineering Society: Beijing, China, 2018; pp. 593–595. (In Chinese) [Google Scholar]

- Mohammadi, A.; Amiri, M. Assessment of Environmental Risks and Opportunities in Operation Phase of Hydropower Plants. In Proceedings of the 8th International Civil Engineering Congress (ICEC-2016), Karachi, Pakistan, 23–24 December 2016; pp. 185–192. [Google Scholar]

- Li, X.; Yu, J. Attention to Environmental Protection of Small Hydro-power Stations. Am. J. Water Sci. Eng. 2020, 6, 76–80. [Google Scholar]

- Ni, J. Common problems and solutions of bearing in generator set operation. Undergr. Water 2021, 43, 241–242. (In Chinese) [Google Scholar]

- Watanabe, S.; Yasuda, M. How to avoid severe incidents at hydropower plants. Int. J. Fluid Mach. Syst. 2017, 10, 296–306. [Google Scholar]

- Xu, X.; Wang, W.; Zhao, G.; Chen, H.; Qin, Y. Analysis and Treatment of the Oil Spill Problem of Thrust Bearing in the No.3 Generator in Shuibuya Hydropower Plant. Hydropower New Energy 2021, 35, 9–12. (In Chinese) [Google Scholar]

- Tang, Y.; Zhou, X.; Deng, T.; Lv, T. Analysis and Treatment on High Temperature of Thrust Bearing Pads for Hongping Storage Hydropower Plant. Int. J. Hydroelectr. Energy 2018, 36, 157–160. (In Chinese) [Google Scholar]

- Singh, A.P. An overall optimum design of a sector-shaped thrust bearing with continuous circumferential surface profiles. Wear 1987, 117, 49–77. [Google Scholar] [CrossRef]

- Pajaczkowski, P.; Spiridon, M.; Schubert, A.; Brito, G.C.; Marra, J.M. Itaipu binacional hydro power plant thrust bearing design optimization for higher efficiency. J. Mech. Eng. Autom. 2015, 5, 95–106. [Google Scholar] [CrossRef]

- Derong, A. Analysis and discussion on the cooling technology of thrust bearing pad for hydrogenerator set of Yeywa hydropower Station. Mech. Electr. Tech. Hydropower Stn. 2015, 38, 9–11. (In Chinese) [Google Scholar]

- Gui, S.; Ding, G. Analysis on cause of temperature on high side in thrust bush of dongfeng hydropower station. Guizhou Water Power 1996, 4, 41–47. (In Chinese) [Google Scholar]

- Ray, R.W.; Ingram, E.A. Bearings & seals: Innovations and good ideas; innovative approaches to designing, installing, retrofitting, and operating two major components of a hydroelectric plant are saving facility owners time and money. Power Eng. 2010, 114, 50–55. [Google Scholar]

- Kirschner, O.; Ruprecht, A.; Riedelbauch, S. Experimental investigation of the flow in a simplified model of water lubricated axial thrust bearing. IOP Conf. Ser. Earth Environ. Sci. 2014, 22, 012005. [Google Scholar] [CrossRef]

- Oguma, T.; Nakagawa, N.; Mikami, M.; Long, T.; Takimoto, F. Water Lubricated guide bearing with self-aligning segments. Int. J. Fluid Mach. Syst. 2013, 6, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yin, Z.; Jiang, D.; Gao, G. The design of hydrodynamic water-lubricated step thrust bearings using CFD method. Mech. Ind. 2014, 15, 197–206. [Google Scholar] [CrossRef]

- Martsynkovskyy, V.; Liubchenko, K.; Prokopenko, A.; Lazarenko, A. Thrust bearing with fluid pivot. J. Phys. Conf. Ser. 2021, 1741, 012038. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, D.; Qin, X. Water Turbine Generator Set Bearing Oil Throwing Treatment. Corpus of Pumped Storage Power Station Engineering Construction 2015; Power Grid Peaking and Pumped Storage Professional Committee of China Hydropower Engineering Society, China Electric Power Press China Electric Power Press: Beijing, China, 2015; pp. 563–566. (In Chinese) [Google Scholar]

- Jiang, S.; Gu, D. Cause analysis and treatment of thrust bearing oil dump in Ruili River hydropower Station. Yunnan Water Power 2012, 28, 117–118. (In Chinese) [Google Scholar]

- He, B.; Zhao, Y.; Li, R.; Liang, Y.; Lv, M. Cause Analysis and Treatment of Oil Leakage and Oil Mist Overflow of Thrust Bearings in Mianhuatan Hydropower Station. J. Chang. Inst. Technol. (Nat. Sci. Ed.) 2019, 20, 28–31. (In Chinese) [Google Scholar]

- In, W.; Li, L.; Jiang, X. Analysis and treatment of oil throwing problem of thrust combination bearing of hydroturbine generator set in Zaoshi hydropower Station. Mech. Electr. Inf. 2013, 4, 52–53. (In Chinese) [Google Scholar]

- Yao, Y. Technology of preventing bearing oil dump in sinanjiang hydropower Station. Yunnan Water Power 2013, 29, 120–121. (In Chinese) [Google Scholar]

- Zhang, L.; Zhang, L. Design and measures of anti-oil throwing of hydrogenerator bearing. Small Hydro Power 2015, 4, 68–69. (In Chinese) [Google Scholar]

- Deng, Z.; Li, F.; Wang, L.; Lu, F.; Yu, Y.; Liu, Y. Study and treatment of oil throwing and oil mist in thrust/lower guide bearing of Xixiayuan Power Station. Sustainable development of hydropower and technical progress of RCC dam construction. In Proceedings of the 2015 Annual Conference of China Dam Association, Chengdu, China, 24 September 2015; The Yellow River Water Conservancy Press: Chengdu, China, 2015; pp. 166–169. (In Chinese). [Google Scholar]

- Duan, X.; Miao, C. Diagnosis and Permanent Control Countermeasure of Splashing of Oil from the Hydro-generator Thrust Bearing and Lower Guide Bearing of Ertan Hydropower Plant. Mech. Electr. Equip. 2010, 27, 40–42. (In Chinese) [Google Scholar]

- Tokarev, M.I. Experience in the operation and repair of individual components of the units at the Ust’-Kamenogorsk hydroelectric station. Hydrotech. Constr. 1988, 22, 179–184. [Google Scholar] [CrossRef]

- Wei, W. The Hydraulic Turbine Thrust Bearing Flings the Oil Reason to Search Analyzes. Equip. Manuf. Technol. 2009, 4, 88–89. (In Chinese) [Google Scholar]

- Deng, Y.; Xu, J.; Yang, L.; Feng, G. Numerical simulation and experimental research on oil mist overflowing for a giant hydropower generator. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2346–2355. [Google Scholar] [CrossRef]

- Yang, J.; Wang, T.; Zhou, F.; Cai, J. Prevention and control on oil mist of generator thrust bearing in Gezhouba Hydropower Station. Yangtze River 2018, 49, 103–106. (In Chinese) [Google Scholar]

- Ustalova, T.P.; Ustalov, V.A. Technical developments to prevent fouling of generator parts with oil. Hydrotech. Constr. 1995, 29, 438–442. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Hu, X.; Zhou, Q. Technical renovation of contact sealing cover of upper guide bearing in Wuyiqiao Hydropower station. Sichuan Water Power 2014, 33, 123–124. (In Chinese) [Google Scholar]

- Liu, Y.; Tao, F.; Ran, J. Analysis on the technical renovation of generator guide bearing seal end cover in Jinyintai Hydropower Station. In Proceedings of the Workshop on Operation Technology of Mechanical and Electrical Equipment of Sichuan, Guizhou and Yunnan Hydro Power Plants, Chengdu, China, 15 September 2010; pp. 70–72. (In Chinese). [Google Scholar]

- Ma, Y. Treatment of oil thrown-off from thrust bearing of 700MW hydro-generator in Longtan Hydropower Station. Mech. Electr. Tech. Hydropower Stn. 2010, 33, 50–52. (In Chinese) [Google Scholar]

- Lei, Z.; Hu, Y. Analysis of oil throwing reason of oil groove cover plate of lower guide bearing in Sanbanxi Power Plant. Mech. Electr. Tech. Hydropower Stn. 2018, 41, 54–56. (In Chinese) [Google Scholar]

- Liu, X.; Guo, W. Ravel out Throw off Oil of Bearing Thrust in Hydroclectric Power Station. J. Electr. Power 2007, 4, 406–407. (In Chinese) [Google Scholar]

- Lebeck, A.O. Experiments and modeling of zero leakage backward pumping mechanical face seals. Tribol. Trans. 2008, 51, 389–395. [Google Scholar] [CrossRef]

- Liu, C.; Cao, S.; Tian, X.; Pan, D.; Li, G.; Wang, H. Oil mist emission strategy of generator bearing based on P- fuzzy PID control. Sci. Technol. Innov. 2018, 34, 13–15. (In Chinese) [Google Scholar]

- Wang, R.; Cao, S.; Tian, X.; Pan, D.; Wang, Y.; He, S. An improved genetic—PID algorithm based oil mist emission control strategy for unit bearings. Appl. Sci. Technol. 2019, 46, 70–75. (In Chinese) [Google Scholar]

- Harrag, A.; Messalti, S. Variable step size modified P&O MPPT algorithm using GA-based hybrid offline/online PID controller. Renew. Sustain. Energy Rev. 2015, 49, 1247–1260. [Google Scholar]

- Burgan, H.I.; Aksoy, H. Daily flow duration curve model for ungauged intermittent subbasins of gauged rivers. J. Hydrol. 2022, 604, 127429. [Google Scholar] [CrossRef]

- Li, M. Analysis and treatment technology of oil dump in thrust/lower guide tank of large hydropower station. Mech. Electr. Tech. Hydropower Stn. 2020, 43, 31–33. (In Chinese) [Google Scholar]

- Deng, S. Structural characteristics and oil dump treatment of hydraulic guide bearing in Ertan Hydropower Station. Mech. Electr. Tech. Hydropower Stn. 1999, 4, 13–15. (In Chinese) [Google Scholar]

- Zou, K.; Zhu, L.; Liu, J.; Feng, L. The Practice of Oil Mist Control for Large Hydro-generator Thrust Bearing. Large Electr. Mach. Hydraul. Turbine 2020, 4, 51–55. (In Chinese) [Google Scholar]

- Li, L. Analysis and Treatment of the Oil Spill and Oil Mist Leakage Problems of Hydro-turbine Generator Units in the Right Bank Power Plant of Xiluodu Hydropower Station. Hydropower New Energy 2017, 4, 78–80. (In Chinese) [Google Scholar]

- Zheng, K.; Xu, K.; Qiang, L. Cause analysis and improvement measures of oil spill of unit combination bearing in Xiluodu hydropower Station. Water Resour. Hydropower Eng. 2015, 46, 59–61. (In Chinese) [Google Scholar]

- Wang, H.; Zhang, Y.; Lin, S.; Ye, Q. Analysis and modification of oil dump of upper guide bearing. Electr. Saf. Technol. 2012, 14, 41–42. (In Chinese) [Google Scholar]

- Cao, K. Oil-throw treatment for generator’s thrust bearing of Shuibuya Hydropower Station. Hydropower New Energy 2010, 4, 60–62. (In Chinese) [Google Scholar]

- Jin, C.; Xu, G. Treatment for Oil-swing of Xiaolangdi Hydro-generator Thrust Bearing. Northeast. Electr. Power Technol. 2003, 4, 23–24. (In Chinese) [Google Scholar]

- Jin, C.; Xu, G. Treatment for Oil-swing of Xiaolangdi Hydro-generator Thrust Bearing. Appl. Energy Technol. 2002, 4, 11–12. (In Chinese) [Google Scholar]

- Novotný, P.; Hrabovský, J.; Juračka, J.; Klíma, J.; Hort, V. Effective thrust bearing model for simulations of transient rotor dynamics. Int. J. Mech. Sci. 2019, 157, 374–383. [Google Scholar] [CrossRef]

- Pajączkowski, P.; Schubert, A.; Wasilczuk, M.; Wodtke, M. Simulation of large thrust-bearing performance at transient states, warm and cold start-up. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 96–103. [Google Scholar] [CrossRef]

- Fillon, M.; Wodtke, M.; Wasilczuk, M. Effect of presence of lifting pocket on the THD performance of a large tilting-pad thrust bearing. Friction 2015, 3, 266–274. [Google Scholar] [CrossRef] [Green Version]

- Papadopoulos, C.I.; Kaiktsis, L.; Fillon, M. Computational fluid dynamics thermohydrodynamic analysis of three-dimensional sector-pad thrust bearings with rectangular dimples. J. Tribol. 2014, 136, 011702. [Google Scholar] [CrossRef]

- Wasilczuk, M.; Rotta, G. On the possibilities of decreasing power loss in large tilting pad thrust bearings. Int. Sch. Res. Not. 2013, 2013, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Fouflias, D.G.; Charitopoulos, A.G.; Papadopoulos, C.I.; Kaiktsis, L. Thermohydrodynamic analysis and tribological optimization of a curved pocket thrust bearing. Tribol. Int. 2017, 110, 291–306. [Google Scholar] [CrossRef]

- Bakir, F.; Rey, R.; Gerber, A.G.; Belamri, T.; Hutchinson, B. Numerical and experimental investigations of the cavitating behavior of an inducer. Int. J. Rotating Mach. 2004, 10, 15–25. [Google Scholar] [CrossRef] [Green Version]

- Brennen, C.E. Fundamentals of Multiphase Flow; Cambridge University Press: Pasadena, CA, USA, 2005. [Google Scholar]

- Chen, Z.; Yu, B.; Zhang, H. Pressure Distribution of Hydraulic Turbine Guide Bearing Rotating Sump. Large Electr. Mach. Hydraul. Turbine 2010, 2, 57–60. (In Chinese) [Google Scholar]

- Wen, Y. Research on Static Characteristic of Tilting-Pad Thrust Bearing in Pumping Storage Units Based on CFD; HoHai University: Nanjing, China, 2014. (In Chinese) [Google Scholar]

- Lu, D. Flow-Field Analysis and Structure Optimization of Oil Sump in Thrust Bearing of Large-Scale Water Turbine Generator; Harbin Institute of Technology: Harbin, China, 2010. (In Chinese) [Google Scholar]

- Najar, F.A.; Harmain, G.A. Novel approach towards thrust bearing pad cooling. In Proceedings of the ASME 2014 Gas Turbine India Conference, New Delhi, India, 15–17 December 2014. [Google Scholar]

- Pang, J.; Liu, X.; Ren, M.; Zhang, P. Analysis on the Causes of Oil Mist in the Lower Guide Bearings of Hydrogenerator Units. J. Eng. Themal Energy Power 2021, 36, 1–7. Available online: http://kns.cnki.net/kcms/detail/23.1176.TK.20210630.0856.002.html (accessed on 12 July 2021). (In Chinese).

- Leopard, A.J. Tilting pad bearings: Limits of operation. Lubr. Eng. 1976, 32, 637–644. [Google Scholar]

- Wang, Y.; Jiang, D.; Yin, Z.; Gao, G.; Zhang, X. Load Capacity Analysis of Water Lubricated Hydrostatic Thrust Bearing Based on CFD. J. Donghua Univ. (Nat. Sci. Ed.) 2015, 41, 428–432. (In Chinese) [Google Scholar]

- Dadouche, A.; Fillon, M.; Bligoud, J.C. Experiments on thermal effects in a hydrodynamic thrust bearing. Tribol. Int. 2000, 33, 167–174. [Google Scholar] [CrossRef]

- Srikanth, D.V.; Chaturvedi, K.K.; Reddy, A.C.K. Determination of a large tilting pad thrust bearing angular stiffness. Tribol. Int. 2012, 47, 69–76. [Google Scholar] [CrossRef]

- Zhi, F.; Hu, W.; Yan, Z.; Wang, Z. Calculation of lubricity and analysis of influencing factors for small spring-supported thrust bearing. J. Hydroelectr. Eng. 2015, 34, 157–162. (In Chinese) [Google Scholar]

- Wasilczuk, M.; Rotta, G. Modeling lubricant flow between thrust-bearing pads. Tribol. Int. 2008, 41, 908–913. [Google Scholar] [CrossRef]

- Qu, B.; Ma, N.; Huang, Q.; Wen, Y.; Shi, Z. Research on Lubrication Performance of Tilting-Pad Thrust Bearing Based on Fluid-Structure Two-way Coupling Theory. Lubr. Eng. 2015, 40, 72–78. (In Chinese) [Google Scholar]

- YAO, Z.; Wen, Y.; Qu, B.; Huang, Q.; Mao, X.; Shi, Z.; Xiong, Y. Numerical Analysis of Operation Mechanism of Thrust Bearing Oil Film Under the Stable Working Conditions of Pumped Storage Power. South-North Water Transf. Water Sci. Technol. 2014, 12, 104–107. (In Chinese) [Google Scholar]

- Shi, Z. The Study on Lubricating Property of Vertical Bloc Tilting-Pad Water-Guide Bearing Based on CFD; HoHai University: Nanjing, China, 2015. (In Chinese) [Google Scholar]

- Andres, L.A.; Wu, T.; Maeda, H.; Tomoki, O. A computational fluid dynamics modified bulk flow analysis for circumferentially shallow grooved liquid seals. ASME J. Eng. Gas Turbines Power Eng. 2018, 140, 012504. [Google Scholar] [CrossRef]

- Kim, S.H.; Ha, T.W. Prediction of leakage and rotor dynamic coefficients for the circumferential-groove-pump seal using CFD analysis. J. Mech. Sci. Technol. 2016, 30, 2037–2043. [Google Scholar] [CrossRef]

- Mortazavi, F.; Palazzolo, A. Prediction of rotordynamic performance of smooth stator-grooved rotor liquid annular seals utilizing computational fluid dynamics. ASME J. Vib. Acoust. 2018, 140, 031002. [Google Scholar] [CrossRef]

- Li, Z. Investigations on the Leakage Flow and Rotordynamic Characteristics of the Pocket Damper Seal; Xi’an Jiaotong University: Xi’an, China, 2013. (In Chinese) [Google Scholar]

- Li, Z.; Li, J.; Feng, Z. Comparison of rotordynamic characteristics predictions for annular gas seals using the transient computational fluid dynamic method based on different single-frequency and multi-frequency rotor whirling models. ASME J. Tribol. 2016, 138, 011701. [Google Scholar] [CrossRef]

- Li, Z.; Fang, Z.; Li, J. Review of the Leakage Flow and Rotordynamic Characteristics of the Annular Dynamic Seals in Liquid and Multiple Phases Conditions. J. Xi’an Jiaotong Univ. 2020, 54, 1–22. (In Chinese) [Google Scholar]

- Grzegorz, R.; Michal, W. CFD analysis of the lubricant flow in the supply groove of a hydrodynamic thrust bearing pad. Int. Jt. Tribol. Conf. 2007, 48108, 307–309. [Google Scholar]

- Zhang, Y. CFD Analysis on Evaporation during Refueling; Jiangsu University: Zhenjiang, China, 2017. (In Chinese) [Google Scholar]

- Hu, Z. Research on Two-Phase Flow Characteristics of Oil-Gas in Aero-Engine Bearing Chamber; Shenyang Aerospace University: Shenyang, China, 2020. (In Chinese) [Google Scholar]

- Sun, B. Numerical Simulation of Splash Lubrication Oil Quantity Imbalance between Two Columns of Cylinder in a V-Type Diesel Engine; Dalian University of Technology: Dalian, China, 2018. (In Chinese) [Google Scholar]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Xu, G.; Cai, L.; Ullmann, A.; Brauner, N. Experiments and simulation of water displacement from lower sections of oil pipelines. J. Pet. Sci. Eng. 2016, 147, 829–842. [Google Scholar] [CrossRef]

- Xu, J.; Hao, Z.; Wang, Y.; Liu, J.; Zhang, Y. Numerical Simulation on Oil Spill at Different Positions on the Back Surface of a Blunt Body. IOP Conf. Ser. Mater. Sci. Eng. 2019, 649, 012027. [Google Scholar] [CrossRef]

- Zhang, Y.; Zang, W.; Zheng, J.; Cappietti, L.; Zhang, J.; Zheng, Y.; Fernandez-Rodriguez, E. The influence of waves propagating with the current on the wake of a tidal stream turbine. Appl. Energy 2021, 290, 116729. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Lin, X.; Wang, R.; Zhang, C.; Zhao, J. Experimental investigation into downstream field of a horizontal axis tidal stream turbine supported by a mono pile. Appl. Ocean Res. 2020, 101, 102257. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Zheng, J.; Zhang, J.; Zheng, Y.; Zang, W.; Lin, X.; Fernandez-Rodriguez, E. Experimental investigation into effects of boundary proximity and blockage on horizontal-axis tidal turbine wake. Ocean Eng. 2021, 225, 108829. [Google Scholar] [CrossRef]

- Wu, Y. Numerical Study on the Evaporation Process of Lubricating Oil Droplet; Dalian University of Technology: Dalian, China, 2017. (In Chinese) [Google Scholar]

- Lippert, A.M. Modeling of Multi-Component Fuels with Application to Sprays and Simulation of Diesel Engine Cold Start; University of Wisconsin-Madison: Madison, WI, USA, 1999. [Google Scholar]

- Torres, D.J.; O’Rourke, P.J.; Amsden, A.A. A discrete multi-component fuel model. At. Sprays 2003, 13, 131–172. [Google Scholar]

- Yi, P. Numerical Study of Multi-Component Vaporization Model for Practical Fuel Droplets under Engine-Relevant In-Cylinder Conditions; Dalian University of Technology: Dalian, China, 2016. (In Chinese) [Google Scholar]

- Song, J.; Chen, J.; Zhang, Z.; Wang, C. Research on Oil Mist Condensation in Lubrication Pipe Based on CFD. Appl. Mech. Mater. 2010, 29, 1447–1450. [Google Scholar] [CrossRef]

- Yang, T.; Yang, J. Numerical Comparison and Investigation of Condensation Heat-transfer Performance in ACC Base Tubes with Lee Model and VOF Method. J. Chin. Soc. Power Eng. 2018, 38, 996–1003. (In Chinese) [Google Scholar]

- Qiu, G.; Cai, W.; Wu, Z.; Jiang, Y.; Yao, Y. Analysis on the value of coefficient of mass transfer with phase change in Lee′s equation. J. Harbin Inst. Technol. 2014, 46, 15–19. (In Chinese) [Google Scholar]

- Kahraman, G. Increasing the Power Generation by Raising the Capacity of the Thrust Bearing Oil Cooling System in Hydroelectric Power Plants. J. Fail. Anal. Prev. 2020, 20, 1445–1449. [Google Scholar] [CrossRef]

- Liu, W. Treatment on Bearing Oil Throwing and Bearing Liner Temperature for Generator at Ertan Hydropower Station. Sichuan Water Power 2001, 4, 49–51, 56, 94. (In Chinese) [Google Scholar]

- Tao, H. Analysis and Design of Shaft Collar Pump External Circular to Guide Bearing for Hydraulic Turbine; Harbin Institute of Technology: Harbin, China, 2017. (In Chinese) [Google Scholar]

| Hydropower Station | The Event | Country |

|---|---|---|

| Sanliping [16] | The temperature of the lower guide bearing pad was extremely high, and the daily oil leakage of the oil tank was up to 2 kg | China |

| Cataract [17] | Lubricating oil leakage resulted in the rising temperature of the bearing. The unit was shut down | USA |

| Caijiazhou [18] | The oil slinger fell, causing a scraping sound in the turbine guide bearing. Oil mist leakage followed from the bearing cover | China |

| Gutianxi [19] | Lubricating oil leakage developed. The oil level in the tank decreased on average 5–8 mm per day. The water guide mechanism was attached to a large amount of oil | China |

| Lonhmentan [20] | Serious oil throwing in the water guide oil tank leads to low oil levels, activating the high-temperature bearing tile alarms | China |

| Zhouning [21] | Low oil level alarm activated. The water guide was throwing up to 2.37 L of oil per day | China |

| Yantan [22] | The dust of the brake plate mixed with the oil mist is first polluting the internal environment of the generator and then increasing the stator temperature | China |

| Tianwan river [23] | The throwing of oil on the seal was significant. The running oil level of the thrust tank dropped rapidly, with a speed of 10 mm/day | China |

| Xiaolangdi [24] | The unit was started manually, throwing nearly 100 L of lubricating oil | China |

| Balimela [25] | The deposition of oil on the banks of the Surlikonda barrage and oil film over the water surface indicated clear contamination affecting the microflora | India |

| Baoku River [26] | The lubricating oil of water bearing leaked through the turbine head cover drainage or seal into the river, causing damage to water quality | China |

| Ahai [27] | The turbine oil is thrown out of the thrust oil tank and discharged from the tail water, which affects the downstream river ecology and water quality safety | China |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Zhang, Y.; Liu, B.; Ge, X.; Zheng, Y.; Fernandez-Rodriguez, E. Research on Oil Mist Leakage of Bearing in Hydropower Station: A Review. Energies 2022, 15, 2632. https://doi.org/10.3390/en15072632

Sun J, Zhang Y, Liu B, Ge X, Zheng Y, Fernandez-Rodriguez E. Research on Oil Mist Leakage of Bearing in Hydropower Station: A Review. Energies. 2022; 15(7):2632. https://doi.org/10.3390/en15072632

Chicago/Turabian StyleSun, Jie, Yuquan Zhang, Bin Liu, Xinfeng Ge, Yuan Zheng, and Emmanuel Fernandez-Rodriguez. 2022. "Research on Oil Mist Leakage of Bearing in Hydropower Station: A Review" Energies 15, no. 7: 2632. https://doi.org/10.3390/en15072632

APA StyleSun, J., Zhang, Y., Liu, B., Ge, X., Zheng, Y., & Fernandez-Rodriguez, E. (2022). Research on Oil Mist Leakage of Bearing in Hydropower Station: A Review. Energies, 15(7), 2632. https://doi.org/10.3390/en15072632